Hydraulic positioning clamping mechanism for shaft machining

A clamping mechanism and hydraulic positioning technology, which is applied to metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of uneven technology, reliability, stability, and durability, lack of sensibility, rational understanding and deep Issues such as lack of in-depth research on basic knowledge and development direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

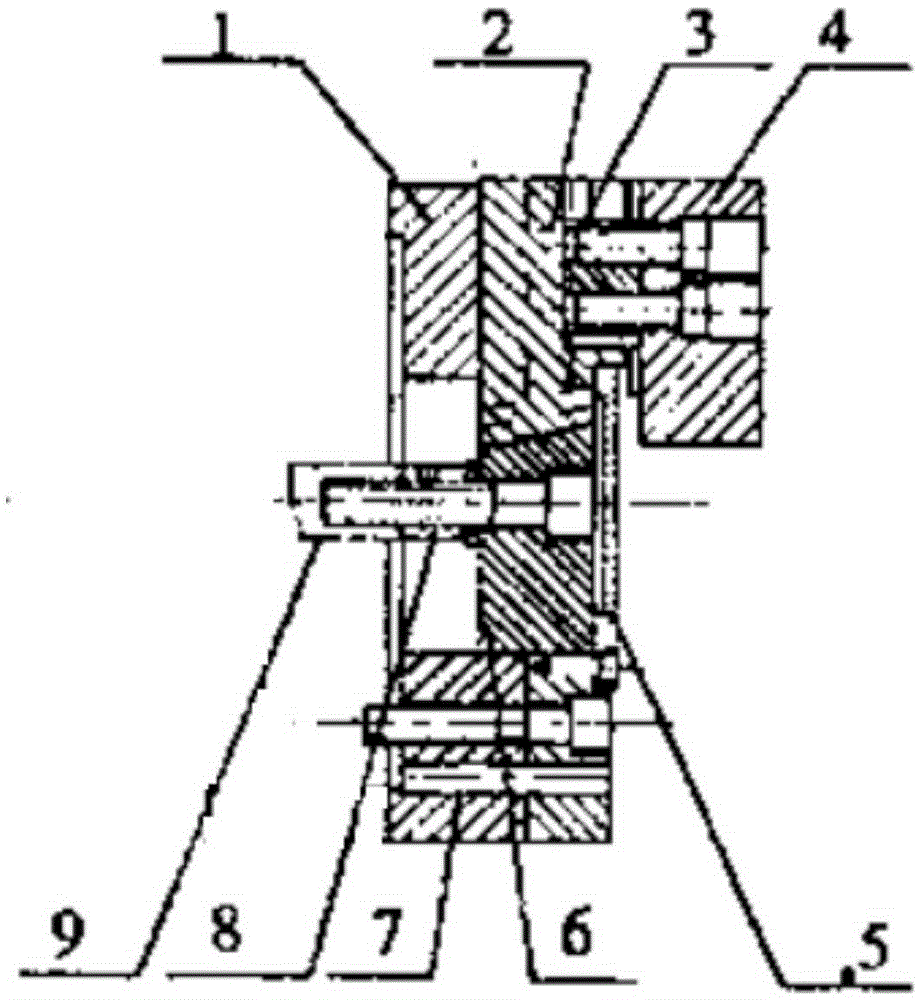

[0021] The clamping mechanism is composed of three clamping claws. The angle between two clamping claws is 120°. The joint shaft 6 is connected with the hydraulic piston rod 9 through bolts. The joint shaft 6 is designed to be clamped at 20° with the horizontal axis. Angular dovetail structure, and is connected with the translation base 2, the hydraulic piston rod 9 drives the joint shaft 6 to move left and right by moving left and right, and at the same time, the translation base 2 has an inclination angle with the contact surface of the joint shaft 6, so that the translation base The seat 2 moves centripetally or centrifugally along the radial direction. The baffle plate 5 is connected with the cylindrical disc 1 through bolts to prevent dust from falling into the joint shaft 6, and the hydraulic piston rod 9 has a sealing ring 8 to isolate the liquid medium in the hydraulic cylinder. The clamping jaw base 4 is connected with the translation base 2 through the bolt 3, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com