Anti-theft label sealing method and adhesive anti-theft unsealing label

An anti-theft and self-adhesive technology, applied in the field of product sealing, can solve the problems of unusable, unusable for sealing, limited application range of electromagnetic induction aluminum foil sealing sheets, etc., and achieve the effect of convenient use and convenient sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

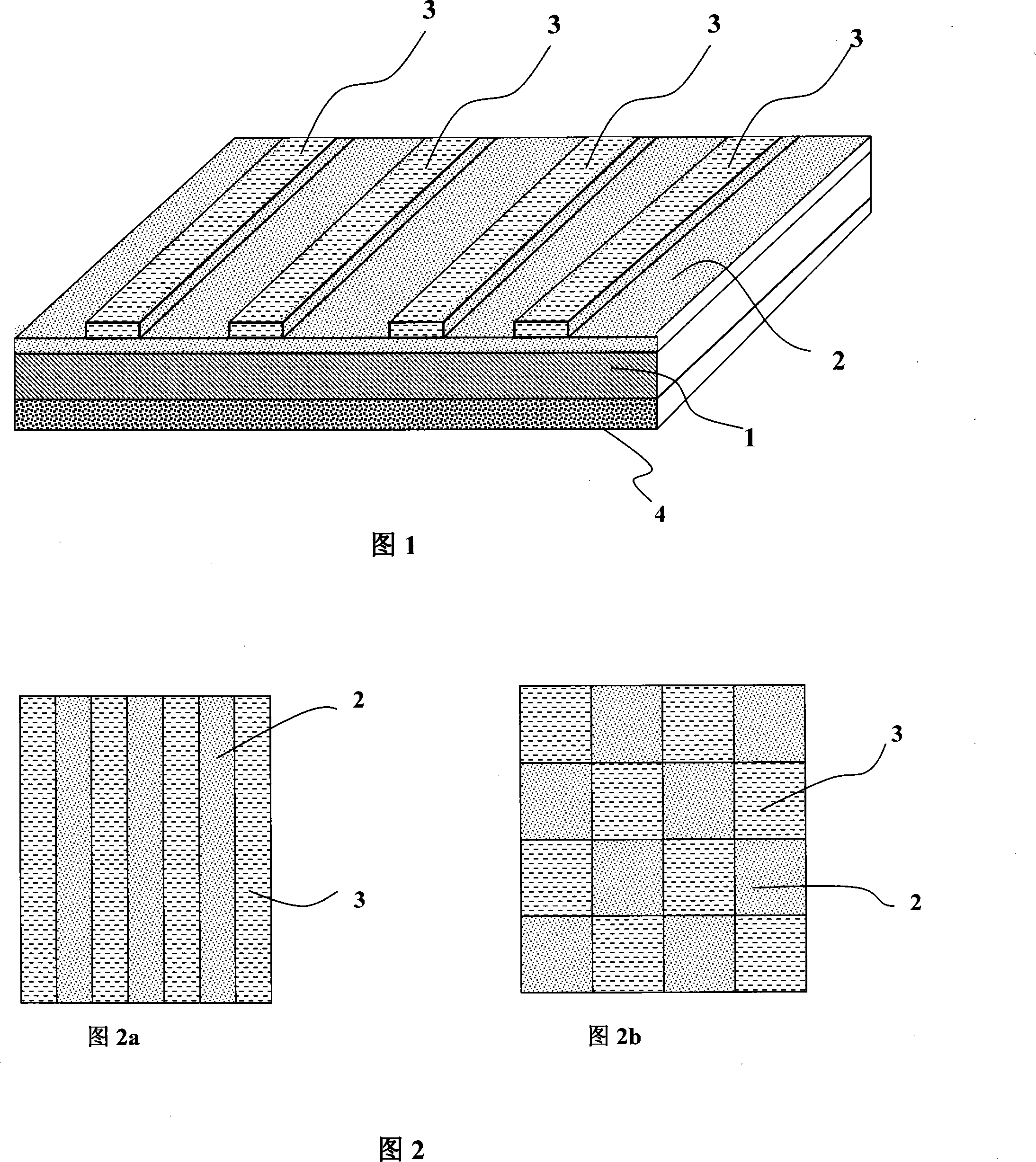

[0042] As shown in Figure 1, purchase an electromagnetic induction aluminum foil sealing film roll with a thickness of 50 μm, a width of 220 mm, and a softening point of hot melt adhesive of 100 ° C, and place it in the RRP-230 hot melt adhesive spray coating machine On the unwinder, the glassine backing paper with a width of 225mm is passed around the pressure roller and the electromagnetic induction aluminum foil sealing film is bonded and rolled.

[0043] Start the machine, and spray a kind of hot-melt self-adhesive (also known as pressure-sensitive adhesive) strip on the hot-melt adhesive layer (2) of the electromagnetic induction aluminum foil sealing film, so that the width of each self-adhesive line is kept at 1 -2mm, adjust the distance between the nozzles, so that the self-adhesive lines (3) sprayed on the hot-melt adhesive layer (2) maintain a distance of 3-8mm, and then the self-adhesive electromagnetic induction aluminum foil sealing film can be produced. It is als...

Embodiment 2

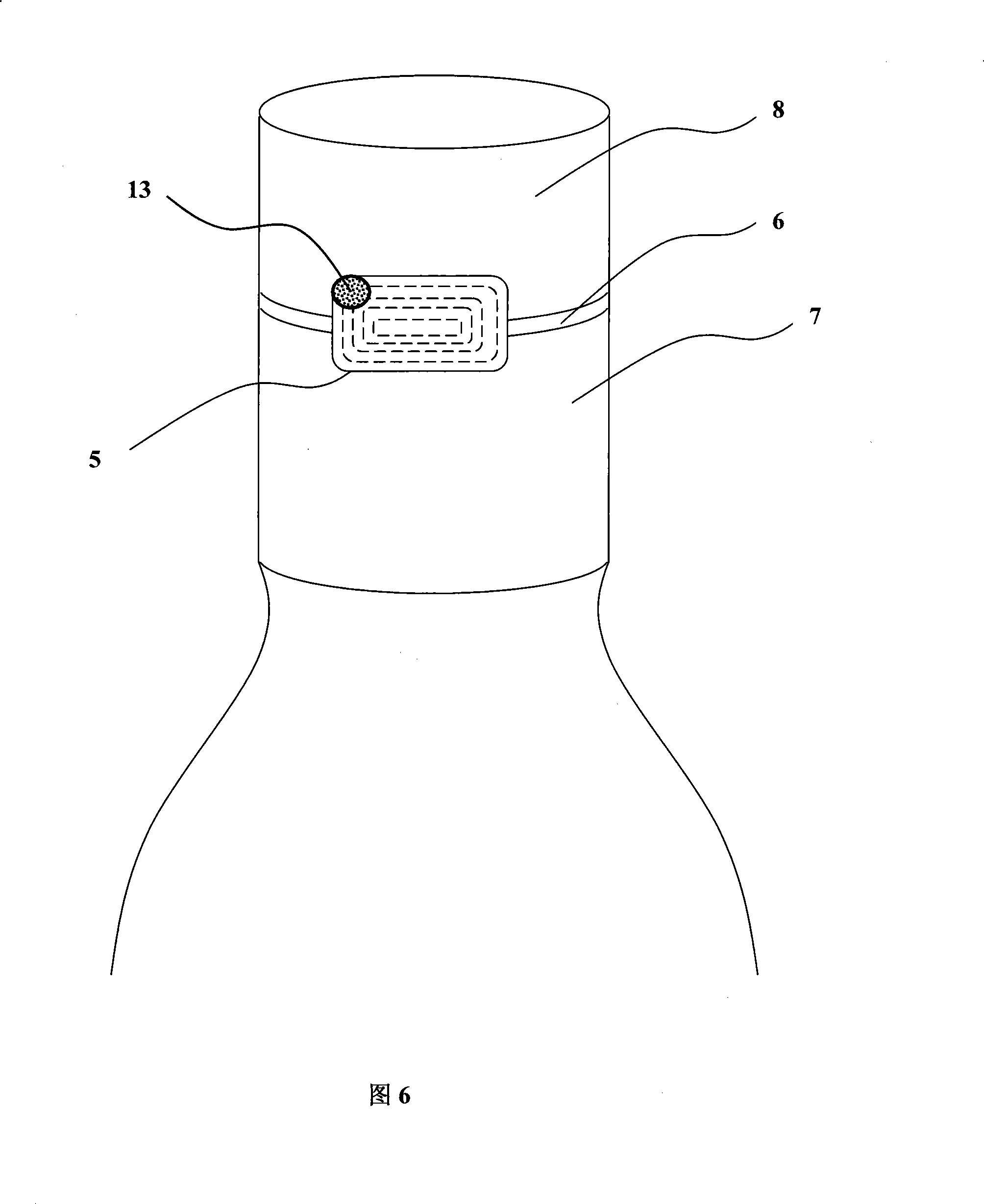

[0051] As shown in Figure 5, purchase a kind of strong adhesive self-adhesive (also known as pressure-sensitive adhesive) trademark paper, print or compound the anti-counterfeiting label information layer (4) on it, and print a temperature-indicating color on a prominent position Block layer (13). In order to prevent the temperature-indicating color block layer (13) from becoming discolored and ineffective due to the influence of the ambient temperature during storage, it is best to select an irreversible temperature-changing ink with a discoloration temperature of 45-99°C. In this way, if the counterfeiter heats the self-adhesive label, the temperature-indicating color block layer (13) must change color, for example, from colorless to red. As long as the manufacturer prints notices such as "do not buy when a certain position turns red" on the product, counterfeiters must not dare to use heating to remove the self-adhesive anti-theft seal (5).

[0052] Design, print and die-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com