Sealing method of heat pipe and finished product of sealing method

A sealing and heat pipe technology, which is applied to the sealing method of thermally conductive components and their finished products, can solve the problems of low heat pipe yield, time-consuming sealing process, eccentricity at the end of the heat pipe, etc., so as to improve welding quality, improve yield, reduce The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the heat pipe sealing method and its finished product of the present invention in detail, and realize the invention according to the content of the invention, the preferred embodiment shown in the drawing is further described in detail as follows:

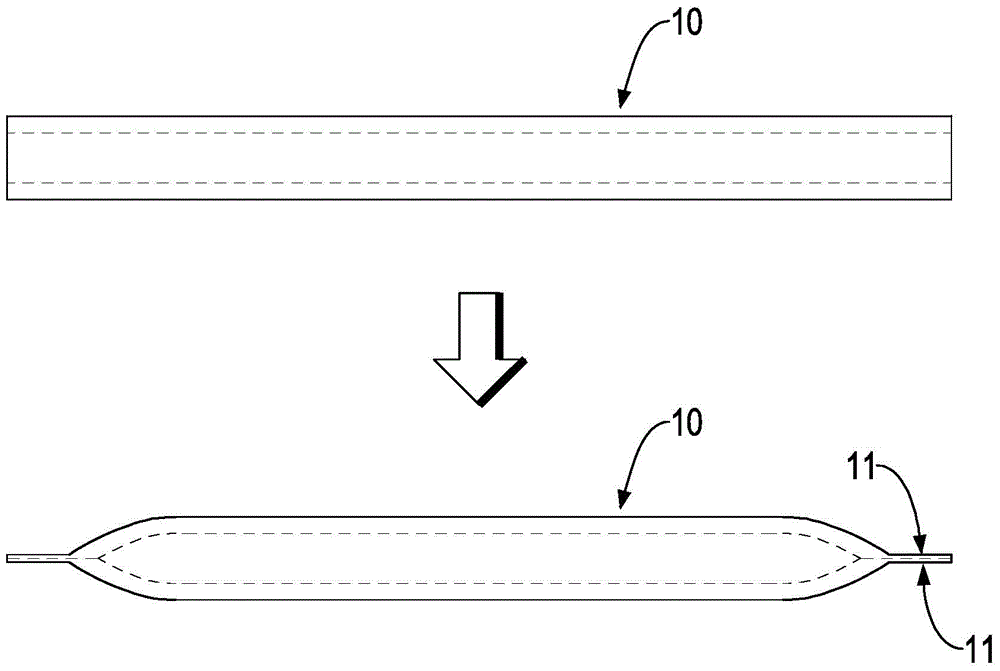

[0032] The present invention is a heat pipe sealing method and its finished product, please refer to figure 1 Shown is a preferred embodiment of the sealing method of the heat pipe, by the above-mentioned sealing method can produce such as Figure 4A and Figure 4B Finished heat pipe shown.

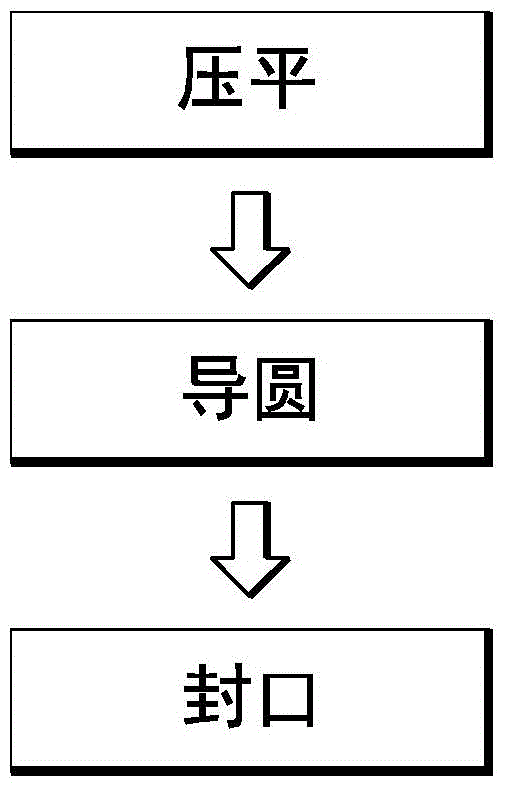

[0033] like figure 1 As shown, the sealing method of the above-mentioned heat pipe includes the steps of flattening, rounding and sealing in sequence, wherein:

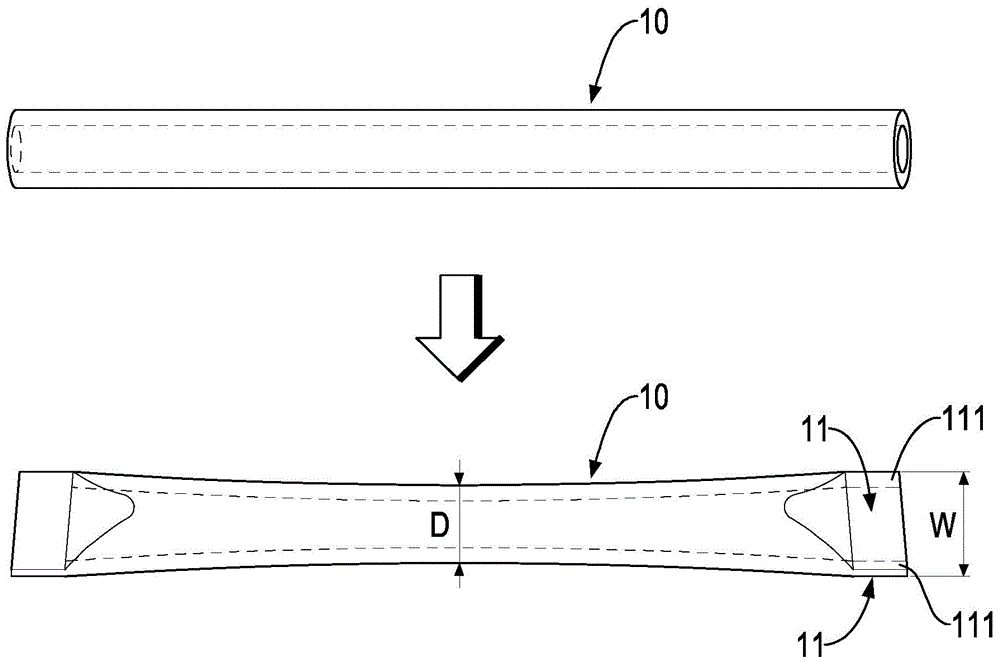

[0034] Flattening procedure, see Figure 2A and Figure 2B , the two ends of a tube body 10 made of metal are flattened with a flattener, so that the ring-shaped ends of the tube body 10 are flattened into two pressing surfaces 11 that are attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com