Wet parting process for concrete blocks or plates

A technology for concrete blocks and plates, used in manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve problems such as tight cohesion, failure to break and reduce yield, avoid damage and improve clamping. Accuracy and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

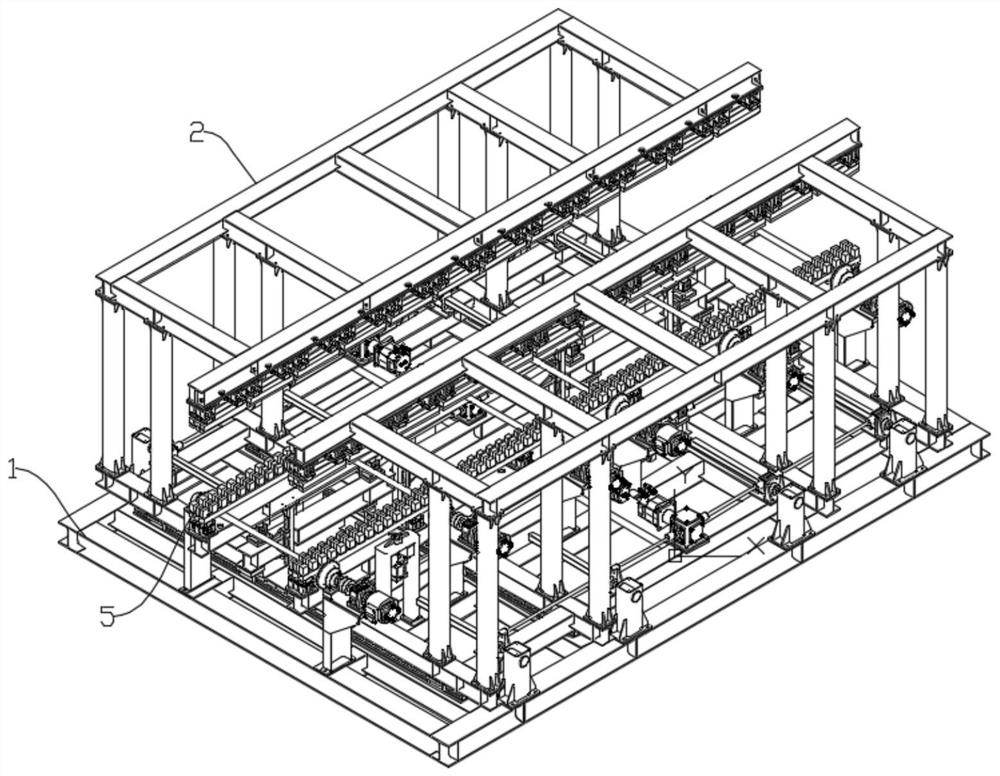

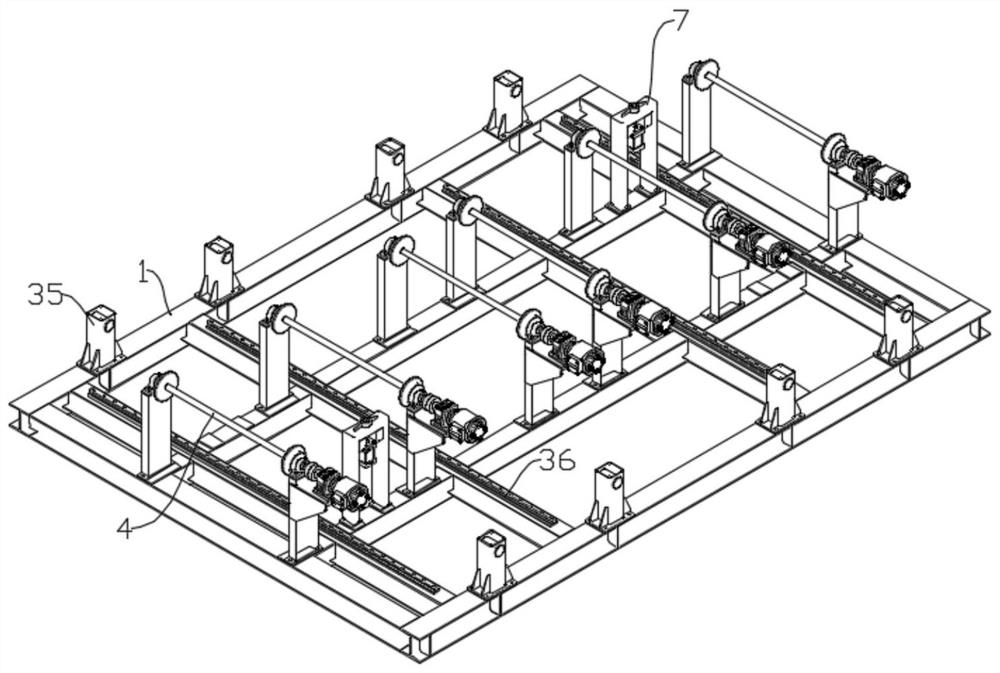

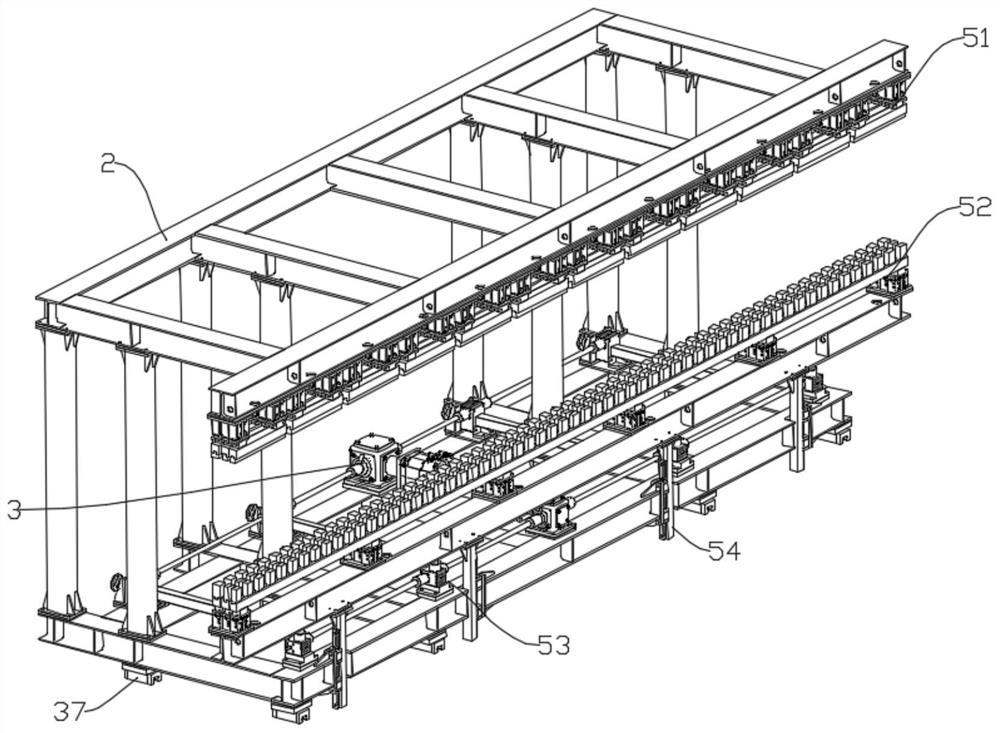

[0077] A wet breaking system for concrete blocks or slabs is used to break apart the concrete body before steam curing. The specific structure and working principle will be described in detail below.

[0078] Such as Figure 18 As shown, the system includes a cutting device 13, a cutting conveyor track 11, a semi-finished product crane 9, a turning machine 10, a horizontal steam curing track 12, a wet breaking machine, a stacking crane 14 and a steam curing conveyor 15.

[0079] Among them, the cutting device 13 is used to cut the concrete body, and stack the cut body vertically, this is because it is more convenient to stack the cut body vertically, and the stack is more neat. If the green bodies are stacked horizontally, on the one hand, the operation is more troublesome, and the green bodies are easy to be scattered and damaged;

[0080] The cutting conveyor track 11 is located on one side of the turning machine 10 , one end of which is connected to the cutting device 13 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com