Tube arranging device for steel tube fork of loader

A technology of loader and steel pipe, applied in the direction of lifting device, etc., can solve the problems of single working mode and low efficiency, and achieve the effect of improving work efficiency, reducing use cost and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

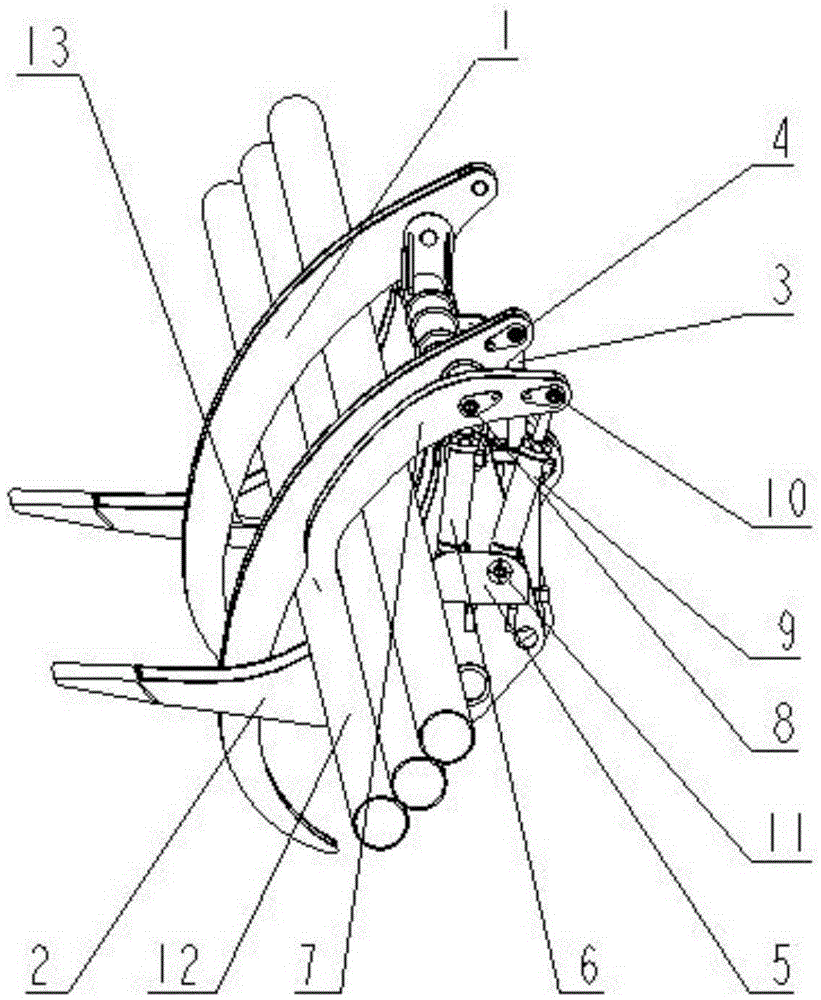

[0026] Such as figure 1 As shown, a loader steel pipe fork pipe device mainly includes the upper fork body 1, the lower fork body 2, and the hydraulic cylinder I3 that controls the upper fork body 1 and realizes the cohesion and opening of the upper fork body 1 and the lower fork body 2 , the rear end of the upper fork body 1 is connected with the hydraulic cylinder I3, and the upper fork body 1 is driven to rotate around the pin shaft 4 through the hydraulic oil cylinder I3; The mechanism includes a fixed support 5, a lifting cylinder 6, a hydraulic cylinder II 9 and a branch fork 7, the fixed support 5 is fixed on the outer surface of the lower fork body 2, and each of the lifting cylinder 6 and the hydraulic cylinder II 9 has one end connected to the fixed support 5, The other end and the branching fork 7, the lifting cylinder 6 and the hydraulic cylinder II 9 jointly control the cohesion and opening of the branching fork 7.

[0027] In the steel pipe fork arrangement devi...

Embodiment 2

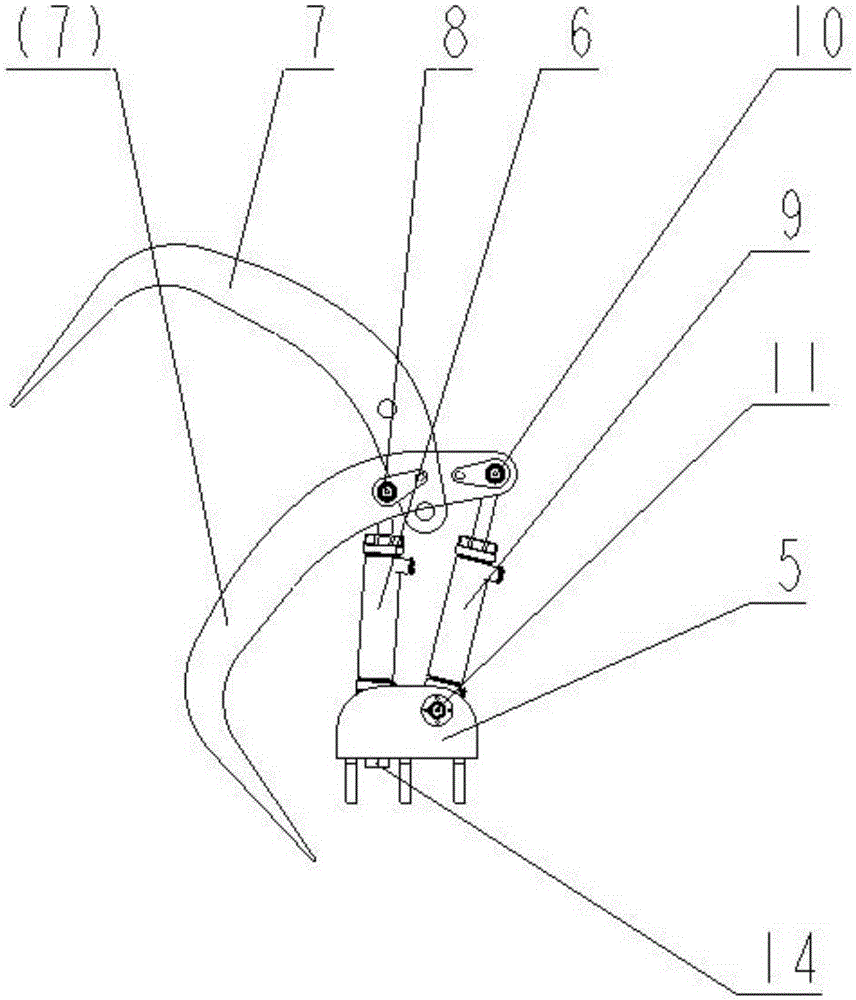

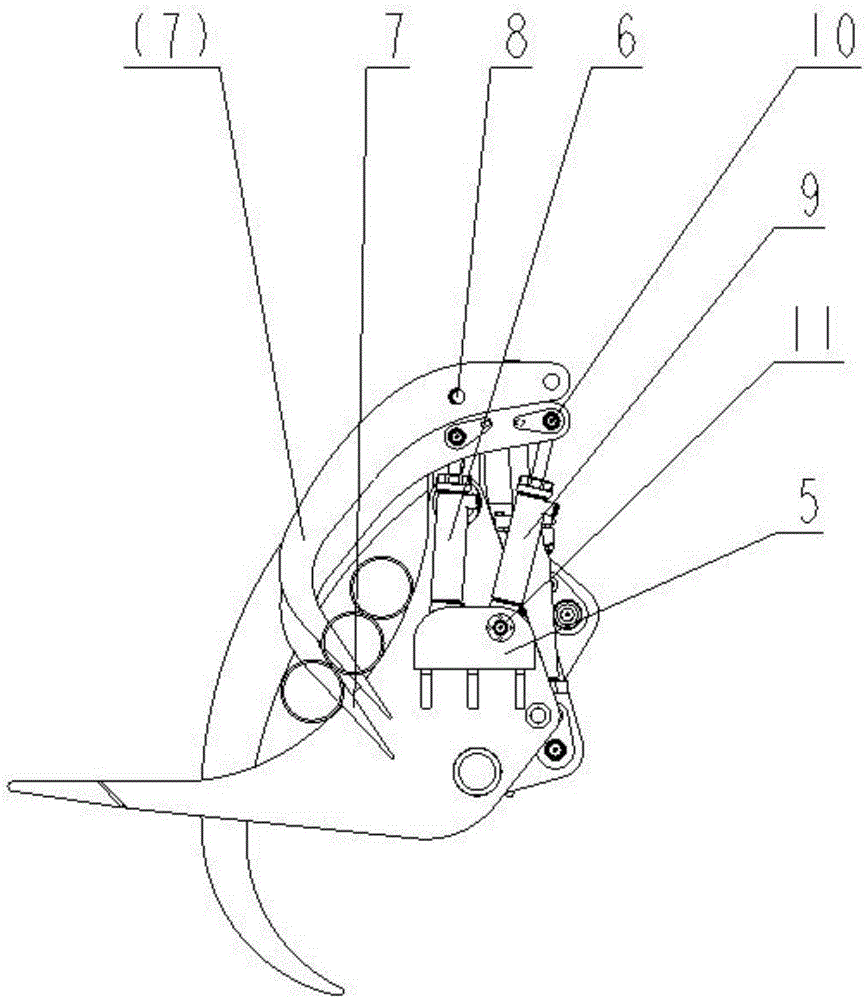

[0029] The difference from Embodiment 1 is: the branching fork 7 is provided with a middle pin 8 and a pin shaft I10, the cylinder end of the lifting cylinder 6 is fixed on the fixed support 5, and the cylinder end does not have any degree of freedom, and the piston rod of the lifting cylinder 6 The end is connected with the middle pin 8 of the branching fork 7, and the lifting cylinder 6 can only do lifting movement in the vertical direction; the piston rod of the hydraulic cylinder II9 and the branching fork 7 are connected through the pin shaft I10, and the cylinder body of the hydraulic cylinder II9 is connected through the pin shaft Ⅱ11 is connected with the fixed support 5, and both ends of the hydraulic cylinder Ⅱ9 have degrees of freedom and can rotate around pin shafts Ⅰ10 and Ⅱ11.

Embodiment 3

[0031] The difference from embodiment 2 is that the branching fork 7 is composed of left support plate 7-2, right support plate 7-1, upper sealing plate 7-3, and lower sealing plate 7-4. The sealing plate is welded, and there are two hinged holes on the branch fork 7, and the lifting cylinder 6 and the hydraulic cylinder II9 are respectively connected through the middle pin 8 and the pin shaft I10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com