A kind of manufacture method of anti-radiation eeprom

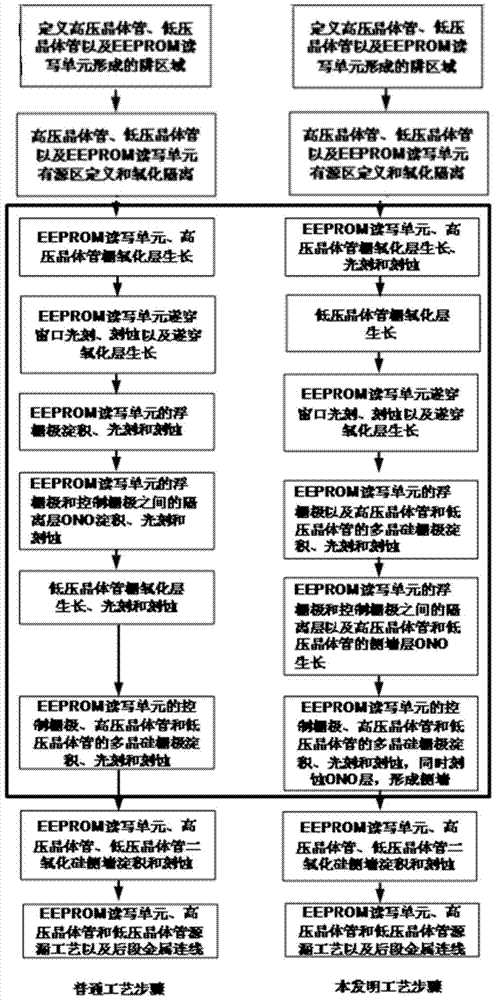

A manufacturing method and anti-irradiation technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems that circuits cannot work normally under radiation conditions, electrical signals are unstable, etc., and achieve improved resistance Radiation performance, small defect density, and the effect of improving radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Hereinafter, the manufacturing method of the radiation-resistant EEPROM proposed by the present invention will be introduced in detail.

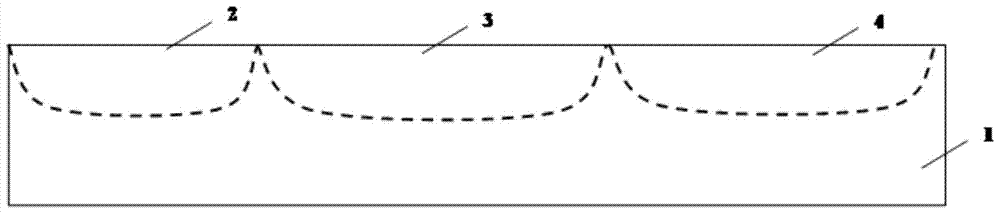

[0044] Such as diagram 2-1 As shown, P-type silicon 1 is used as the substrate material, its crystal orientation is , and the resistivity of the material is 15-25Ω·cm. The photolithographic definition of the well area is carried out through the mask plate: the ion implantation area of the low-voltage transistor 2 well, the EEPROM memory unit 3 well, and the high-voltage transistor 4 well. Then ion implantation, glue removal, and high-temperature diffusion to form a low-voltage transistor well region, an EEPROM memory cell region well region, and a high-voltage transistor well region.

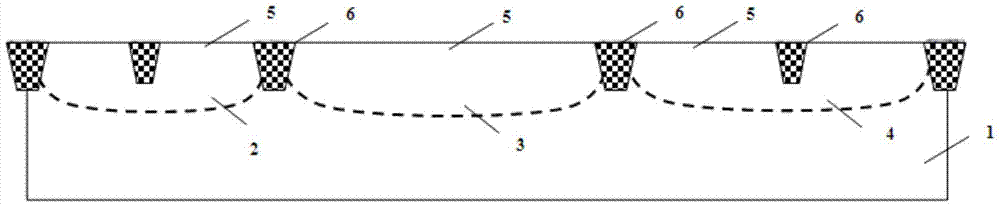

[0045] Such as Figure 2-2 As shown, an oxidation isolation is formed. Through the local oxidation process LOCOS or the shallow trench isolation process STI, multiple regions isolated by field oxides are formed on the P-type silicon 1, which are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com