Aluminum-plastic film for lithium battery packaging

A technology of aluminum-plastic film for packaging, which is applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of high requirements for solvent bonding layer and difficulty in quality assurance, and achieve tensile and compressive strength and hardness properties Good, good heat resistance, strong impact strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with each specific embodiment and accompanying drawing, the present invention will be further described:

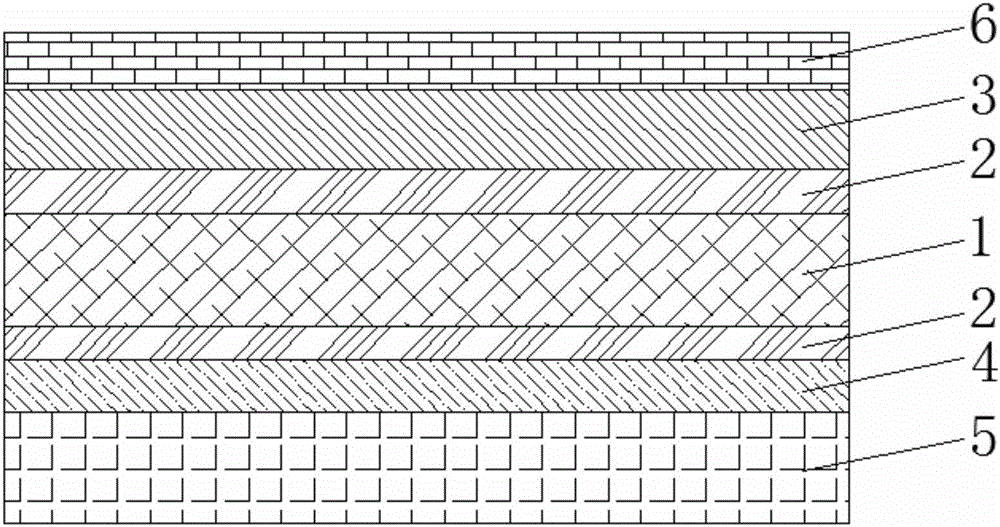

[0020] See figure 1 As shown, an aluminum-plastic film for lithium battery packaging has good electrolyte resistance, good formability, good heat-sealing strength, good barrier property, and good flatness. This kind of aluminum-plastic film for lithium battery packaging has a layered structure, which consists of an aluminum base layer (AL) 1 in the middle, and is distributed sequentially from the aluminum base layer (AL) 1 to a new functional adhesive resin layer (AD) 2, a two-component Adhesive coating nylon layer (OPA) 3, UV coating 6, from the aluminum base layer (AL) 1 down to the new functional adhesive resin layer (AD) 2, homopolypropylene (PP) 4, copolymerized polypropylene layer (CPP)5. Since the layered structure of the flexible aluminum-plastic film material for lithium batteries of the present invention is distributed, the stress o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com