Multifunctional egg packing equipment

A packaging equipment and multi-functional technology, applied in the field of poultry egg grading equipment, can solve the problems of not using multi-functional packaging equipment compatible with two or more egg tray specifications, single packaging equipment, etc., to reduce the cost of packaging equipment, The effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

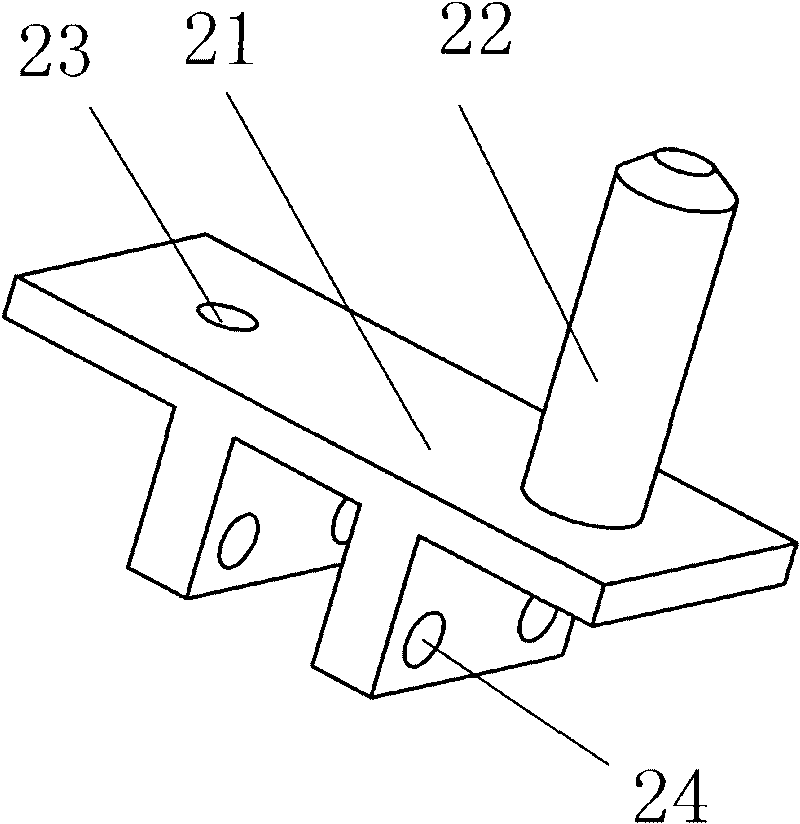

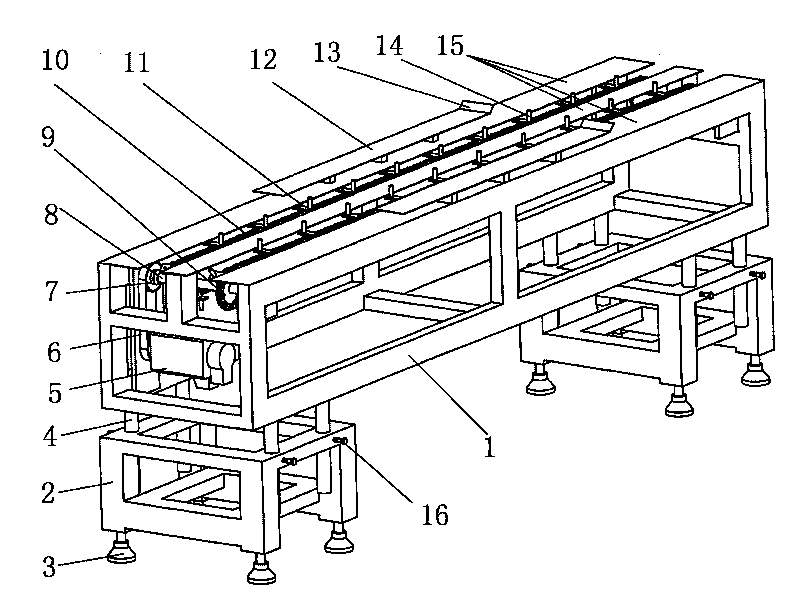

[0012] exist figure 1 Among them, the body 1 is installed on the bracket 2, the body 1 has a height adjustment strut 4, the bracket 2 is equipped with an adjustable support 3 and the bracket 2 is provided with a locking screw 16, and the locking screw 16 is used to fix the height adjustment strut 4. The height adjustment pillar 4 can realize the larger size adjustment of the height of the fuselage 1, and the adjustable support 3 is used to support the whole equipment, and can realize the fine adjustment of the height of the equipment to facilitate the installation of the equipment. The motor 5 is fixedly installed on the fuselage 1, and a transmission shaft 8 is respectively installed at both ends of the fuselage 1, and two sprockets 9 are respectively fixedly installed on each transmission shaft 8, so that between the two transmission shafts 8 There are two pairs of relative sprocket wheels 9 between. In addition, a pulley 7 is also fixedly installed on one of the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com