Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "High defect rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

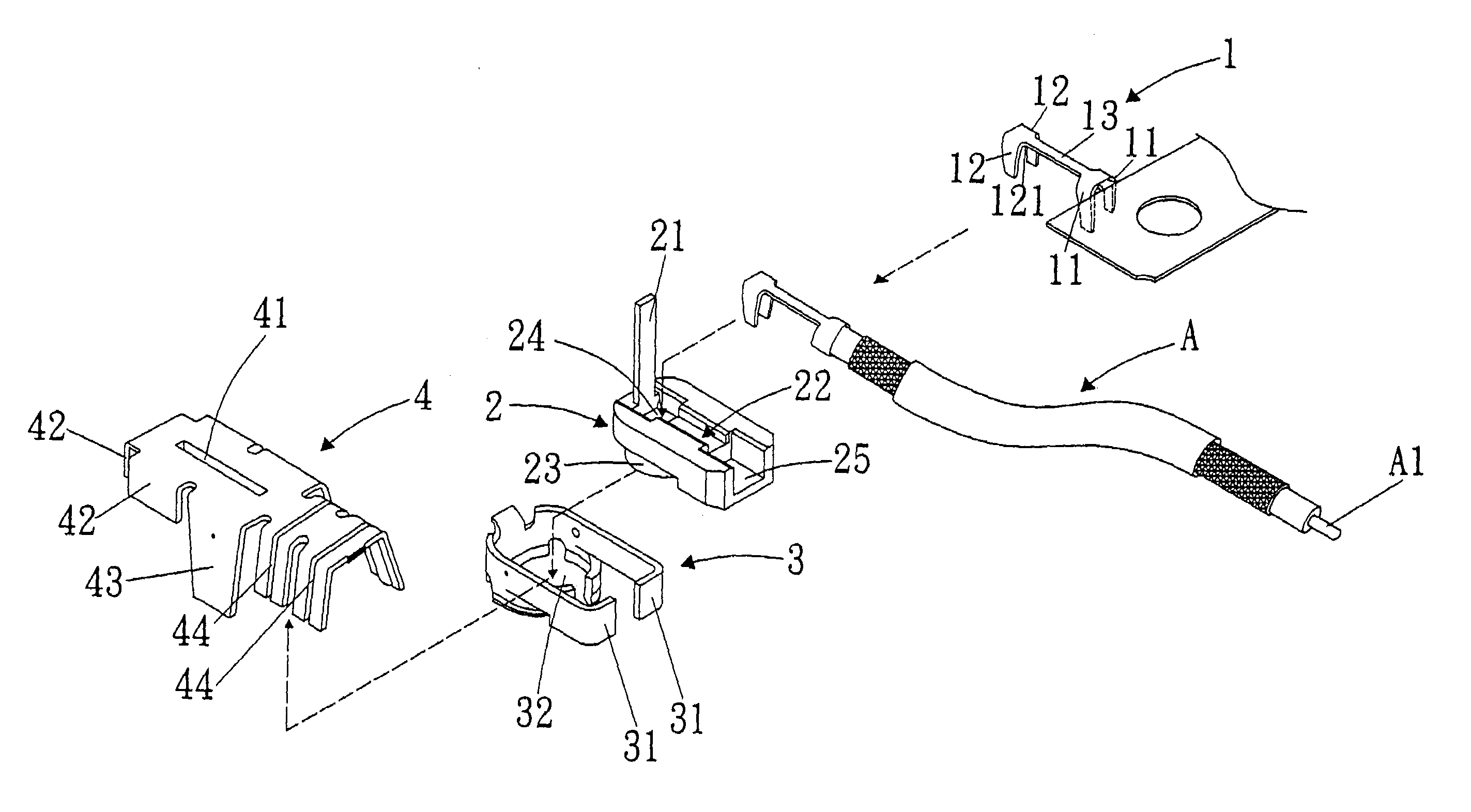

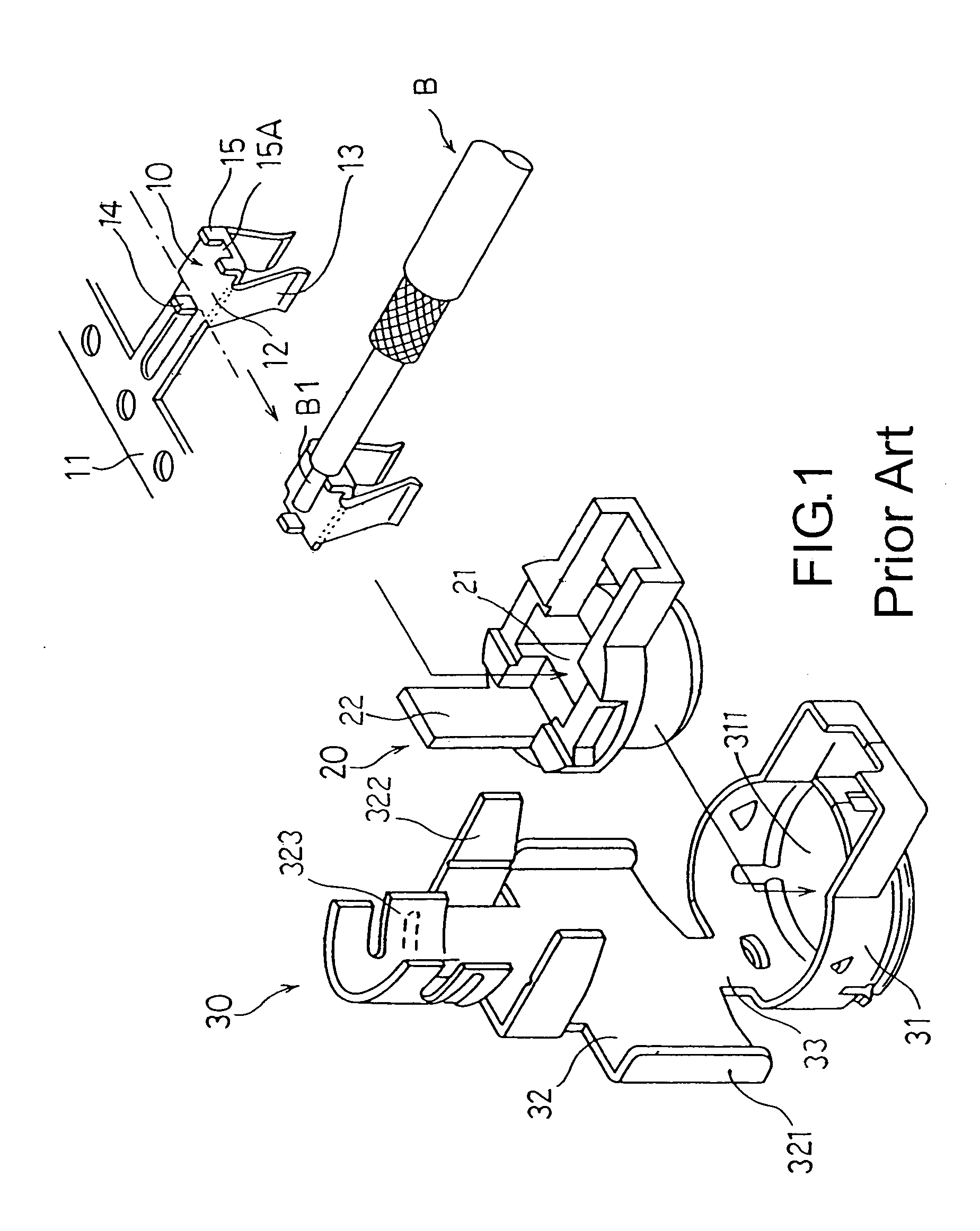

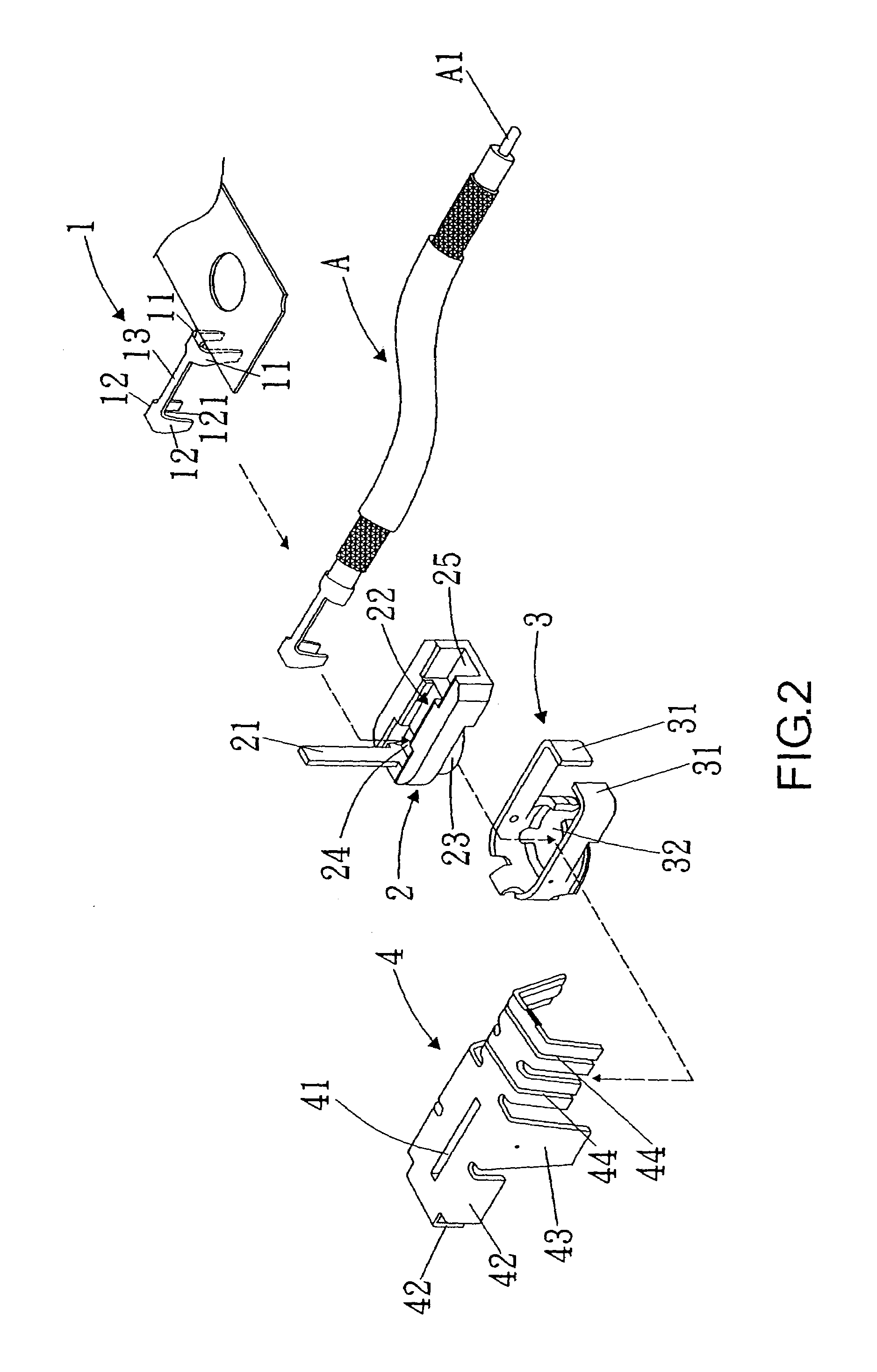

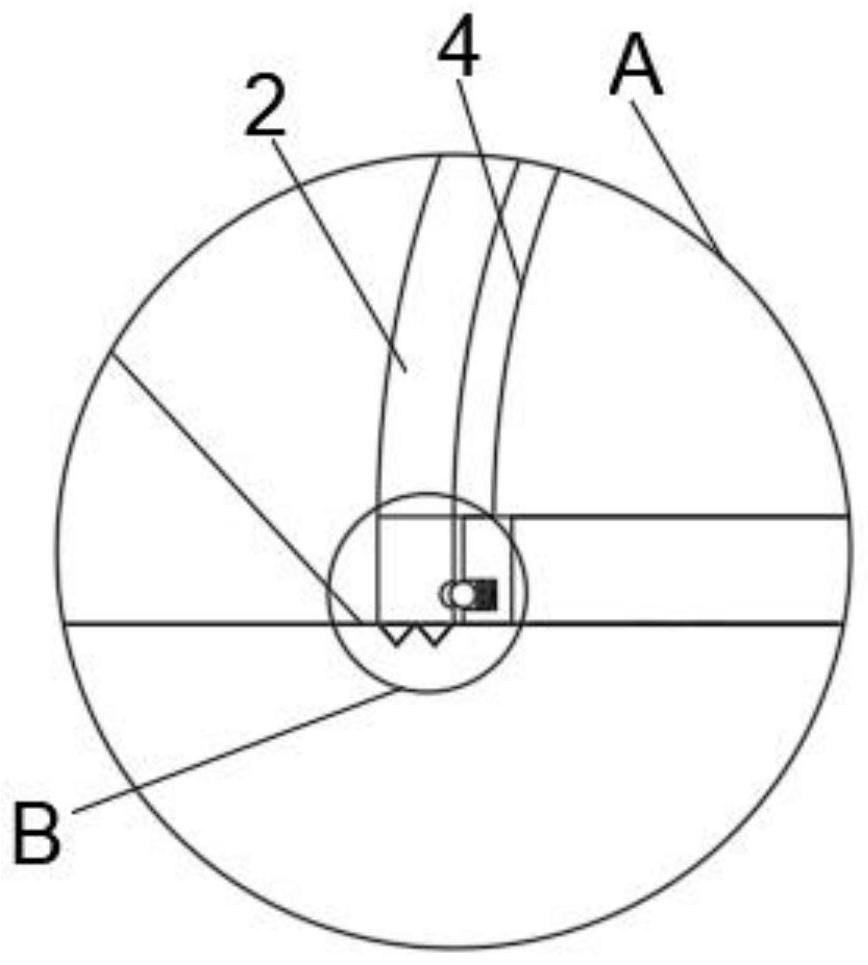

Micro coaxial connector

InactiveUS6971913B1Lower manufacturing requirementsIncrease productionElectrically conductive connectionsTwo pole connectionsCoaxial cableFlexural strength

The micro coaxial connector includes a signal terminal, a main body, and two grounding elements. The signal terminal has a pair of tag-like contact arms and bending arms at a front and rear end thereof, and a strip plane at a middle section thereof. The contact arms are for contacting with a base of a printed circuit board (PCB). The main body is for receiving the signal terminal and serving as an insulation. The two grounding elements are separated designs. The cylindrical-shaped first grounding element is for receiving and fastening the main body, and has a pair of extension arms for providing the coaxial cable with suitable clamping forces. The second grounding element is a cover-like body, and has a strip-like projection for increasing strength against bending of the second grounding element and preventing loosening of components.

Owner:SPEED TECH

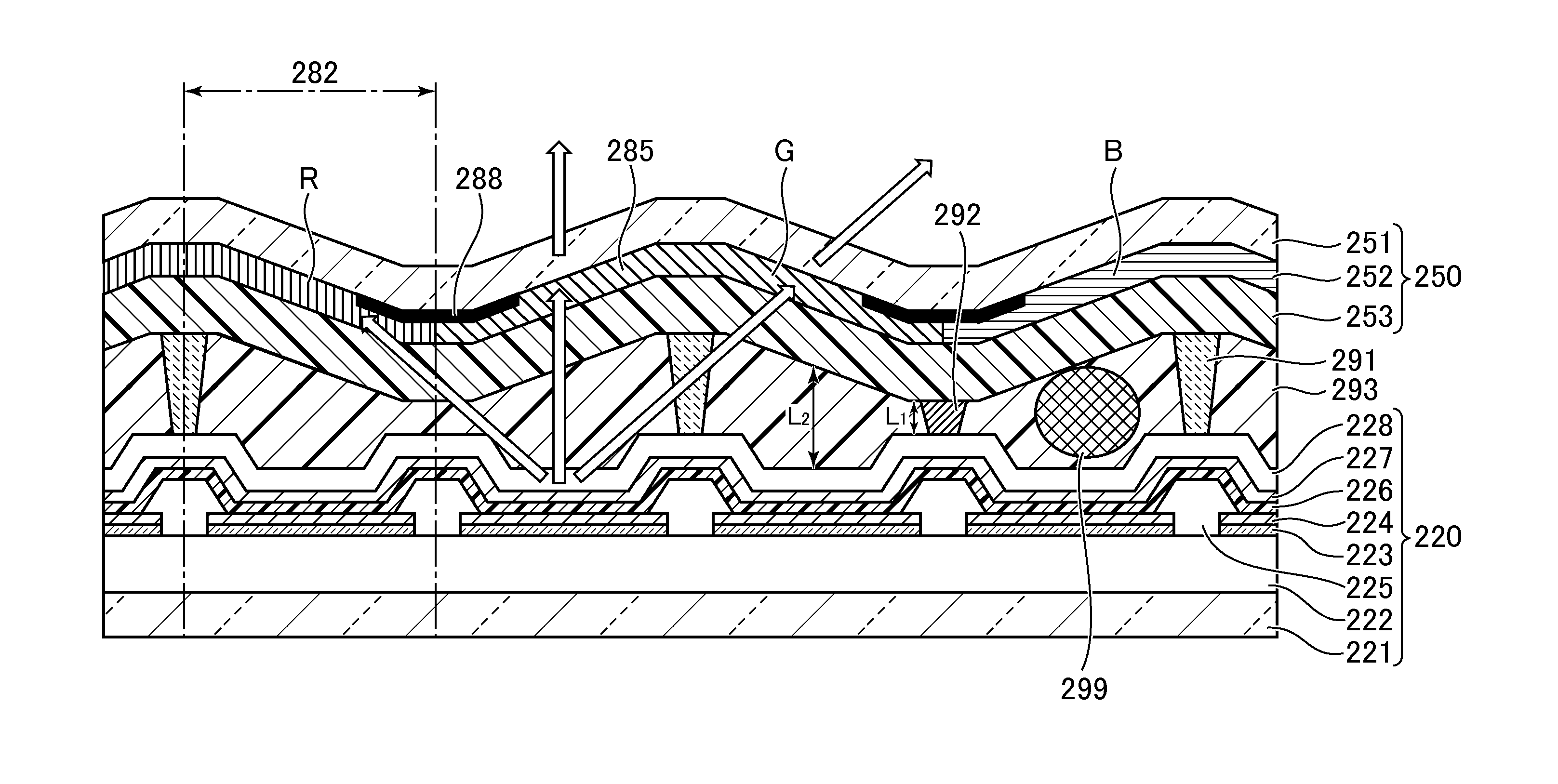

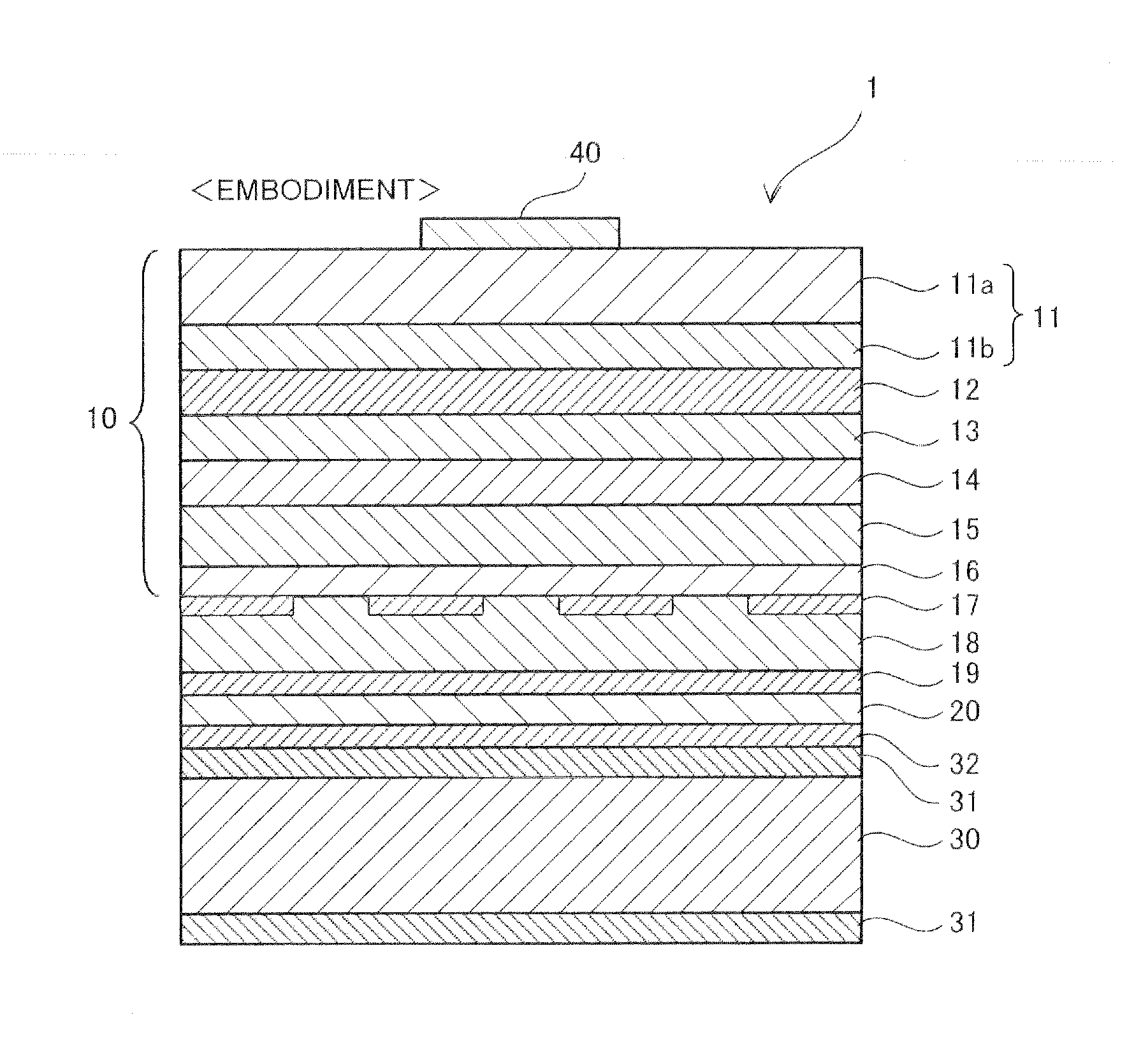

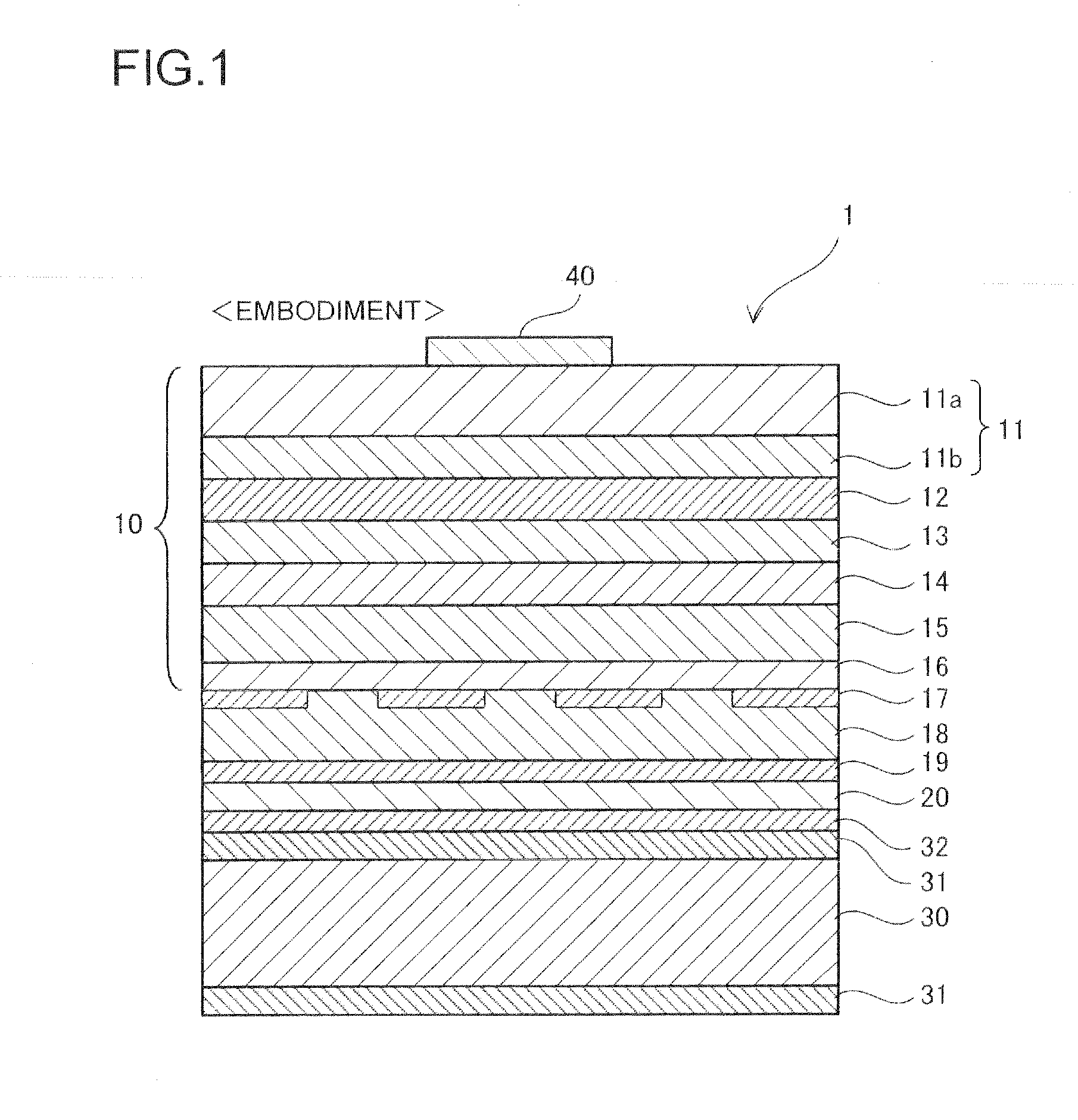

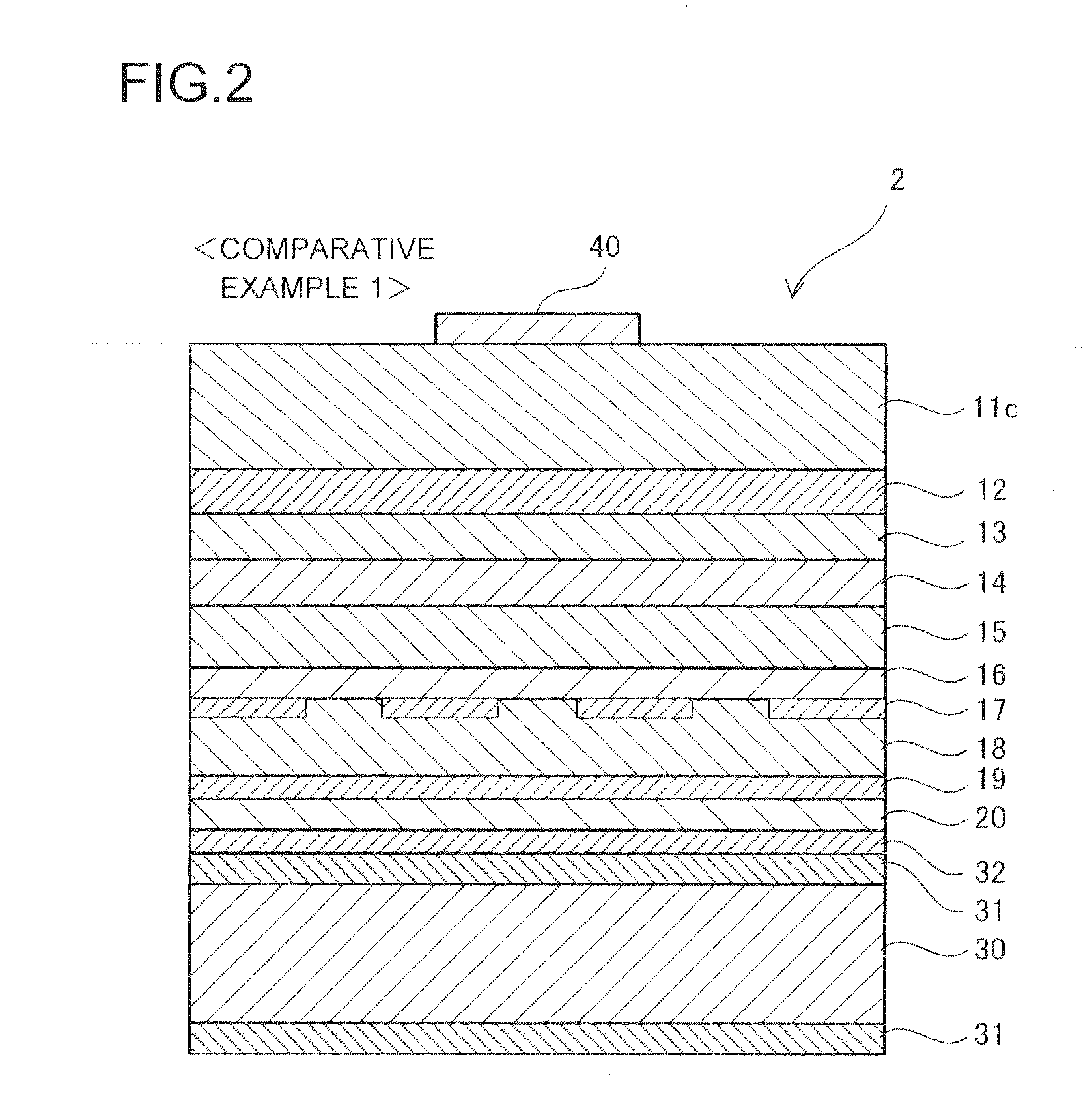

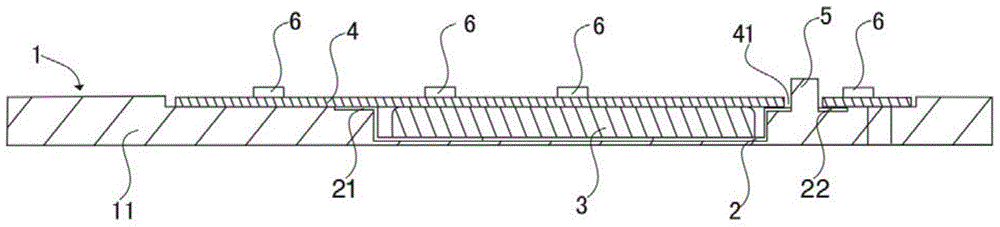

Organic el display device

ActiveUS20150162386A1Large luminous areaColor can be suppressedSolid-state devicesSemiconductor/solid-state device manufacturingColor gelDisplay device

An organic EL display device includes a thin film transistor substrate in which a light-emitting element is provided for each of plural sub-pixels constituting each pixel, a counter substrate provided with a coupled color filter which is a color filter arranged to be extended over plural adjacent sub-pixels and allowing light in one wavelength region to pass through and a light-shielding film which is arranged on a boundary between adjacent color filters to allow lights in different wavelength regions to pass through and shields light, a filler arranged between the thin film transistor substrate and the counter substrate and made of a transparent organic material, and a filler thickness adjustment part which adjusts to cause a thickness of the filler in a region where the light-shielding film is provided to be thinner than a thickness of the filler in a region where the light-emitting element is provided.

Owner:JAPAN DISPLAY INC

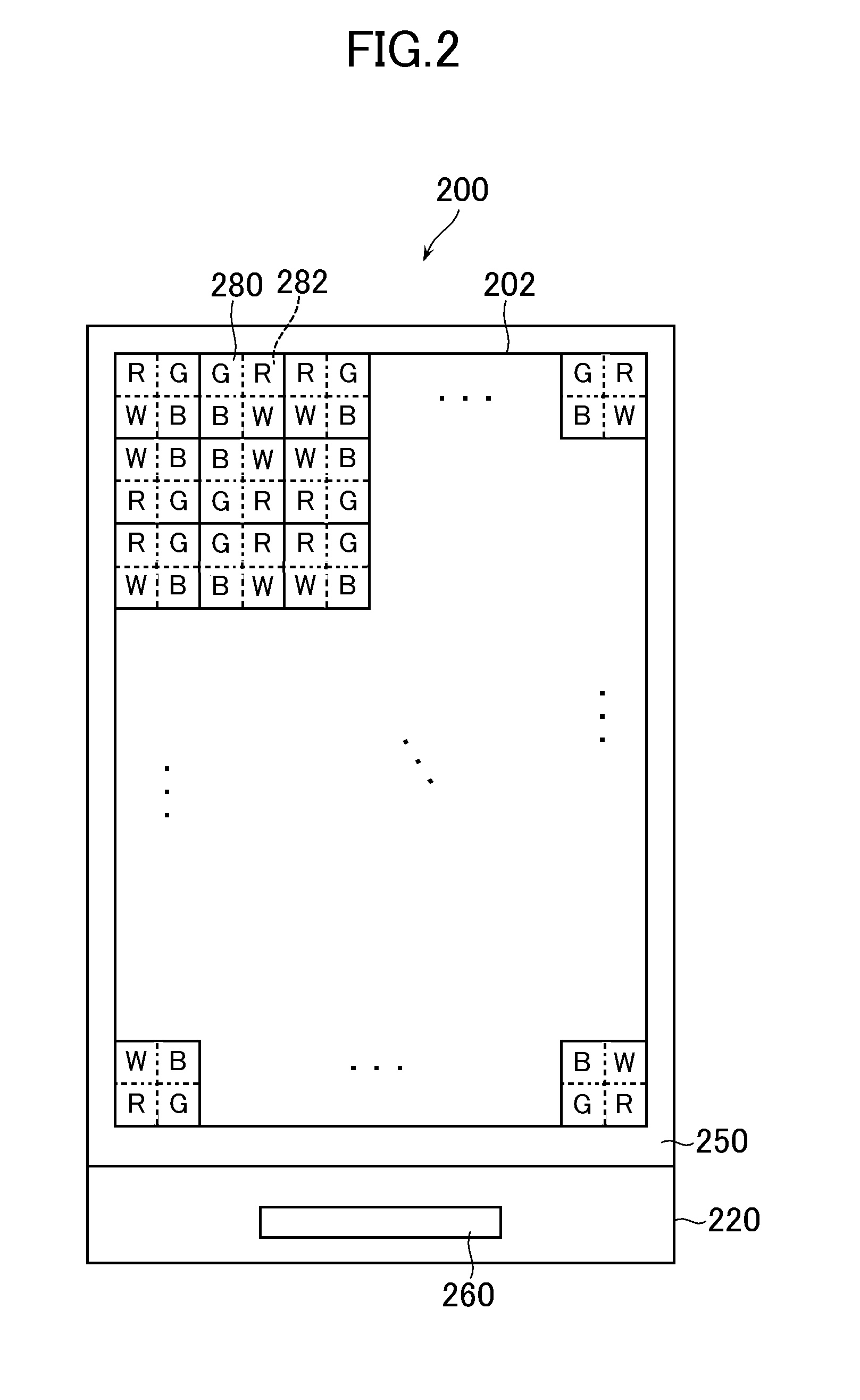

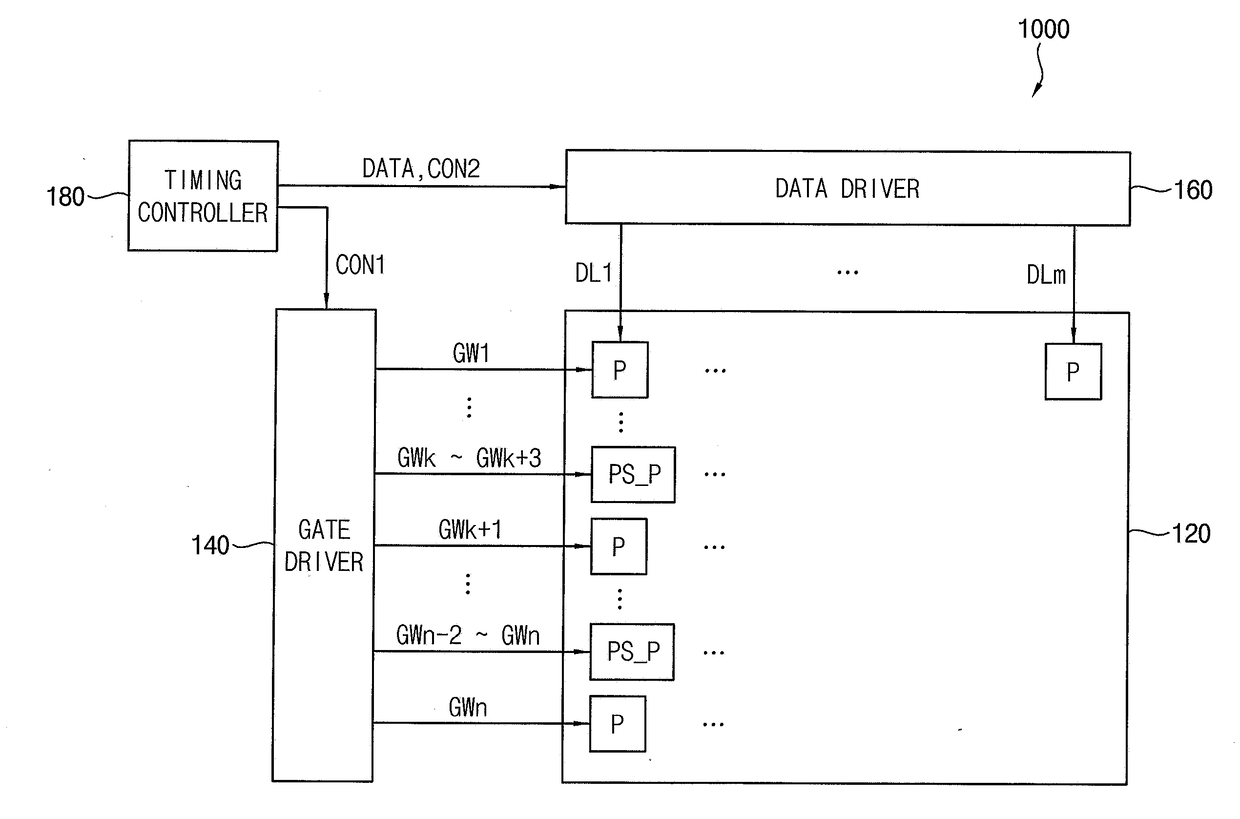

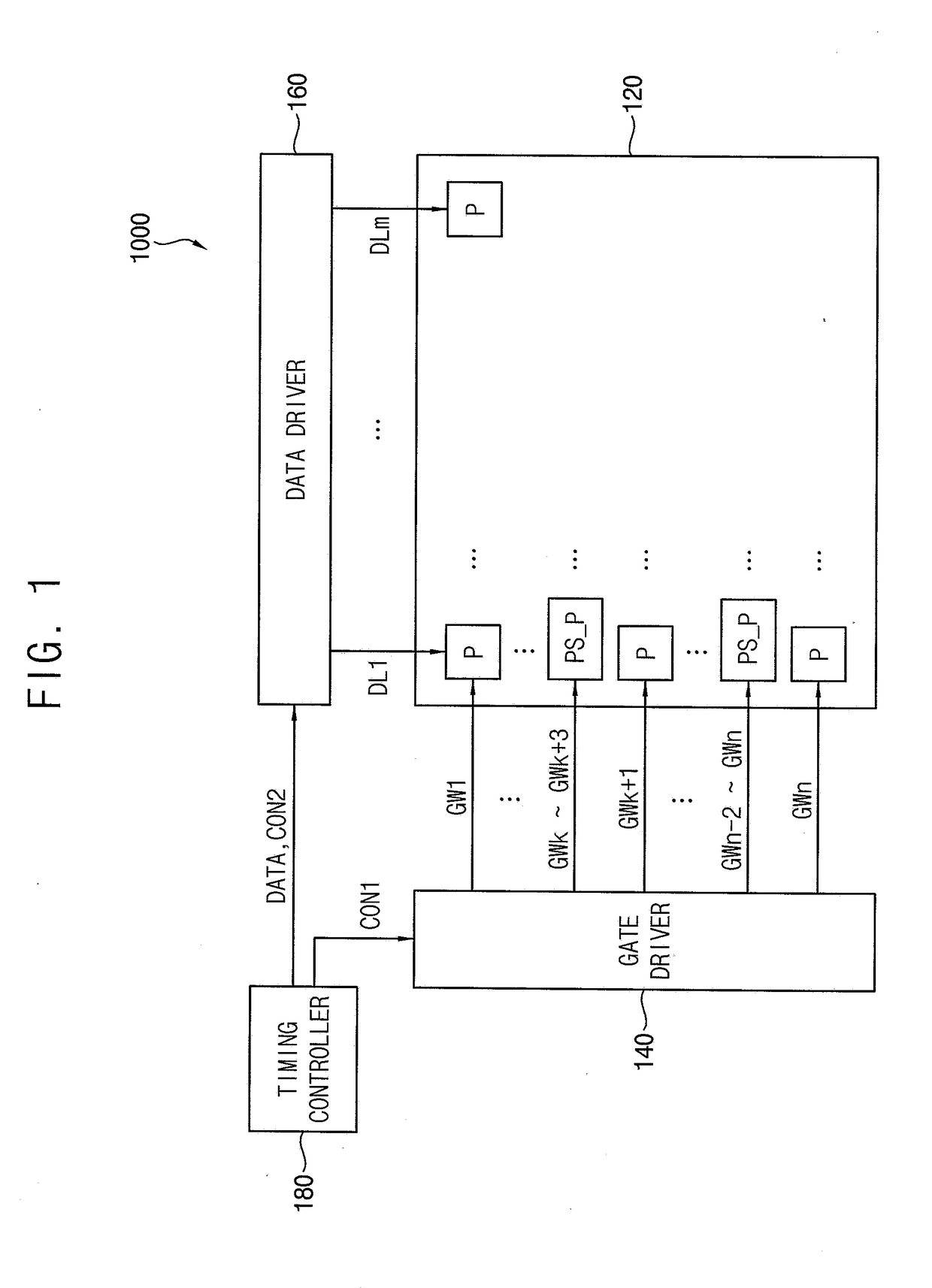

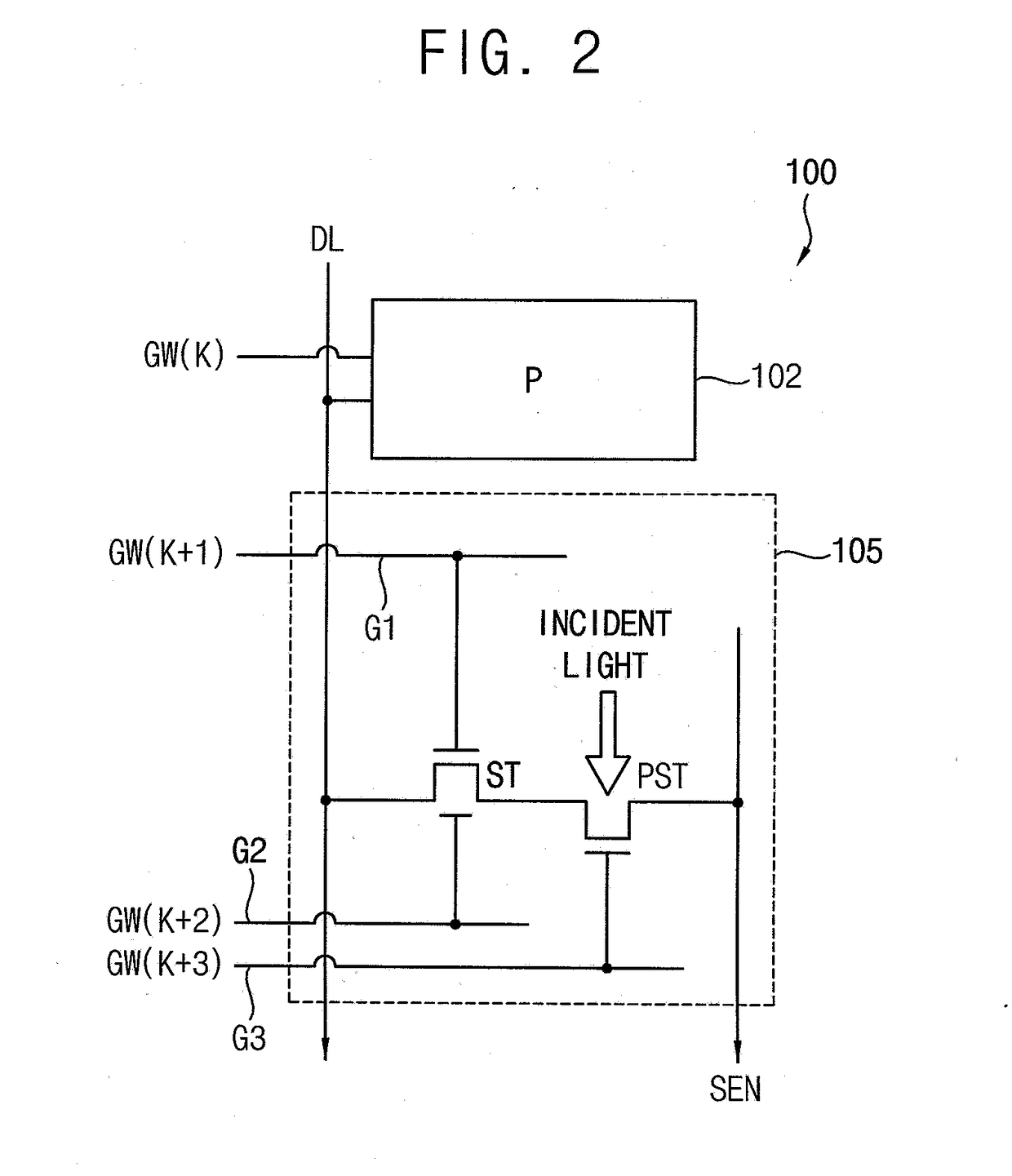

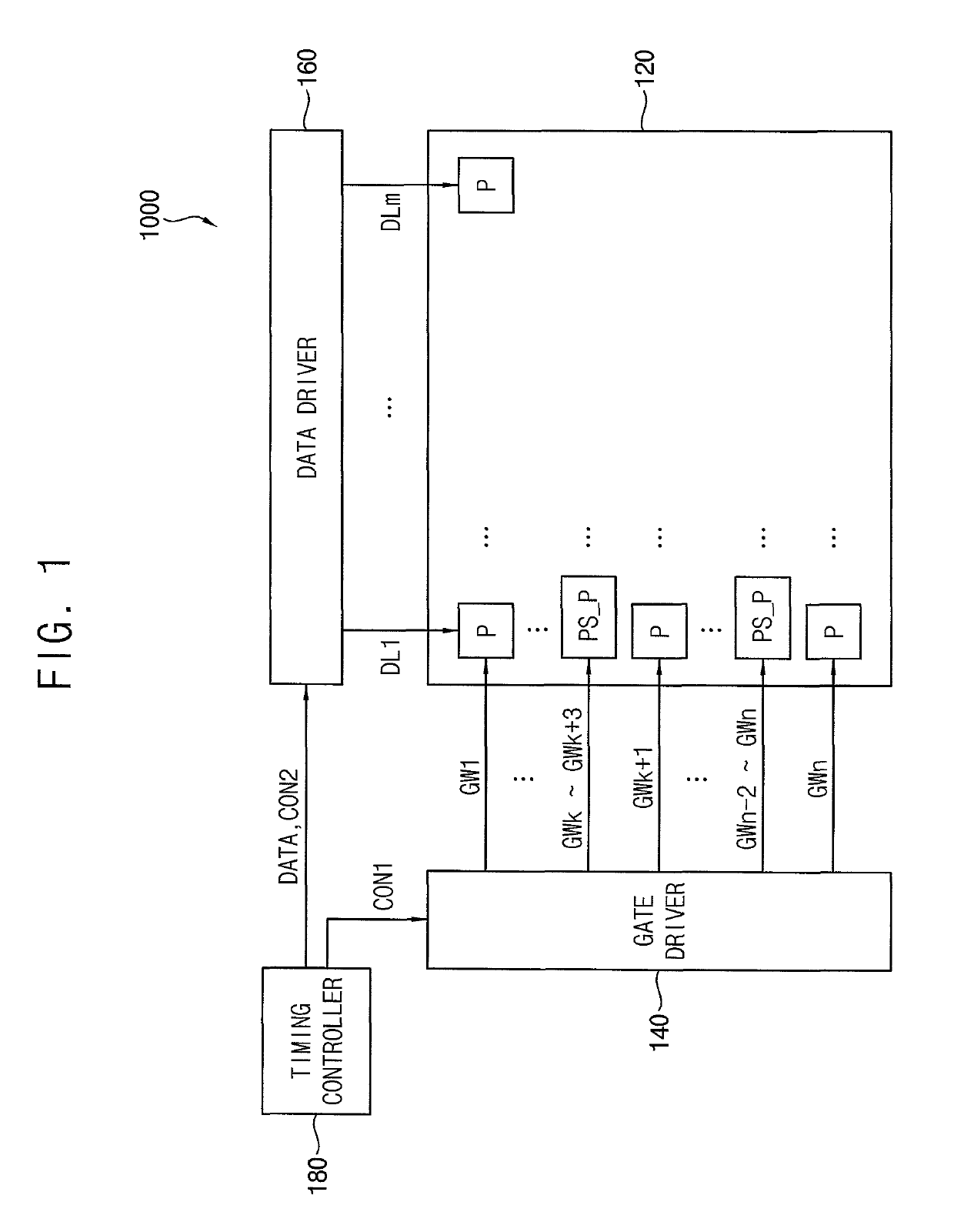

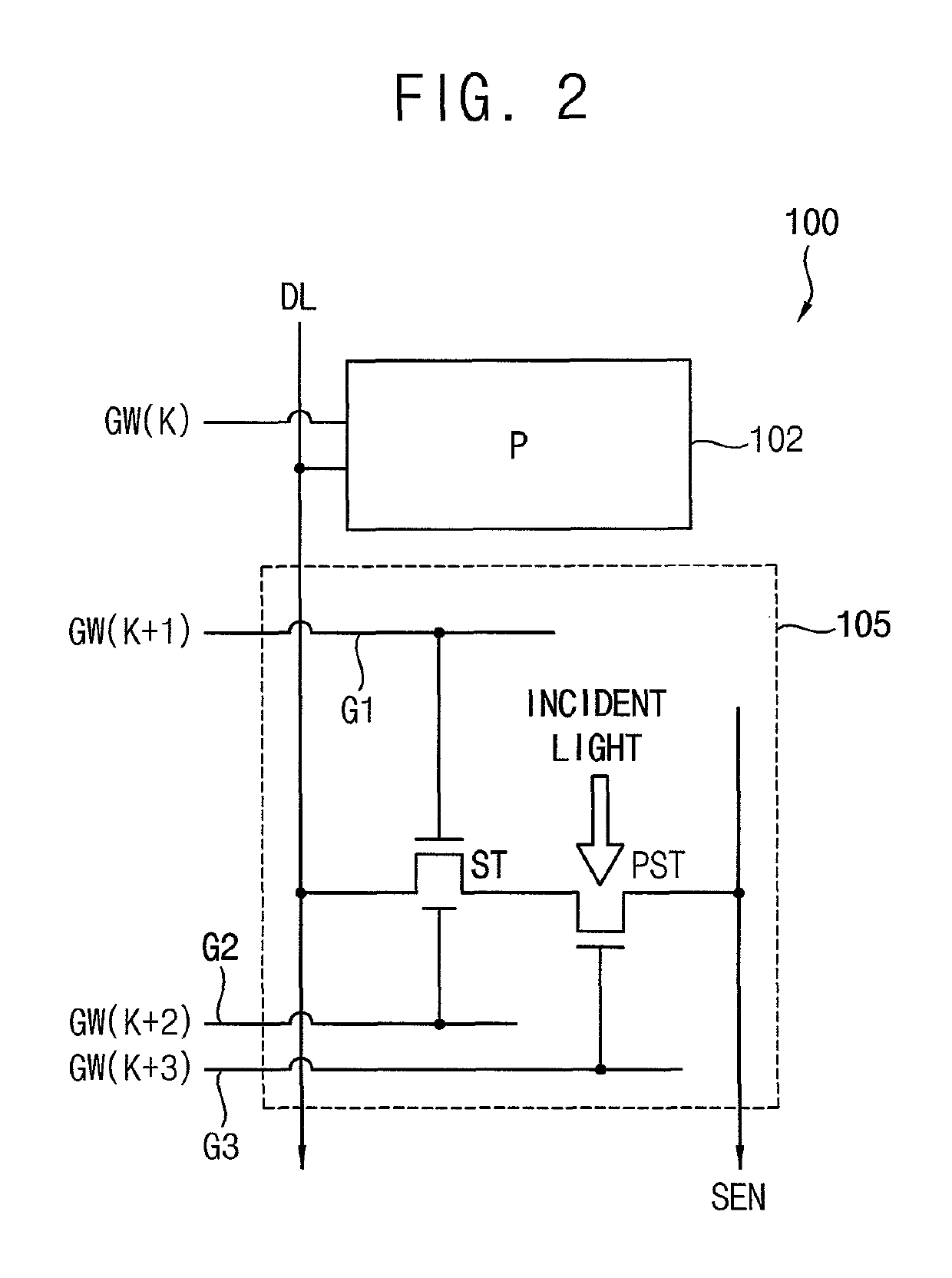

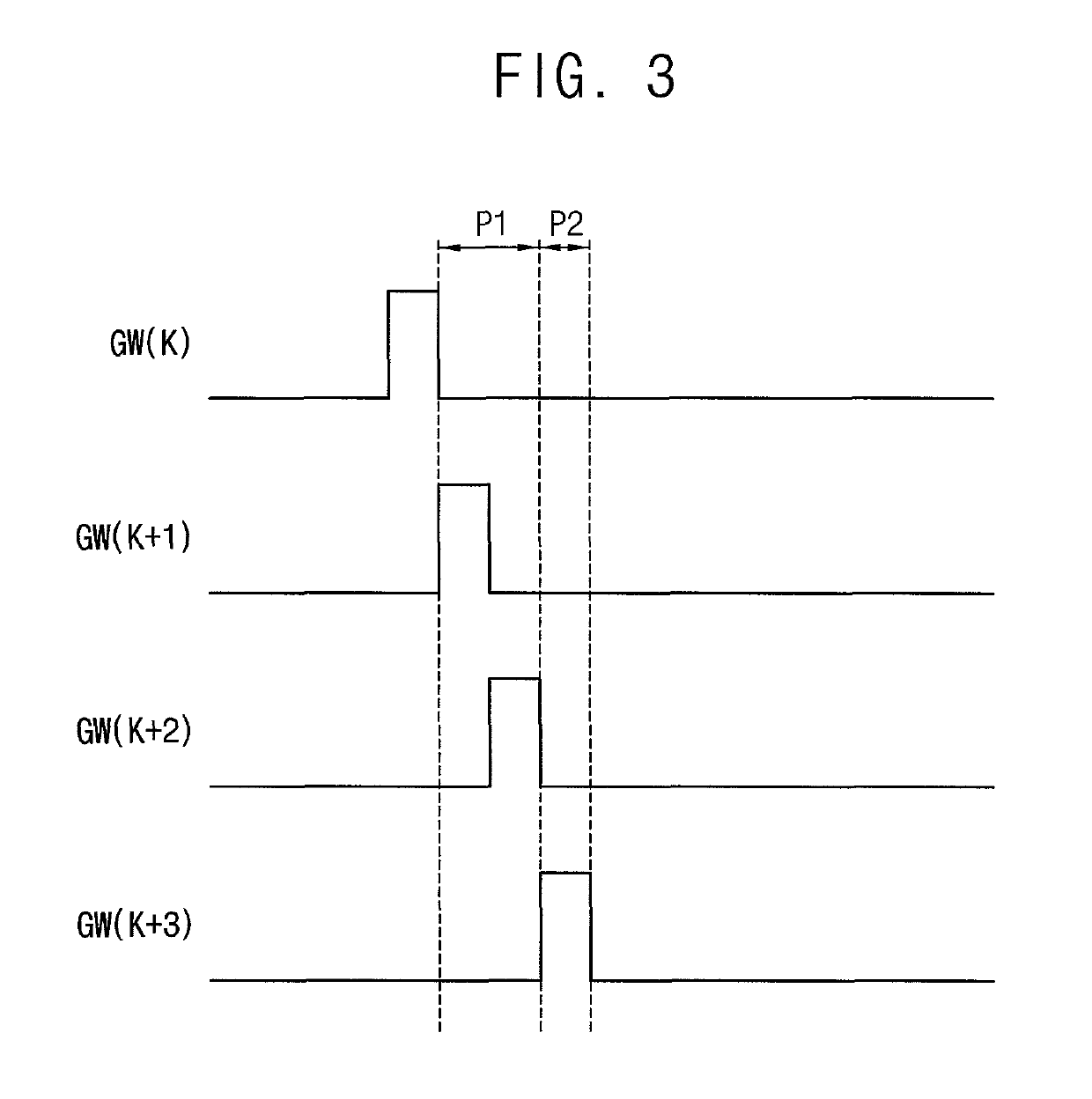

Photo sensor circuit, photo sensor pixel, and display device having the photo sensor pixel

ActiveUS20180203537A1High degreeHigh defect rateSolid-state devicesInput/output processes for data processingDisplay deviceBottom gate

A photo sensor pixel includes a pixel circuit including a driving transistor, a switching transistor having a double gate structure and a photo sensing transistor connected in series with the switching transistor. The pixel circuit drives a light emitting element therein based on a data voltage provided thereto through a data line, the switching transistor includes a top gate electrode and a bottom gate electrode, which are connected to different gate lines, respectively, and the photo sensing transistor senses incident light.

Owner:SAMSUNG DISPLAY CO LTD

Semiconductor light-emitting device

ActiveUS20110175057A1High defect rateSuppress mutationSolid-state devicesSemiconductor devicesActive layerLight emitting device

The device including an active layer composed of AlGaInP, and an n-type clad layer and a p-type clad layer disposed so as to sandwich the active layer, the n-type clad layer and the p-type clad layer each having a bandgap greater than the bandgap of the active layer. The n-type clad layer includes a first n-type clad layer composed of AlGaInP and a second n-type clad layer composed of AlInP; and the second n-type clad layer has a thickness in the range from 40 nm to 200 nm.

Owner:STANLEY ELECTRIC CO LTD

Forming process of pattern layer on surface of glass substrate

InactiveCN102774216AHigh defect rateIncrease production costDecorative surface effectsPrinting inkEngineering

The invention provides a forming process of a pattern layer on the surface of a glass substrate. According to the forming process, ultraviolet light-curing printing ink is printed on the glass substrate and then undergoes ultraviolet light curing to form the pattern layer. The beneficial effects of the invention are as follows: the process overcomes the problems that the amount of energy consumed by drying equipment in traditional ink printing is great, defective products easily form because of pollution by dust fall since drying time is long and fraction defective of finished products is greatly increased in the process of traditional pattern formation on the surface of glass and overcomes the defects of considerable consumption of manpower and time, increased production cost and incapability of realizing large scale quantitative production in the process of drafting a pattern by human hands; and a printing process for a glass material with the advantages of a fast production speed, effectiveness in avoiding fraction defective caused by deficient manufacturing procedures and capacity of saving resources is provided.

Owner:JETCOAT SHANGHAI CO LTD CHINA

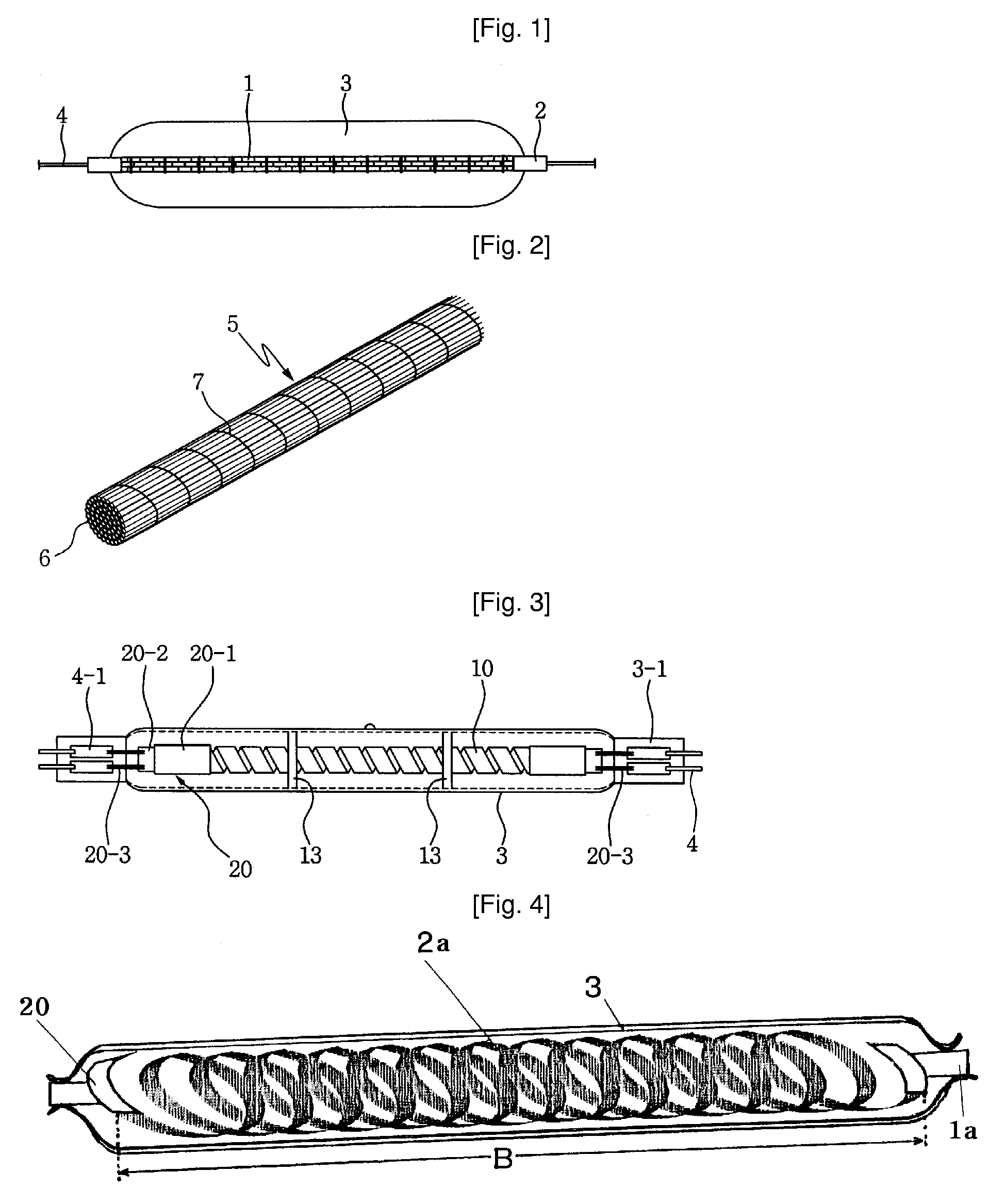

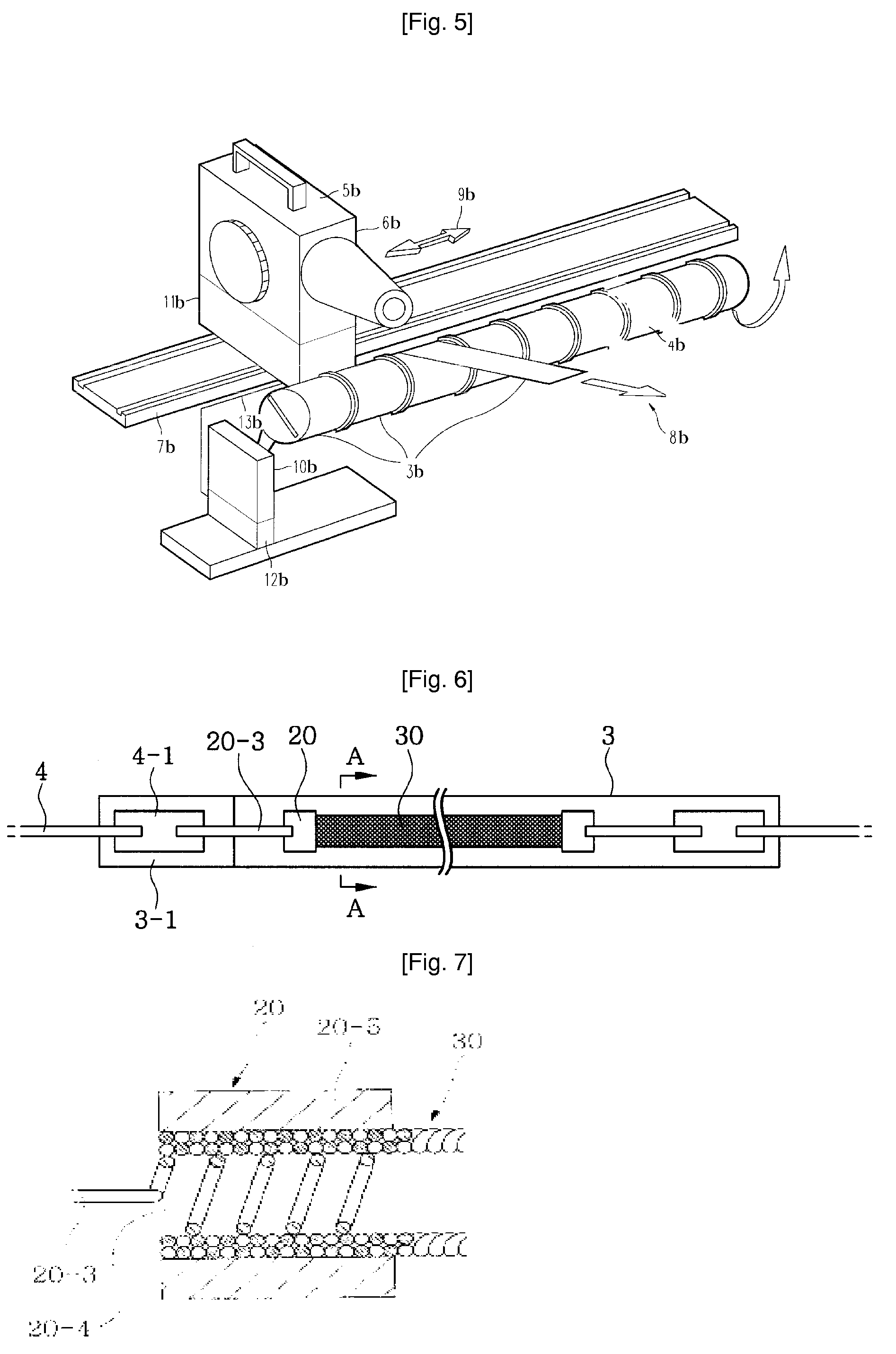

Method for Manufacturing Pipe-Type Woven Carbon Fibers and Carbon Fiber Heating Lamp Using The Pipe-Type Woven Carbon Fibers

ActiveUS20080185375A1Increased durabilityEasy to adjustCeramic shaping apparatusHeating element materialsFiberCarbon fibers

Disclosed herein are a method of manufacturing a carbon-fiber pipe which is hollow and has a net shape, by knitting carbon fibers and general fibers, applying carbon or ceramic, and heating to burn the general fibers, and a carbon fiber heating lamp using the carbon-fiber pipe. The heating lamp includes a vacuum glass tube, a tubular carbon fiber pipe (30) which is knitted using carbon fiber (6) and general fiber as a raw material and has a hollow part, and a heating element. The heating element comprises the hollow tubular carbon fiber pipe (30) which has a predetermined length and is installed in the vacuum glass tube, and generates heat using power supplied from an exterior through both terminals provided on an outer portion of the vacuum glass tube.

Owner:LG ELECTRONICS INC

Hot melting detachment prevention dynamic token and detachment prevention method of hot melting detachment prevention dynamic token

ActiveCN104092548AProblems preventing direct copying of internally stored informationPrevent theftUser identity/authority verificationHot meltInformation integration

Owner:SHANGHAI PEOPLENET SECURITY TECH

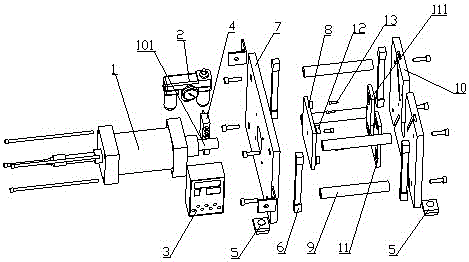

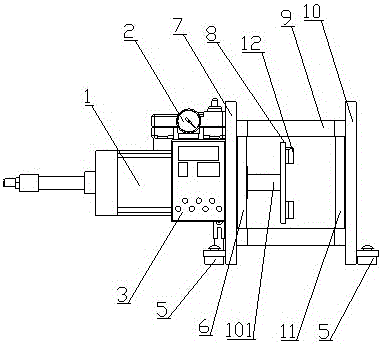

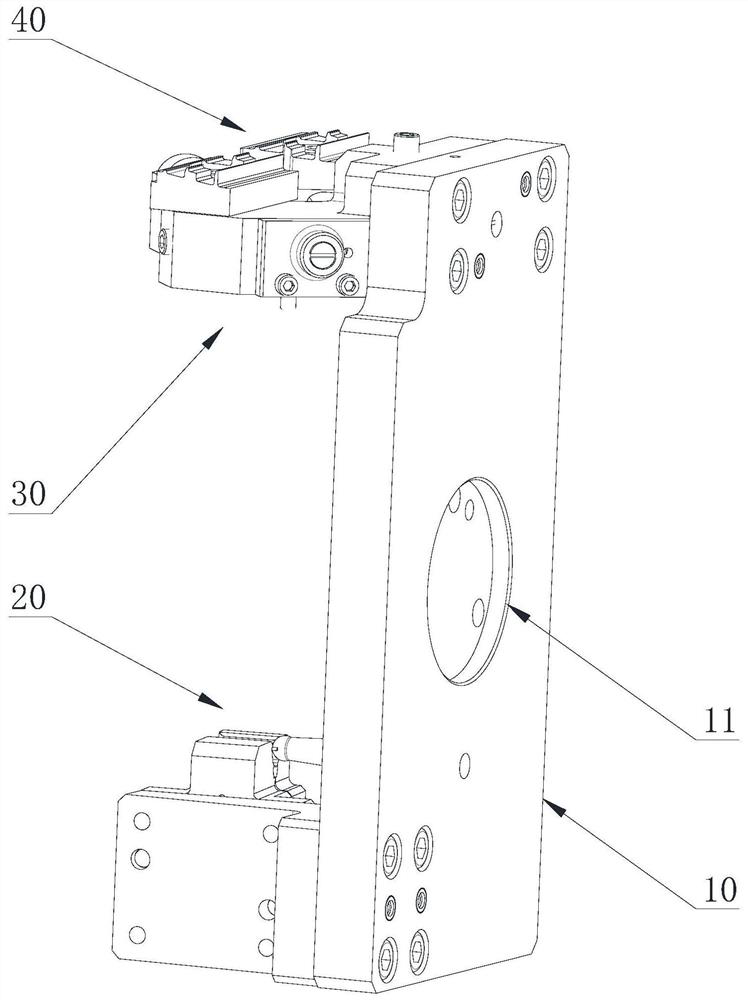

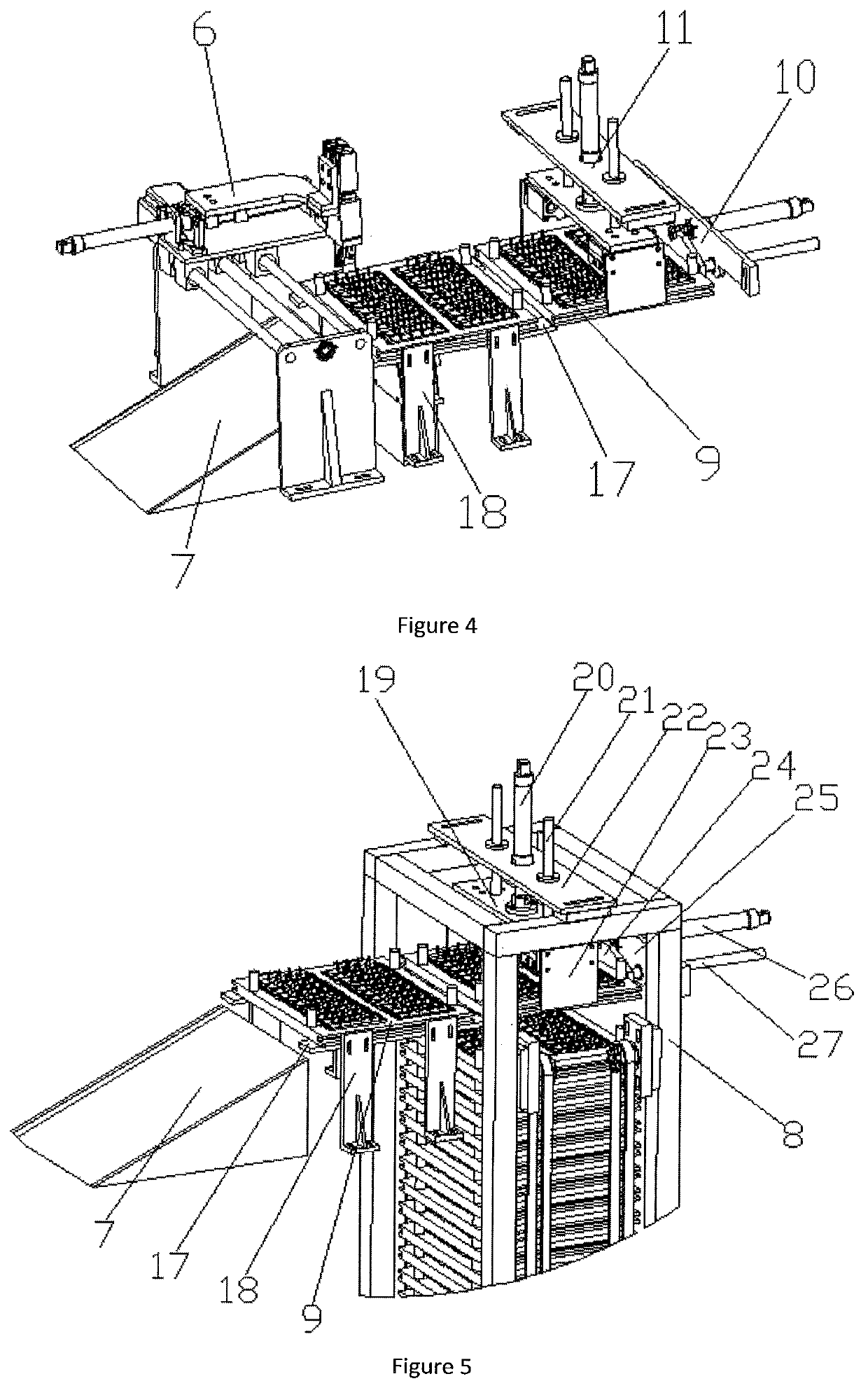

Drainage opening material cutting horizontal type device matched with mechanical arm

PendingCN107521051AImprove work efficiencyOptimize the function of mutual positioningForeign matterAir filtration

The invention discloses a drainage opening material cutting horizontal type device matched with a mechanical arm. The device comprises an air cylinder, an air filtration pressure regulating valve, a microcomputer controller, an electromagnetic valve, double-hand start buttons, safety gratings, a front fixing plate, a tool clamp, positioning guide columns, a rear fixing plate, a product fixing clamp, tools and positioning pins. Compared with the prior art, the device has the advantages that the mechanical arm takes out a product from a die and directly put the product into the clamp, different products can be produced in batches by only replacing jigs, and therefore the working efficiency can be improved; the mutual positioning function of the tool clamp and the product fixing clamp can be optimized, and therefore the precision can be improved; the shape of the tool can be optimized, and the tool can be a straight knife, a circular knife, an R-angle-shaped knife and a circular-arc-shaped knife; in the working process, if any foreign matter enters the safe working area, the safety gratings can perform detection automatically, give a signal to equipment, give an alarm and stop working, and therefore the safety coefficient can be improved; the function of the double-hand start buttons is adopted, and therefore the phenomenon that accidents occur in the debugging process of the equipment can be avoided.

Owner:苏州默斯曼尔机械科技有限公司

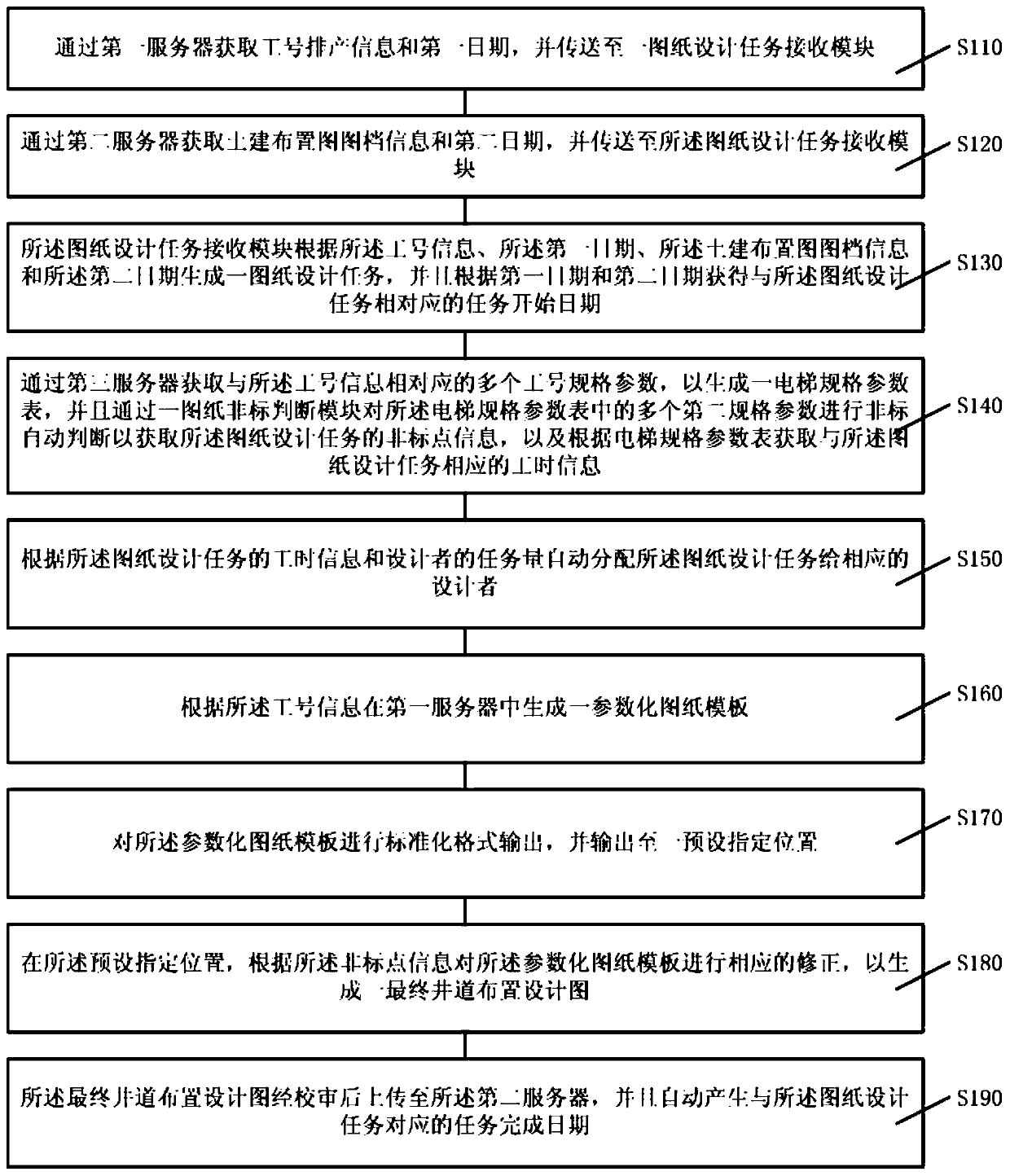

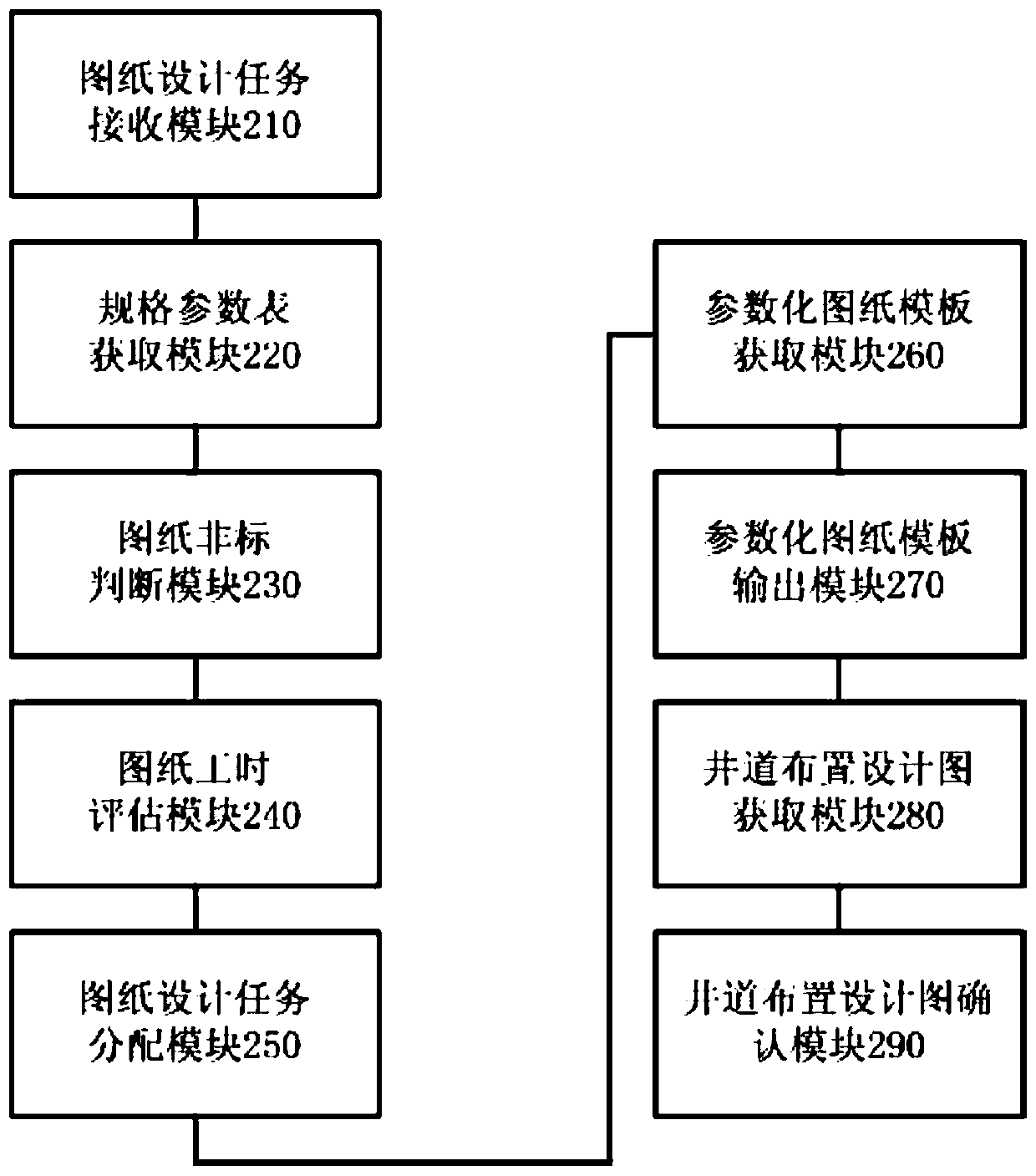

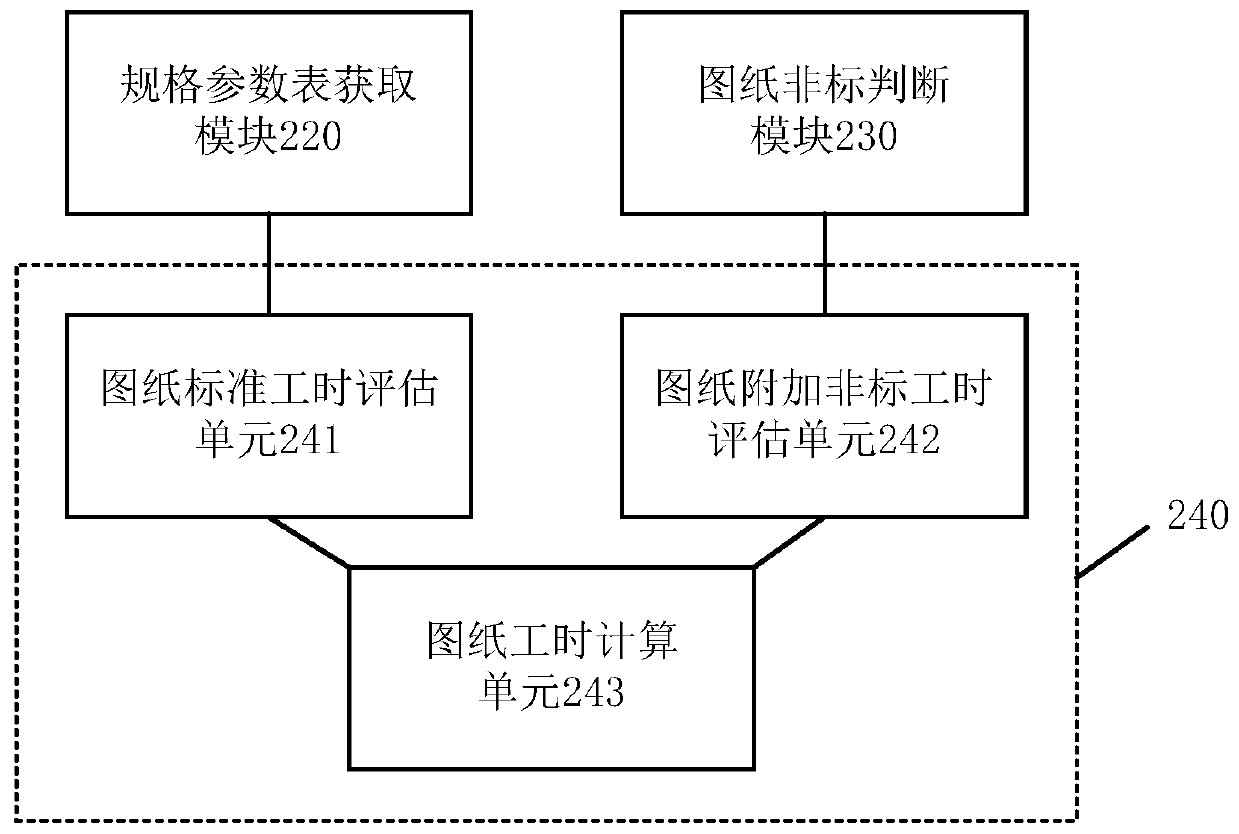

Hoistway arrangement diagram design plan management automation method and system

ActiveCN109977489AReduce query timeImprove design efficiencyGeometric CADSpecial data processing applicationsDesign planInformatization

The invention discloses a hoistway arrangement diagram design plan management automation method and system, which utilize an informatization technology to realize hoistway arrangement diagram design plan management automation so as to improve the working efficiency.

Owner:HITACHI ELEVATOR SHANGHAI +1

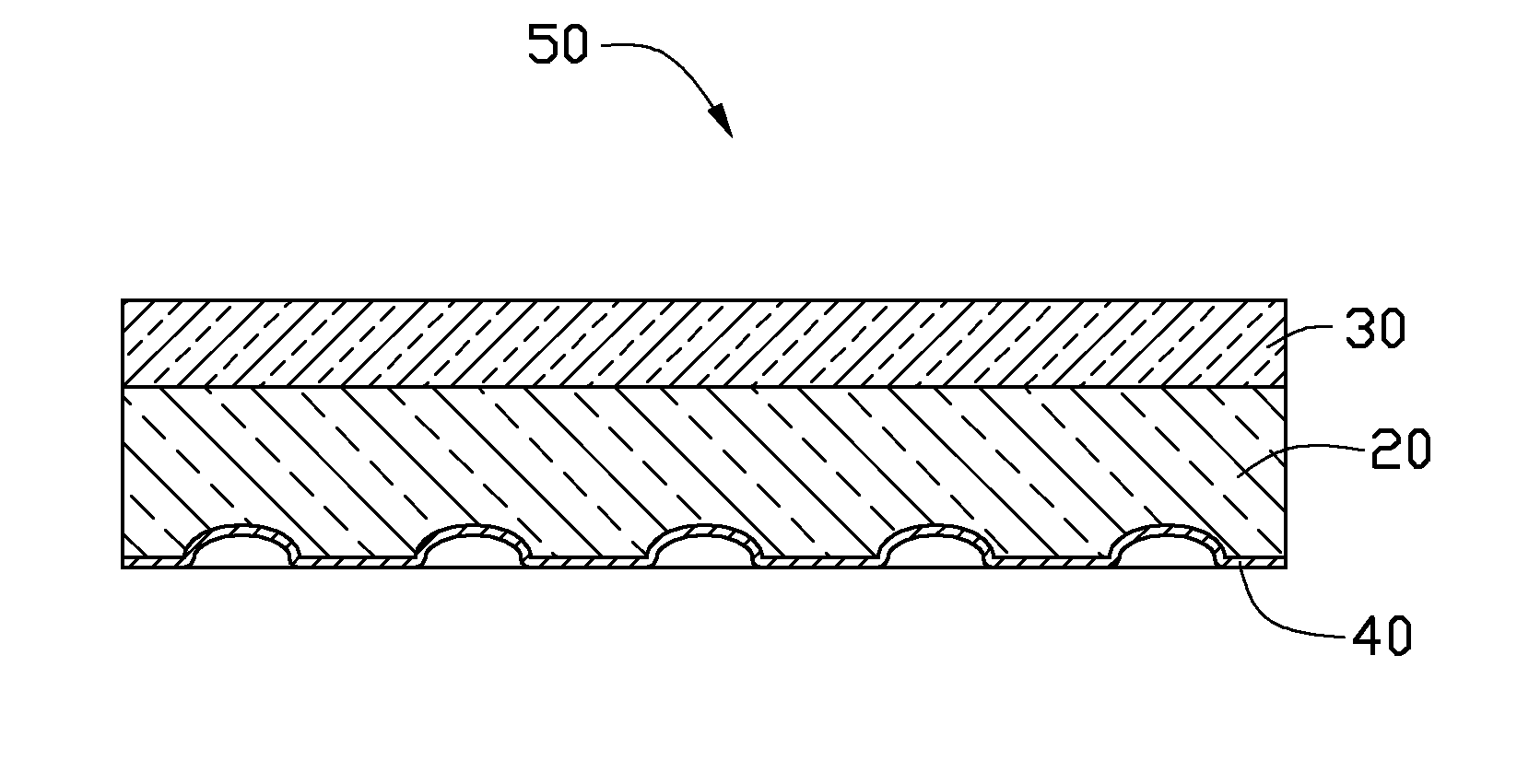

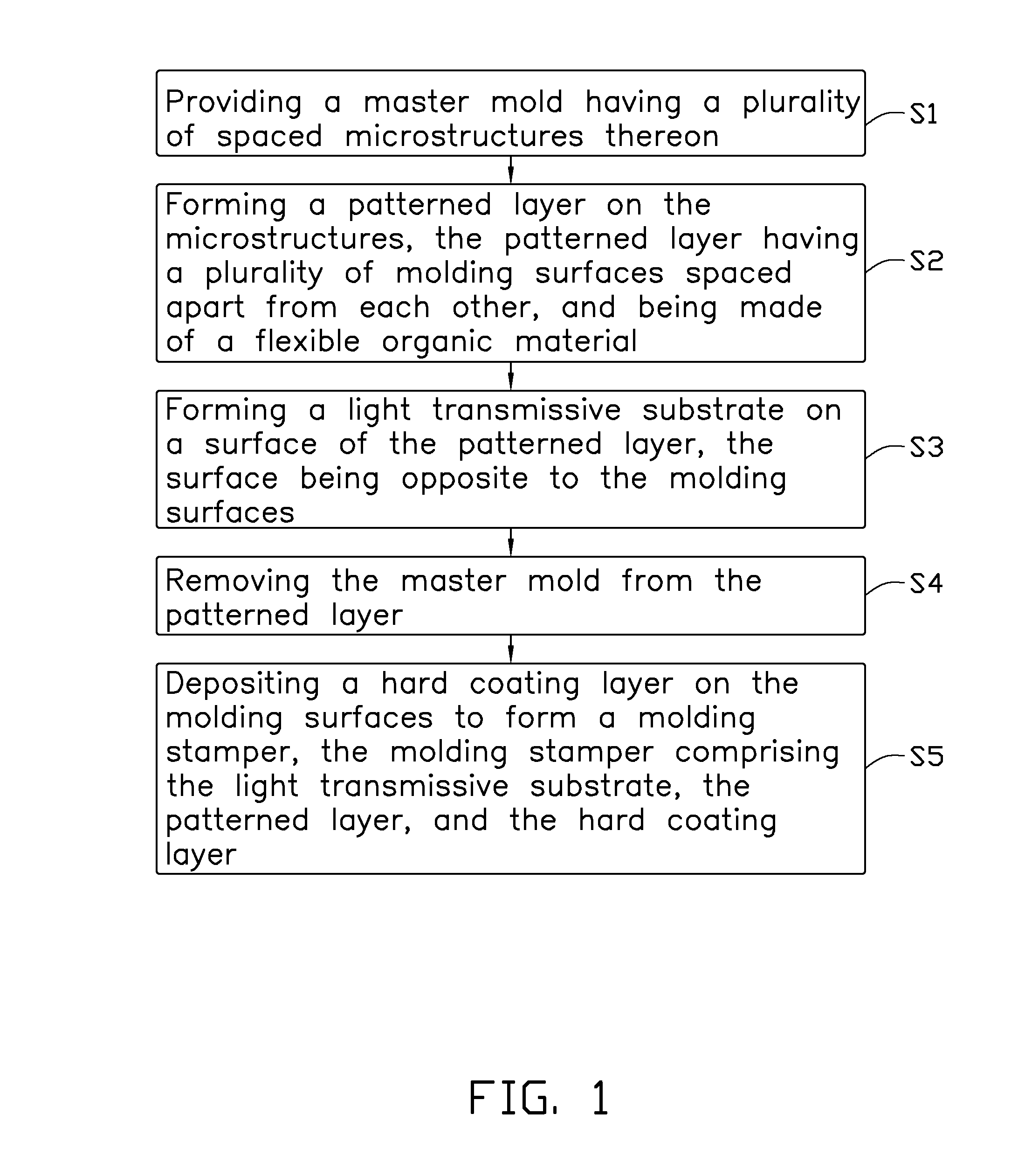

Molding stamper and method for fabricating same

InactiveUS20100301517A1Low productionImprove surface roughnessDough-sheeters/rolling-machines/rolling-pinsConfectioneryShell moldingMicrostructure

An exemplary method for fabricating a molding stamper includes the following steps. Firstly, a master mold having microstructures spaced apart from each other is provided. Secondly, a patterned layer is formed on the microstructures, the patterned layer having molding surfaces apart from each other, and being made of a flexible organic material. Thirdly, the master mold is removed from the patterned layer. Finally, a hard coating layer is deposited on the molding surfaces to form a molding stamper.

Owner:HON HAI PRECISION IND CO LTD

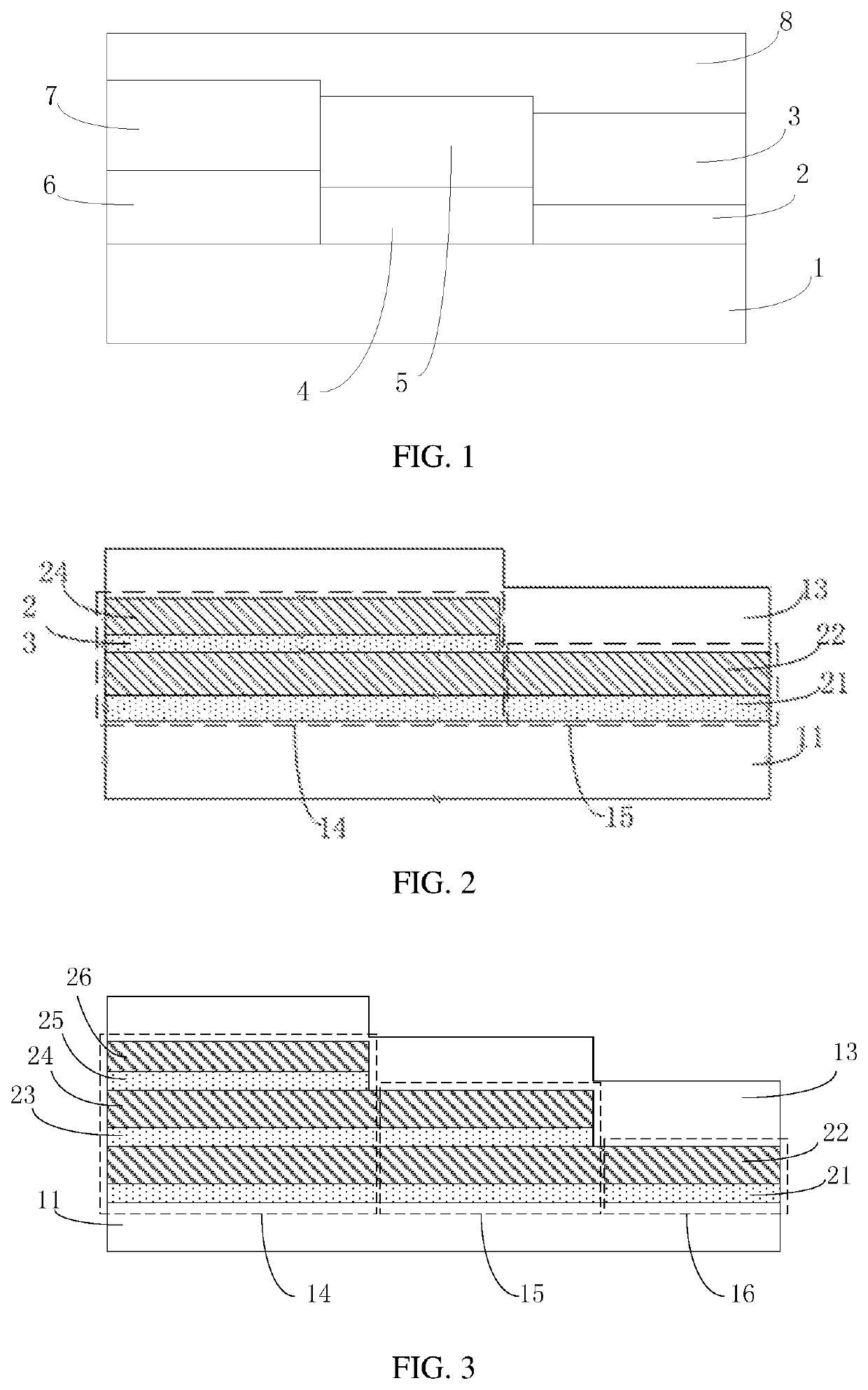

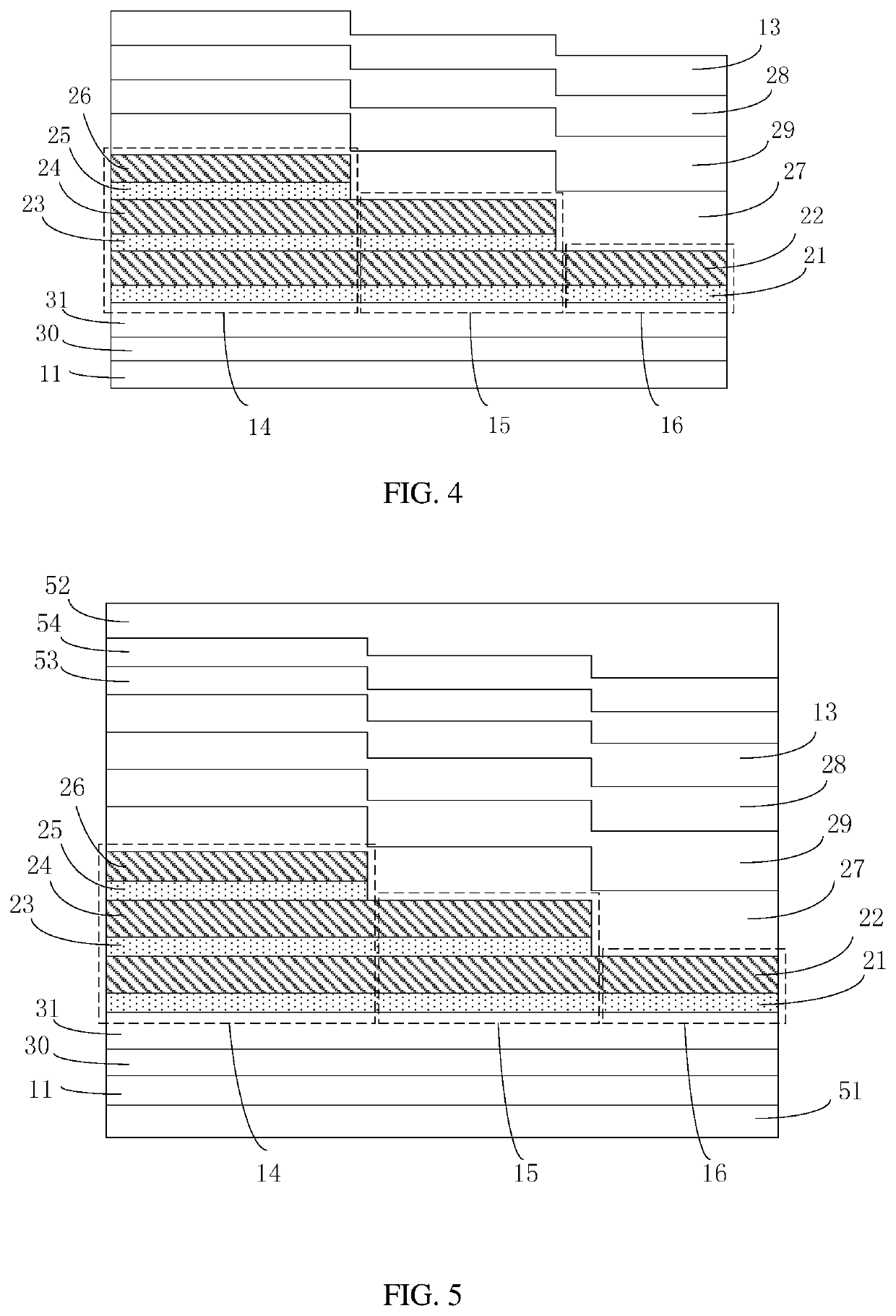

Organic electroluminescent device and display panel

ActiveUS20200411789A1Simple structureReduce usageSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceElectron blocking layer

The invention discloses an organic electroluminescent device and a display panel. The organic electroluminescent device includes: a first electron blocking layer and a first light emitting layer in a first pixel region, a first electron blocking layer, a first light emitting layer, a second electron blocking layer, and a second light emitting layer in a second pixel region, and a first electron blocking layer, a first light emitting layer, a second electron blocking layer, a second light emitting layer, a third electron blocking layer, and a third light emitting layer in the third pixel region.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON

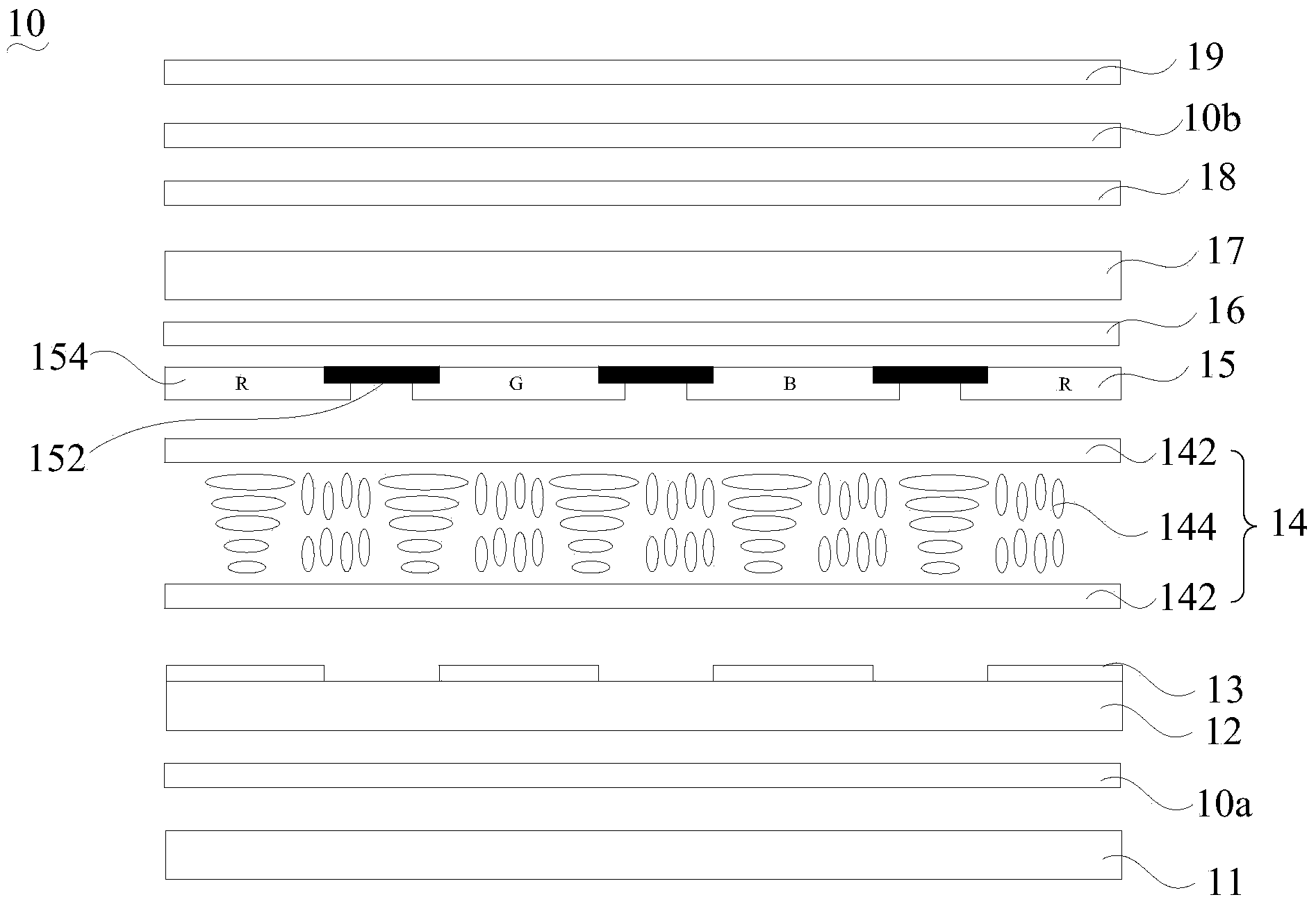

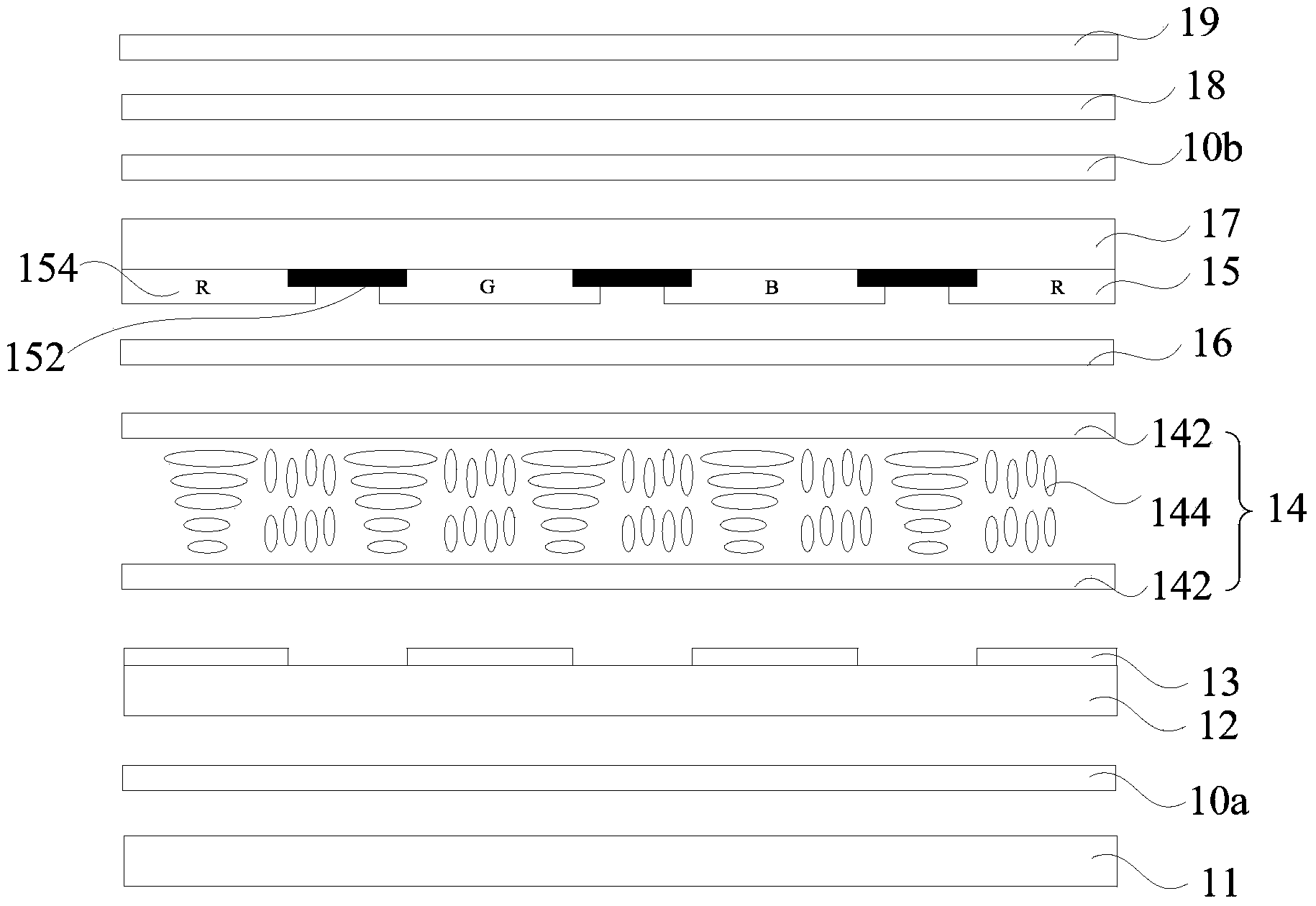

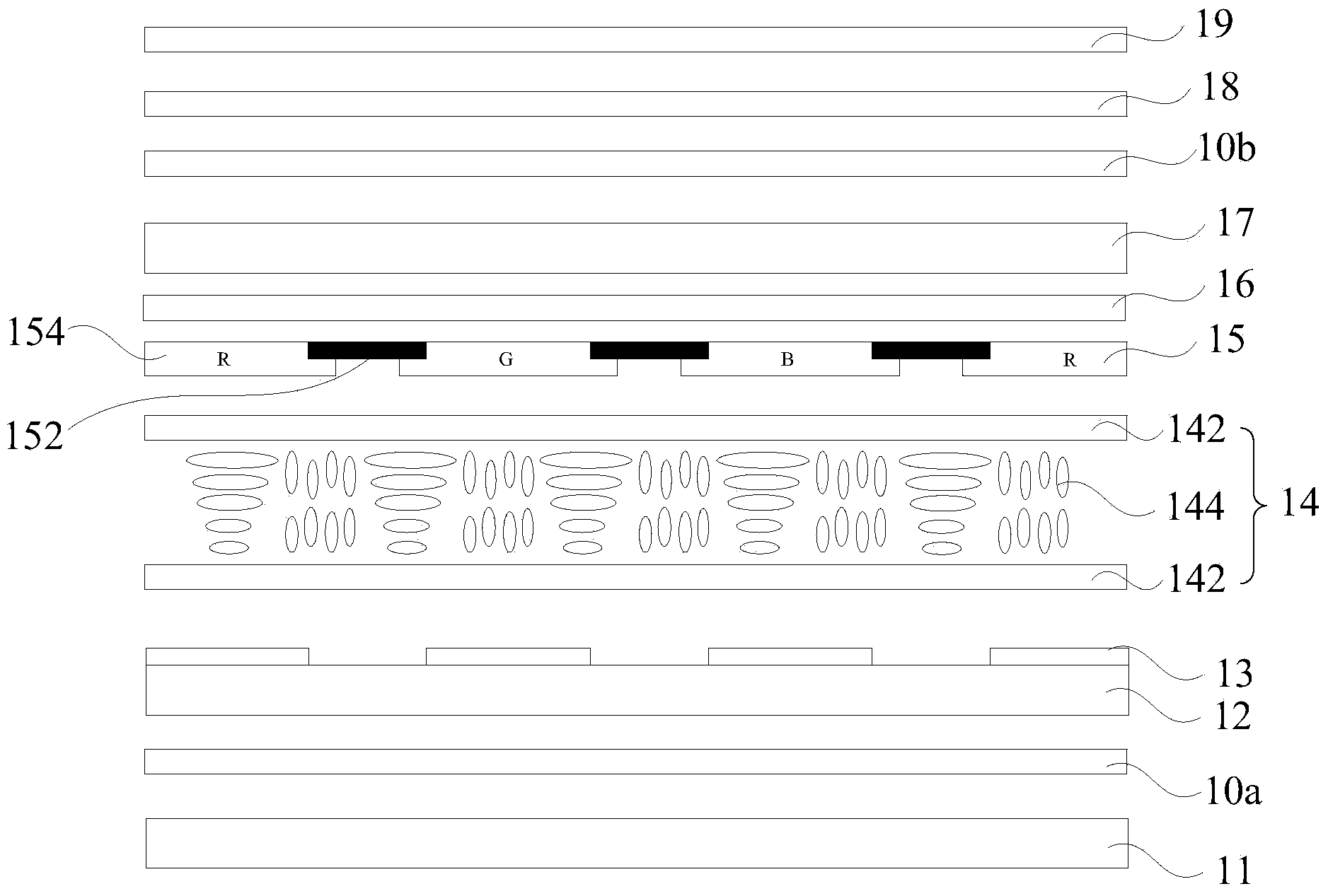

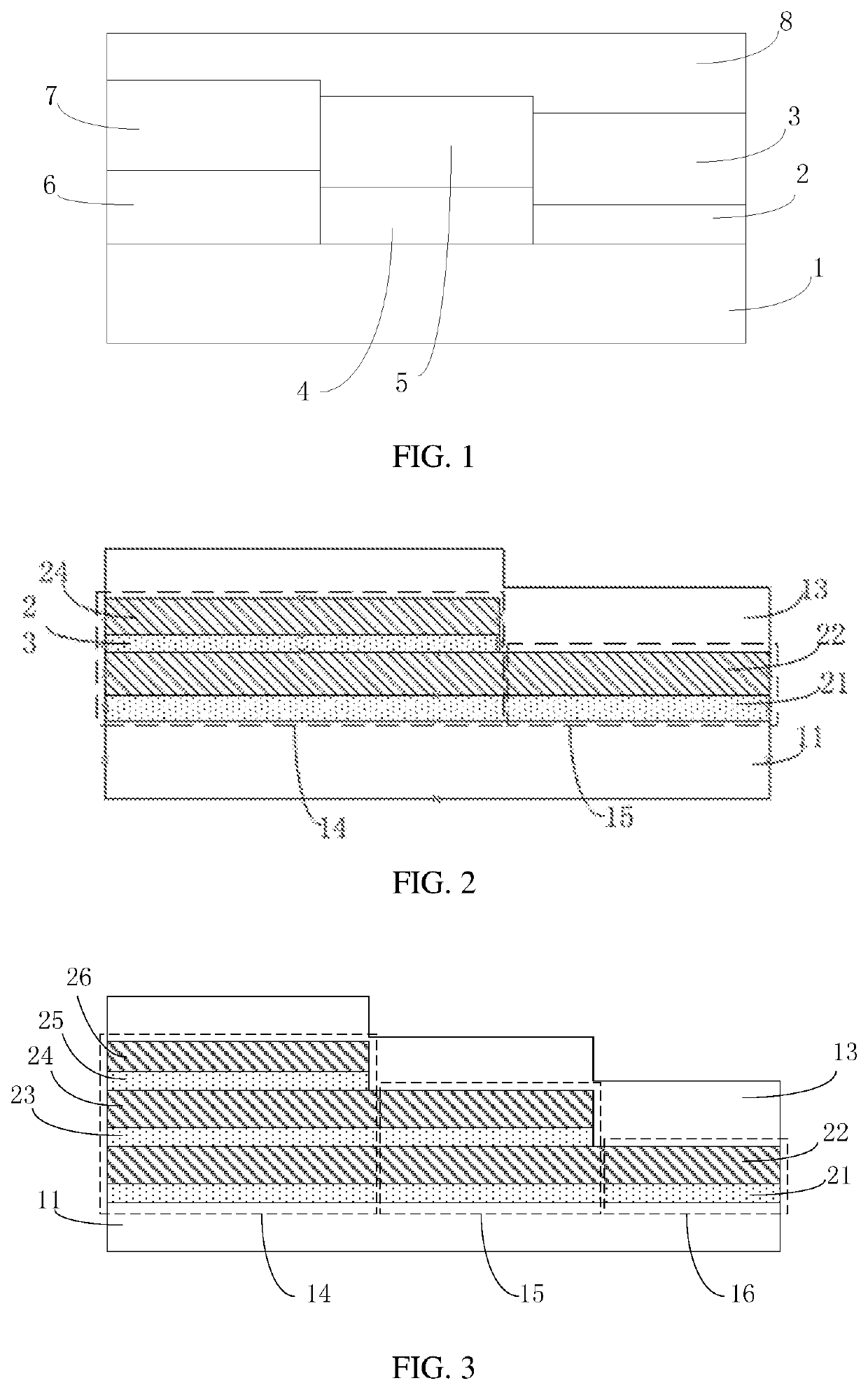

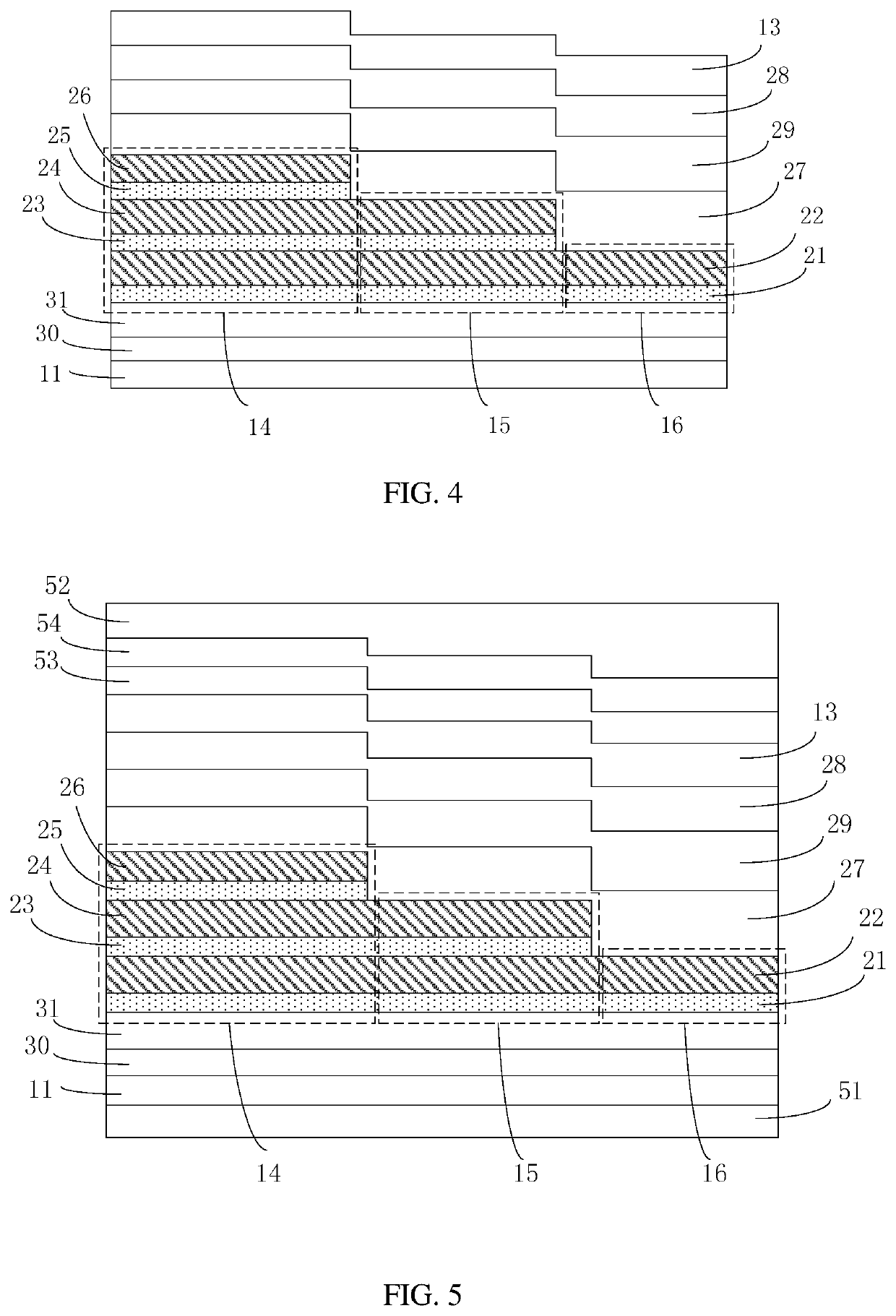

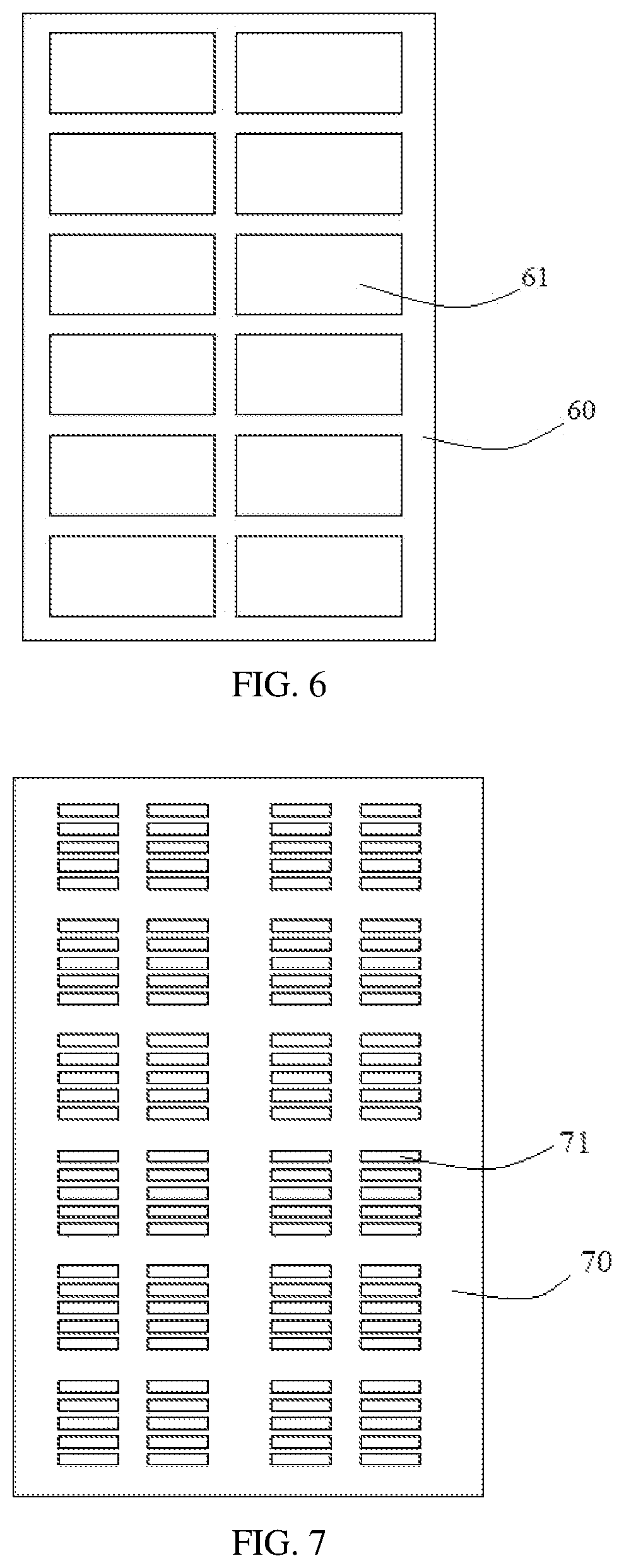

Touch display screen

InactiveCN104238859AWith display functionWith touch functionNon-linear opticsInput/output processes for data processingEngineeringLiquid crystal molecule

The invention provides a touch display screen. The touch display screen comprises a first substrate, a liquid crystal module, a filter layer, a second substrate and a first polaroid, wherein the first substrate, the liquid crystal module, the filter layer, the second substrate and the first polaroid are stacked in sequence; the surface, facing one side of the liquid crystal module, of the first substrate is provided with TFT (thin film transistor) electrodes; one side, facing the liquid crystal module, of the second substrate is provided with common electrodes; the TFT electrodes and the common electrodes are used for jointly controlling the arrangement state of liquid crystal molecules in the liquid crystal module; the touch display screen also comprises a transparent conducting layer arranged on the surface, backing on to one side of the liquid crystal module, of the second substrate or the surface of the first polaroid; the transparent conducting layer comprises a matrix and conducting nanometer wires filled in the matrix; the matrix is solidified transparent photosensitive resin; the transparent conducting layer is patterned to form touch electrodes; the touch electrodes are matched with the common electrodes to form a double-layer touch induction structure, and the double-layer touch induction structure is used for determining coordinates of a touch point. The touch display screen has the characteristics of being thin and low in production cost.

Owner:NANCHANG O FILM TECH CO LTD +2

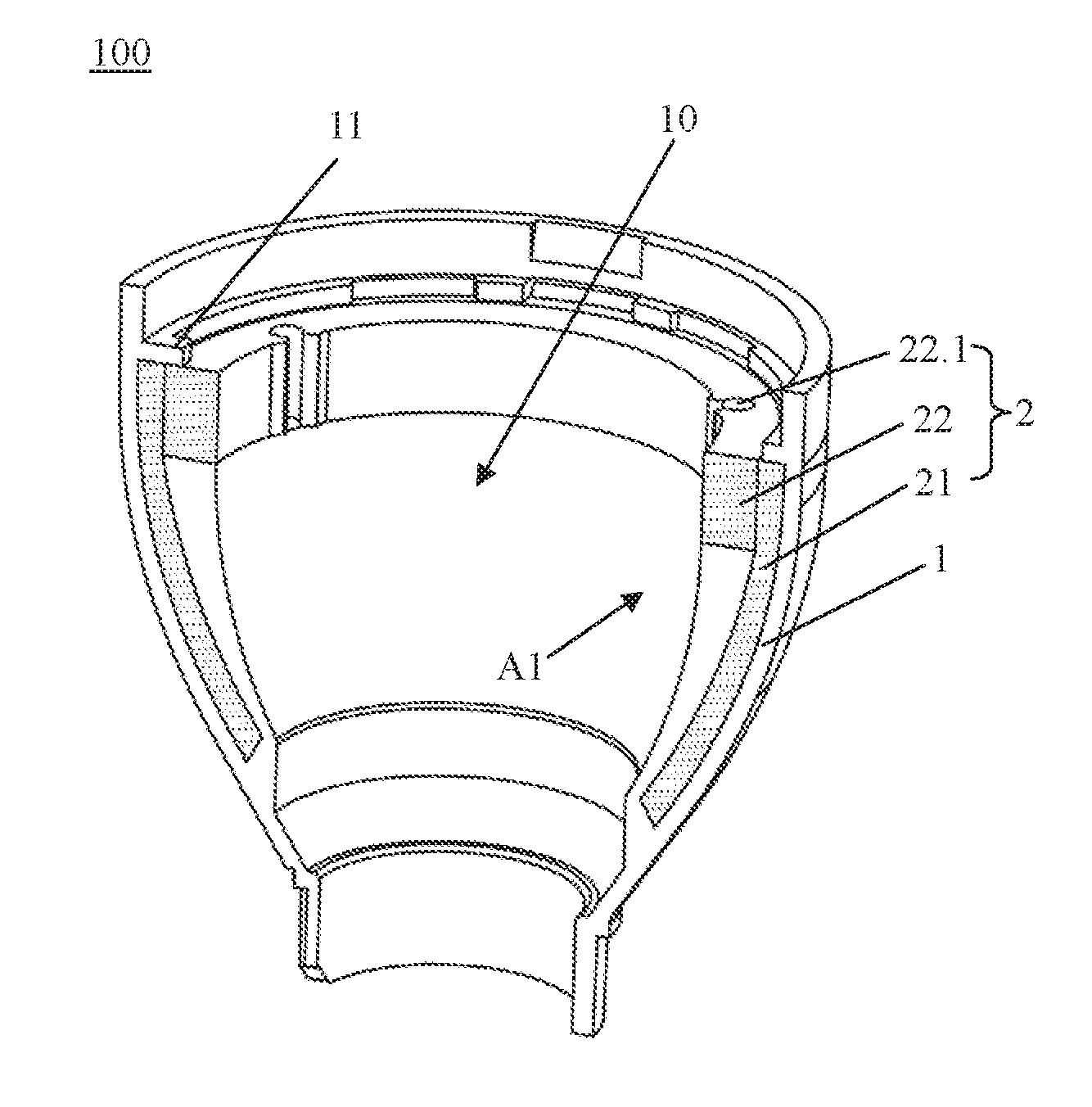

Lamp holder and manufacturing method thereof and illuminating device having the lamp holder

InactiveUS20160138793A1Reduce defective rateEasy to manufactureLighting heating/cooling arrangementsProtective devices for lightingBiochemical engineeringComputer module

Various embodiments may relate to a lamp holder of a lighting module, including a first housing and a second housing made from different materials, wherein the second housing includes a body part and an assembling part in thermal contact with each other, wherein the second housing is embedded integrally in the first housing and in thermal contact with the first housing, and the assembling part and the body part are installed together. In addition, various embodiments further relate to a method for manufacturing the lamp holder and an illuminating device having the lamp holder.

Owner:LEDVANCE GMBH

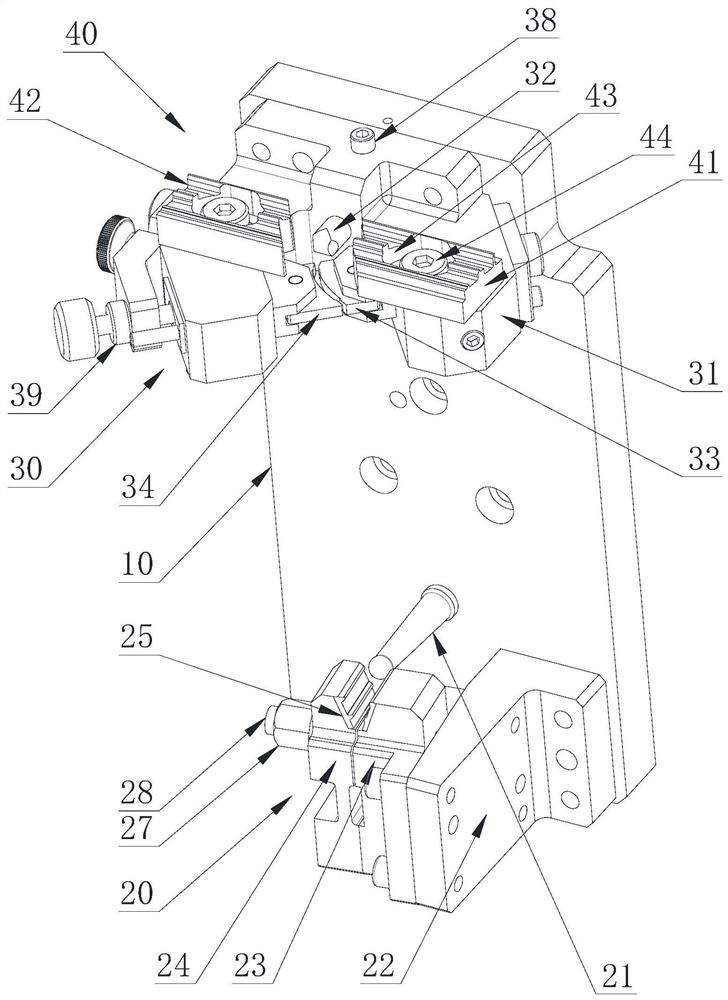

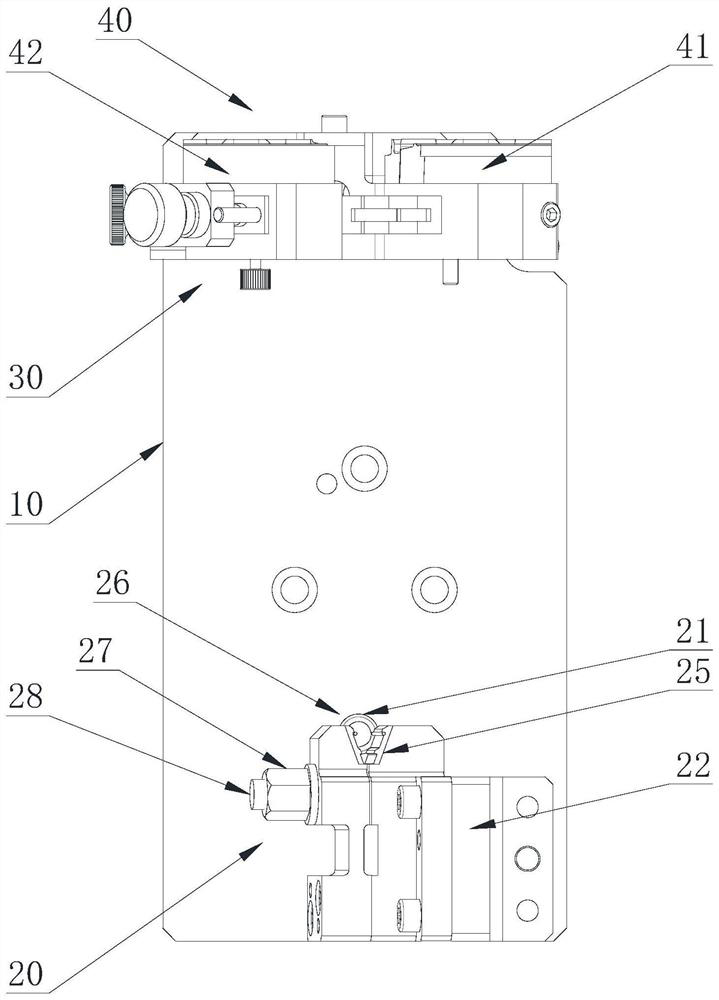

Turbine blade sealing tooth machining clamp and clamping method thereof

InactiveCN113478262AAvoid tremorsAvoid deformationPositioning apparatusMetal-working holdersTurbine bladeEngineering

The invention discloses a turbine blade sealing tooth machining clamp and a clamping method thereof, and belongs to the technical field of aero-engines. The turbine blade sealing tooth machining clamp comprises a base, a tenon clamping assembly, a blade tip clamping assembly and a blade crown clamping assembly. The tenon clamping assembly is used for clamping the tenon portion of a turbine blade and comprises a positioning ball, a tenon support, a tooth base and a tooth block. The blade tip clamping assembly is used for clamping the blade tip portion, close to a blade crown, of the turbine blade. The blade crown clamping assembly is used for clamping the blade crown portion of the turbine blade. The two ends of the turbine blade are clamped respectively, the blade tip portion close to sealing teeth is fixed, and therefore the system rigidity of a workpiece and the clamp is increased, and the situation that the reject ratio is high due to vibration and deformation generated during machining of the sealing teeth is avoided.

Owner:AECC AERO SCI & TECH CO LTD

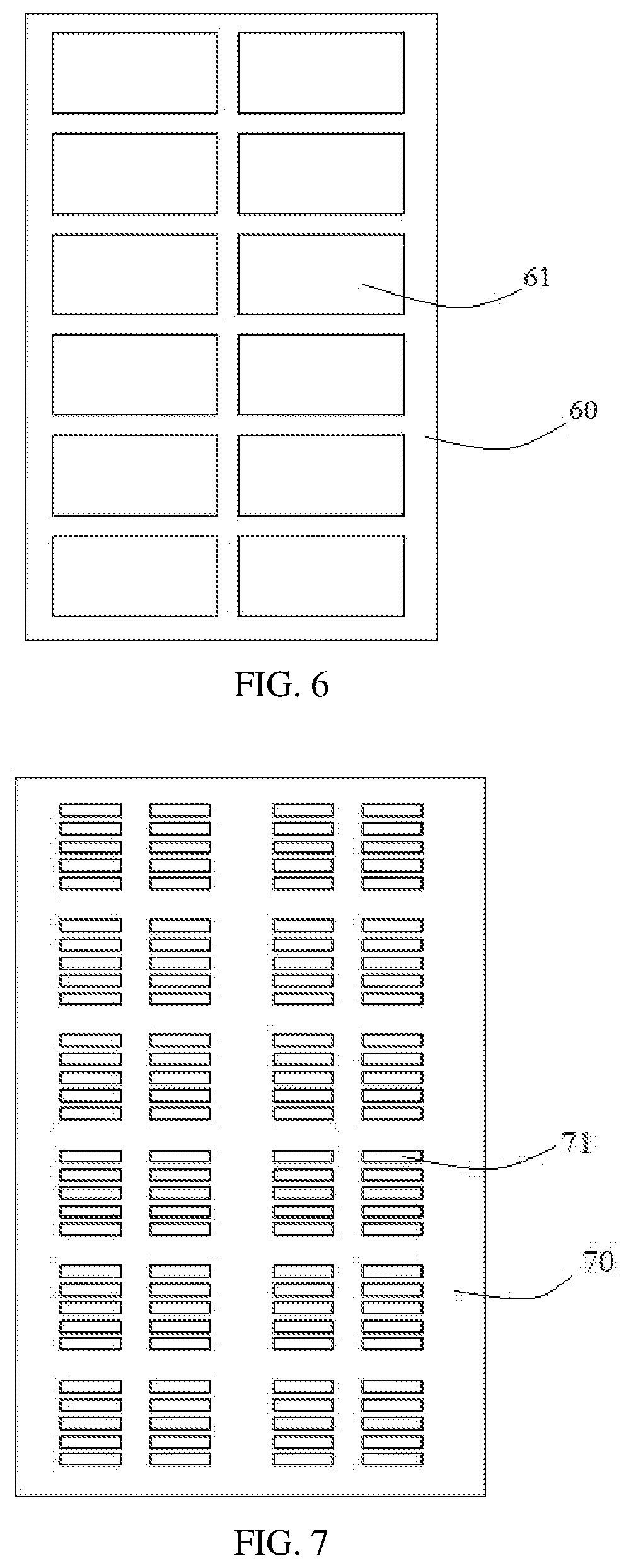

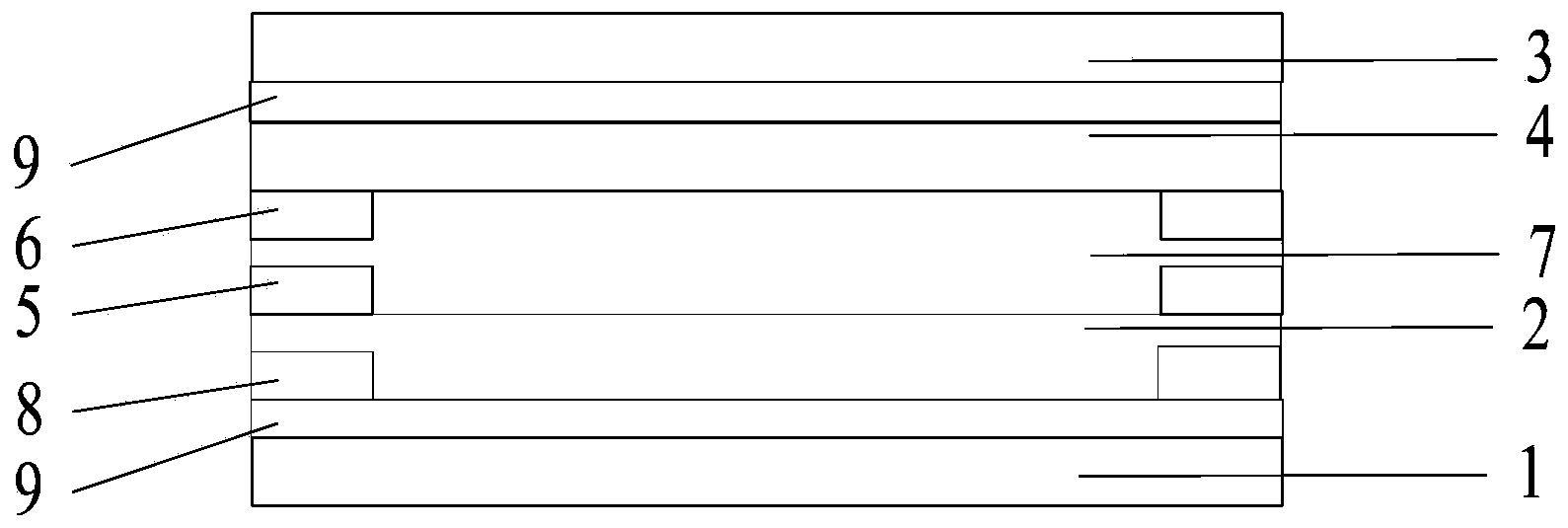

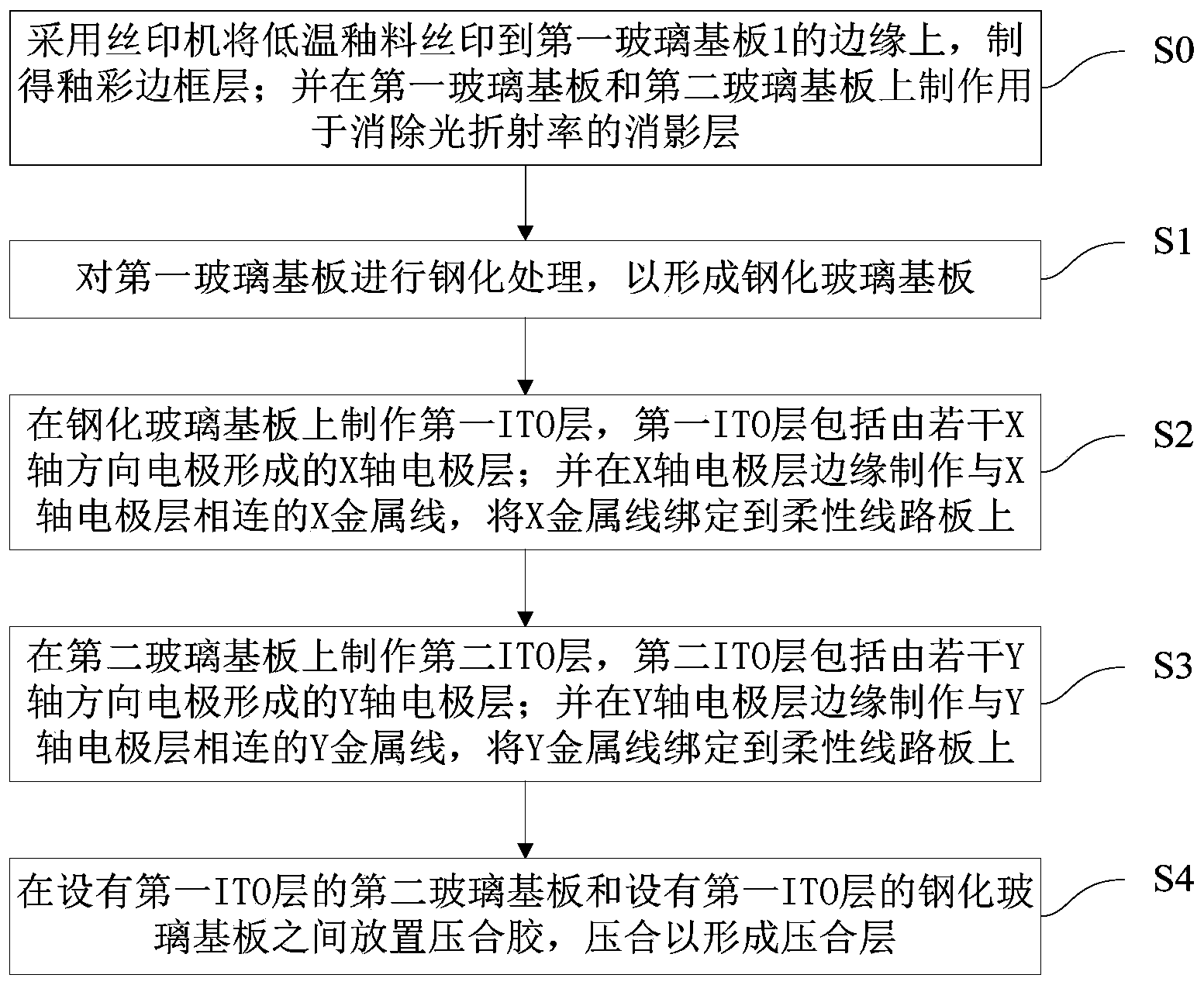

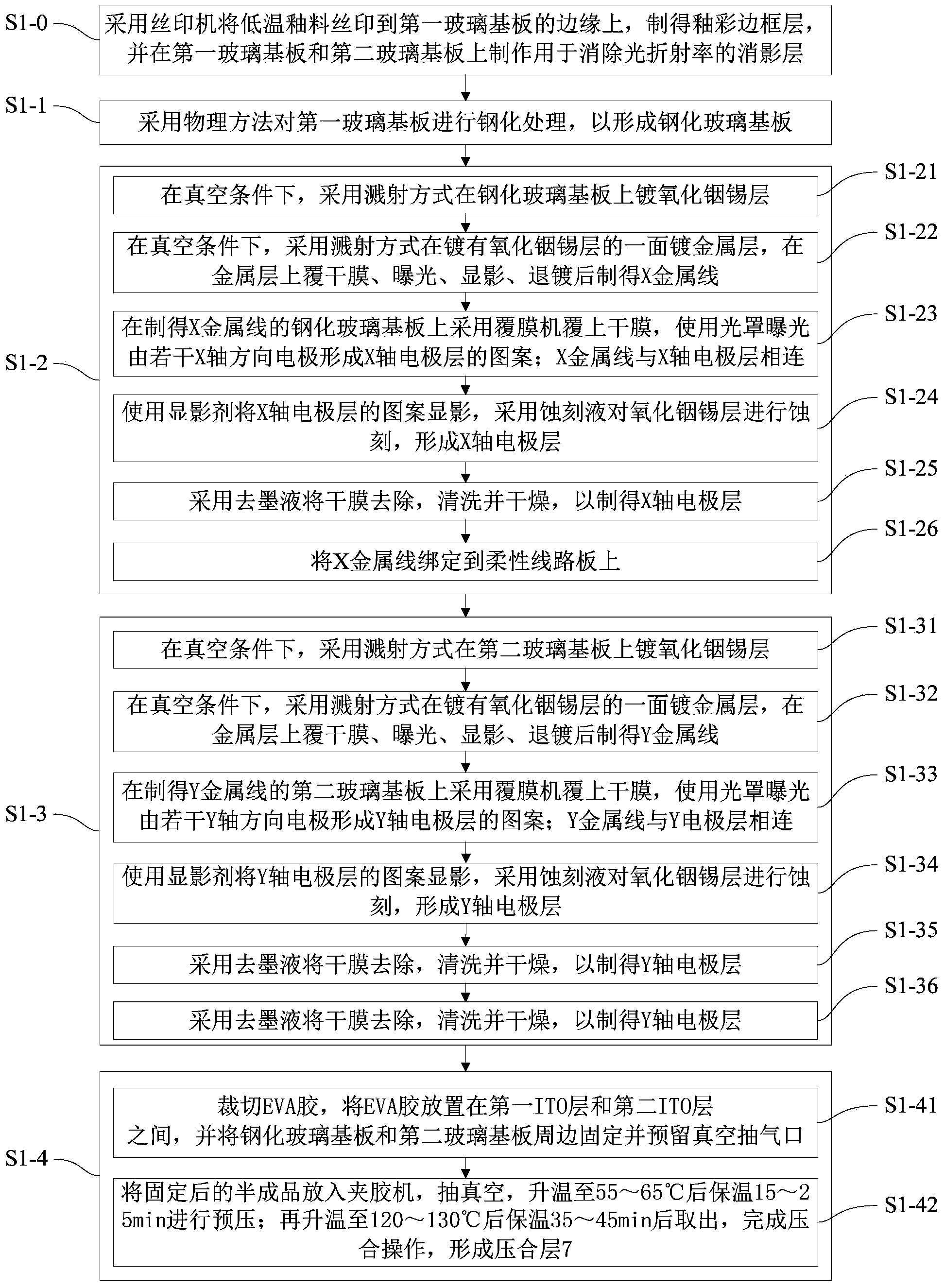

High-strength projection-type capacitive screen and manufacturing method thereof

InactiveCN104049823AHigh compressive strengthHigh defect rateInput/output processes for data processingFlexible circuitsUltimate tensile strength

The invention discloses a high-strength projection-type capacitive screen and a manufacturing method of the capacitive screen. The high-strength projection-type capacitive screen comprises a first glass substrate, a first ITO layer, a second glass substrate and a second ITO layer, wherein the first ITO layer is arranged on the first glass substrate, and the second ITO layer is arranged on the second glass substrate. The first ITO layer is connected with the second ITO layer through a lamination layer. The first glass substrate is a tempered glass substrate. The first ITO layer includes an X-axis electrode layer formed by a plurality of electrodes in the X-axis direction. The second ITO layer includes a Y-axis electrode layer formed by a plurality of electrodes in the Y-axis direction. The edge of the X-axis electrode layer is further provided with a metal wire X connected with the X-axis electrode layer. The edge of the Y-axis electrode layer is further provided with a metal wire Y connected with the Y-axis electrode layer. The metal wire X and the metal wire Y are respectively connected with a flexible circuit board. The lamination layer is an EVA glue layer or a PVB glue layer. The projection-type capacitive screen is high in impact strength; in addition, bridging process is omitted from the manufacturing method, and therefore the product yield can be effectively increased.

Owner:向火平

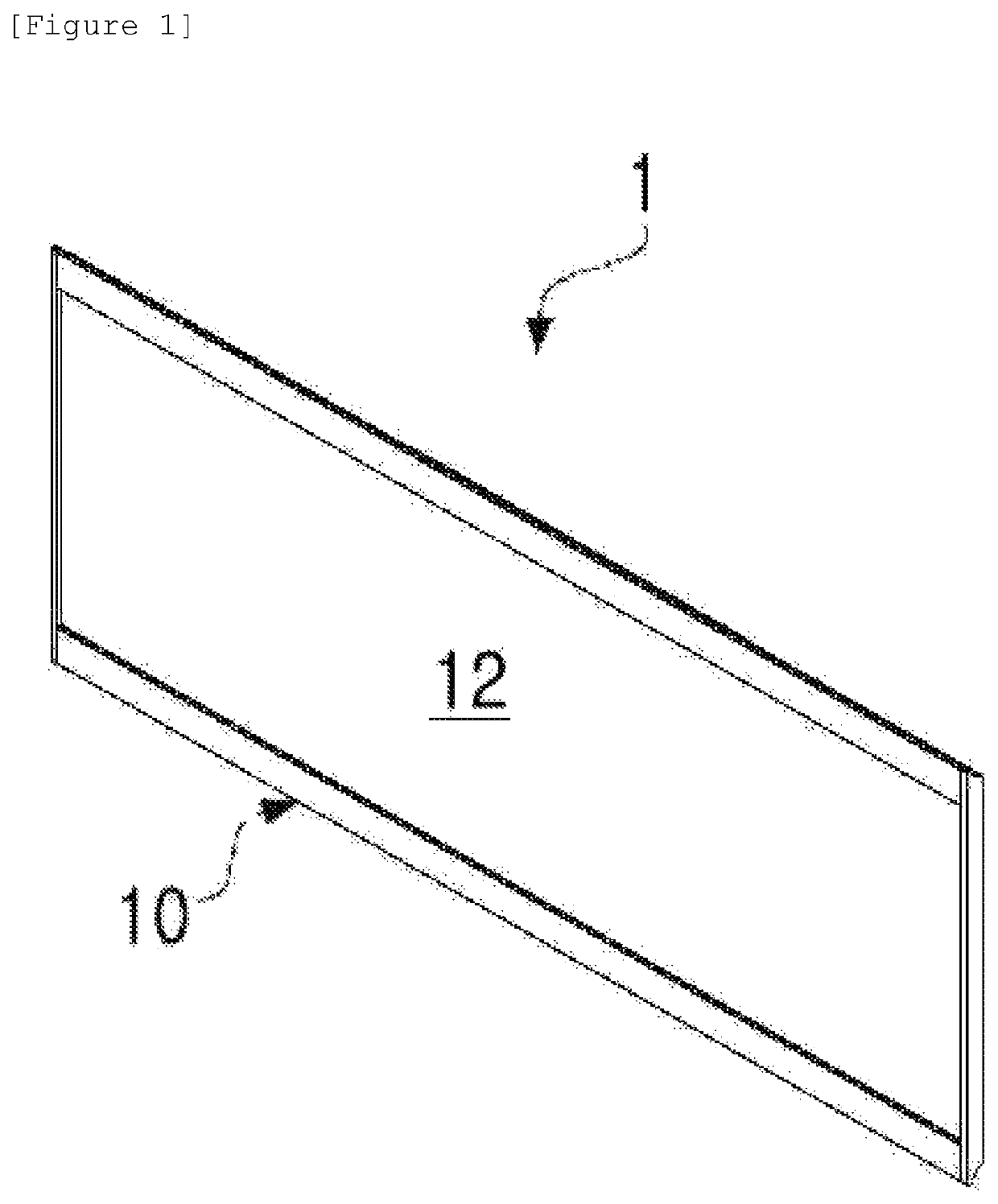

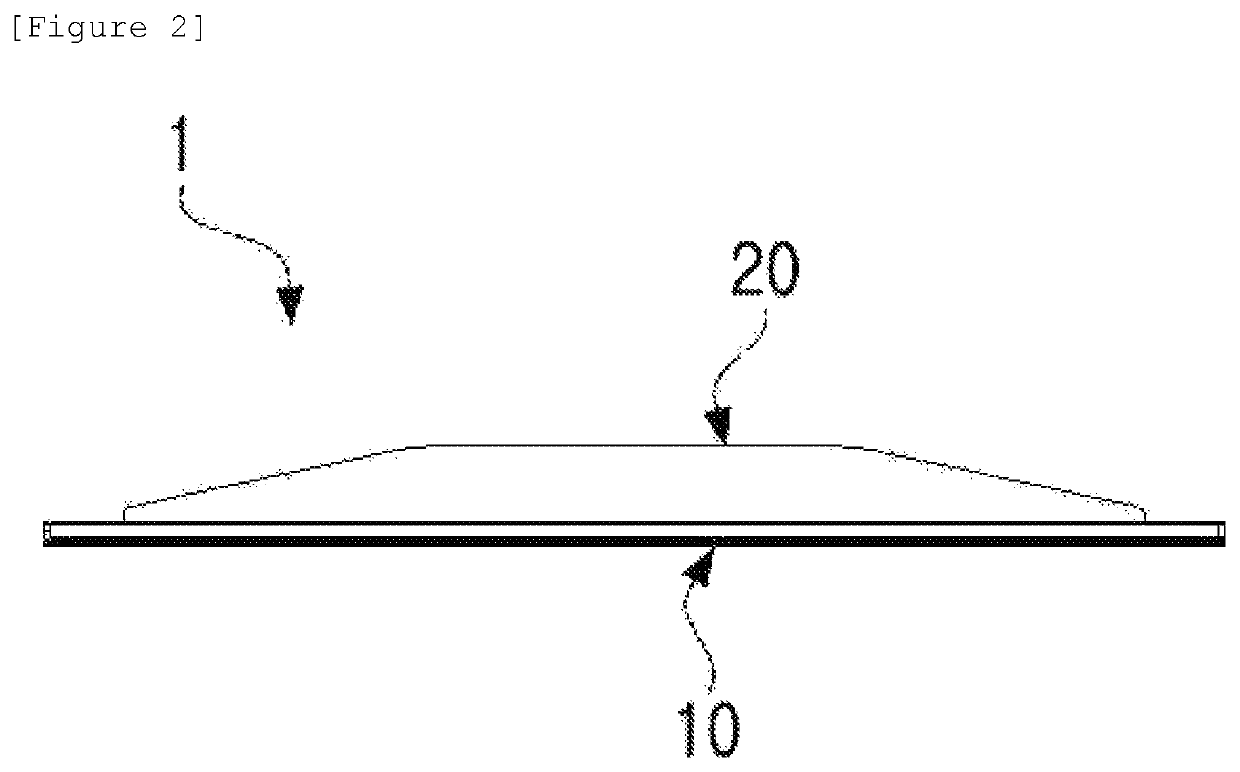

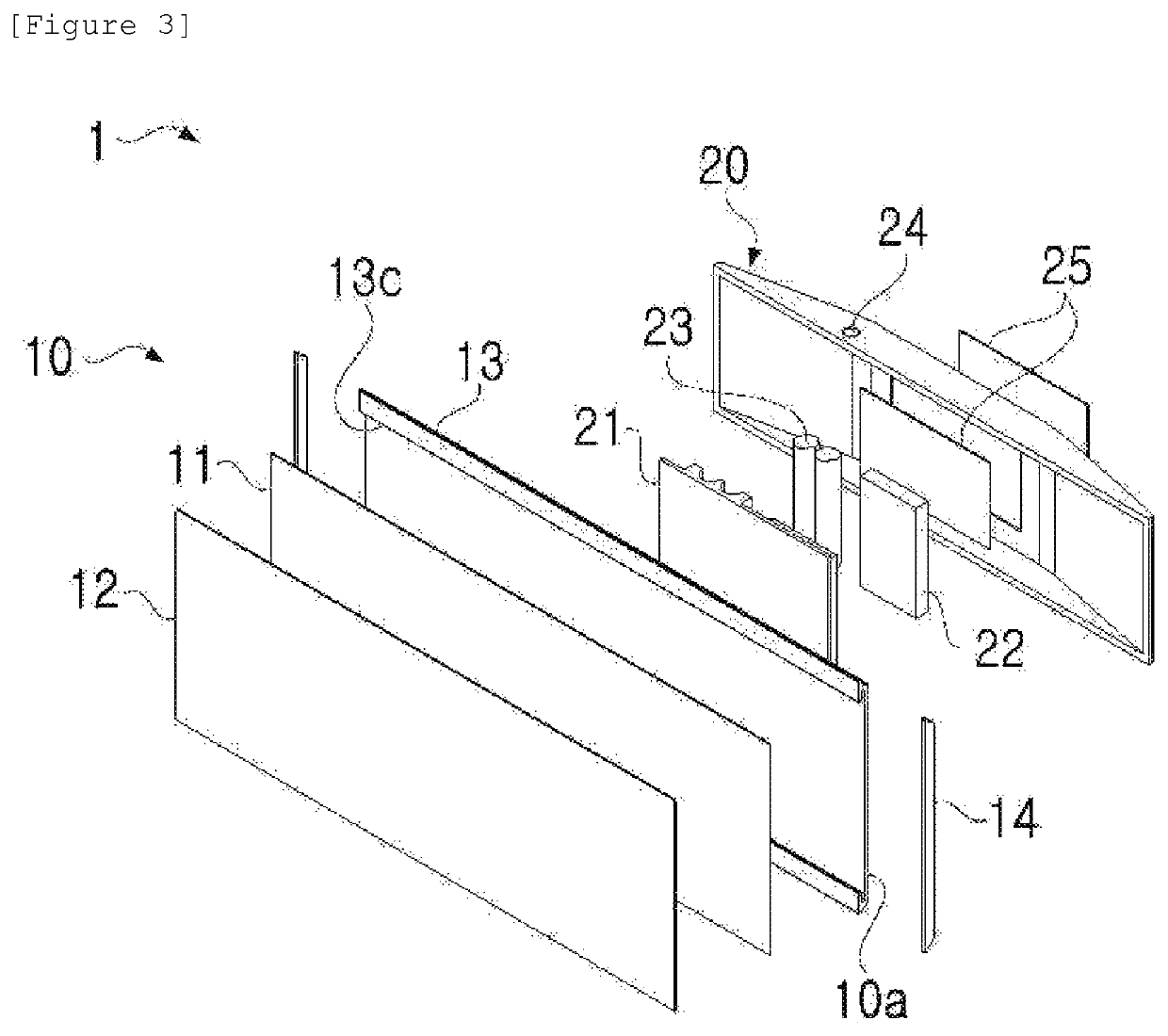

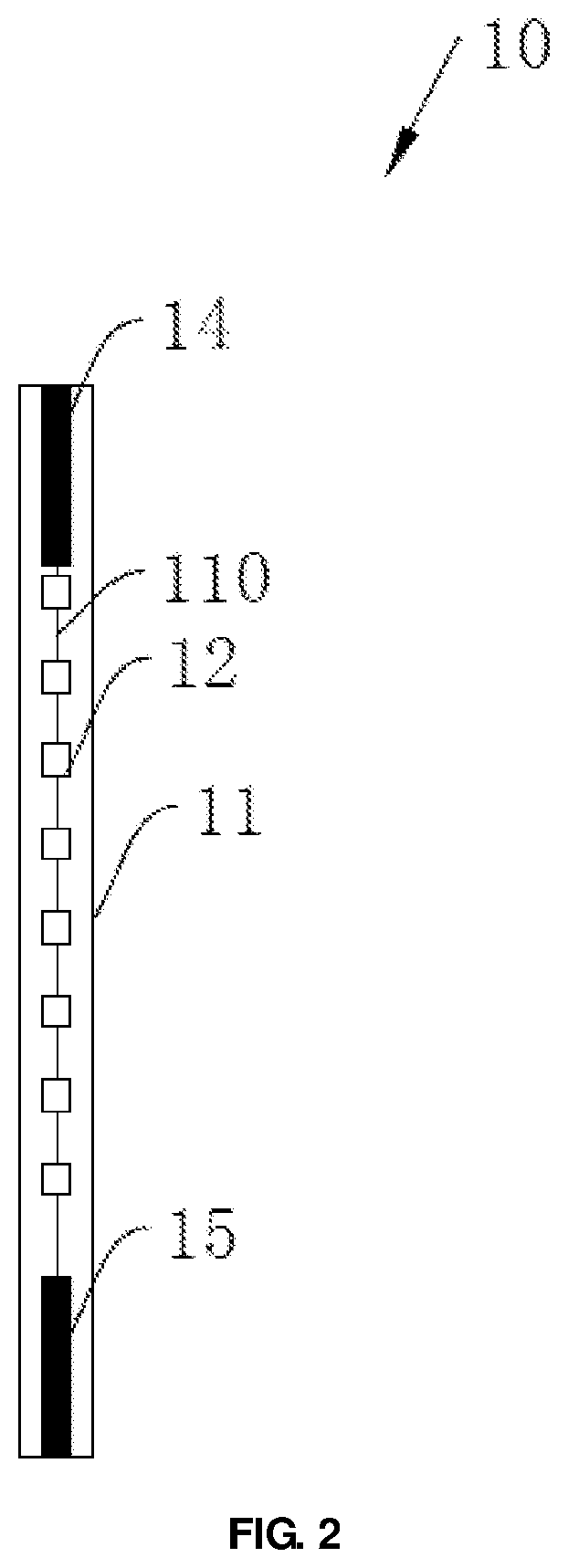

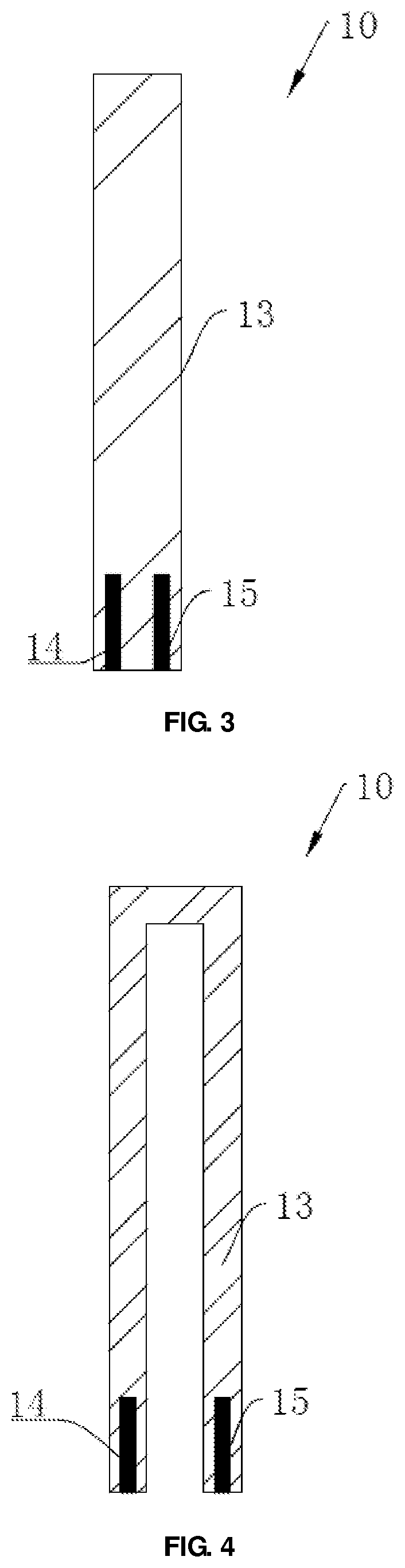

Multipurpose assistance lamp with OLED lighting sheet housing structure

ActiveUS10563826B2Increase brightnessSlim and elegant in designPlanar light sourcesLighting support devicesElectrical batteryMaterials science

Owner:LG DISPLAY CO LTD

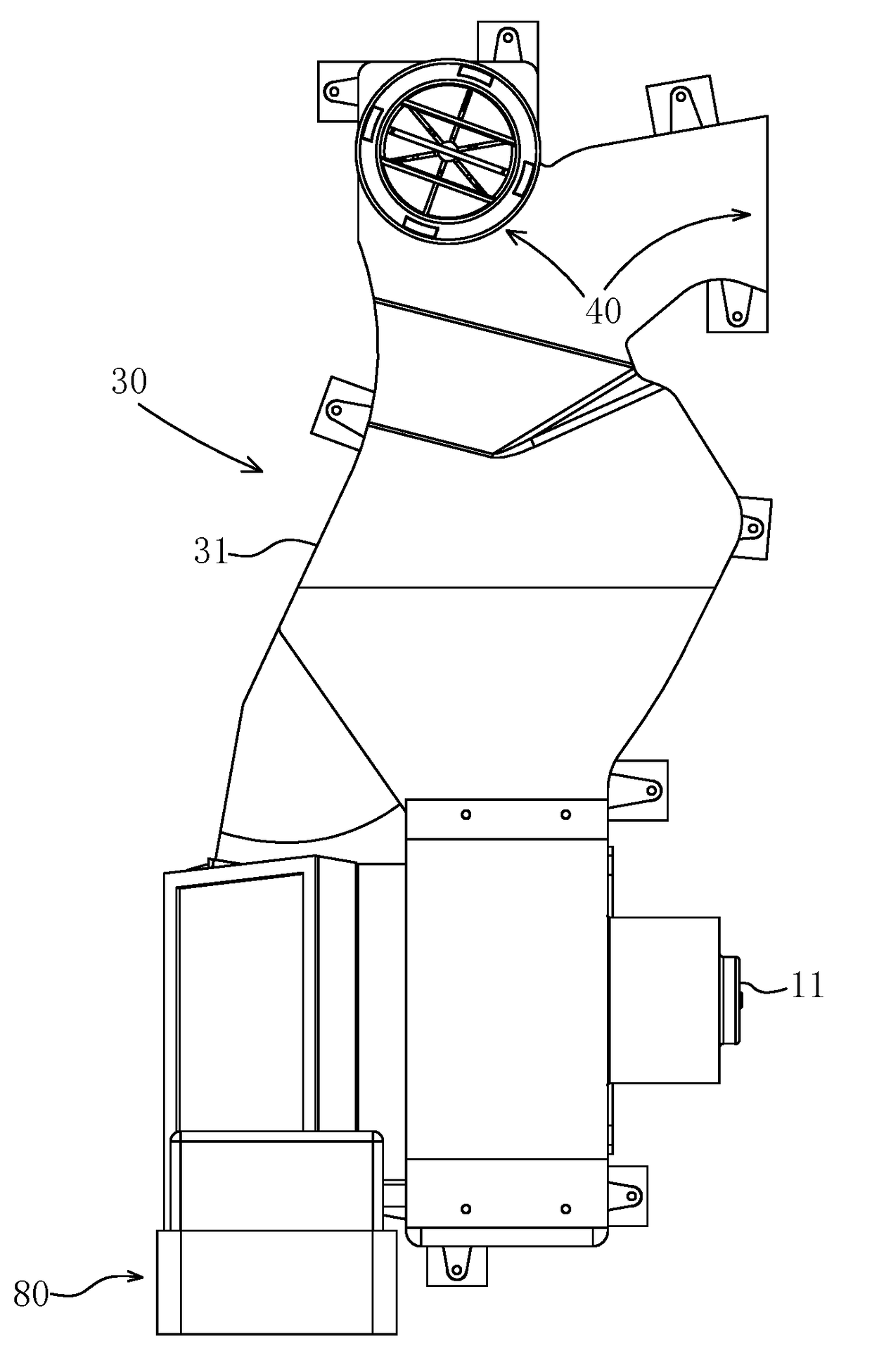

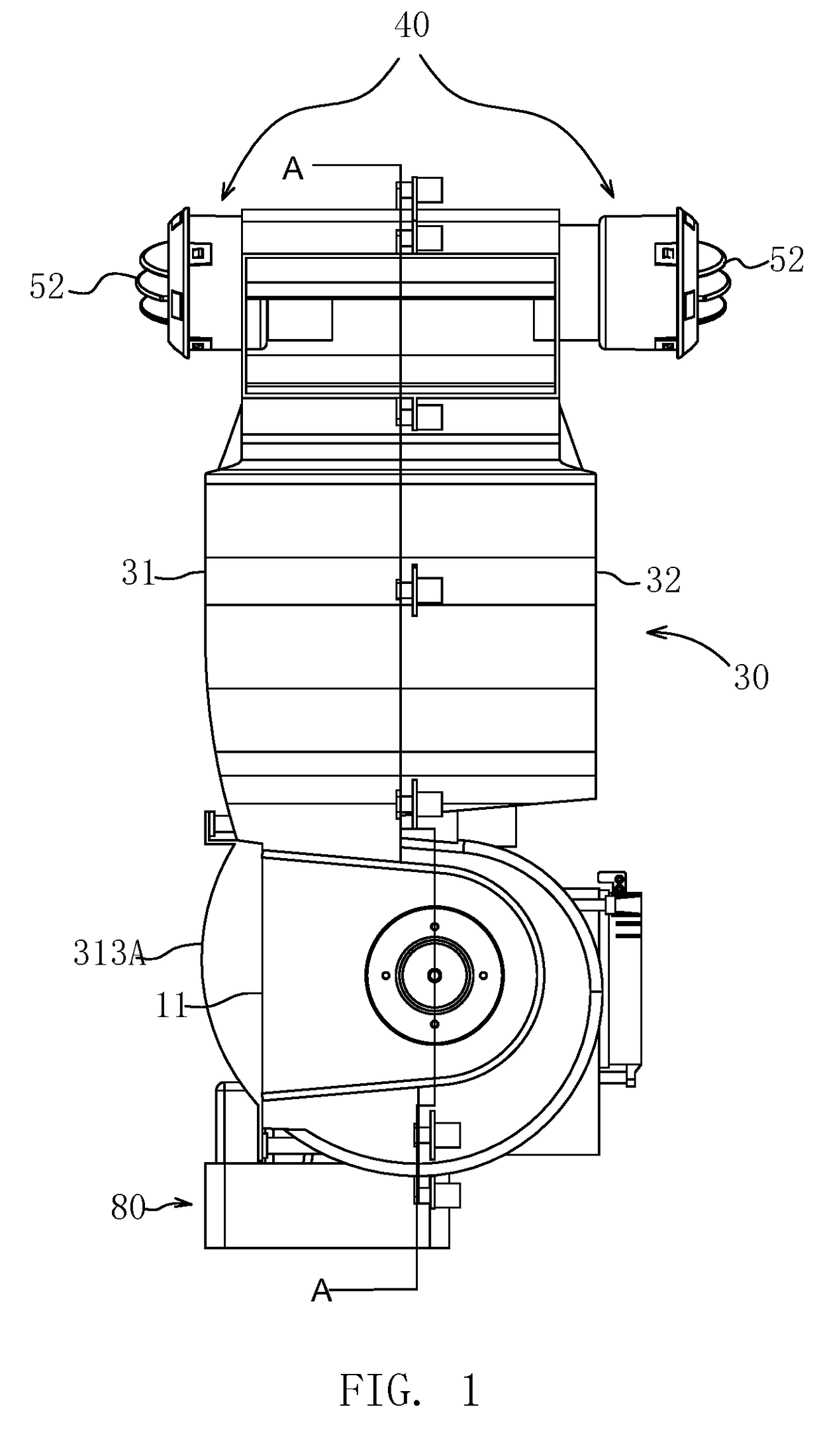

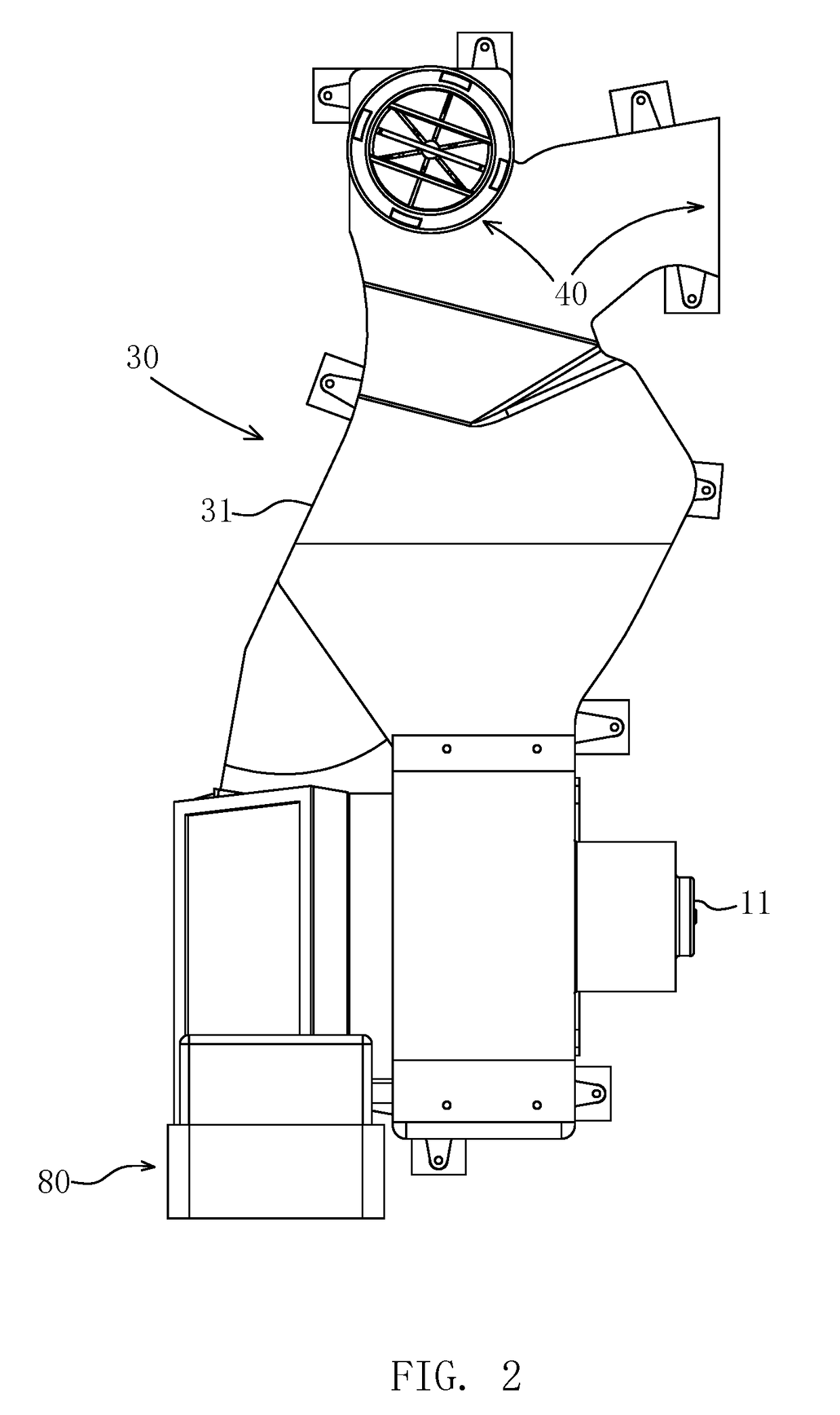

Integratable Movement Device for Ventilating Equipment

InactiveUS20170184316A1Easy to assembleIncrease productionAir heatersFree-cooling systemsElectric machineEngineering

An integratable movement device for ventilating equipment includes an electric machine such as a motor and a fan wheel connected with the electric machine. The movement device further includes a housing, wherein the electric machine and the fan wheel are installed in an inner lower portion of the housing. An upper portion of the housing integrally forms one or more venting outlets. A plurality of venting outlet units is provided at the venting outlets respectively. A chamber provided between the venting outlets and the fan wheel in the housing defines a venting channel. The housing having the venting outlets and the venting channel, along with the venting outlet units, the electric machine and the fan wheel configure the integratable movement device that is able to be directly assembled into the ventilating equipment.

Owner:SHENZHEN SUNZONE ELECTRICAL APPLIANCES

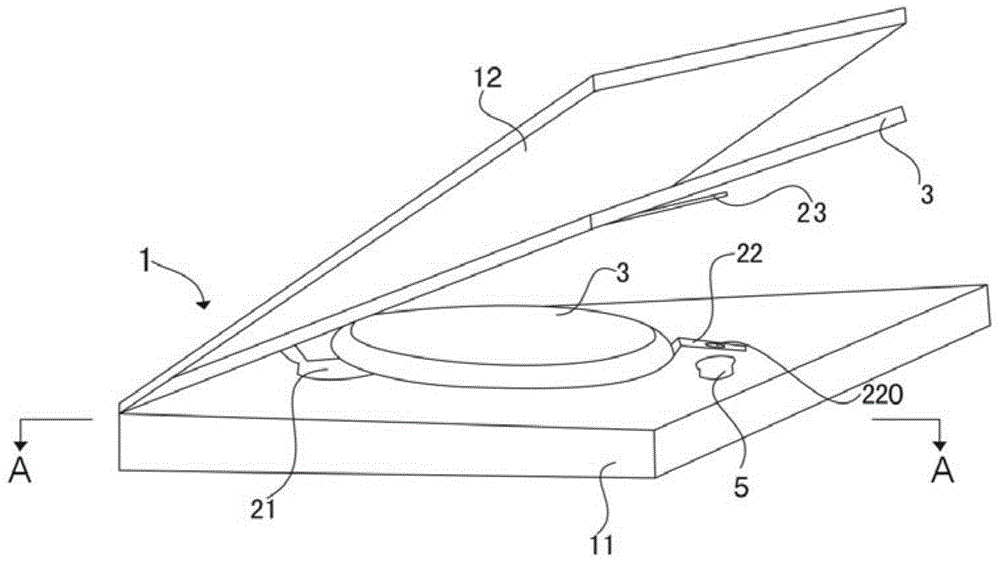

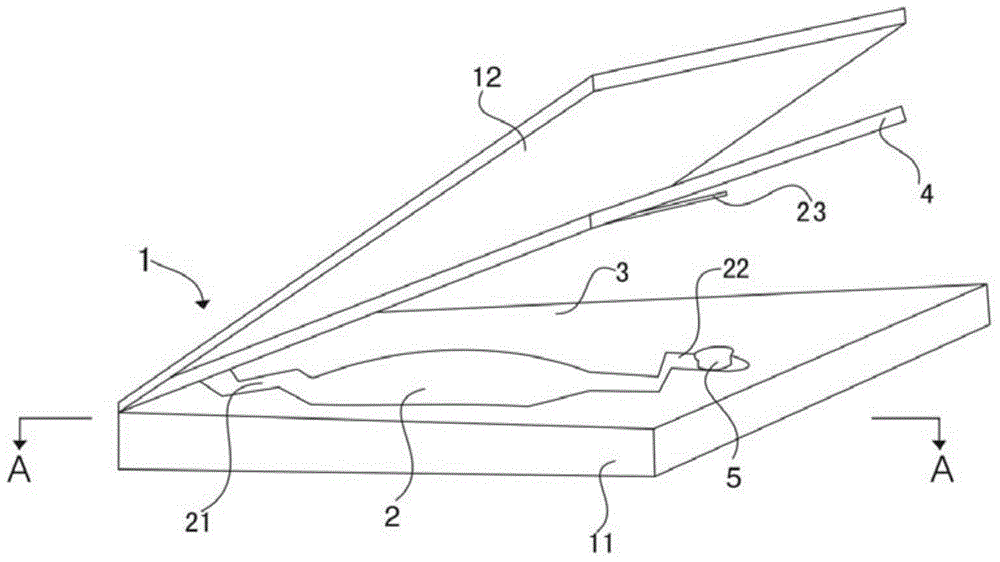

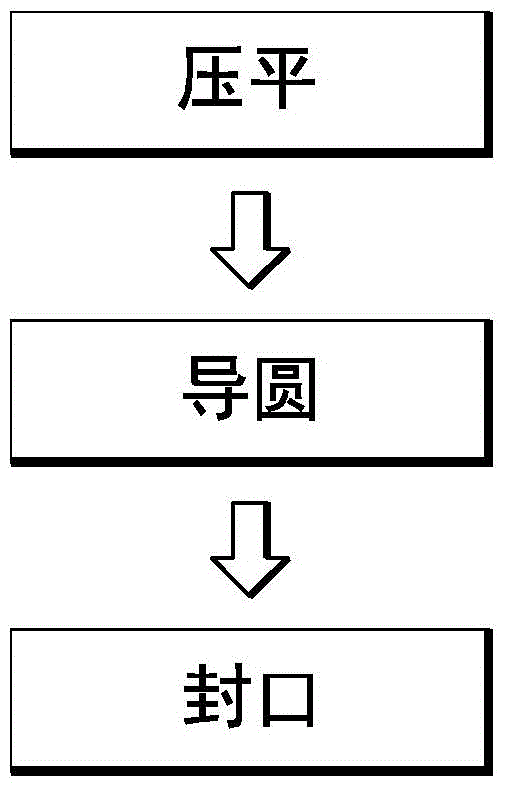

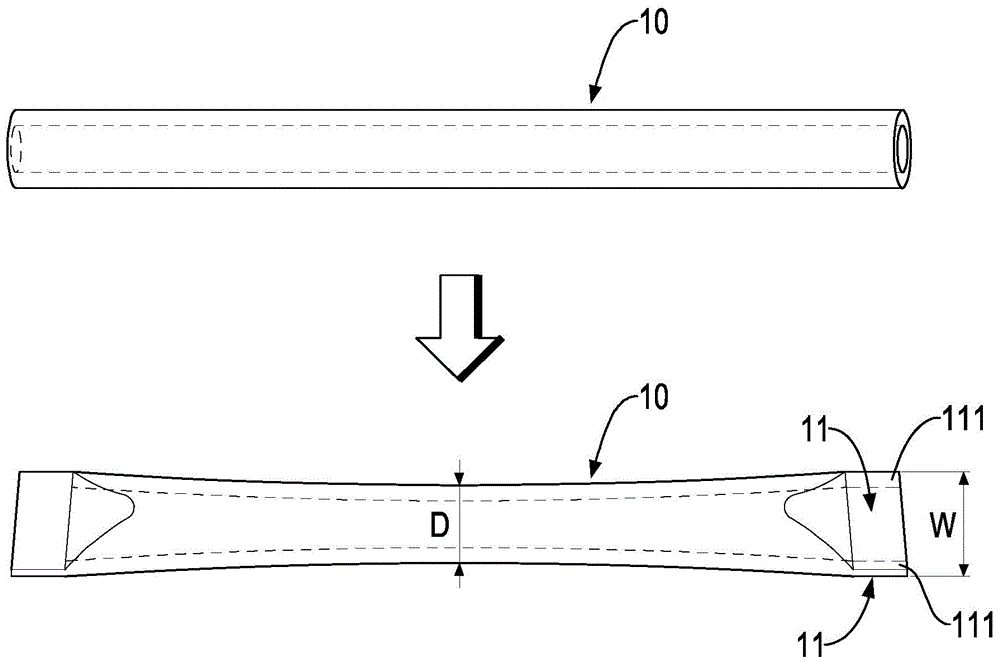

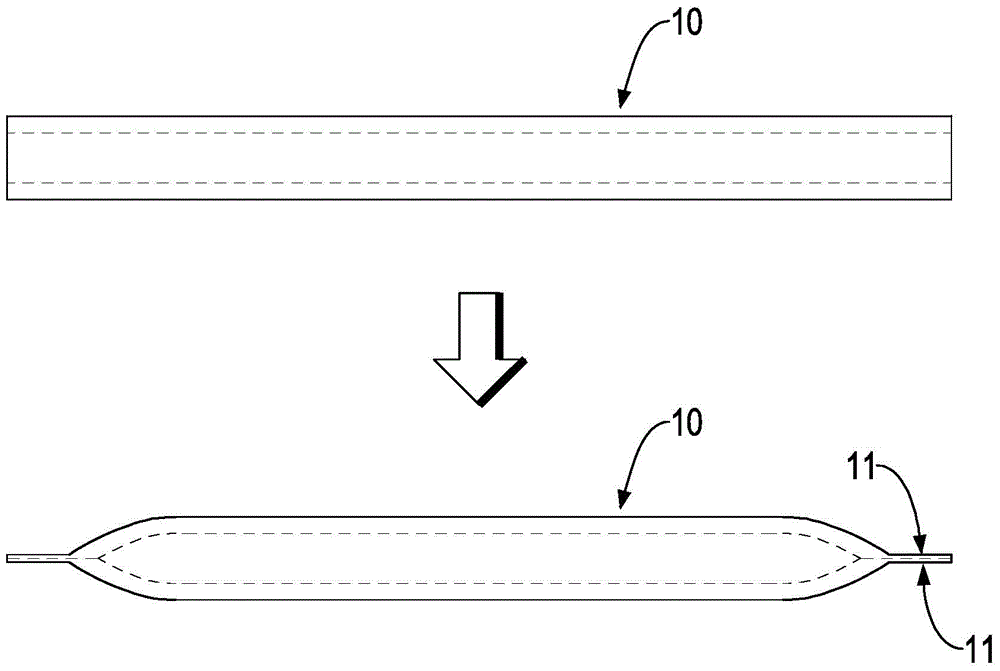

Sealing method of heat pipe and finished product of sealing method

The invention relates to a sealing method of a heat pipe and a finished product of the method. According to the method, the annular-wall-shaped tail ends of a pipe body are locally flattened into two pressing faces attached to each other by flattening the pipe wall of the metal round pipe from the tail end through a flattener, fillet cutting is conducted on the two sharp corners of the pressing faces through a cutting device so that each sharp corner can form fillet arcs after being cut, the two pressing faces are fixedly connected and combined with each other to form a flat sealing section in an ultrasonic wave welding manner, and then sealing of the heat pipe is completed. Sealing is completed in a pressing manner, the worry that round pipe tail end eccentricity is caused in the partial pipe pressing process is eliminated, the flow of pipe shrinkage is omitted, and the effect of improving the manufacturing efficiency and yield of the heat pipe is achieved.

Owner:泽鸿(广州)电子科技有限公司

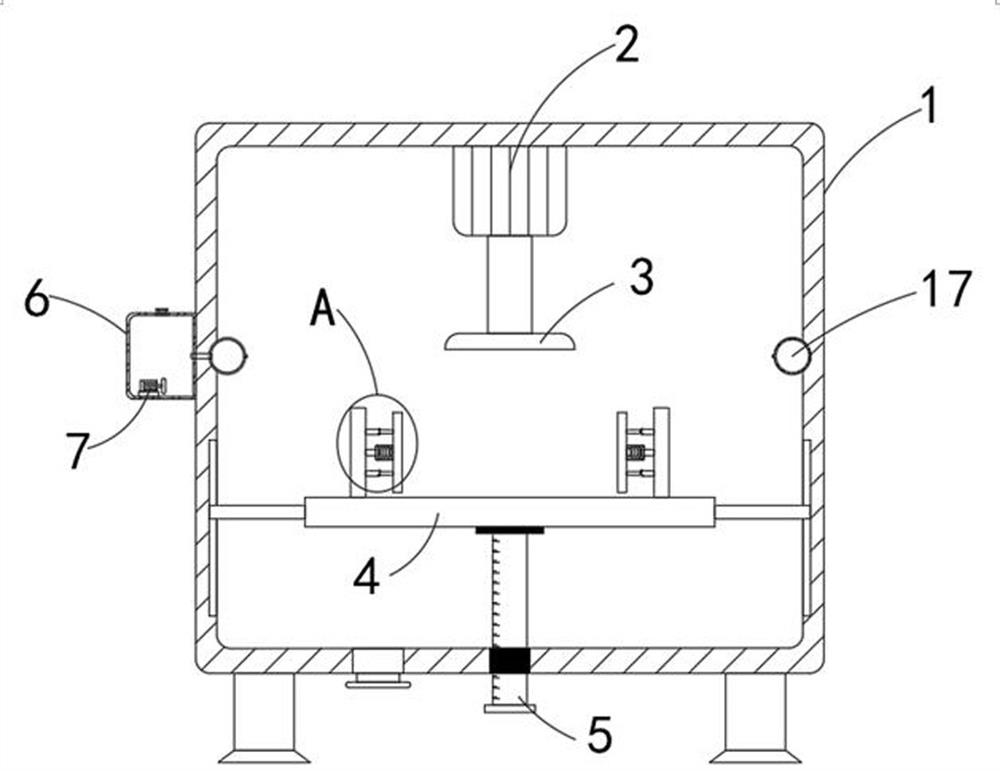

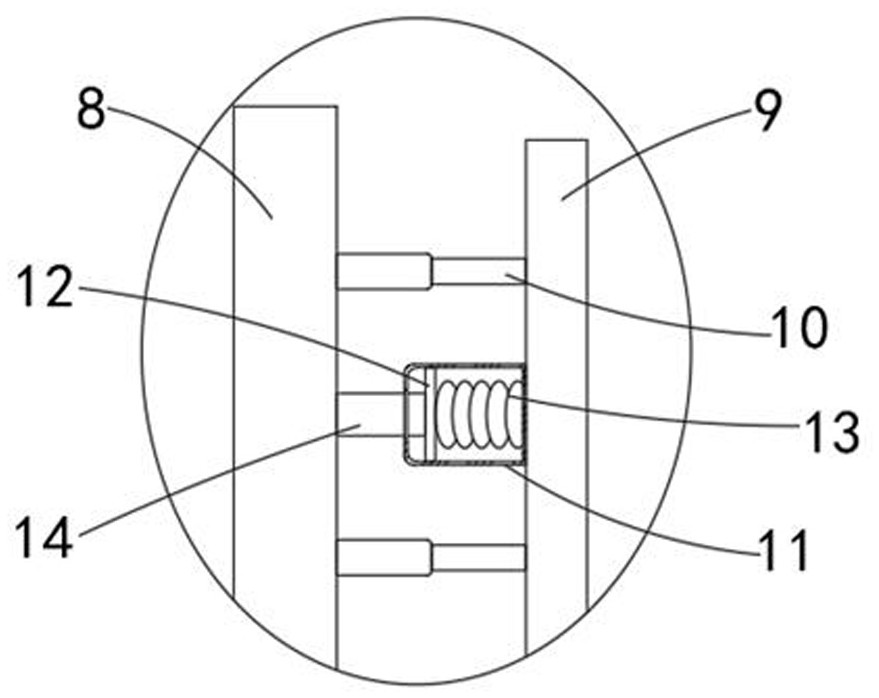

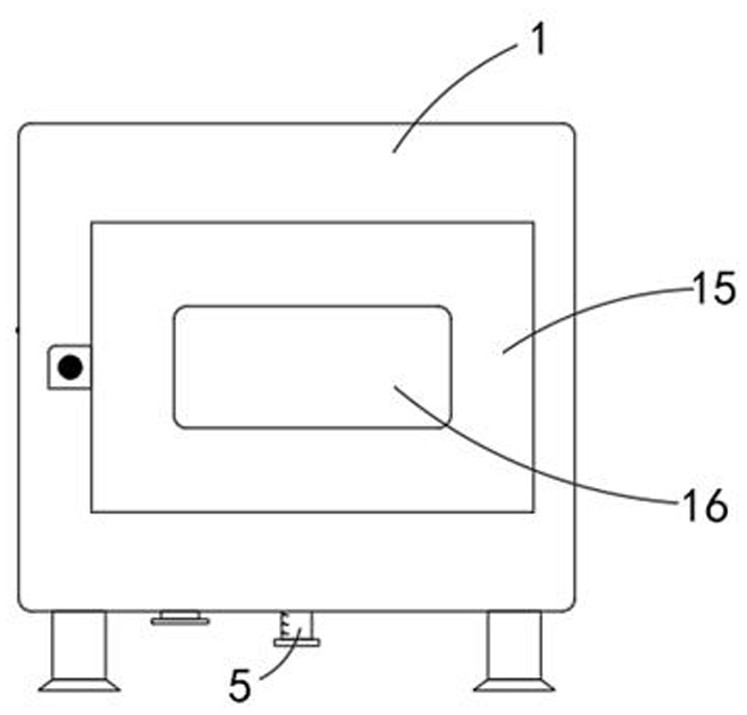

Grinding device for screw mold machining

InactiveCN113021131AExtended service lifeAvoid severe wear and tearGrinding drivesGrinding machinesElectric machineryEngineering

The invention discloses a grinding device for screw mold machining. The grinding device comprises a grinding box, a driving motor is fixedly arranged on the inner wall of the upper side of the grinding box, an output shaft of the driving motor is fixedly connected with a grinding disc, a lifting base corresponding to the grinding disc in position is arranged in an inner cavity of the grinding box, the lower side wall of the grinding box is in threaded connection with an adjusting bolt, the adjusting bolt upwards penetrates through the lower side wall of the grinding box and is rotationally connected with the lower side wall of the lifting base, limiting rods which are symmetrical in position are arranged on the two side walls of the lifting base, limiting grooves matched with the limiting rods are formed in the inner walls of the two sides of the grinding box, and fixing plates which are symmetrical in position are arranged on the upper side wall of the lifting base. A traditional fastening and clamping mode is avoided, cooling liquid can be automatically sprayed in the working process of the grinding disc, the service life of the grinding device is prolonged, the grinding efficiency of the grinding device is improved, the working intensity of workers is reduced, and certain practicability is achieved.

Owner:高煌东

Photo sensor circuit, photo sensor pixel, and display device having the photo sensor pixel

ActiveUS10275094B2High degreeHigh defect rateSolid-state devicesRadiation controlled devicesBottom gateDisplay device

A photo sensor pixel includes a pixel circuit including a driving transistor, a switching transistor having a double gate structure and a photo sensing transistor connected in series with the switching transistor. The pixel circuit drives a light emitting element therein based on a data voltage provided thereto through a data line, the switching transistor includes a top gate electrode and a bottom gate electrode, which are connected to different gate lines, respectively, and the photo sensing transistor senses incident light.

Owner:SAMSUNG DISPLAY CO LTD

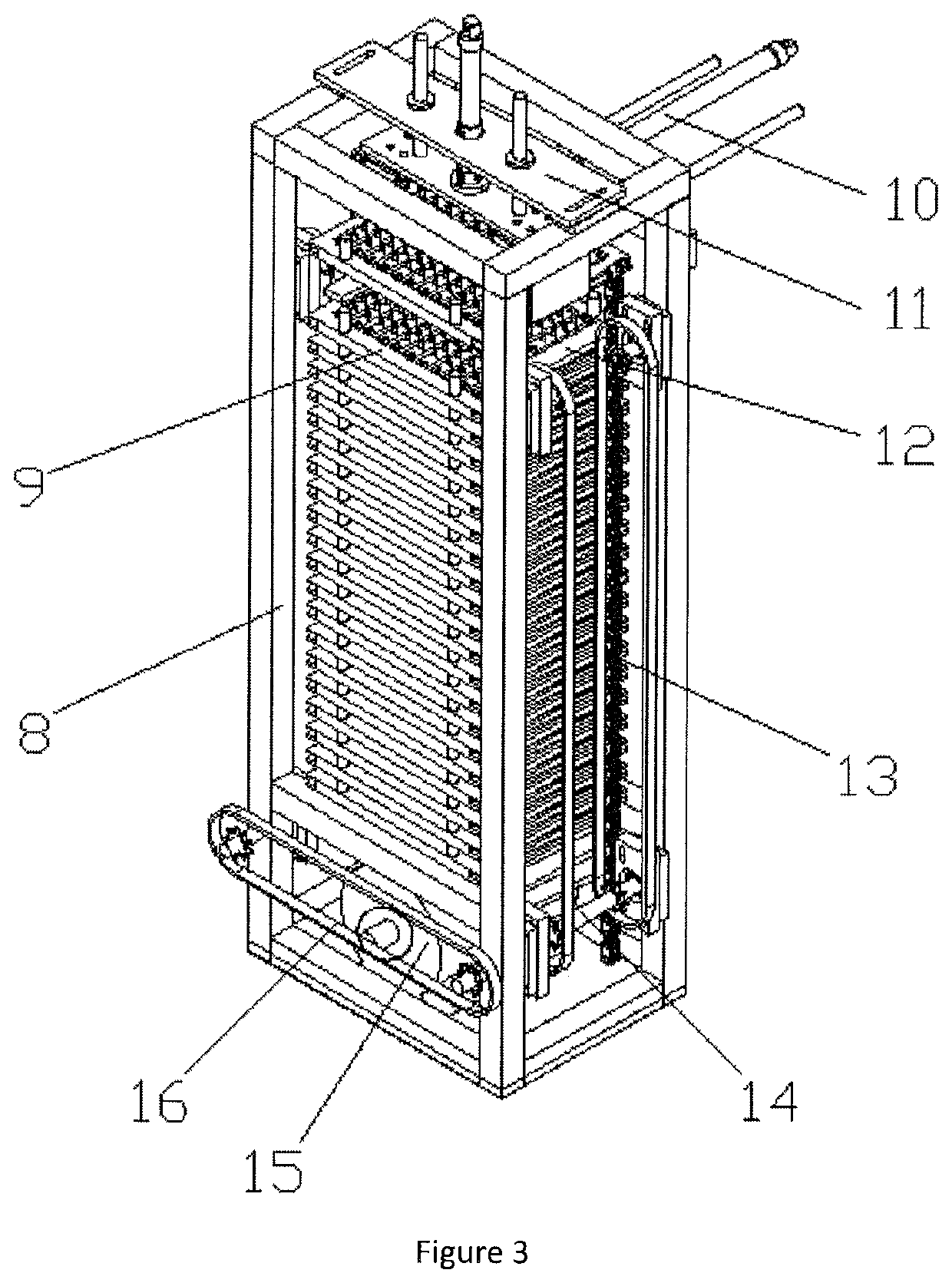

LED filament and lamp, and manufacturing process of LED filament

ActiveUS20200326039A1High defect rateManufactured lowLighting support devicesElectric circuit arrangementsFluorescenceHemt circuits

An LED filament and lamp, and a manufacturing process of an LED filament the LED filament includes a PCB substrate and multiple LED chips, connecting circuits are provided on the PCB substrate, a positive pin and a negative pin are provided at two ends of the connecting circuit, respectively, and each LED chip is electrically connected to the connecting circuit; and a fluorescent glue layer is provided outside the PCB substrate and the LED chips, and the positive pin and the negative pin are exposed from the fluorescent glue layer. The LED lamp includes the LED filament. The manufacturing process of an LED filament enables manufacturing an LED filament. For the LED filament and lamp, and the manufacturing process of an LED filament, a PCB substrate is used as a base material, connecting circuits are fabricated on the PCB substrate, the connecting circuits are directly used for connecting LED chips.

Owner:HANGZHOU BINARY OPTOELECTRONICS & TECH CO LTD

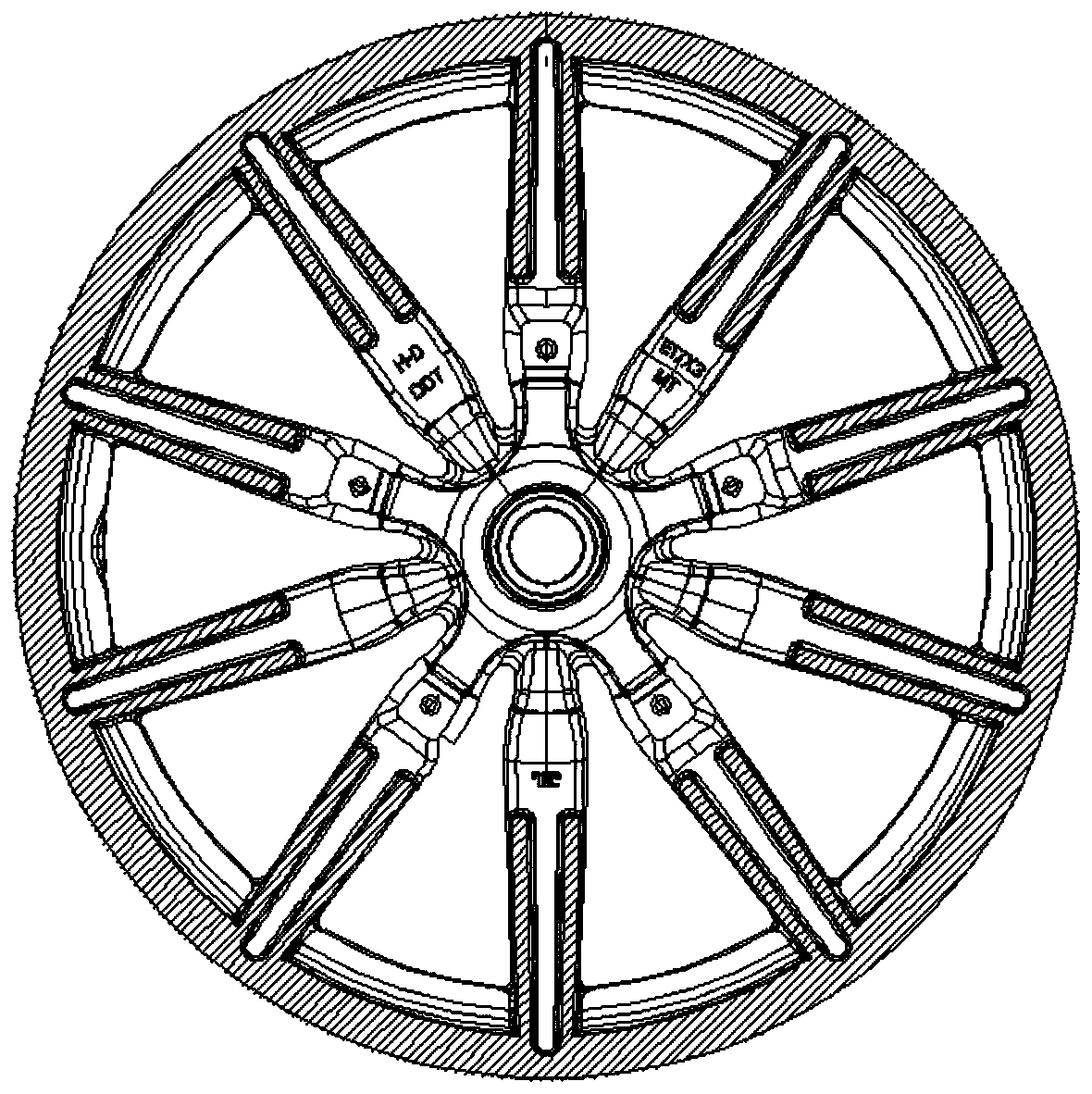

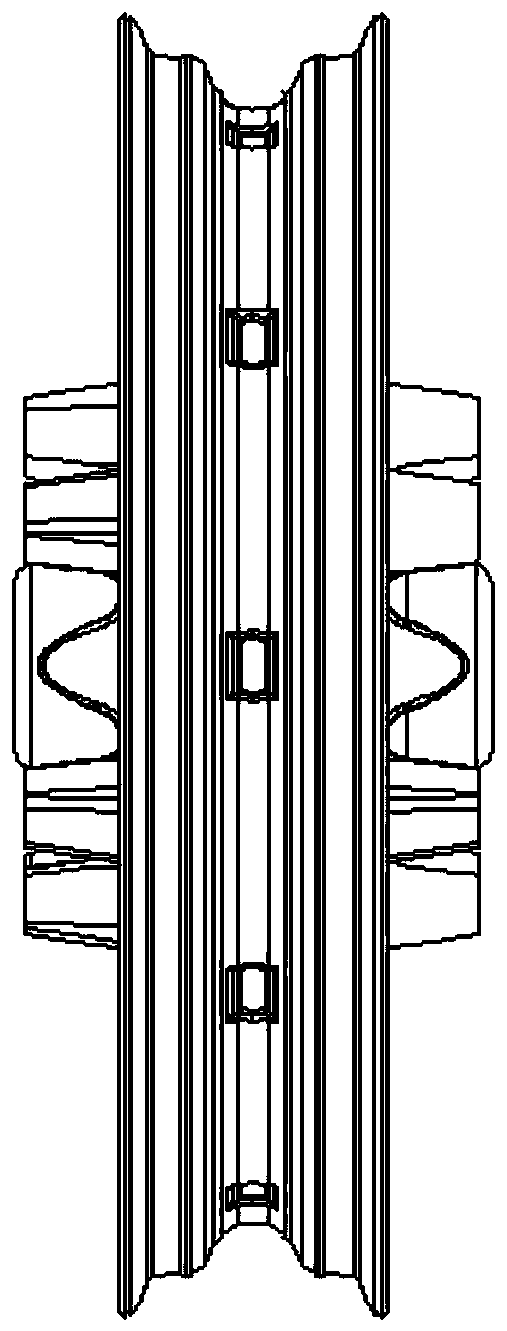

Motorcycle hub composite electroplating method

The invention provides a motorcycle hub composite electroplating method. The problems of the low production rate, the high processing cost and the poor generality of an existing hub composite electroplating method are solved. The motorcycle hub composite electroplating method comprises the following steps that a, the rough machining is conducted on a motorcycle hub billet, the machining allowanceis left in the electroplating area, and other areas are machined into the finished product size; b, coating and spraying are conducted on the rough-machined billet; c, the fine machining is conductedon the electroplating area, the allowance of the electroplating area is turned off, and an aluminum alloy matrix is exposed; d, the pre-treatment washing before electroplating is conducted to remove the oil stains and the dust from the surface; e, a plurality of nickel is electroplated on the fine machined area; and f, the chrome is electroplated on the basis of the electroplating of the multi-layer nickel. The motorcycle hub composite electroplating method is widely used in the technical field of hub surface treatment.

Owner:WEIHAI WANFENG MAGNESIUM IND DEV

Organic electroluminescent device and display panel

ActiveUS10937983B2High defect rateSimple structureSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceElectron blocking layer

The invention discloses an organic electroluminescent device and a display panel. The organic electroluminescent device includes: a first electron blocking layer and a first light emitting layer in a first pixel region, a first electron blocking layer, a first light emitting layer, a second electron blocking layer, and a second light emitting layer in a second pixel region, and a first electron blocking layer, a first light emitting layer, a second electron blocking layer, a second light emitting layer, a third electron blocking layer, and a third light emitting layer in the third pixel region.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON

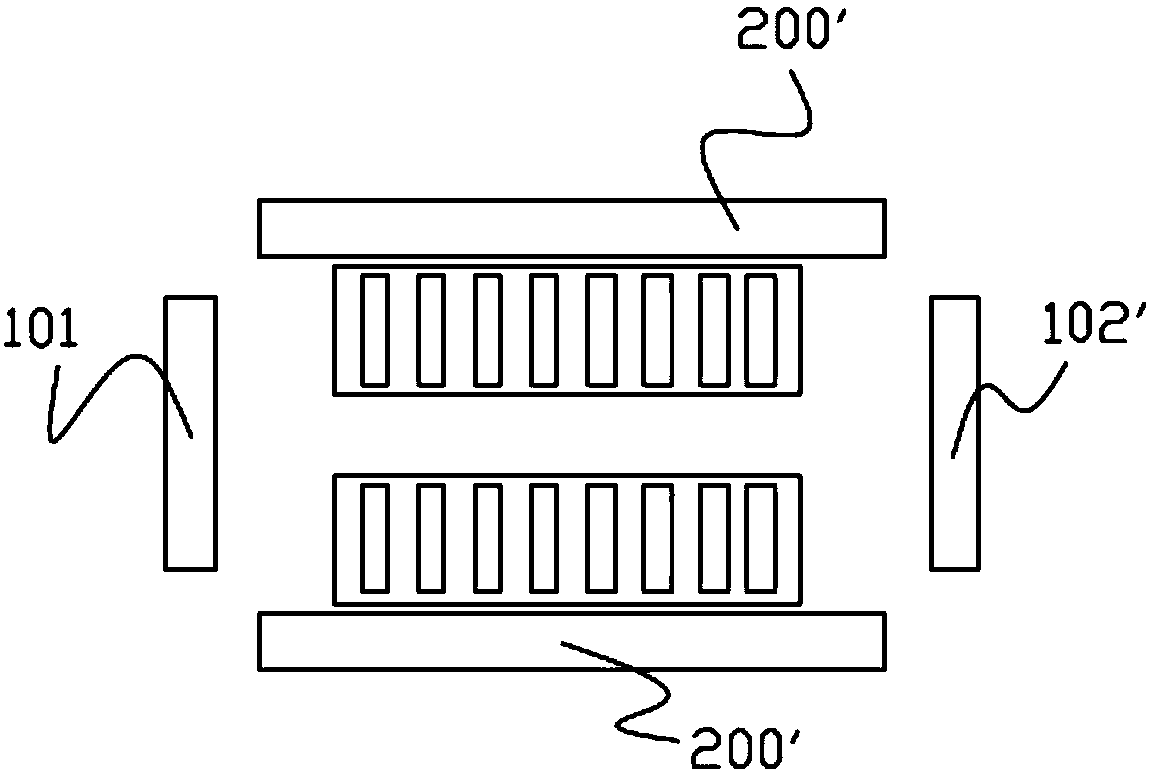

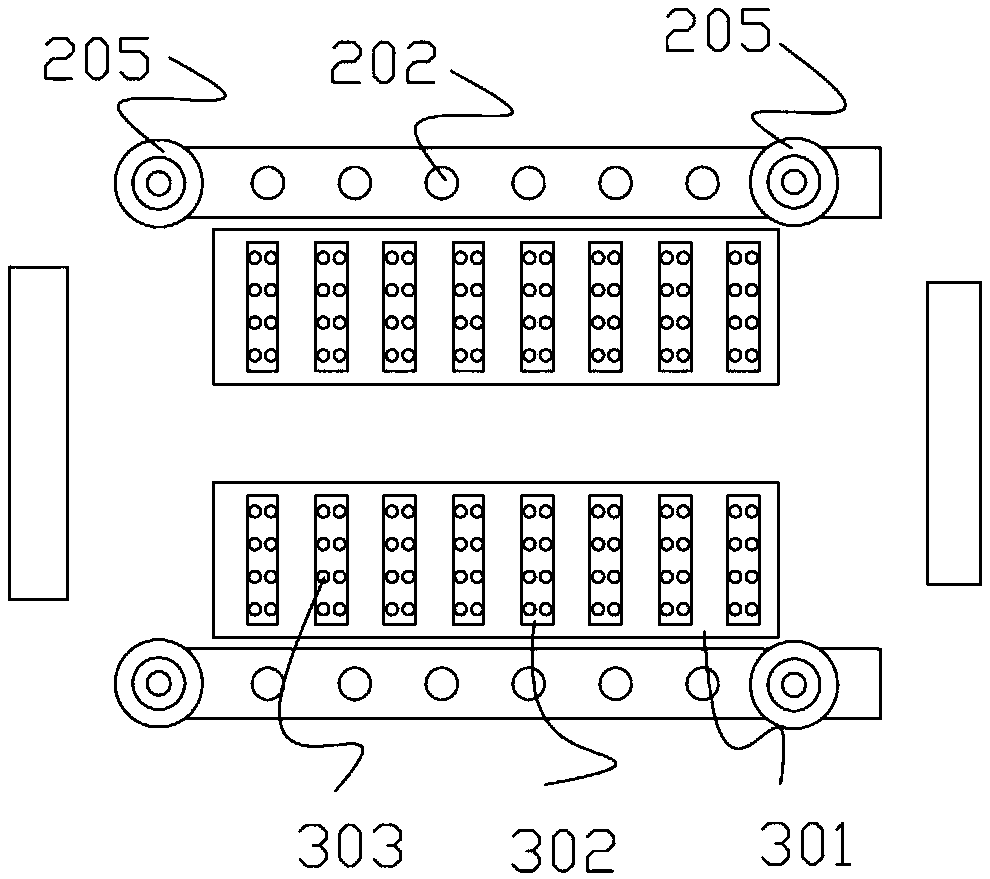

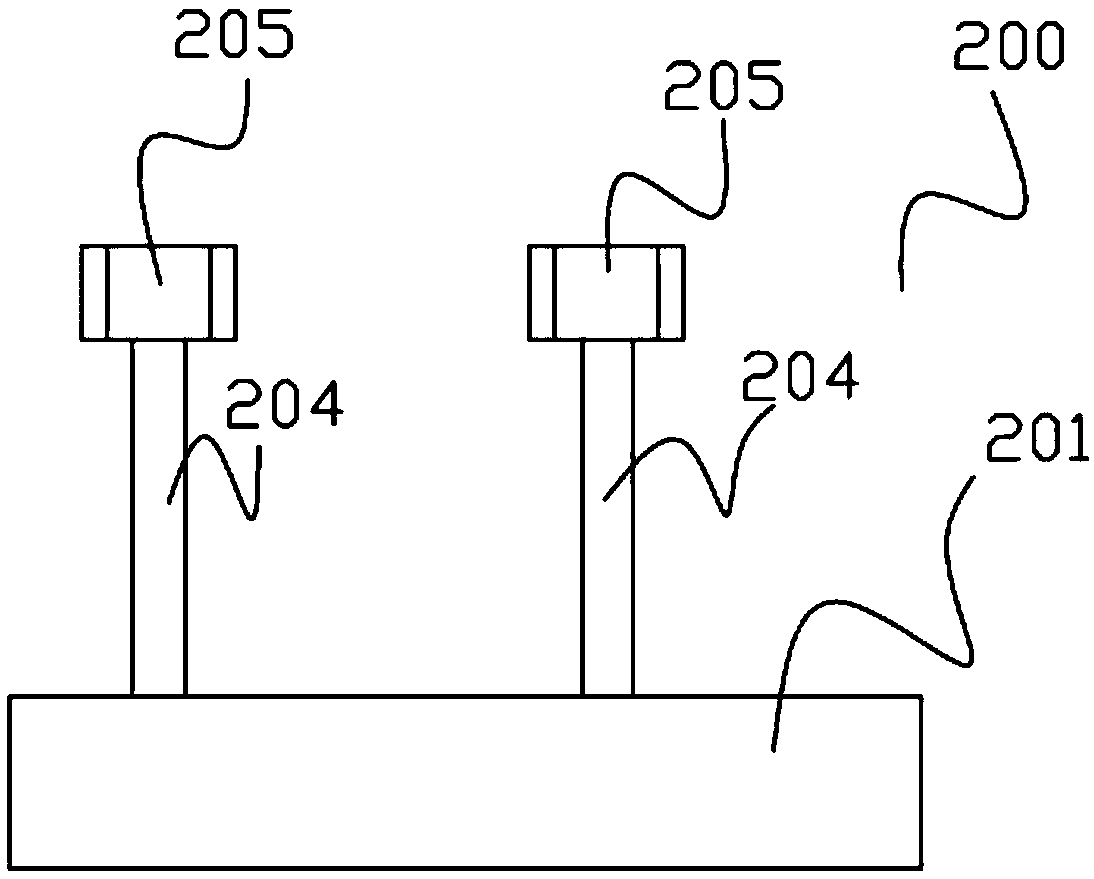

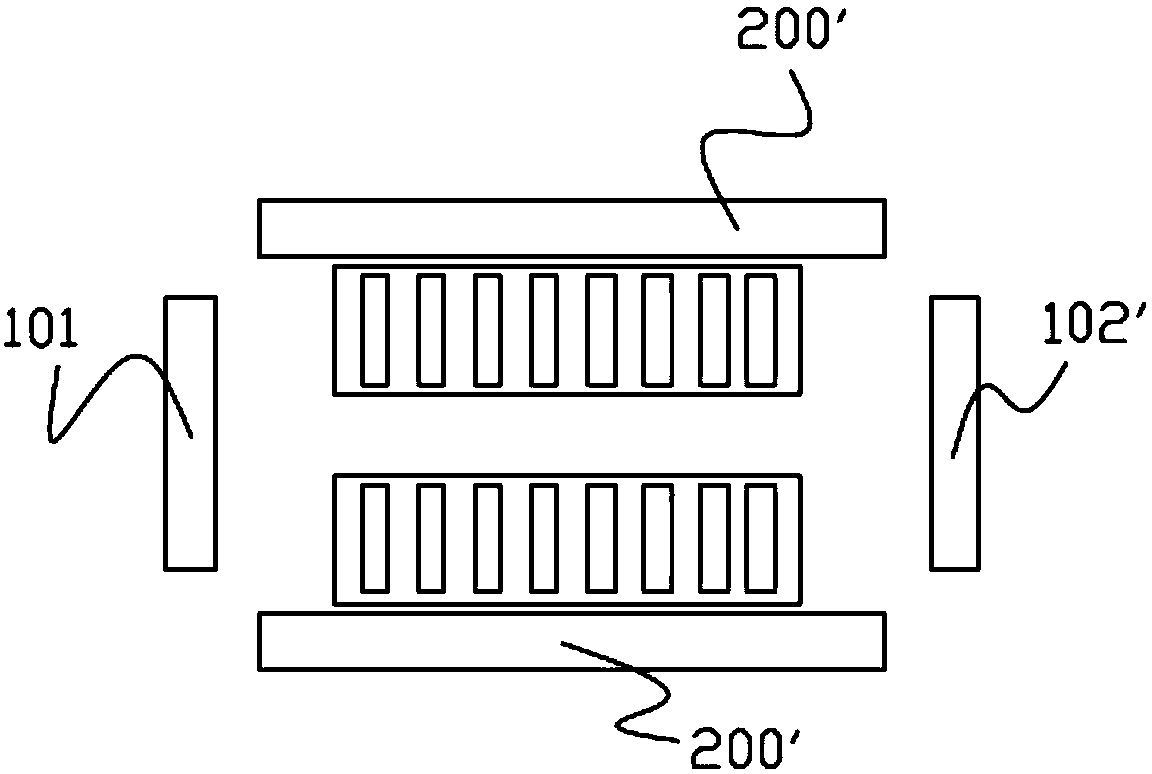

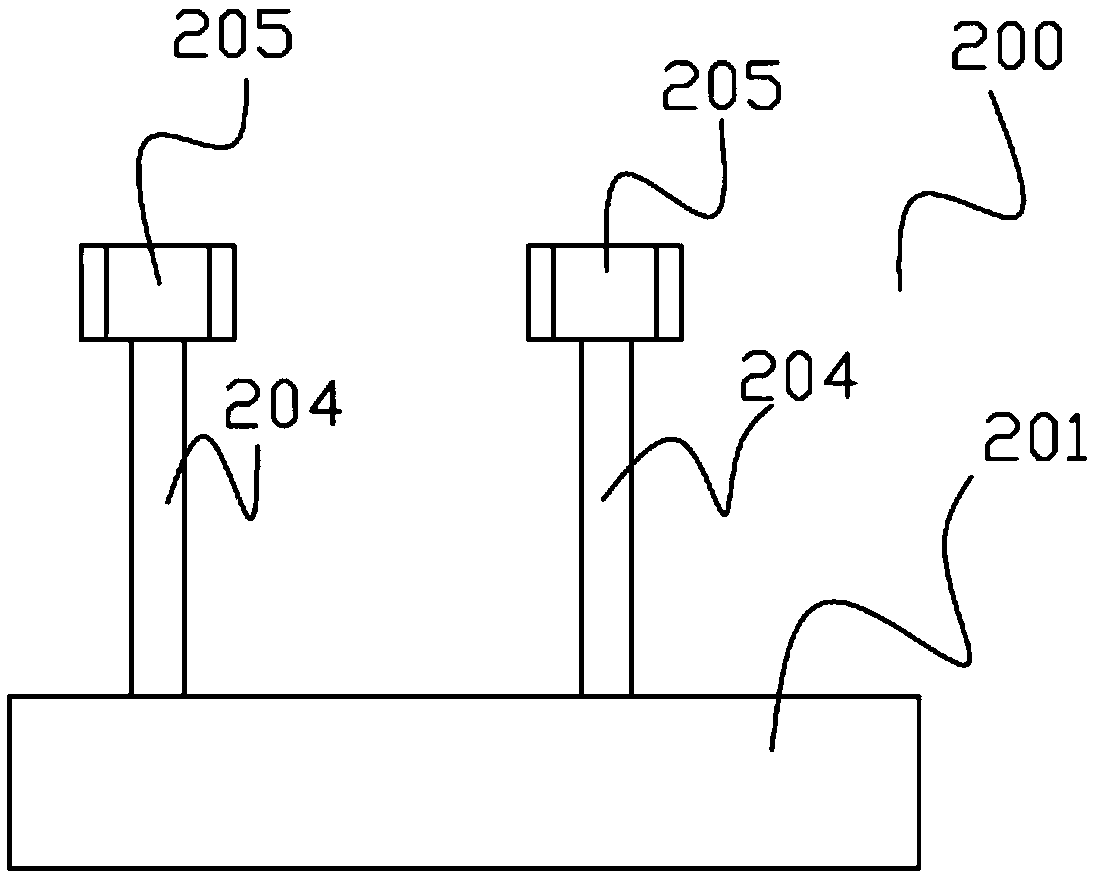

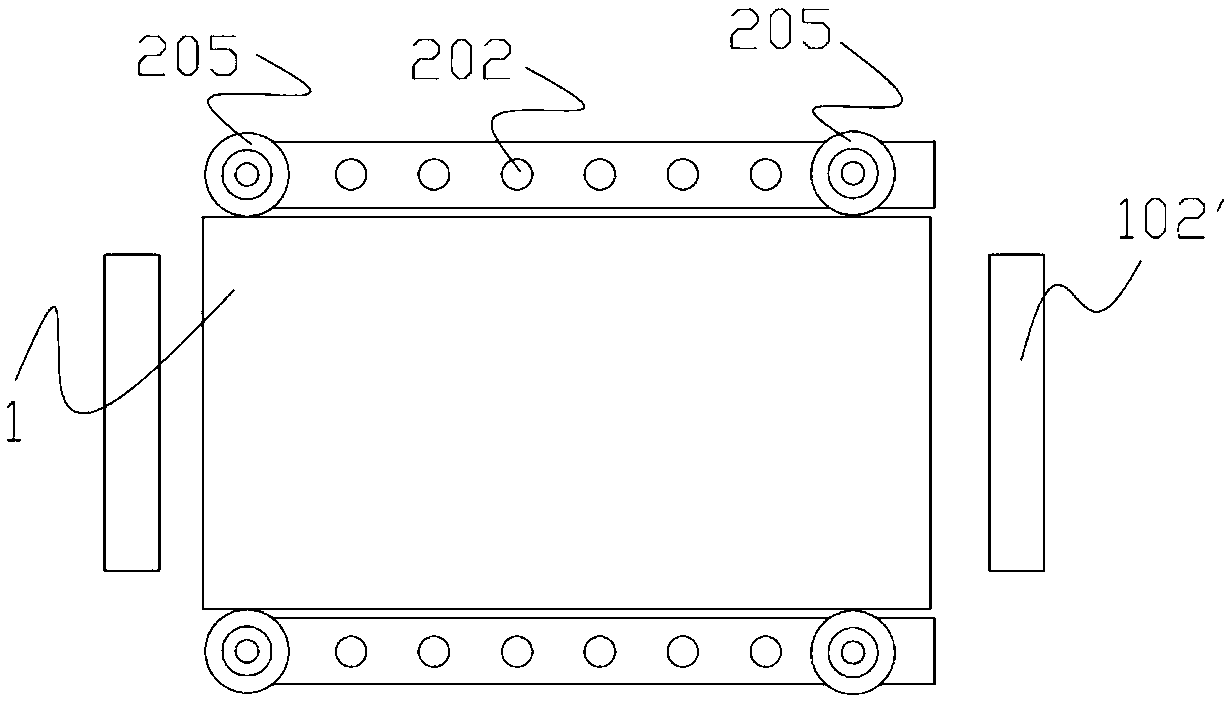

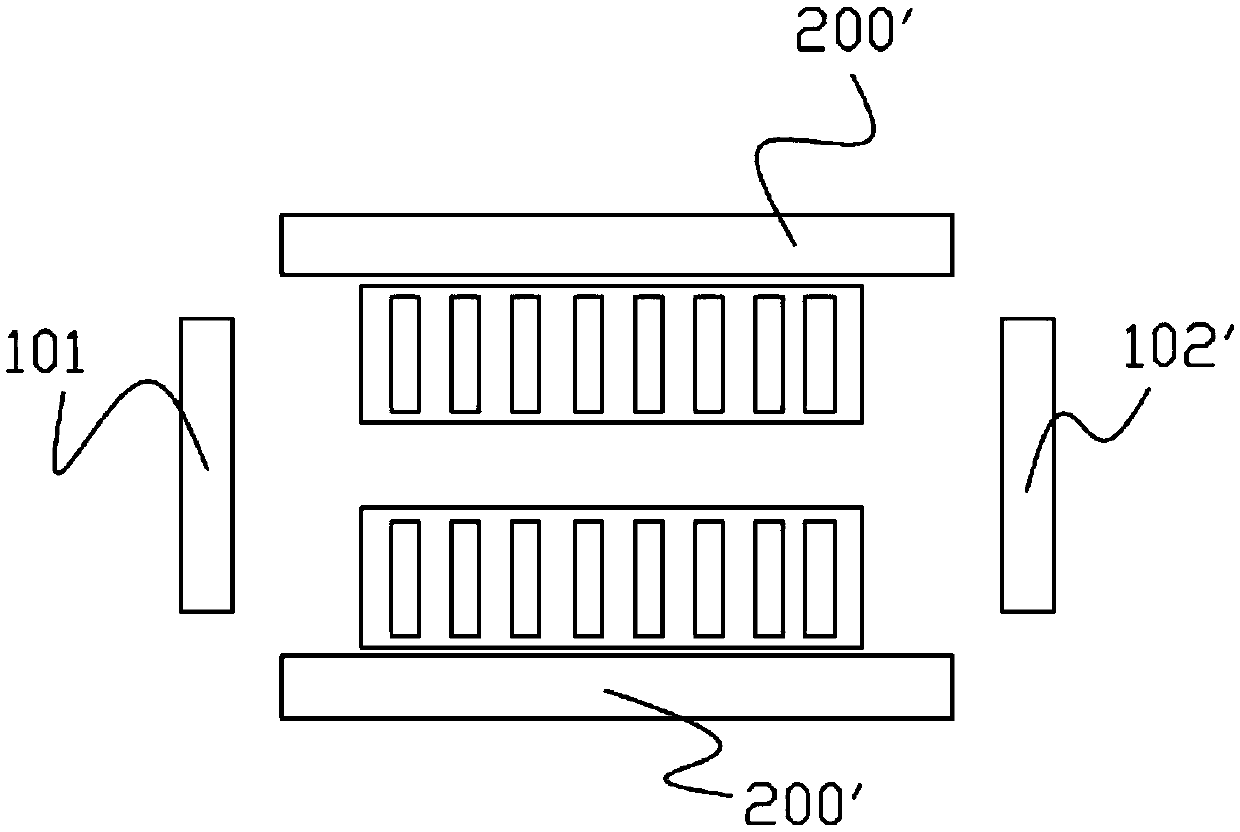

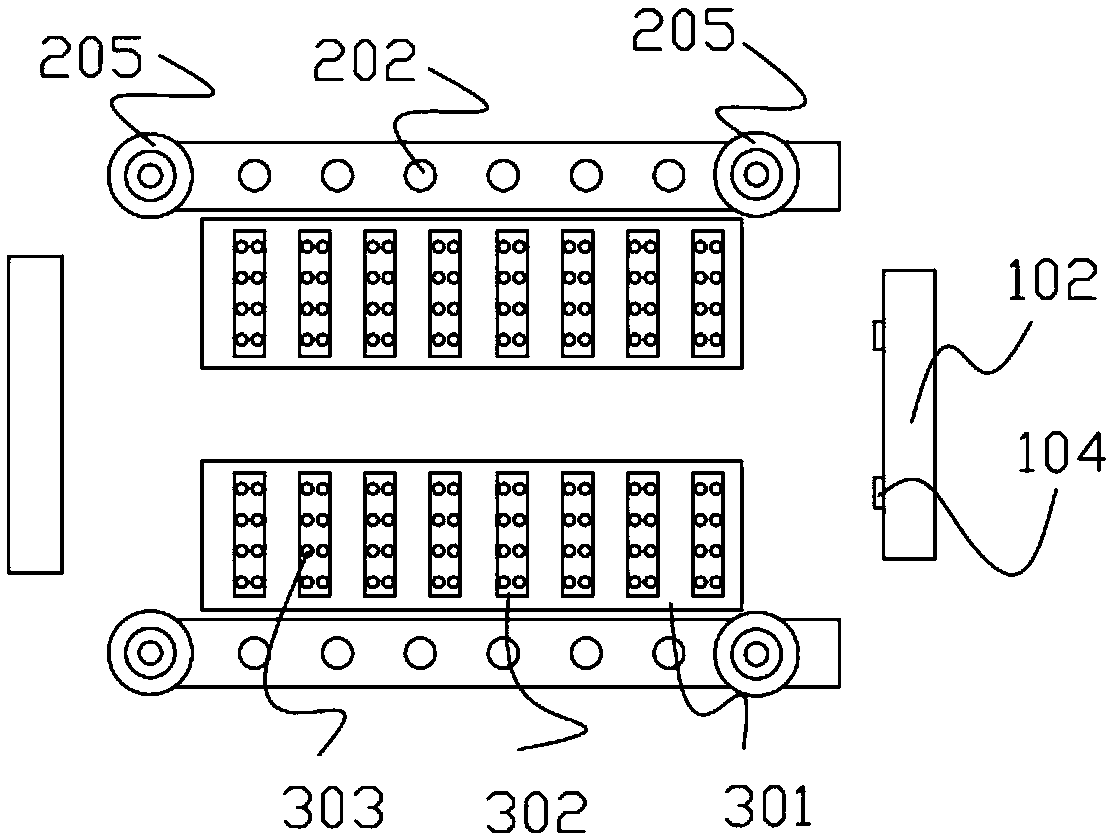

Transverse clamping mechanism capable of reducing BL foreign matter badness

InactiveCN111331333AReduce hard contactHigh defect rateMetal working apparatusForeign matterStructural engineering

The invention relates to a transverse clamping mechanism capable of reducing BL foreign matter badness. The transverse clamping mechanism comprises a transverse locating assembly and a bottom supporting assembly. The transverse locating assembly comprises a base and a locating part, and the base is fixedly connected with the output end of a telescopic air cylinder. Multiple mounting holes are evenly distributed on the base. The locating part comprises at least two locating rods and clamping parts arranged at the tops of the locating rods, and mounting blocks cooperating with the mounting holesare arranged at the bottom ends of the locating rods. The clamping parts are rotationally connected with the locating rods. The bottom supporting assembly comprises a supporting plate and multiple fins. At least one jacking air cylinder is arranged at the bottom end of the supporting plate. The fins are vertically fixed to the supporting plate and distributed in the longitudinal direction of an assembly line, and multiple steel balls are evenly distributed at the tops of the fins. The transverse locating parts and a back plate are in rolling contact, and therefore hard contact of the transverse locating parts and protrusions on the side wall of the back plate is greatly reduced, the quantity of foreign matter generated by relative friction is reduced, and the reject ratio of foreign matter generated in the assembly process is improved.

Owner:陕西科尔智控科技有限公司

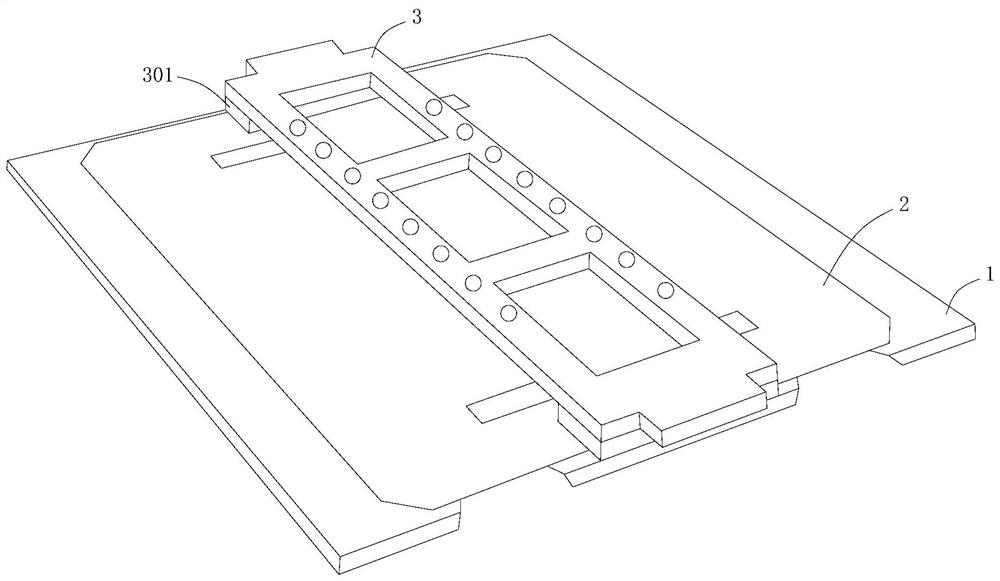

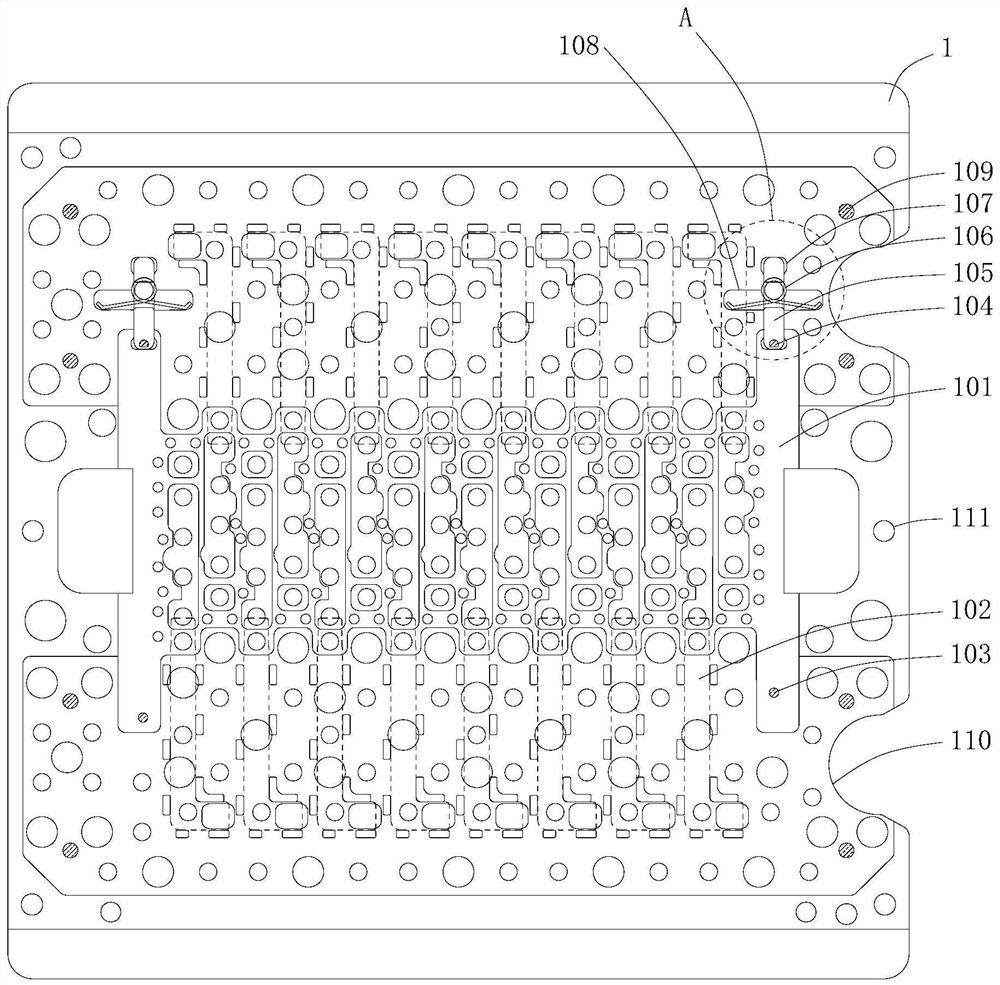

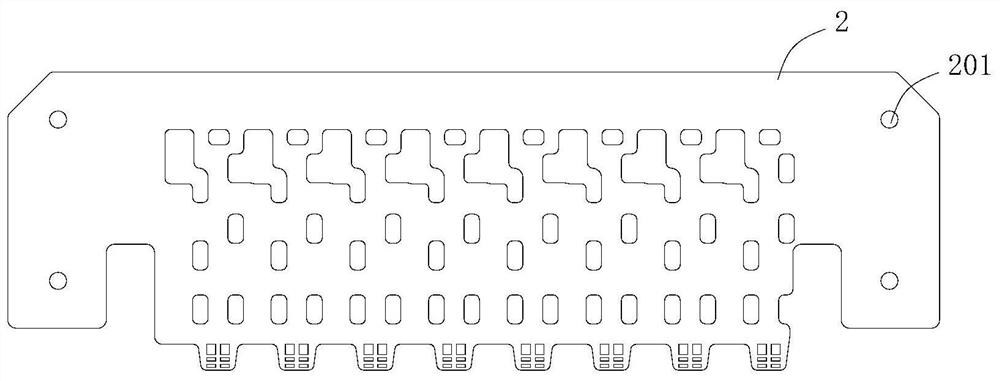

A fpc soft and hard combination board sandwich pressing carrier

ActiveCN112911838BIncrease productivityImprove yield rateMultilayer circuit manufactureStructural engineeringMechanical engineering

The invention discloses a FPC soft and hard combination board sandwich pressing carrier, which includes a tray, which is made of magnetic metal, and a hard board placement station for placing hard boards and a plurality of soft boards for placing soft boards are arranged on the tray Placement station, the bonding areas of multiple soft boards are superimposed on the corresponding hard boards; magnetic steel sheet, the magnetic steel sheet is set above the soft board and connected with the tray magnetically, and the soft board is fixed on the soft board. The board is placed on the station; the cover, the cover is set above the magnetic steel sheet, the bottom of both ends of the cover are equipped with magnets, and are magnetically connected to the tray through the magnets, and the cover is also provided with multiple for Spring pins for pressing the joint area of soft board and hard board. The invention is suitable for the production of rigid-flex boards with a hard board in the middle and a plurality of soft boards on both sides. The structure is simple and the operation is convenient, which greatly improves the production efficiency and yield of the rigid-flex board and reduces production costs.

Owner:锦耀智能精密制造(深圳)有限公司

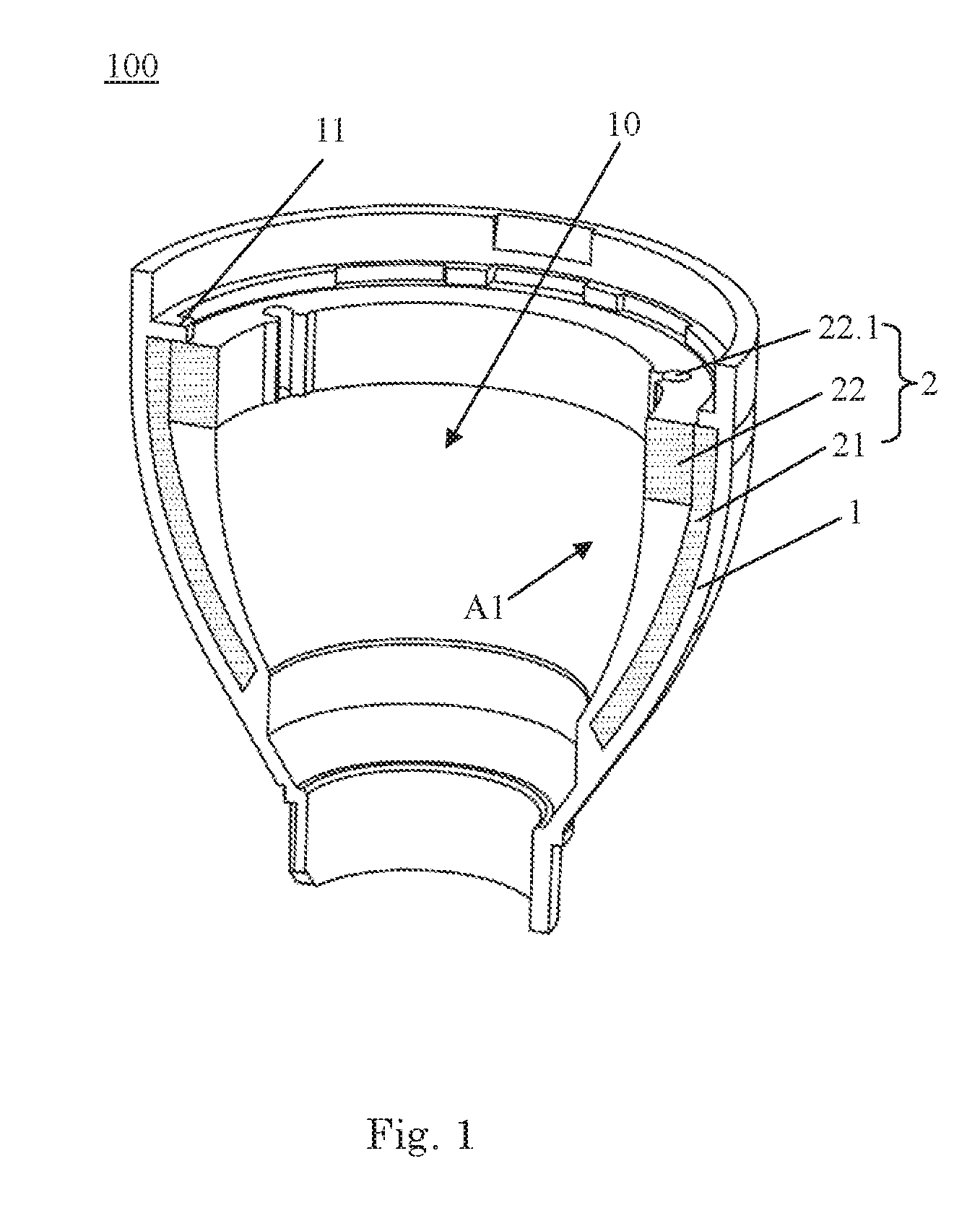

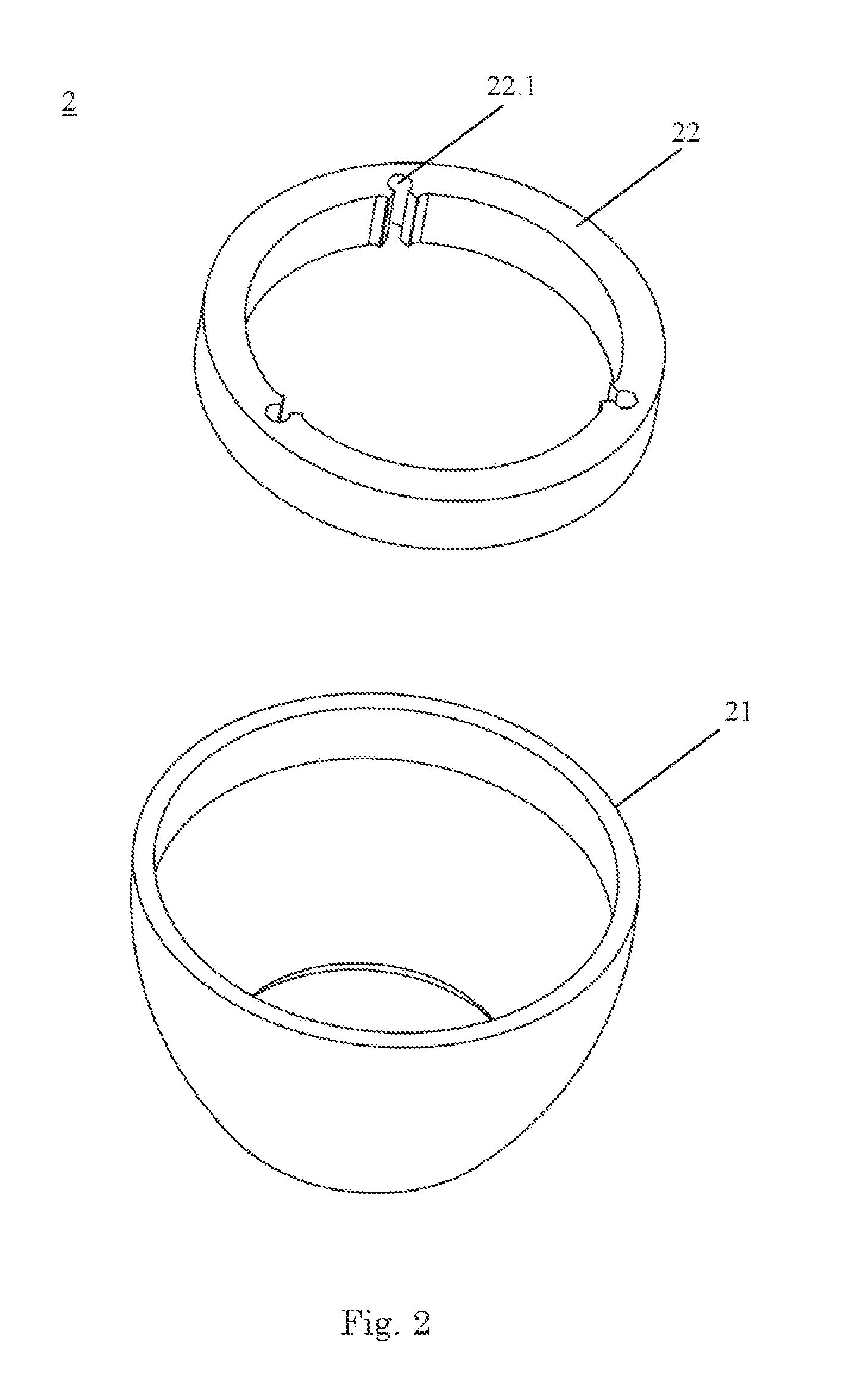

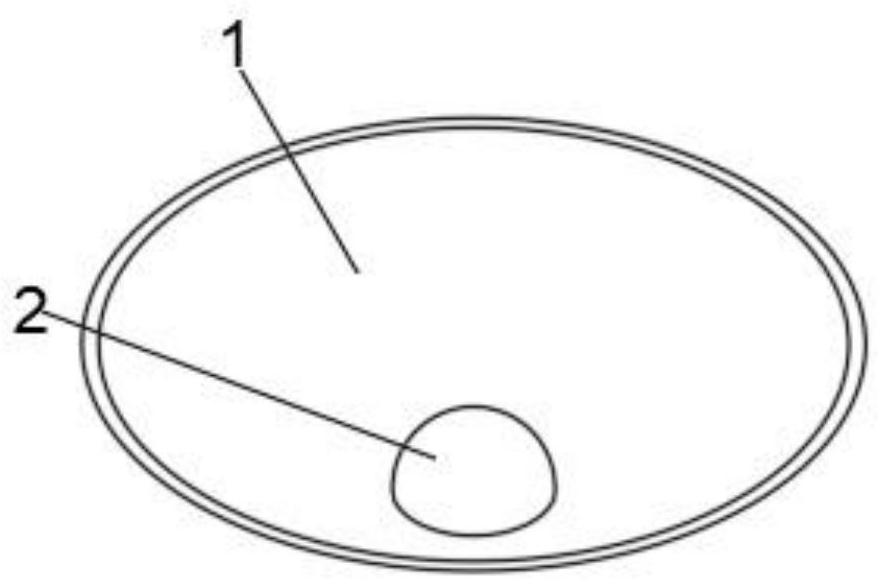

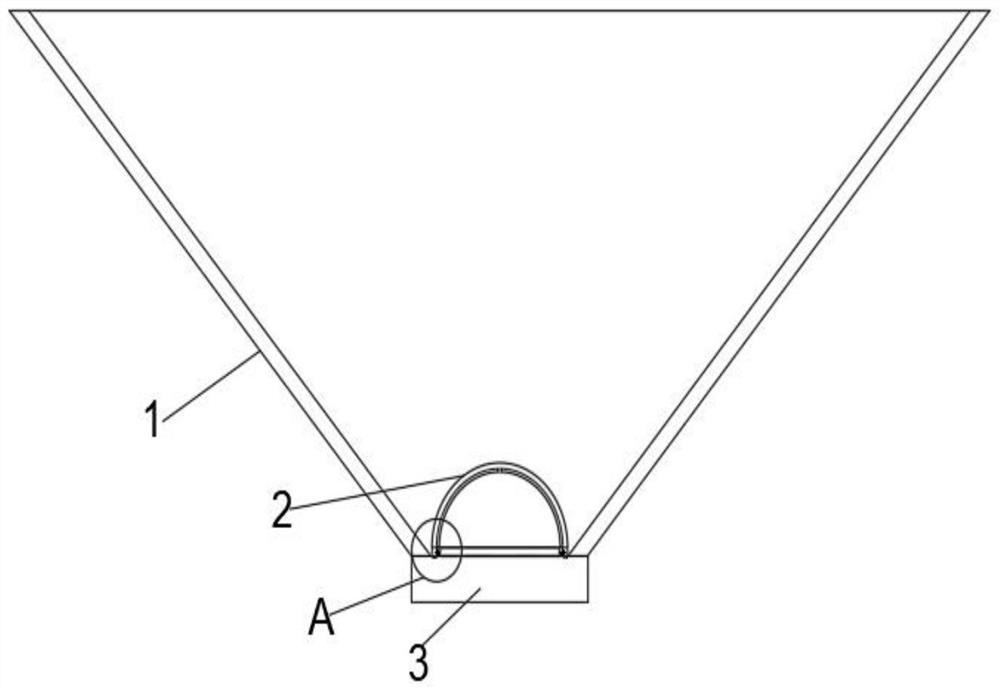

Laser 3D horn cone paper carcass composite basin, dustproof cover and manufacturing method thereof

PendingCN112672257AEasy to installEasy to disassembleNon-planar diaphragms/conesEngineeringStructural engineering

The invention relates to the technical field of drum paper carcasses, and discloses a laser D stereo horn drum paper carcass composite basin and dustproof cover, which comprises a horn-shaped drum basin, the bottom of the drum basin is fixedly provided with a magnetic circuit system, and the magnetic circuit system is provided with a dustproof cover, a laser 3D stereo horn drum paper carcass composite basin and a dustproof cover. After the annular block is in threaded connection with the annular connecting block, the positions of the semicircular grooves correspond to those of the rectangular grooves, at the moment, the clamping balls and the elastic waves lose extrusion force on the clamping balls and the elastic waves from the inner wall of the annular block, then the elastic waves rebound, the rectangular grooves are pushed, the clamping balls are clamped into the semicircular grooves, and the secondary fixing effect is achieved; and therefore, the falling of the dustproof cover due to the vibration generated by the audio during the subsequent music playing process can be avoided.

Owner:刘木生

Friction-prevention back plate transverse positioning assembly

InactiveCN111331332AReduce hard contactHigh defect rateAssembly machinesMetal working apparatusForeign matterClassical mechanics

The invention relates to a friction-prevention back plate transverse positioning assembly. The friction-prevention back plate transverse positioning assembly comprises bases symmetrically mounted along the axis of an assembly line, and positioning parts detachably connected with the bases, the bases are fixedly connected with output ends of telescopic air cylinders, multiple mounting holes are evenly formed in the bases, each positioning part comprises at least two positioning rods and clamping parts on the tops of the positioning rods, the bottom ends of the positioning rods are provided withmounting blocks matched with the mounting holes, the clamping parts are rotatably connected with the positioning rods, the positioning parts of the transverse positioning assembly and a back plate are in rolling type contact, hard contact between the positioning parts and convex closures on the side walls of the back plate can be greatly reduced, the foreign body amount generated by opposite friction can be reduced, and the foreign body reject ratio generated by the assembling process can be improved.

Owner:陕西科尔智控科技有限公司

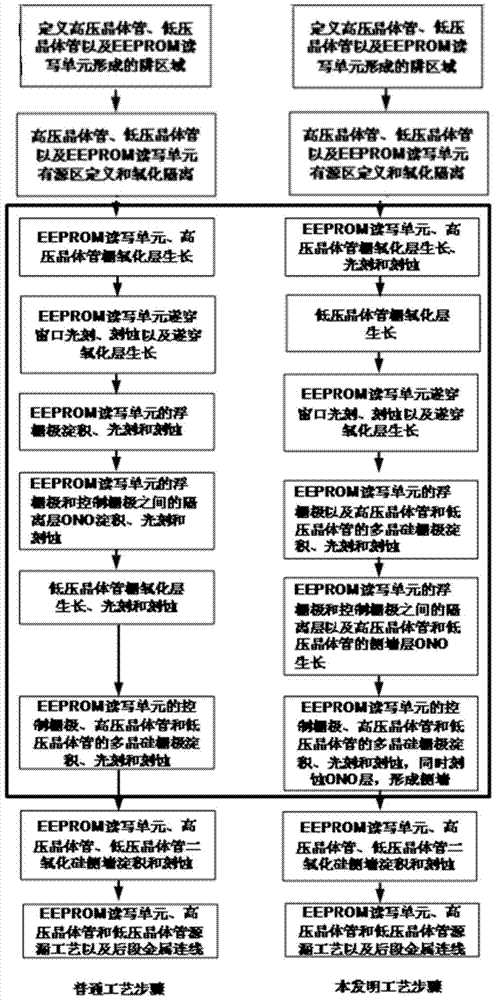

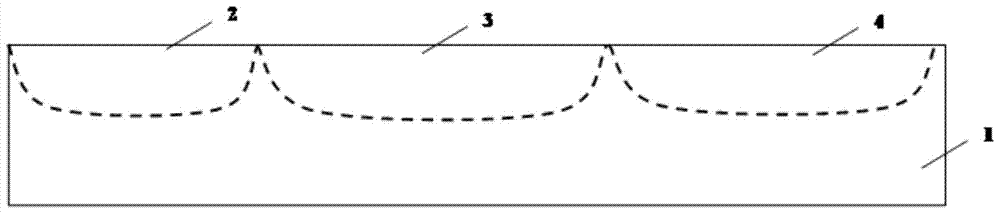

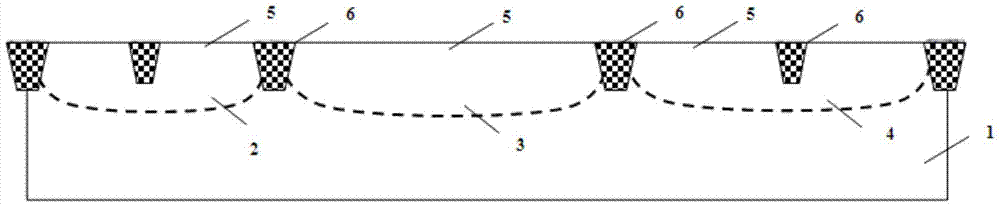

A kind of manufacture method of anti-radiation eeprom

ActiveCN104362128BHigh defect rateReduce defective rateSolid-state devicesSemiconductor/solid-state device manufacturingDielectricLow voltage

The invention provides a method for manufacturing an anti-radiation EEPROM. The memory includes devices: storage units and high and low voltage transistors of peripheral circuits. It is characterized in that the manufacturing method before the formation of the source and drain of each device is different from the ordinary manufacturing method. : The dielectric ONO layer used for the isolation between the floating gate and the control gate in the memory unit is used as the side wall of the high and low voltage transistor gate of the peripheral circuit at the same time, that is, the material of the side wall of the high and low voltage transistor gate is changed, by The silicon oxide film in the conventional manufacturing method is replaced by a composite film of silicon oxide and silicon nitride. The method of the present invention makes full use of the existing common manufacturing method, does not add additional process steps, only by adjusting the gate oxide growth sequence of the low-voltage transistor in the peripheral circuit, so as to ensure that the structure and electrical performance of the high-voltage and low-voltage transistor devices involved are consistent. Change, and improve the anti-radiation performance of the device, thereby improving the anti-radiation performance of the entire EEPROM. The method of the invention is suitable for mass production.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

Backing plate positioning mechanism for BL automatic assembly production line

InactiveCN111331331AReduce hard contactReduce the amount of foreign matterMetal working apparatusForeign matterEngineering

The invention relates to a backing plate positioning mechanism for a BL automatic assembly production line. The backing plate positioning mechanism comprises a transverse positioning assembly and a longitudinal positioning assembly which are perpendicular to each other, wherein the longitudinal positioning mechanism is arranged in the longitudinal direction of an assembly line; the longitudinal positioning assembly comprises a front positioning structure and a rear positioning structure, and a buffer body is arranged on the side, close to the rear positioning structure, of the front positioning structure; the transverse positioning assembly comprises a base and at least two positioning parts, each positioning part comprises a positioning rod and a clamping part, the positioning rod is detachably connected with the base, and the clamping part is rotationally connected with the positioning rod; and the backing plate positioning mechanism further comprises a bottom supporting assembly, the bottom supporting assembly comprises a supporting plate and a plurality of fins, at least one jacking air cylinder is arranged at the bottom end of the supporting plate, the fins are vertically fixed on the supporting plate and distributed in the longitudinal direction of the assembly line, and multiple steel balls are uniformly distributed at the tops of the fins. The positioning mechanism canreduce both the foreign matter rejection rate and the assembly rejection rate of the automatic assembly production line.

Owner:陕西科尔智控科技有限公司

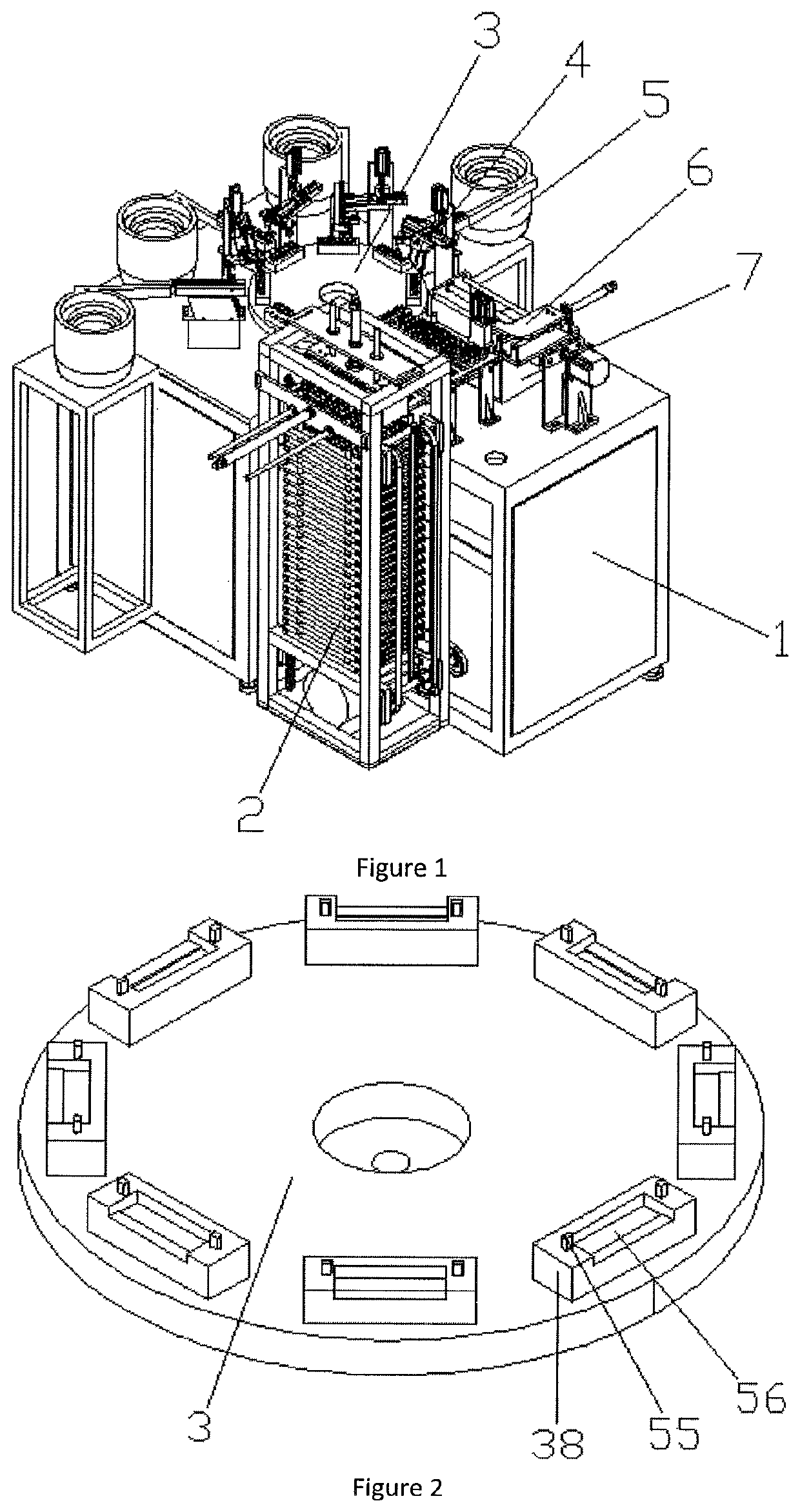

Automatic assembly machine for combined control button

ActiveUS11117229B2Decrease productivityLarge resource consumptionAssembly machinesElectric switchesDistribution controlControl engineering

An automatic assembly machine fora combined control button, includes a frame, a power distribution control box, a turntable and turntable drive disposed on the frame so as to fit with each other, wherein the base fixtures fitting controller bases are evenly disposed along the circumference of the turntable; the front side of the frame located at the right side of the turntable is disposed with a base feeding mechanism; the rear side of the base feeding mechanism located on the frame is provided with a base transportation device fitting with the base fixtures; and the left side of the base transportation device along the rotating direction of the turntable is provided with a button assembly mechanism cooperating with the base fixtures.

Owner:DONGGUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com