Full-automatic double-sided tape pasting equipment with compound functions

A technology of double-sided tape and compound function, which is applied in the field of compound function automatic pasting double-sided tape equipment, which can solve problems such as unreliable product quality, low production efficiency, and uncontrollable production tempo, so as to achieve convenient production tempo and high production efficiency. High and reliable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

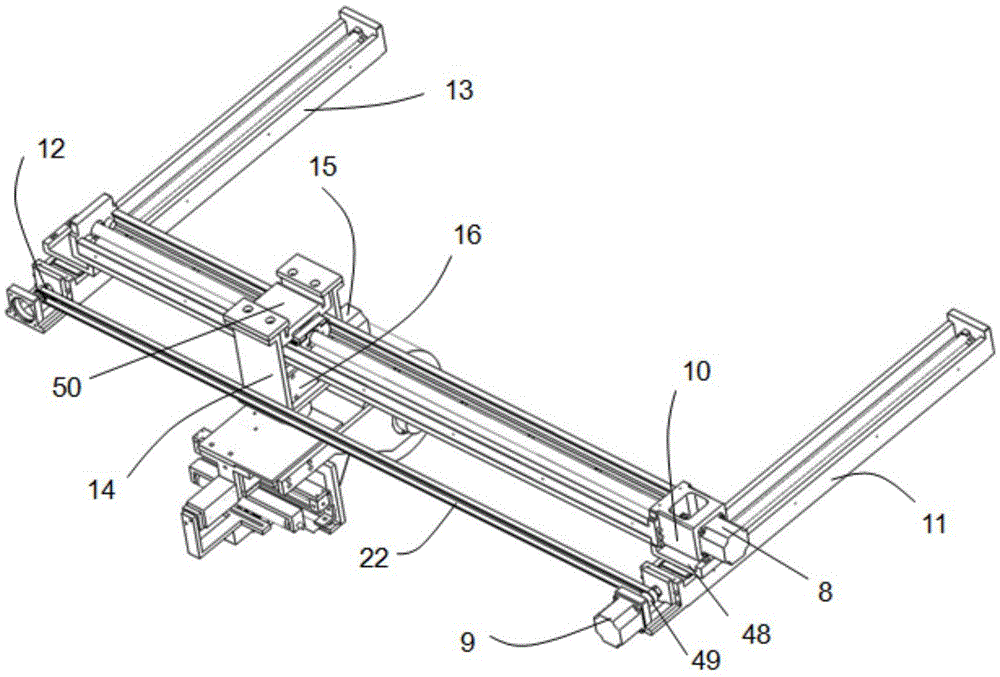

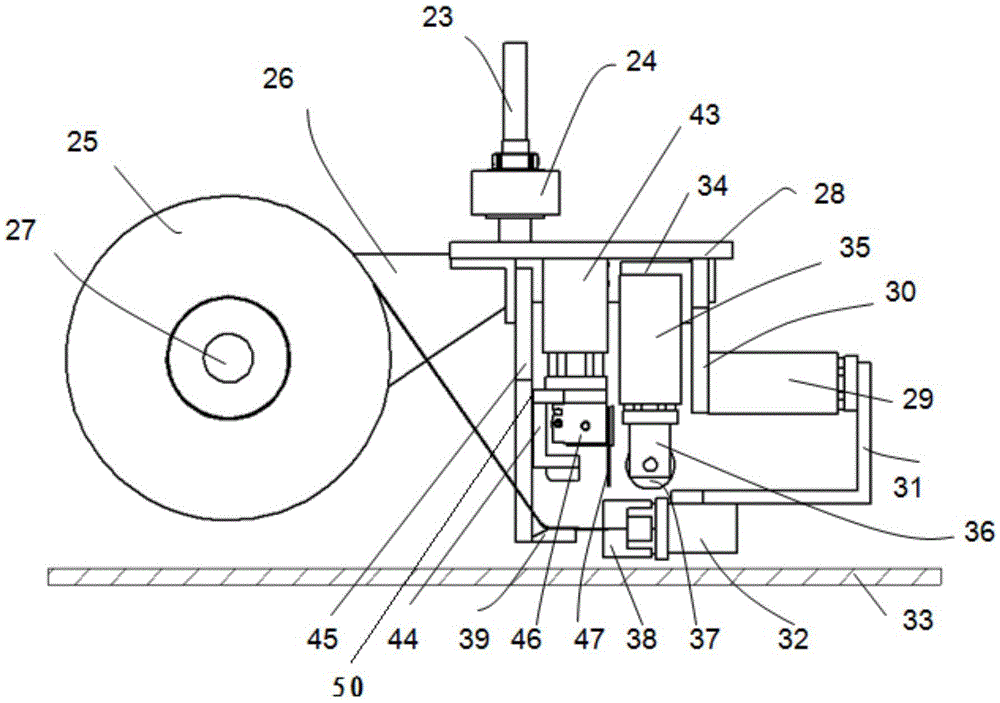

[0022] Such as Figures 1 to 8As shown, the described a kind of composite function fully automatic pasting double-sided adhesive tape equipment is characterized in that it comprises a workbench 1, the workbench 1 is provided with a workbench 21, and the two sides of the workbench 1 are respectively provided with ball screw The left single-arm motion mechanism 11 and the right single-arm motion mechanism 13 formed by the nut pair and the linear motion guide rail pair are respectively provided with a left synchronous pulley 49 and a right synchronous pulley on the left single-arm motion mechanism 11 and the right single-arm motion mechanism 13 12. The left synchronous pulley 49 is connected to the longitudinal motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com