Circulating type centrifugal oil washing machine

A kind of oil washing machine and circulation technology, which is applied in the field of circulating centrifugal oil washing machine, can solve the problems such as difficult inflow, achieve the effect of easy handling, easy collection, and guaranteed fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

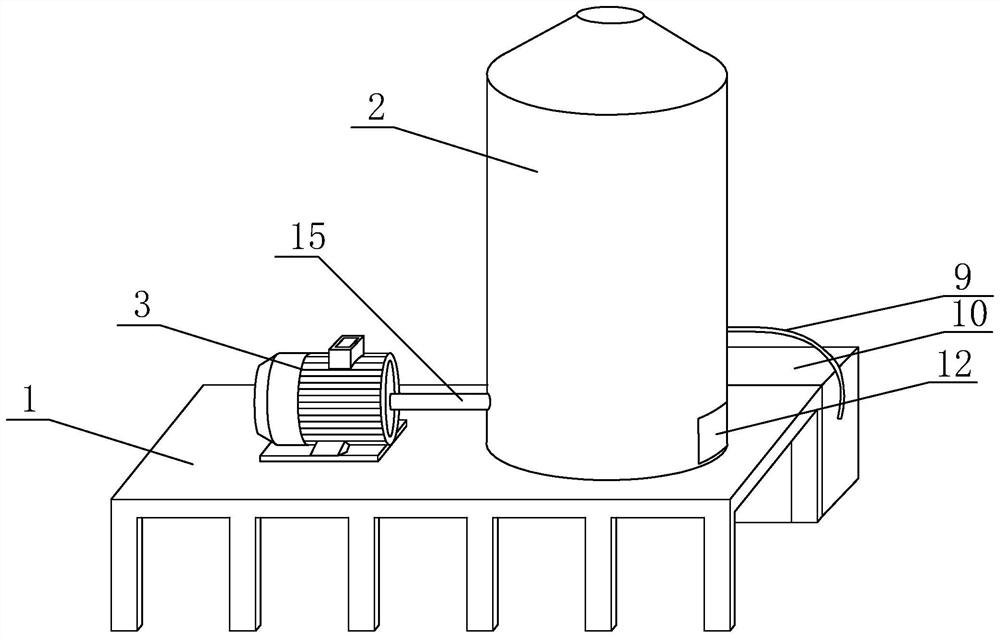

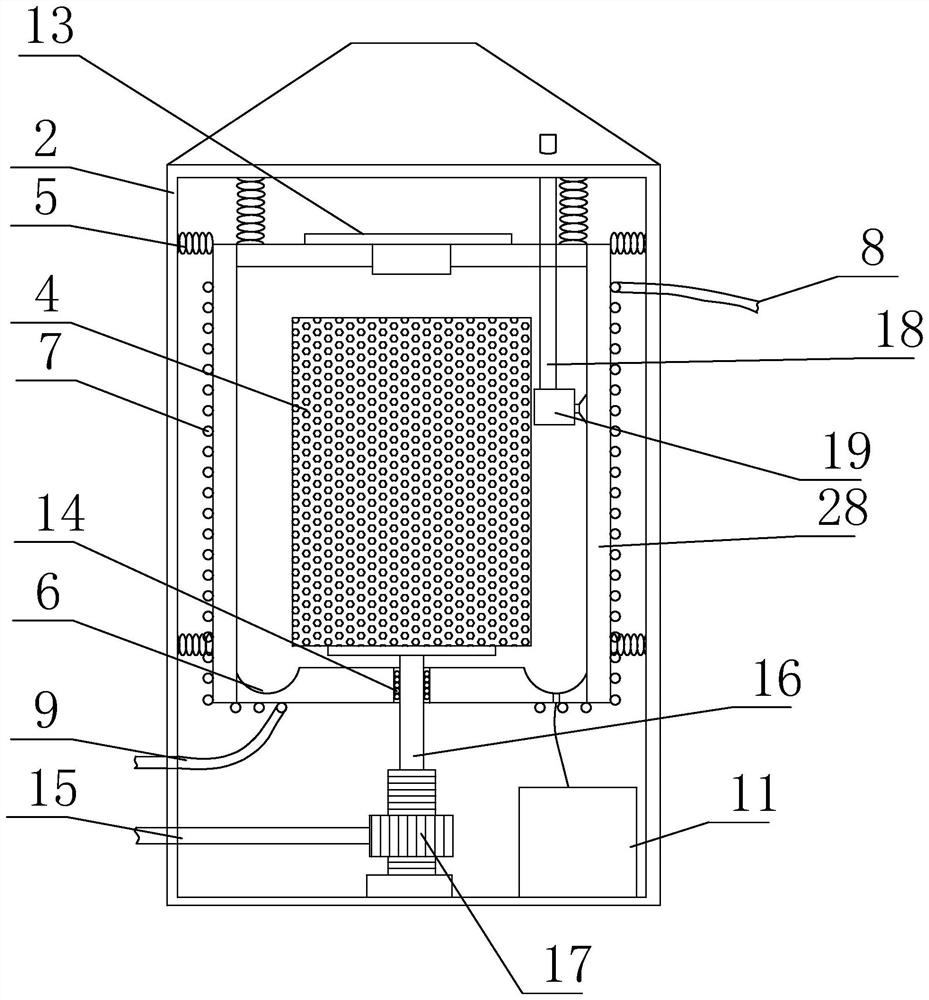

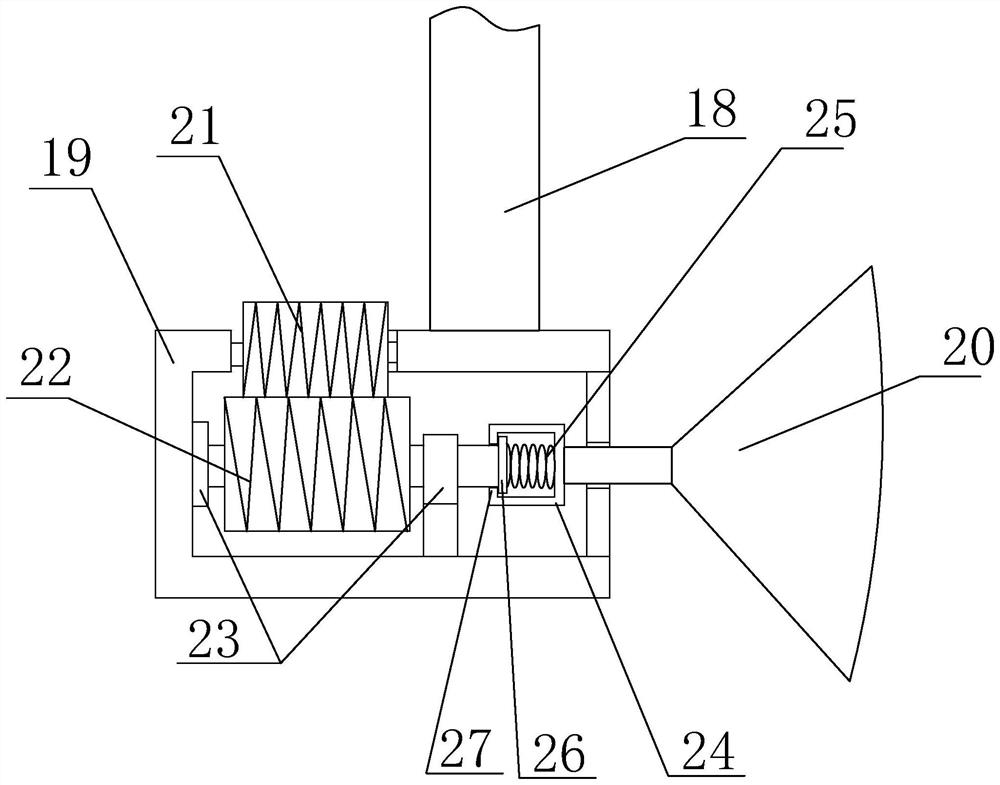

[0021] The present invention is described in further detail below:

[0022] For details, see Figure 1 to Figure 3 :

[0023] A circulating centrifugal oil washing machine, comprising a frame 1, an oil pan shell 2 arranged on the frame 1, a motor 3 arranged on one side of the oil pan shell 2, and a centrifugal barrel located inside the oil pan shell 2 4 and the transmission mechanism for connecting the output shaft of the motor 3 to the centrifugal barrel 4, and also includes an oil retaining barrel 28 arranged outside the centrifugal barrel 4 and a heating mechanism capable of heating the oil retaining barrel 28, the oil retaining barrel 28 Set concentrically with centrifugal barrel 4, the periphery of oil retaining barrel 28 is fixed on the inner wall of pan shell 2 by several extension springs 5, and is provided with discharge port at the upper end of oil retaining barrel 28, the bottom of oil retaining barrel 28 A mounting hole for the transmission mechanism to pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com