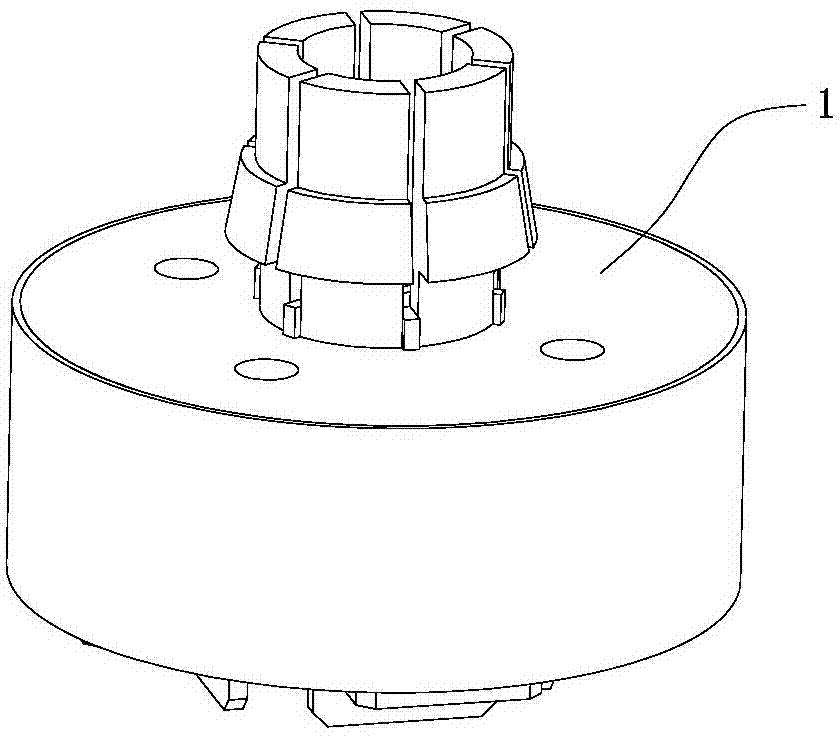

Clamping paw with centering function

A gripper and function technology, applied in the field of electronic component plug-in machine equipment, can solve the problems of no front-to-back alignment, lower gripping accuracy of the manipulator gripper, and higher rejection rate, and achieves the improvement of gripping accuracy and the simple and convenient control action. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

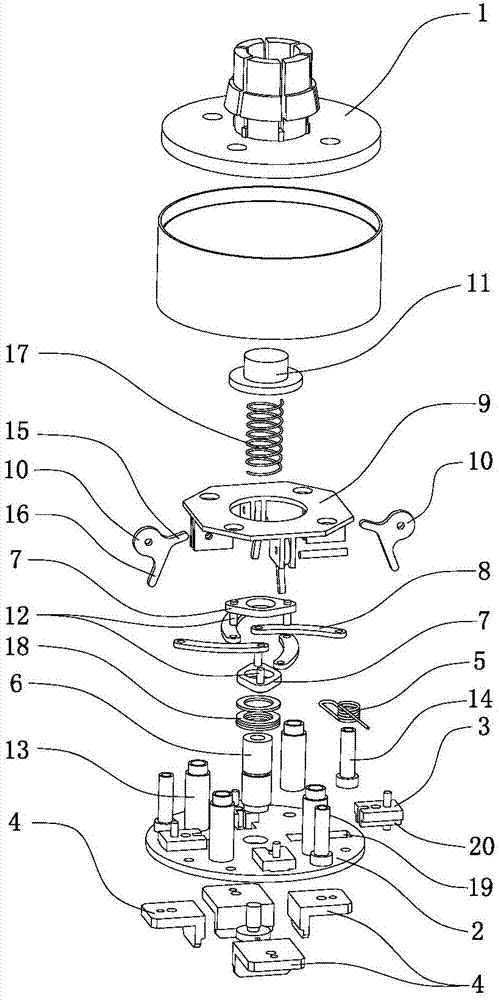

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0021] Such as Figure 1 to Figure 3 Shown is the first embodiment of the clamping gripper with the centering function of the present invention, which includes the gripper connecting cover 1 and the gripper body 2 arranged under the gripper connecting cover 1, and the middle part of the gripper connecting cover 1 is provided with a second A through hole, the claw body 2 is equipped with at least three radially movable claw sliders 3, and each claw slider 3 is equipped with a material clip 4; the side of the claw slider 3 A spring 5 is installed, and the two ends of the spring 5 are respectively connected with the gripper body 2 and the gripper slider 3; the middle part of the gripper body 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com