Hydraulic feeding device

A hydraulic and feeding claw technology, applied in the field of metallurgical forging, can solve problems such as fine and complex structures, damage, and decreased control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

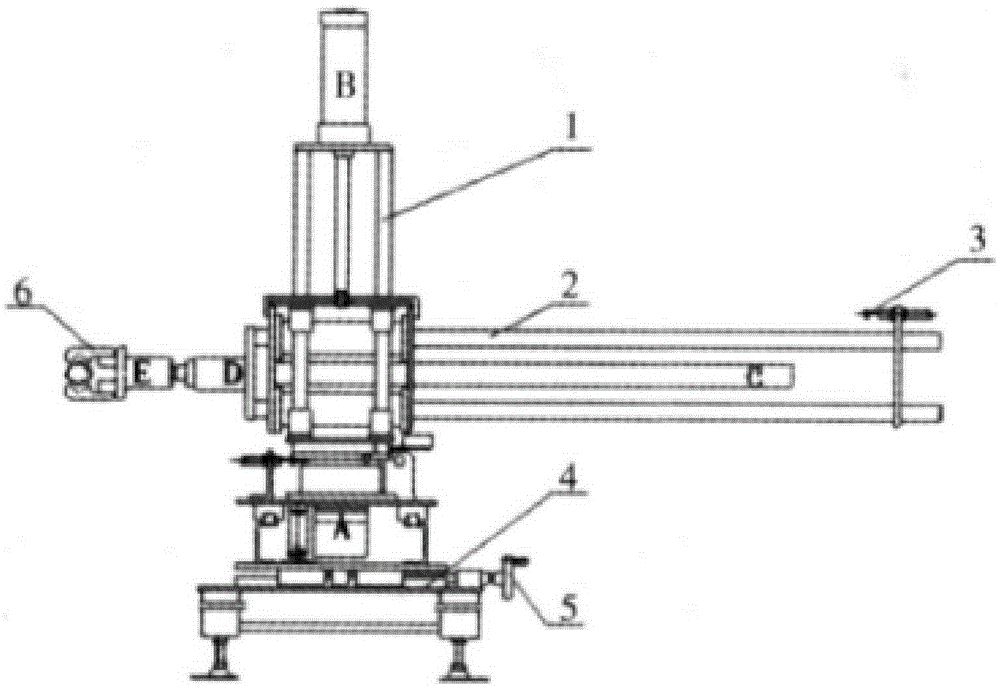

[0021] The device is fixed to the ground through four cylindrical legs. After the base is fixed on the ground, the rotating hydraulic table is fixed to the base. The rotating hydraulic table controls its rotation angle through hydraulic pressure. The rotation range is 0°-240°, and the liquid inlet is controlled Entry and exit of hydraulic media. Then install the screw device on the rotating hydraulic platform, and fix it by bolts. There are three screw columns, as shown in the figure, and then install the corresponding hydraulic cylinder on the square positioning box. The threaded hole matched with the rod column sets the positioning box on the lead screw. The height adjustment range of the positioning box is 200mm-800mm. The feeding claw is connected to the top of the hydraulic cylinder, so that the feeding claw can adjust its running length along with the expansion and contraction of the hydraulic cylinder, and its length adjustment range is 160mm-960mm. After the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com