High-strength projection-type capacitive screen and manufacturing method thereof

A production method and projection technology, applied in the field of capacitive screens, can solve the problems of difficult yield control, poor light transmission, heavy structure, etc., and achieve the effect of saving process, avoiding direct contact and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

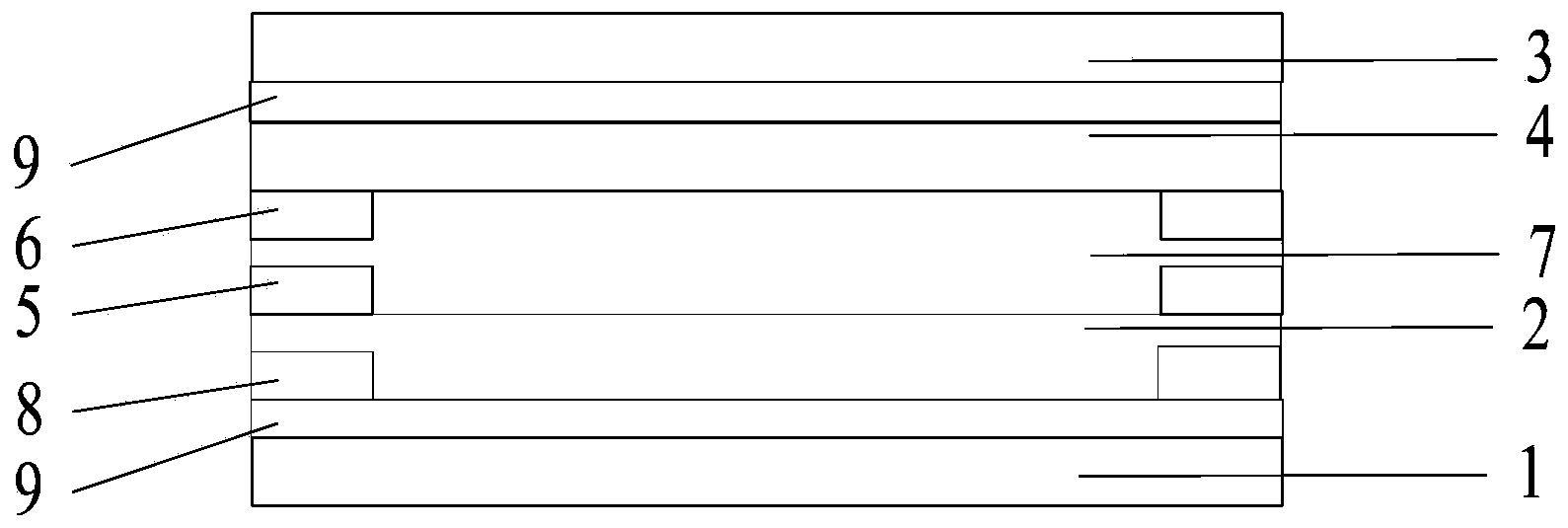

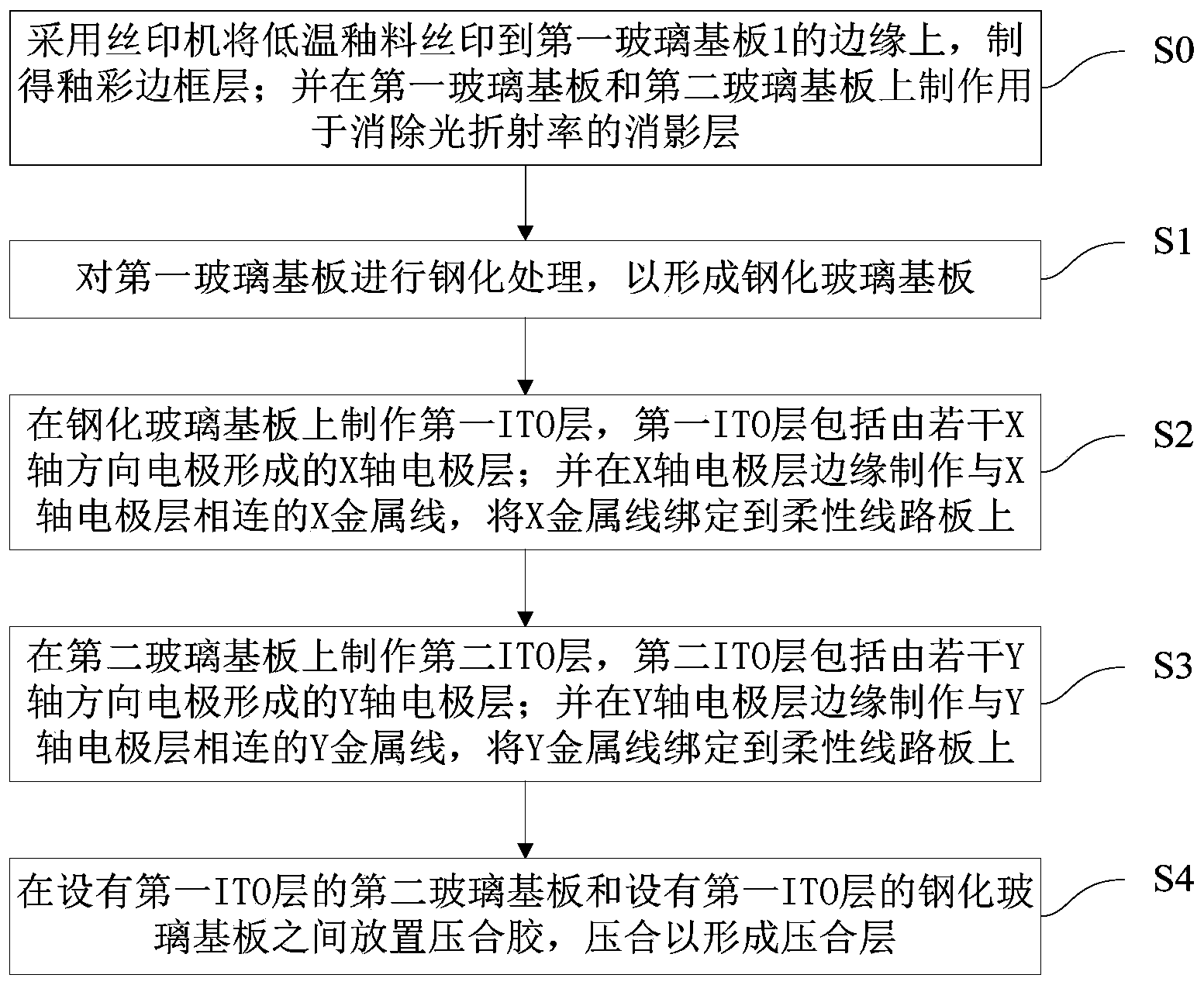

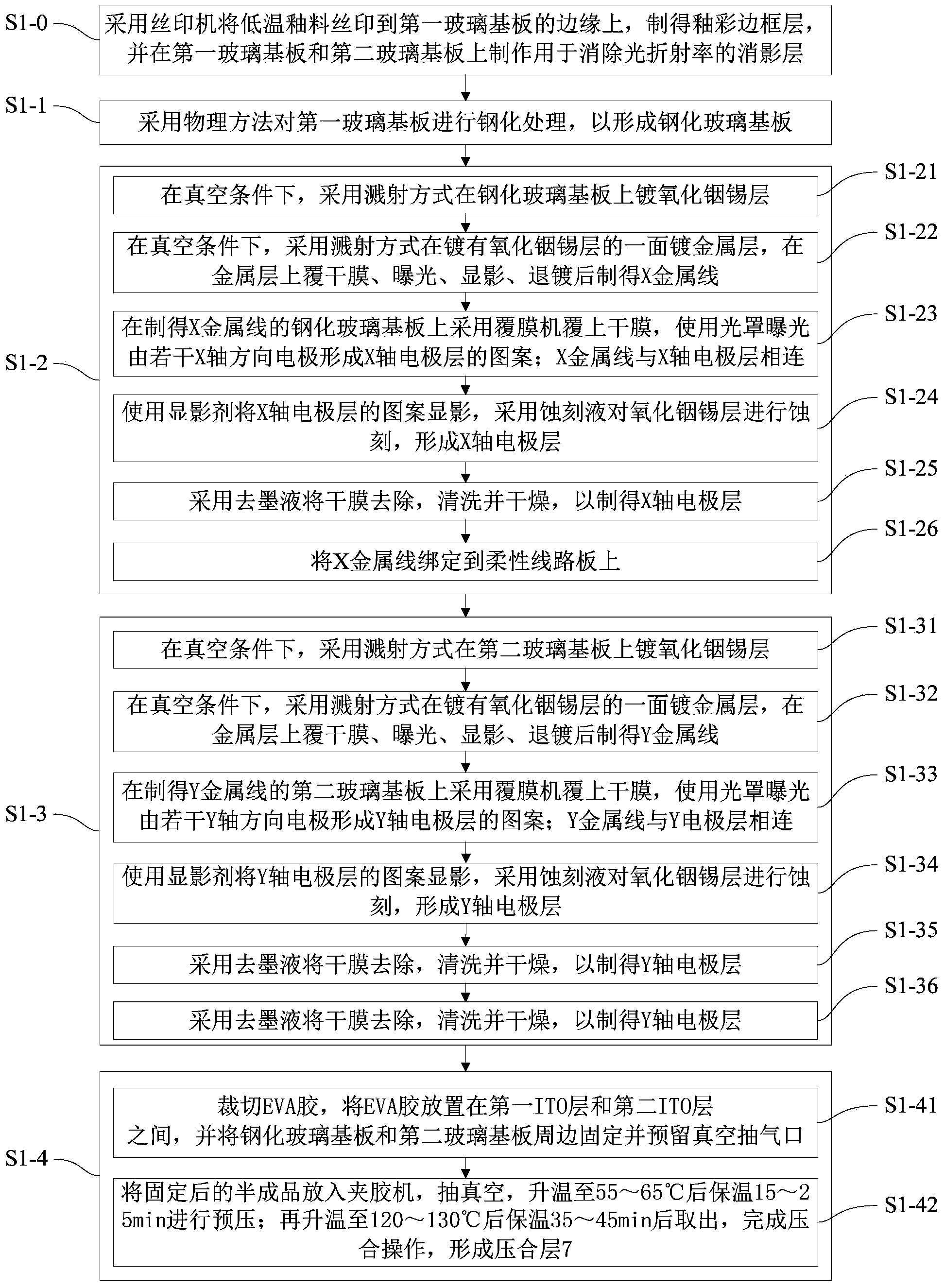

[0064] Such as figure 2 , image 3 As shown, the present invention also provides a method for manufacturing a high-strength projected capacitive screen, comprising the following steps:

[0065] S1-0: use a screen printing machine to screen-print the low-temperature glaze onto the edge of the first glass substrate 1 to obtain a glaze frame layer 8; The disappearing layer9. Among them, the low-temperature glaze is a glaze with a temperature of 400-700°C. When the low-temperature glaze is screen-printed on the first glass substrate 1, it needs to be baked at a temperature of 400-700°C, so that the baked glaze has Strong covering force. More specifically, the screen printing of low-temperature glaze onto the edge of the first glass substrate 1 specifically includes the following steps: bottom plate, drying board, development, drying, revision, printing, drying, and finished product; wherein, drying board includes screen selection, frame selection , Stretching, drying, coating...

Embodiment 2

[0094] Such as figure 2 , Figure 4 As shown, the present invention also provides a method for manufacturing a high-strength projected capacitive screen, comprising the following steps:

[0095] S2-0: use a screen printing machine to screen-print the low-temperature glaze onto the edge of the first glass substrate 1 to obtain a glaze frame layer 8; The disappearing layer9. Understandably, step S2-0 is consistent with the manufacturing method of step S1-0 in Embodiment 1.

[0096] S2-1: Using a chemical method to temper the first glass substrate 1 to form a tempered glass substrate. Specifically, step S2-1 includes: treating the first glass substrate 1 with a high-temperature ion exchange method or a low-temperature ion exchange method.

[0097] Specifically, the high-temperature type ion exchange method is at a temperature greater than or equal to the softening point of the glass of the first glass substrate 1, adding Na 2 O or K 2 The first glass substrate 1 of O is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com