Automatic clamp, automatic grabbing device, mechanical arm and robot

A grabbing device and automatic technology, which is applied in the fields of automatic grabbing devices, manipulators, robots, and automatic fixtures, can solve problems such as economic losses, affecting the normal operation of the production line, and grabbing failures, achieving cost savings, strong versatility, The effect of high gripping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further elaborated.

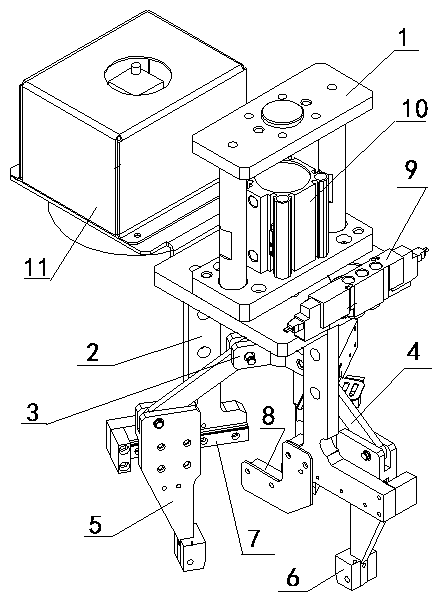

[0025] First, combine the figure 1 The automatic fixture according to the embodiment of the present invention is described, which is used for automatic equipment capable of driving the moving position of the automatic fixture. It can be applied to various industrial automation or logistics operation fields, etc., and has a wide range of application scenarios and significant economic and social benefits.

[0026] The automatic fixture of the present invention has a driving module, a jaw module, a transmission module, a sensing module and a processing module. In this example, if figure 1 As shown, the automatic clamp is installed on the mounting base 1, and the mounting base 1 can be installed on an automatic grabbing device, a mechanical arm, a robot or other automatic grabbing functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com