Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

588results about "Packaging eggs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

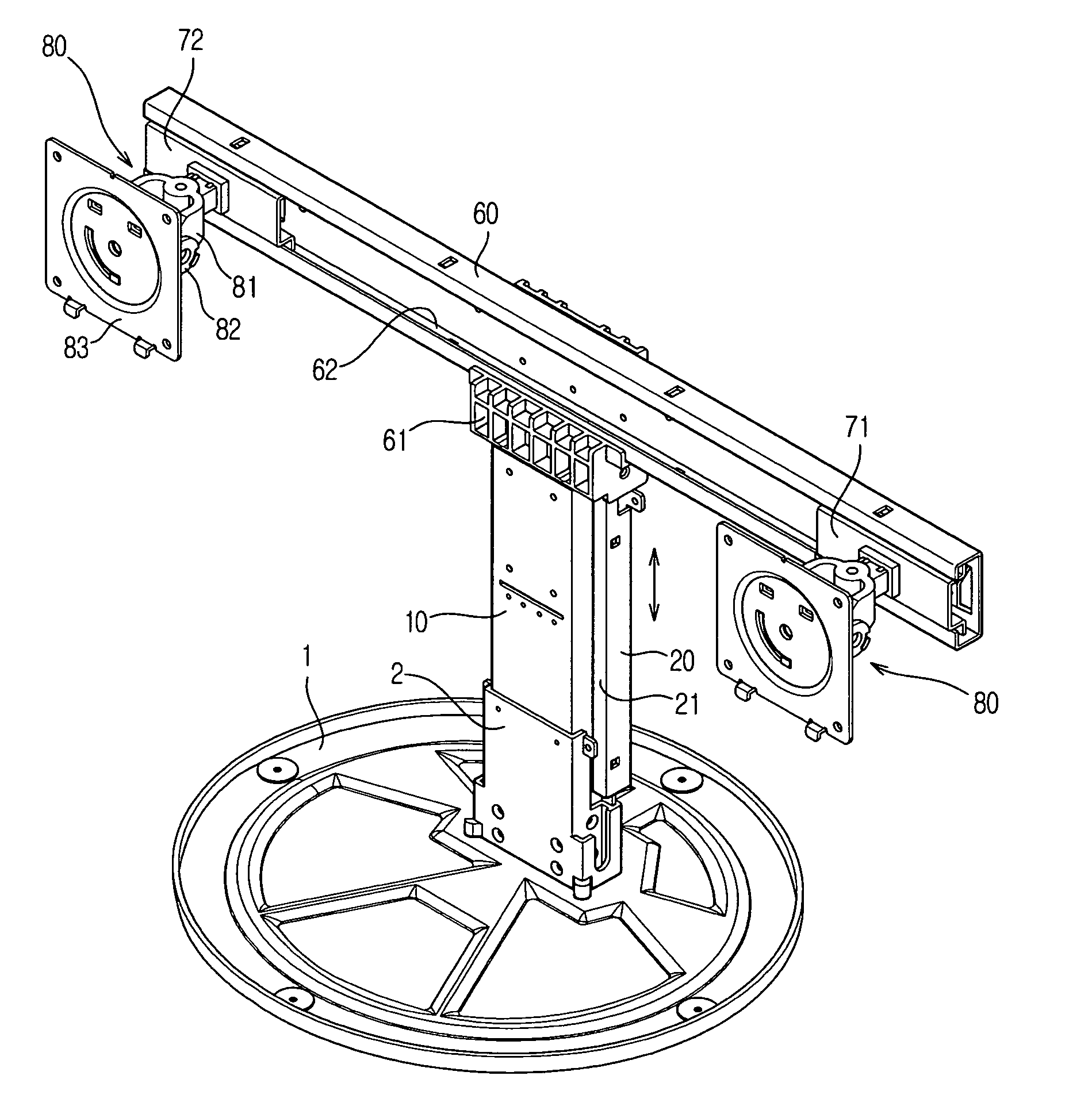

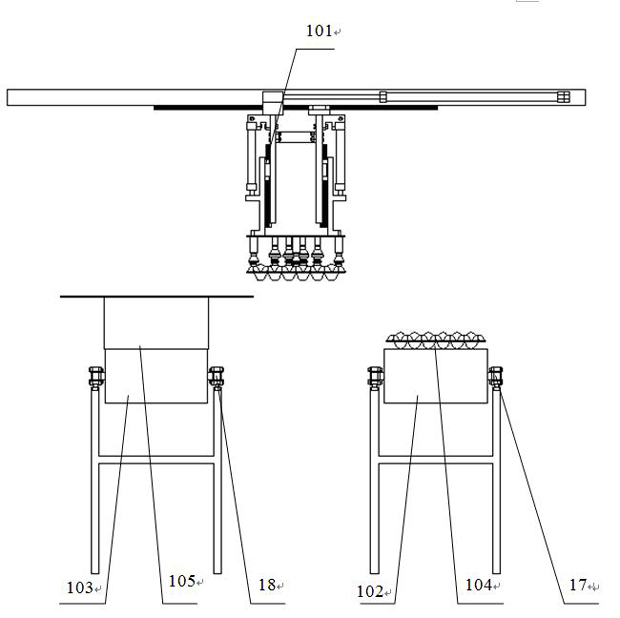

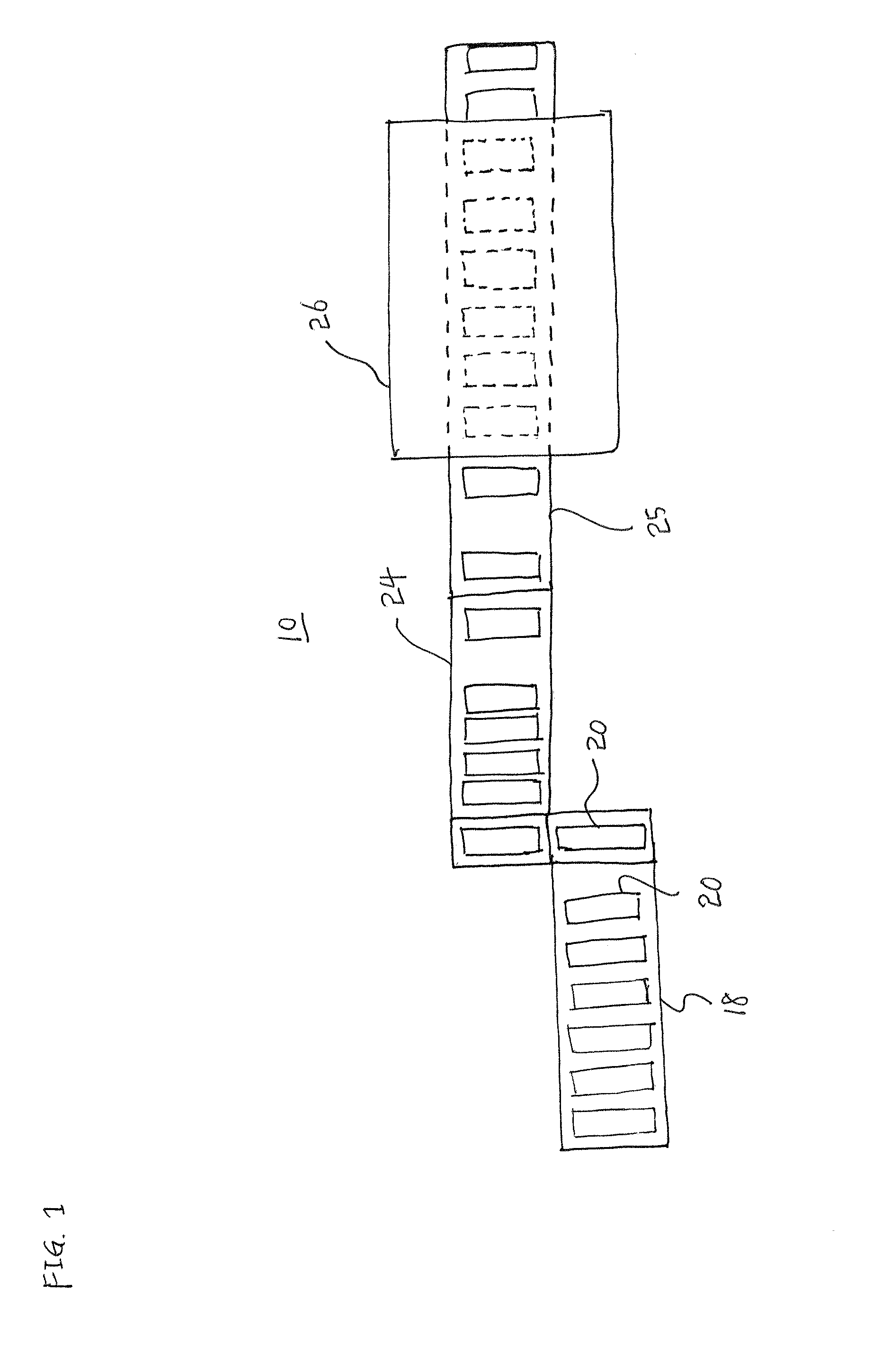

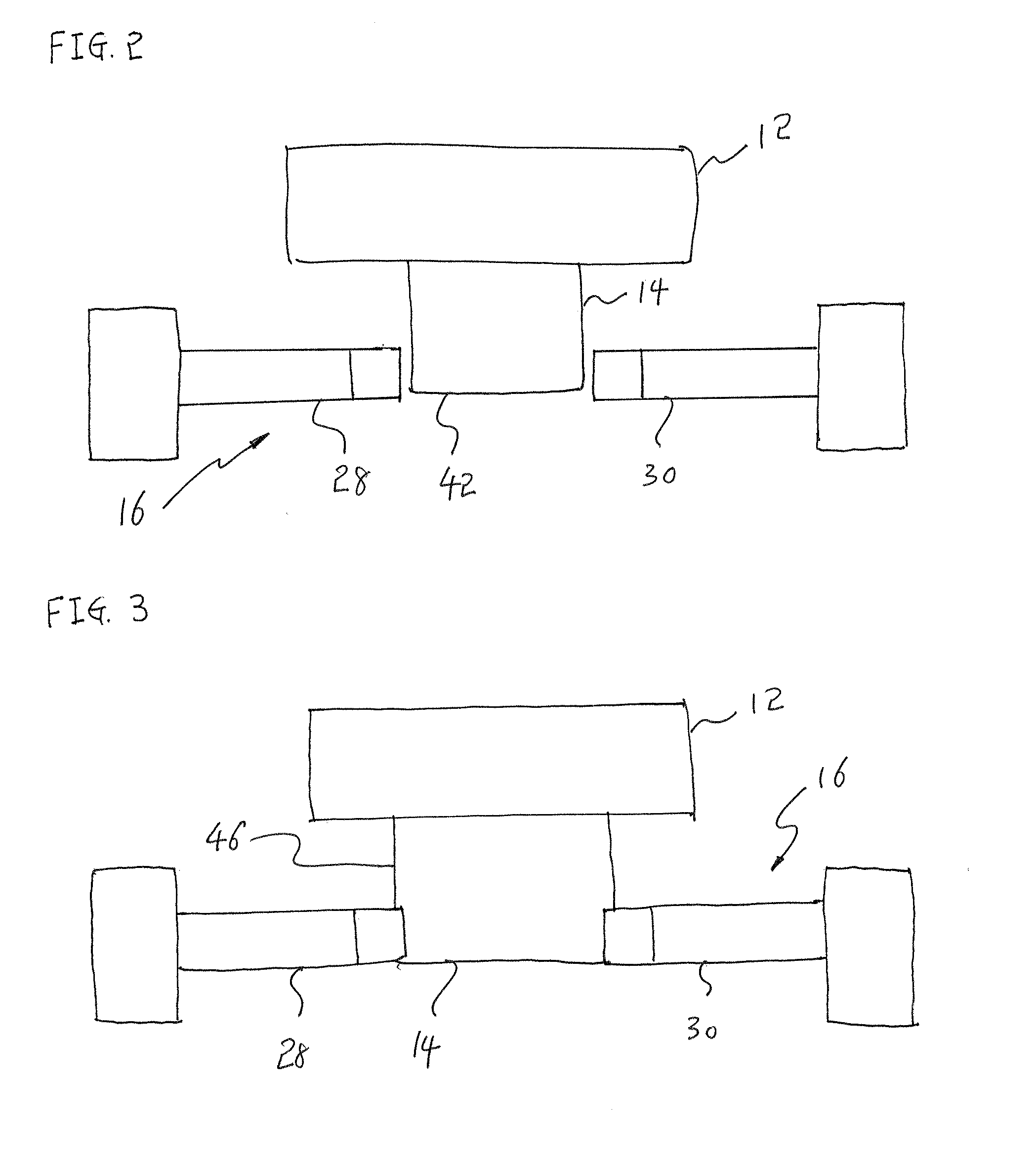

Supporting device for display units

A supporting device for display units enables height adjustment with ease and accuracy, and stably maintains the adjusted height while allowing a plurality of display units to be mounted thereon. The supporting device includes a stationary member, an elevation member coupled to the stationary member so as to be raised or lowered, a rack gear secured to the stationary member, a pinion gear installed to the elevation member so as to engage with the rack gear, and a restriction unit installed to the elevation member to restrict or allow rotation of the pinion gear. The supporting device further comprises an upper-side supporting member installed to an upper portion of the elevation member, first and second movable members to move along a guide rail of the upper-side supporting member, and connecting devices installed to the respective movable members to connect the display unit, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

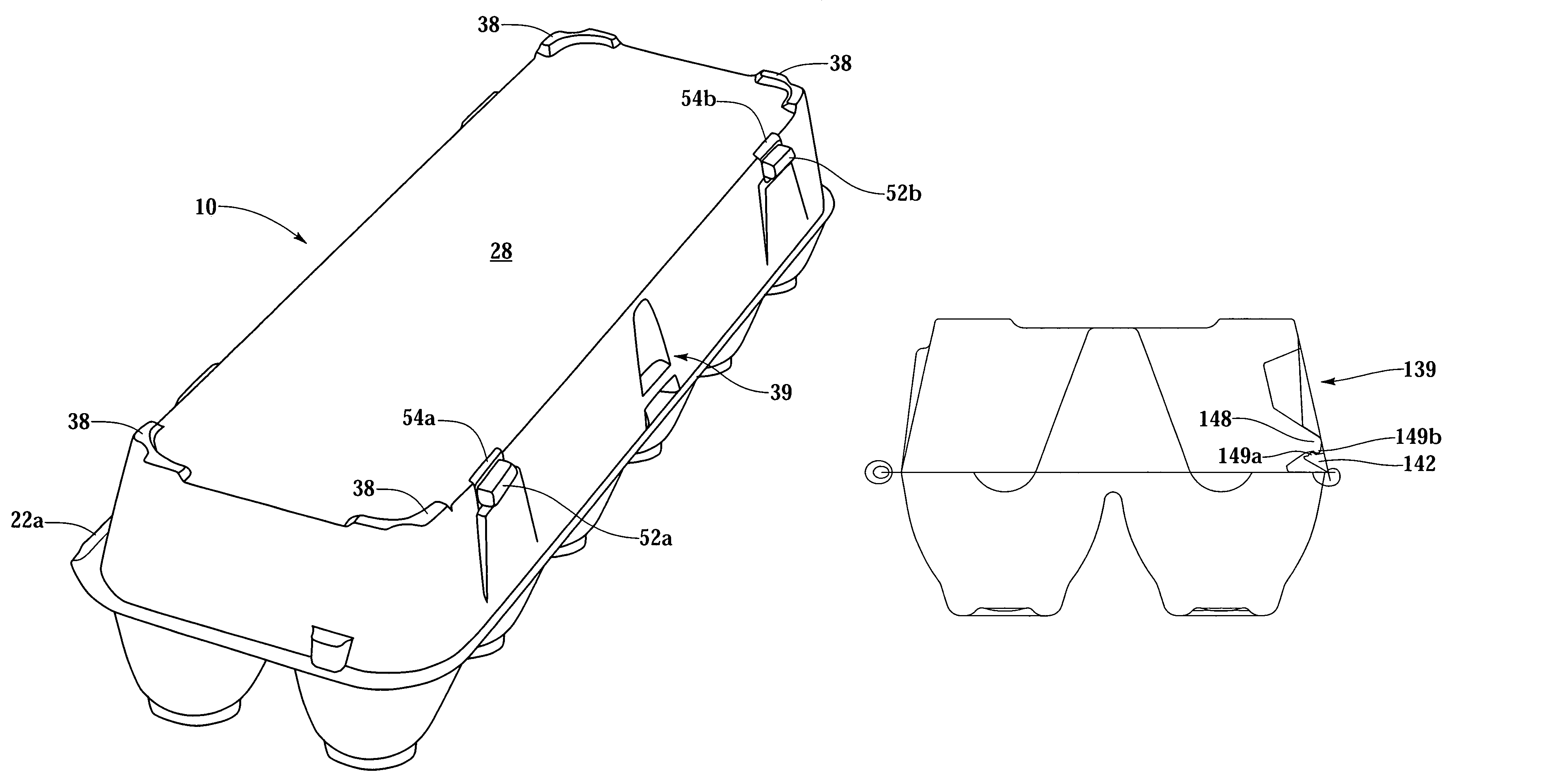

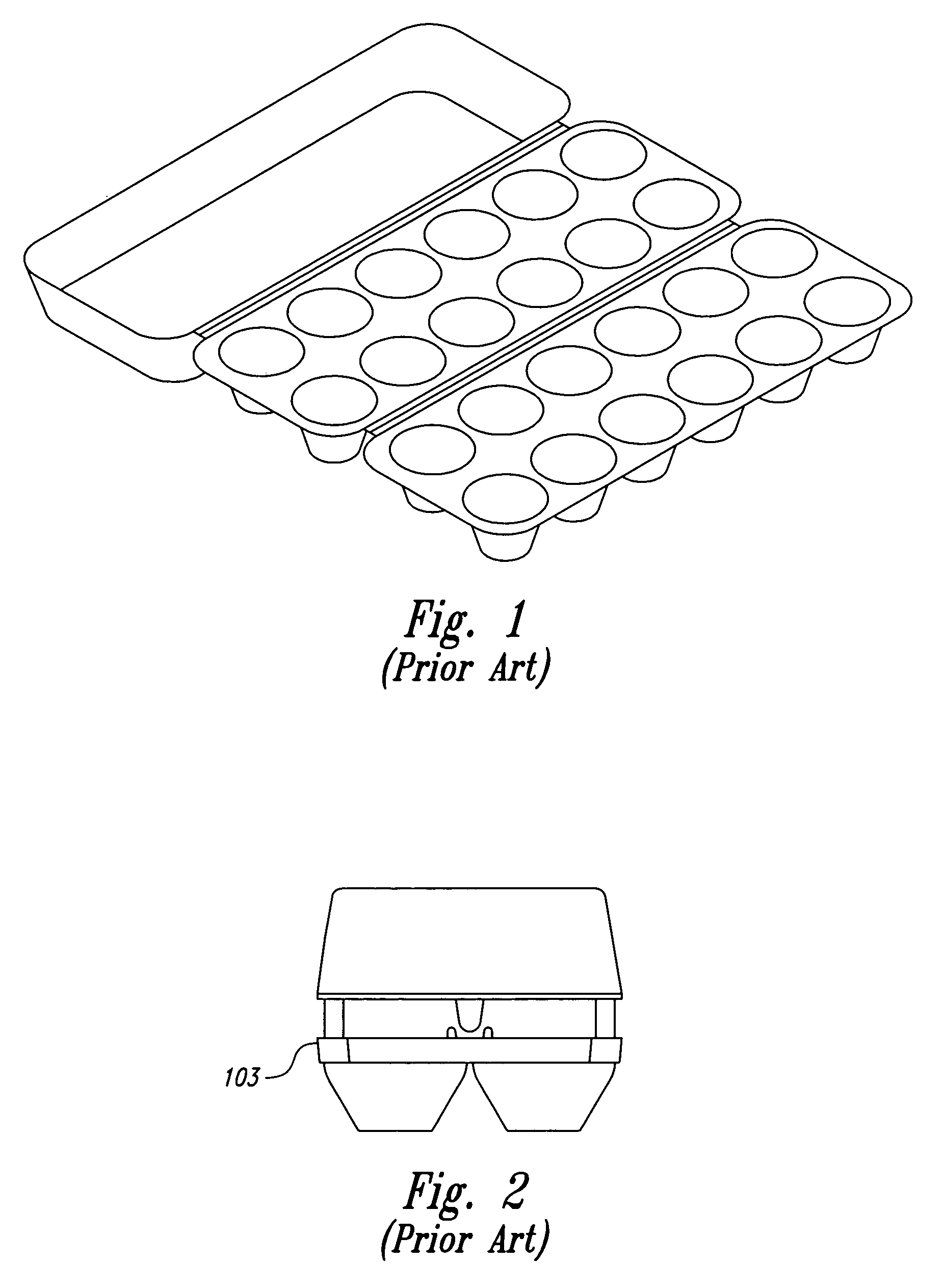

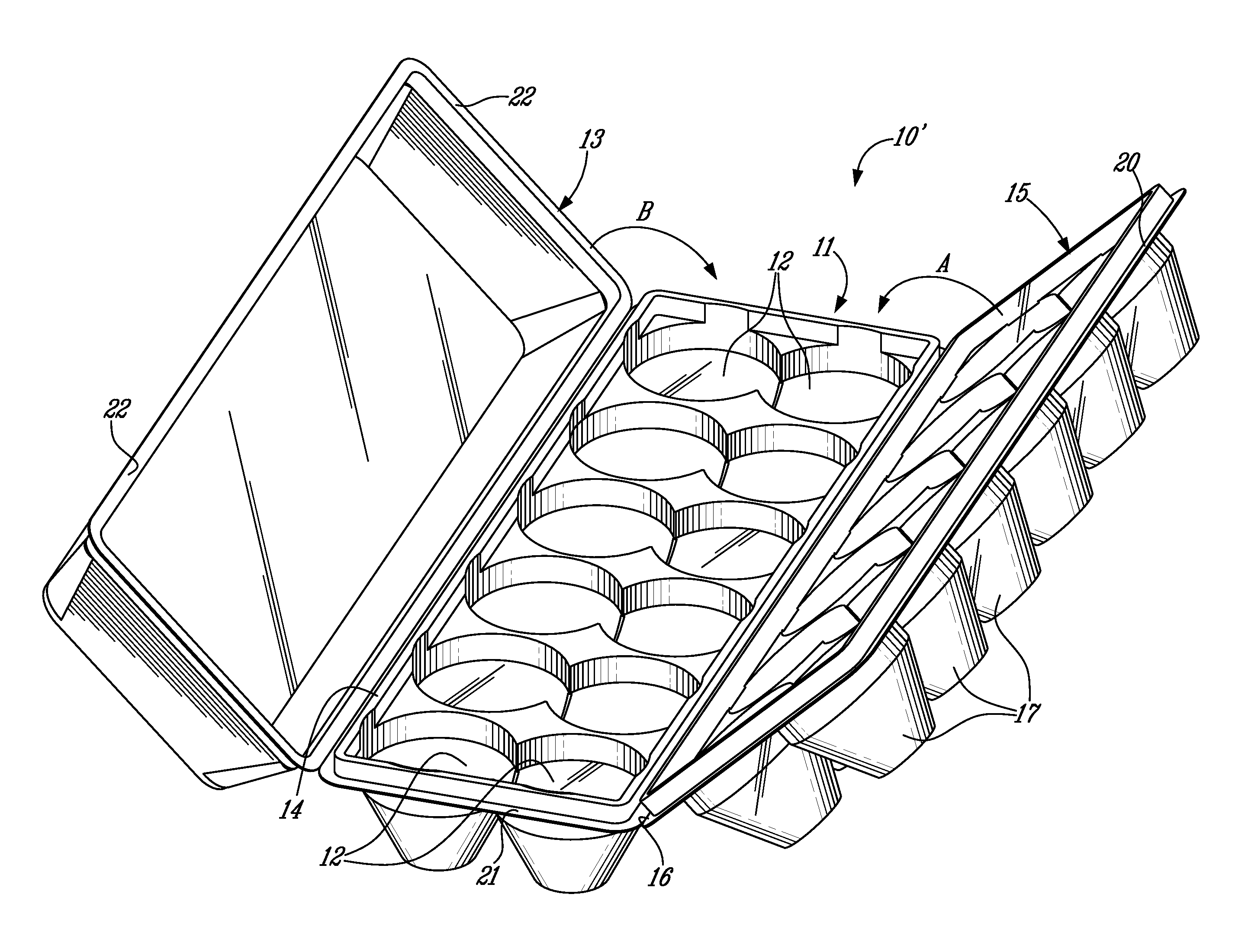

Egg carton

An egg carton comprises a base having a plurality of egg cells, the base being attached to a lid and locking flap by at least one hinge member. The lid has a plurality of closing apertures adapted to receive a plurality of buttons located on the locking flap. The lid further has an outer closure mechanism adapted to interlock with an inner closure mechanism located on the locking flap. The egg carton may also be equipped with a venting system.

Owner:PACTIV CORP

Tamper resistant seals for transparent or other egg cartons

InactiveUS20060060493A1Promote crashHigh mechanical strengthPackaging eggsContainers to prevent mechanical damageCartonEngineering

A tamper proof seal for egg cartons that is particularly suitable for transparent egg cartons is described The seal is typically located on the side rims of the tray and lid. The seal is comprised of first contact area on the tray rim and a second contact area on the lid rim. The first and second contact areas are mechanically engaged or bonded together to form a sealed area between the lid and the tray that prevents the lid from being opened from the tray. A tear-away section on the tray and lid rim surrounds the sealed area. The tear-away section allows the sealed area to be easily removed from the egg carton by tearing-away the sealed area from the rim thereby allowing the egg carton to be opened.

Owner:AARDEMA MARVIN RICHARD AARDEMA & JOHN CAMPHOUSE

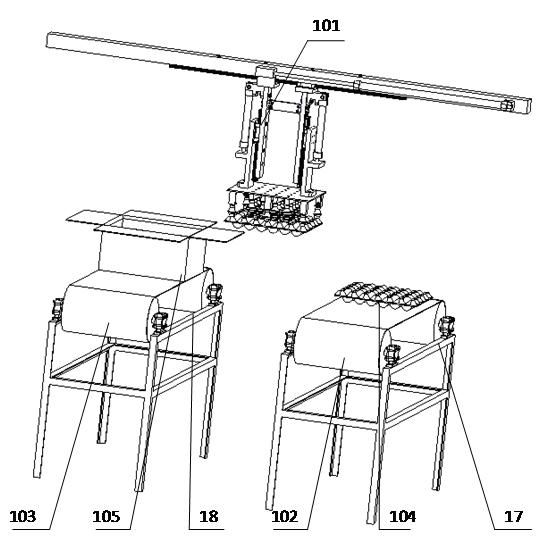

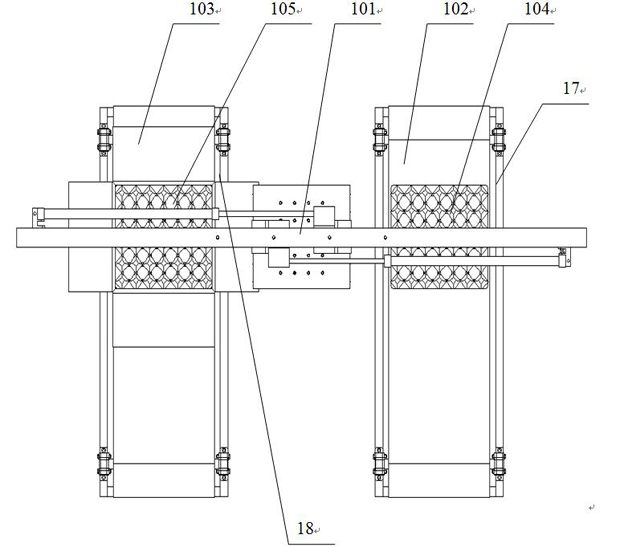

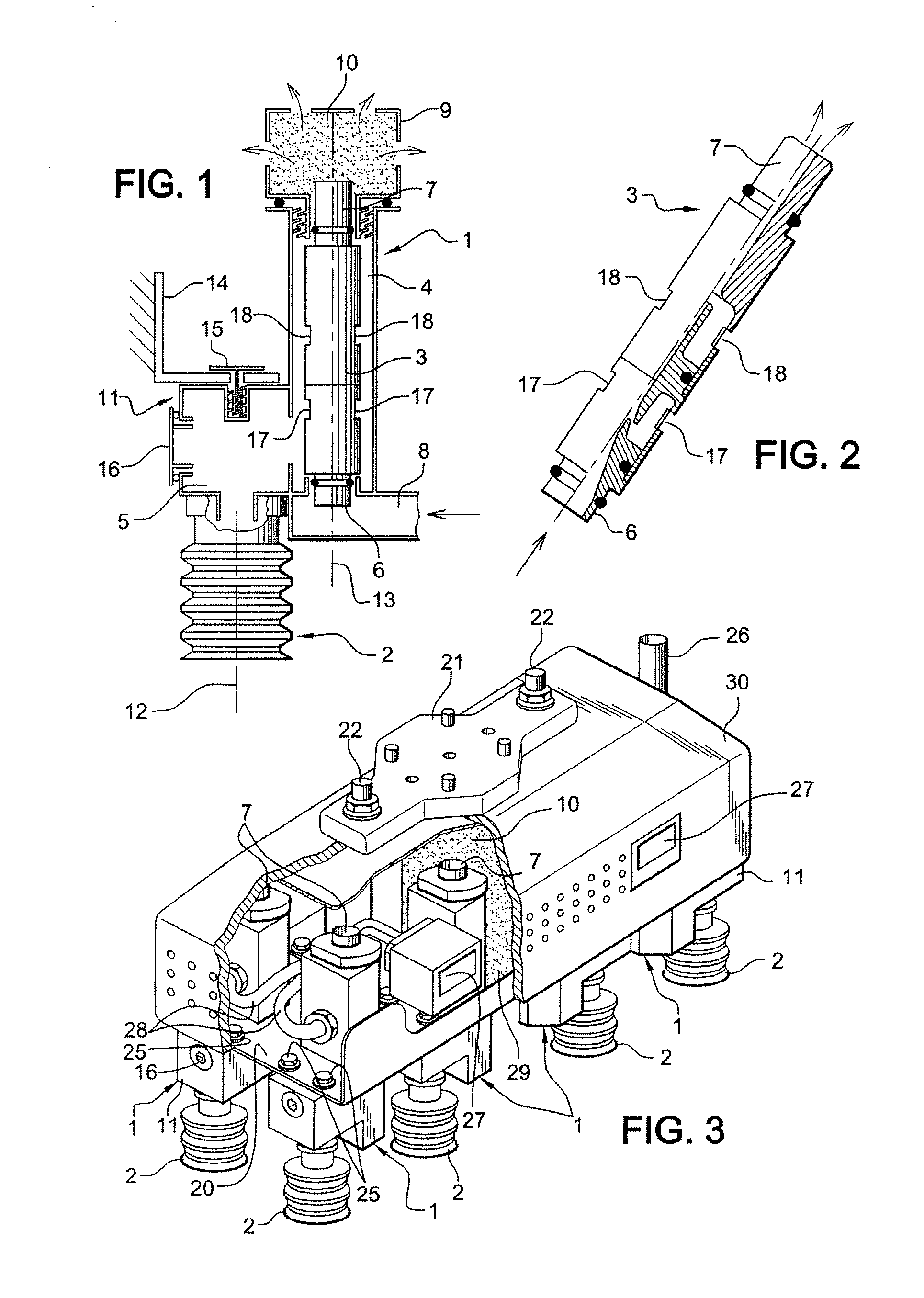

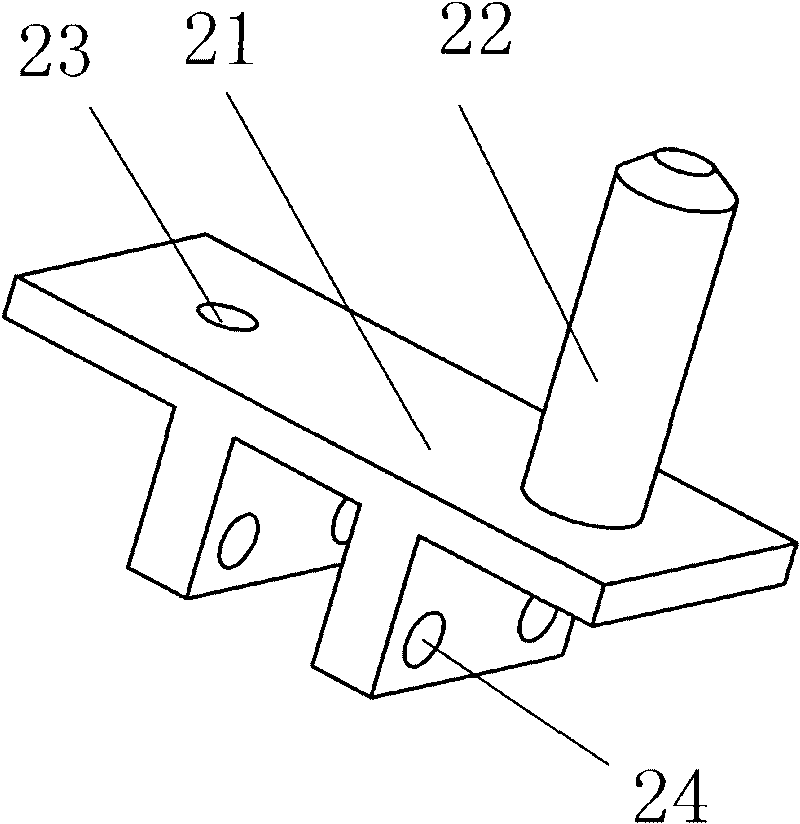

Automatic egg boxing mechanical arm as well as boxing method and control method thereof

InactiveCN101982375AGuaranteed accuracyReduce maintenance costsProgramme-controlled manipulatorPackaging eggsProduction lineProgrammable logic controller

The invention discloses a novel automatic egg boxing mechanical arm as well as a boxing method and a control method thereof. The boxing mechanical arm consists of a mechanical arm system and a control system, and is arranged on the tail end of the existing egg classification production line by a bracket; a horizontal cylinder of the mechanical arm and a guide rail slider are synergized to realize horizontal motion of the mechanical arm; a cylinder and a guide rail slider which are arranged vertically in the vertical direction drive the lower arm of the mechanical arm to do vertical motion; an egg suction cup and an egg support suction cup are arranged on a lower arm bracket, and are matched with open and close of an electromagnetic valve to realize grasp and release actions to the eggs and the egg support; eggs and cartons are conveyed by a stepping motor and a conveying belt; and the mechanical arm and the conveying belt are controlled by a (programmable logic controller (PLC) control module.

Owner:JIANGSU UNIV

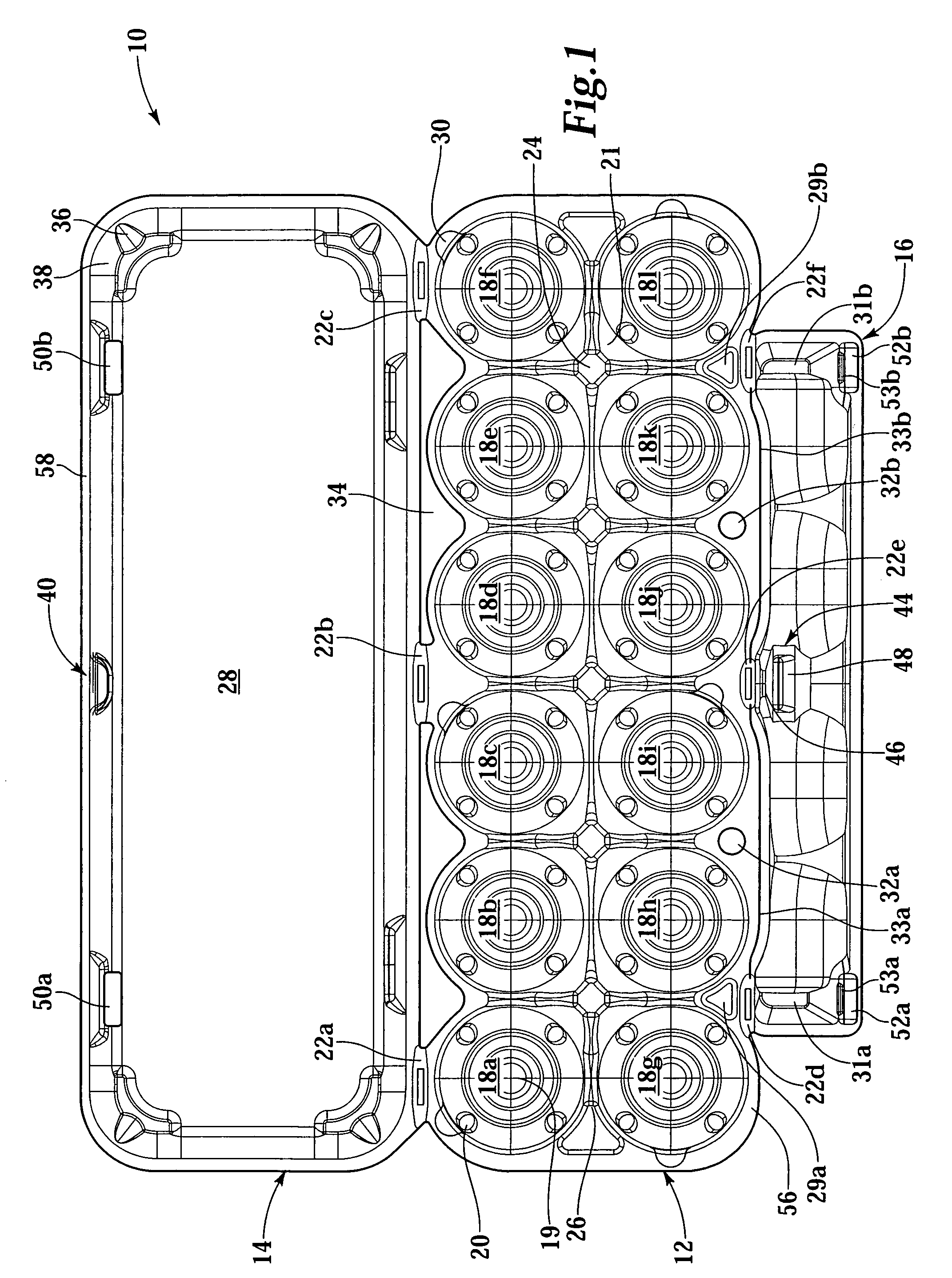

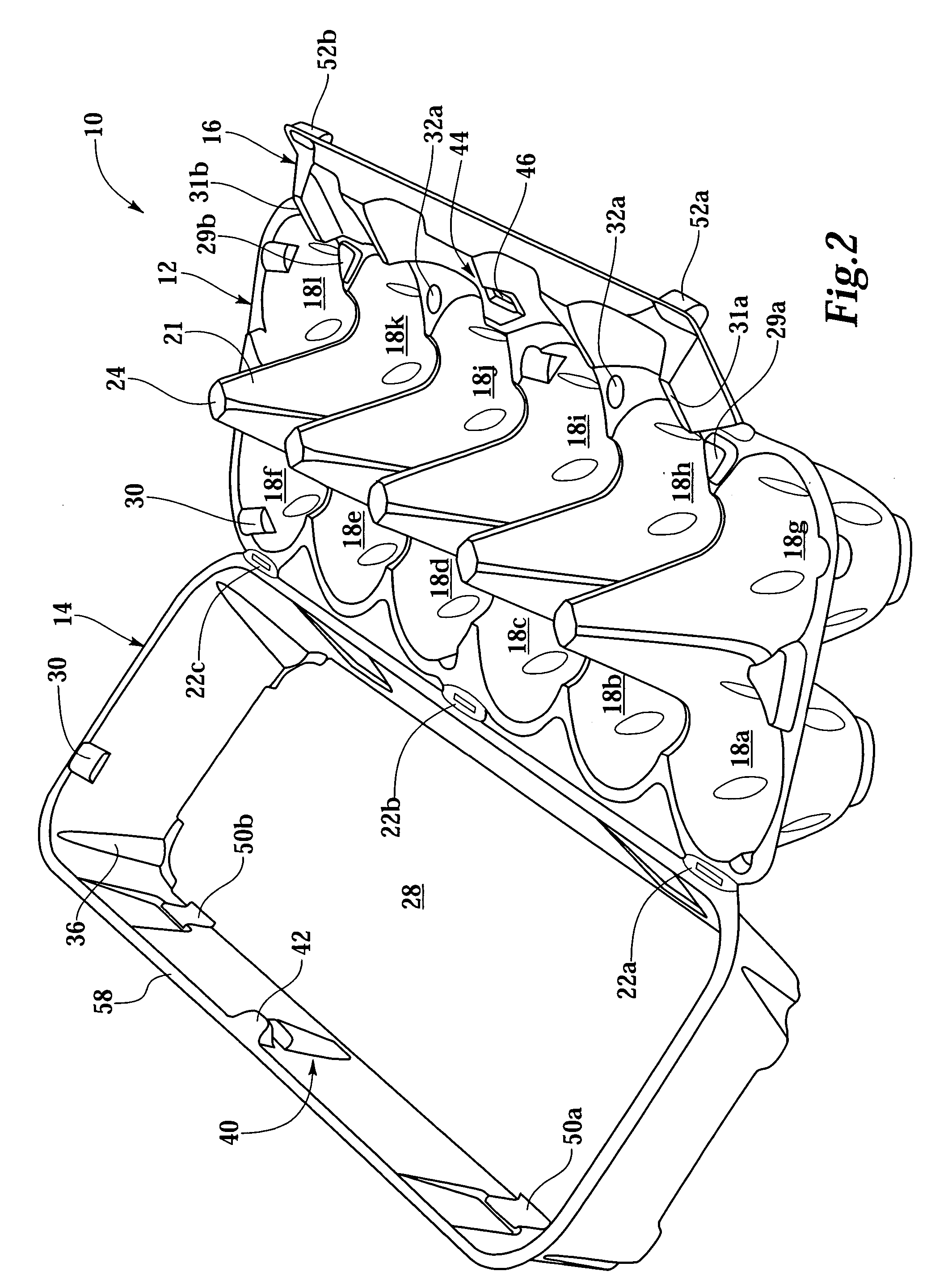

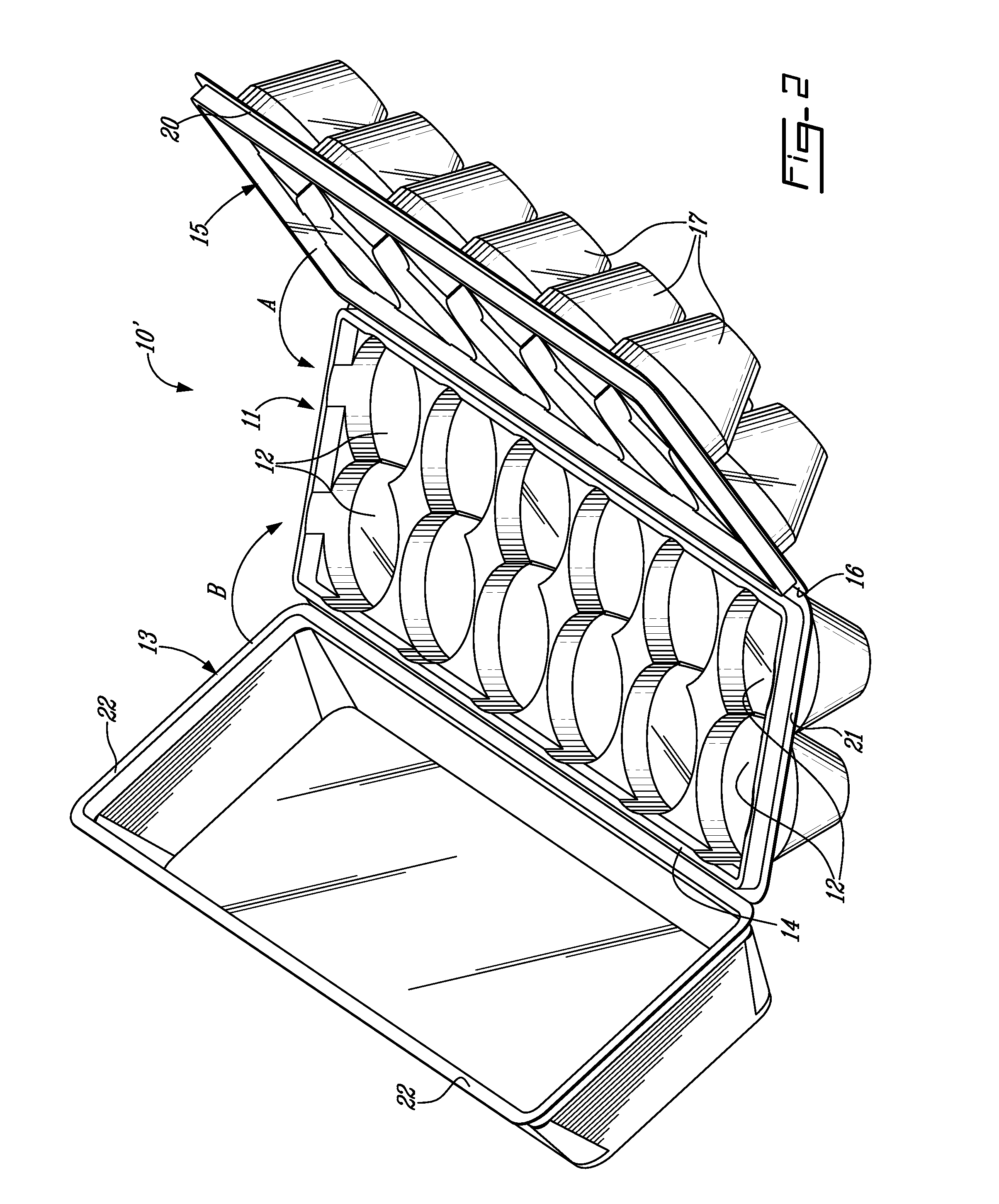

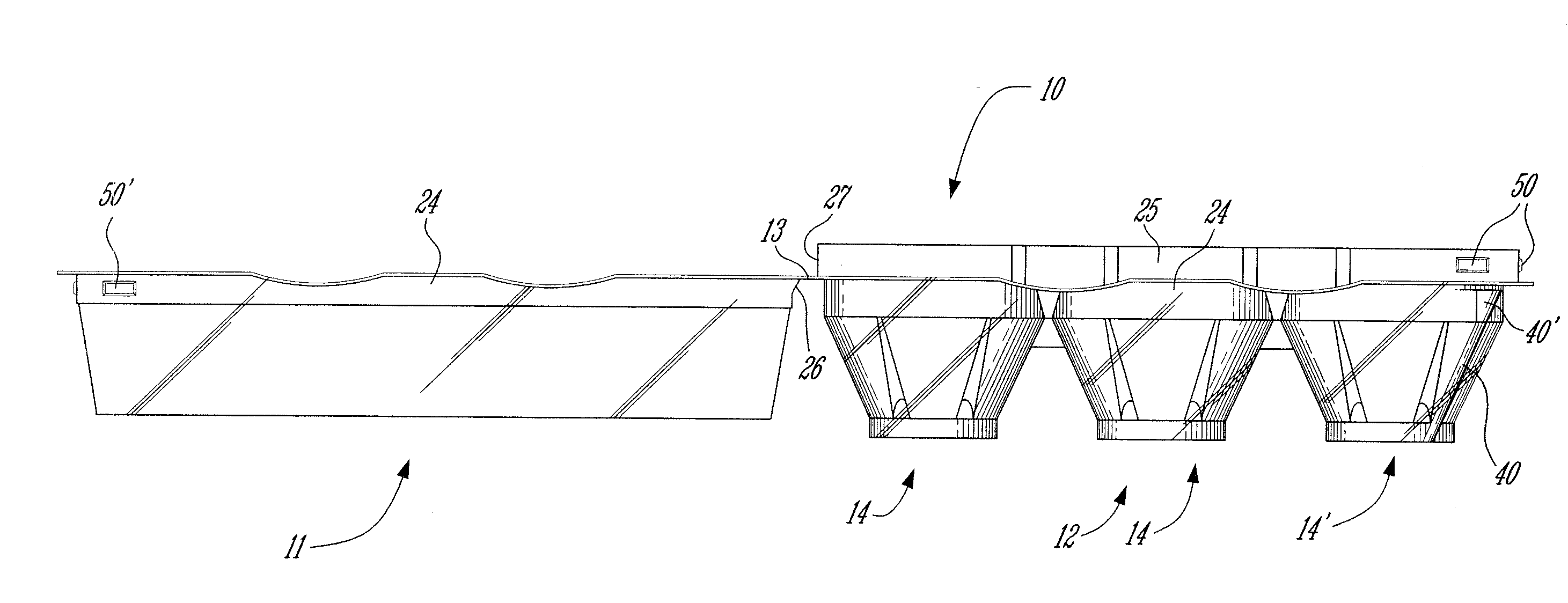

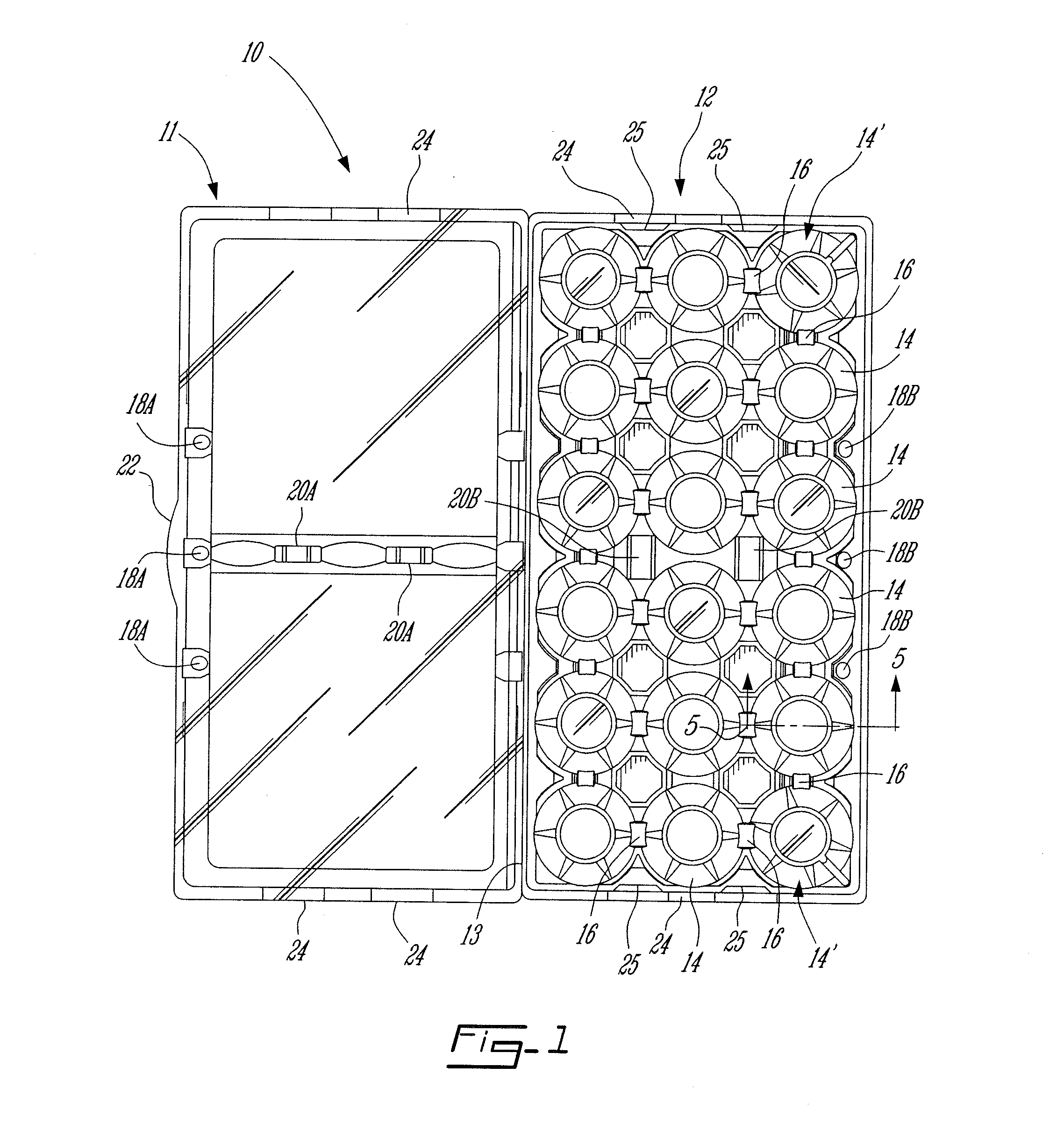

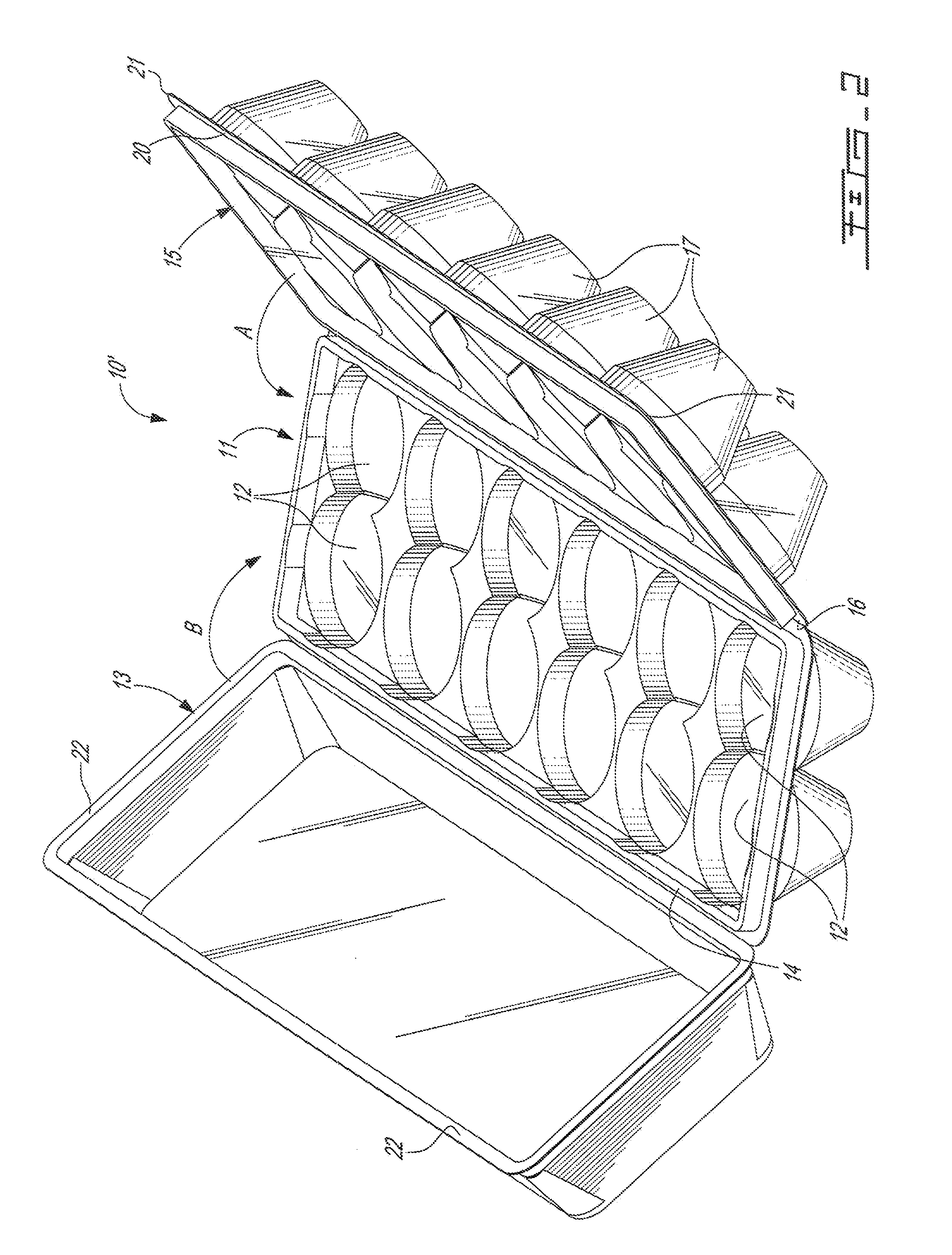

Transparent egg carton with closure flap

Transparent egg cartons suitable for being made from a variety of transparent polymeric materials and particularly from polylactic acid or other biodegradable polymers are described. The egg cartons use a “W” shaped hinge or box hinge element for hingedly connecting the lid to the tray or a flap to the tray. The flap is made with lattice struts to increase the lateral strength thereof, and contains at least three button tabs for interlocking the flap with the lid. The lateral most button tabs are located about ⅛th the length of the flap from the ends of the flap. The egg cartons have an awning portion that extends from the front surface of the lid to cover the “W” shaped hinge or box hinge when the lid is closed. A space is provided between the edge of the awning and the hinge for a consumer to place a finger for disengaging the lid from the flap.

Owner:CLEARVIEW CARTONS

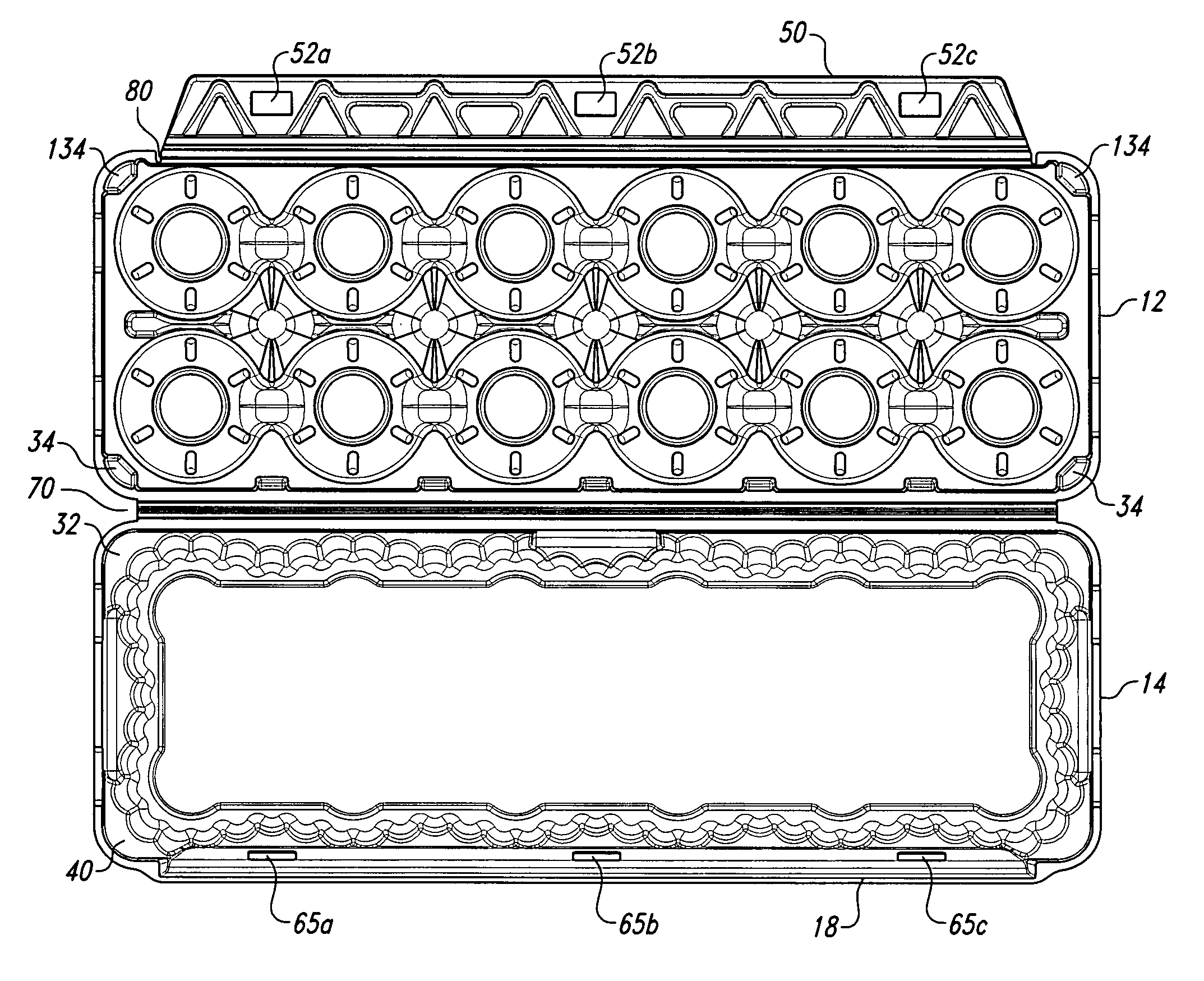

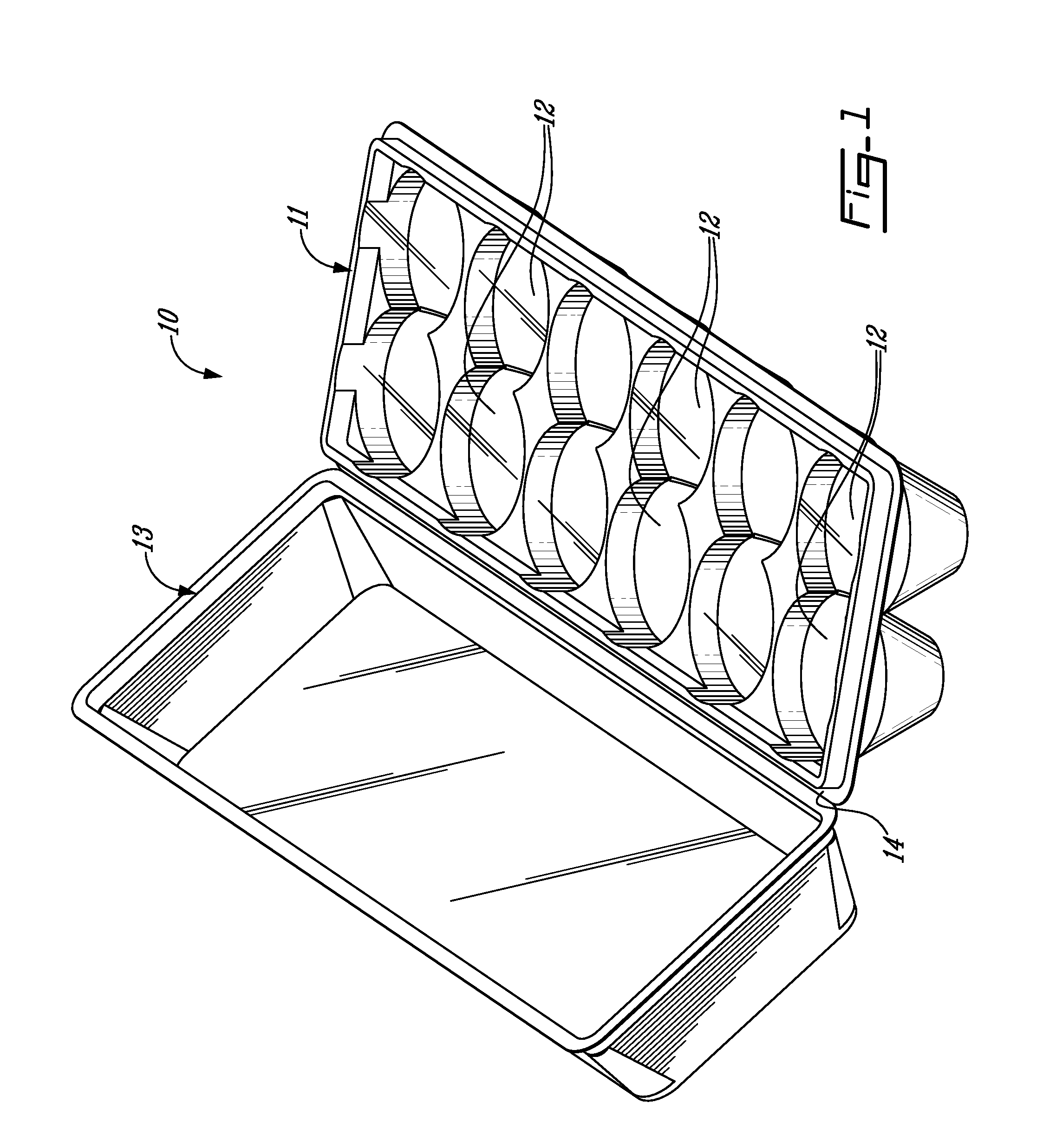

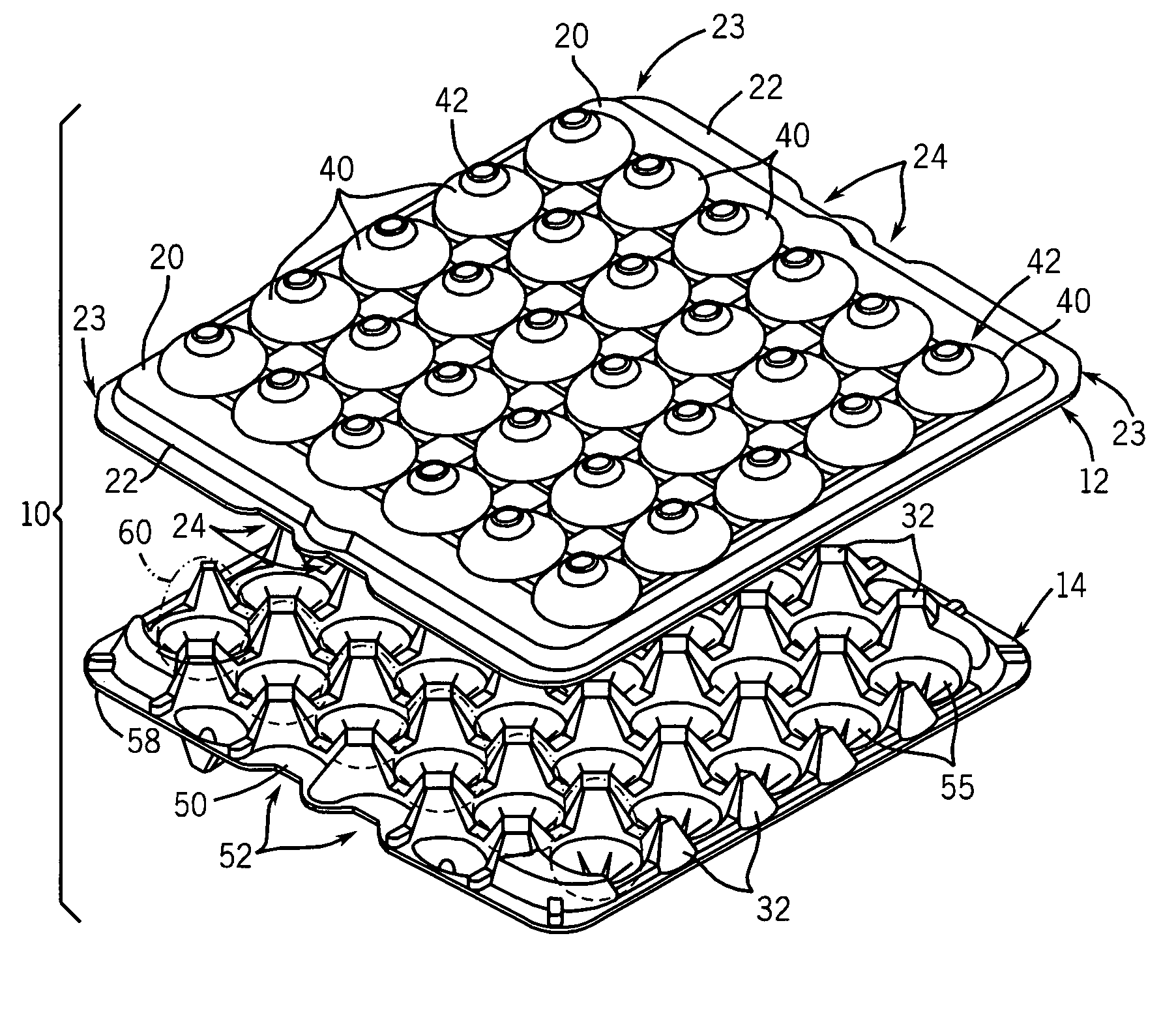

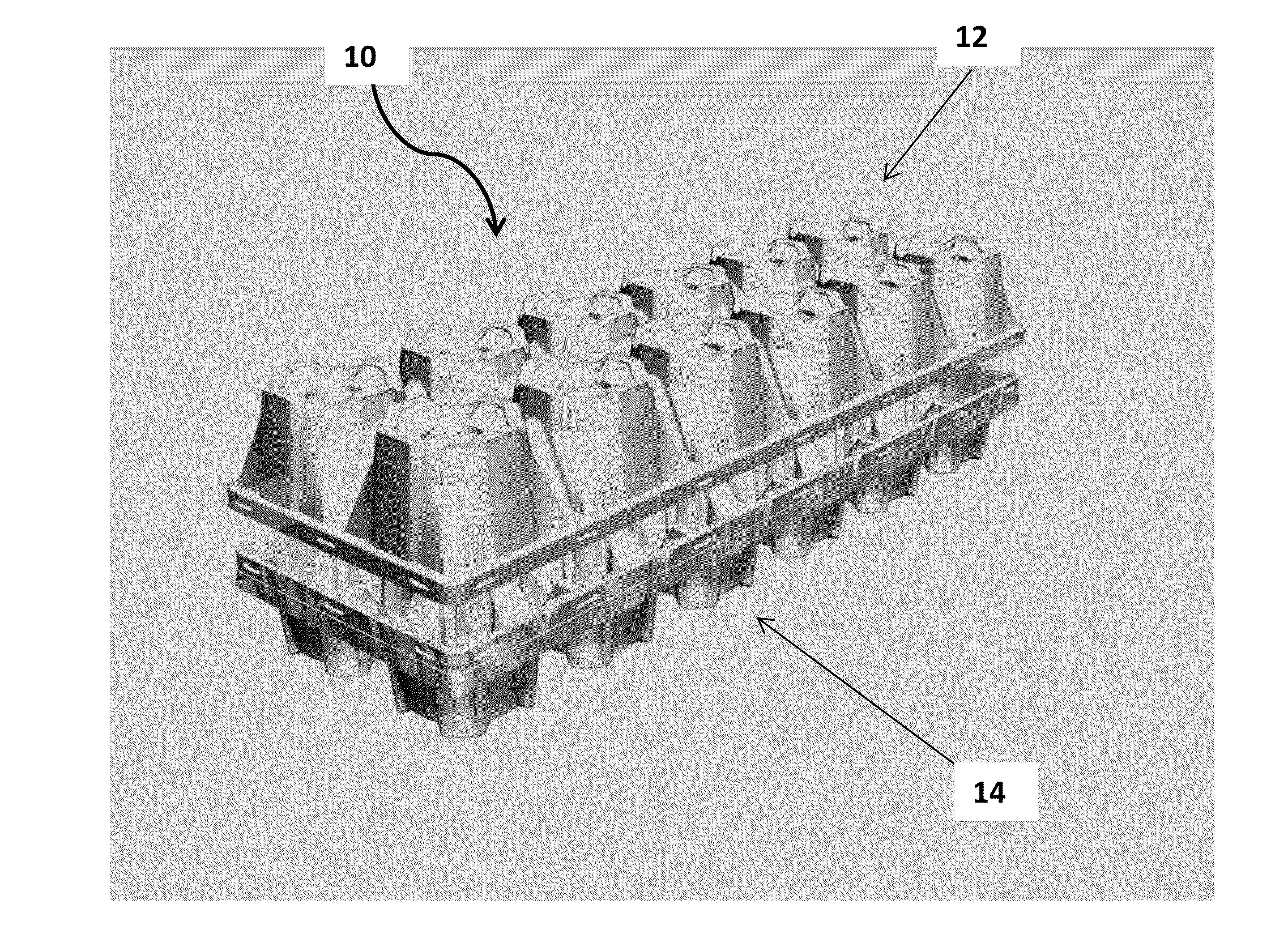

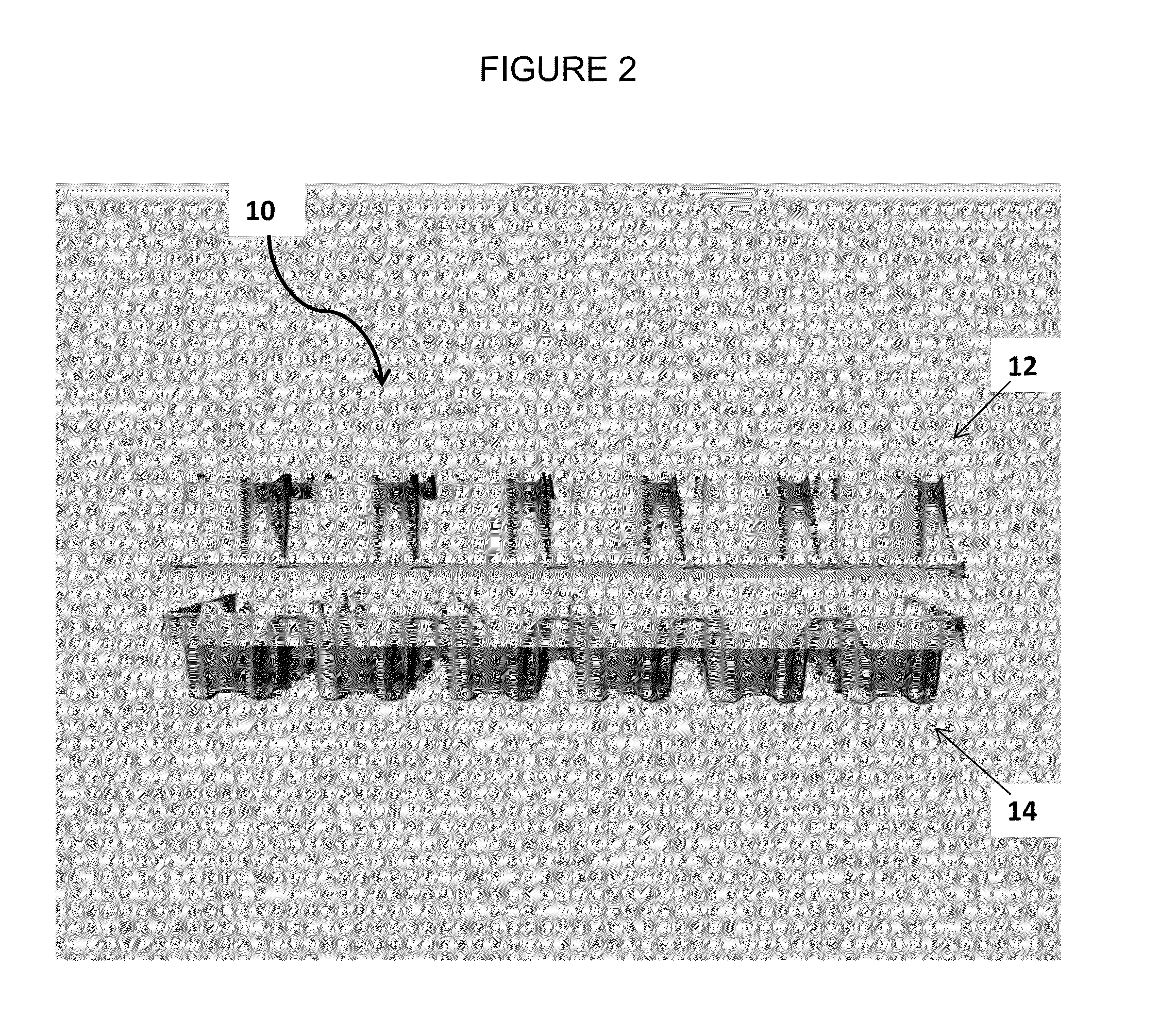

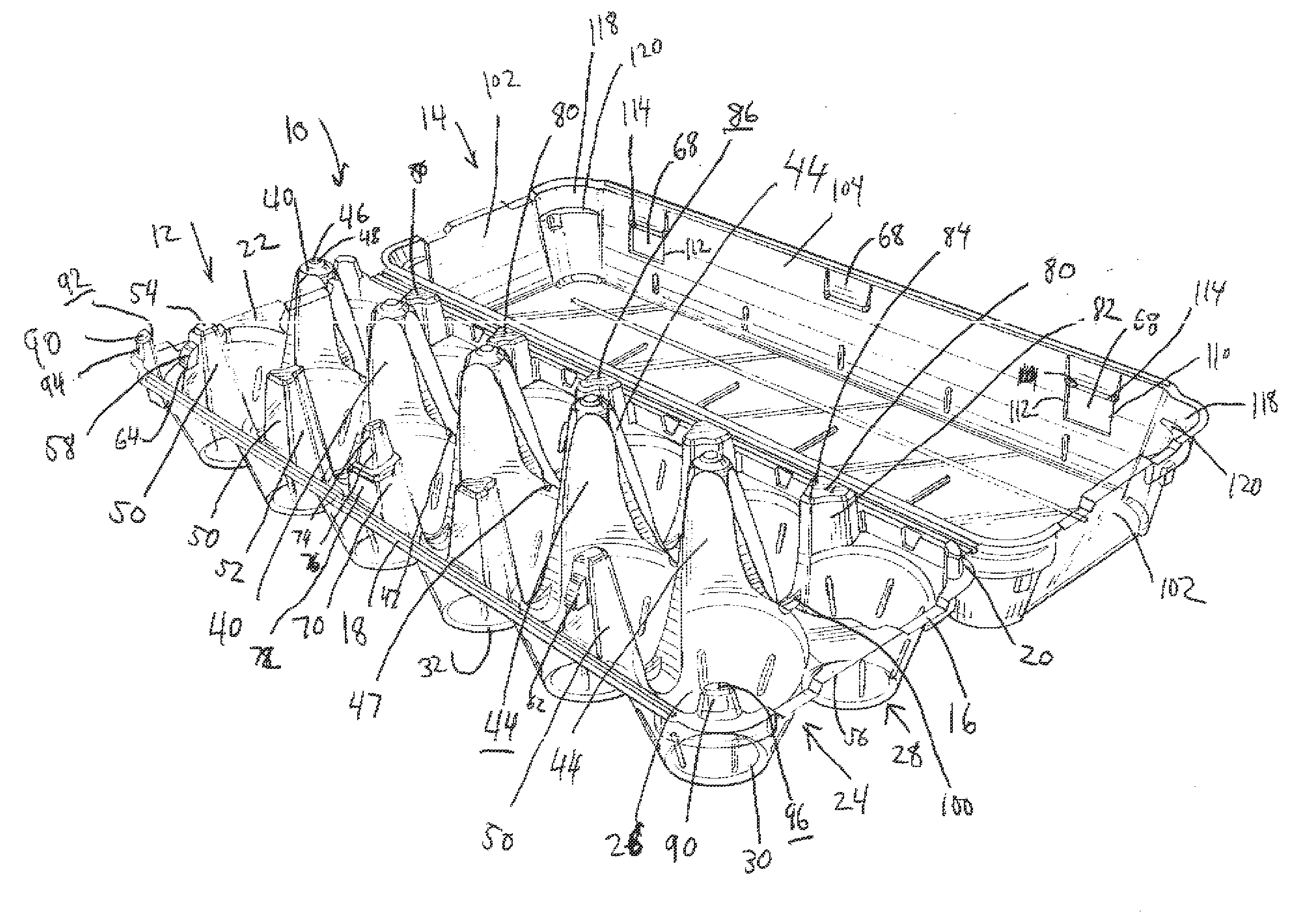

Egg carton with mating cell and lid post structure

Plastic egg cartons having mating cell and lid posts for improved egg protection. The carton has a base tray and hinged lid, the tray including a plurality of cells for receiving individual eggs, and the tray having a plurality of cell posts each formed at an intersection of four adjacent cells as an extension of the sidewalls of the four adjacent cells. Preferable, each cell post has four generally planar ramp surfaces, one disposed respectively on each of the four sidewall extensions. The lid has a plurality of lid posts for mating with the cell posts when the lid is in a closed position.

Owner:TEKNI PLEX

Transparent egg cartons

InactiveUS20050178689A1High mechanical strengthBio-packagingPackaging eggsCartonBiodegradable polymer

Transparent egg cartons suitable for being made from a variety of transparent polymeric materials and particularly from polylactic acid or other biodegradable polymers are described. The egg cartons use a “W” shaped hinge or box hinge element for hingedly connecting the lid to the tray or a flap to the tray. The flap is made with lattice struts to increase the lateral strength thereof, and contains at least three button tabs for interlocking the flap with the lid. The lateral most button tabs are located about ⅛th the length of the flap from the ends of the flap. The egg cartons have an awning portion that extends from the front surface of the lid to cover the “W” shaped hinge or box hinge when the lid is closed. A space is provided between the edge of the awning and the hinge for a consumer to place a finger for disengaging the lid from the flap.

Owner:CLEARVIEW CARTONS

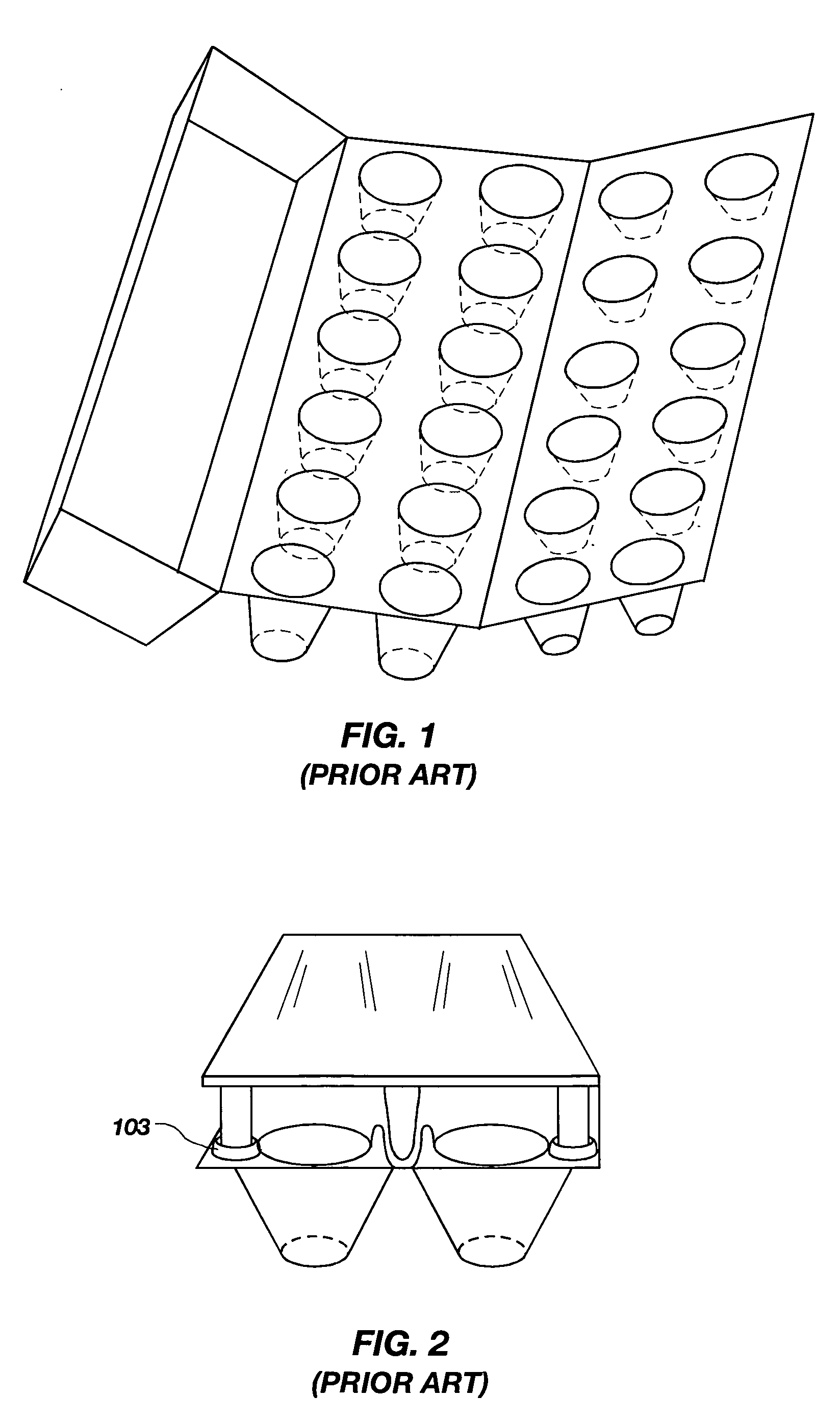

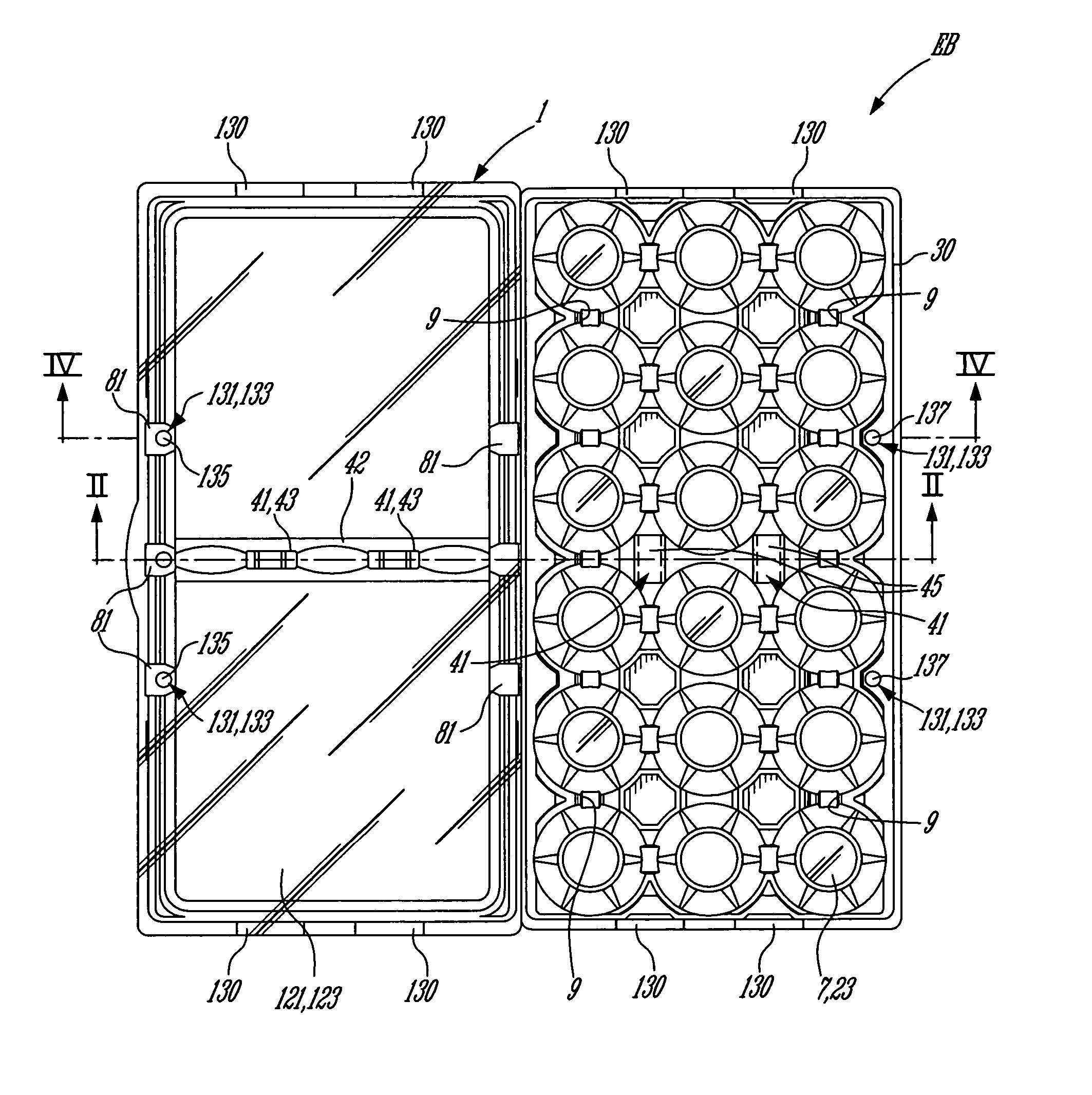

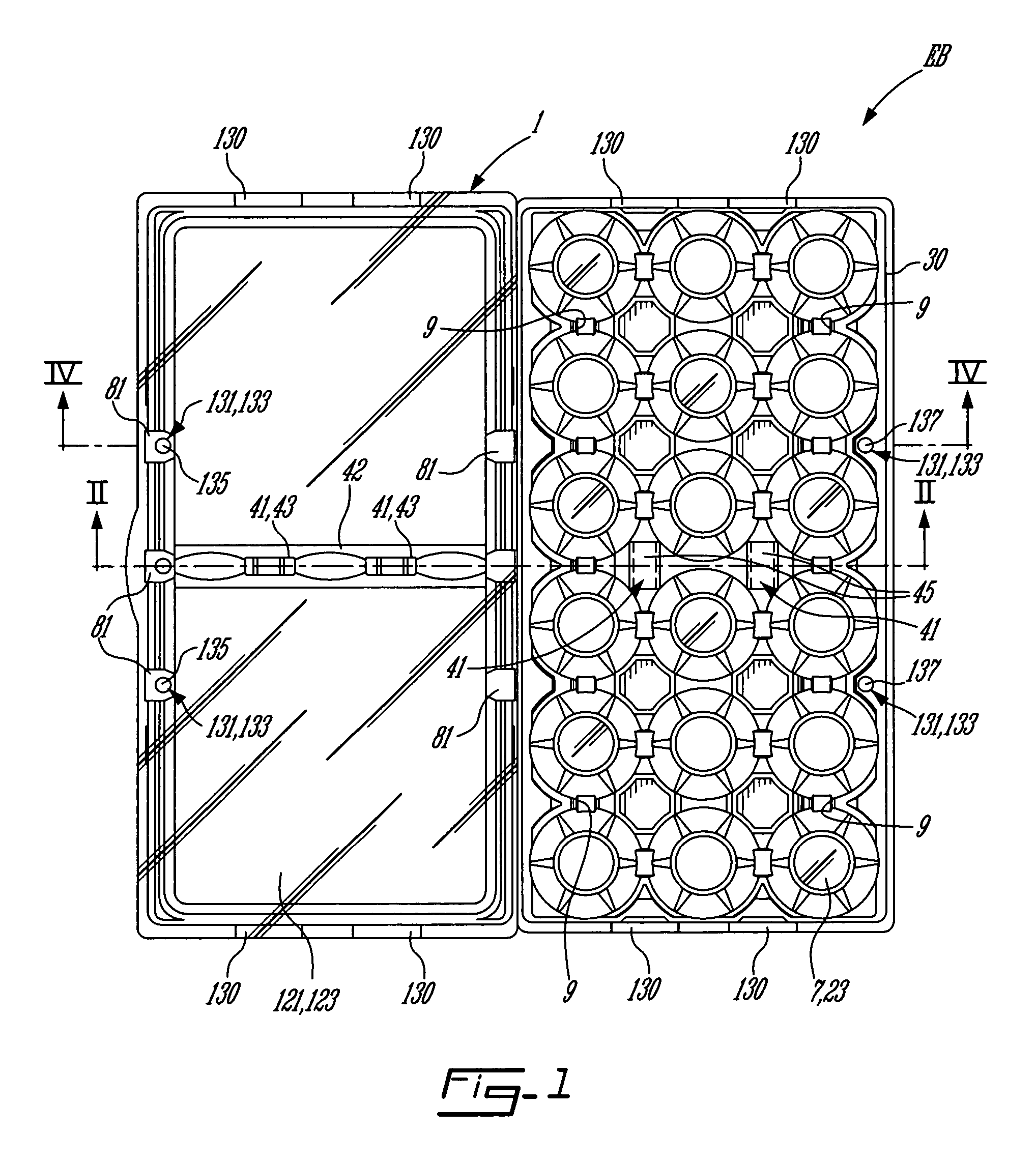

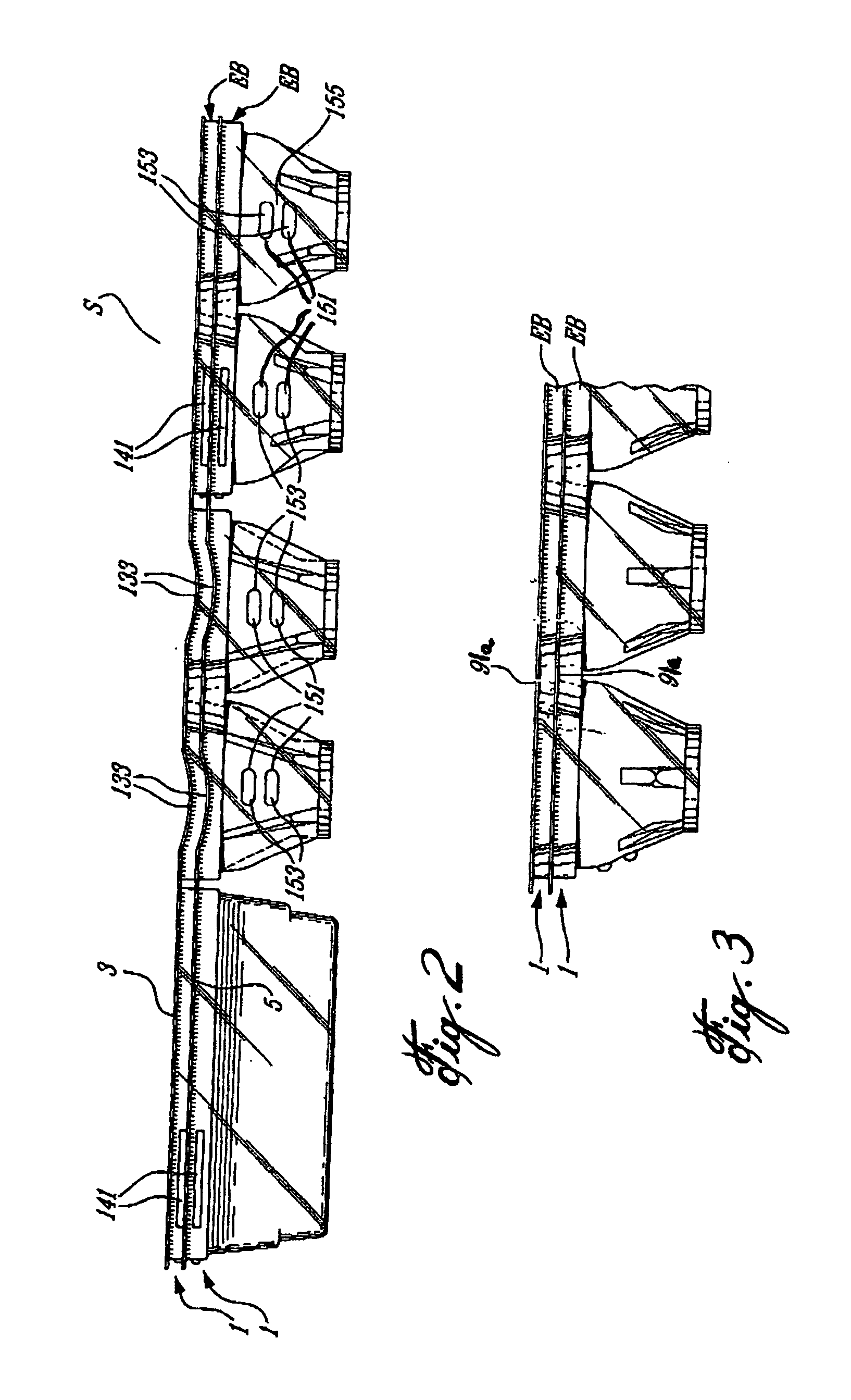

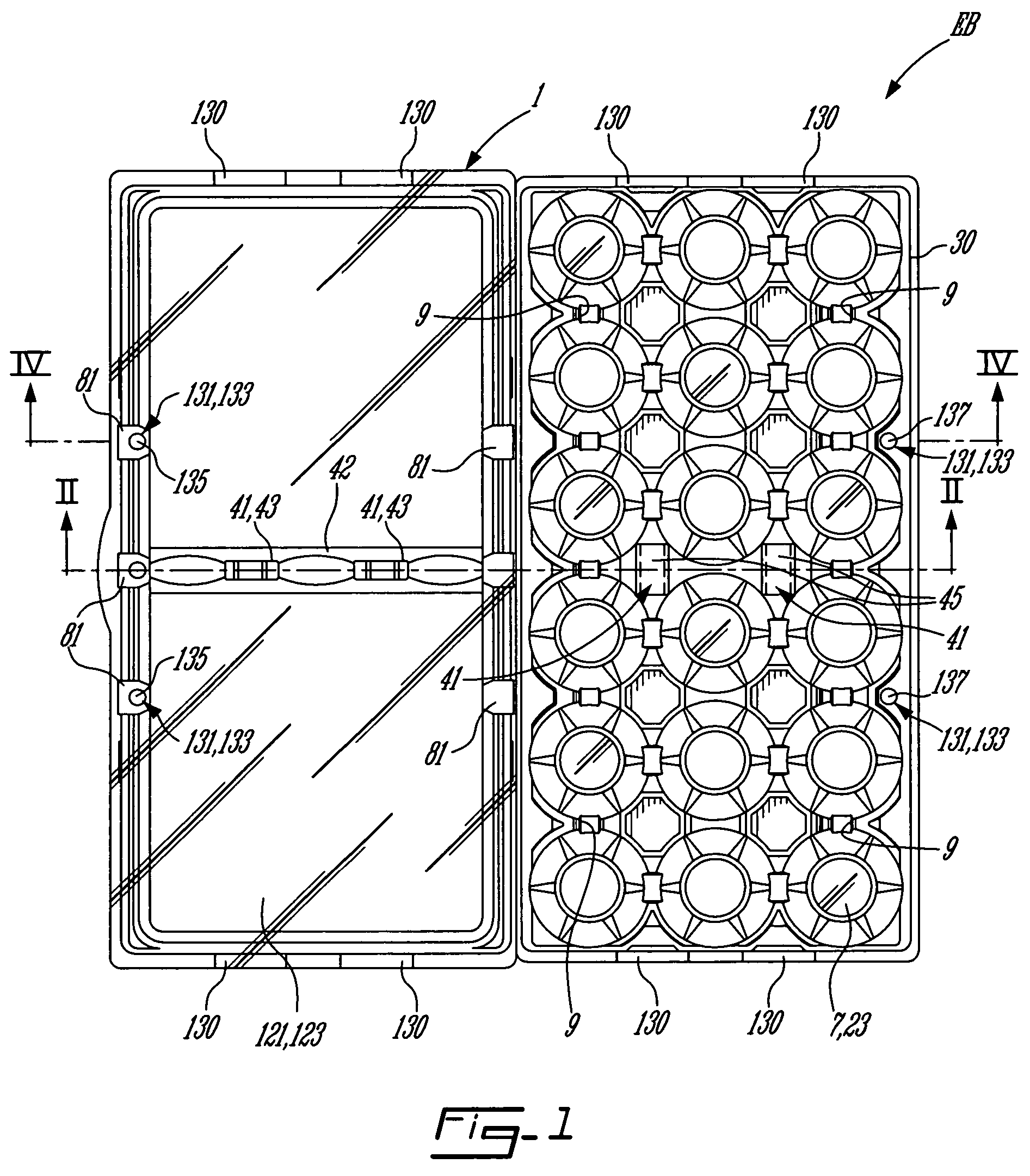

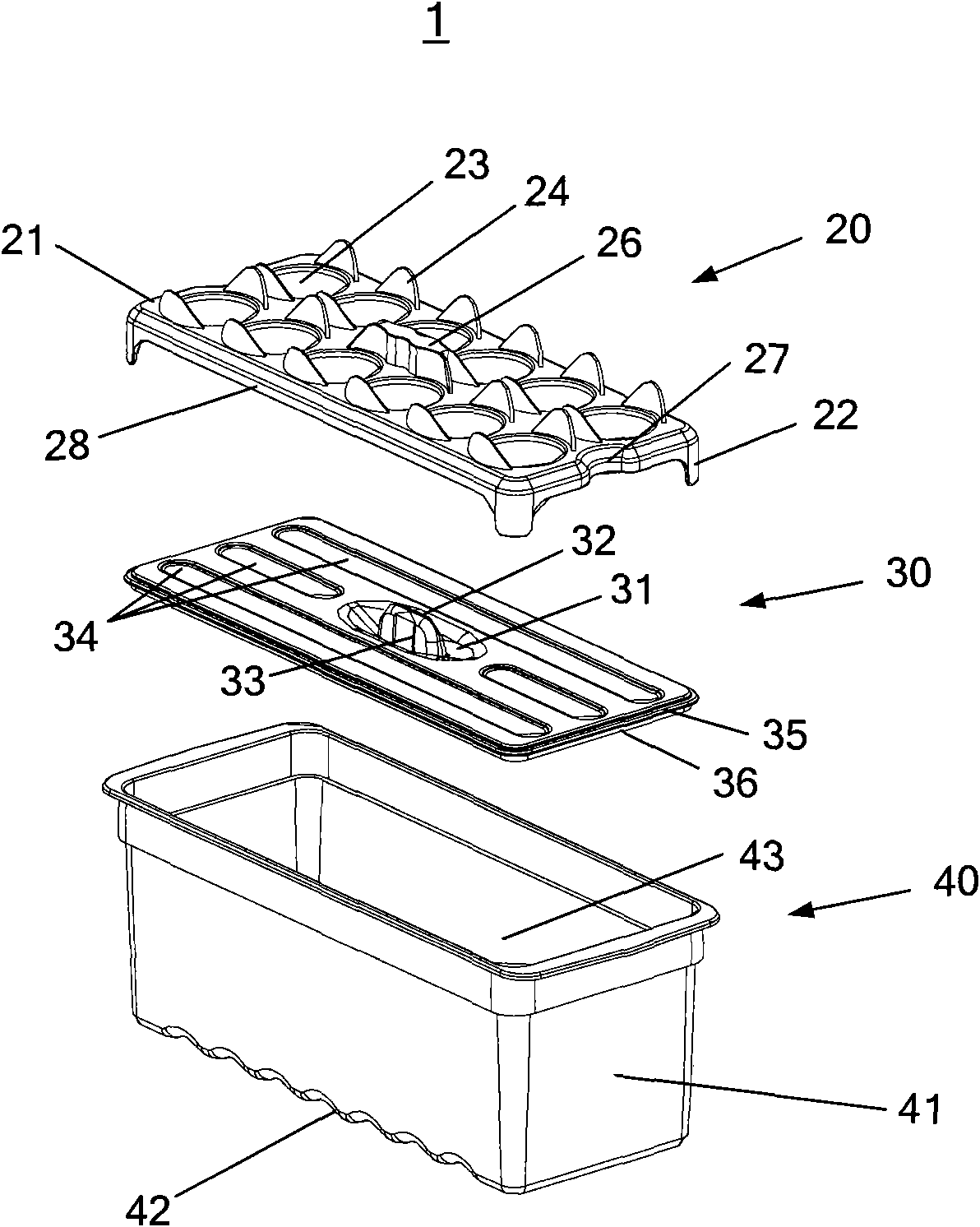

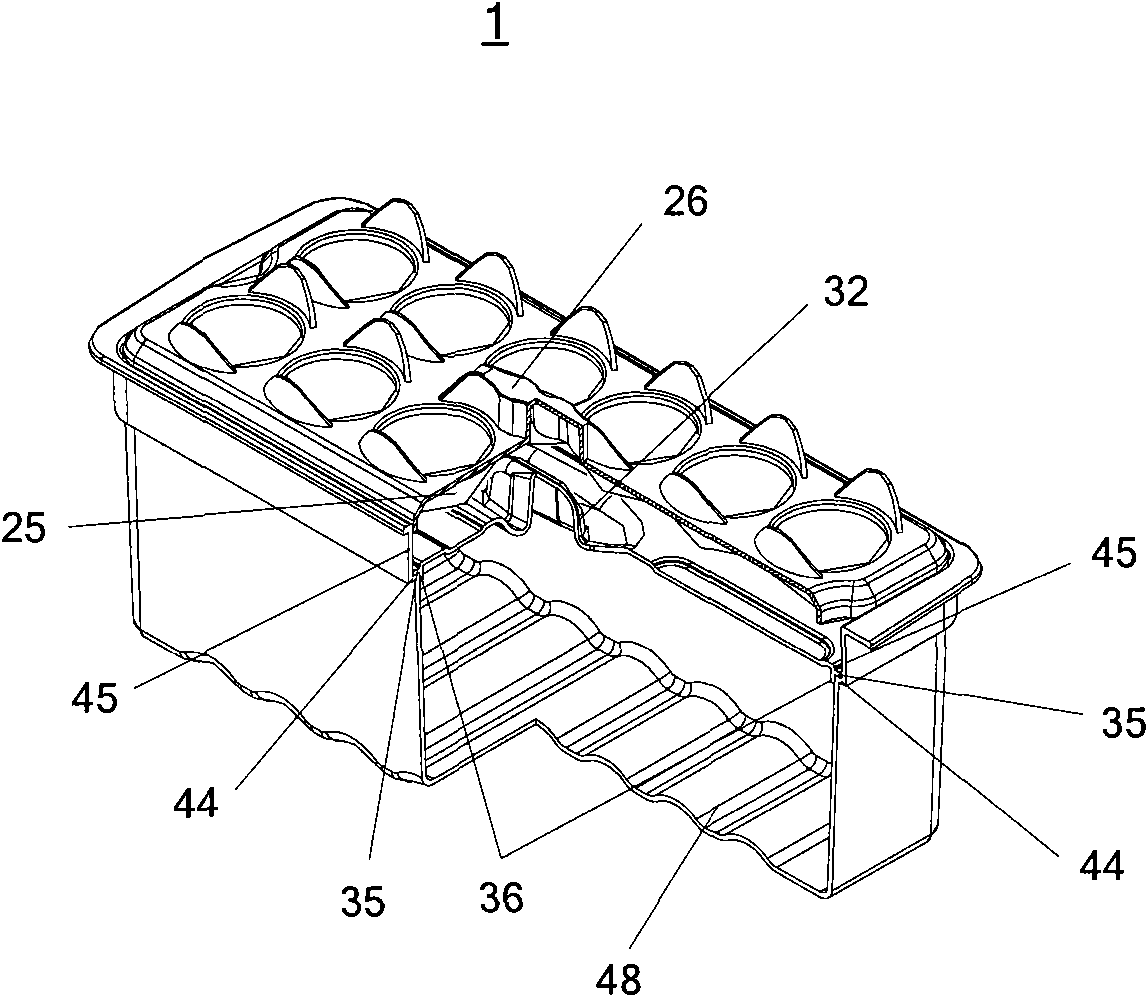

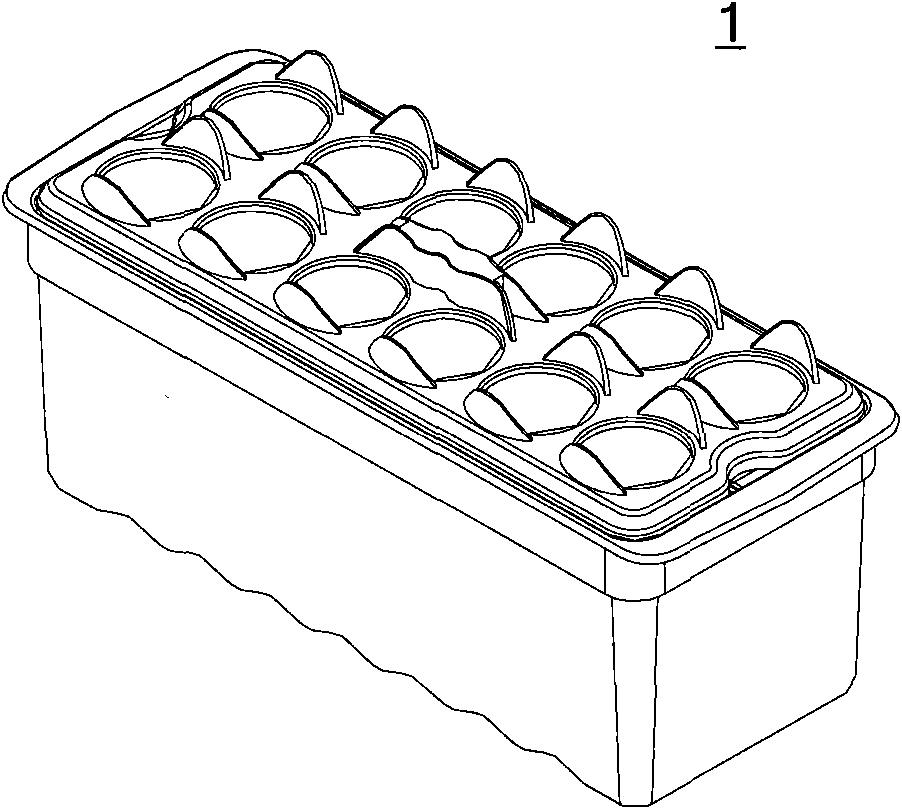

Stackable egg-box, stack of egg-boxes and method for destacking said egg-box

ActiveUS20070151892A1Easy to storeEasy fluid communicationInternal framesPackaging eggsPlastic materialsEngineering

A stackable tray obtained by vacuum molding of a sheet of plastic material, said tray comprising, in open position: a) a top and a bottom; b) at least one receiving cavity opened upwardly, c) a hinge portion dividing said tray into a cover portion and a base portion; said receiving cavity being at least provided in said base portion; d) spacing means to keep, in a stack of trays, the top portion and the bottom portion of neighboring trays at distance from each other to thereby prevent interlocking therebetween; and e) at least one two-part locking means, each part being provided in the top of the sheet and positioned to engaged one into the other when the cover portion is folded over the base portion along the hinge portion to bring the tray into a closed position defining a box. A stack of said trays and a method using said trays.

Owner:PACTIV CANADA

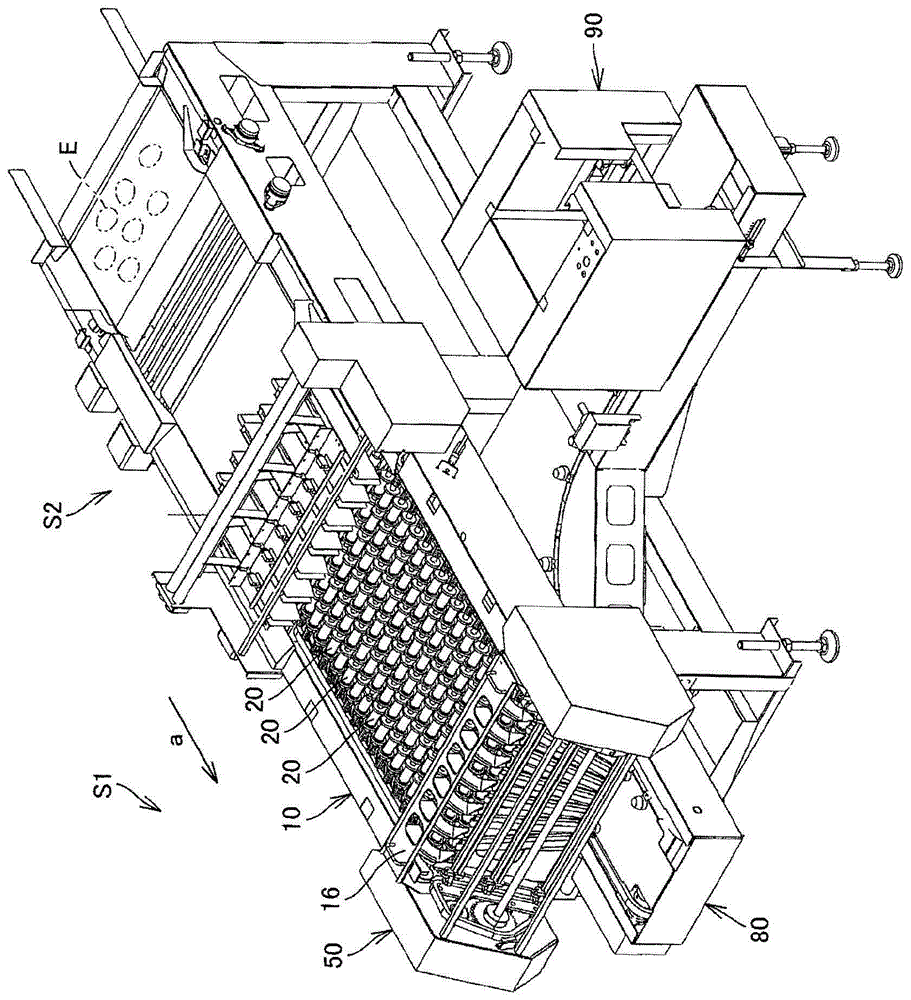

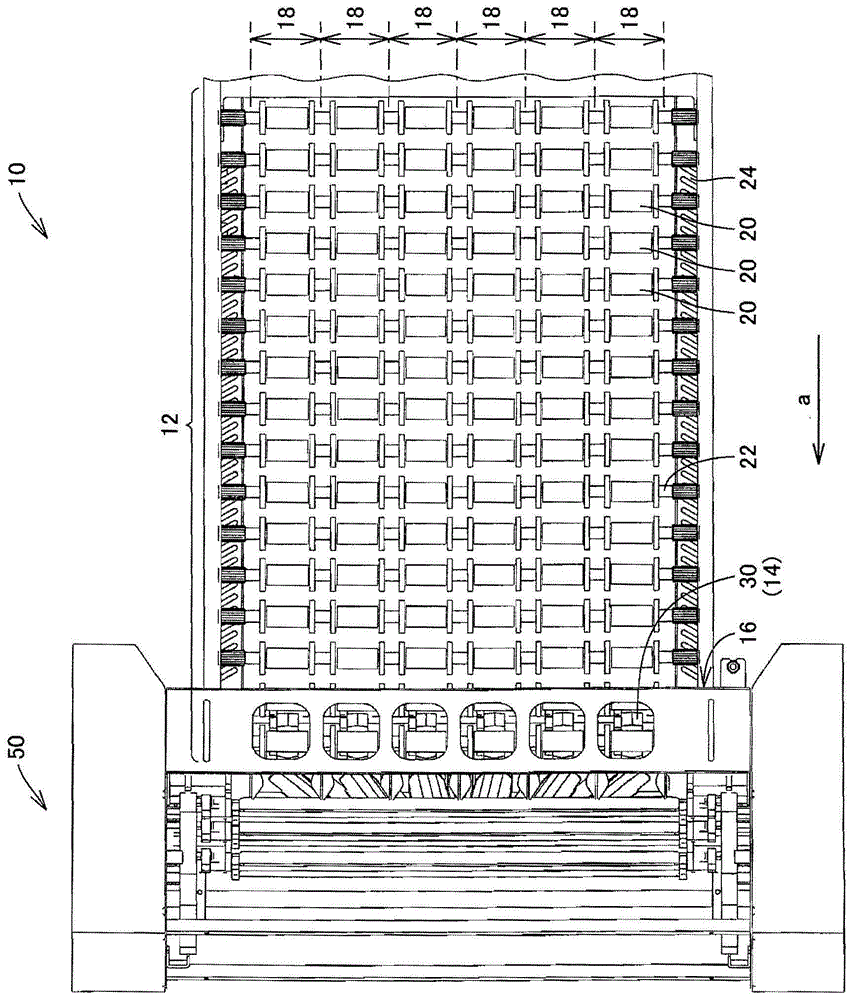

Drop assistance apparatus, filler system, and filling assistance method

The invention provides a drop assistance apparatus, a filler system, and a filling assistance method. The drop assistance apparatus (50) includes a slider (52) over which an object slides down and a catch and hold assembly (54) catching and holding the object sliding down over the slider (52) in cooperation with the slider (52). The catch and hold assembly (54) includes a catch and hold member (56) catching and holding the object so as to support the same from below in cooperation with an inclined surface of the slider (52), a support member (58) supporting the catch and hold member (56) so as to catch and hold the object and moving in a direction away from the slider (52), and a force application member (62) applying rotational force biasing toward the slider (52) to the catch and hold member (56). The catch and hold member (56) is rotatably supported by the support member (58) so that the object is caught and held by the catch and hold member (56) as the force application member (62) applies the rotational force biasing toward the slider (52).

Owner:股份公司南备尔

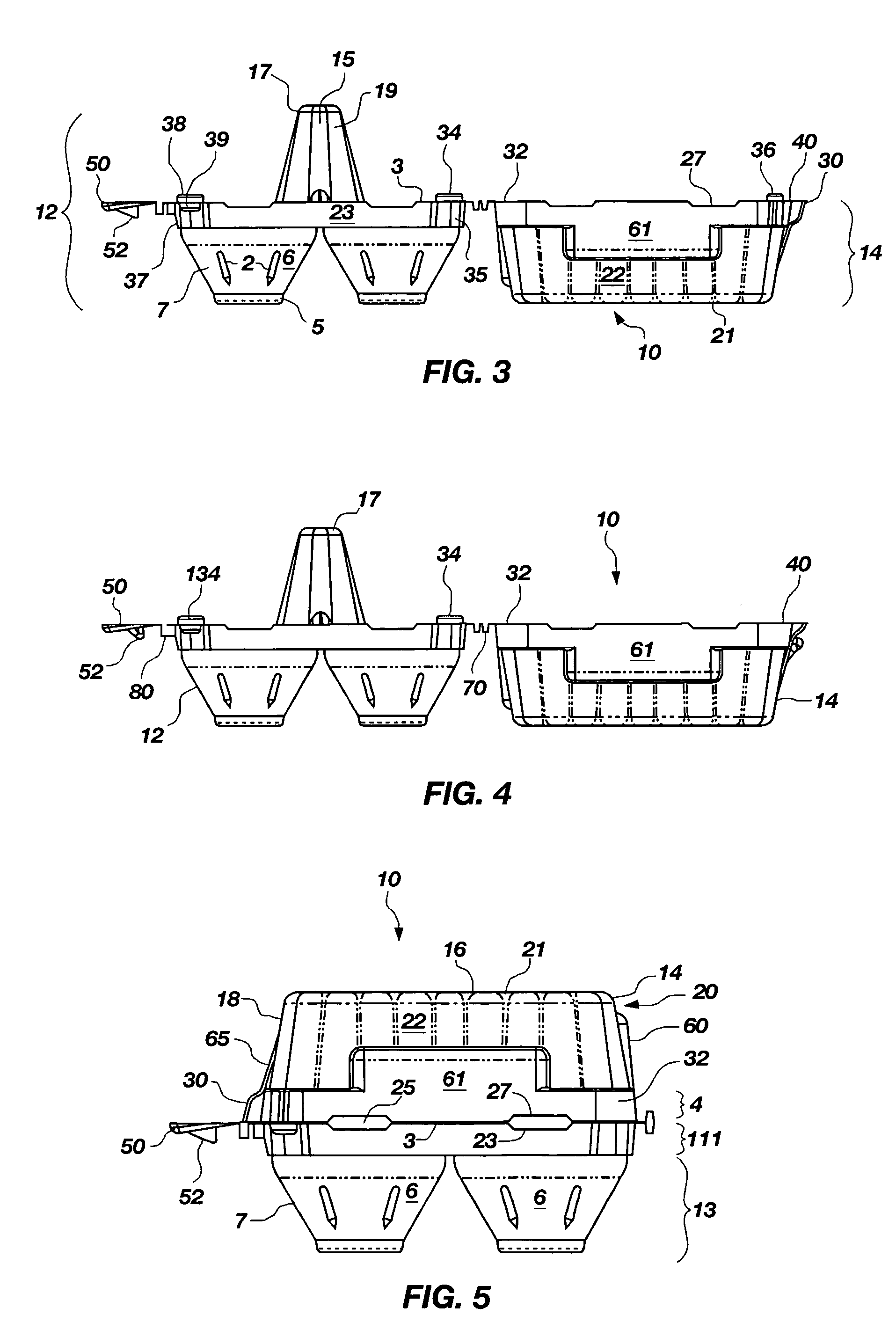

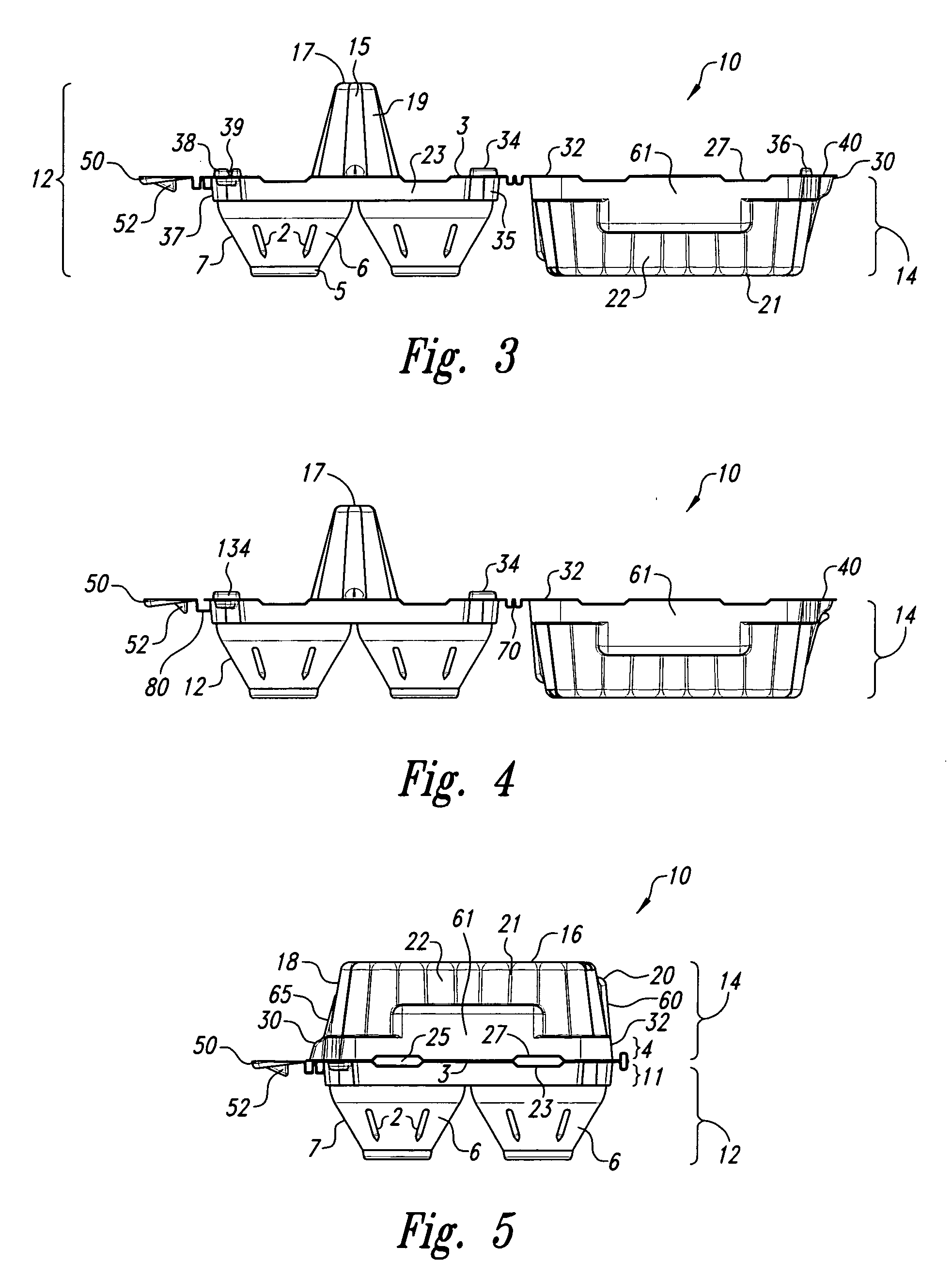

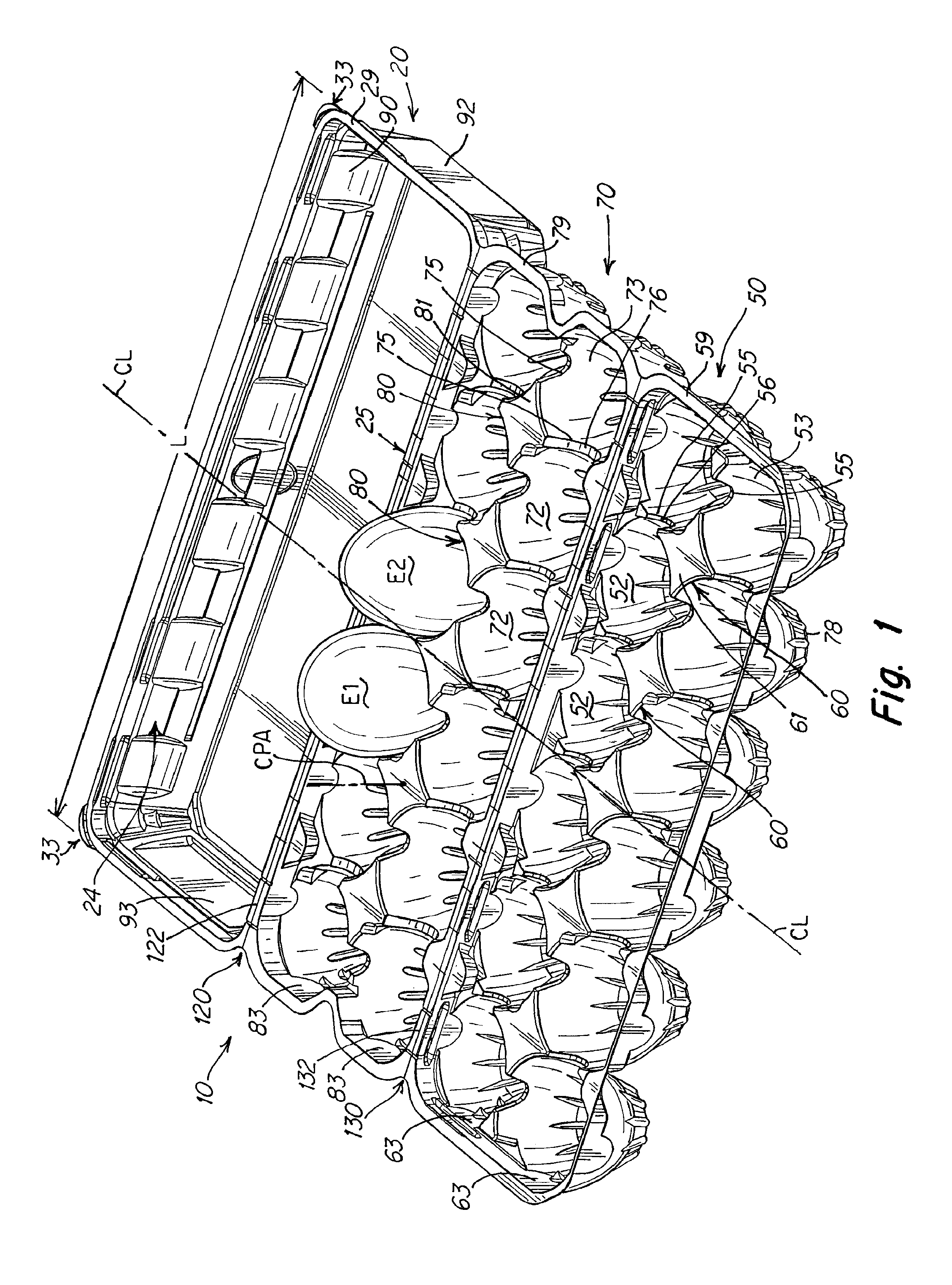

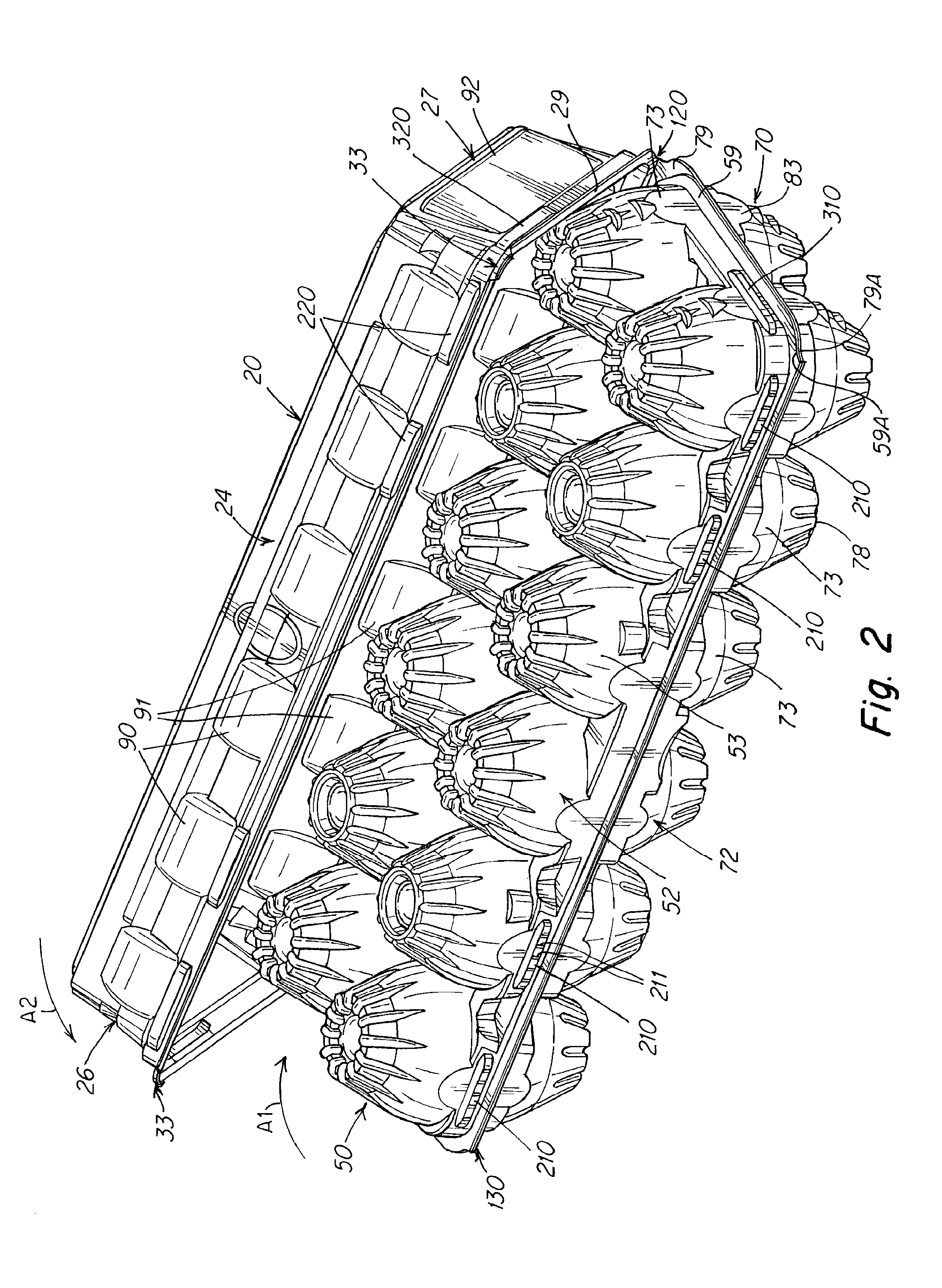

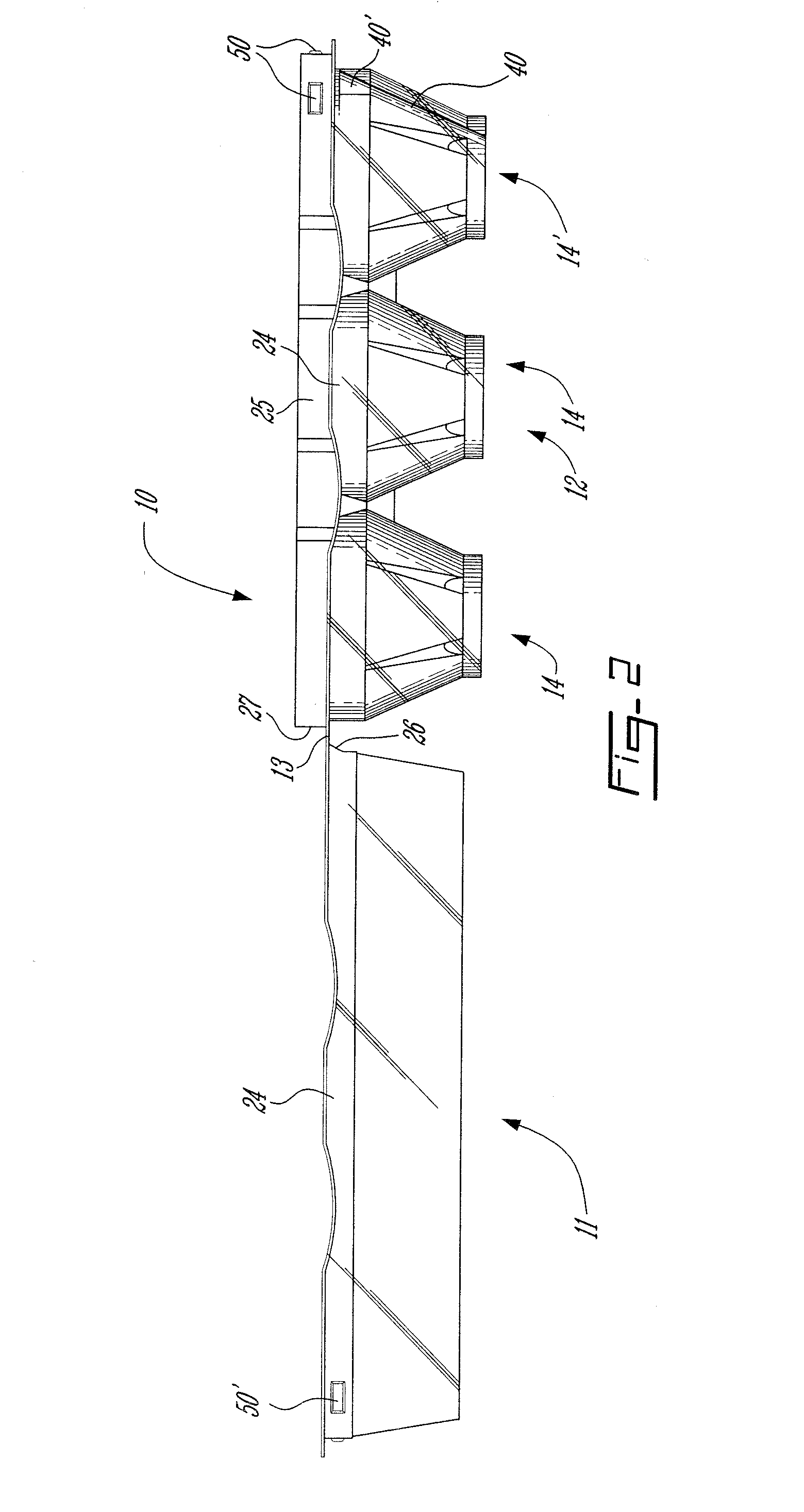

Tri-fold egg carton for jumbo eggs

A tri-fold plastic egg carton for protecting jumbo eggs in both oriented and non-oriented positions. A cell base and cell cover are hingedly connected in a closed position with the cover over the base to form a complimentary 2×6 matrix of cell pockets for holding individual eggs. A lid is hingedly connected to another edge of the base for closing over the assembled cover and base. The non-hinged peripheral edges of the base, cover and lid form a trim perimeter having a turned up lip edge, the lip edges mating when the carton is in the closed position to increase the carton strength. The carton can accommodate a full range of jumbo eggs, and accept a variety of smaller size eggs, while fitting within standard cases and half-cases.

Owner:TEKNI PLEX

Stackable egg-box, stack of egg-boxes and method for destacking said egg-box

ActiveUS20050189256A1Avoid interlockOvercomes drawbackPackaging eggsTray containersPlastic materialsEngineering

A stackable tray obtained by vacuum molding of a sheet of plastic material, said tray comprising, in open position: a) a top and a bottom; b) at least one receiving cavity opened upwardly; c) spacing means to keep, in a sack of trays, the top portion and the bottom portion of neighboring trays at distance from each other to thereby prevent interlocking. A stack of said trays and a method using said trays.

Owner:PACTIV CORP

Egg container with stack-spacing system

A container for receiving frangible items comprising a sheet of polymer formed into: a base portion and at least one cover portion with a hinge between the base portion and the cover portion. Abutment spacer are formed at an edge between the peripheral walls and the top wall and each comprise an abutment surface projecting into the concavity from one of the peripheral walls, and support walls relating the abutment surface to the top wall, with at least one of the support walls being in an acute angle relation with the top wall of the cover portion. Alignment channels are in at least one of the peripheral walls defining an alignment protrusion through the sheet of polymer, the alignment channel / protrusion being oriented vertically for guiding the nesting of an upper one of the cover portion descending into a lower one of the cover portion.

Nestable lid for packaging systems

ActiveUS20060219594A1Low costImprove item securityPackaging eggsContainers to prevent mechanical damageMechanical engineering

Owner:PACTIV LLC

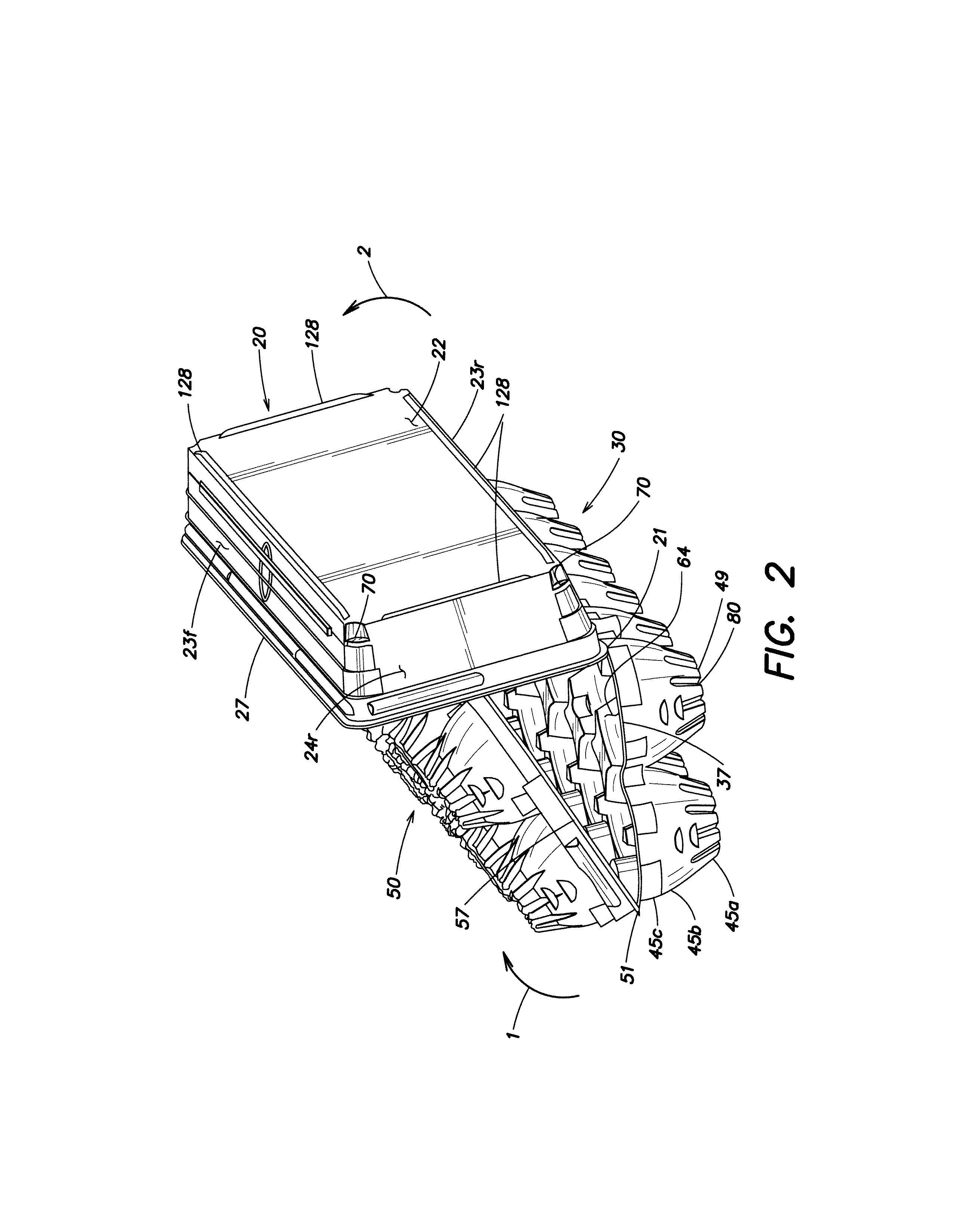

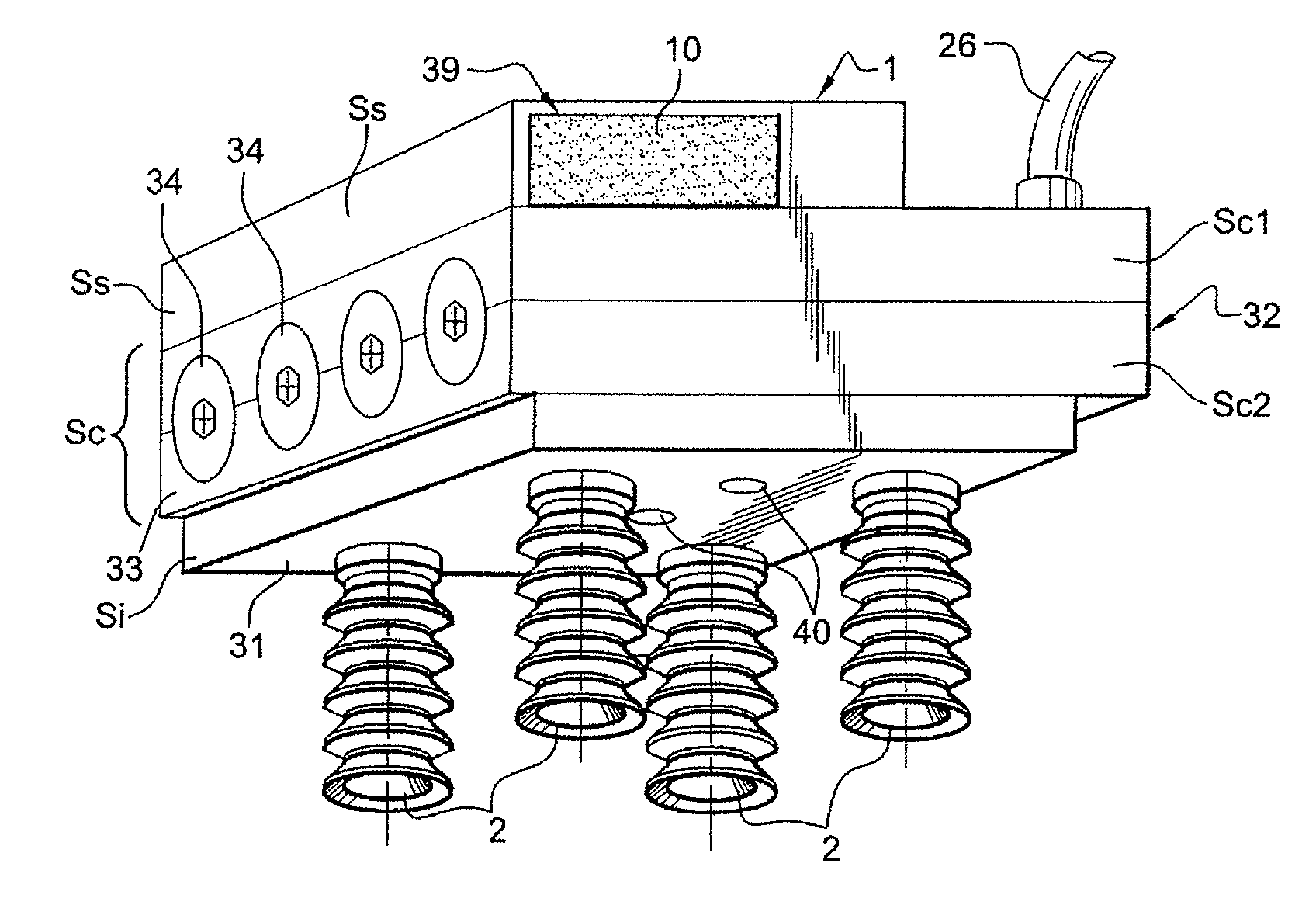

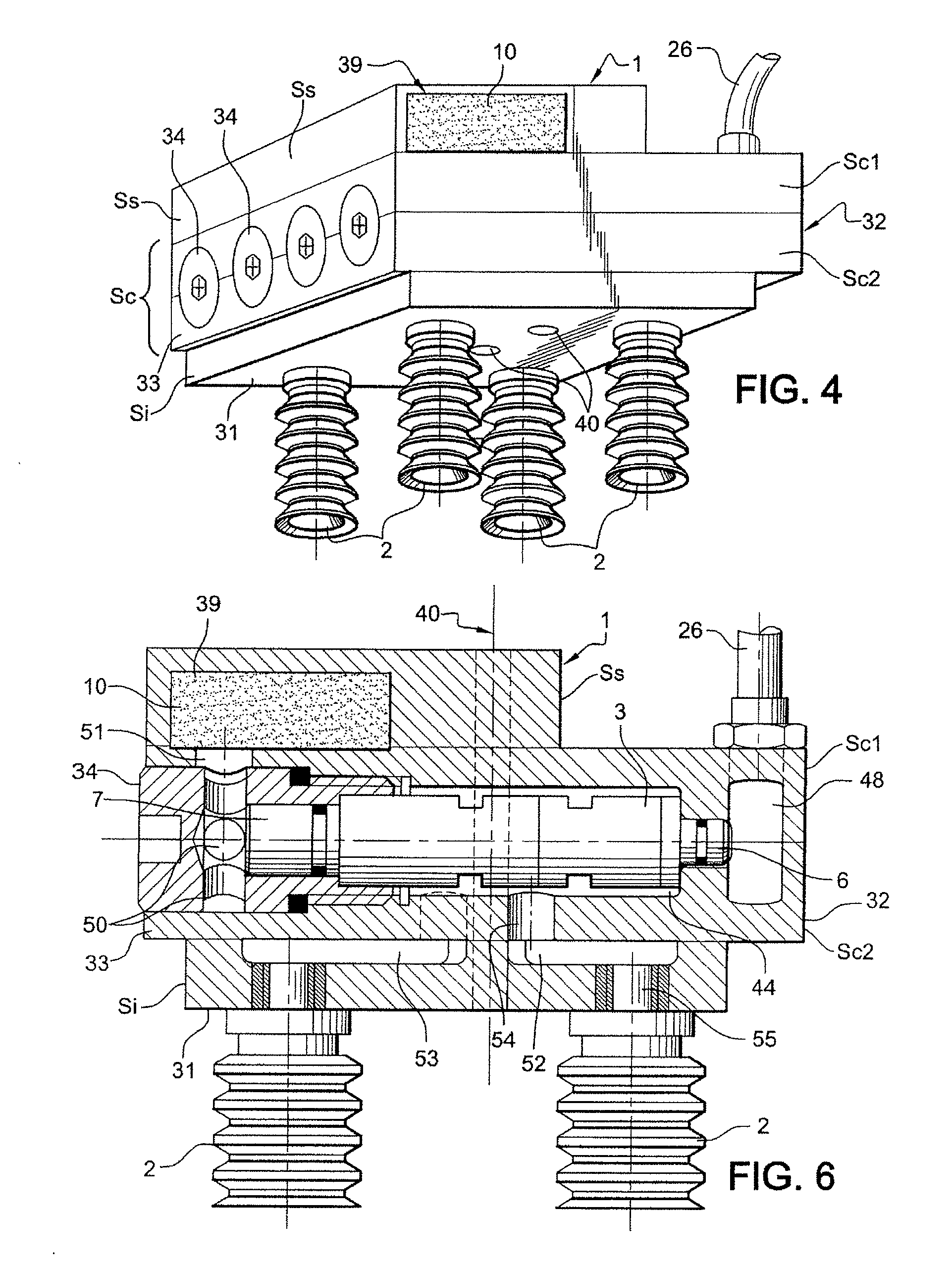

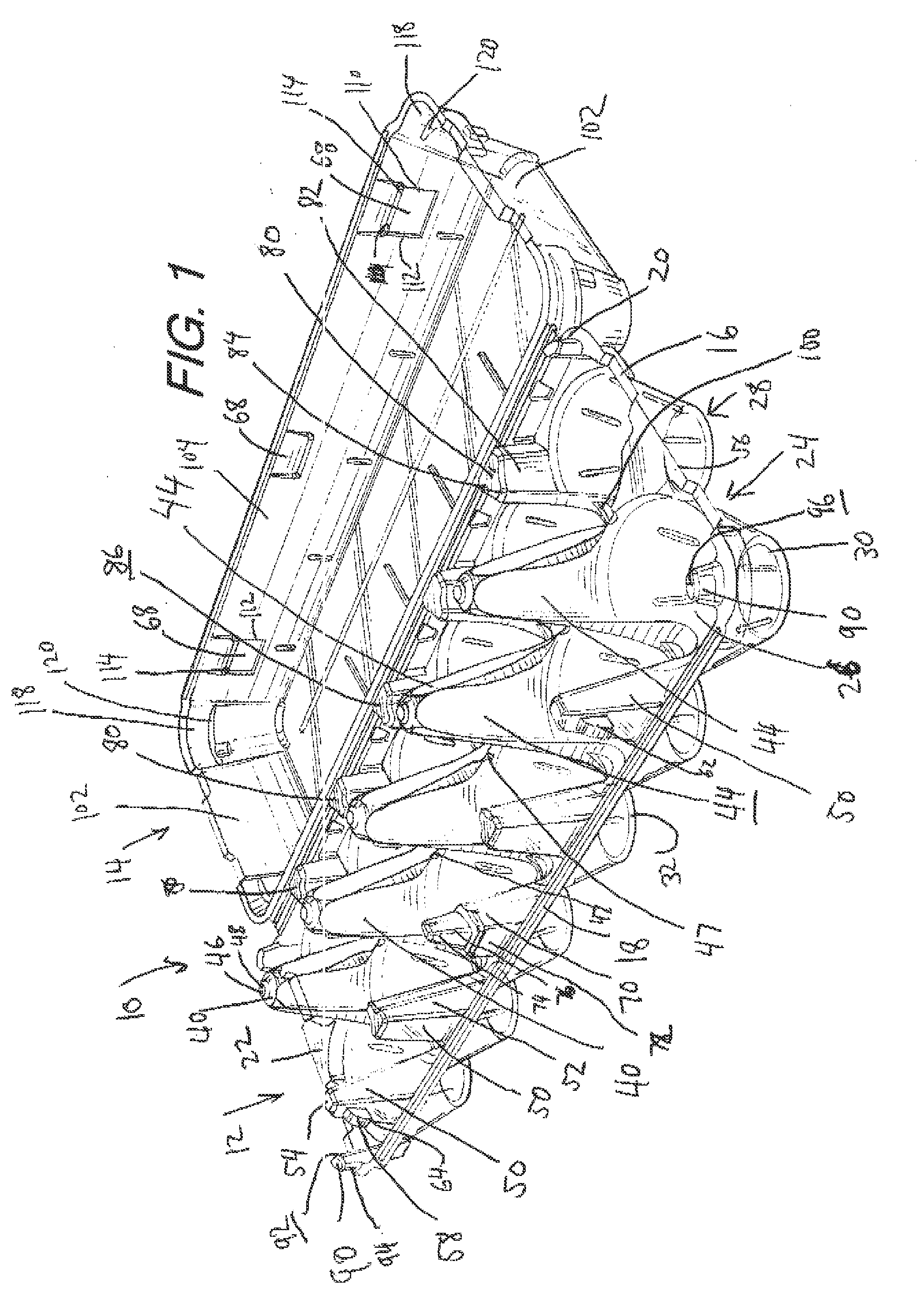

Compact tools with suction cups for handling robot

The invention relates to a tool that comprises a body (1) in the form of a compact unit made of an appropriate material of the thermoplastic resin material type. The body (1) is adapted for placing the vacuum generator as close as possible to the suction cup (2). It comprises: on the one hand, a bore for housing the vacuum generator in the form of a cartridge (3), wherein said bore defines the vacuum chamber (44) and communicates, on the side corresponding to the inlet of said cartridge (3), with the pressurised air supply, and on the other side, i.e. the side corresponding to the outlet of said cartridge, with an expansion chamber (39) in the form of a silencer; and on the other hand, a very short inner circuit between said vacuum chamber (44) and the suction cup (2), that comprises one or more cavities and / or openings.

Owner:SIDEL PARTICIPATIONS SAS

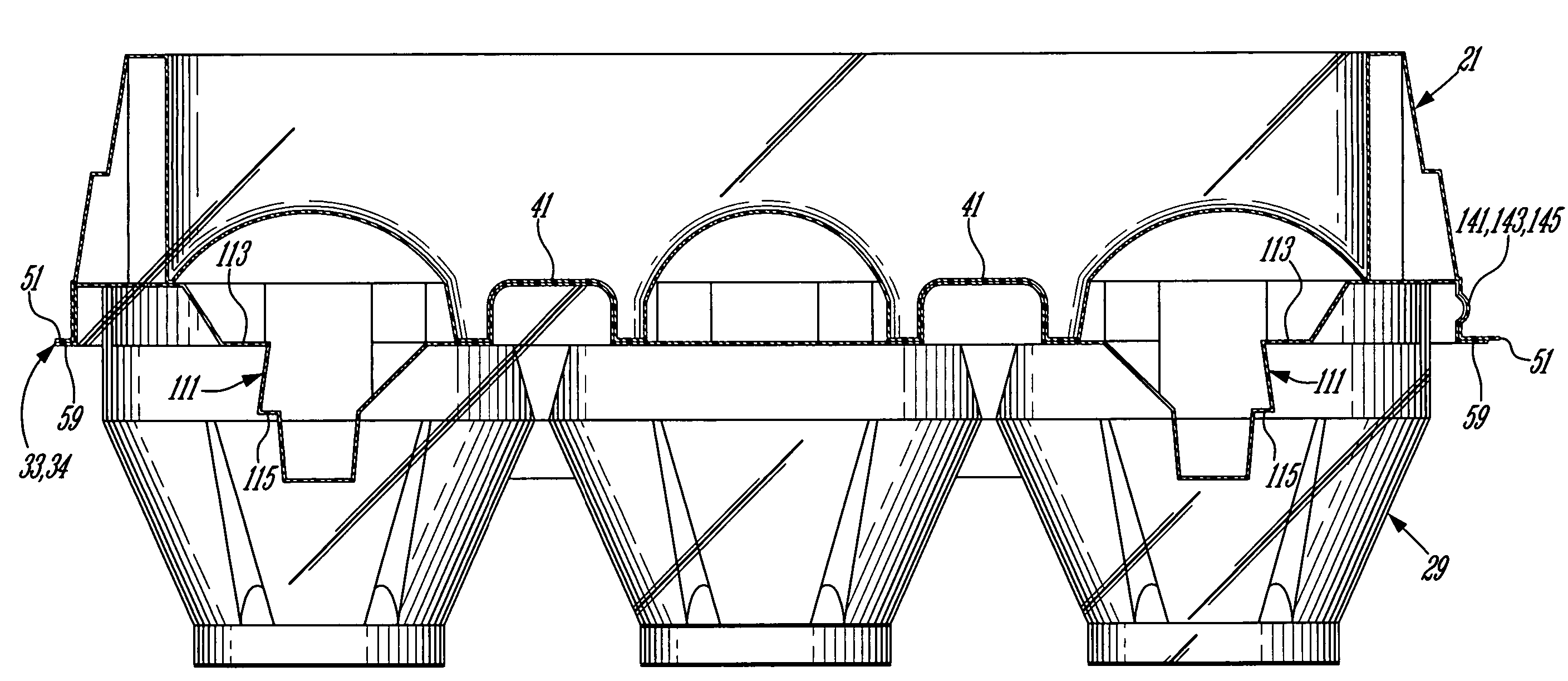

Stackable egg-box, stack of egg-boxes and method for destacking said egg-box

ActiveUS7686181B2Improve protectionSubstantial rigidityInternal framesPackaging eggsPlastic materialsEngineering

A stackable tray obtained by vacuum molding of a sheet of plastic material, the tray comprising, in open position: a) a top and a bottom; b) at least one receiving cavity opened upwardly; c) a hinge portion dividing the tray into a cover portion and a base portion; the receiving cavity being at least provided in the base portion; d) spacing members to keep, in a stack of trays, the top portion and the bottom portion of neighboring trays at distance from each other to thereby prevent interlocking therebetween; and e) at least one two-part locking members, each part being provided in the top of the sheet and positioned to engage one into the other when the cover portion is folded over the base portion along the hinge portion to bring the tray into a closed position defining a box. A stack of the trays and a method using the trays are also provided.

Owner:PACTIV CANADA

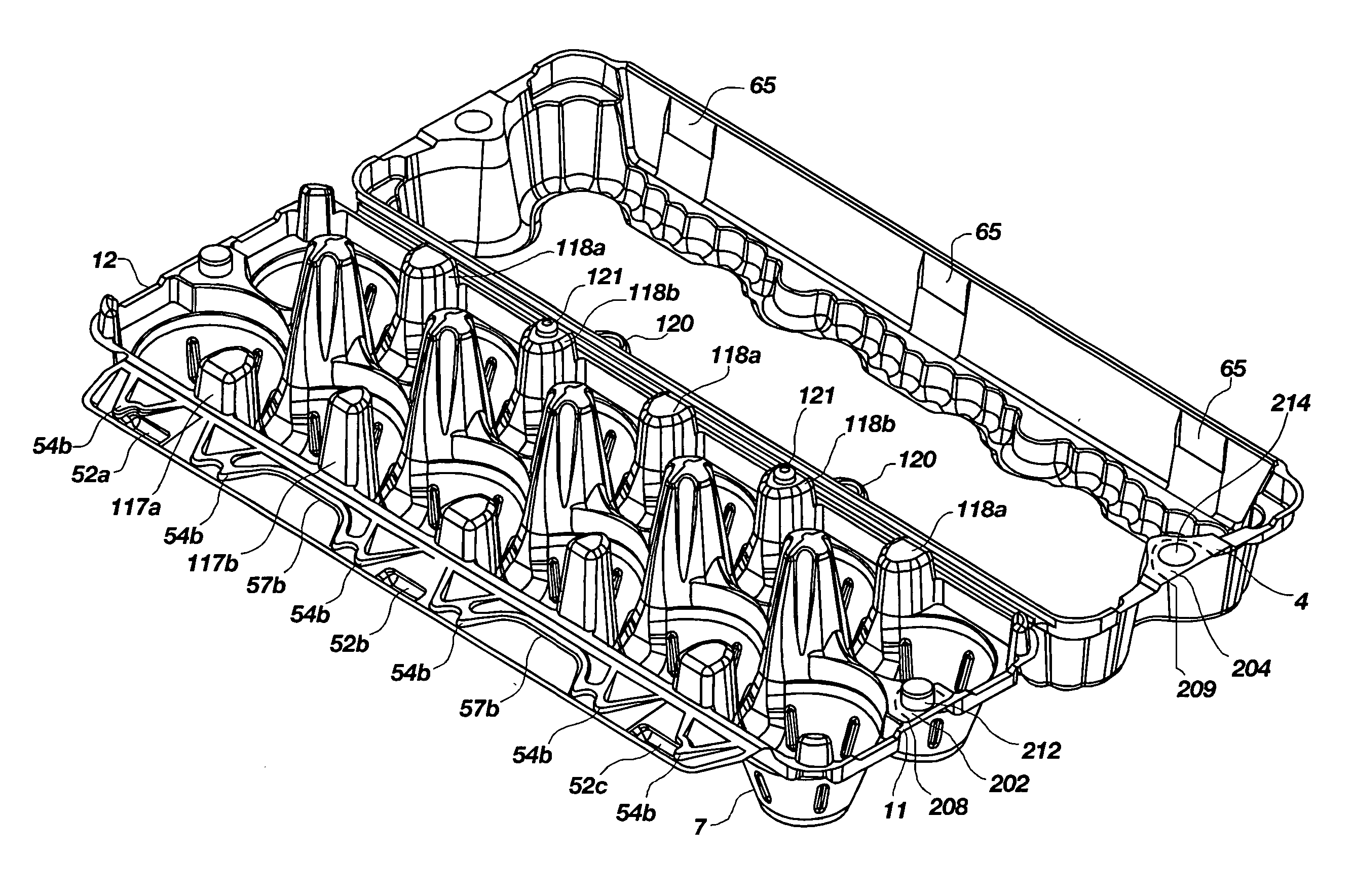

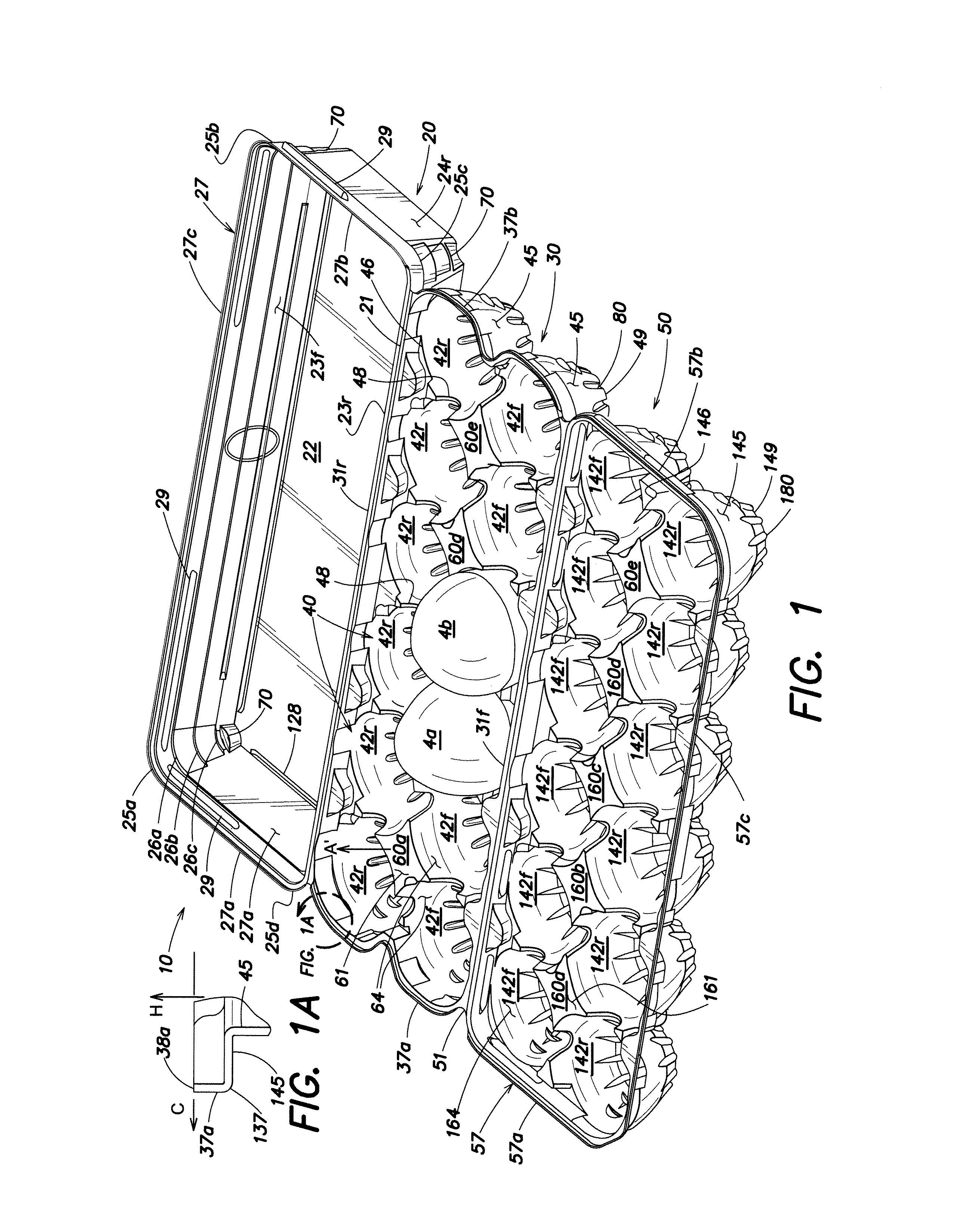

Tri-fold egg carton with lid sidewall protrusions

ActiveUS9169058B1Easy to handleSecure and easy loading and protectionPackaging eggsNon-removalbe lids/coversCartonEngineering

Improvements have been made to one or more of a lid, cover, and base of a tri-fold egg carton, the improvements allowing the secure and easy loading and protection of jumbo sized eggs, in cartons that can be processed and packaged with standard equipment and in standard case sizes. Further, in one or more embodiments the improvements provide improved processability with automated labeling equipment. In one or more embodiments, the improvements allow for improved de-nesting of multiple empty cartons, prior to filling.

Owner:TEKNI PLEX

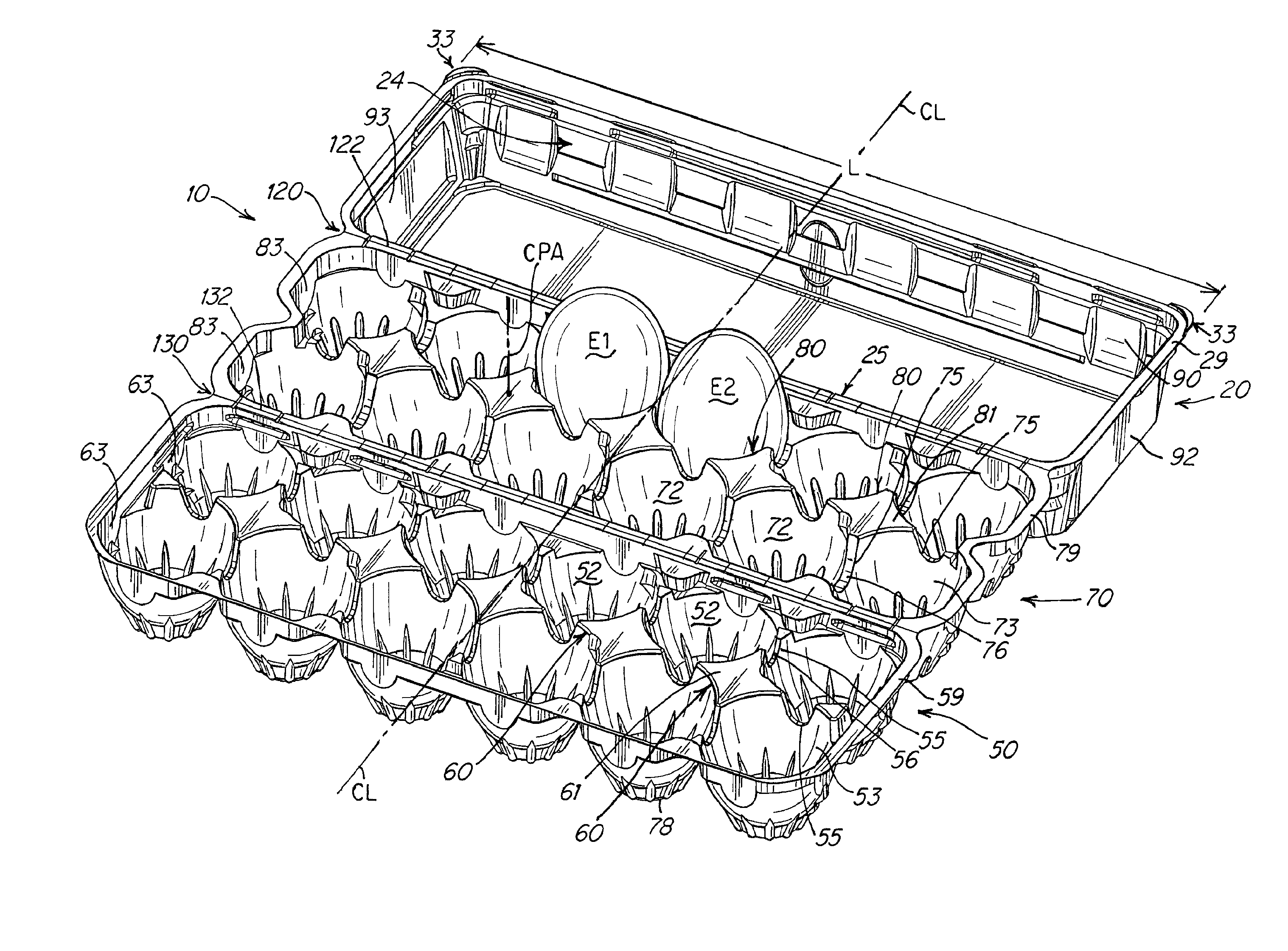

Container for frangible articles such as eggs

ActiveUS20080283437A1Provide structural integrityPackaging eggsContainers to prevent mechanical damageEngineeringMechanical engineering

A container for frangible articles comprising a tray molded in a sheet of polymeric material having a hinge portion separating a bottom portion from a cover portion with the cover portion being pivotable into engagement with the bottom portion to conceal the frangible articles in the container. The bottom portion comprises rows of cavities with each cavity adapted to support a frangible article. The cavities have lugs projecting inwardly and from bottom to top from a main surface of the cavity to support the frangible article while maintaining air gaps between the frangible article and the main surface. Corner cavities are positioned at opposite leading corners of the bottom portion and each have a protective rib oriented toward its respective leading corner and projecting outwardly from the main surface and from bottom to top to provide structural integrity to the opposite leading corners of the container.

Owner:PACTIV CANADA

Transparent egg carton

The present invention provides an egg carton having a tray having a first row of a first plurality of spaced egg compartments and a second row of a second plurality of spaced egg compartments, the first row of egg compartments being disposed in parallel spaced relationship to the second row of egg compartments; a plurality of spaced tower elements extending along a centerline of the tray and extending vertically from a plane of the tray, each tower element having four egg contacting surfaces; a plurality of spaced post elements extending along a front edge of the tray and extending vertically from a plane of the tray, each post element having two egg contacting surfaces; and a lid hingedly connected along a rear edge of the tray and movable from an open condition to a closed condition.

Owner:CLEAR VIEW CARTONS

Portable table carrier for construction plans

Owner:GORDILS BEN

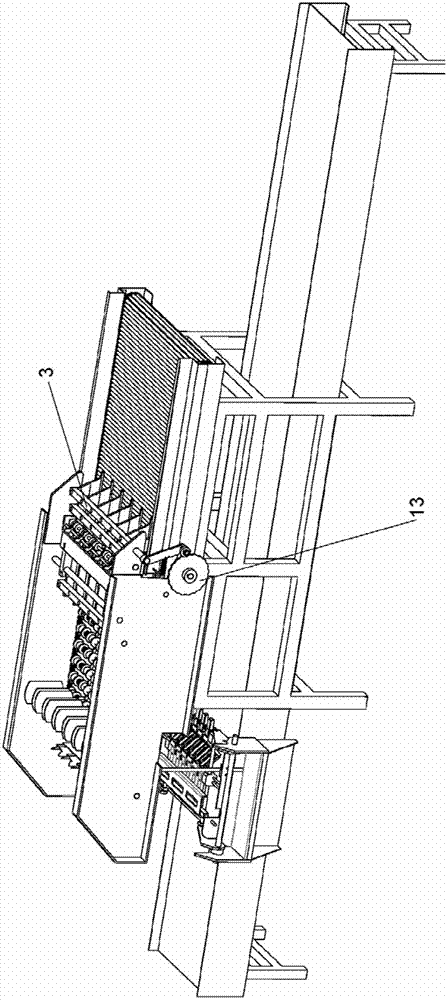

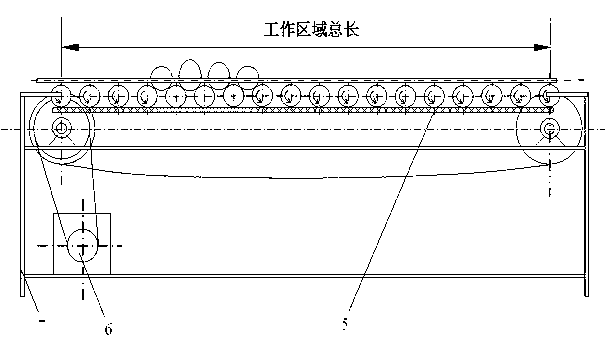

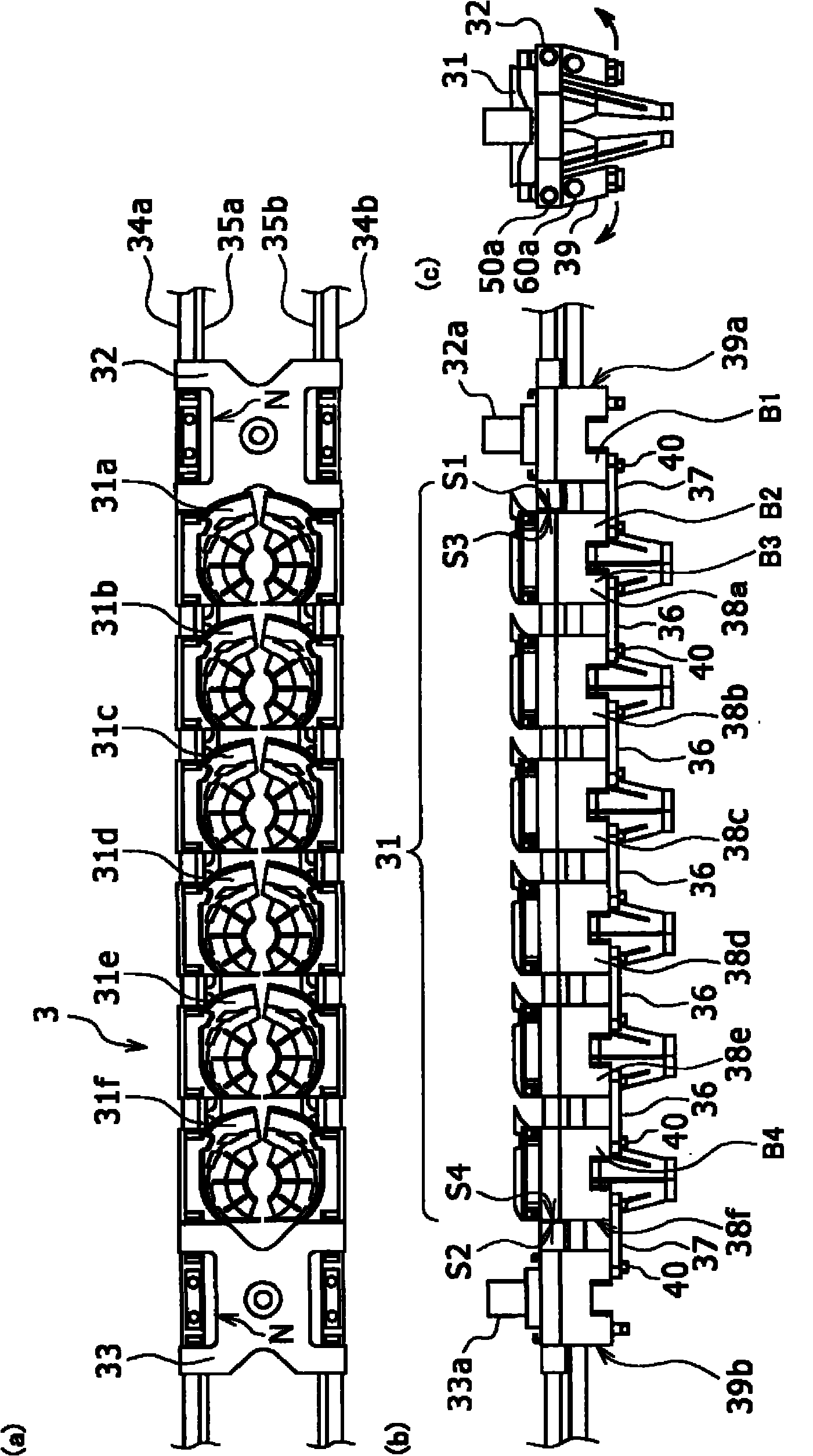

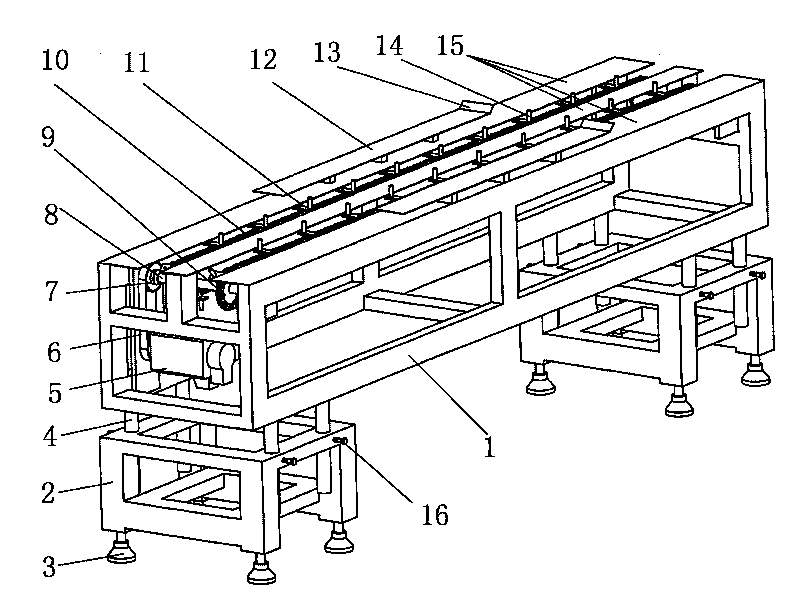

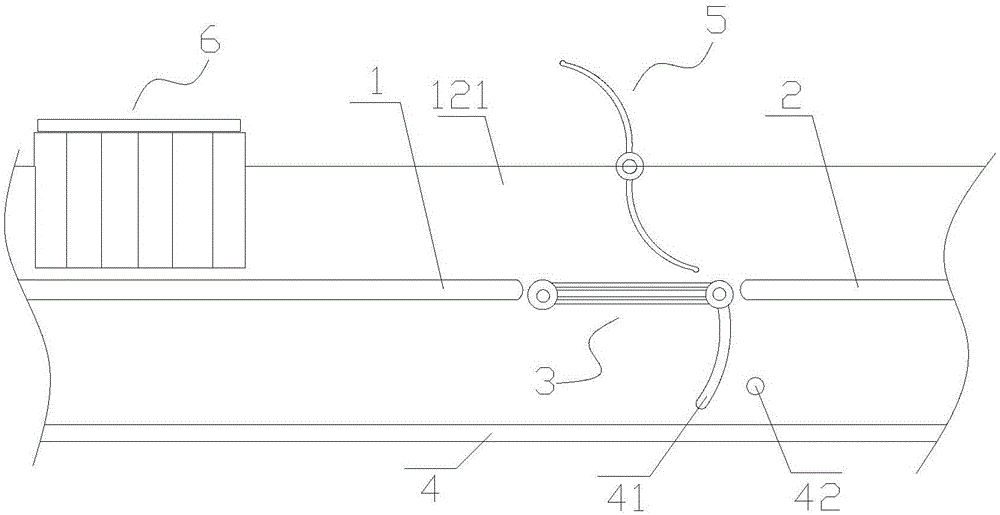

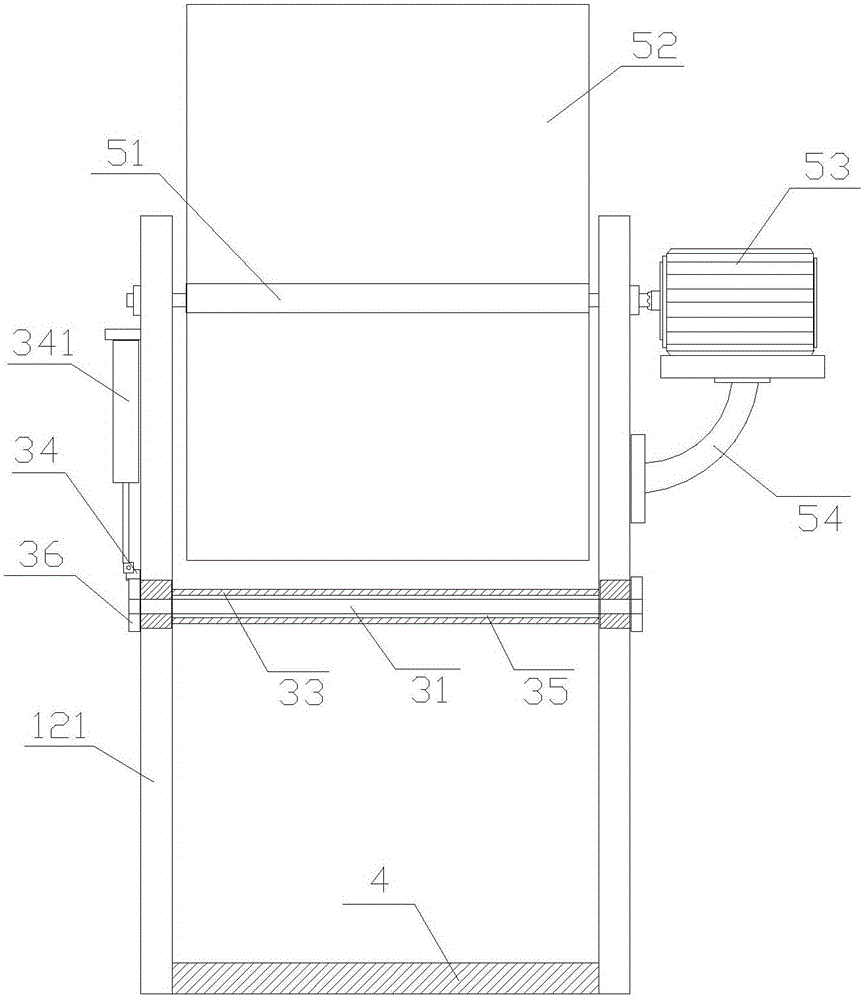

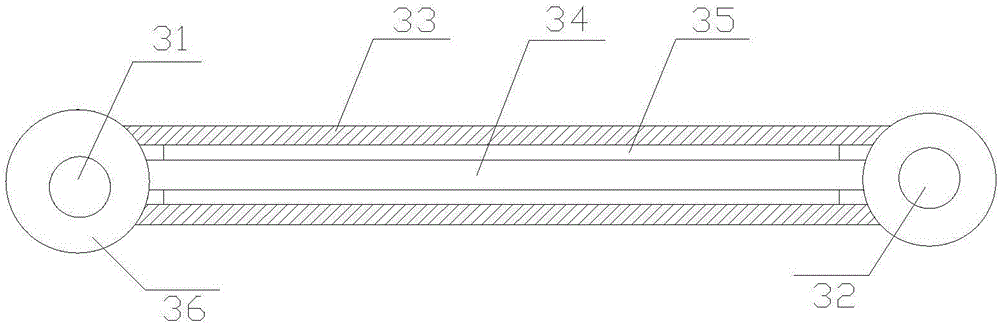

Automatic packaging equipment for realizing big/small end order arrangement of poultry eggs

ActiveCN102730218ASuitable for graded packaging operationsSimple and complete structurePackaging eggsEngineeringMechanical engineering

The invention discloses automatic packaging equipment for realizing the big / small end order arrangement of poultry eggs. A feed mechanism is mounted on a conveying inlet of a frame; an egg supporting conveying platform is mounted at the bottom of the frame; side fixed plates are fixedly arranged on both sides of the frame, which approach a conveying outlet; a flow guiding mechanism and a six-egg synchronizing mechanism are mounted between the side fixed plates on the two sides and towards one side of the conveying inlet; a conveying mechanism is mounted below the flow guiding mechanism; a big / small end reversing mechanism is mounted above the conveying mechanism and near the conveying outlet; a rotary guiding mechanism is mounted on one side of the conveying mechanism; the conveying mechanism, the big / small end reversing mechanism and the rotary guiding mechanism are mounted between the side fixed plates on the two sides; and a supporting placing mechanism positioned below the rotary guiding mechanism is mounted on the egg supporting conveying platform. By using the automatic packaging equipment, the feed, the flow guidance, the six-egg synchronization, the conveyance, the big / small end reversion, the supporting entrance guidance, the supporting placement and the egg supporting conveyance are completed automatically. The equipment is simple in structure, high in efficiency and good in reliability, and is suitable for the hierarchical packaging work of various poultry eggs and egg supporters in different specifications.

Owner:ZHEJIANG UNIV

Egg Package Assembly

InactiveUS20080279991A1Quality improvementPrevents accidental openingReady-for-oven doughsWrappers shrinkageLength contractionElectrical and Electronics engineering

An egg package assembly includes a protective case that contains predetermined number of eggs and a sleeve that fixedly surrounds the protective case. The protective case comprises a base and a lid. The sleeve comprises a thin packing film that is shrunk by heat. The sleeve is provided having a length similar to that of the case and a width wider than that of the case. After heat shrinking, the sleeve conforms to the shape of the case and fixed to the case. The length of the sleeve shrinks and allows the ends of the case to be exposed.

Owner:KWON DONGHEUM

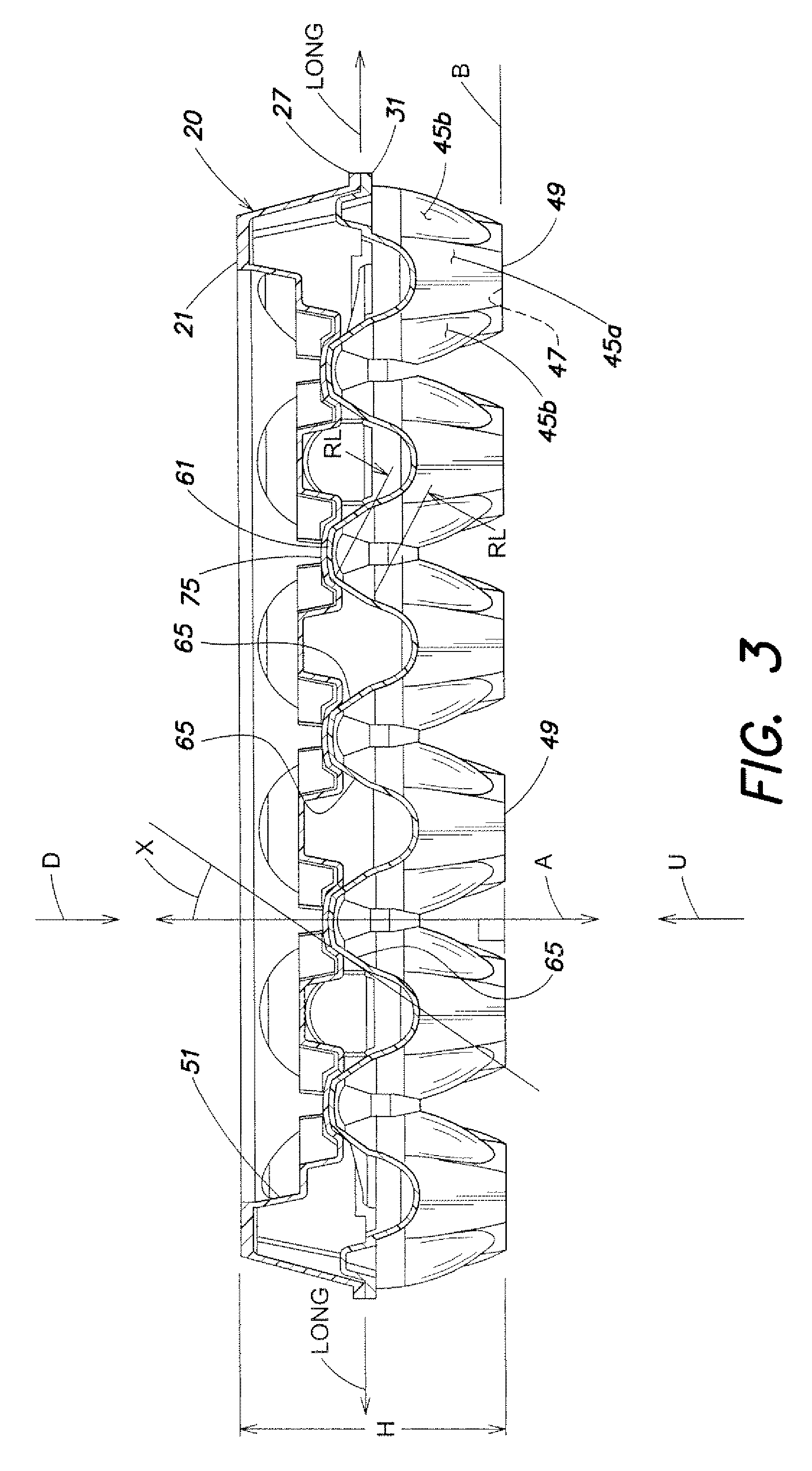

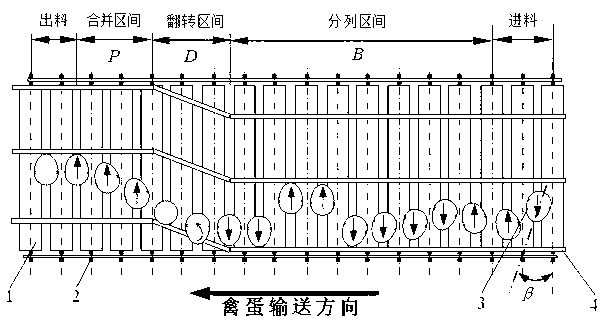

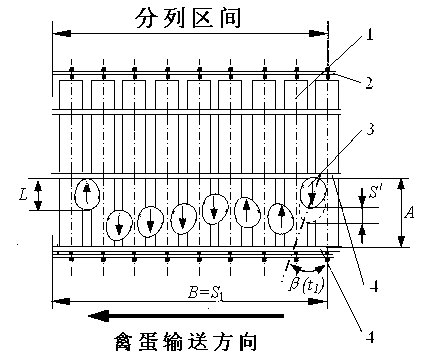

Design method of automatic orienting device for big ends of eggs

InactiveCN102717914AStructural parameter optimizationOptimize structure sizePackaging eggsMachineMaximum displacement

The invention discloses a design method of an automatic orienting device for big ends of eggs. The automatic orienting device for the big ends of eggs comprises a rowing region, an overturning region and a combing region in sequential arrangement. Time t1 required for an egg to complete the maximum displacement A-L on support rollers along an axial direction within the rowing section is computed via a formula, length of the rowing section is obtained according to the time t1 and the formula; length W of a bending section of each limit guide rod in the overturning region is computed via the formula; length D' of the overturning region, time t2 required for an egg to complete the maximum displacement A-L on support rollers along an axial direction within the combing region is computed, and length of the combing region is computed; and total length of a working area is obtained by summing the B, the D', the P, the length of a feeding region and the length of a discharging region. By the aid of the design method of the automatic orienting device for the big heads of eggs, structural parameters of above regions and bending sections of the limit guide rods are optimized, structural size of a whole machine is further optimized, and transmission efficiency between the eggs and the support rollers is improved.

Owner:JIANGSU UNIV

Egg case

ActiveCN101850879AIncrease storage spaceLighting and heating apparatusPackaging eggsZoologyRefrigerated temperature

Owner:HAIER GRP CORP +1

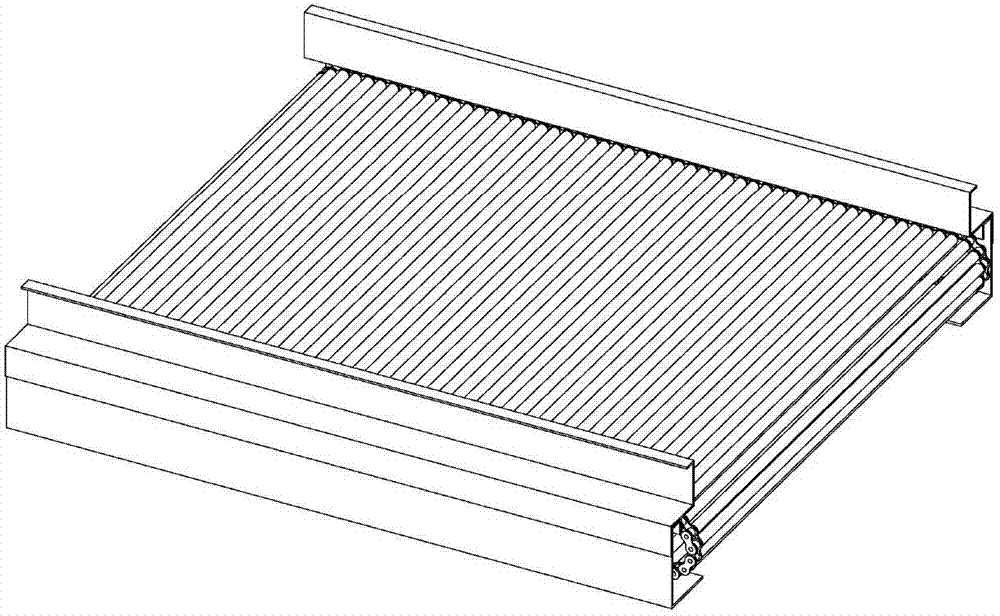

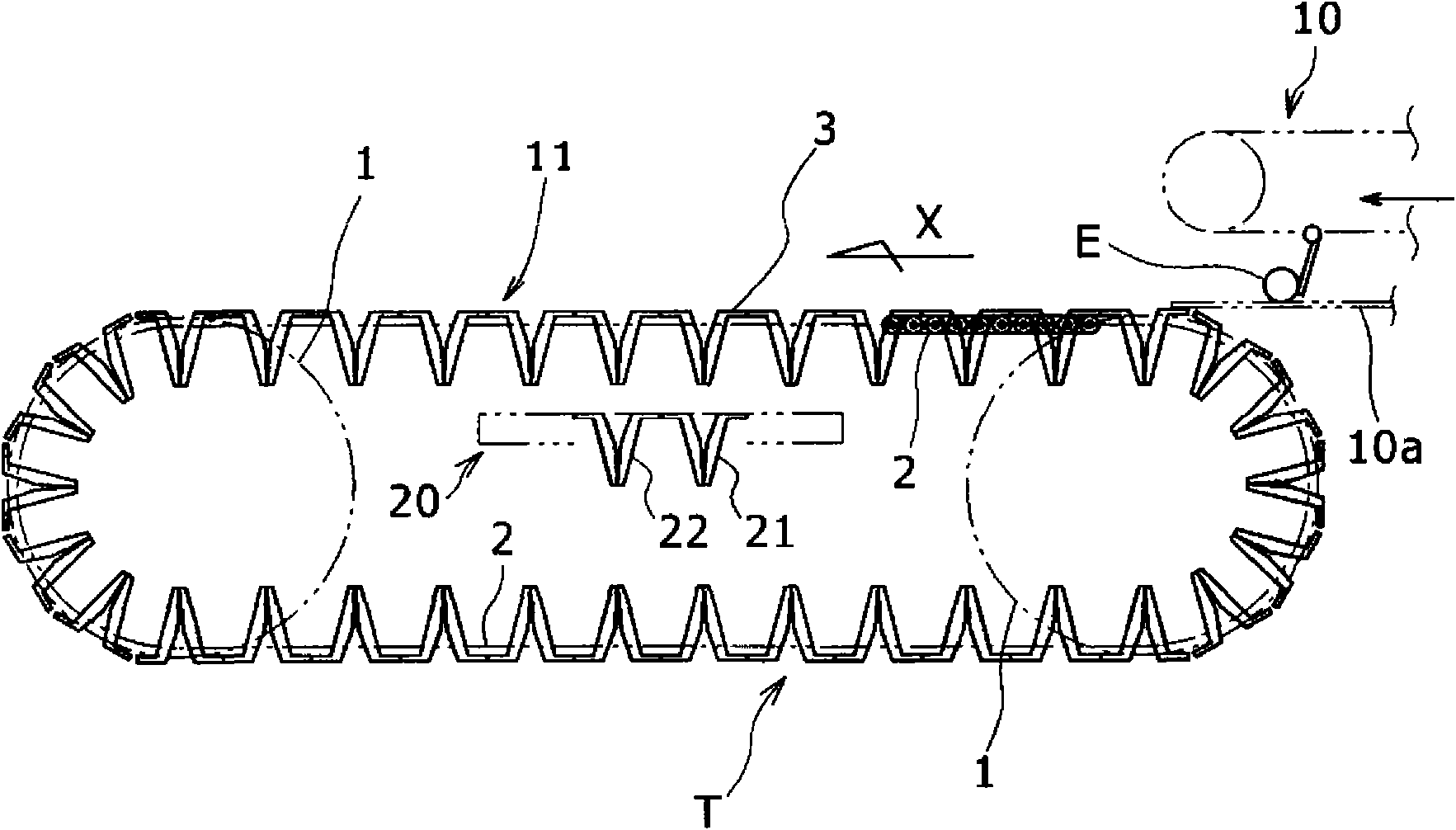

Device for transferring eggs

ActiveCN101772464AHigh speed processingStabilizationPackaging eggsConveyor partsEngineeringElectrical and Electronics engineering

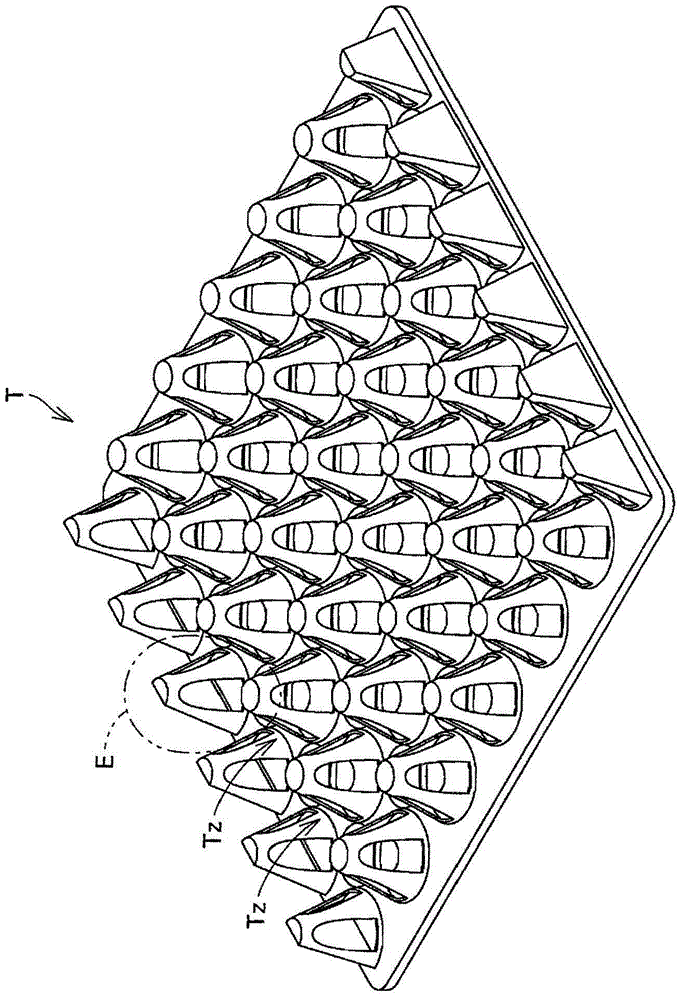

A device for transferring eggs comprises a regulation board (4) for limiting the containing seat pitch of an egg transfer unit (3) to a pitch substantially equal to the containing seat pitch in the line direction of a next position conveyor (20) in a process for carrying the egg transfer unit (3) having a predetermined number of containing seats slidable in the carrying width direction respectively, and an accelerating / discharging section (5) for urging the egg transfer unit (3) in the same direction as the carrying direction of the next position conveyor (20) and synchronizing the moving speed of the egg transfer unit (3) in the urging direction substantially with the carrying speed of the next position conveyor (20) when the egg transfer unit (3) having a pitch limited substantially equal to the containing seat pitch in the line direction of a next position conveyor (20) by the regulation board (4) arrives above the next position conveyor (20), and discharging the eggs (E) containedin the egg transfer unit (3) collectively to the containing seats of the next position conveyor (20).

Owner:股份公司南备尔

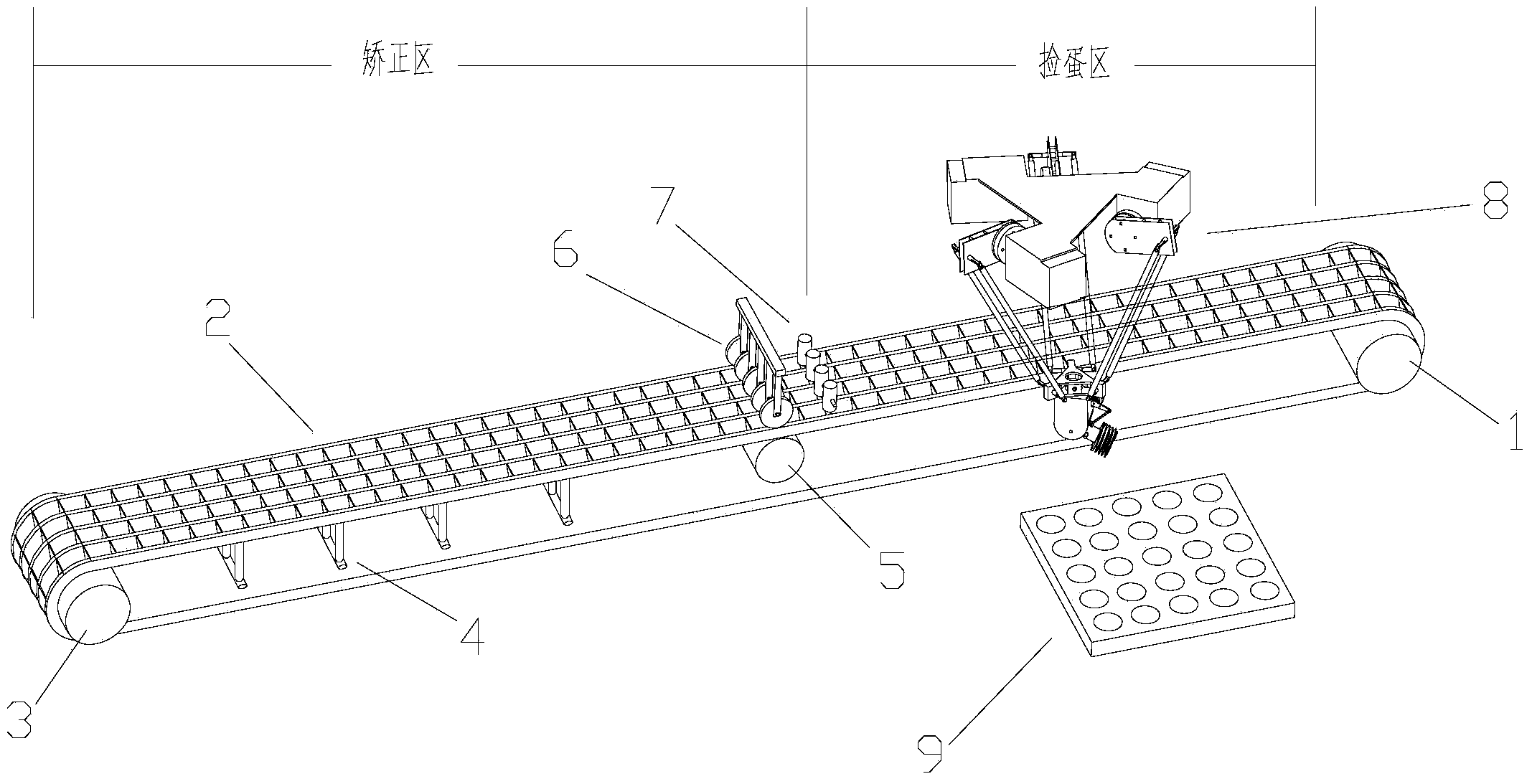

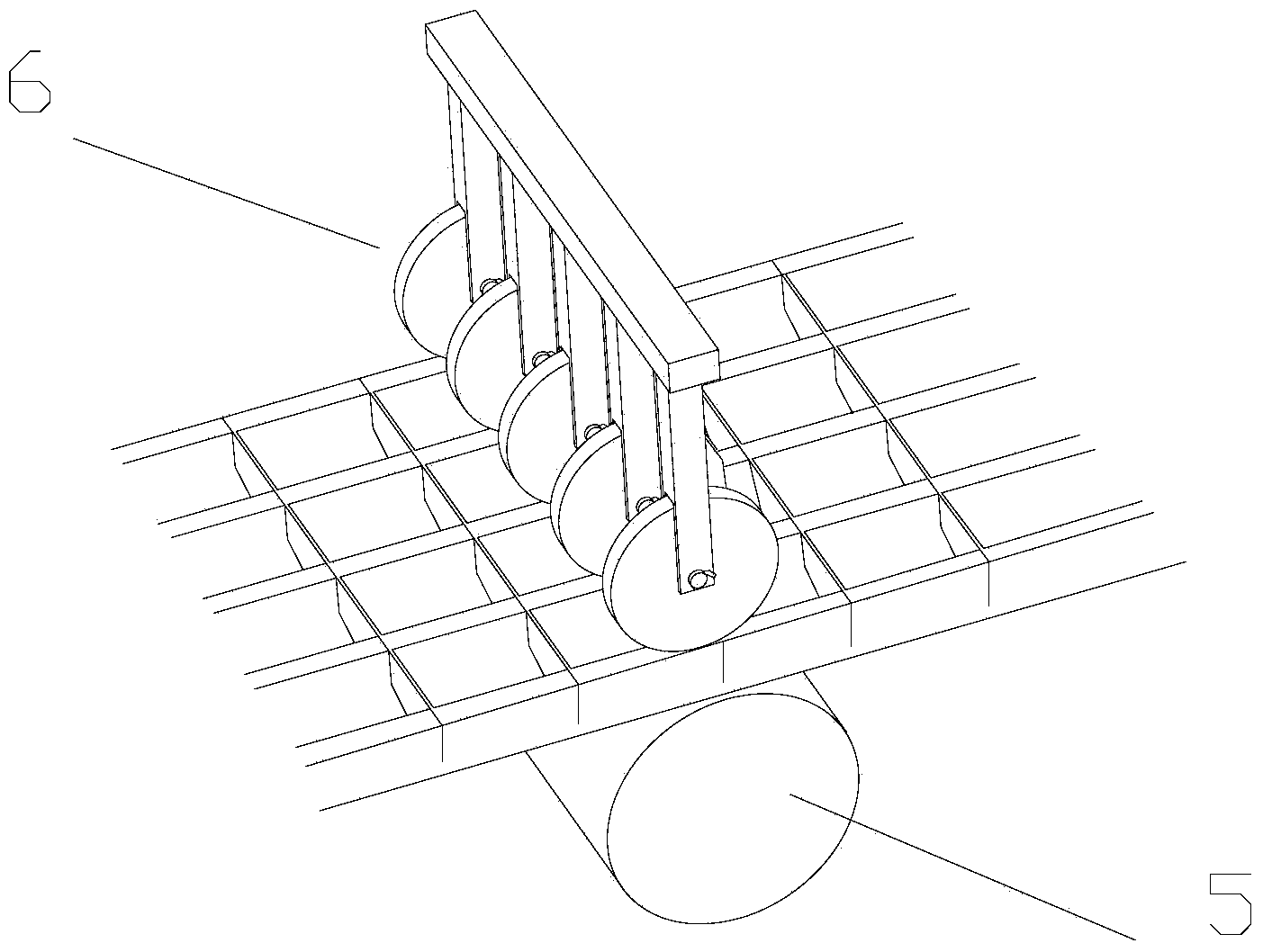

Poultry egg conveying automatic positioning and packaging robot and working method thereof

The invention relates to a poultry egg conveying automatic positioning and packaging robot and a working method of the poultry egg conveying automatic positioning and packaging robot. The poultry egg conveying automatic positioning and packaging robot comprises a poultry egg conveying device, a vibration correcting device, a poultry egg packaging parallel robot body and a poultry egg automatic packaging robot control system, wherein the poultry egg conveying device is used for collecting, storing and conveying poultry eggs, the vibration correcting device is used for making the disorderly poultry eggs on a conveyor belt in an orderly state, the poultry egg packaging parallel robot body is used for picking up the poultry eggs and placing the poultry eggs into trays, and the poultry egg automatic packaging robot control system is used for carrying out positioning control over the coordinates of the poultry eggs and control over the motion of the parallel robot body. By the arrangement of the poultry egg conveyor belt with an automatic positioning function and the parallel robot body with poultry egg picking, rotating and fixed-point placing functions and the arrangement of an end actuator, positioning accuracy is guaranteed, cost is reduced, and the operation of automatically collecting eggs, placing the eggs into trays and packaging the eggs in a poultry farm is achieved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Hinge configuration for container for frangible items

A container for receiving frangible items comprises a sheet of polymer formed into a base portion having a plurality of item-receiving cavities for supporting frangible items. A cover portion has an item-covering concavity for covering the frangible items. A first hinge portion is positioned between a first longitudinal edge of the base portion and the cover portion for rotating the cover portion onto the base portion to hold the frangible items captive in the item-receiving cavities. The first hinge portion comprises a pair of longitudinal grooves formed into the first hinge portion and extending parallel to the first longitudinal edge of the base portion, with a web defined between the longitudinal grooves, and a hinge-reinforcement wall at least one end of the longitudinal grooves. A fold line is formed in the web and in the hinge-reinforcement wall when the cover portion is rotated onto the base portion.

Owner:PACTIV CANADA

Multifunctional egg packing equipment

The invention discloses multifunctional egg packing equipment, which comprises a machine body and a motor arranged on the machine body, wherein the two ends of the machine body are provided with a transmission shaft respectively; two chain wheels are fixedly arranged on each transmission shaft; a belt wheel is fixedly arranged on one of the transmission shafts; the motor is connected with the belt wheel through a belt; a conveying chain is respectively arranged between the corresponding chain wheels of the two transmission shafts; stirring mechanisms are fixedly arranged on each conveying chain at intervals; the two sides of a work table surface of the machine body are provided with a guide device respectively; each guide device is provided with a stirring piece which is positioned at the entrance of an egg packing area. The multifunctional egg packing equipment has the advantages of obtaining the equipment which is suitable for packing two different types of egg supports without changing the equipment, and improving the reliability of the package with a clamshell egg support.

Owner:ZHEJIANG UNIV

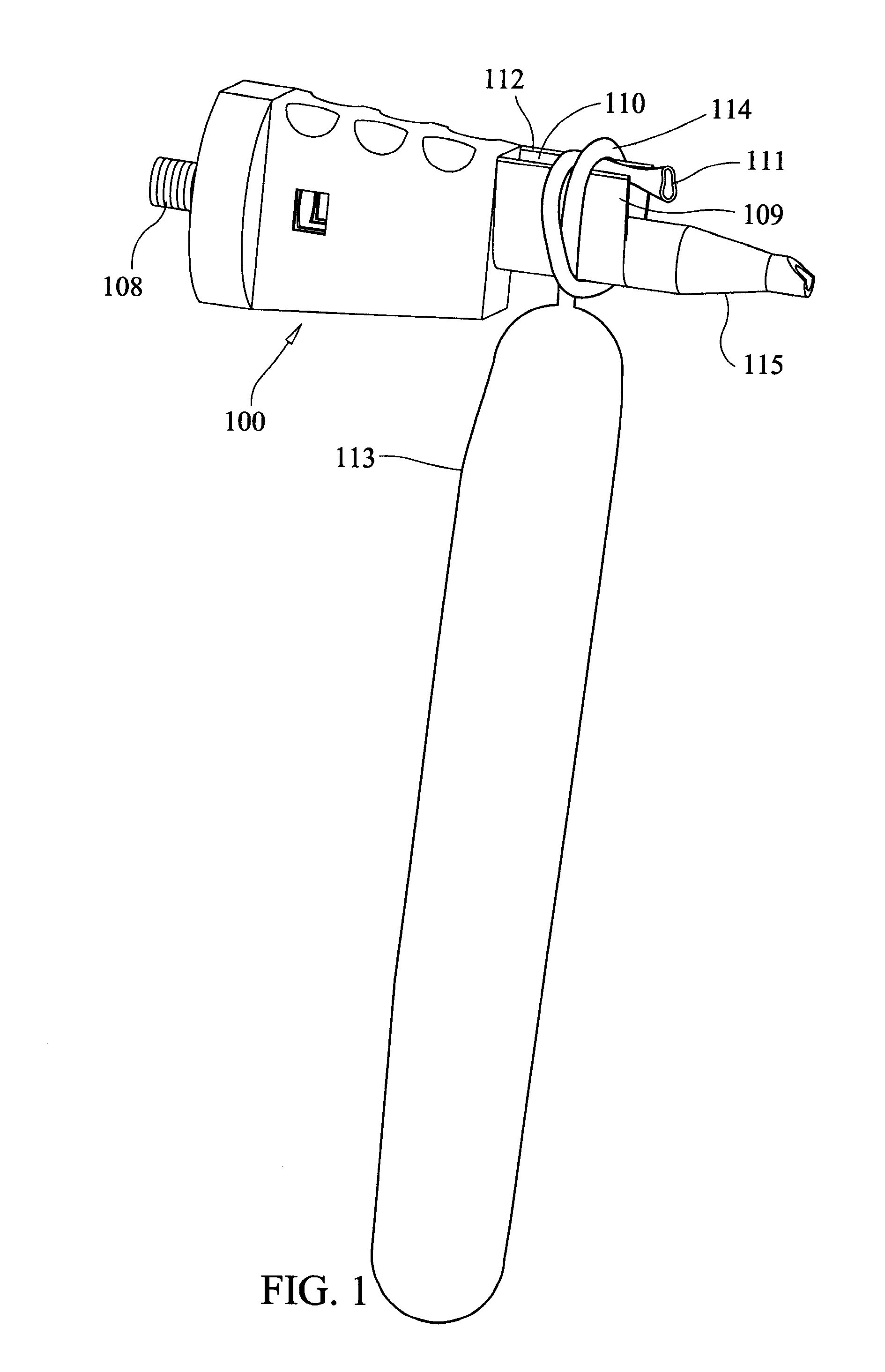

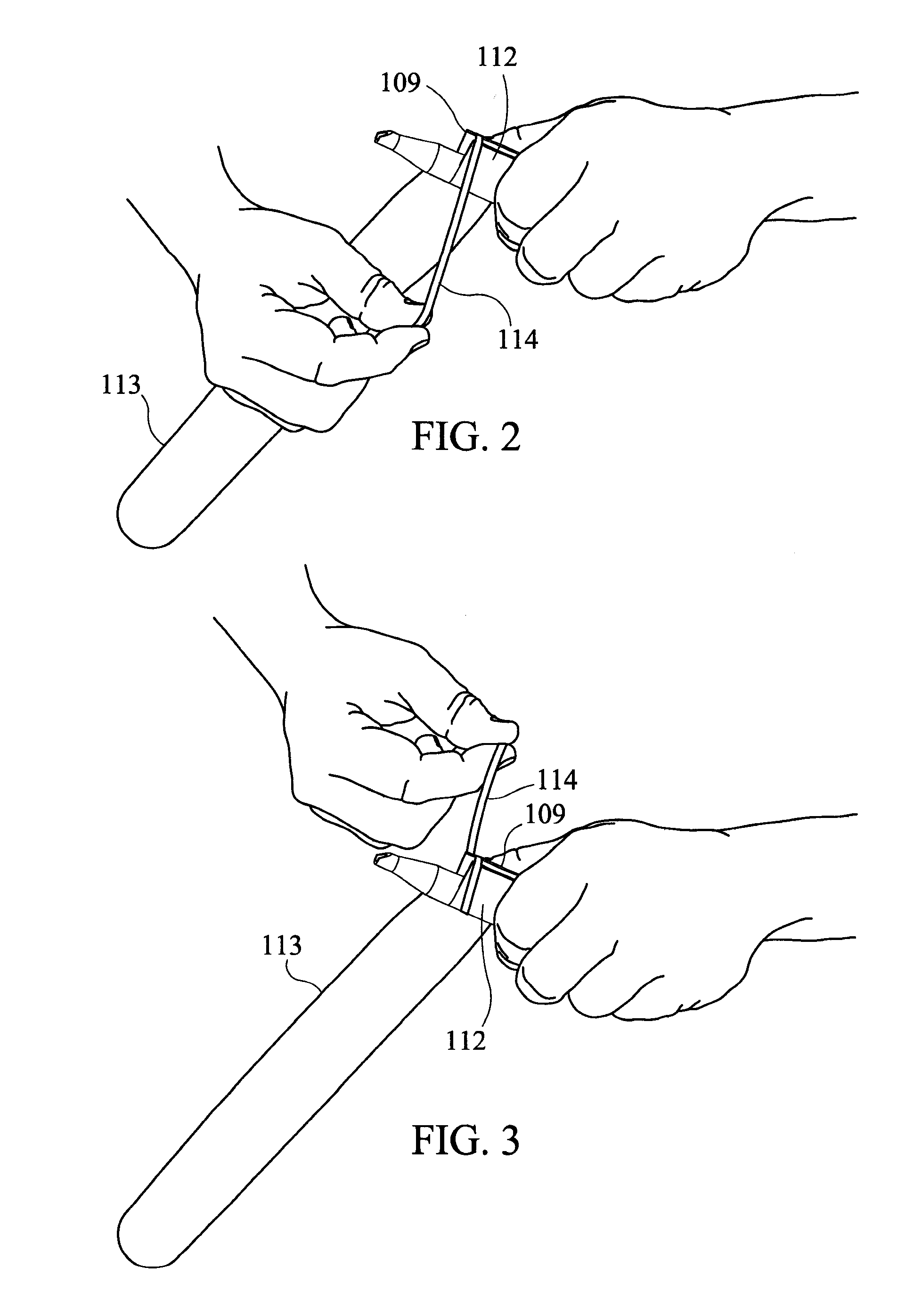

Balloon Tying Apparatus and Method

ActiveUS20110253255A1Efficient and fast processingEfficient retrievalLiquid fillingPackaging eggsGeneral surgery

Owner:DELLAQUILA PETER JAMES

Weighing and removing mechanism of egg sorting device

ActiveCN105151429ASafe automatic sortingDoes not deal crush damagePackaging eggsPackaging automatic controlEngineeringMechanical engineering

The invention discloses a weighing and removing mechanism of an egg sorting device. The weighing and removing mechanism comprises an upper conveyor belt and a lower conveyor belt arranged under the upper conveyor belt. Lateral baffles are shared by the upper conveyor belt and the lower conveyor belt; the upper conveyor belt is composed of a front conveyor belt body and a rear conveyor belt body, an automatic partition system is arranged at the upstream end of the front conveyor belt body, and the front conveyor belt body and the rear conveyor belt body are connected in a transition mode through a weighing instrument plate which is connected with a controller; the upstream end of the weighing instrument plate is connected with the tail end of the front conveyor belt body and is rotatably fixed to the lateral baffles, and the downstream end of the weighing instrument plate can be driven to rotate downwards around the upstream end of the weighing instrument plate; the weighing instrument plate is inclined when rotating in place so as to connect the lower conveyor belt and the upper conveyor belt, and a shifting device is correspondingly arranged at the positions, above the weighing instrument plate, of the lateral baffles. By means of the weighing and removing mechanism, eggs which are too heavy or too light can be removed and then conveyed out through the different conveyor belts, and consistency of the specifications of the eggs packed in cases is guaranteed.

Owner:湖州佳灏信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com