Friction-prevention back plate transverse positioning assembly

A lateral positioning and anti-friction technology, used in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of assembly material damage, hysteresis in problem discovery, and waste of personnel, to reduce the amount of foreign matter, reduce hard contact, The effect of improving the foreign body defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

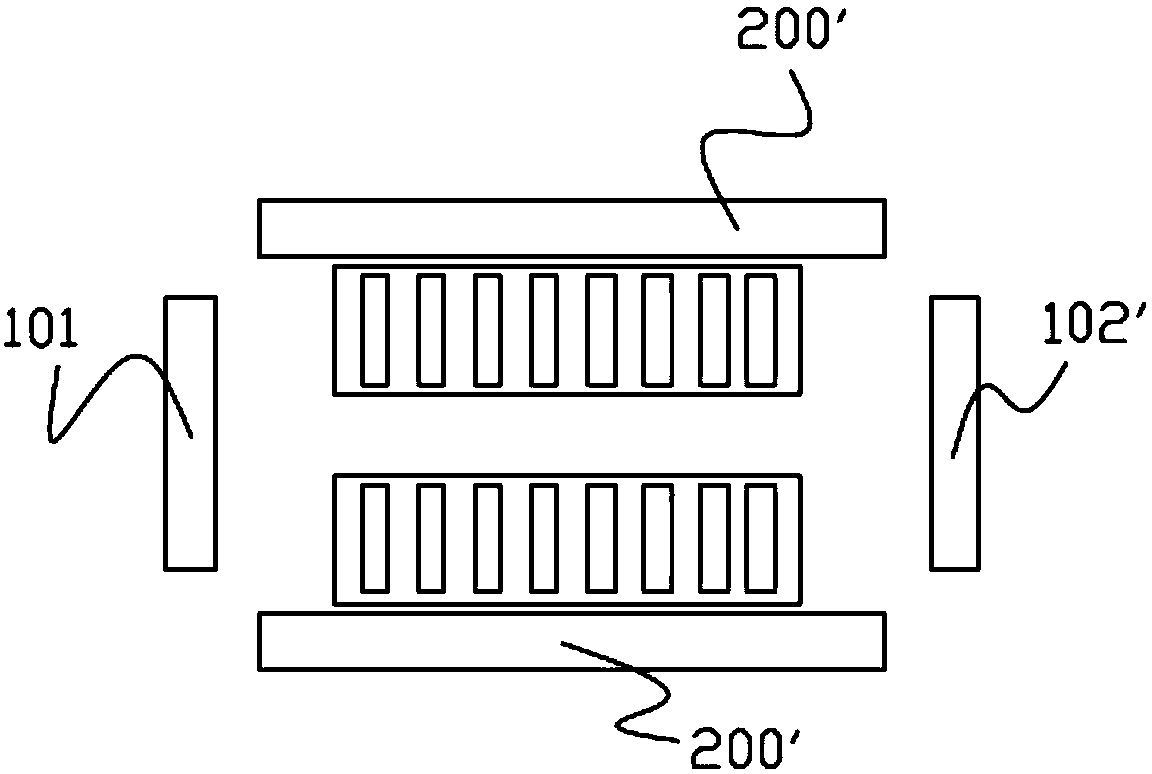

[0026] join figure 1 , the lateral positioning member 200' in the prior art serves as a lateral clamping member through a long condition in order to meet the lateral positioning of backboards of different sizes, and the outer wall of the backboard is not smooth, and when clamping, the backboard There is also a small amount of longitudinal movement of the plate, which will cause displacement between the back plate and the clamping parts, which will cause the back plate and / or the clamping parts to be worn and produce foreign objects; due to the movement of the back plate, assembly line rollers, and machine During the movement of the arm, the airflow in the machine will be disturbed for a short time, causing the generated foreign objects to fall onto the backplane, or be placed on the surface of the film material on the backplane, causing foreign objects to be defective.

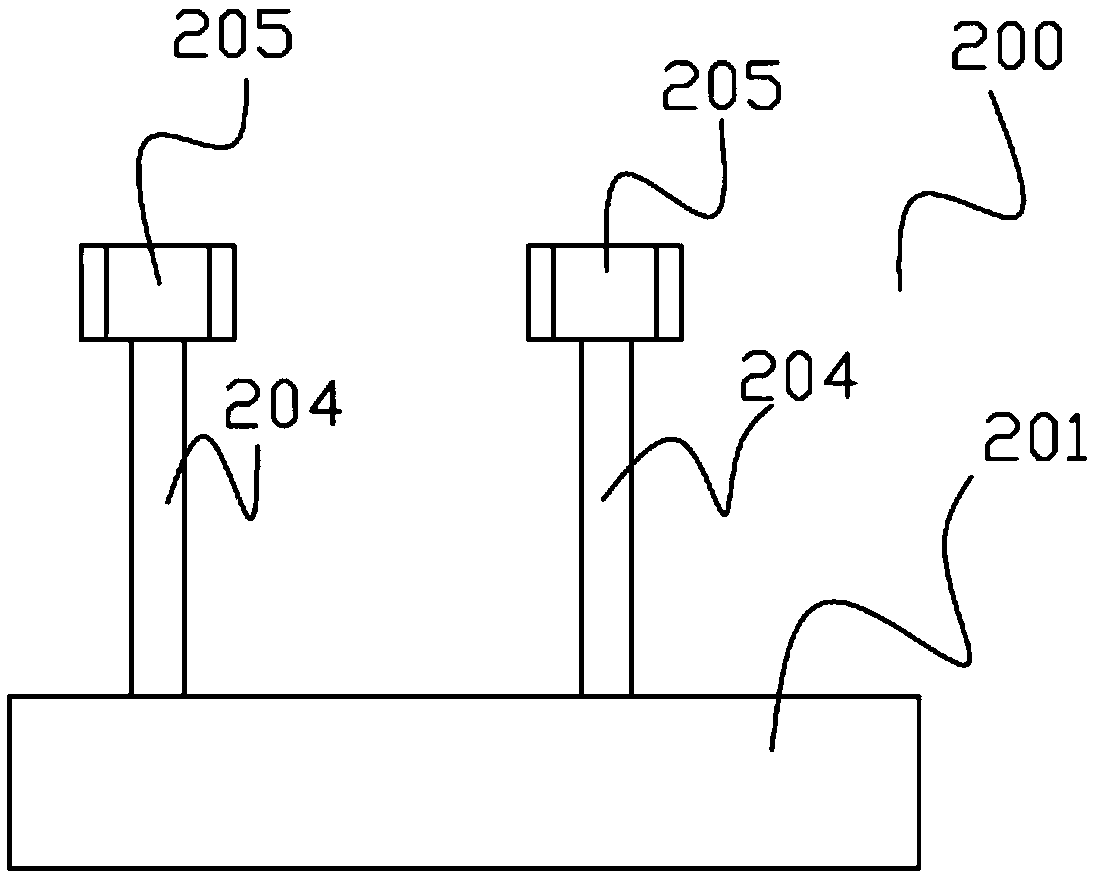

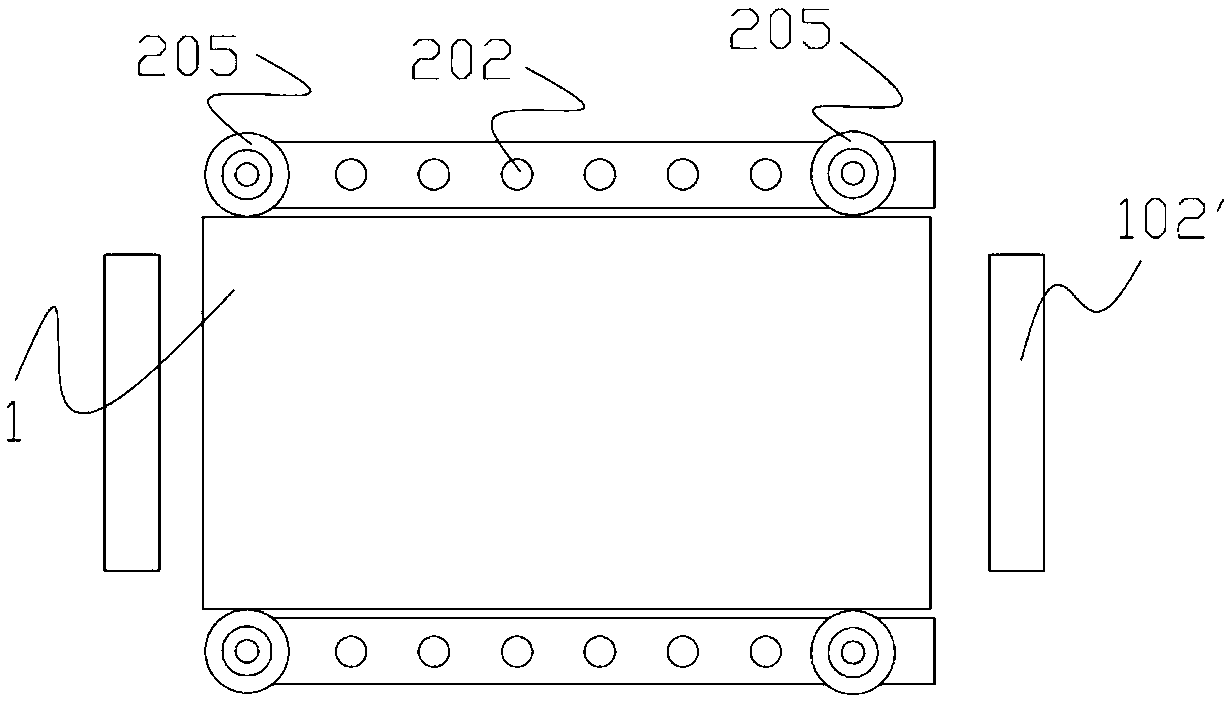

[0027] In order to solve the problem that the frictional force between the existing backplane lateral posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com