Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

298results about How to "Achieve gripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

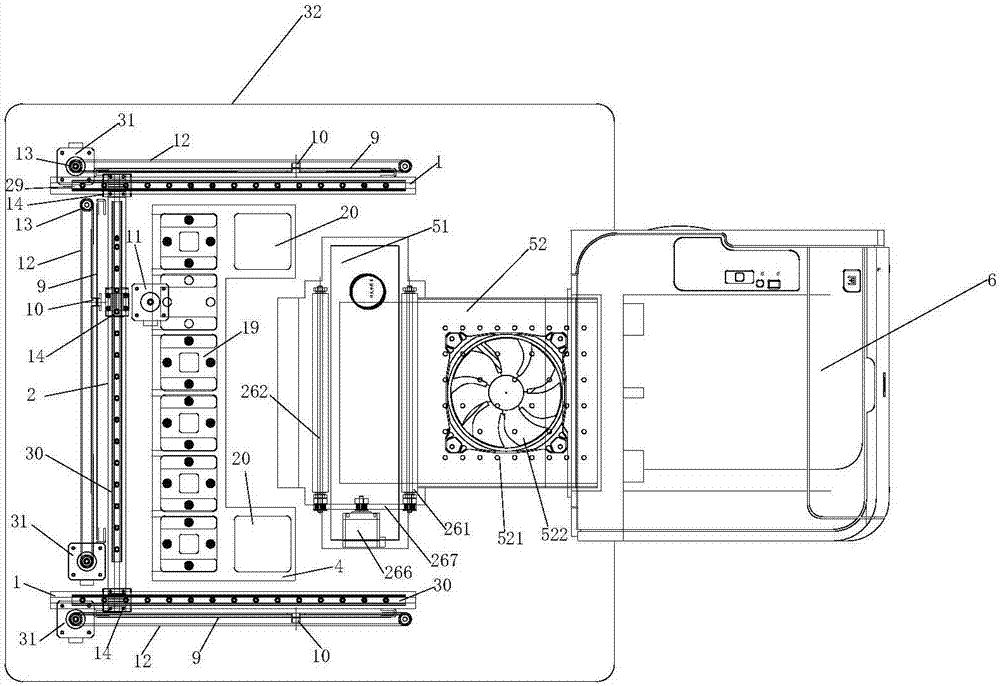

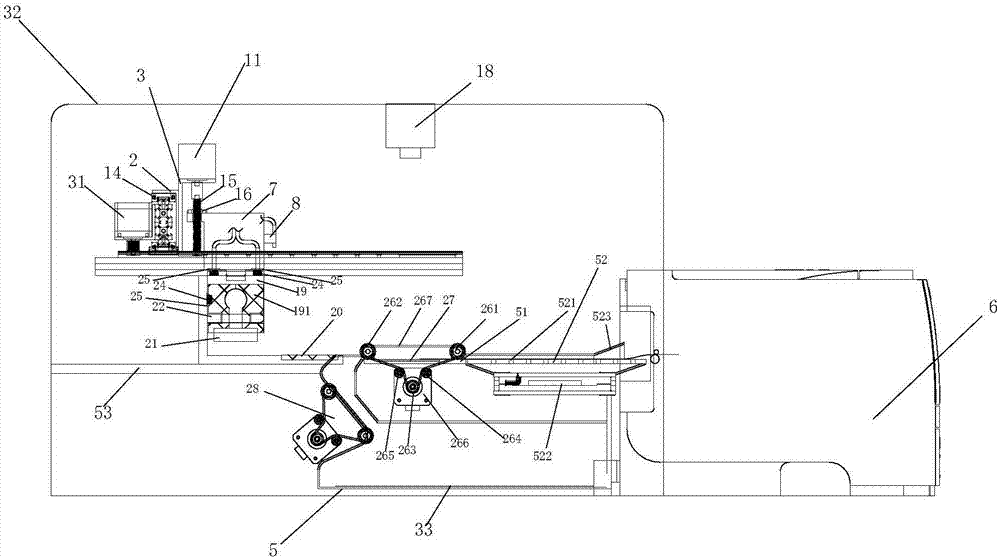

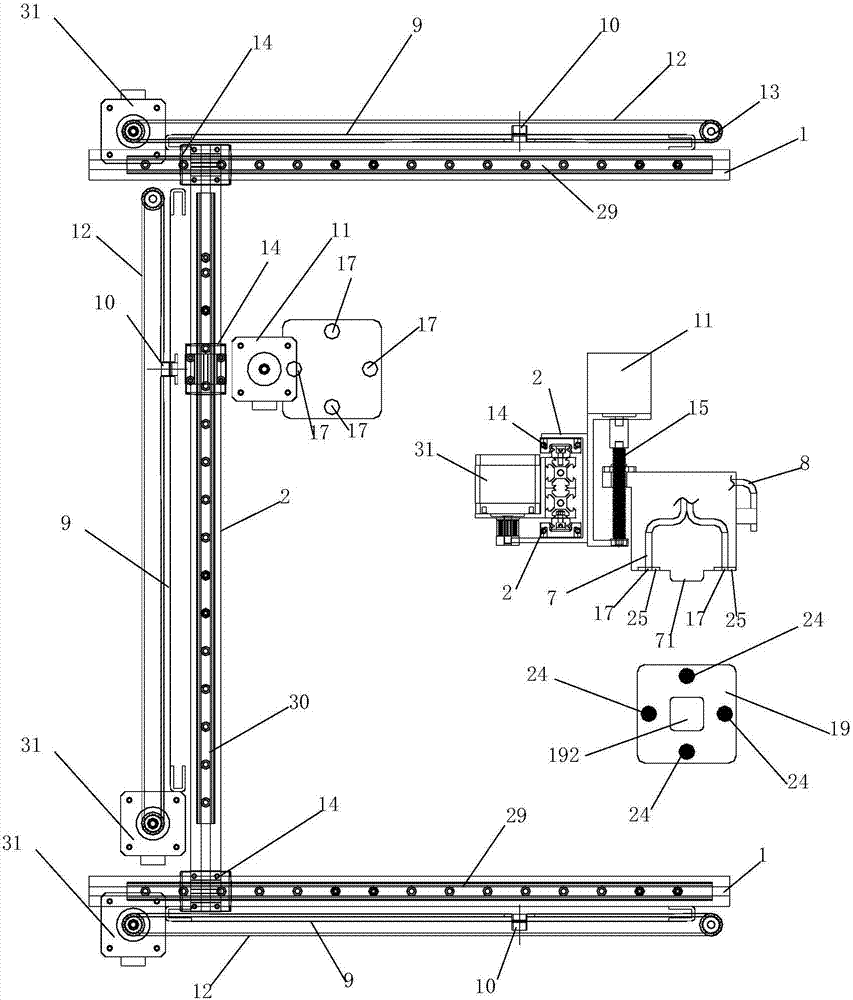

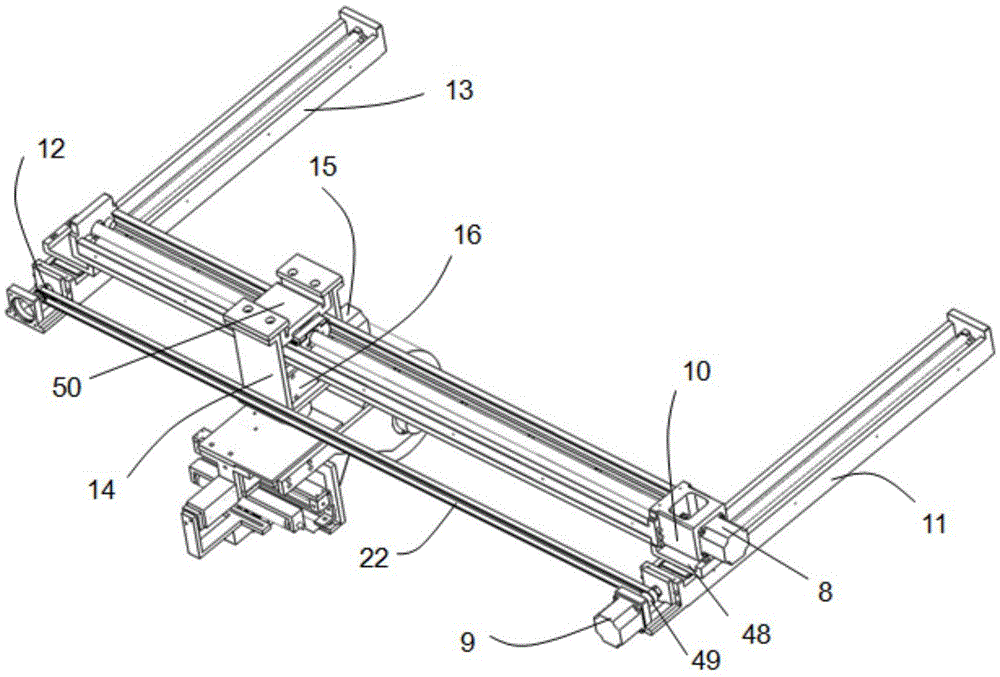

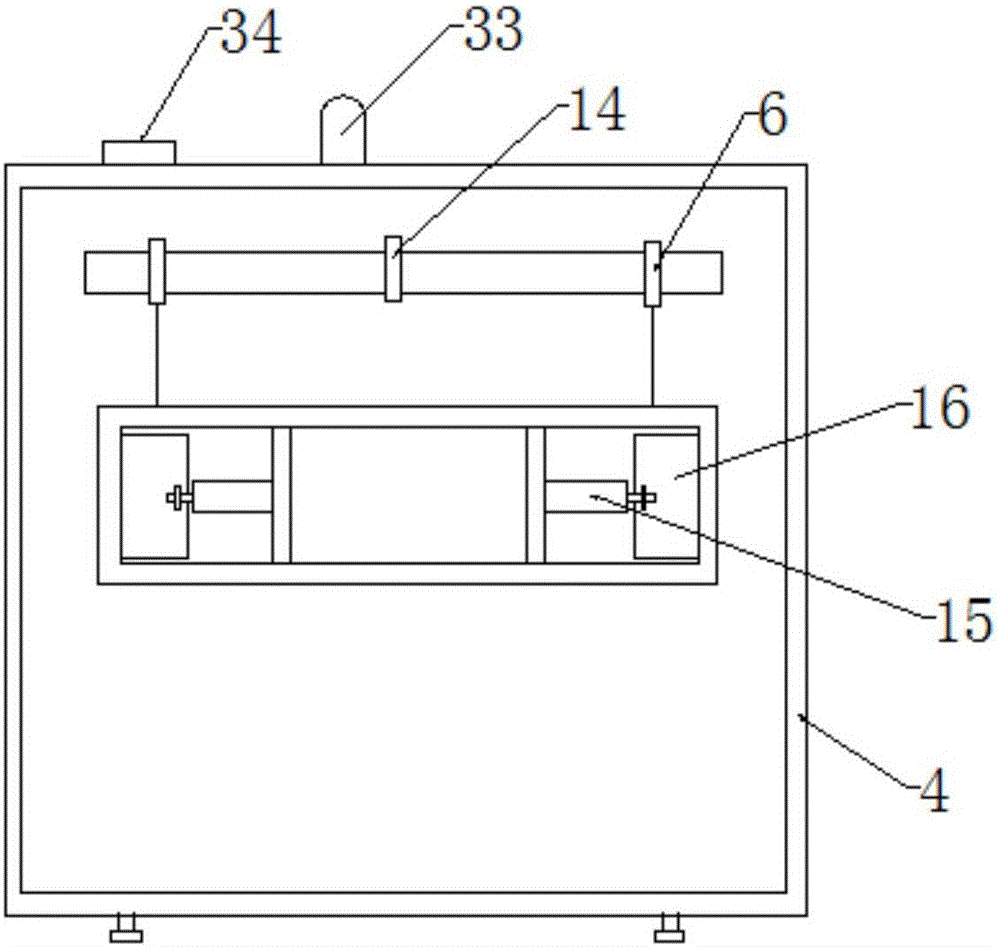

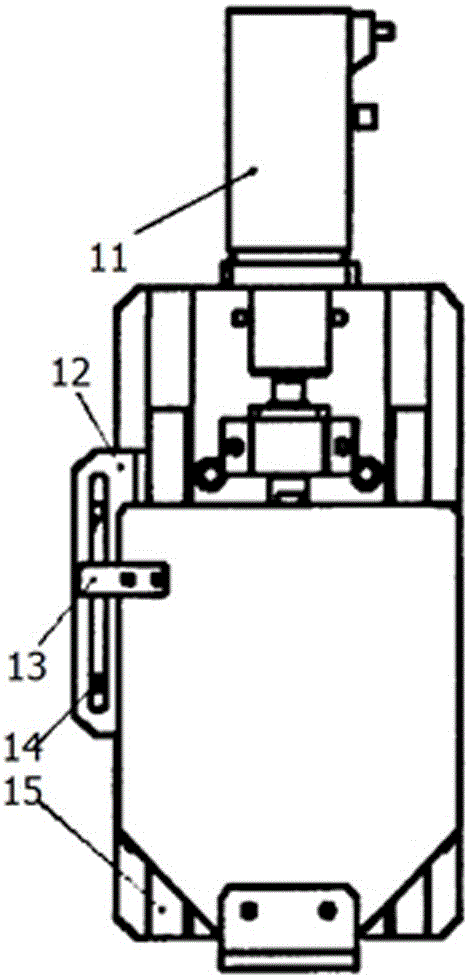

Printing and sealing device

ActiveCN106985549AAchieve grippingAchieve placementTypewritersStampingPulp and paper industryInstrumentation

The invention provides a printing and sealing device. The device comprises a bracket module, a seal frame, a console, a printer and a controller; the seal frame is provided with a seal for sealing; the bracket module is provided with a clamping structure for clamping the seal; the clamping structure can be controlled by the controller to move on the bracket module in any direction; the clamping structure is provided with a paper position detecting instrument; the top of the console is divided into a sealing area and a paper guide area; the paper guide area is positioned in a paper outlet of the printer; the controller and the paper position detecting instrument are connected wirelessly or through a signal wire; position signals of papers acquired by the paper position detecting instrument are input in the controller; the signals are initial data of positions of the papers; and the controller analyzes and compares the data of the appointed seal position and the initial data, and controls the clamping structure to move to the appointed position according to the compared and analyzed results. The printing and sealing device has such advantages as precise positioning and conveying, capability of quickly moving to an appointed area, and convenience to operate.

Owner:胡金钱

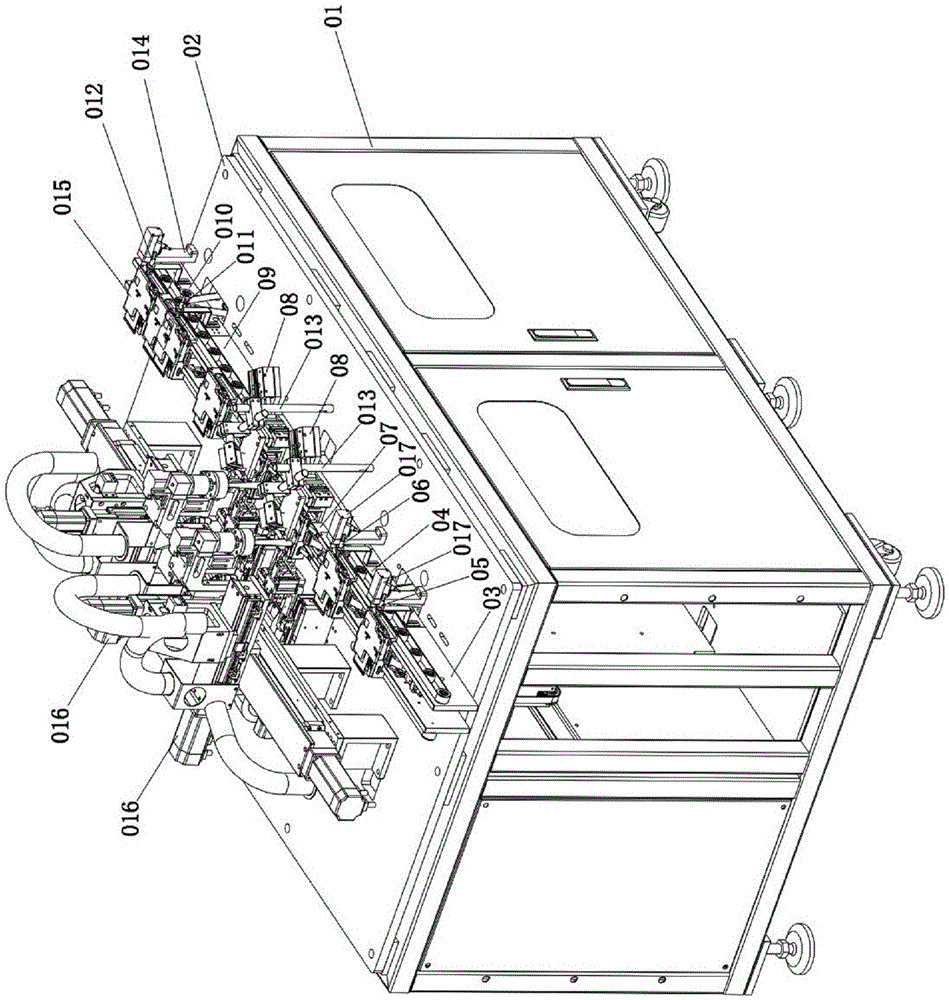

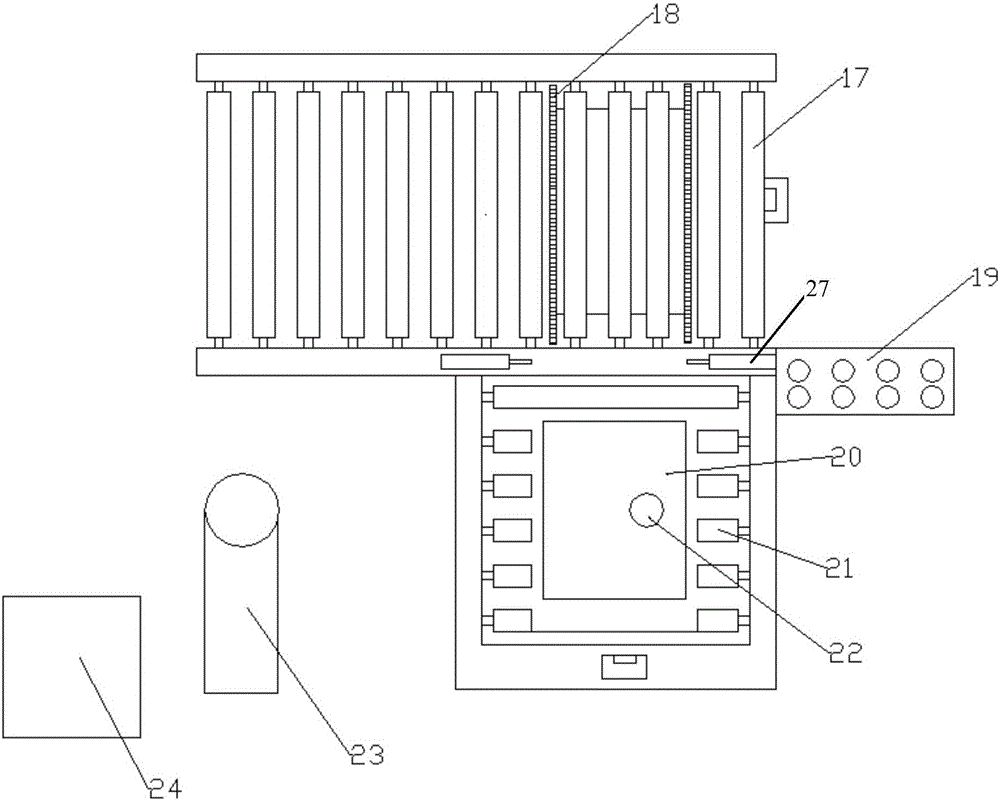

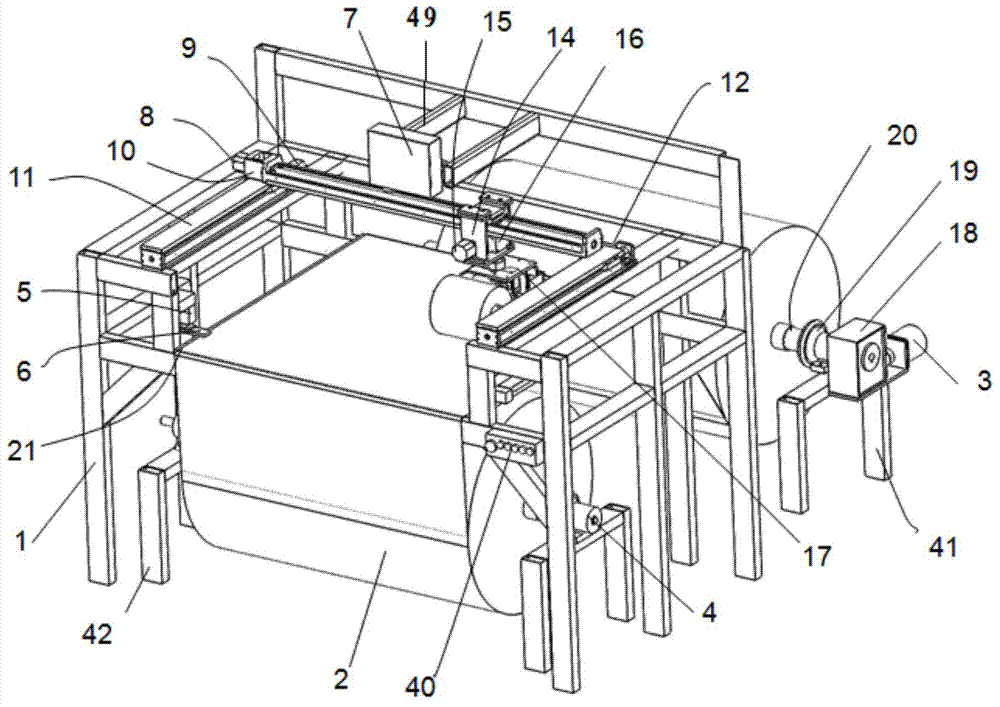

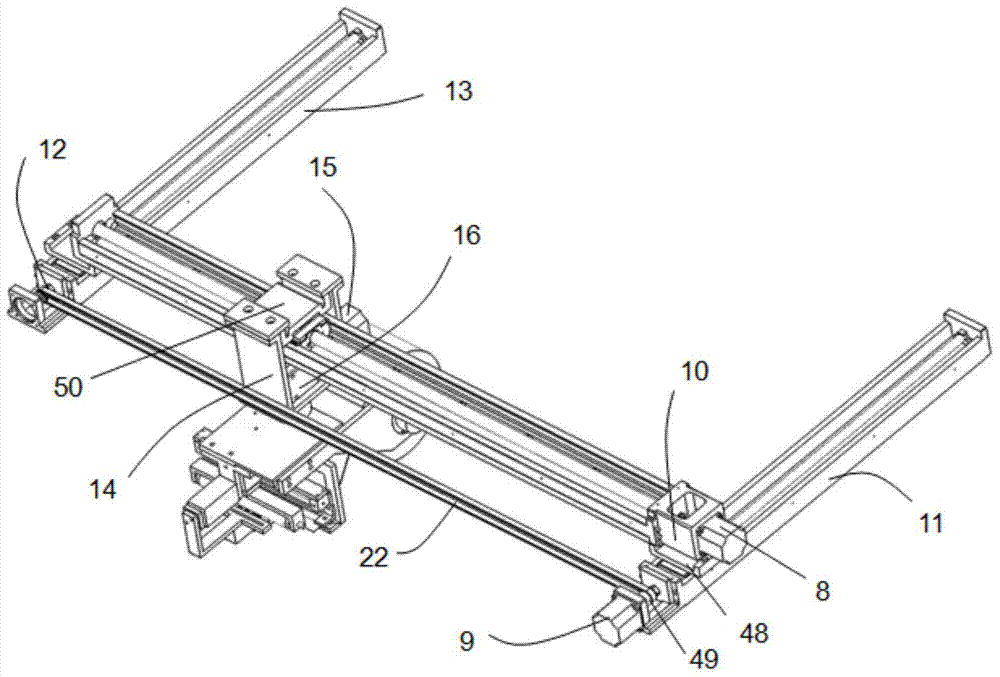

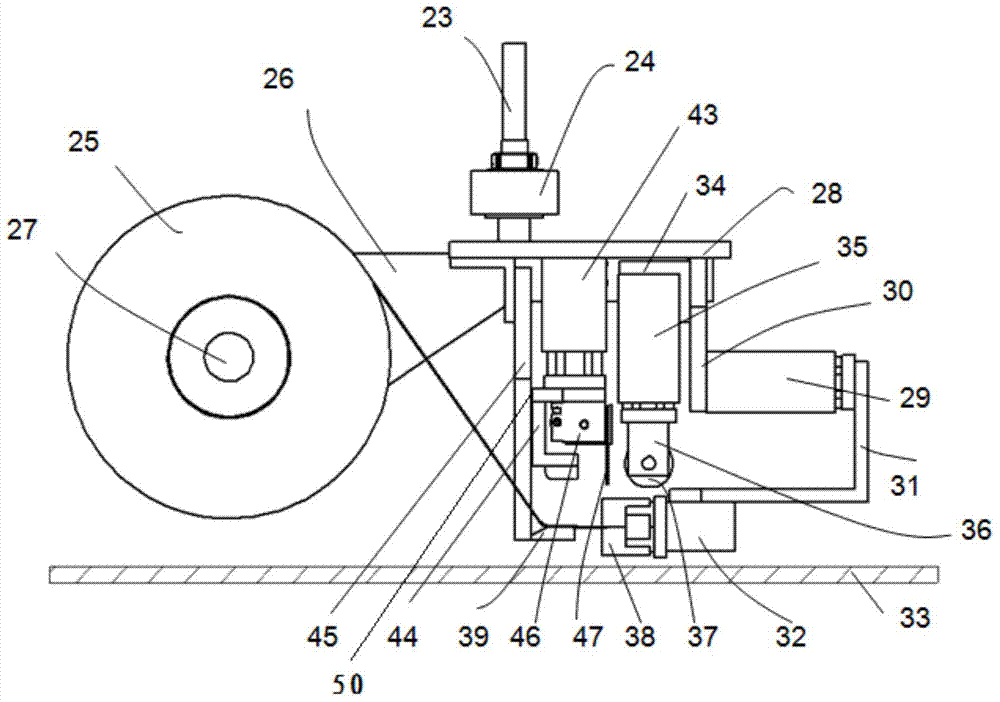

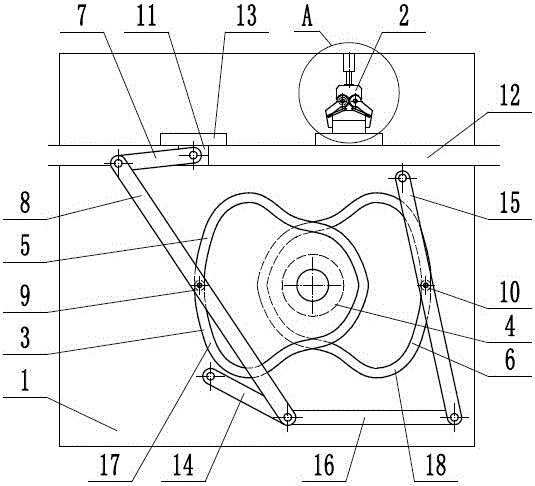

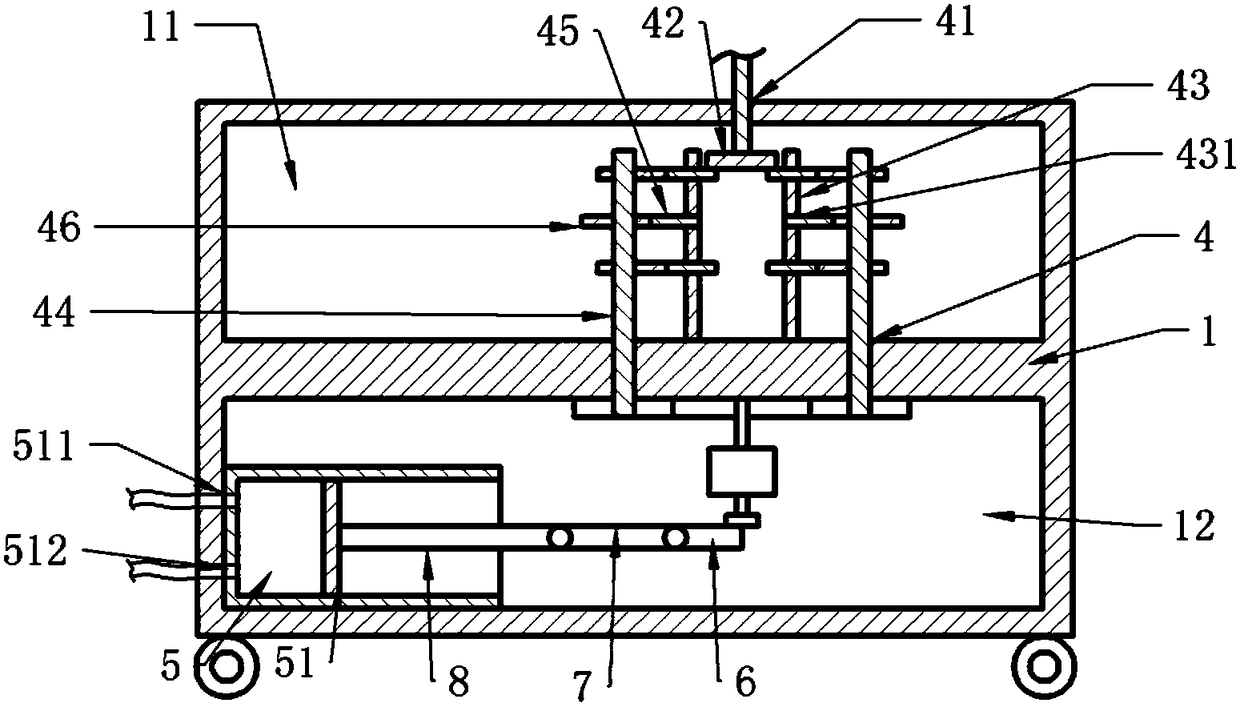

Full-automatic double-sided tape pasting equipment with compound functions

The invention relates to the technical field of double-sided tape pasting equipment, in particular to full-automatic double-sided tape pasting equipment with compound functions. The full-automatic double-sided tape pasting equipment with the compound functions is characterized in that a working table is included, and the working table is provided with a working table board; a left single-boom operation mechanism and a right single-boom mechanism are arranged on two sides of the working table correspondingly; the lower end of the left single-boom mechanism and the lower end of the right single-boom mechanism are connected with a pasting handpiece body; a feeding mechanism bracket is arranged at the front end of the lower portion of the working table board; a deviation rectification control system is arranged at the rear portion, corresponding to a feeding drum, of the working table; a constant tension control device is arranged in front of the working table board; a tape replacement unit is arranged on one side of the working table; the working table is further provided with an electrical button plate. Tape is pasted stably and firmly in a non-stick mode and can be replaced automatically; compared with the manual tape-replacement mode, the equipment has higher production efficiency and more reliable production quality, and production steps are more convenient to calculate and master.

Owner:NORTH CHINA INST OF AEROSPACE ENG

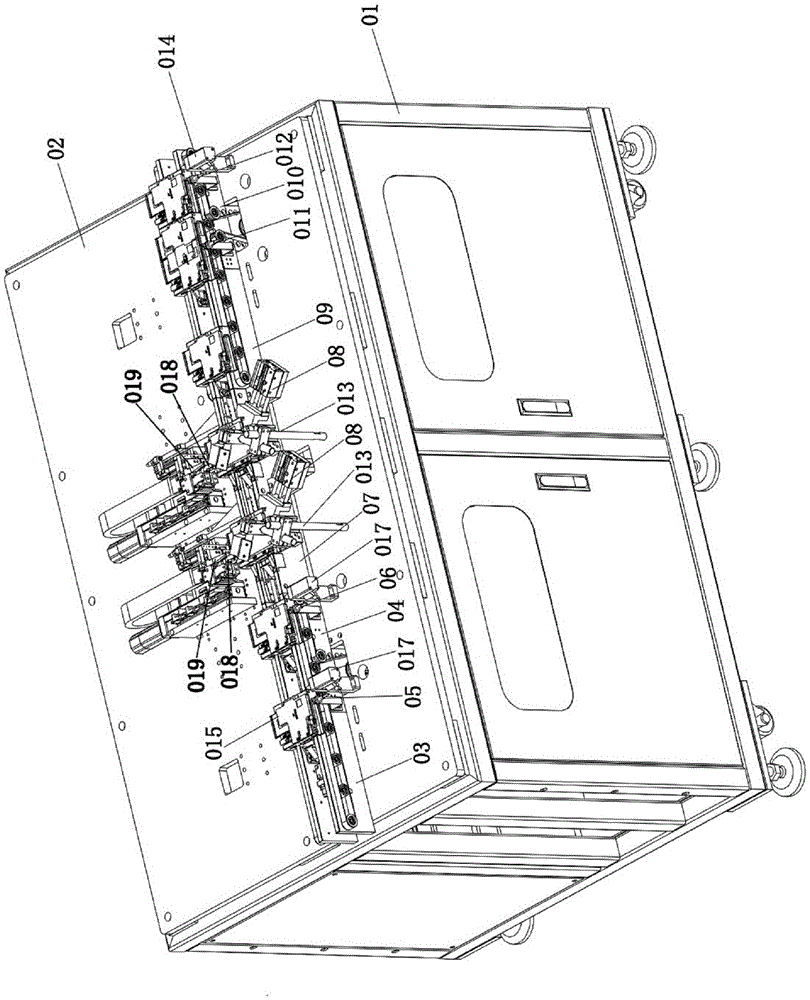

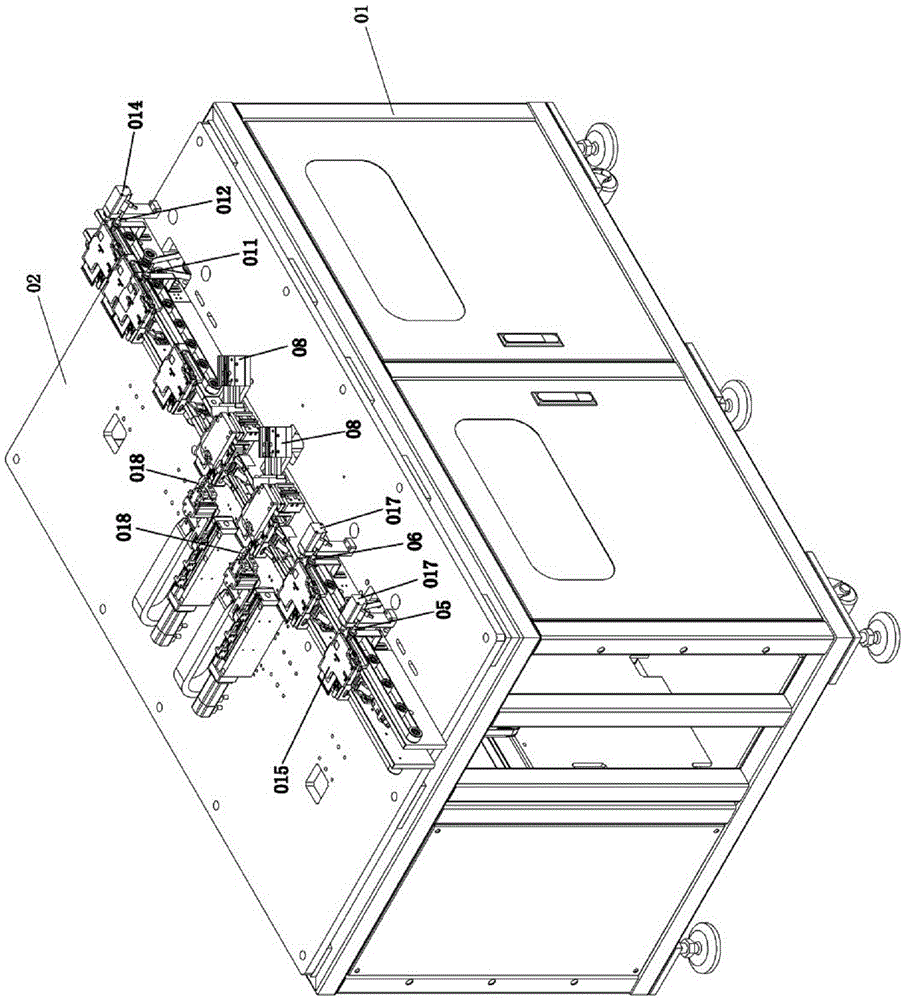

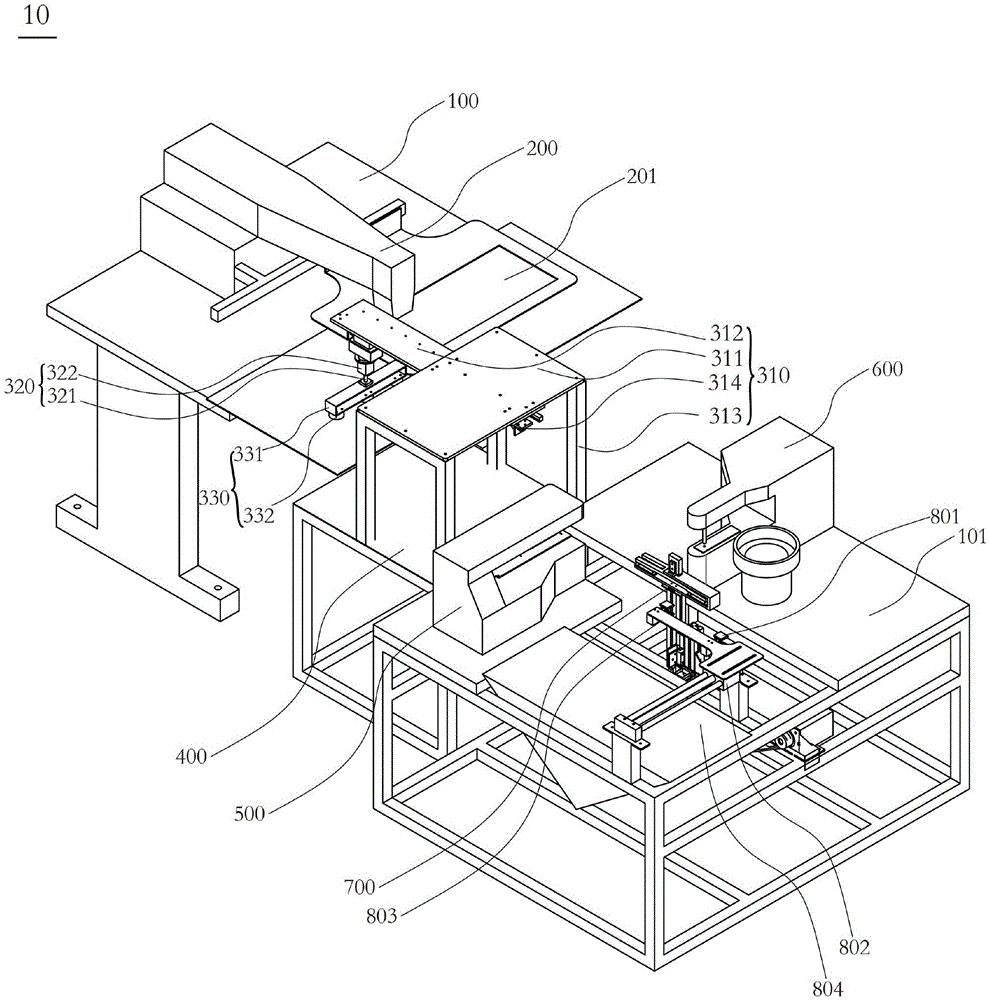

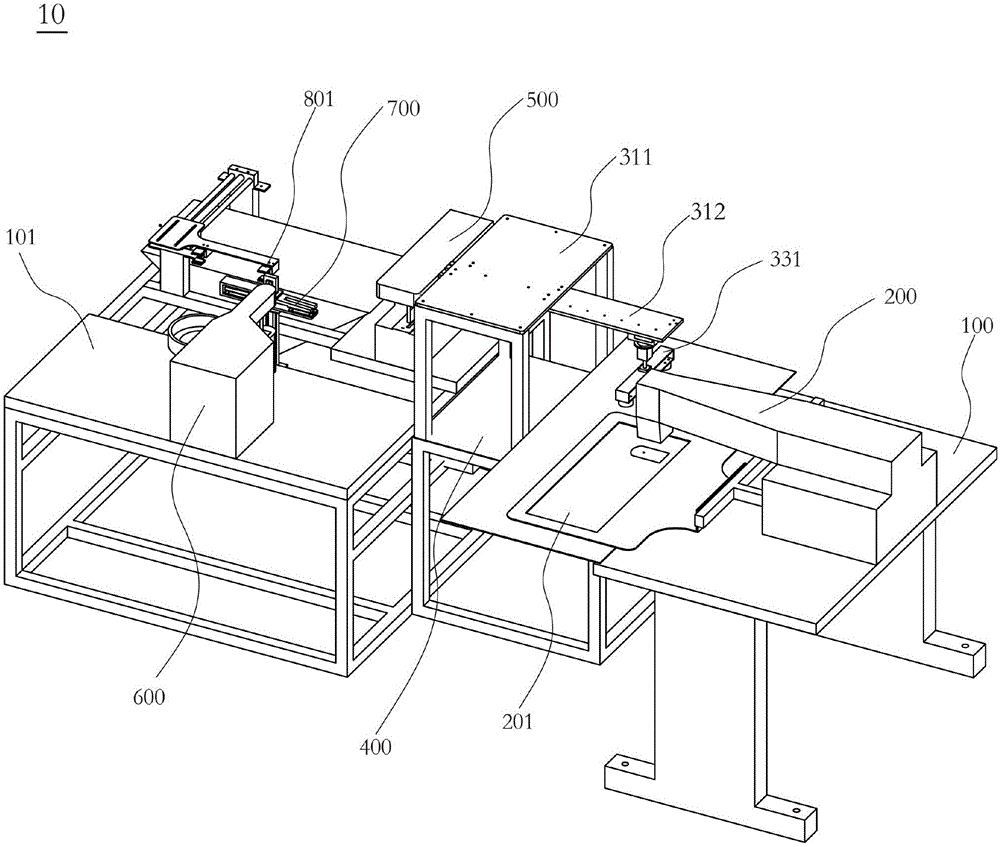

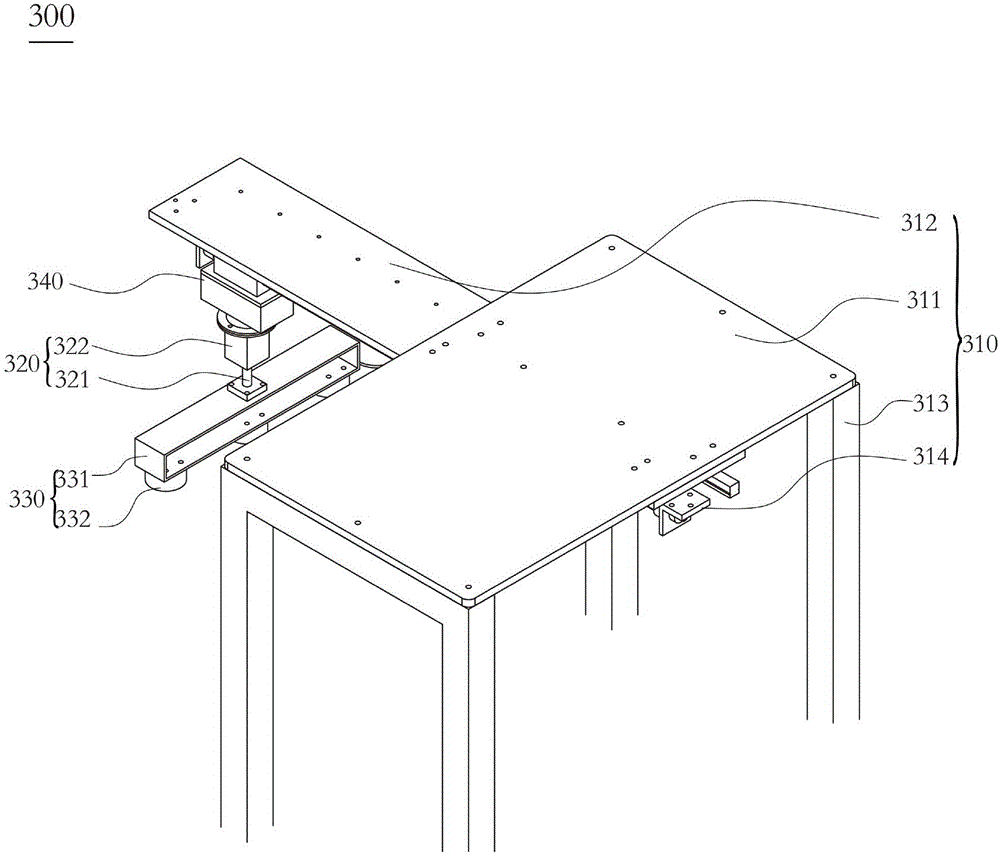

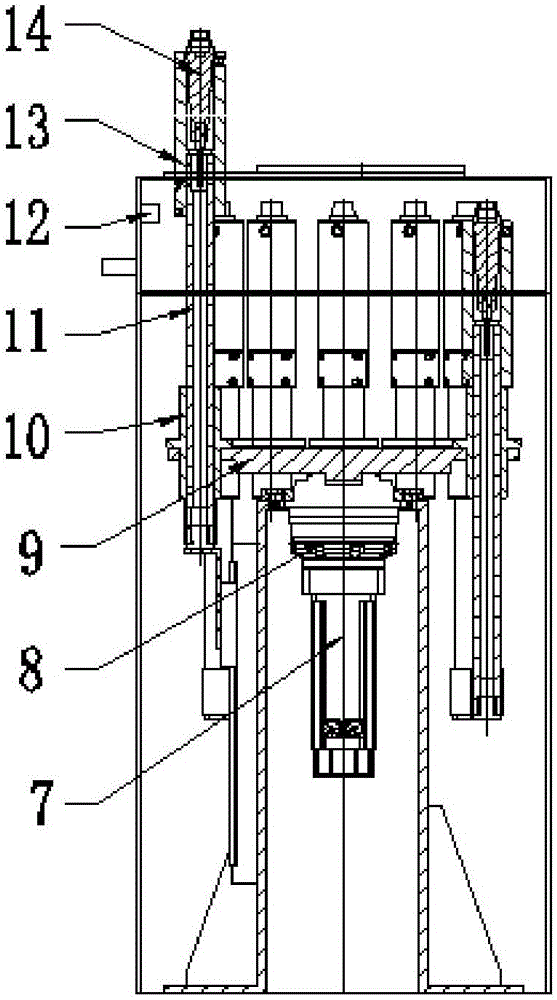

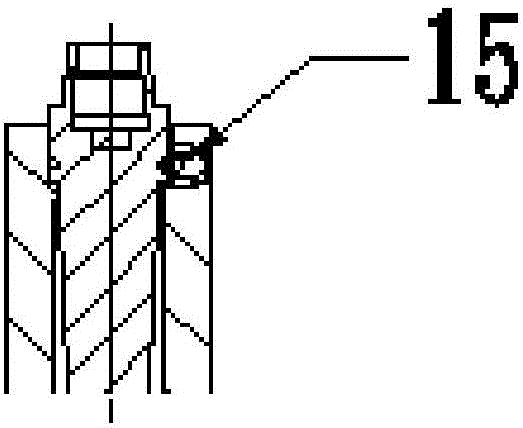

Automatic buckling device used for buckling connection between battery connector and battery test board

ActiveCN105467173AThe connection is compact and reasonableSimplified and smooth action designMeasurement instrument housingMechanical conveyorsElectrical batteryTest board

The invention discloses an automatic buckling device used for buckling connection between a battery connector and a battery test board. The above mentioned device comprises a support, in which is arranged installation space; a device bench disposed on the top part of the support; a tool provided with a battery and a battery test board; a tool shifting mechanism, a battery test board clamping mechanism, a battery flat cable shaping mechanism, and a buckling mechanism, which are disposed on the device bench. The tool can be used to clamp and fasten the battery and the battery test board, and the tool shifting mechanism can be used to move the tool to the working station, and then the battery test board clamping mechanism and a CCD assembly can be used to complete the positioning calibration, and in addition, a flat cable guiding mechanism can be used for the connector flat cable shaping and guiding, and at last the buckling mechanism can be used for the automatic buckling connection between the battery connector and the battery test board, and therefore the automation and the mass production of the battery test can be realized.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

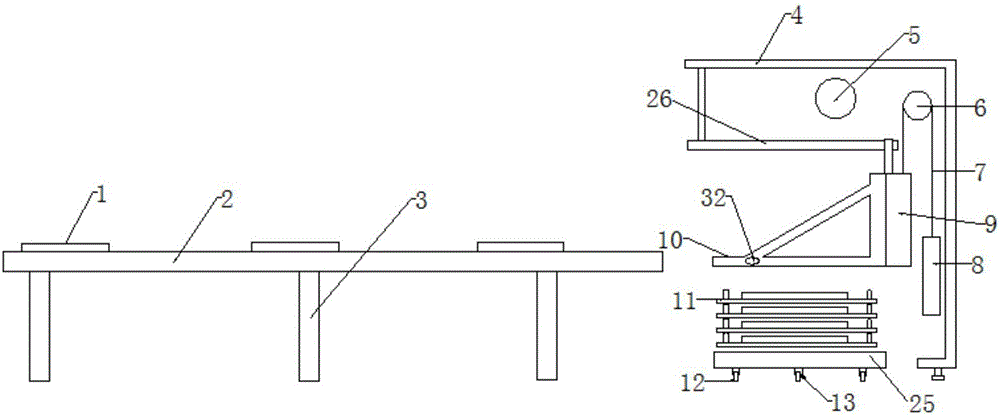

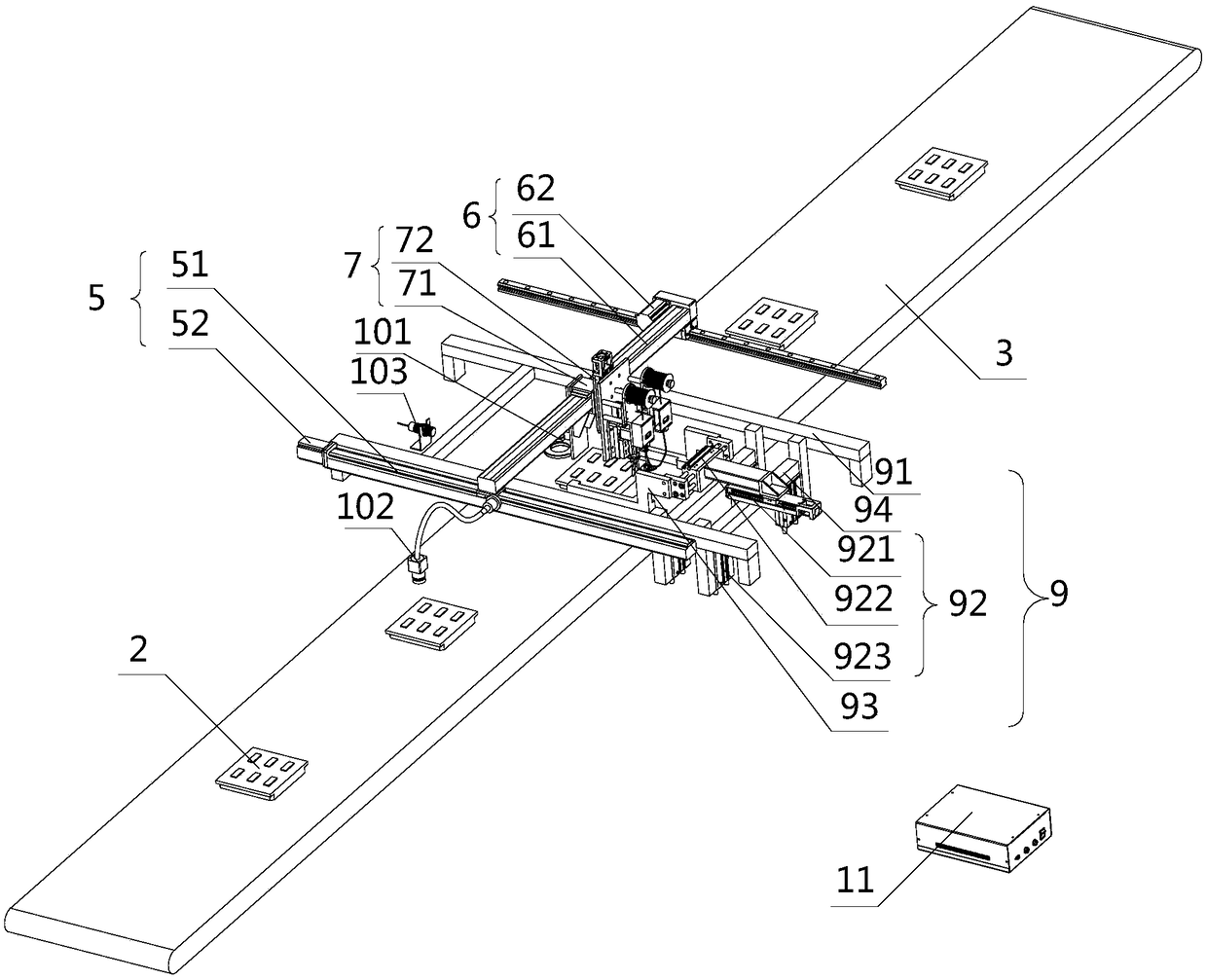

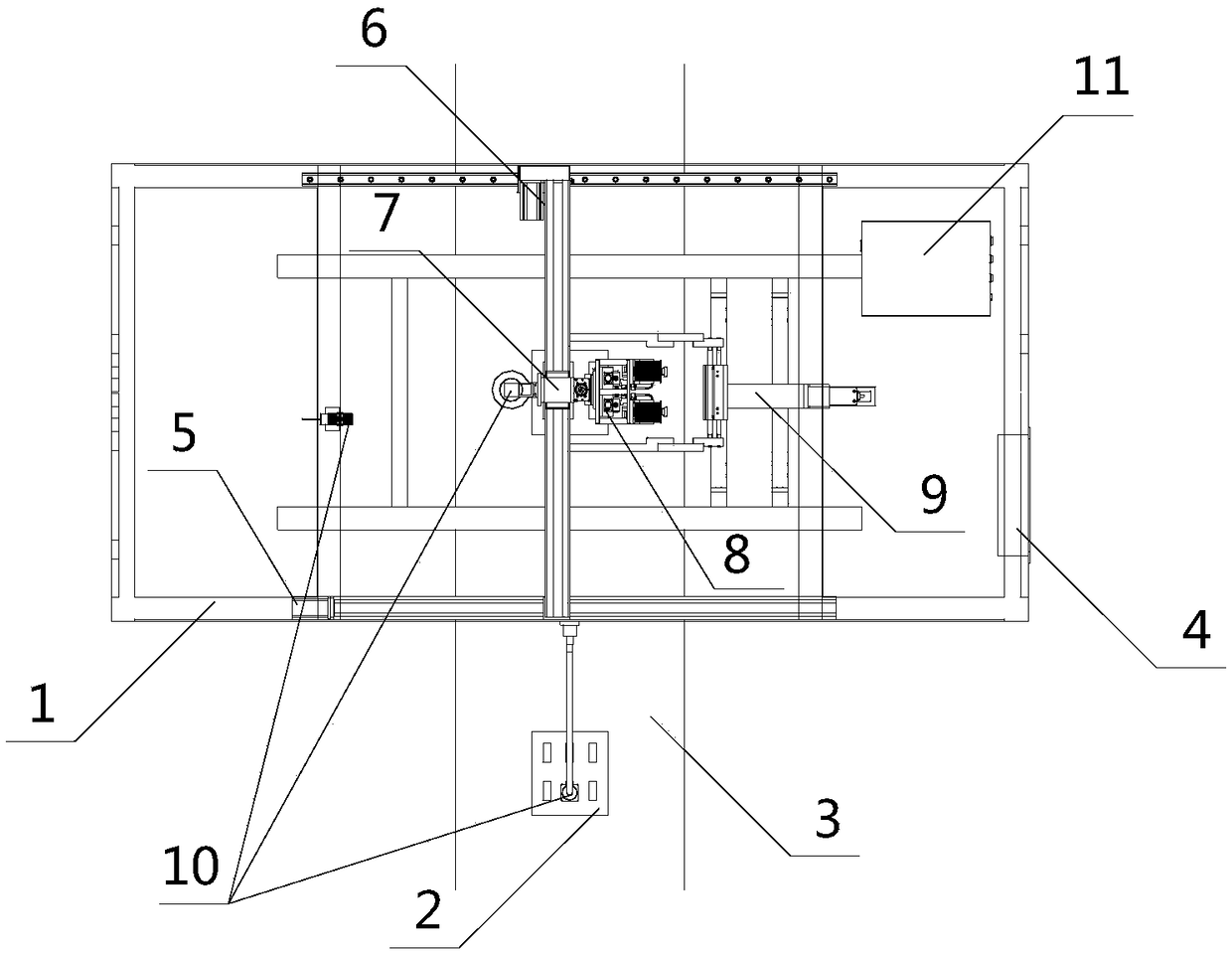

Automatic stitching, buttonholing and buttoning system and method

ActiveCN105019155AAutomate operationSave human effortWork-feeding meansWork-collecting devicesEngineeringAutomatic testing

The invention discloses an automatic stitching, buttonholing and buttoning system and method. The automatic stitching, buttonholing and buttoning system comprises a workbench, a stitching device, a feeding device, a positioning device, a buttonholing device, a buttoning device and a clamping device. The stitching device is arranged on the workbench for stitching cut pieces. The feeding device is provided with a bonding component for bonding the cut pieces and a feeding drive component for driving the bonding component to move. The positioning device is provided with a positioning table facet and a blowing component. The positioning table fact is arranged on the workbench. The blowing component is provided with a plurality of blowing nozzles. The blowing nozzles are fixed to the positioning table fact. The buttonholing device is arranged on the workbench and used for conducting buttonholing on the cut pieces. The buttoning device is arranged on the workbench and used for conducting buttoning on the cut pieces. The clamping device is arranged on the workbench and used for clamping the cut pieces to the buttonholing device and the buttoning device from the positioning table facet. By means of the automatic stitching, buttonholing and buttoning system, the production quality is guaranteed, and production efficiency is high.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

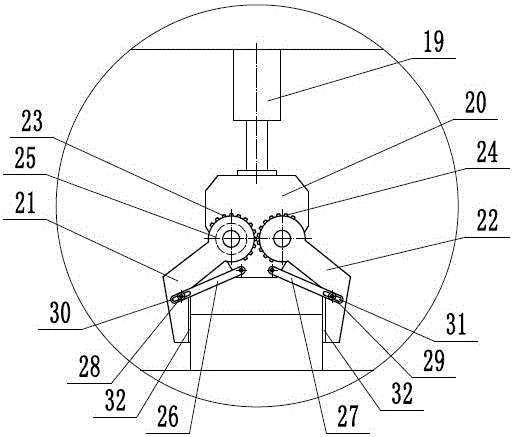

Clamping type manipulator

ActiveCN105459150AGuarantee product qualityAvoid pollutionArmsConveyor partsManipulatorDust particles

The invention discloses a clamping type manipulator. The clamping type manipulator comprises a manipulator base, a lifting driving mechanism arranged on the manipulator base, and a clamping mechanism arranged at the top end of the lifting driving mechanism, wherein the a manipulator base lateral movement driving mechanism is arranged on one side of the manipulator base; the clamping mechanism comprises a pair of rotary driving assemblies which are arranged at the top end of the lifting driving mechanism in a spaced mode; the rotary output end of each rotary driving assembly is connected with a revolving arm; the pair of revolving arms is arranged in parallel and the rotation directions of the revolving arms are opposite; clamping jaw fixing blocks are arranged on the revolving arms; clamping jaws used for clamping the edges of chip containing boxes are arranged on the clamping jaw fixing blocks; position sensors are arranged on the clamping jaw fixing blocks. The clamping type manipulator has the beneficial effects that 1, according to the clamping type manipulator, the chip containing boxes are directly clamped through the clamping jaws, and dust particle pollution and metal pollution are prevented, and thus the production quality of chips is ensured; and 2, clamping and transferring of the chip containing boxes can be achieved conveniently; the transferring speed is greatly increased; the transferring time is shortened; the work efficiency is improved.

Owner:SHANGHAI TUNA ELECTRIC MECHANIC EQUIP CO LTD

Circuit breaker assembly line and controlling method thereof

ActiveCN105109996AImprove production capacity and production efficiencyGuarantee product qualityControl devices for conveyorsMetal working apparatusMachine pressEngineering

The invention discloses a circuit breaker assembly line and a controlling method thereof. The assembly line comprises a lifting and sending device used for lifting and sending assembling jigs, a conveying device used for conveying the assembling jigs, a loading device used for placing circuit breaker shells on an assembly table and a control device, wherein the lifting and sending device is arranged at the start end of the conveying device; a plurality of working tables are arranged at the side edge of the conveying device; the loading device is arranged at the side edges of the working tables; the control device is separately connected with the lifting and sending device, the conveying device, the loading device and each working table. The circuit breaker assembly line has the following benefits that the assembly line production mode is adopted, so that the production efficiency and production capacity are greatly improved; the application of a press machine is avoided, so that damage to the workpieces is avoided, and the quality of the product is effectively guaranteed; a plurality of working tables are adopted, and a plurality of circuit breakers can be assembled at the same time, so that the assembly line is large in conveying capacity, high in speed and capable of achieving same-line divided transportation of products of multiple types; and through the loading device, the lifting of the circuit breaker shells is realized, so that the general assembly efficiency is further improved.

Owner:YIHE ELECTRIC GRP

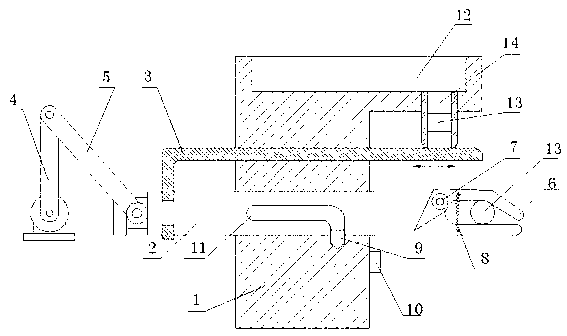

Automatic pasting double side tape device

The invention relates to the technical field of equipment for pasting double side tapes, in particular to an automatic pasting double side tape device. The automatic pasting double side tape device is characterized by comprising a workbench, wherein a left single arm movement mechanism and a right single arm movement mechanism which are composed of ball screw nut pairs and linear motion guide rail pairs are respectively arranged on the left side and the right side of the workbench, a transverse single arm movement mechanism which stretches across the surface of the workbench is installed on the left single arm movement mechanism and the right single arm movement mechanism, a speed change gearbox fixing mechanism at the upper end of a pasting machine head main body is fixedly hung on a nut of the transverse single arm movement mechanism, an output end at the lower end of a speed change gearbox is connected with a rotation shaft of a rotation machine head, the lower end of the rotation shaft is connected with the pasting machine head main body, a feed mechanism support is arranged below the surface of the workbench, a material coiling mechanism support is arranged at the rear of the workbench, corresponding to a feed roller, and a cloth is wound around a feed air swelling shaft and the feed roller and then is arranged on the surface of the workbench. The automatic pasting double side tape device achieves clamping, pulling, pasting, rolling and cutting functions of an adhesive tape, and can enable a pasting machine head to move to an arbitrary point above the surface of the workbench.

Owner:NORTH CHINA INST OF AEROSPACE ENG

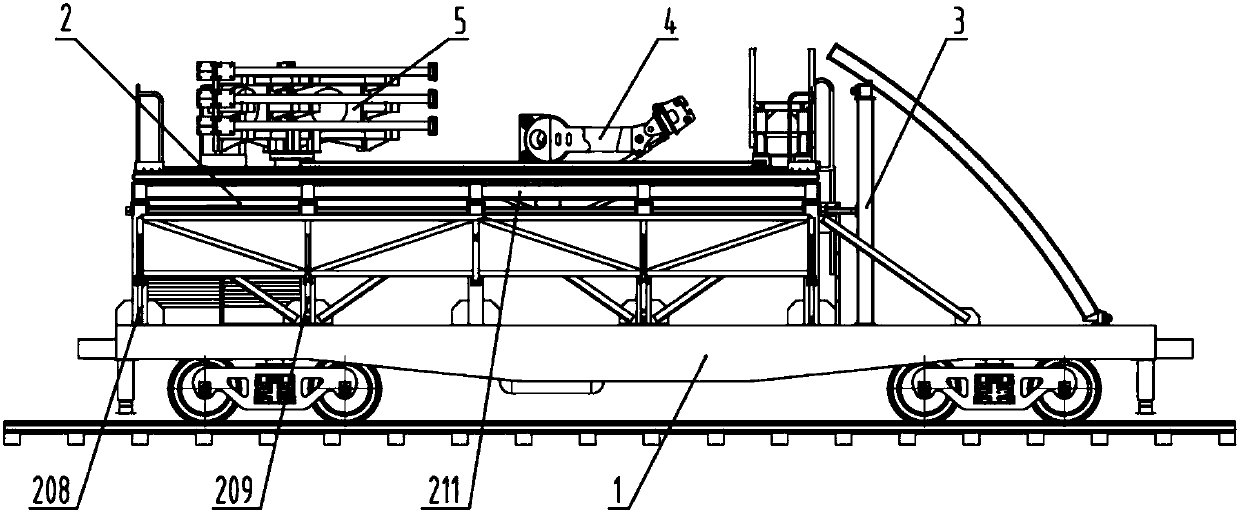

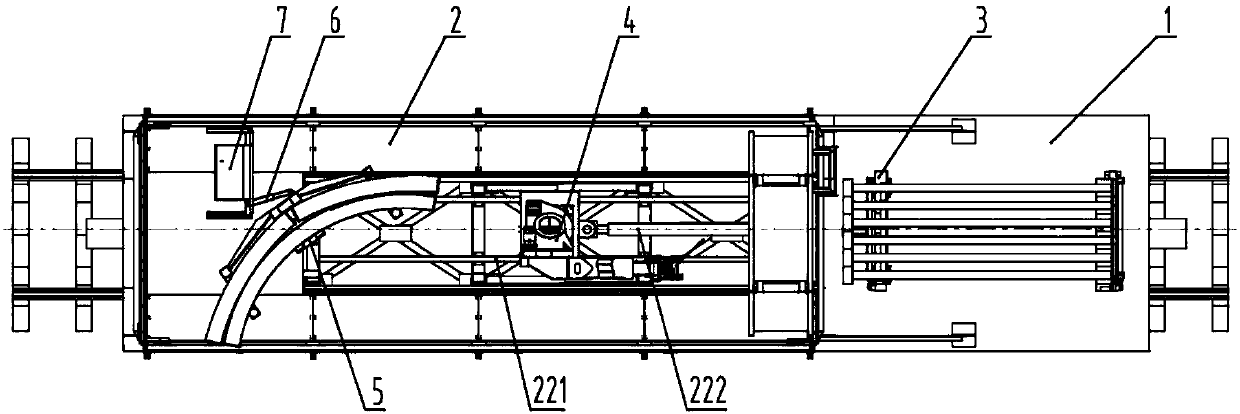

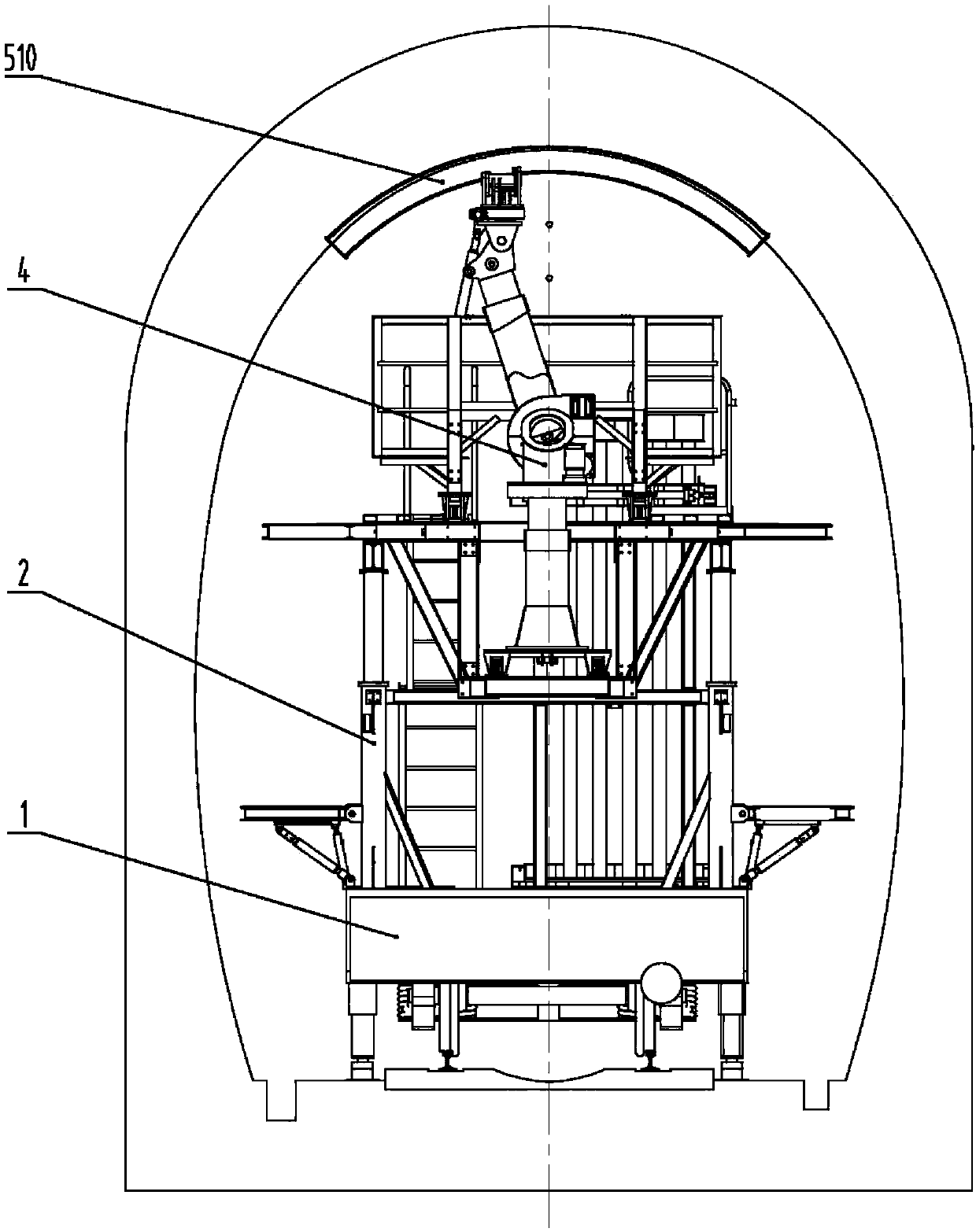

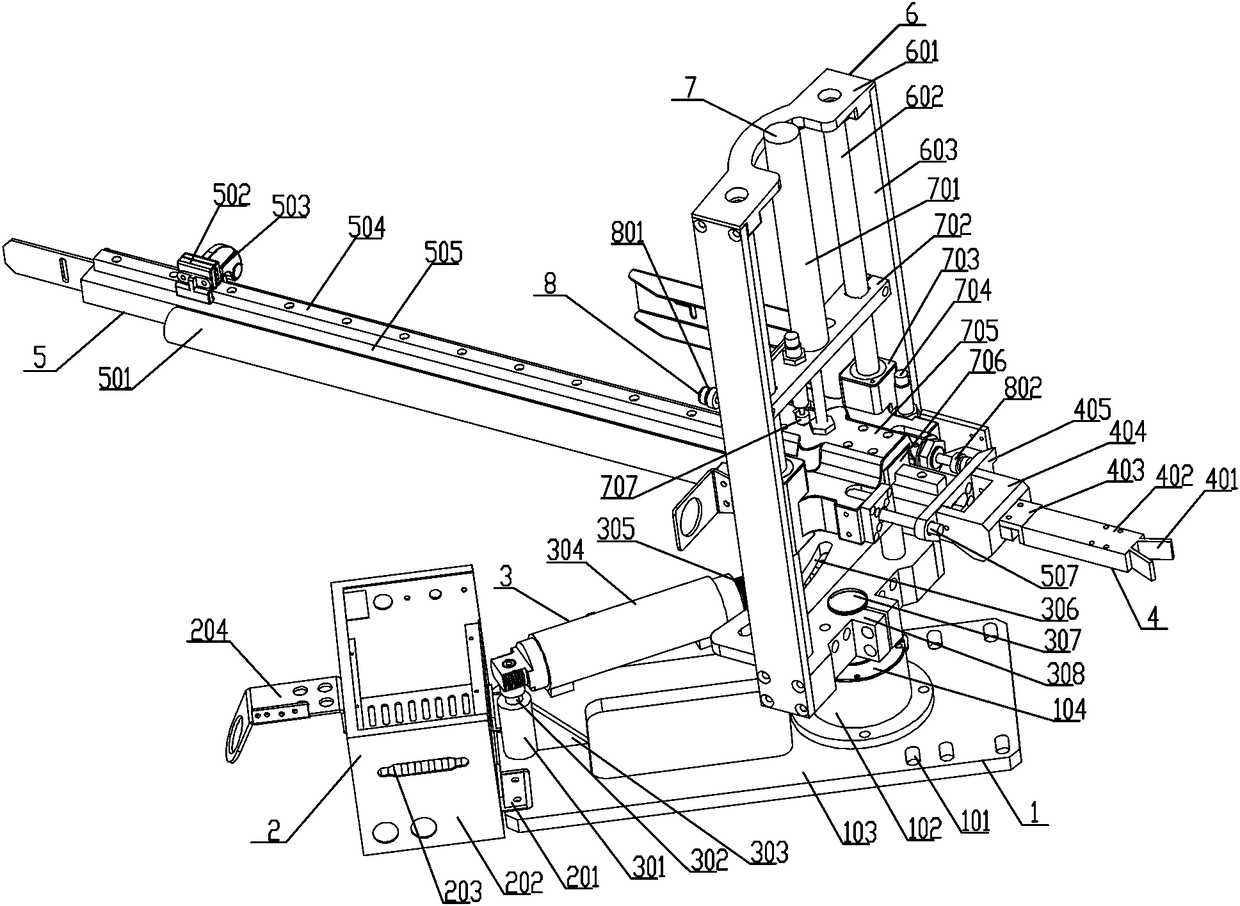

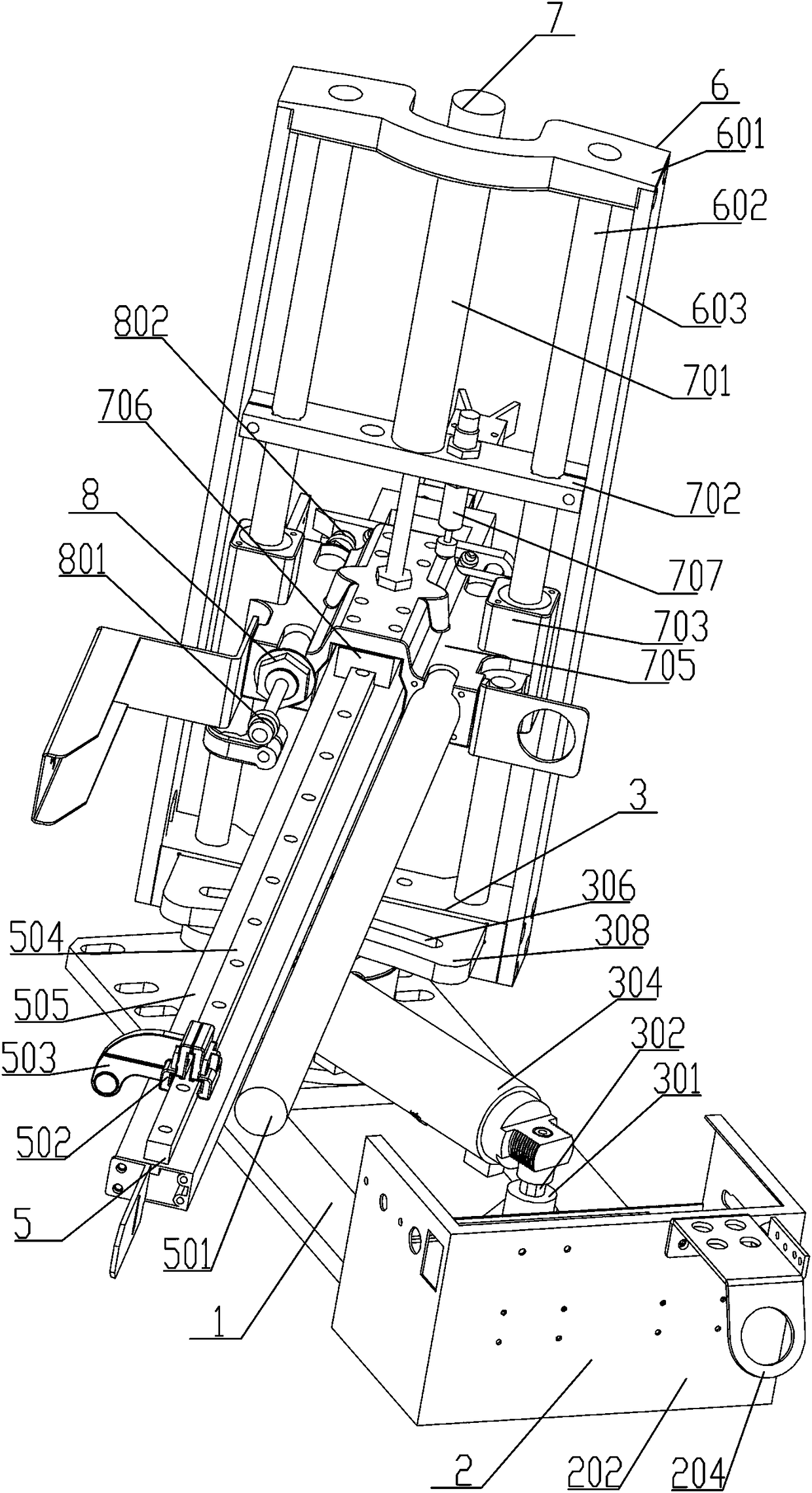

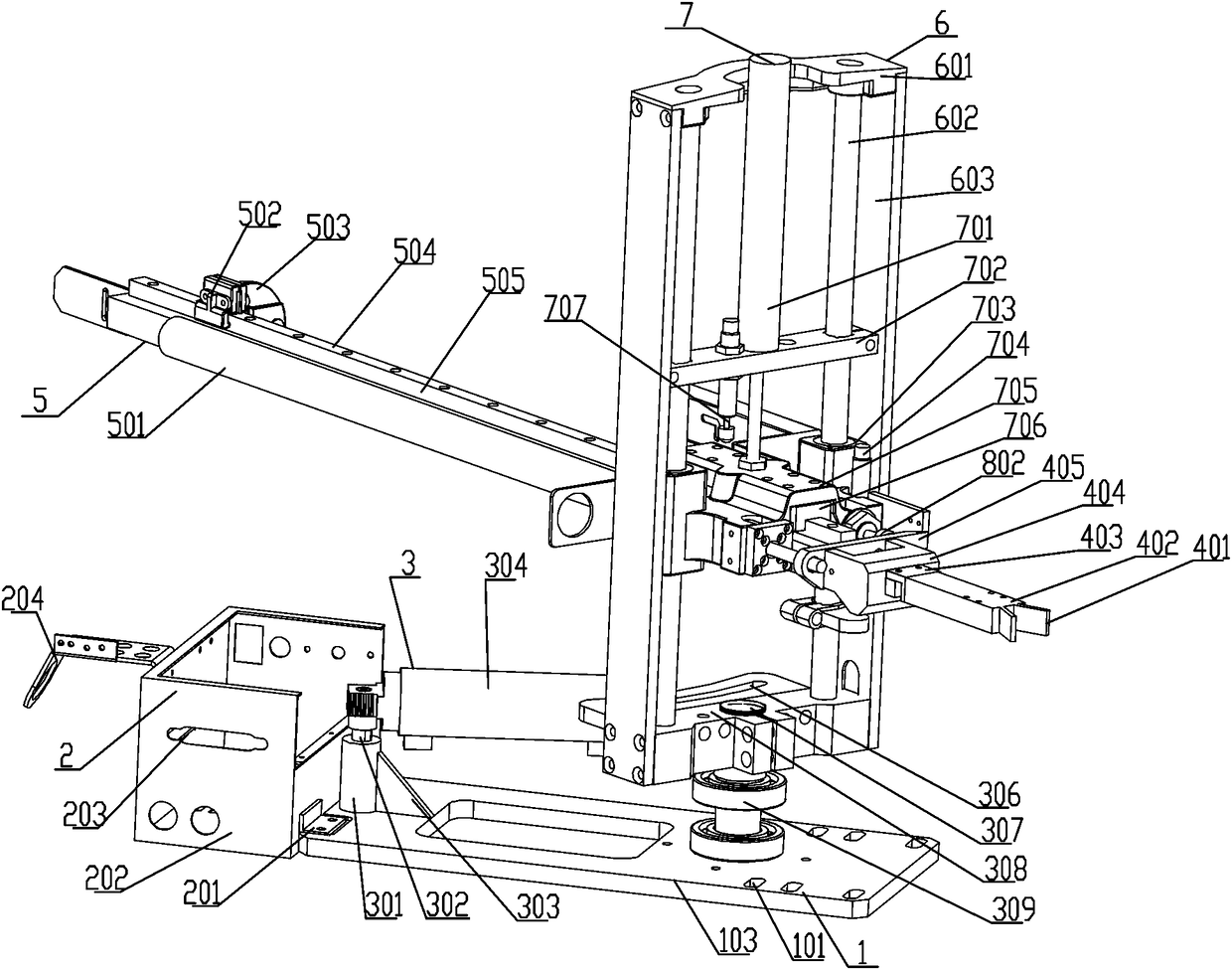

Steel arch frame mounting trolley used for operation tunnel disease treatment and steel arch frame mechanical mounting method used for operation tunnel disease treatment

PendingCN107654245AEasy to moveEasy and quick to reachUnderground chambersTunnel liningElectrical controlDisease treatment

The invention discloses a steel arch frame mounting trolley used for operation tunnel disease treatment. The steel arch frame mounting trolley comprises a steel arch frame mounting operating mechanism, an electrical control part and a hydraulic control part. The steel arch frame mounting operating mechanism comprises a railroad flatbed vehicle, a lift trolley, a side wall steel arch frame feedingmechanism, a steel arch frame mounting machine and an arch top and arch waist steel arch frame feeding mechanism, wherein the lift trolley and the side wall steel arch frame feeding mechanism are installed on the railroad flatbed vehicle, and the steel arch frame mounting machine and the arch top and arch waist steel arch frame feeding mechanism are mounted on the lift trolley. The invention further provides a steel arch frame mechanical mounting method used for the operation tunnel disease treatment. According to the steel arch frame mounting trolley, by arranging the railroad flatbed vehicle, the lift trolley, the side wall steel arch frame feeding mechanism, the steel arch frame mounting machine, the arch top and arch waist steel arch frame feeding mechanism, the electrical control partand the hydraulic control part, side walls and arch top and arch waist steel arch frames can be automatically mounted during tunnel disease treatment, the manpower input is reduced, the mechanizationand automation degrees are high, and the mounting efficiency, quality and operation safety of the steel arch frames of the tunnel disease treatment are sharply improved.

Owner:中铁西南科学研究院有限公司

Stone removing device for hepatobiliary surgical operation

ActiveCN109730746AReasonable structural designEasy to inject medicineSurgeryMedical devicesSyringeEngineering

The invention relates to the technical field of medical instruments, and particularly relates to a stone removing device for hepatobiliary surgical operation. The device comprises an outer tube, a baffle, a stone removing device body and an infusion device, a first through hole is formed between the left and right ends of the outer tube, a cylindrical structure of a second through hole is formed in the front of the first through hole, the rear ends of the first through hole is provided with a first through groove, the baffle is fixedly connected with the middle of the interior of outer tube, afirst through hole and a second through hole are correspondingly formed in the baffle, and a clamping groove is formed in the upper end of the first through hole. The stone removing device has the advantages that the structural design is reasonable, a T-shaped rod is pushed leftwards and rotated to achieve the wrapping of a large stone and the cutting and clamping of remaining small connective tissues, the T-shaped rod is rotated rightwards and pulled to retract the stone removing device back to the interior of the outer tube, a syringe extends out from the second through hole to convenientlyinject medicines, the function is comprehensive, the vision is broad, and the stone removing device is provided with better popularization prospects.

Owner:薛峰

Diode grabbing manipulator

InactiveCN106541388AFlat surfaceUp to suctionProgramme-controlled manipulatorGripping headsIgnition coilEngineering

A diode grabbing manipulator is mainly composed of a left-right transplanting part, a lifting part, a one-dimensional slide table mechanism and a manipulator tail end execution mechanism (paw). According to the diode grabbing manipulator, the pneumatic technology, the servo technology and the vacuum technology are adopted, the structure is compact, suction and assembly of diodes of different ignition coils can be achieved, the high speed orientation and automation of ignition coil assembly are achieved, the diode grabbing manipulator is clean and free of pollution, and the surfaces of the diodes are not damaged.

Owner:褚秀清

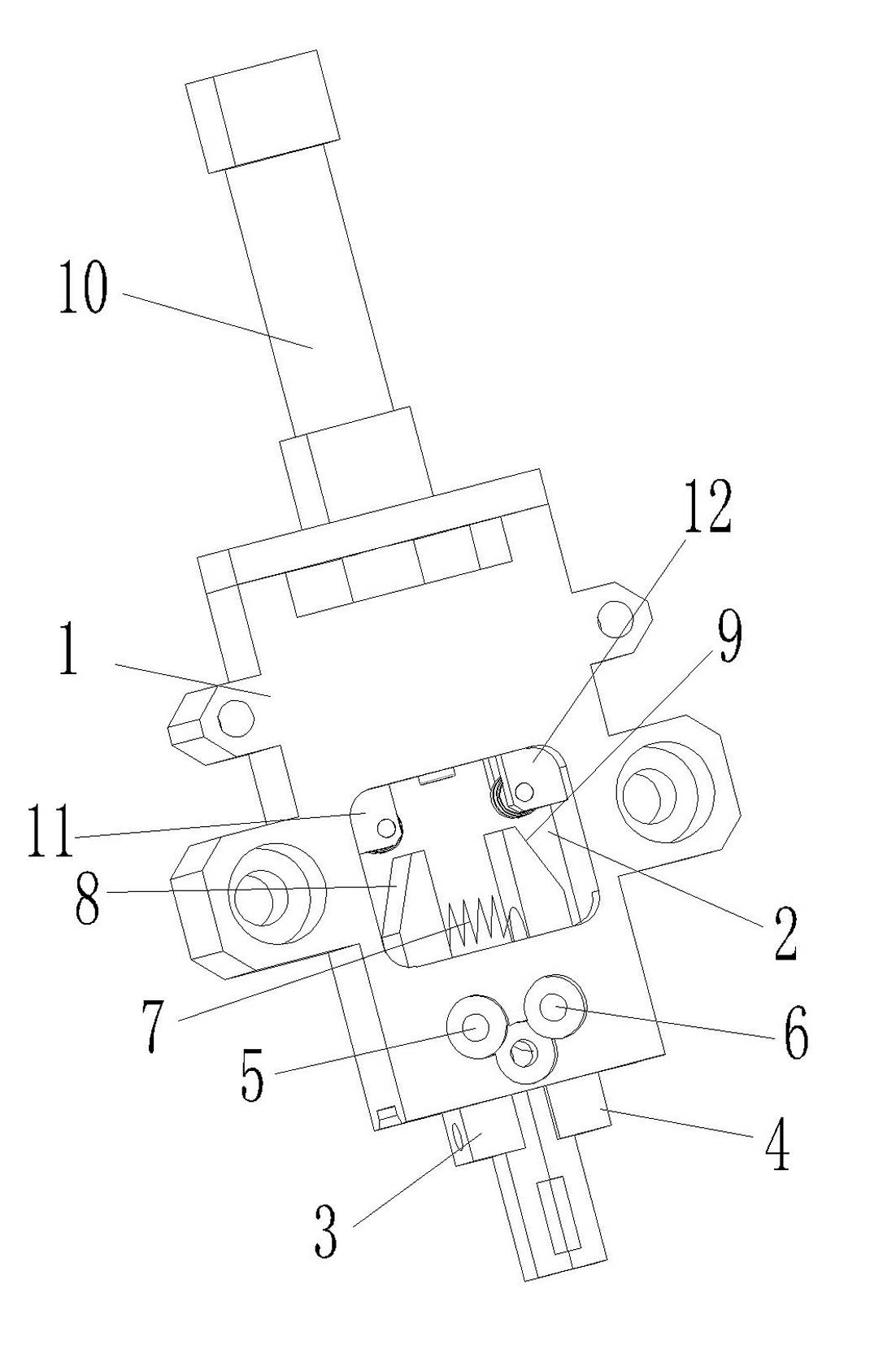

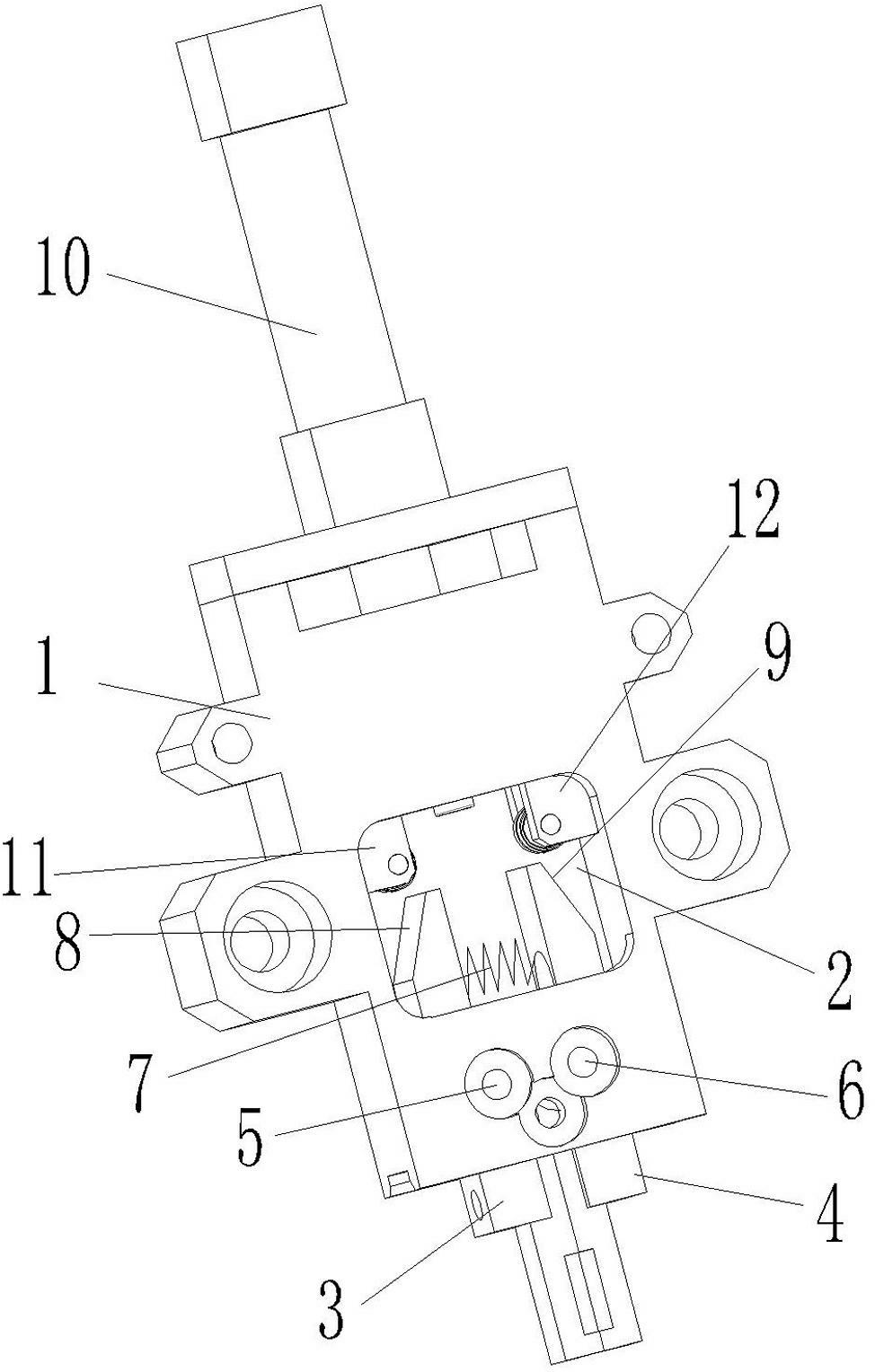

Workpiece holding mechanism

The invention discloses a workpiece holding mechanism, which comprises a support, a first clamping jaw, a second clamping jaw and an air cylinder, wherein the support has an accommodating inner cavity; the lower end faces of the first clamping jaw and the second clamping jaw extend to the accommodating inner cavity of the support from the lower end face of the support; the parts in the accommodating inner cavity of the first and second clamping jaws are regulating parts, and the left parts of the first and the second clamping jaws are holding parts; a pressure spring is arranged between the regulating parts of the first and second clamping jaws; the holding parts of the first and second clamping jaws move close to each other under the action of the pressure spring; the outside side face of the regulating part of the first clamping jaw has a first inclined face, and the outside side face of the regulating part of the second clamping jaw has a second inclined face; the piston rod of the air cylinder extends into the accommodating inner cavity; the tail end of the piston rod of the air cylinder is connected with a lower pressure piece which has a first pressure head and a second pressure head; and the first pressure head is opposite to the first inclined face and the second pressure head is opposite to the second inclined face. In the invention, a workpiece is held by an air cylinder and clamping jaw cooperation mechanism, the structure of the mechanism is simple, and the cost of the mechanism is relatively low.

Owner:宁波市新泽谷机械有限公司

Intelligent welding system and method

PendingCN109332840AReduce manual debugging workloadImprove work efficiency and product qualityMetal working apparatusSoldering auxillary devicesAssembly lineWorkload

The invention relates to an intelligent welding system and method. The system comprises an assembly line, an industrial personal computer, a moving platform, a clamping assembly, a visual system and awelding assembly, wherein the visual system, the clamping assembly and the welding assembly are arranged on the moving platform; the assembly line, the moving platform, the clamping assembly, the welding assembly and the visual system are electrically connected with the industrial personal computer; the clamping assembly can clamp a circuit board moving on the assembly line so as to arrive at thepreset position; and the welding assembly can be used for welding the circuit board clamped by the clamping assembly. According to the intelligent welding system and the method provided by the invention, the visual system acquires image information of the circuit board moving to the preset position, the industrial personal computer recognizes welding pad information on the circuit board, weldingpulse information is generated by combining pre-stored printing information, and the circuit board clamped by the clamping assembly is automatically welded, so that the previous artificial debugging workload is greatly reduced, the working efficiency and the product quality are improved, the welding parameters cannot be adjusted aiming at circuit boards of different circuit structures, and the intelligent degree is high.

Owner:WUHAN XINYUAN TUOER TECH CO LTD

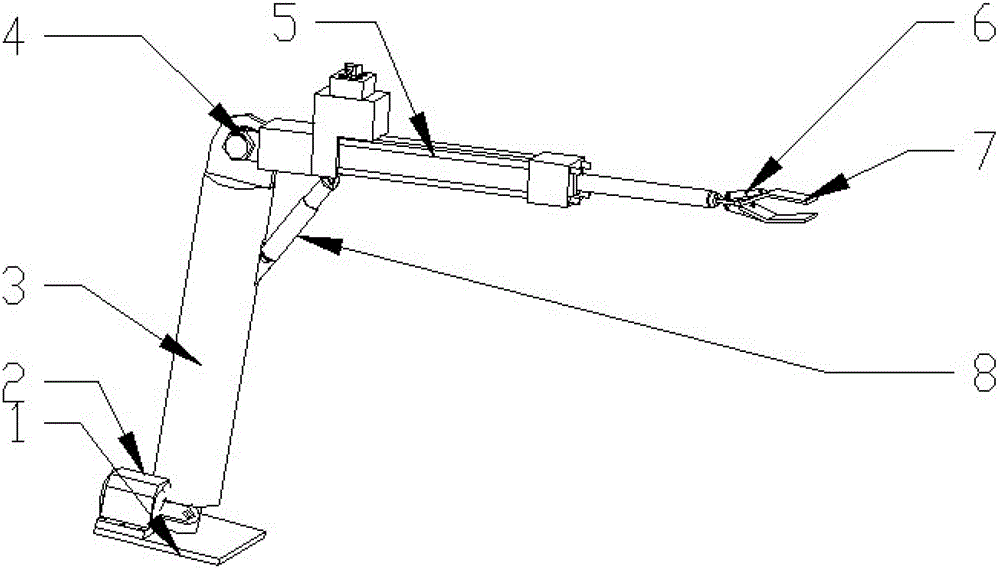

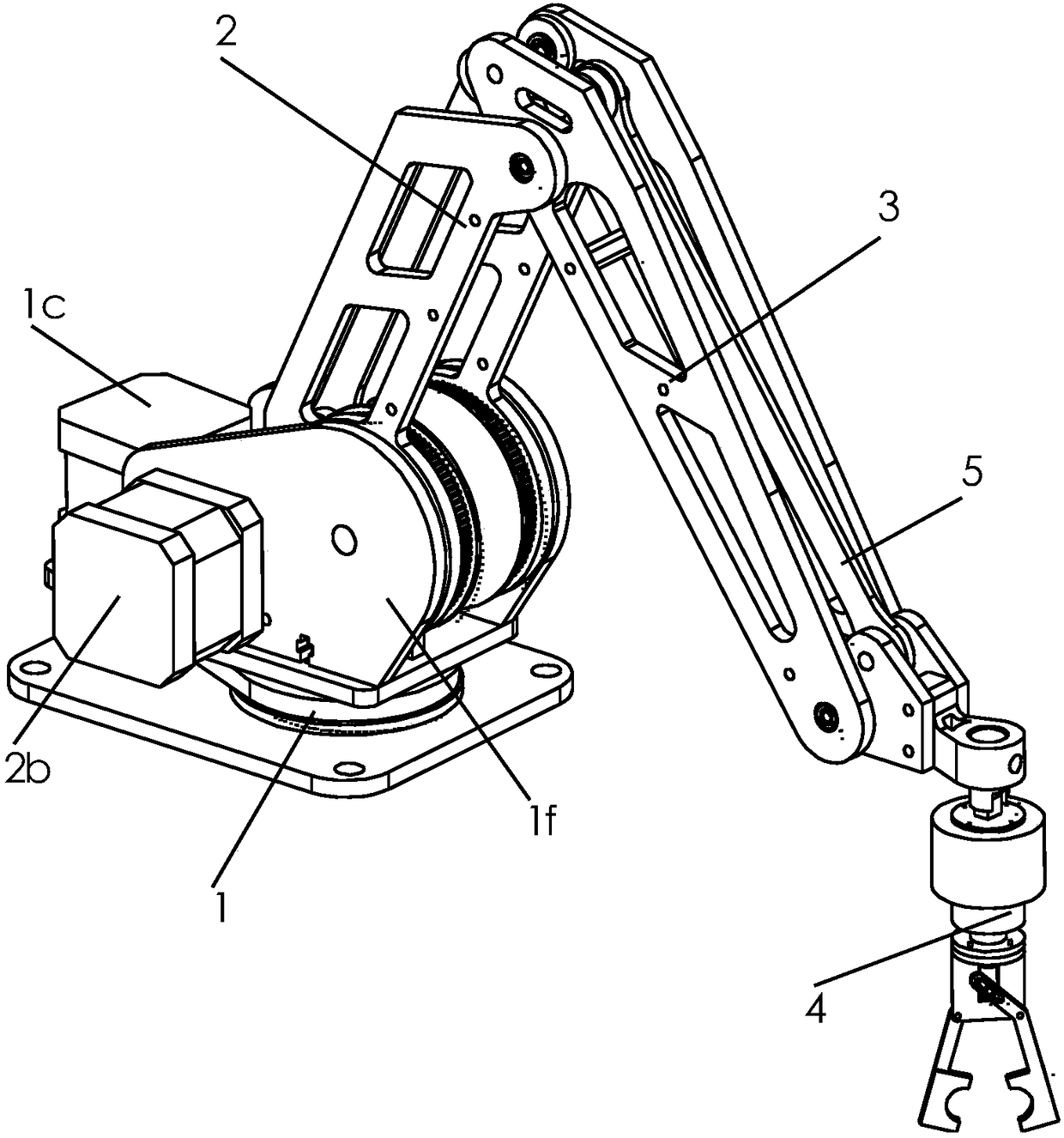

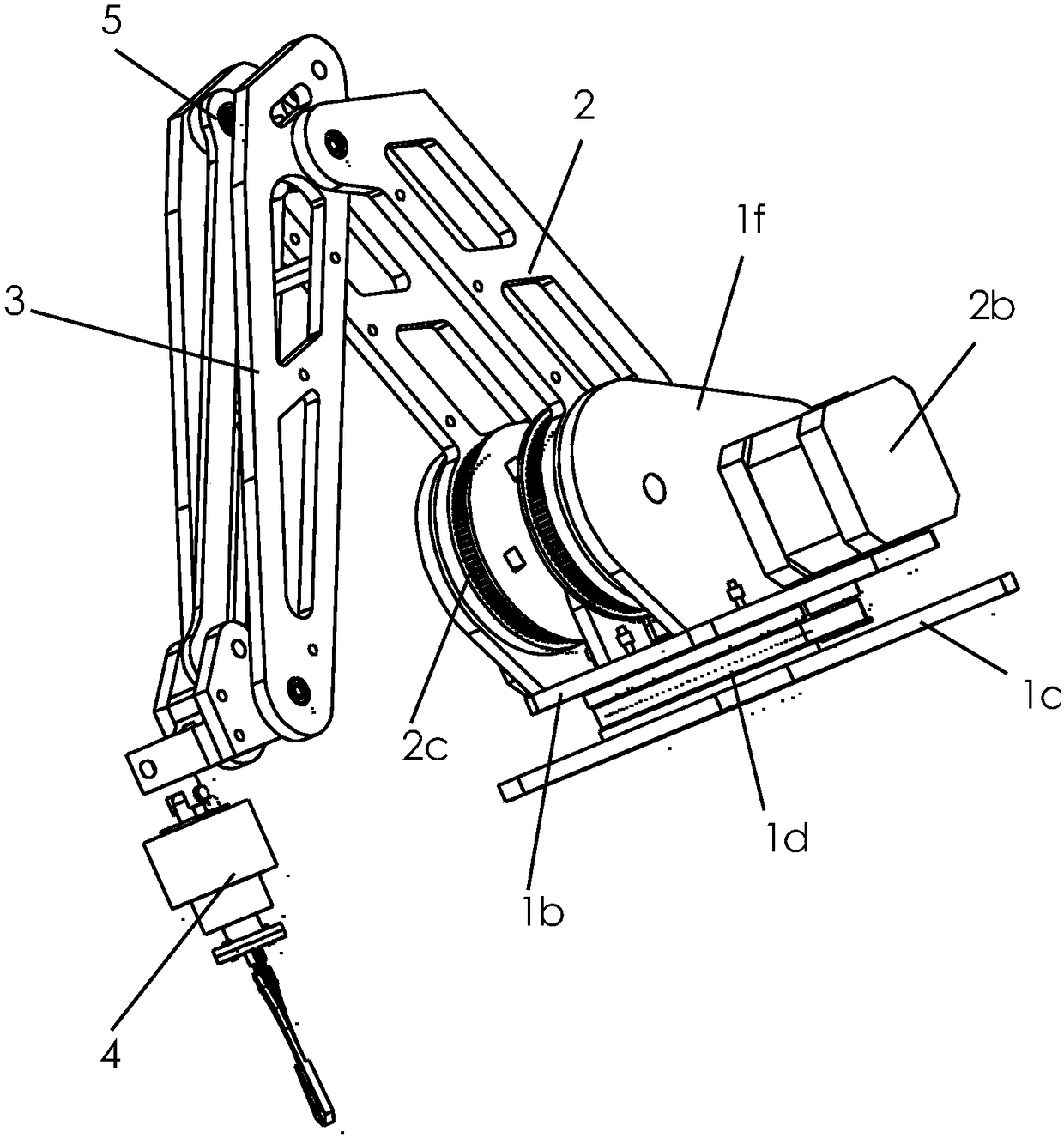

Flexible hydraulic mechanical hand

InactiveCN102975198AAchieve grippingProgramme-controlled manipulatorArmsHydraulic motorHydraulic cylinder

The invention provides a flexible hydraulic mechanical hand, which structurally consists of a base, a hydraulic motor, a rotating rod, a pin, a first hydraulic cylinder, a second hydraulic cylinder, a mechanical claw, a third hydraulic cylinder and a fourth hydraulic cylinder, wherein the rotating rod is arranged on the base, the hydraulic motor is arranged at the bottom of the rotating rod, the first hydraulic cylinder is connected with the rotating rod through the pin, the two ends of the fourth hydraulic cylinder are respectively arranged on the first hydraulic cylinder and the rotating rod, the mechanical claw is connected with the first hydraulic cylinder through the second hydraulic cylinder and the third hydraulic cylinder, the mechanical hand can freely rotate around the rotating rod and can freely extend through the first hydraulic cylinder, the first hydraulic cylinder can be freely lifted through the fourth hydraulic cylinder, and the mechanical hand can realize the clamping of articles in different angles through different extending length of the second hydraulic cylinder and the third hydraulic cylinder.

Owner:厉彦亮

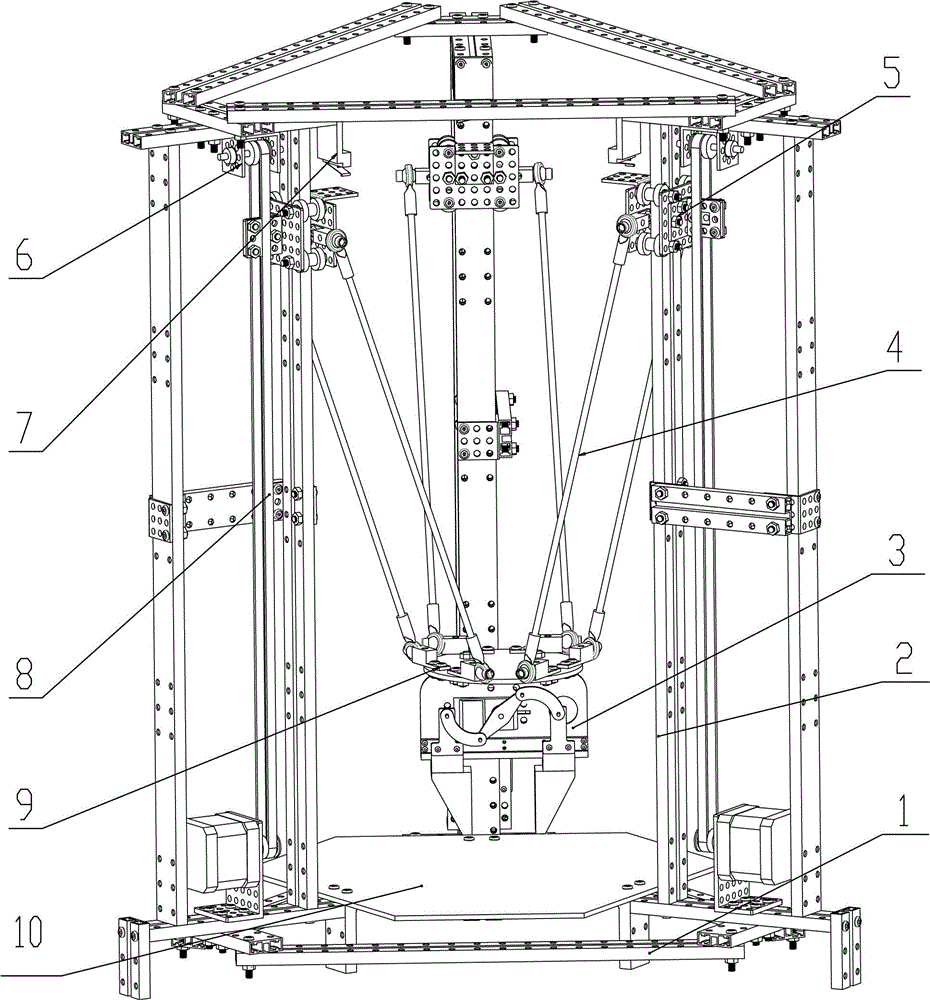

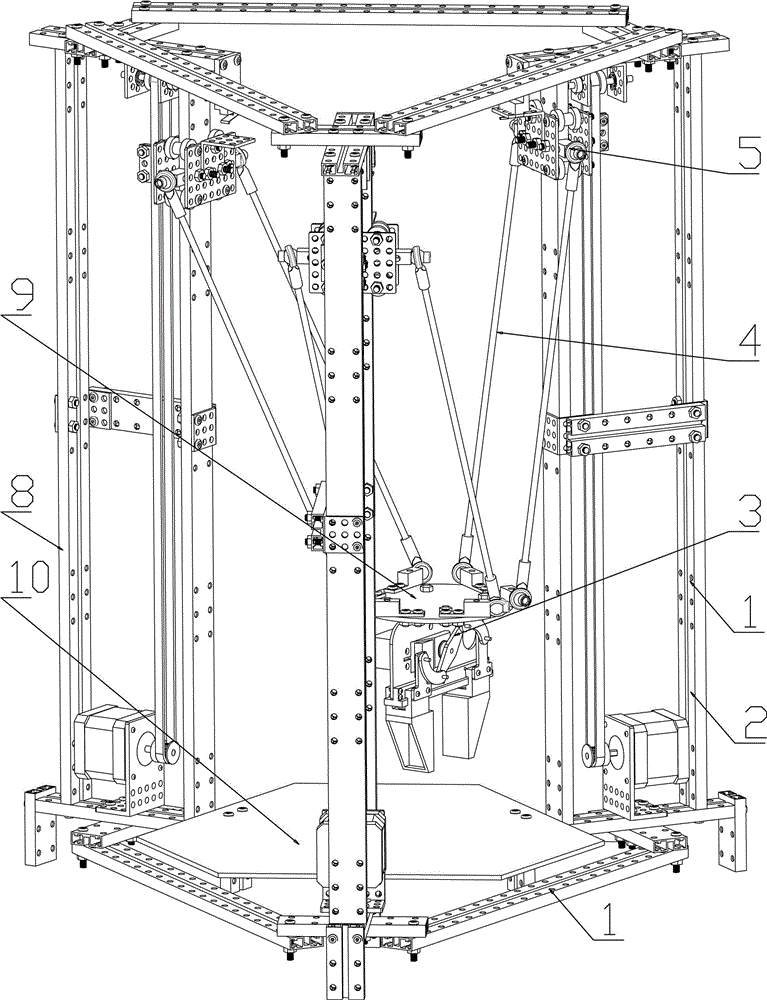

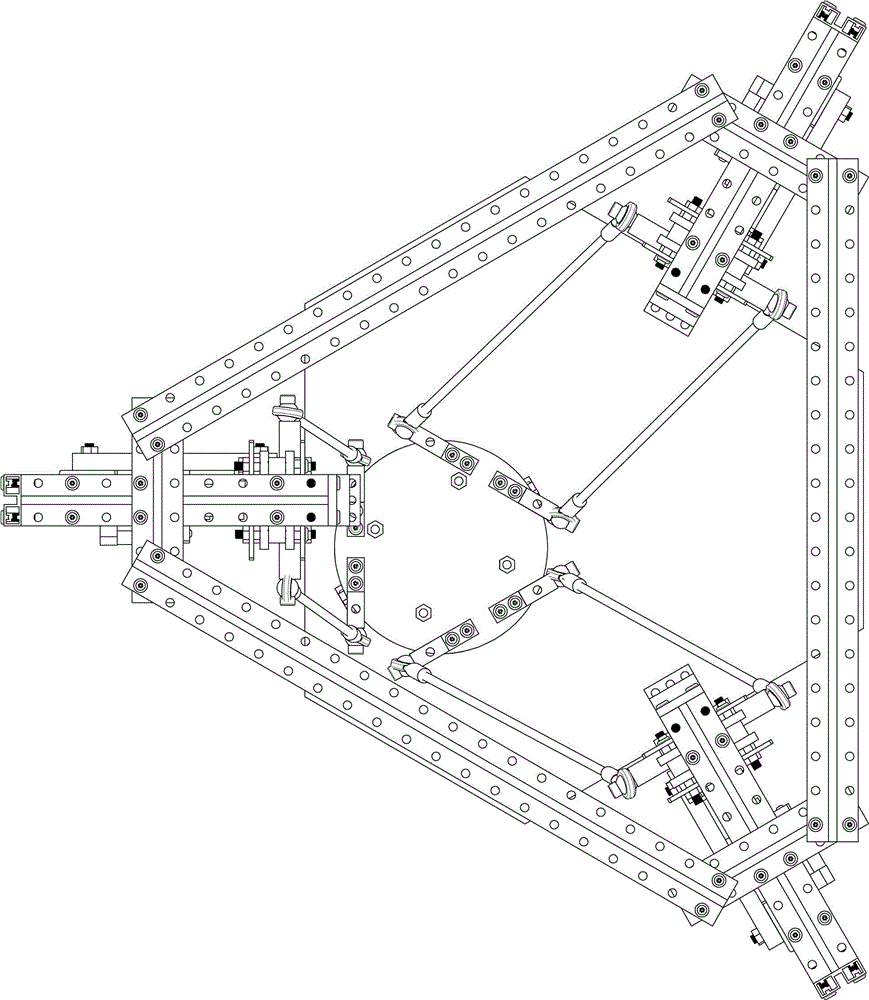

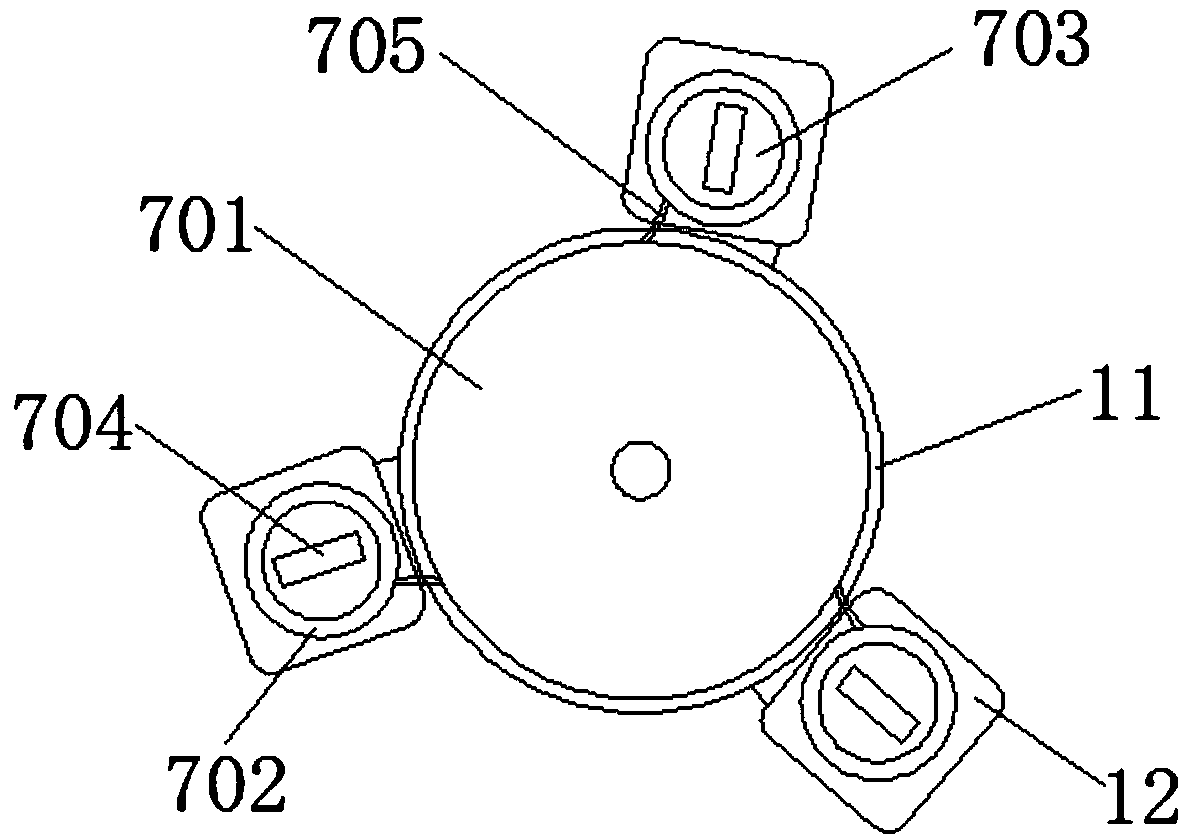

Leap motion parallel mechanical arm based on Leap Motion and operation method and control system of leap motion parallel mechanical arm

The invention relates to a leap motion parallel mechanical arm based on Leap Motion and an operation method and control system of the leap motion parallel mechanical arm. Three connecting supports and three stepping motor supports are alternately connected end to end to form a hexagonal frame base. Minitype touch switches are fixedly mounted on the stepping motor supports. Synchronous belts for driving pulley block supports to slide vertically are arranged on synchronous belt pulley frames. The upper ends of threaded rod assemblies are connected with the pulley block supports, and the lower ends of the threaded rod assemblies are connected with mechanical arm fixing pieces. A mechanical arm body for clamping objects is fixed to the lower ends of the mechanical arm fixing pieces. A bottom tray for storing the objects is arranged under the mechanical arm body. The mechanical arm body is controlled by vertical sliding of the three pulley block supports to take and place the objects stored on the bottom tray. The motion of the mechanical arm is controlled by combining the leap motion technology and the Leap Motion controller, a traditional program control method is replaced, and automatic control can be achieved conveniently.

Owner:佟彧

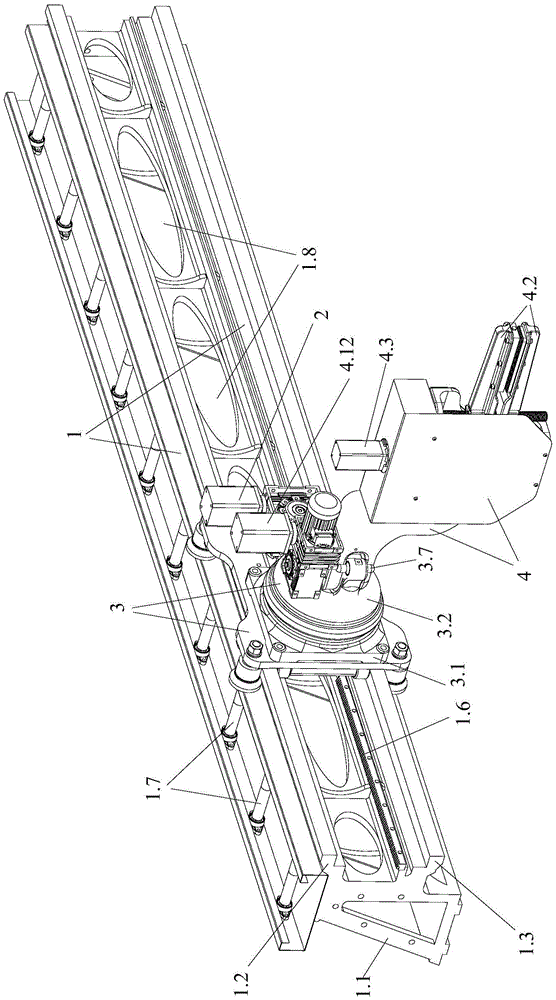

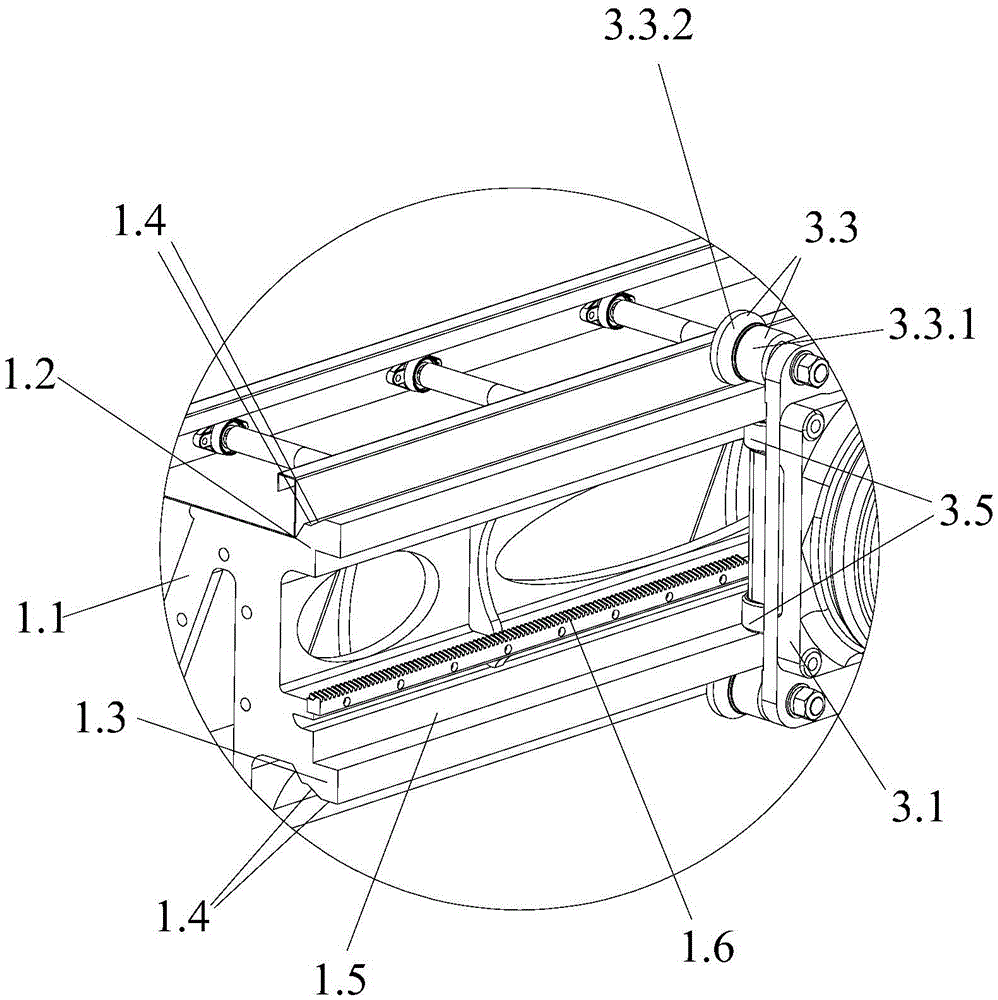

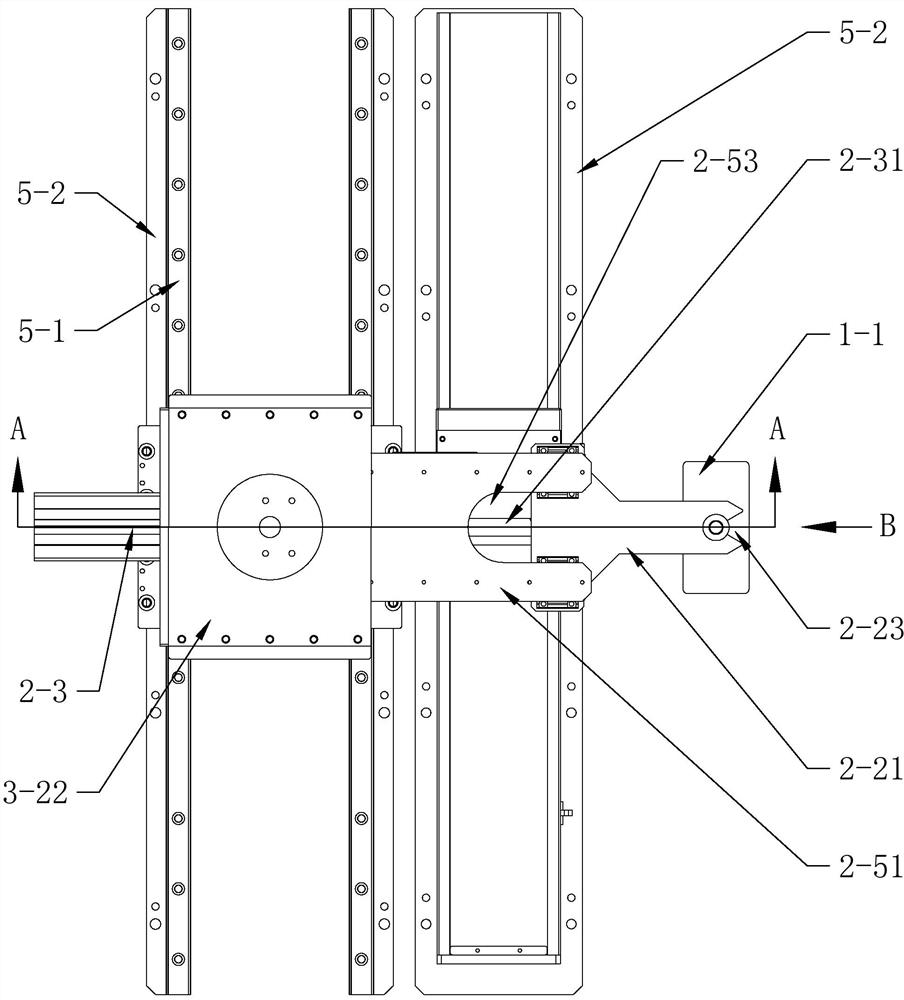

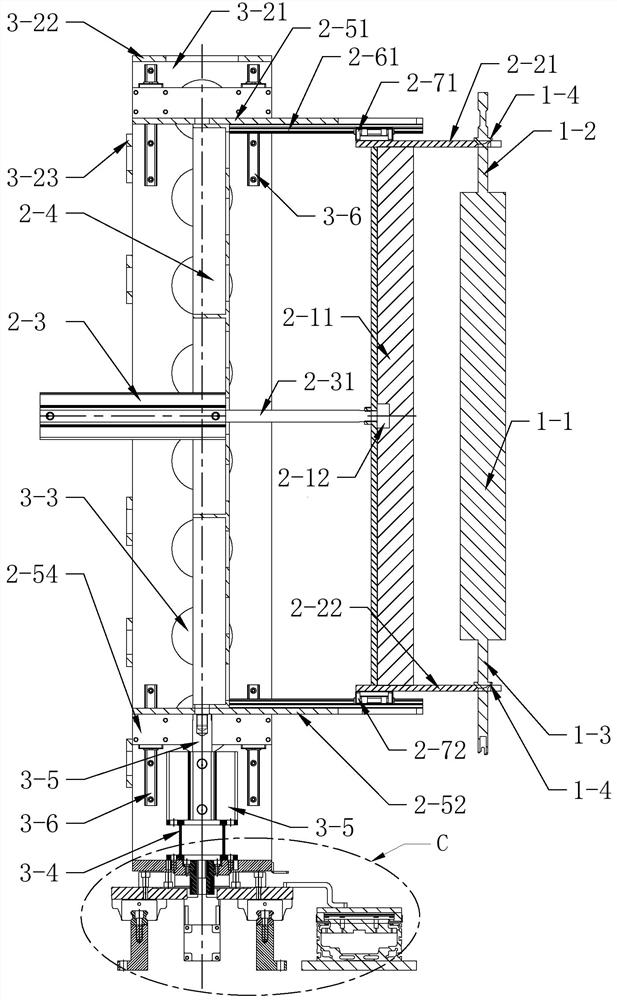

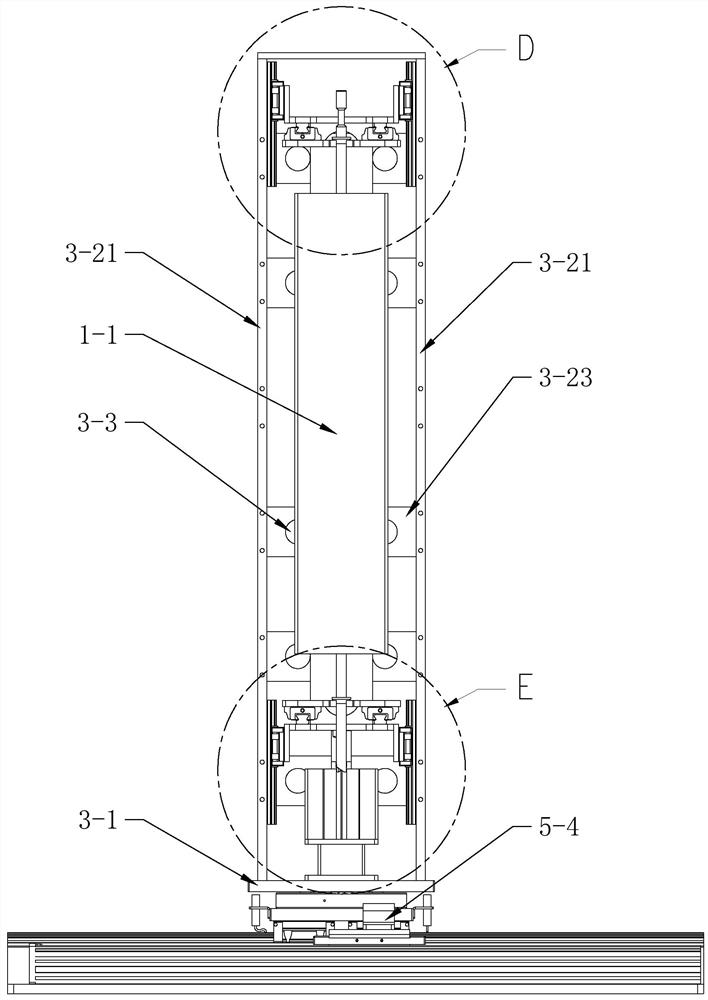

Vertical profile single-rail traction robot

The invention provides a vertical profile single-rail traction robot. The vertical profile single-rail traction robot comprises a vertical walking rail, a mechanical arm for clamping and towing a profile, a transmission mechanism, a driving mechanism for connecting with the transmission mechanism, and a control mechanism; the mechanical arm is buckled on the side surface of the vertical walking rail, and is slidingly connected with the side surface of the vertical walking rail to realize walking movement by hanging on the side surface of the vertical walking rail; the transmission mechanism consists of a transmission device 1 arranged on the mechanical arm and a transmission device 2 arranged on the vertical walking rail; and the control mechanism is respectively in signal connection with the driving mechanism and the mechanical arm. The vertical profile single-rail traction robot adopts the mechanical arm as an actuation mechanism for towing the profile, and is flexible in operation and convenient for control. Meanwhile, the vertical profile single-rail traction robot can shrink the floor area to reduce the production cost, and is not influenced by the ground condition to effectively solve the problem of incapability of guaranteeing the profile towing straightness caused by uneven ground so as to improve the profile towing processing quality.

Owner:广东泰格威机器人科技有限公司

Stack-up device for electric power equipment

InactiveCN105329820AAdjust gripAdjust and place thingsLifting devicesElectric power equipmentPower equipment

The invention discloses a stack-up device for electric power equipment. The stack-up device for the electric power equipment comprises an operating platform. A first motor is arranged inside the operating platform, and an output shaft of the first motor penetrates through and inserts into the top of the operating platform and is connected with a cylinder. The cylinder is located on the operating platform, and the top of the cylinder is connected with a bottom plate. A lifting platform is arranged at the top of the bottom plate. A second motor is arranged on the inner wall of the lifting platform, and an output shaft of the second motor is connected with a rotating shaft. Two first sliding grooves are formed in the surface of the lifting platform. The interiors of the two first sliding grooves are both in sliding connection with supporting rods, and the two supporting rods are connected through a connecting rod. In addition, the other end of a first electronic telescopic rod penetrates through and inserts into a second sliding groove and is connected with an L-shaped sliding block. A clamping component comprises a clamping block. A second electronic telescopic rod is arranged on the inner wall of the left side of the clamping block, and the other end of the second electronic telescopic rod penetrates through and inserts into a first hole groove and is connected with a second connecting post. According to the stack-up device for the electric power equipment, the clamping and placing effects by rotating at 360 degrees are achieved, and the effect of adjusting the clamping sizes is achieved.

Owner:常州亚各来德机电设备制造有限公司

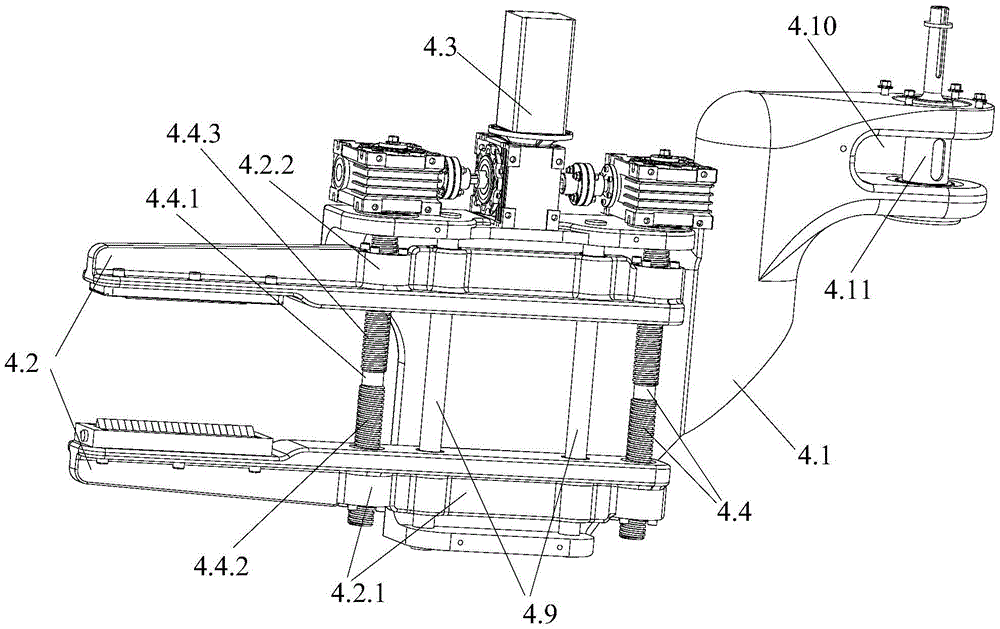

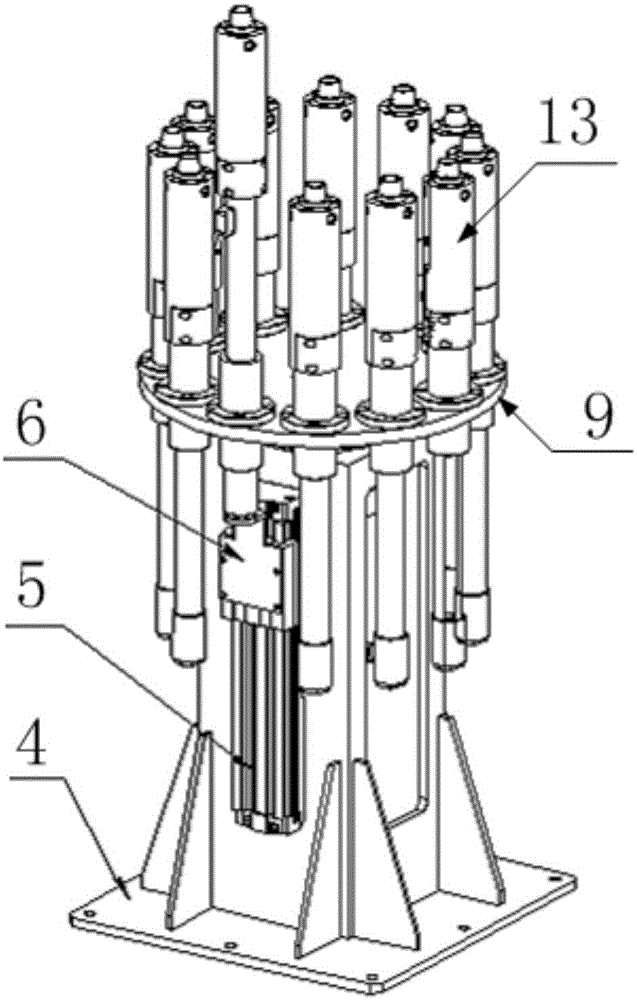

Tool changer and mobile robot drilling-riveting equipment comprising same

InactiveCN106826333AHigh positioning accuracyGuaranteed uptimeFeeding apparatusOther manufacturing equipments/toolsEngineeringRotating disc

The invention discloses a tool changer and mobile robot drilling-riveting equipment comprising the same. The tool changer comprises a tool base, a plurality of liftable tool fixing seats, a tool rotating disc, a rotating device for rotating the tool rotating disc and a lifting device for lifting the tool fixing seats, wherein the rotating device is fixed on the tool base, the tool rotating disc is arranged on the rotating device, the tool fixing seats are arranged on the tool rotating disc, a tool is arranged in a central hole of each tool fixing seat, and the lifting device is fixed on the tool base and located below the tool fixing seats. The tool changer is compact in structure, convenient to control, simple to adjust and high in efficiency.

Owner:上海奇灏特自动化工程有限公司

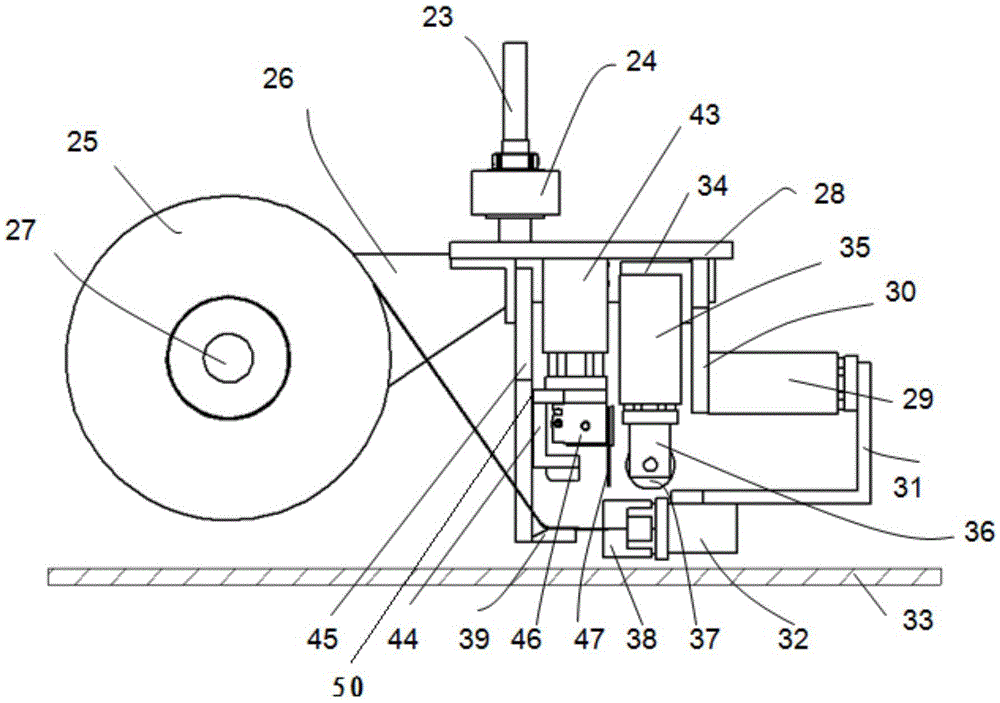

Chipping blowing device for machine tool workpieces

InactiveCN108381279AAvoid harmExtended service lifeMaintainance and safety accessoriesEngineeringMachine tool

The invention relates to the field of machine tool processing auxiliary equipment, and particularly relates to a chipping blowing device for machine tool workpieces. The chipping blowing device comprises an air pump, an air pipe, a rotating base, a mechanical large arm, a mechanical small arm and a clamping jaw, wherein the rotating base comprises a lower support plate and an upper support plate,a first motor is arranged on the top of the upper support plate, an output shaft of the first motor is connected with the rotating base by virtue of a first belt pulley driving mechanism, two second motors are arranged on the top of the upper support plate, the mechanical large arm comprises two first strip-shaped connecting plates, the two first strip-shaped connecting plates are connected with output shafts of the two second motors respectively by virtue of two second belt pulley driving mechanisms, and the clamping jaw is connected with one second belt pulley driving mechanism by virtue ofa horizontal stabilization mechanism. According to the chipping blowing device, the air pipe is clamped by the mechanical arms which can flexibly move and is aligned with a workpiece processing position, and generated chippings are blown away at any time in time, so that the damage caused by chippings to a machine tool is effectively avoided, and the service life of the machine tool is prolonged.

Owner:贵州龙翔能源(集团)有限公司

Scalding-prevention dish clamping device suitable for clamping in narrow gaps

The invention provides a scalding-prevention dish clamping device suitable for clamping in narrow gaps, and relates to the field of kitchen utensils. The problem that it is inconvenient to take bowlsout of a pot of which the caliber is slightly larger than the outer diameter of the bowls is solved. The scalding-prevention dish clamping device suitable for clamping in the narrow gaps comprises a mounting control block, three connecting folding rods are equidistantly and movably mounted at the portion, close to the bottom side, of the side wall of the mounting control block, the bottoms of theconnecting folding rods are movably connected with the tops of sheet-shaped pulling rods through rotary movable blocks, and the bottoms of the sheet-shaped pulling rods penetrate through turning sideplates and are welded to the tops of arc-shaped pulling claws. By means of the scalding-prevention dish clamping device suitable for clamping in the narrow gaps, square rods are clockwise rotated, sothat the sheet-shaped pulling rods are rotated to be nearly parallel to a pot wall, the arc-shaped pulling claws inserted into the gaps restores to the original shape under the elastic effect of torsion springs, and then the bowls can be clamped. The device is easy and convenient to operate, and the situation that the bending radian of the bottom of the bowl clamping device is too large and the clamping device cannot be inserted into the narrow gaps to clamp the bowls is avoided.

Owner:山东和悦非织造材料有限公司

Steel ball feeding machine

The invention discloses a steel ball feeding machine which mainly comprises a support, a driving device, a feeder and a retaining plate. The feeder penetrates the support, one end of the feeder is connected with the driving device which is capable of driving the feeder to move left and right on the support, a discharge outlet is formed at the top end of the support, the retaining plate penetrates the support, one end of the retaining plate is clamped on the feeder, the other end of the retaining plate retains at a port of the discharge outlet, the other end of the feeder is movably connected with a gripper, a tension spring is connected between the gripper and the feeder, and a retaining block is arranged on a frame and is capable of ejecting the gripper to be opened. A crank slider mechanism is used for driving the feeder to feed, a guide groove and a guide pin are arranged on the feeder ingenuously to enable direction of workpieces to be changed while feeding, gripping and releasing of blanks can be achieved by the design of the retaining block on the support and the gripper, the blanks can be fed only by one motor, and the steel ball feeding machine is simple in structure, low in cost and high in working efficiency.

Owner:NANTONG UP MACHINERY ENG

Clamping jaw mechanism

ActiveCN105563474AFlexible adjustment performanceFlexible lockingProgramme-controlled manipulatorGripping headsEngineering

Owner:CWB AUTOMOTIVE ELECTRONICS

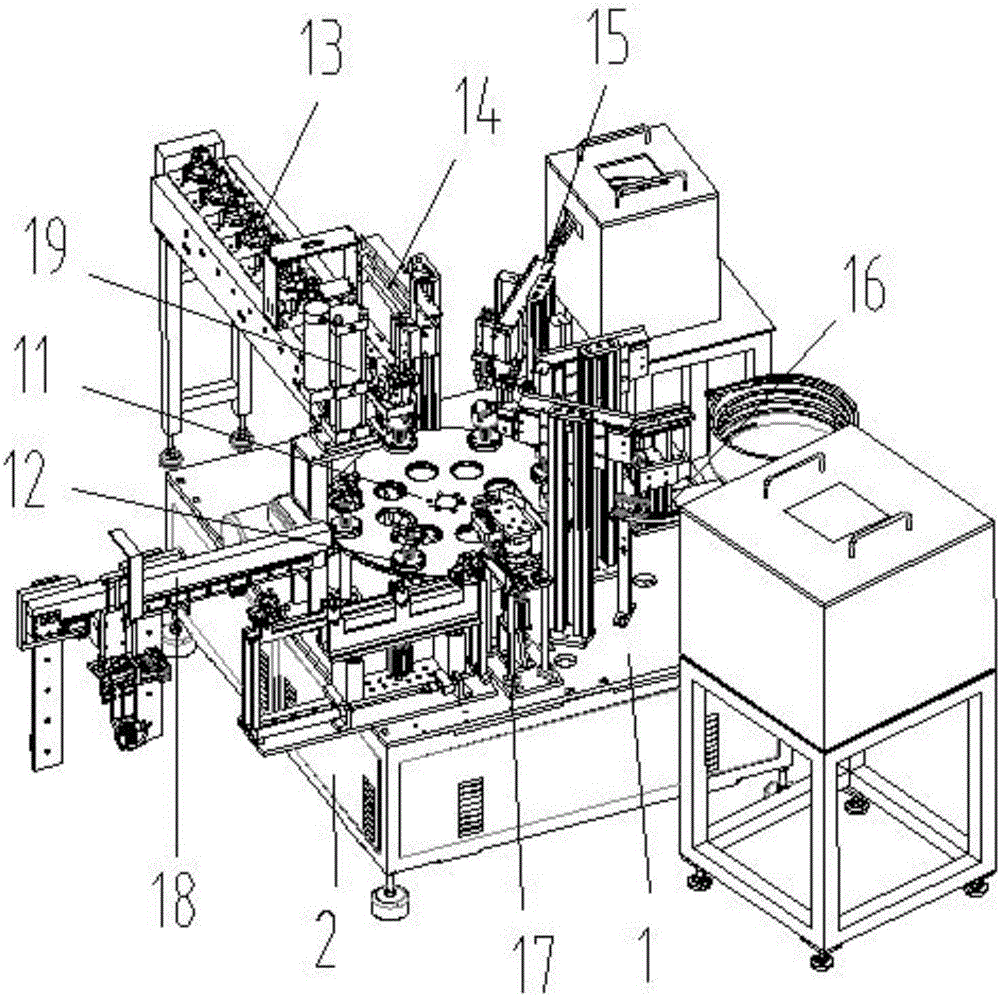

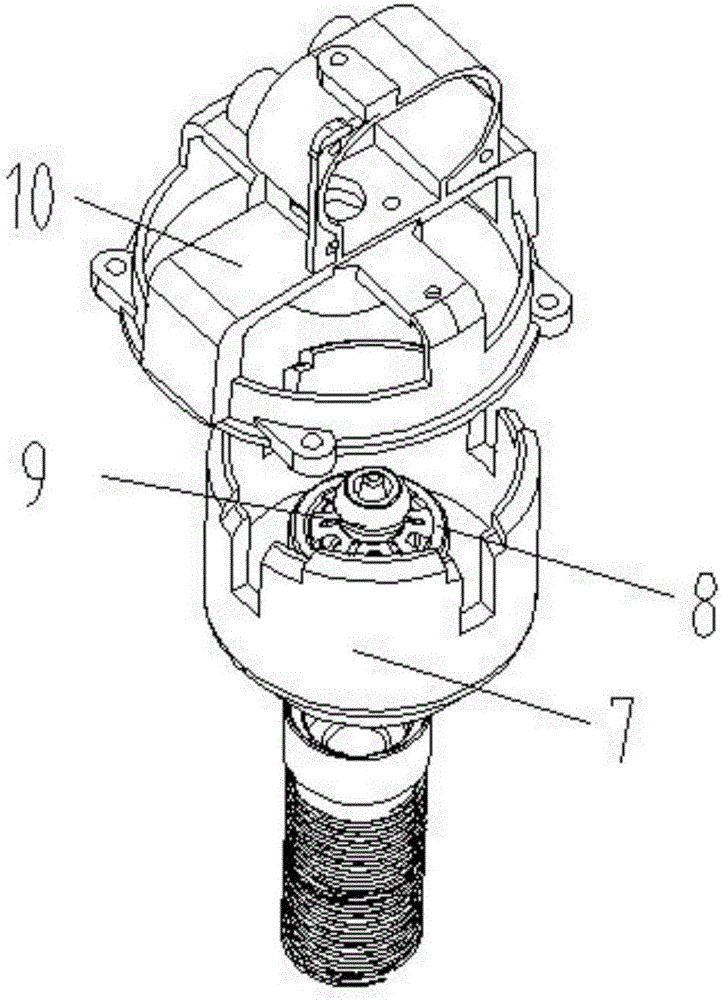

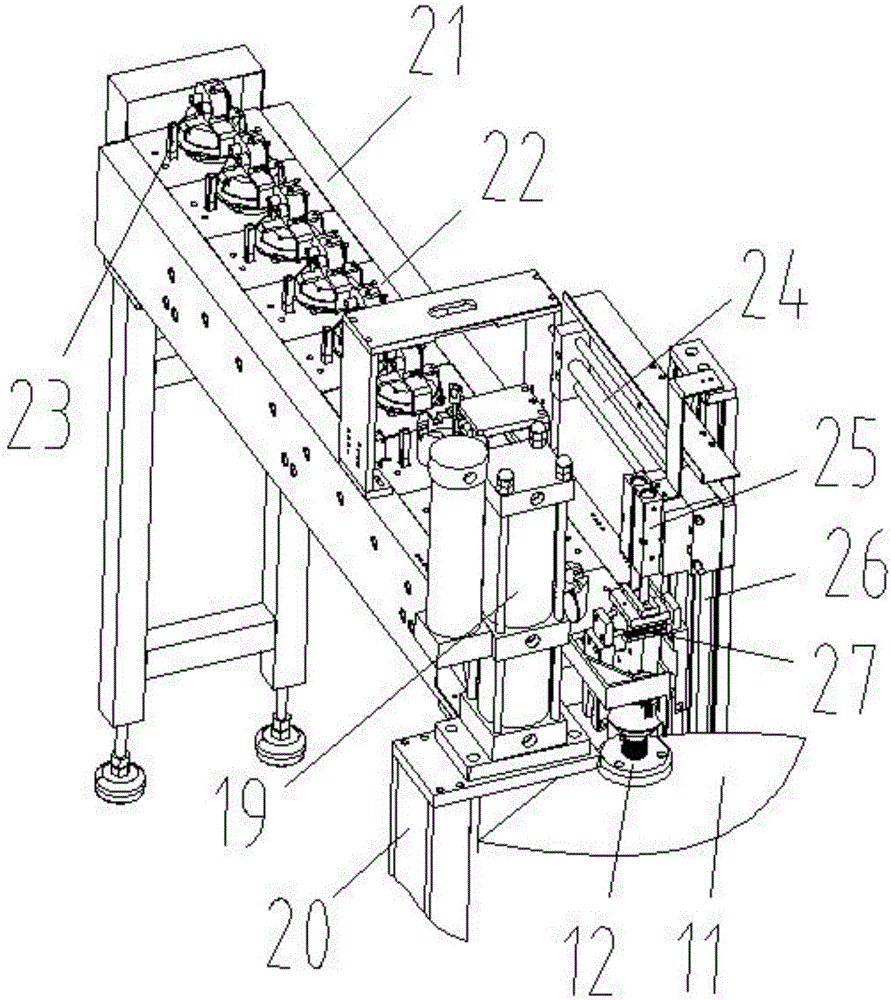

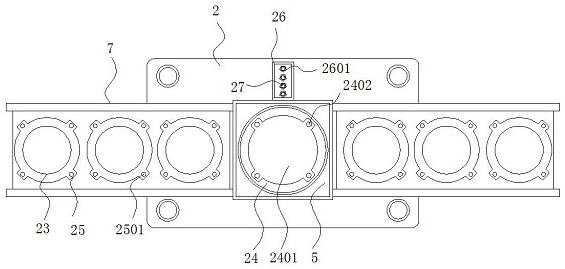

Automatic assembly mechanism of gear oil injector box body

ActiveCN106695318AEnsure accurate dockingImprove efficiencyAssembly machinesMetal working apparatusInjectorManipulator

The invention relates to an automatic assembly mechanism of a gear oil injector box body. The mechanism comprises a frame and a power distribution control box; a turntable is arranged on the frame, and is provided with a turntable carrier; a bottom shell box cover loading device, a box body pressing device, a box body unloading device, a sealing ring loading device and an oil pipe loading device are arranged on the frame in the clockwise direction; the box body pressing device includes a box body pressing base and a box body pressing cylinder; the bottom shell box cover loading device includes a bottom shell box cover conveying device and a bottom shell box body loading manipulator; the bottom shell box cover conveying device includes a box body conveying base arranged on the frame; a bottom shell box cover positioning conveying plate connected with a conveying power device is arranged in the bottom shell box cover conveying base; a positioning hole matched with a bottom shell is formed in the bottom shell box cover positioning conveying plate; and a box cover positioning block matched with the box cover is arranged on the bottom shell box cover positioning conveying plate. The mechanism guarantees precise butt joint of the bottom shell and a box body, and greatly improves the box body assembly efficiency.

Owner:安徽长吉汽车科技有限公司

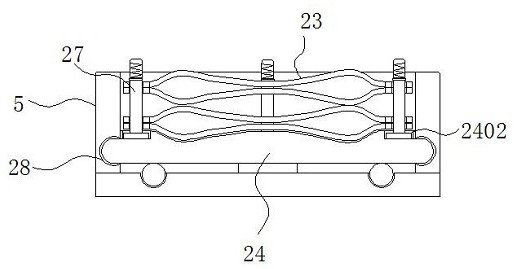

Wave spring assembling device with limiting structure

InactiveCN111958216AImprove assembly efficiencyEase of mass productionMetal working apparatusWorkbenchIndustrial engineering

The invention discloses a wave spring assembling device with a limiting structure. The wave spring assembling device with the limiting structure particularly comprises a workbench, an assembling bench, a suction mechanism and a tightening mechanism. Support frames are installed on two sides of the workbench, vertical columns are fixed at four corners of the top end of the workbench, a first conveying mechanism is installed on the support frame on one side of the workbench, a second conveying mechanism is fixed on the support frame on the other side of the workbench, a control panel is installed on one side, close to the first conveying mechanism, of the interior of the workbench, and a nut conveyor is fixed on one side, close to the second conveying mechanism, of the inner part of the workbench. According to the wave spring assembling device with the limiting structure, by arranging the suction mechanism, the tightening mechanism and the nut conveyor, the suction mechanism can suck wave springs through an electromagnet, automatic feeding and unloading are achieved, the tightening mechanism and the nut conveyor can automatically perform bolt fastening and assembling on overlapped wave springs, and batch production is facilitated.

Owner:东莞市史雷帝三维数控科技有限公司

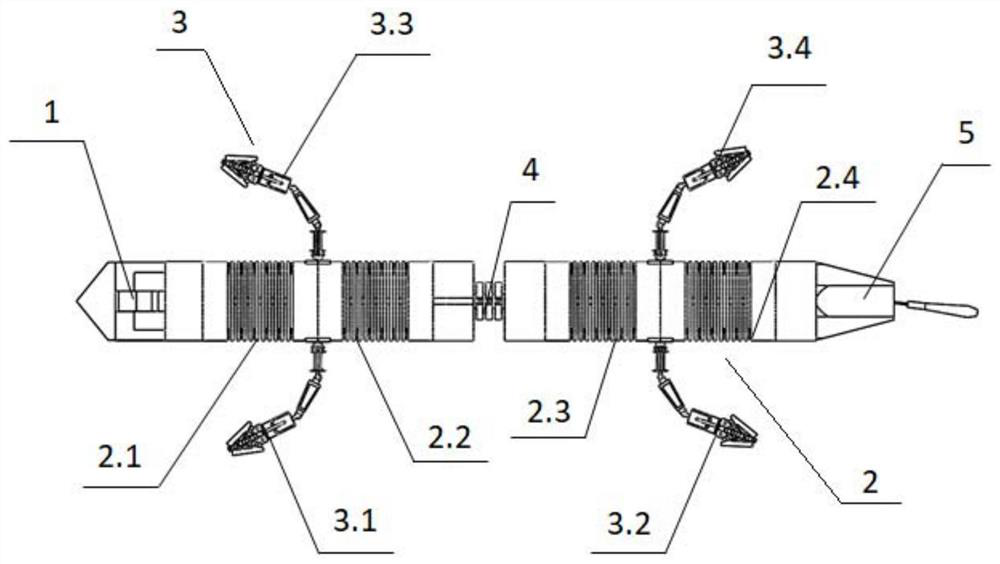

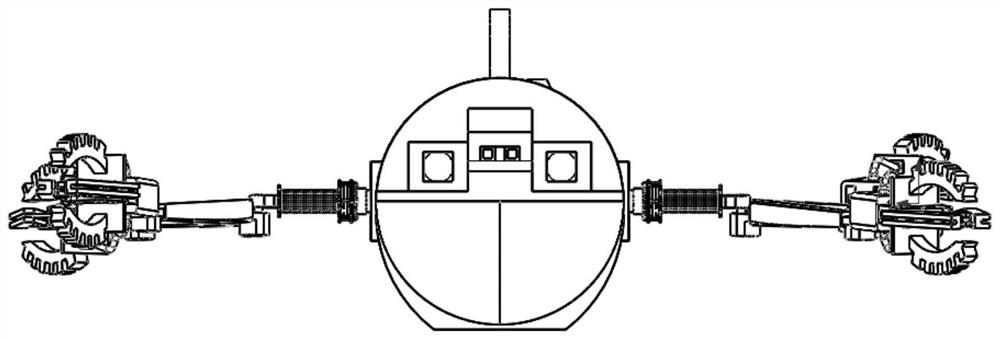

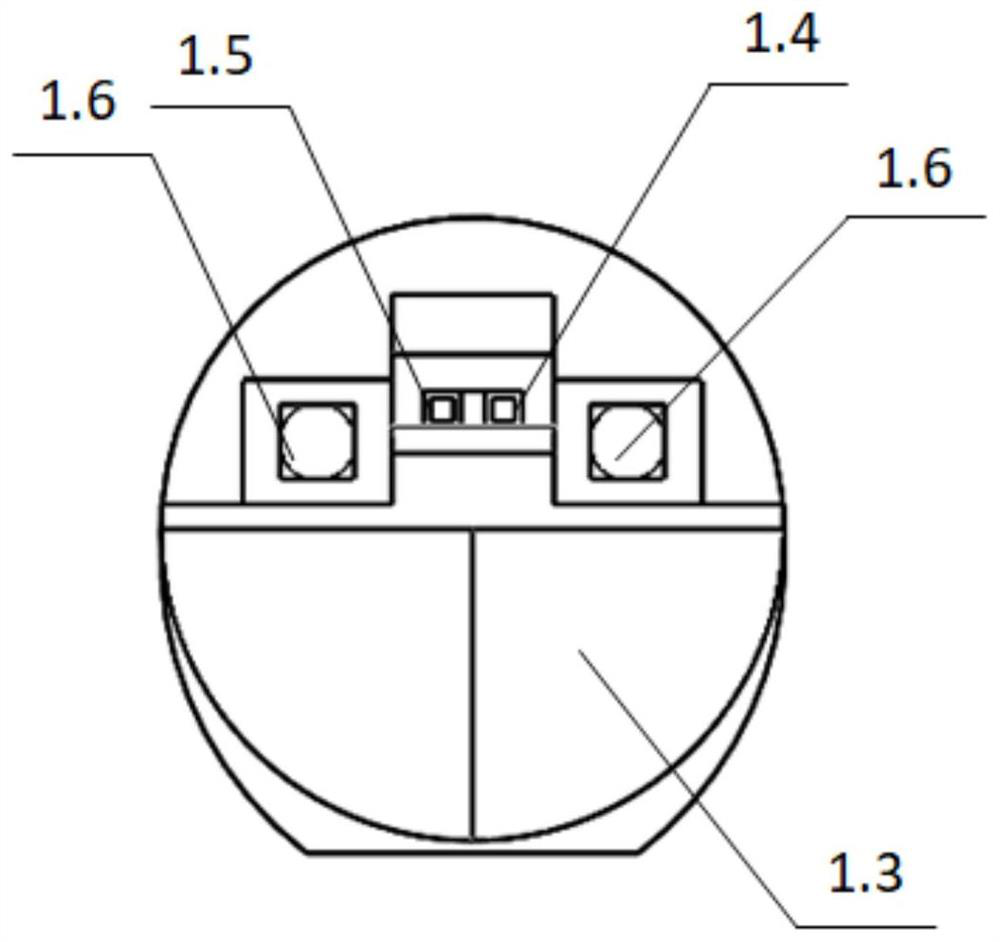

Soft bionic underwater detection robot

ActiveCN112091988AReduce resistanceFlexible swimmingJointsGripping headsControl engineeringElectric machinery

The invention discloses a soft bionic underwater detection robot. The soft bionic underwater detection robot comprises a head detection mechanism, movable base bodies, a mechanical arm module, a spherical hydraulic muscle joint, a tail swing mechanism, a control circuit board and a battery module. Mechanical arms based on a swing mechanism driven by shape memory alloy and a motor in a mixed manneris adopted, a spherical hydraulic muscle joint structure is adopted at the joint of the movable base bodies, the swing degrees of the mechanical arms are changed according to the deformation degree of the spherical joint, and the obstacle passing capacity of the robot is greatly improved. Composite grabbing structures are designed at the tail ends of the mechanical arms, soft hydraulic claws andrigid mechanical claws are combined, and therefore the grabbing capacity of the robot is improved. The tail swing mechanism is based on the electromagnetic principle, and two independently controlledcoils are adopted to attract or repel a magnet between the two coils, so that the swing function is achieved. An ultrasonic detection sensor, an infrared camera and other sensors are integrated in thehead detection mechanism, so that the robot has very high environmental adaptability and working capacity in an underwater natural environment.

Owner:NINGBO UNIV

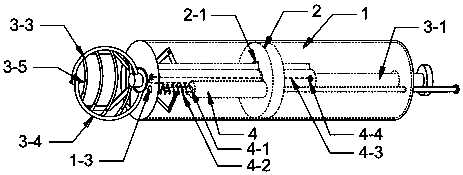

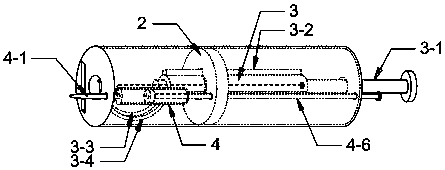

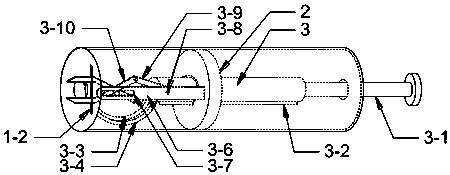

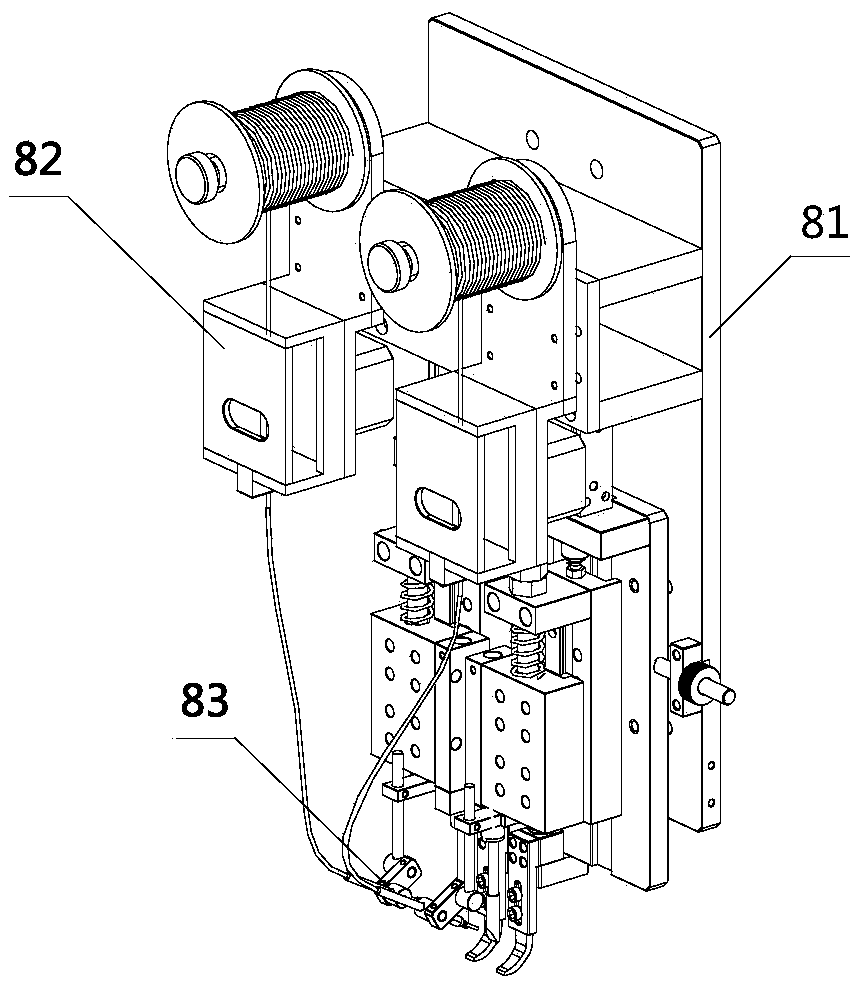

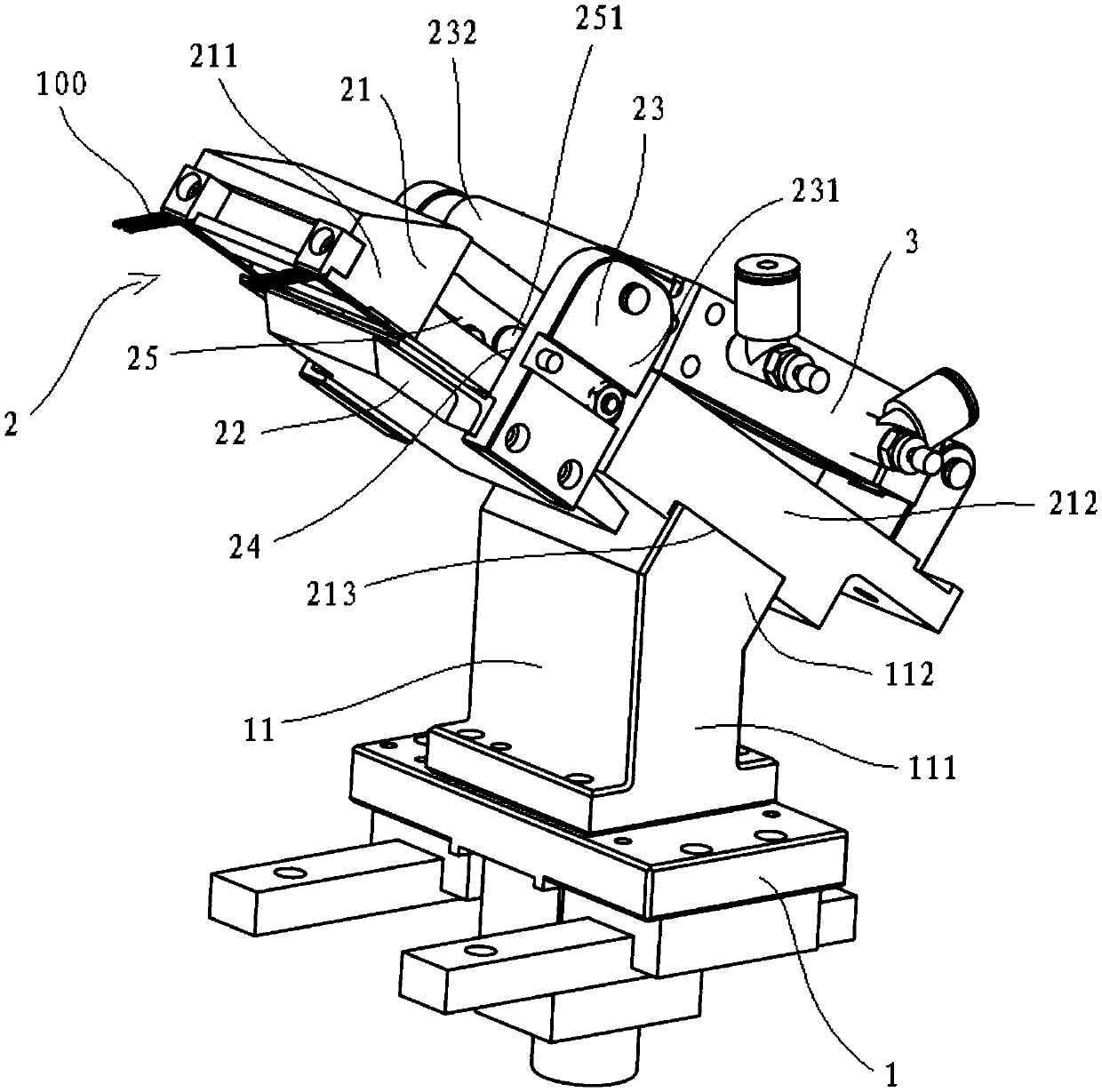

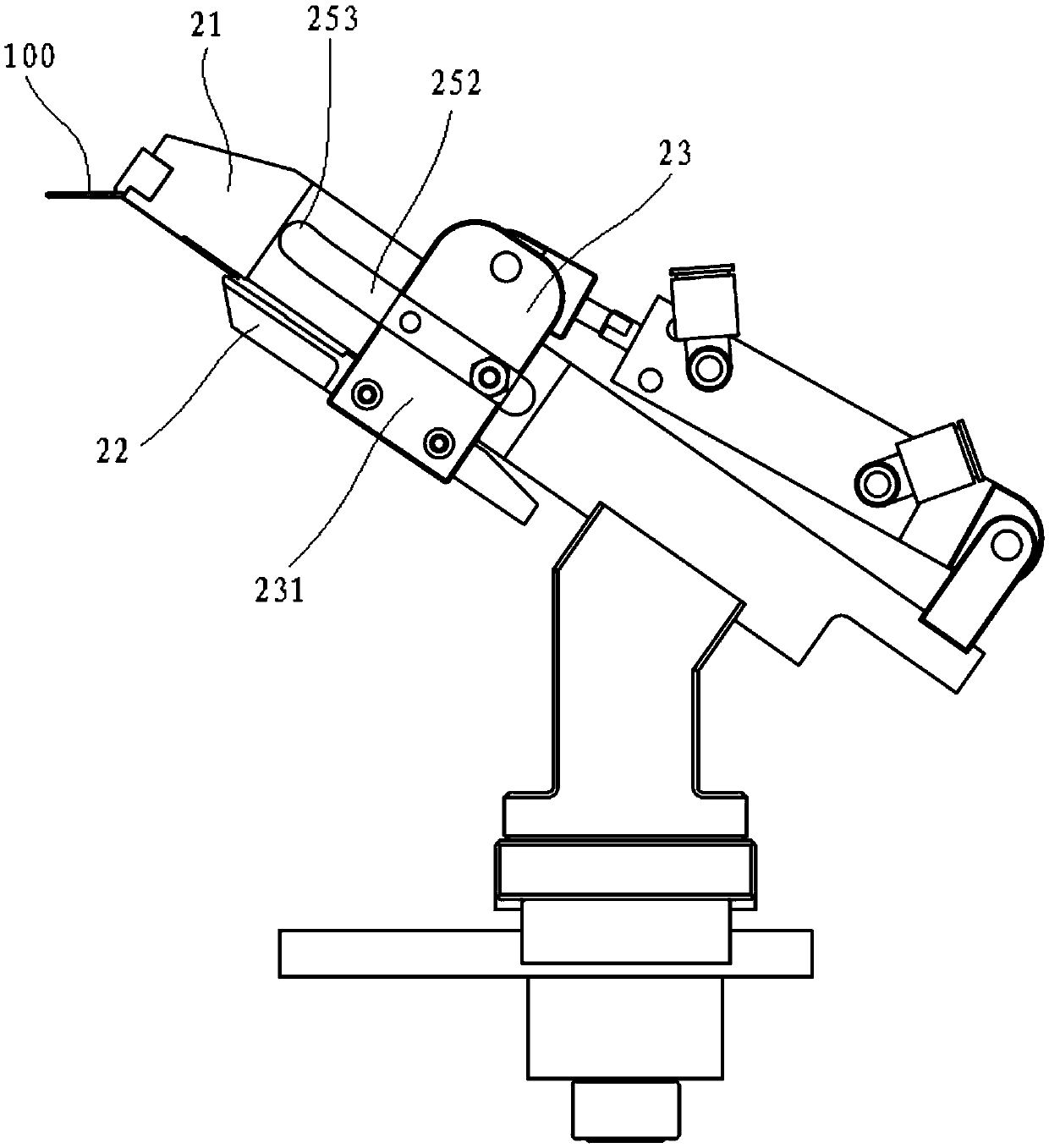

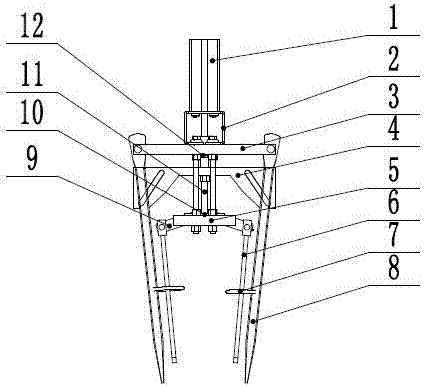

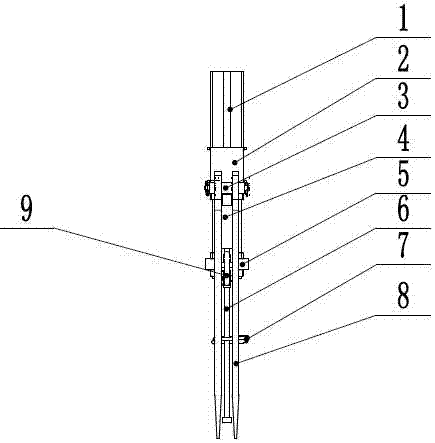

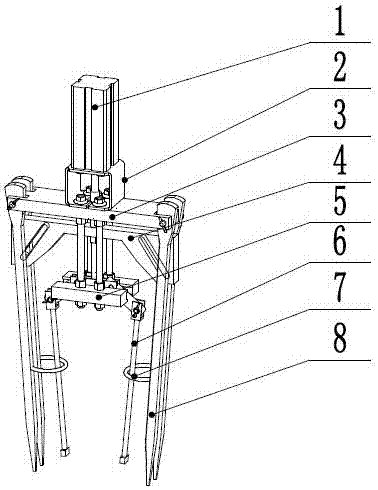

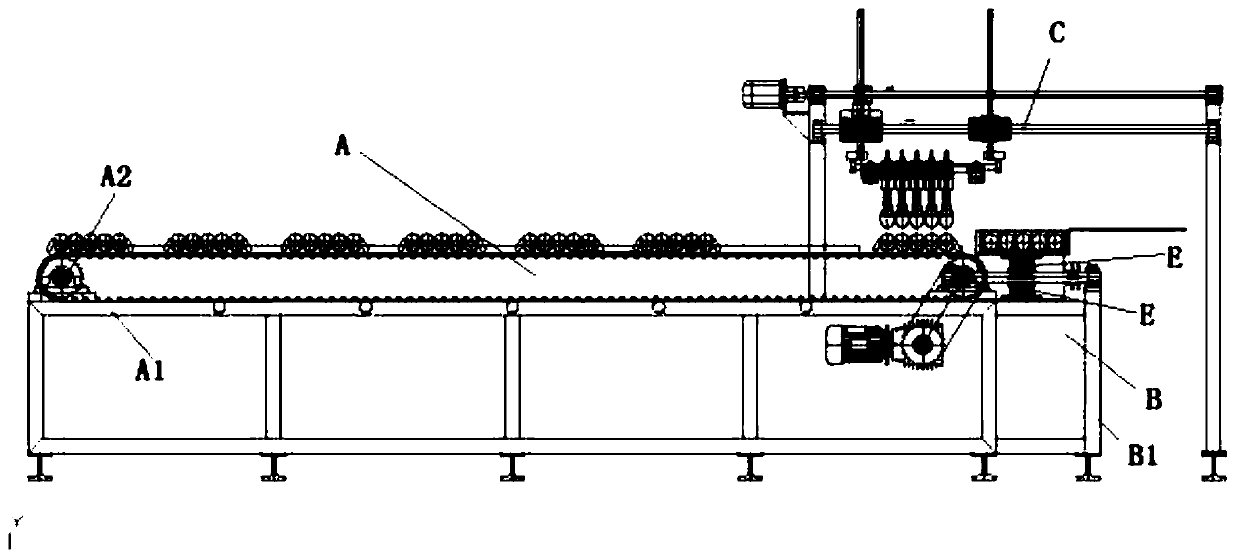

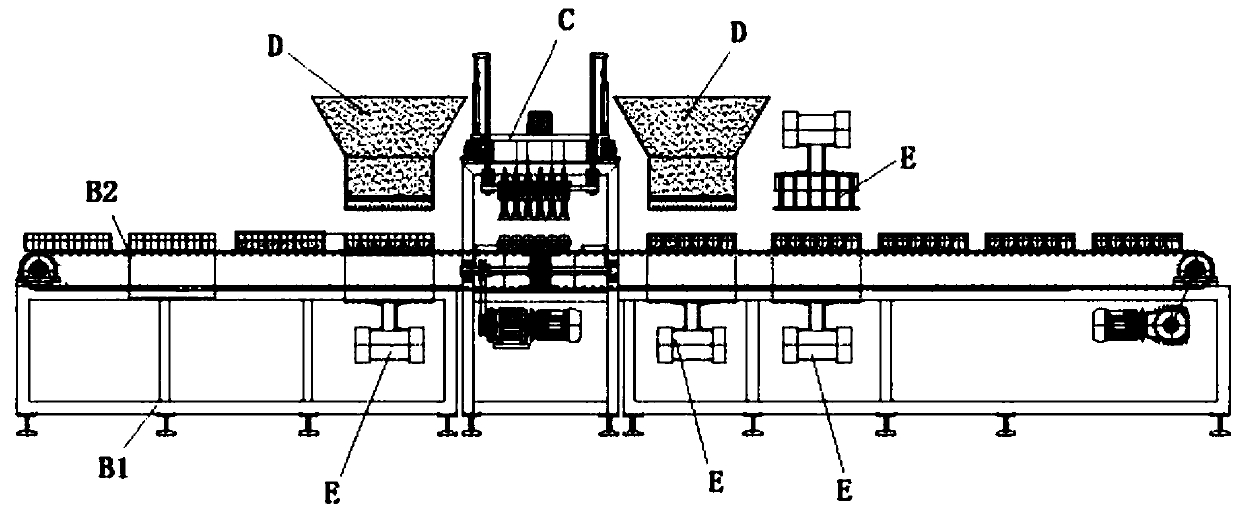

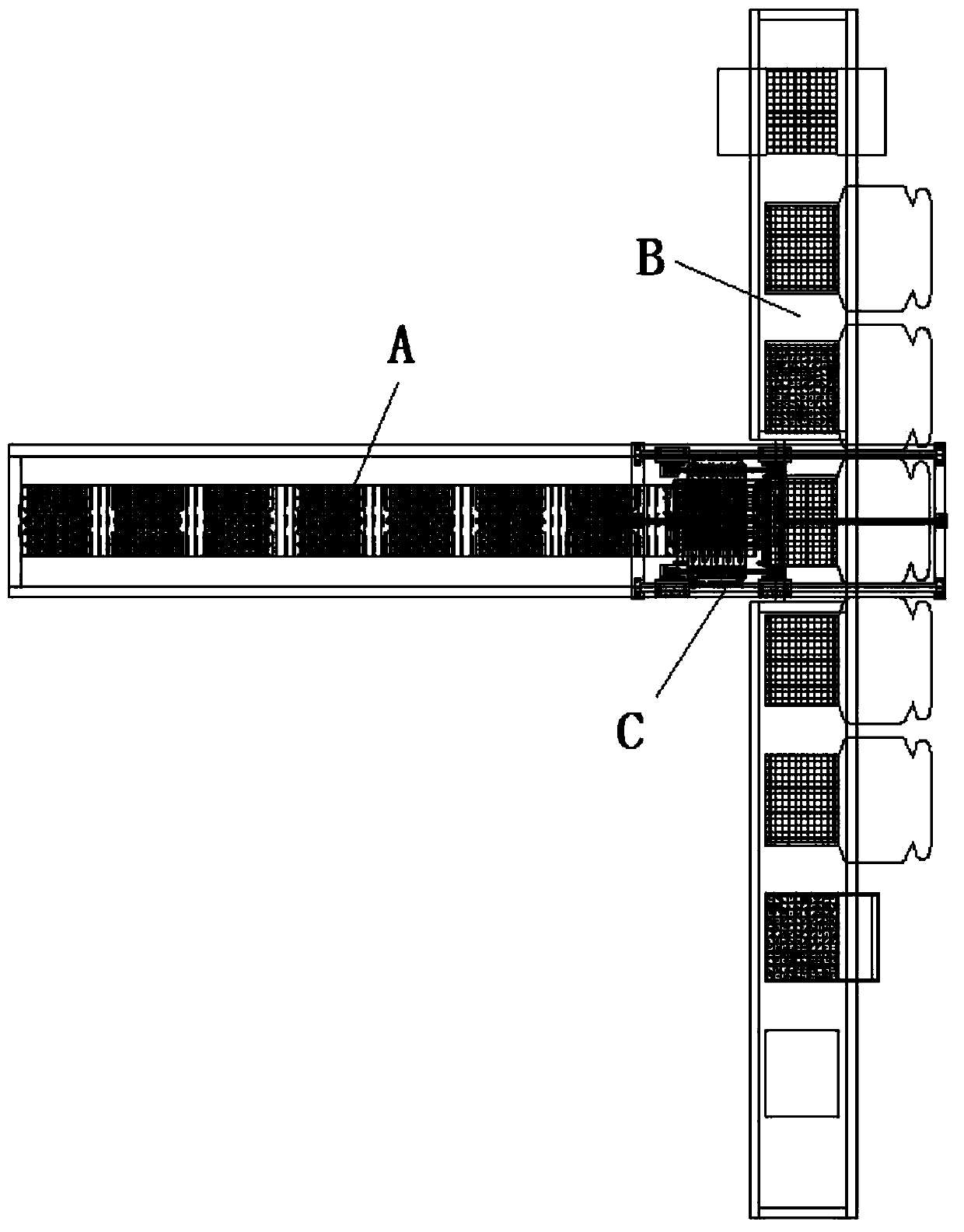

Rail driving type pot seedling transplanting machine tail end executing device

PendingCN106856756AAchieve grippingEasy to controlTransplantingAgricultural engineeringStructural engineering

The invention discloses a rail driving type pot seedling transplanting machine tail end executing device, and aims at providing a tail end executing device with the advantages that the control is simple and convenient; the fault rate is low; the structure is simple; the tail end executing device can be used for whole row seedling taking and aims at a pot seedling transplanting machine. The rail driving type pot seedling transplanting machine tail end executing device consists of an air cylinder, an air cylinder installing frame, a main support disc, a rail plate, a seedling pushing rail block, a seedling pushing needle, a seedling pushing limiting ring, a seedling taking needle, a seedling pushing control rod, a seedling pushing control block, a control connecting rod and a driving connecting rod. The seedling clamping and seedling releasing actions are completed by the rail plate driven by the air cylinder; the seedling pushing action is simultaneously completed by the seedling pushing rail block and the seedling pushing control rod; the air cylinder push rod acts on the seedling pushing control rod and the rail plate to realize the clamping and taking of the pot seedlings.

Owner:SHIHEZI UNIVERSITY

Reciprocating type workpiece feeding device

The invention provides a reciprocating type workpiece feeding device, and belongs to the technical field of machining. The reciprocating type workpiece feeding device comprises a clamping mechanism and a feeding mechanism. A main cam and an auxiliary cam of the feeding mechanism are symmetrically arranged, the upper end of a second rocker is hinged onto a framework, an auxiliary roller is rotatably arranged on the second rocker and is positioned in an auxiliary cam groove, the lower end of the second rocker is hinged to the right end of a third connecting rod, the upper end of a first rocker is hinged onto the formwork, the lower end of the first rocker is hinged to the left end of the third connecting rod and the lower end of a second connecting rod, a main roller is rotatably arranged on the second connecting rod and is positioned in a main cam groove, the upper end of the second connecting rod is hinged to one end of a first connecting rod, the other end of the first connecting rod is hinged to a slider, a left clamping jaw and a right clamping jaw of the clamping mechanism are symmetrically and rotatably arranged on a clamping bearing frame, and a left incomplete gear and a right incomplete gear mesh with each other. The reciprocating type workpiece feeding device has the advantages that workpieces can be quickly fed by the reciprocating type workpiece feeding device in a reciprocating manner, and the reciprocating type workpiece feeding device is large in stroke and high in practicality.

Owner:柳州市万菱科技有限责任公司

Stone clamping device for excavating robot

The invention belongs to the technical field of excavating aids, and discloses a stone clamping device for an excavating robot. The stone clamping device comprises a base and a support plate as well as a clamping mechanism and an adjusting mechanism; the clamping mechanism comprises a mounting shaft and a rotating roller which are hollow; the mounting shaft is slidably connected to the support plate, and provided with a first through hole and a second through hole; the mounting shaft is provided with two baffles, and divided into a negative pressure chamber and a pressure relief chamber by thetwo baffles; the rotating roller is connected to four connecting rods which are provided with industrial vacuum chucks; the base is internally provided with a cavity which is internally provided witha motor, a piston barrel and a piston, and the stone clamping device further comprises a first support rod, a second support rod and a third support rod which are hinged in sequence; the motor is connected to a rotating disk, and the first support rod is fixed to the rotating disk; the third support rod is hinged to the piston; and the piston barrel is provided with an air inlet and an air outlet. According to the stone clamping device disclosed by the invention, the problem that the stone clamping efficiency is low since stones can be clamped one by one only in the prior art is solved.

Owner:CHONGQING UNIV OF ARTS & SCI

Workpiece jig cabin-transfer manipulator for vacuum coating machine

PendingCN111702750AImprove operational reliabilityAvoid high technical requirementsProgramme-controlled manipulatorGripping headsEngineeringMachine

The invention discloses a workpiece jig cabin-transfer manipulator for a vacuum coating machine. Through the movement functions of front-rear extending and retracting, up-down ascending and descending, rotating and horizontal moving along a guide rail of the manipulator, bayonets of an upper claw and a lower claw and jigs are designed to correspond to clamping blocks on inserting rods, through powerful support provided by a supporting plate between the upper claw and the lower claw and bearing of a main frame and a base of the main frame, a single large jig is clamped, the single large jig canbe accurately transferred to a certain functional cabin to be mounted, and then the manipulator is returned for clamping the next jig; the manipulator for the vacuum coating machine is suitable for the single-hung jigs with the large size or the high weight, as for the type of coating machine, a whole workpiece frame does not need to be overall conveyed, thus an oversized cabin door does not needto be specifically designed, and the construction cost is lowered; and as for a cabin-transfer method for the jigs, the number of times of vacuum breaking is effectively decreased, the jigs are heated in a heating cabin and then distributed to coating cabins of different film systems for simultaneous coating of the different film systems, and thus the processing efficiency is greatly improved.

Owner:DONGGUAN HUICHENG VACUUM TECH

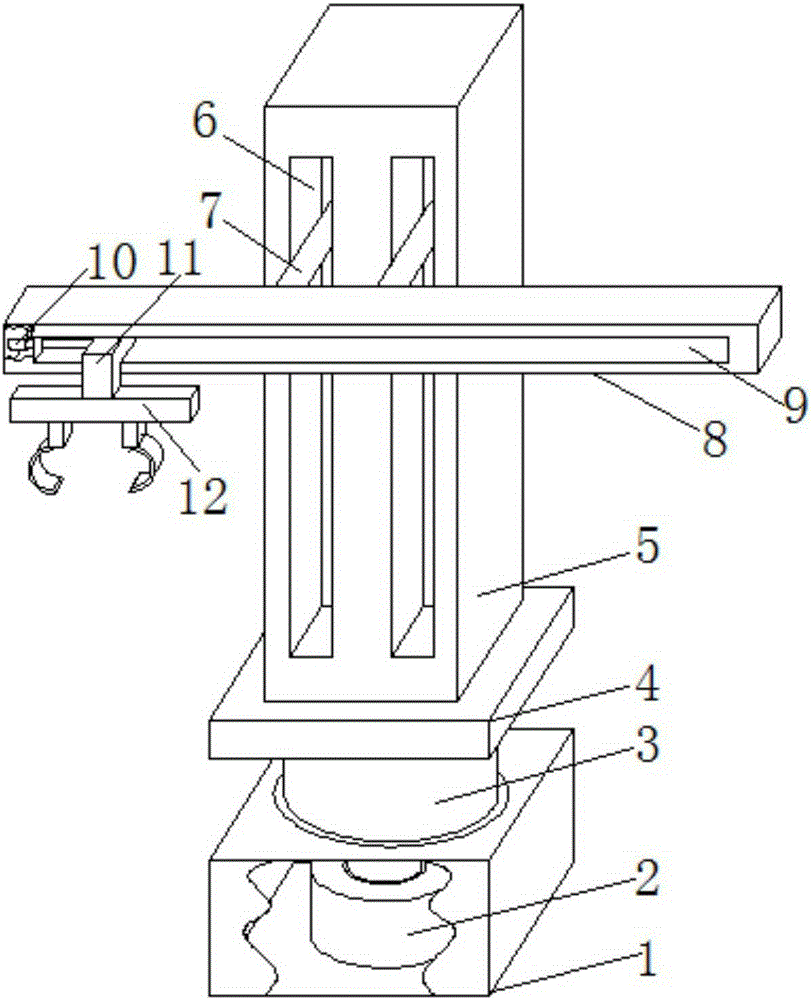

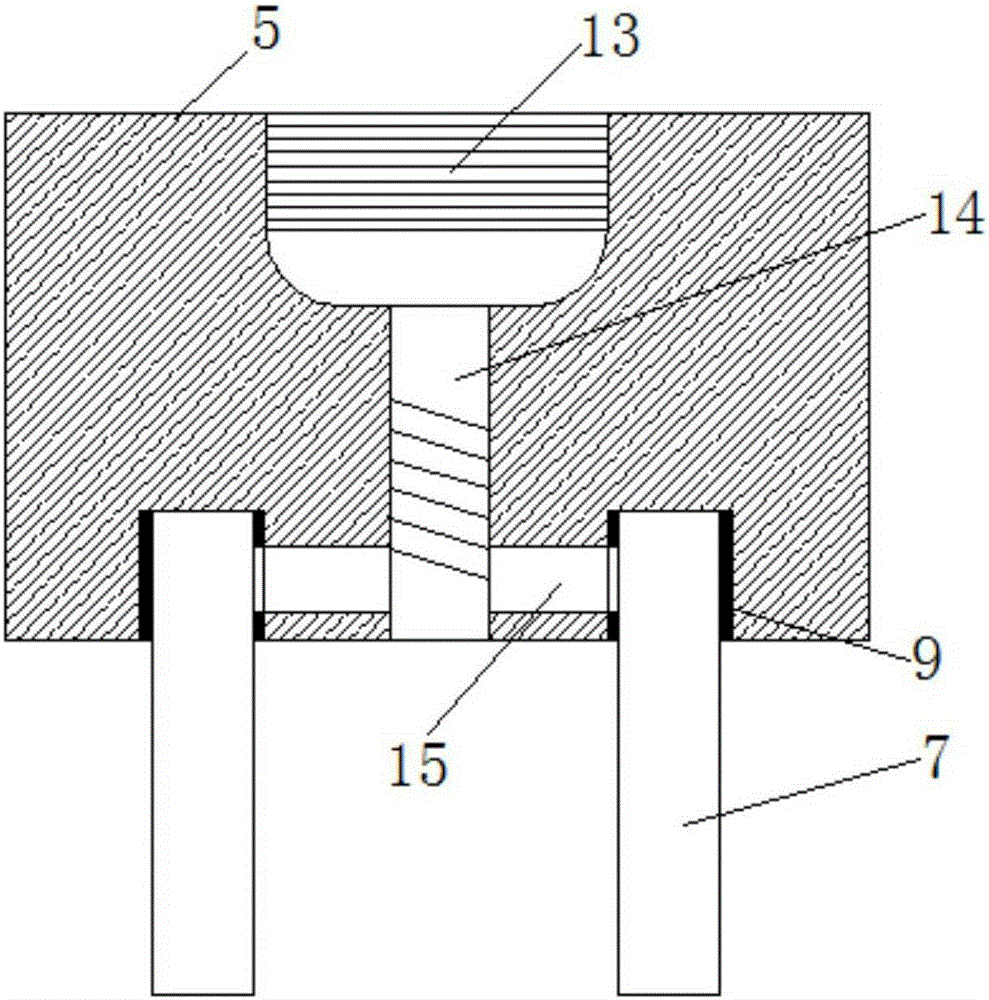

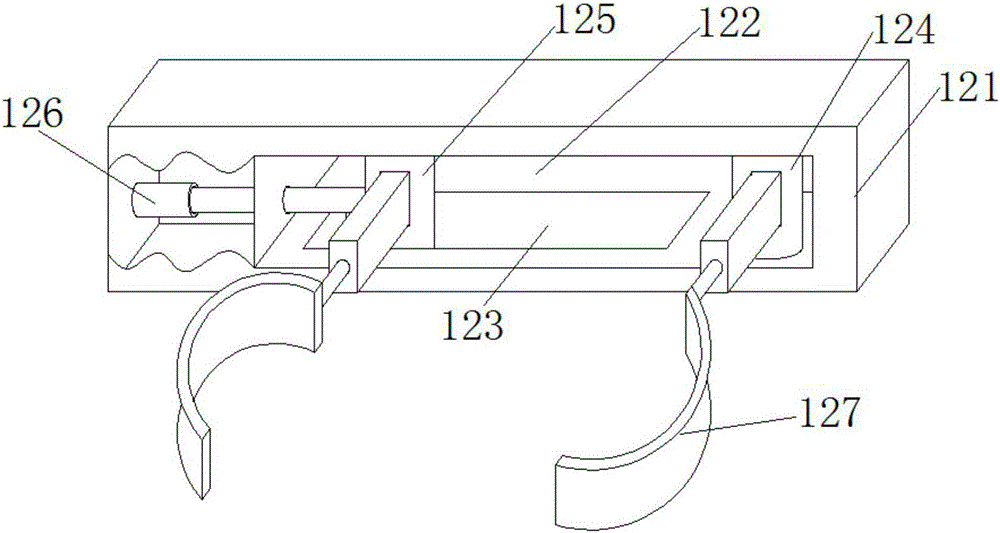

Multi-degree-of-freedom manipulator for construction engineering and operation method

PendingCN108274451AImprove work efficiencyReduce work intensityProgramme-controlled manipulatorArchitectural engineeringMulti degree of freedom

The invention provides a multi-degree-of-freedom manipulator for construction engineering and an operation method. The manipulator comprises a supporting base structure used for supporting the whole manipulator, wherein an electric control device is arranged on one side of the tail part of the supporting base structure, a rotating power device used for driving the manipulator to rotate along the vertical axis is arranged at the top of the supporting base structure, and a top frame structure is supported on a rotating base of the rotating power device; and the top frame structure is provided with a lifting mechanism used for driving the manipulator to vertically ascend and descend, a telescopic mechanism used for driving the manipulator to do telescopic motion is arranged on a lifting baseof the lifting mechanism, and a head of a telescopic beam of the telescopic mechanism is fixedly provided with a manipulator assembly used for implementing grabbing motions. The multi-degree-of-freedom manipulator can be used for operation of grabbing and accurate placing in building construction, and replaces traditional manual workers for operation, so that working efficiency is improved, laborintensity of operators is effectively reduced, and the construction quality is guaranteed.

Owner:湖北乾奥建设工程有限公司

Egg product automatic packing equipment

InactiveCN109911282AEasy to adjustAdjust the maximum spacing in real timePackaging eggsSize changeEngineering

The invention discloses egg product automatic packing equipment. The equipment comprises an egg containing grid conveying device and a package box conveying device, a manipulator transferring device which is used for integrally transferring eggs in egg containing grids to a package box is arranged between the egg containing grid conveying device and the packaging box conveying device, the manipulator transferring device comprises a rack, the rack is provided with a longitudinally moving conveying mechanism, the longitudinally moving conveying mechanism is provided with a liftable conveying mechanism, and the liftable conveying mechanism is connected with a multifunctional integral manipulator which can change size according to the size of the egg containing grids and the packaging box. Theequipment has the advantages that the structure is simple, automatic size changing (a certain size range is set) can be conducted according to different sizes of an original package and an existing package, and therefore the demands of egg integral packaging are met.

Owner:孝感英华机械模具设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com