Automatic egg boxing mechanical arm as well as boxing method and control method thereof

A technology of automatic packing and manipulator, which is applied in the directions of automatic packaging control, manipulator, program control manipulator, etc., can solve the problems of unpracticality, manual packing process, limited production efficiency, etc., and achieves low overall maintenance cost and manufacturing cost. Low, Guaranteed Accuracy Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Accompanying drawing is the specific embodiment of the present invention.

[0039] The content of the present invention will be further described below in conjunction with the accompanying drawings.

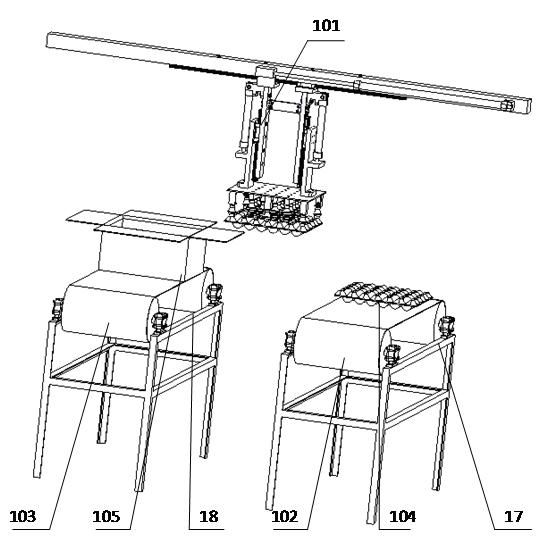

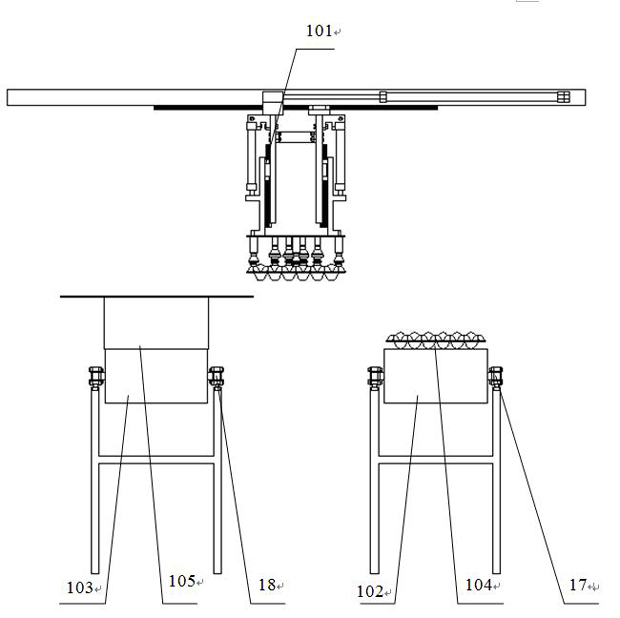

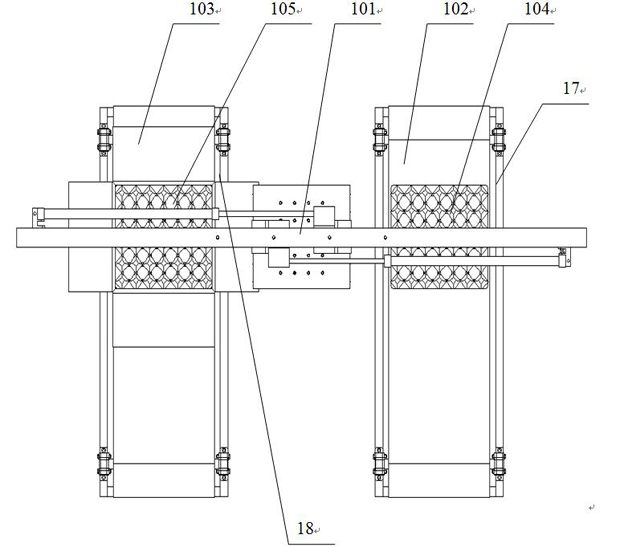

[0040] see figure 1 , figure 2 and image 3 As shown, the mechanical arm 101 is installed on both sides above the feed conveyor belt 102 and the discharge conveyor belt 103, and is fixed by the frame 1. The height of the frame 1 can be determined according to specific production requirements (such as the size of the packing box and the egg tray, etc.). ) to be adjusted; the feed conveyor belt 102 and the discharge conveyor belt 103 are placed symmetrically with respect to the center plane of the transverse axis of the frame 1, and the distance is 285-300mm; the sensor 17 is used to determine the delivery position of the material to be packed, and the sensor 18 is used Determining that the packing box is conveyed in place.

[0041] see Figure 4 and Figure 5 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com