Design method of automatic orienting device for big ends of eggs

A technology of directional arrangement and design method, which is applied in the directions of packaged food, packaged eggs, dairy product packaging, etc., can solve the problems such as the inability to realize the optimization of the length of the working area of automatic directional arrangement, the inability to obtain a compact device in the length direction, etc. The structure size of the machine and the effect of improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

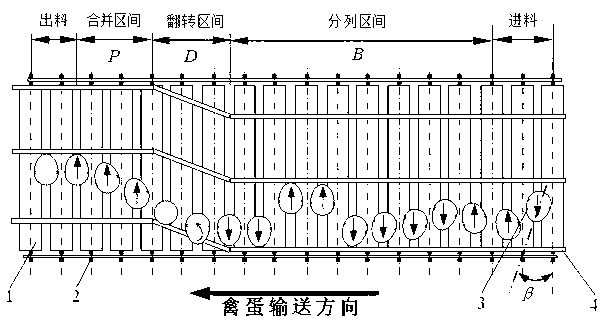

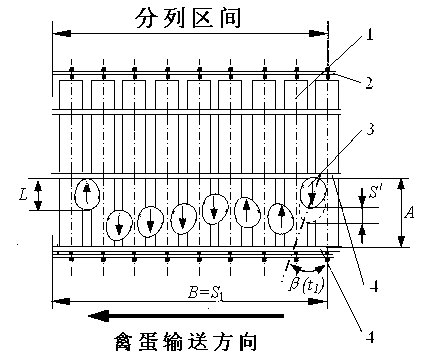

[0062] According to the width of the channel formed by the limit guide rods 4 on both sides A 150mm, roller chain conveying speed v 57mm / s and the major axis diameter of grass eggs L 49.1mm (the minimum value among 200 grass eggs) and the deflection angle of the grass eggs on the support roller , by formula (3) get , Where k=0.64, calculate the time t required to complete the maximum displacement of the axial movement A-L (ie 100.9mm) 1 about 8.7s, then t 1 Substitute into formula (4), namely It is obtained that the interval length B of grass eggs is 495.9mm. The corrected actual design value is 550mm. When the diameter of the roller is 40mm and the center distance between the two support rollers 1 is 57.15mm, set the bending angle of the bending section of the limit guide rod 4 α is 20°, and when 50 grass eggs are turned over on the two support rollers 1, the maximum axial rolling distance X among the 50 grass eggs is 35.2mm. Calculated by formula (5), ...

Embodiment 2

[0064] According to the width of the channel A 150mm, roller chain conveying speed v 57mm / s and the long axis diameter of foreign eggs L 51.1mm (minimum value among 200 foreign eggs) and the deflection angle of foreign eggs on the support roller , get from formula (3) , Where k=0.63, calculate the time t required to complete the maximum displacement of axial movement A-L (ie 98.9mm) 1 about 7.3s, then t 1 Substitute into formula (4) (ie ) to obtain the interval length B of foreign egg division is 416.1mm. The corrected actual design value is 550mm. When the diameter of the roller is 40mm and the center distance between the two supporting rollers is 57.15mm, the bending angle of the bending section of the limit guide rod is set α 20°, when 50 foreign eggs are turned over on the two support rollers, the maximum axial rolling and turning distance X measured among 50 grass eggs is 42.1mm, and the limit guide rod is calculated by formula (5) when the bending angle is ...

Embodiment 3

[0066] According to the width of the channel A 150mm, roller chain conveying speed v 57mm / s and the major axis diameter of duck eggs L 52.9mm (minimum value among 200 duck eggs) and the deflection angle of the duck eggs on the support roller , get from formula (3) , where k=0.67, calculate the time t required to complete the maximum displacement of axial movement A-L (ie 97.1mm) 1 about 9.3s, then t 1 Substitute into formula (4) (ie ) to get the length B of the duck egg sorting interval to be 530.1mm. The corrected actual design value is 550mm. The diameter of the roller is 40mm, the center distance between the two supporting rollers is 57.15mm, and the bending angle of the bending section of the limit guide rod is set α 20°, when 50 duck eggs are turned over on the two supporting rollers, the maximum axial rolling and turning distance X measured among 50 grass eggs is 45.2mm, calculated by formula (5), when the bending angle is 20°, the limit guide rod guides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com