Clamp

A fixture and chuck seat technology, applied in the field of mechanical processing, can solve the problems of loosening of screws for clamping shaft parts, low labor production efficiency, time-consuming and laborious assembly and disassembly, etc., to offset radial component force, save installation and disassembly Time saving and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

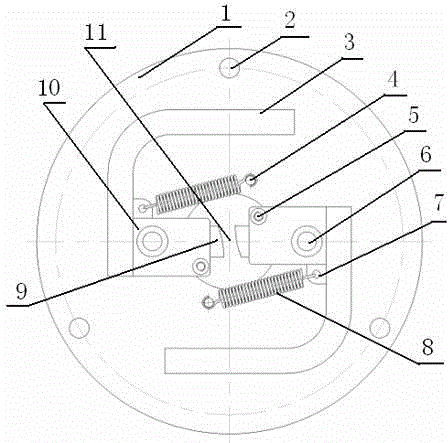

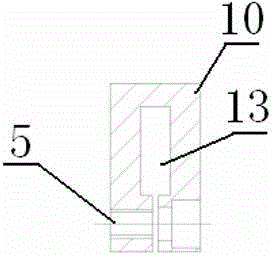

[0021] The present invention as figure 1 , figure 2 , image 3 as shown, a fixture , including the ontology and Fixture components. The main body is connected with the machine tool bolts through the assembly holes. The body is composed of a body chassis with the same structure and size and a detachable body upper plate. said The fixture assembly is composed of two sets of fixture parts with the same structure and shape, and the two sets of fixture parts and The body faces the center of the circle symmetrically set at body chassis, the The fixture parts are mainly composed of centrifugal rod, return spring, collet and collet seat. said The centrifugal rod is " L ” shape, the chuck seat is set at one end of the centrifugal rod, and welded with the centrifugal rod, exist The chuck seat is provided with a positioning card slot for the chuck to be inserted into. The depth and width of the positioning card slot are adapted to the length and width of the chuck. A l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com