Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Guaranteed Material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

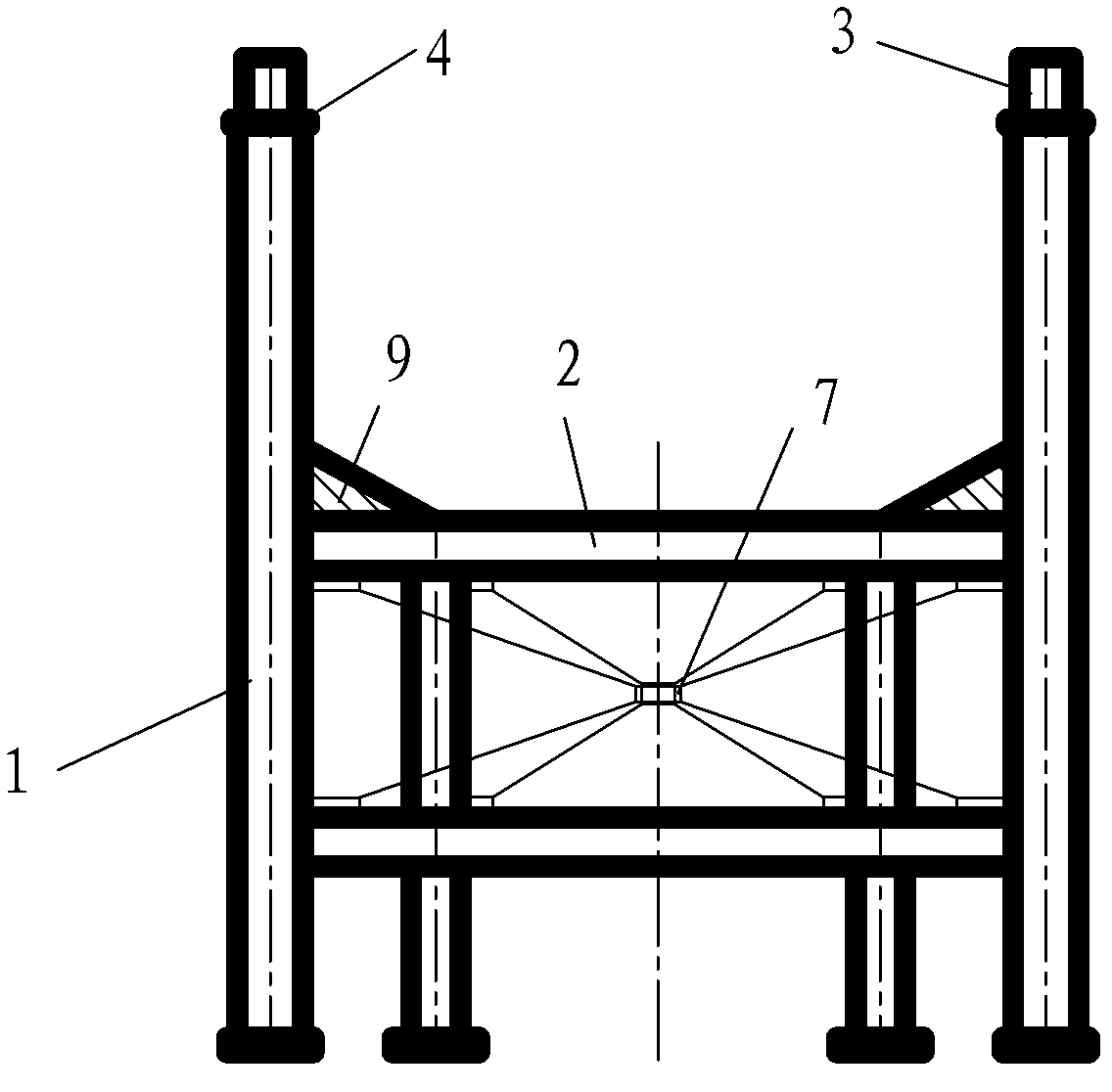

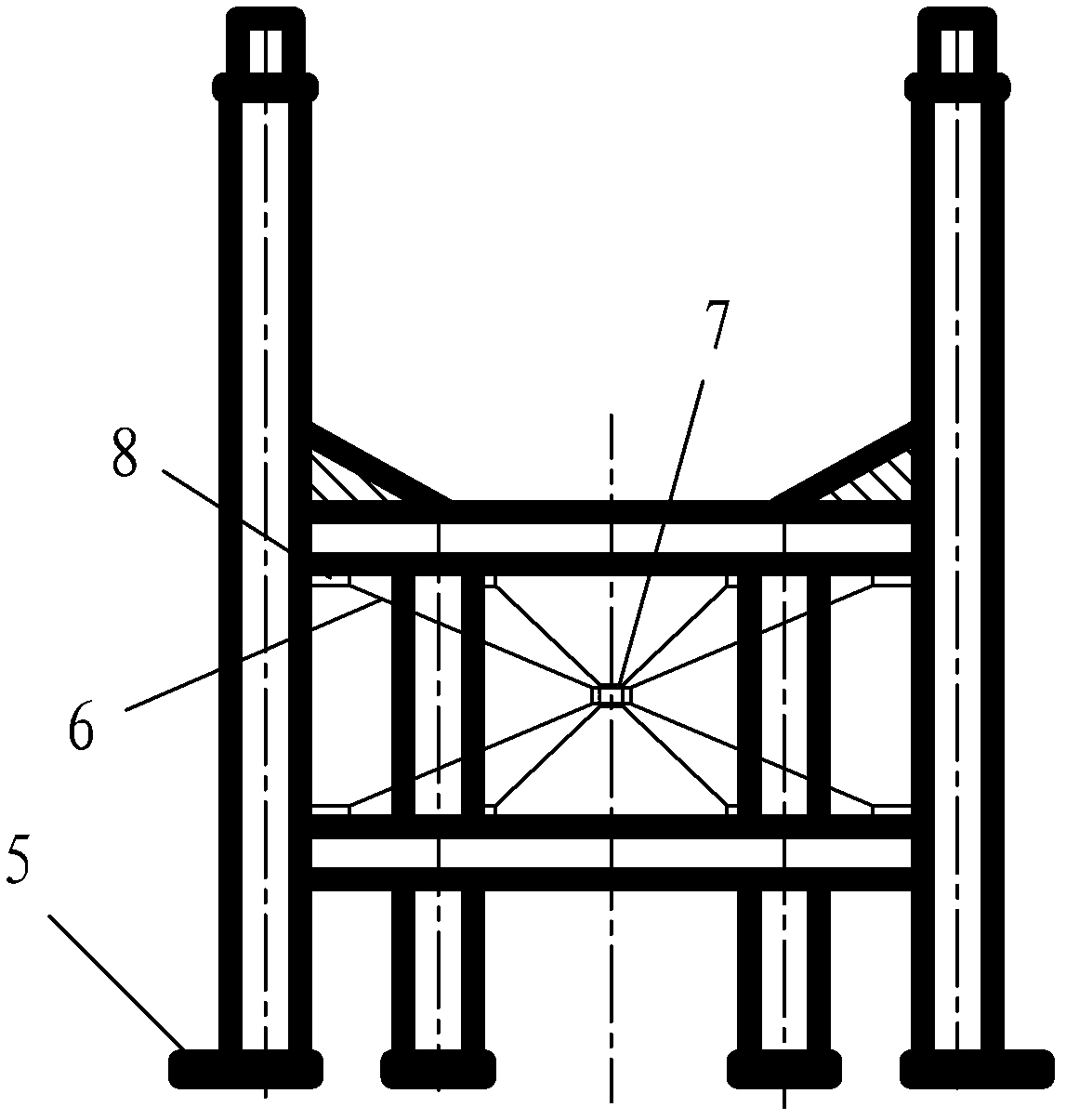

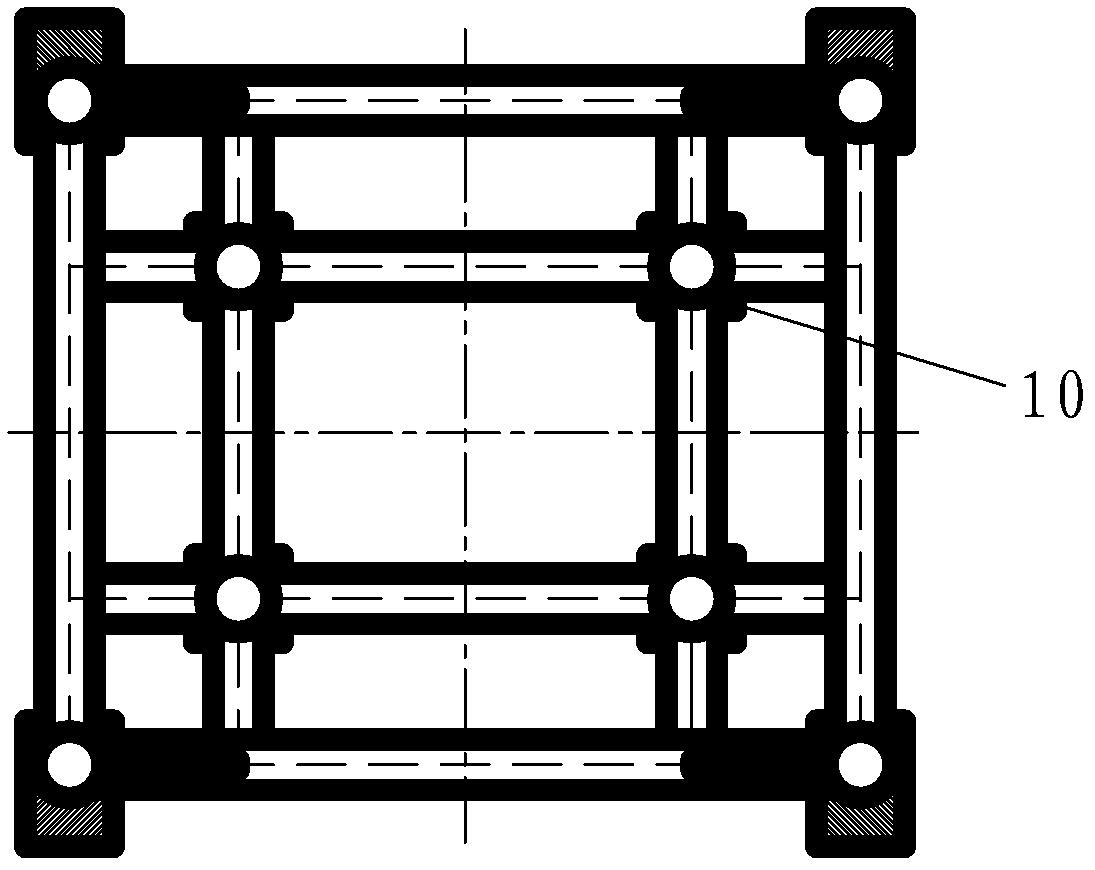

Method for installing converter body equipment and tooling platform

InactiveCN102146492AImprove installation accuracyShorten the construction periodManufacturing convertersBeam angleBuilding construction

The invention discloses a method for installing converter body equipment and a tooling platform. The tooling platform comprises a platform body; the platform body comprises external four steel pipe upright posts and internal four steel pipe upright posts; the internal four steel pipe upright posts are shorter than the external four steel pipe upright posts; the steel pipe upright posts are vertically provided with cross beams, every eight cross beams are positioned on one layer, the cross beams are on the upper and lower layers of the same structure, and the cross beams of each layer are arranged in a ''#'' shape and encircle a square through the external steel pipe upright posts; stiffening plates are arranged below the cross beams connected with the steel pipe upright posts; oblique supporting angle steels are connected on the stiffening plates; a reinforcing plate is arranged at the joint of the upper and low cross beam angle steels; a jack supporting plate is arranged at the tops of the external four steel pipe upright posts; and jack fixing pipes are arranged on the jack supporting plates. The tooling platform assists the installation of a converter, can shorten the construction period and save 60 percent of expense, is convenient for accurate alignment of the equipment, improves the installation precision of the converter body equipment, and ensures the installation quality of the equipment.

Owner:TIANJIN 20 CONSTR

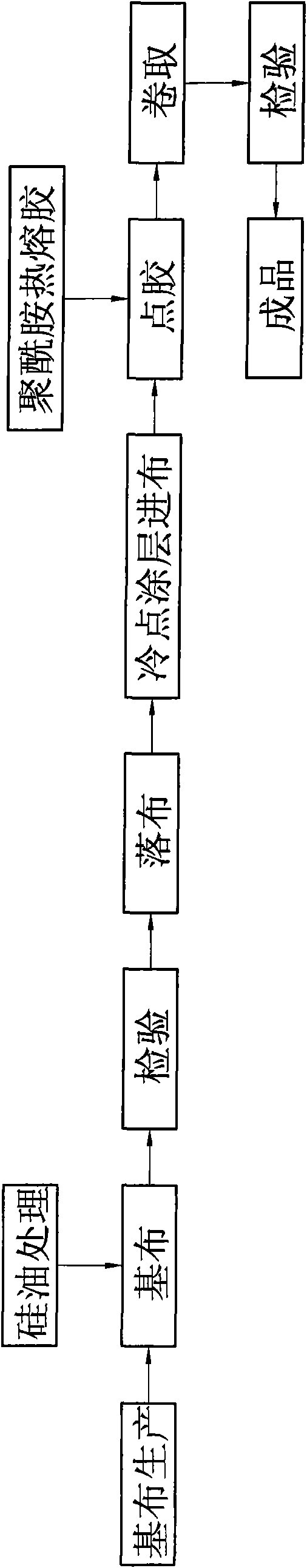

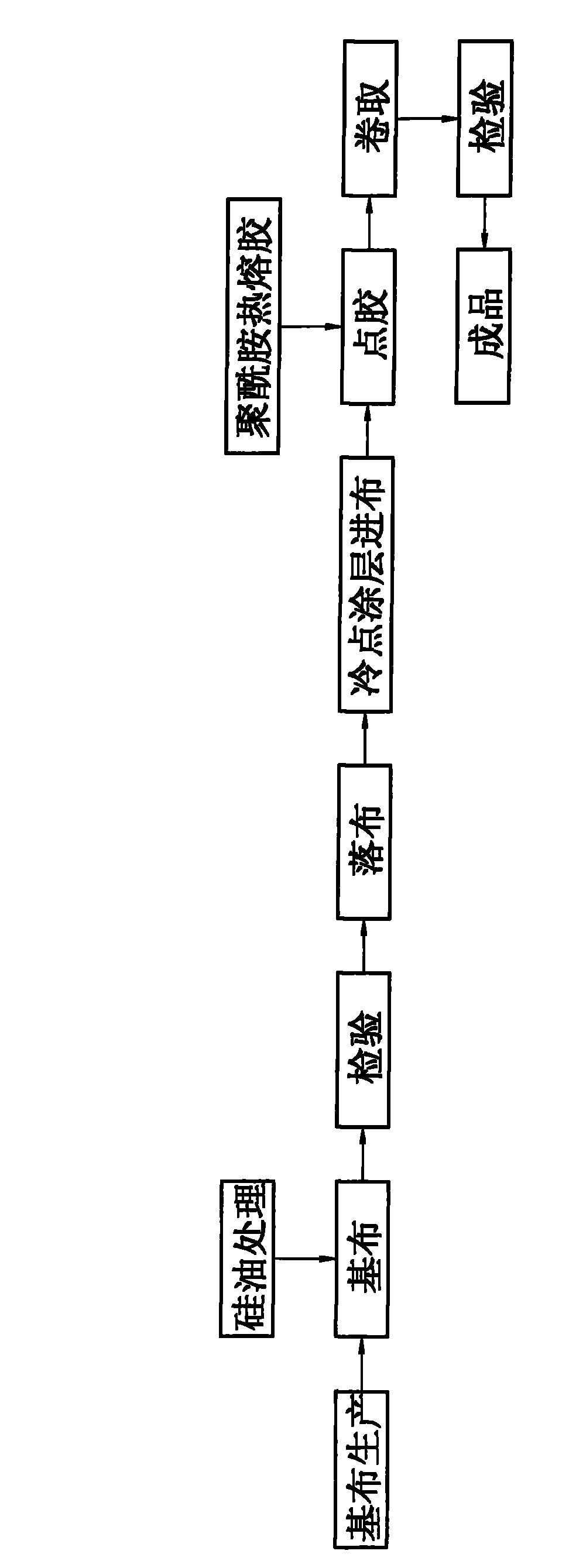

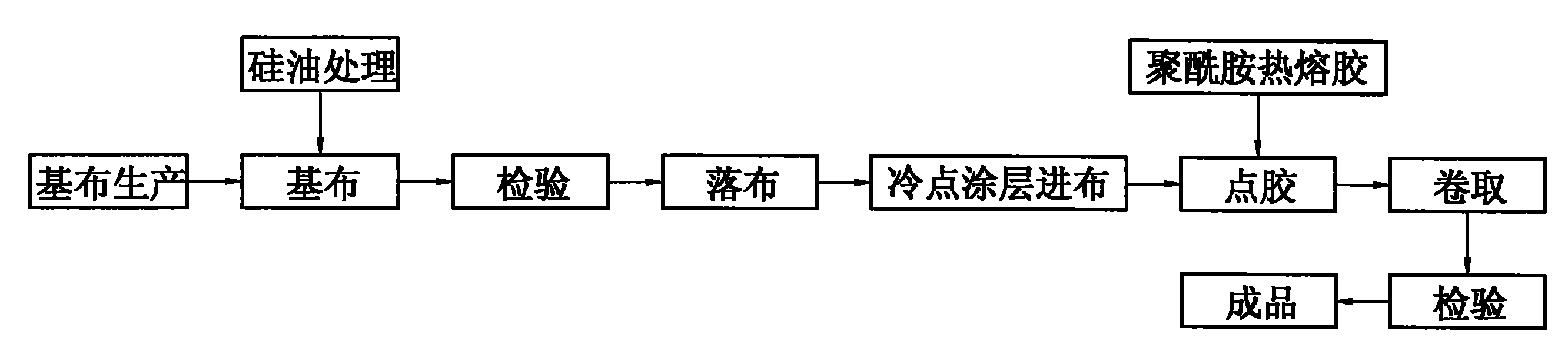

Production process of cold silicone liner

InactiveCN101584507AGuaranteed MaterialGuaranteed styleFibre treatmentGarmentsPolyamideMicroemulsion

The invention discloses a production process of cold silicone liner, comprising the steps as follows: dipping the produced base cloth, adding with non-ionic microemulsion of amino-modified organic siloxane with 20% fabric weight, the treating temperature being 40 to 50 degrees centigrade, the treatment time being 15 to 20 minutes, then padding, the mangle expression being about 50%, then drying under 120 to 150 degrees centigrade, feeding and dispensing the cold coating; directly painting the polyamide hot-melt adhesive on the base cloth through the cylinder blade; the screen meshes of the cylinder being 140 to 180 screen meshes, the aperture being 0.12 mm, the thickness being 0.02 mm, and the vehicle speed being 30m / min, the environmental temperature in shop being 20 to 30 degrees centigrade, the humidity being 60% to 70%. The invention has the advantages of ensuring the original material and style of the base cloth at maximum without heating; and the products have clear cement and the gum does not fall off, and the bonded fastness and the quality stability are high.

Owner:CHANGXING SHIANTE CLOTHING MATERIAL

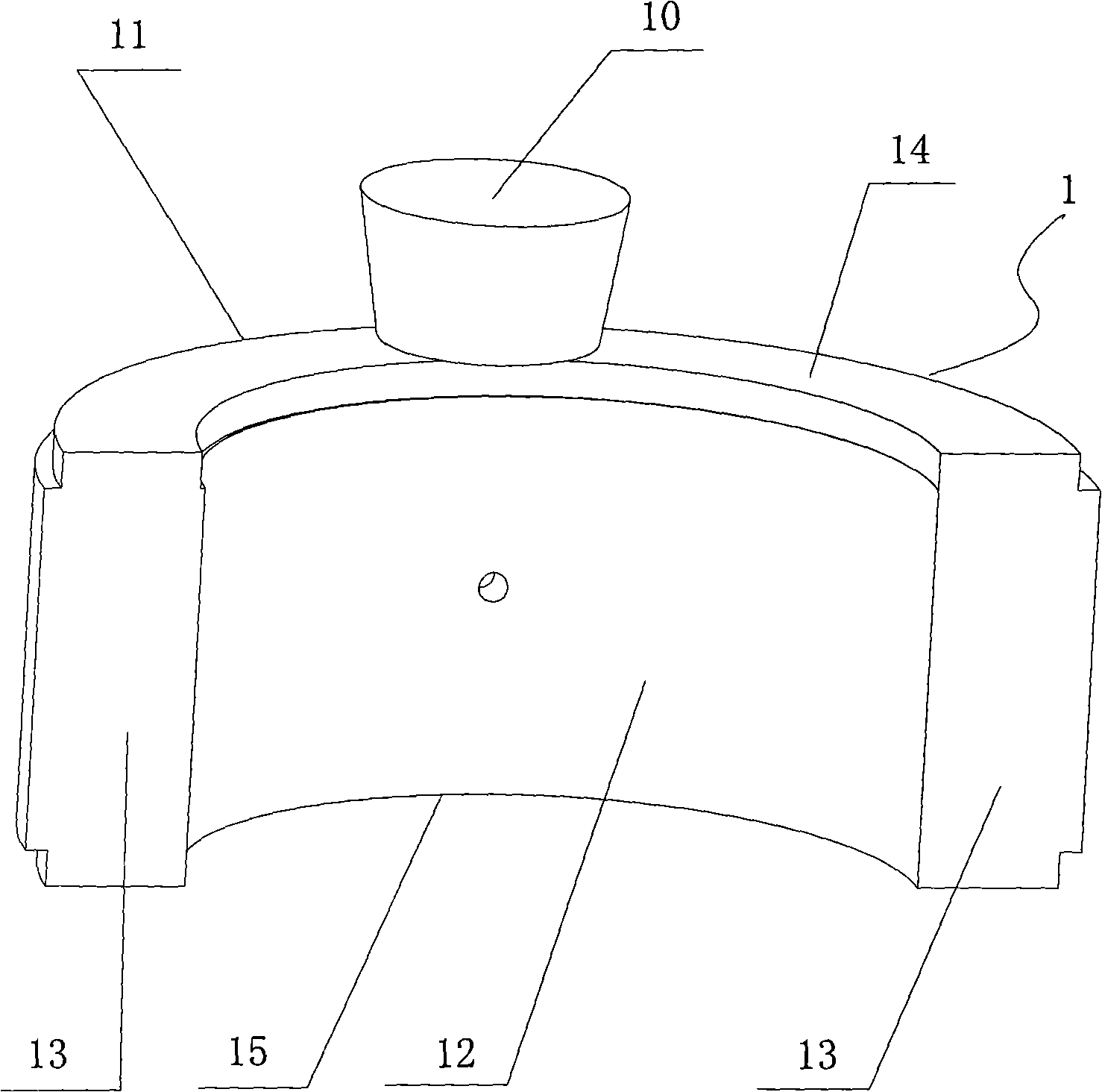

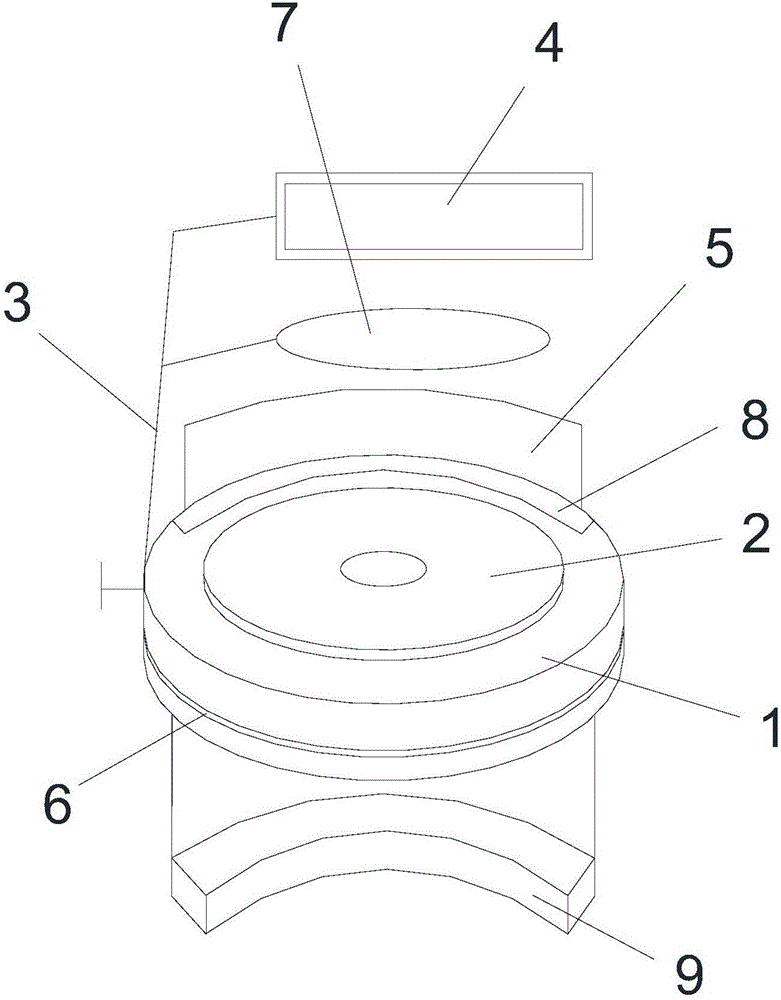

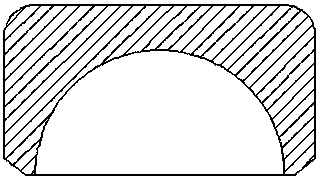

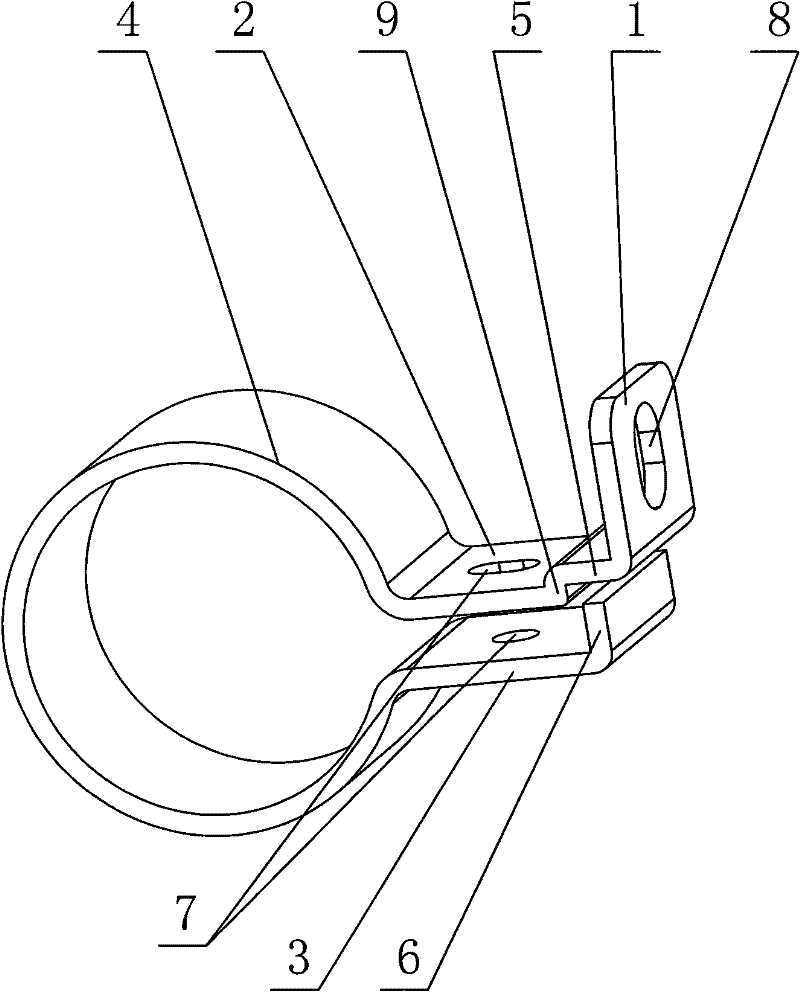

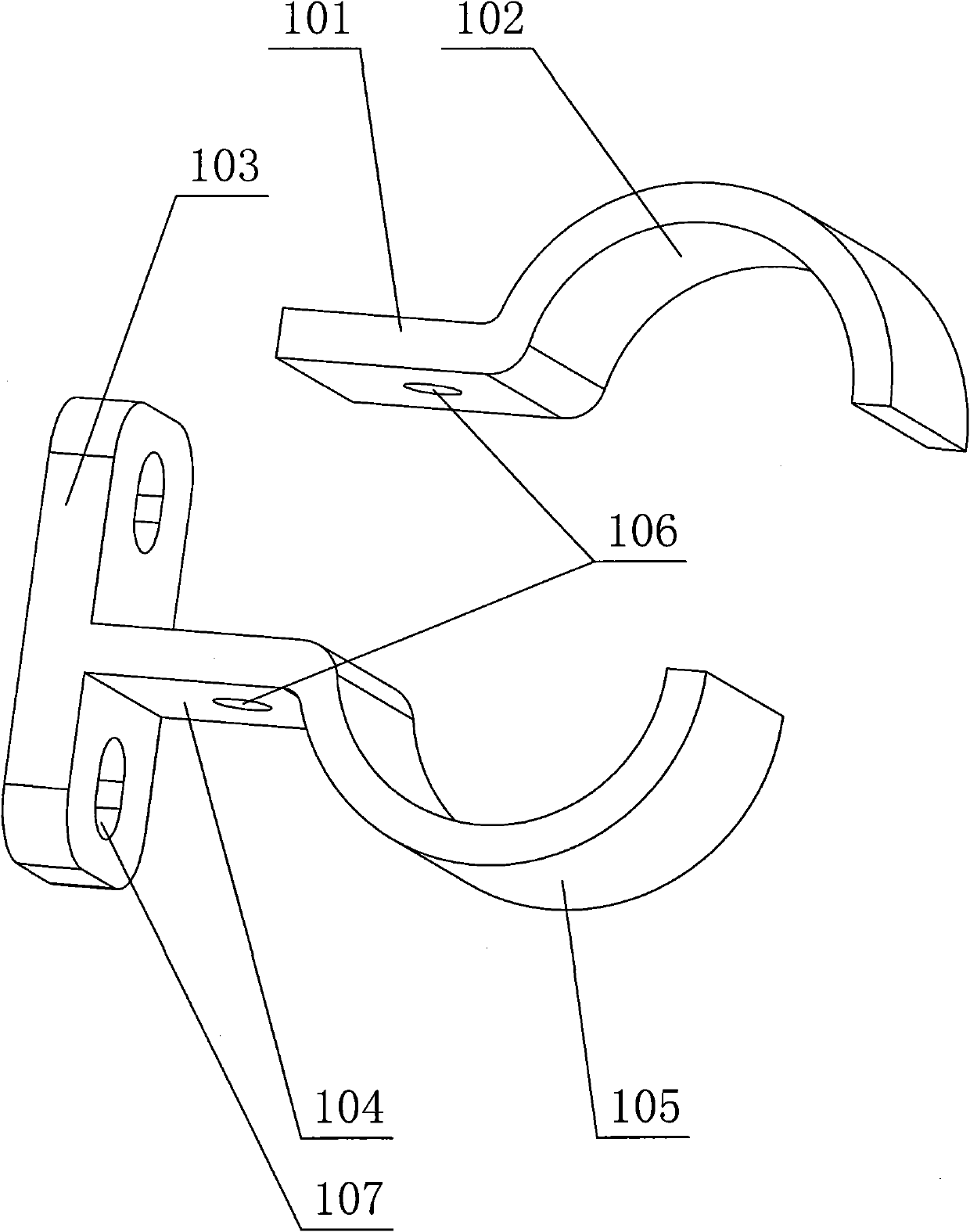

Casting parts structure of electricity generator cast steel shaft bushing and casting method thereof

InactiveCN101274352AGuaranteed MaterialGuarantee casting qualityFoundry mouldsBearing componentsElectricitySteel casting

The invention discloses a casting product structure of a steel-cast gap block of an electric generator and a casting method thereof. The steel-cast gap block is a semicircle cylinder with a spherical zone surface, an inner tiling surface and a commissure surface which are respectively positioned on lateral surfaces of the casting product, two end faces of the steel-cast gap block are respectively positioned at the top and the bottom of the casting product, and a shrink head of the casting product is arranged on one end face of the steel-cast gap block that is positioned at the top of the casting product. The casting method comprises the following steps: molding and core making, raw material smelting, pouring, cleaning of the casting product, rough processing of the casting product and stress annealing, wherein, the pouring takes a bottom pouring way, and a pouring gate is positioned on the other end face of the steel-cast gap block. The casting product structure of the steel-cast gap block of the electric generator and the casting method of the invention arrange the shrink head of the casting product on one end face of the steel-cast gap block that is positioned at the top of the casting product, and the spherical zone surface and the inner tiling surface of the steel-cast gap block is positioned on two lateral surfaces of the casting product, thus basically ensuring the casting quality of the two surfaces of the steel-cast gap block.

Owner:上海电气集团上海电机厂有限公司

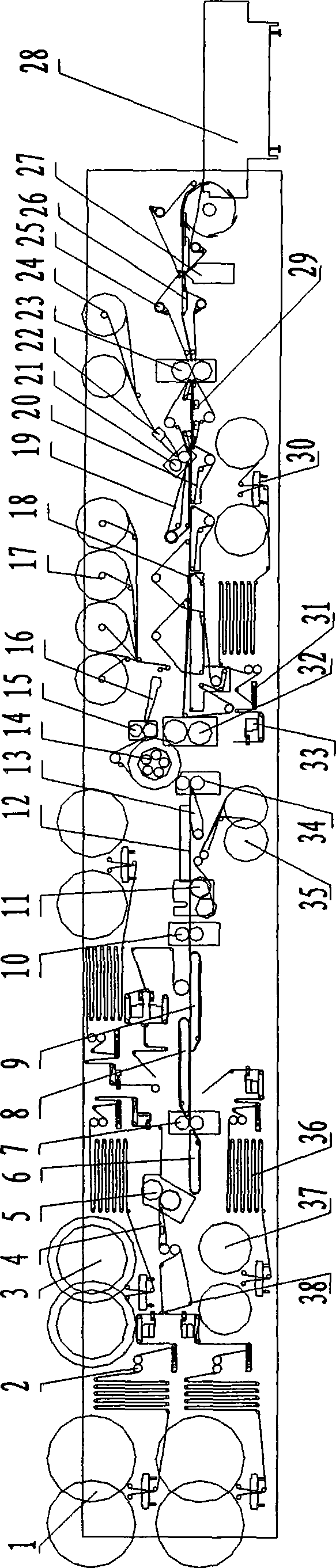

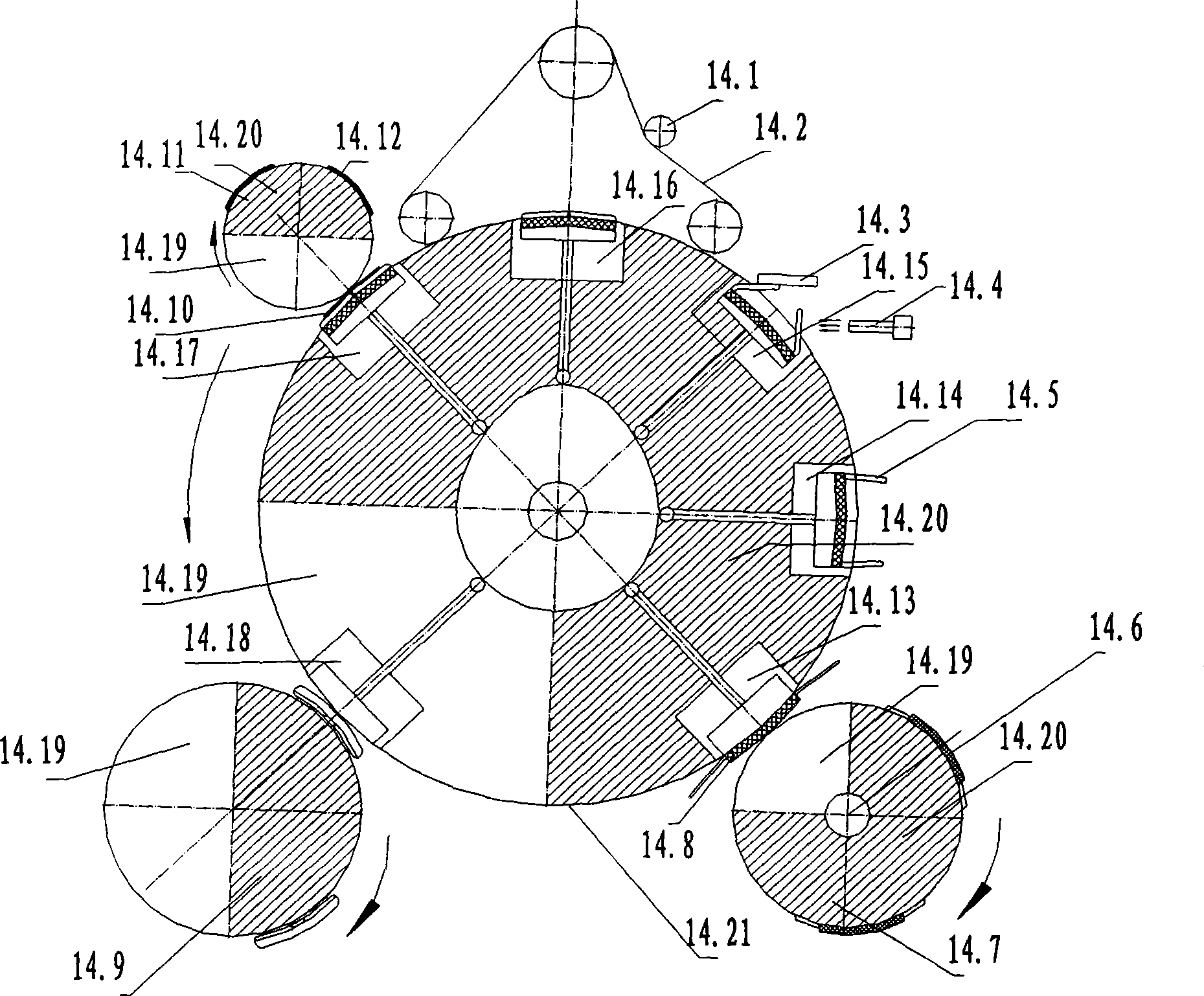

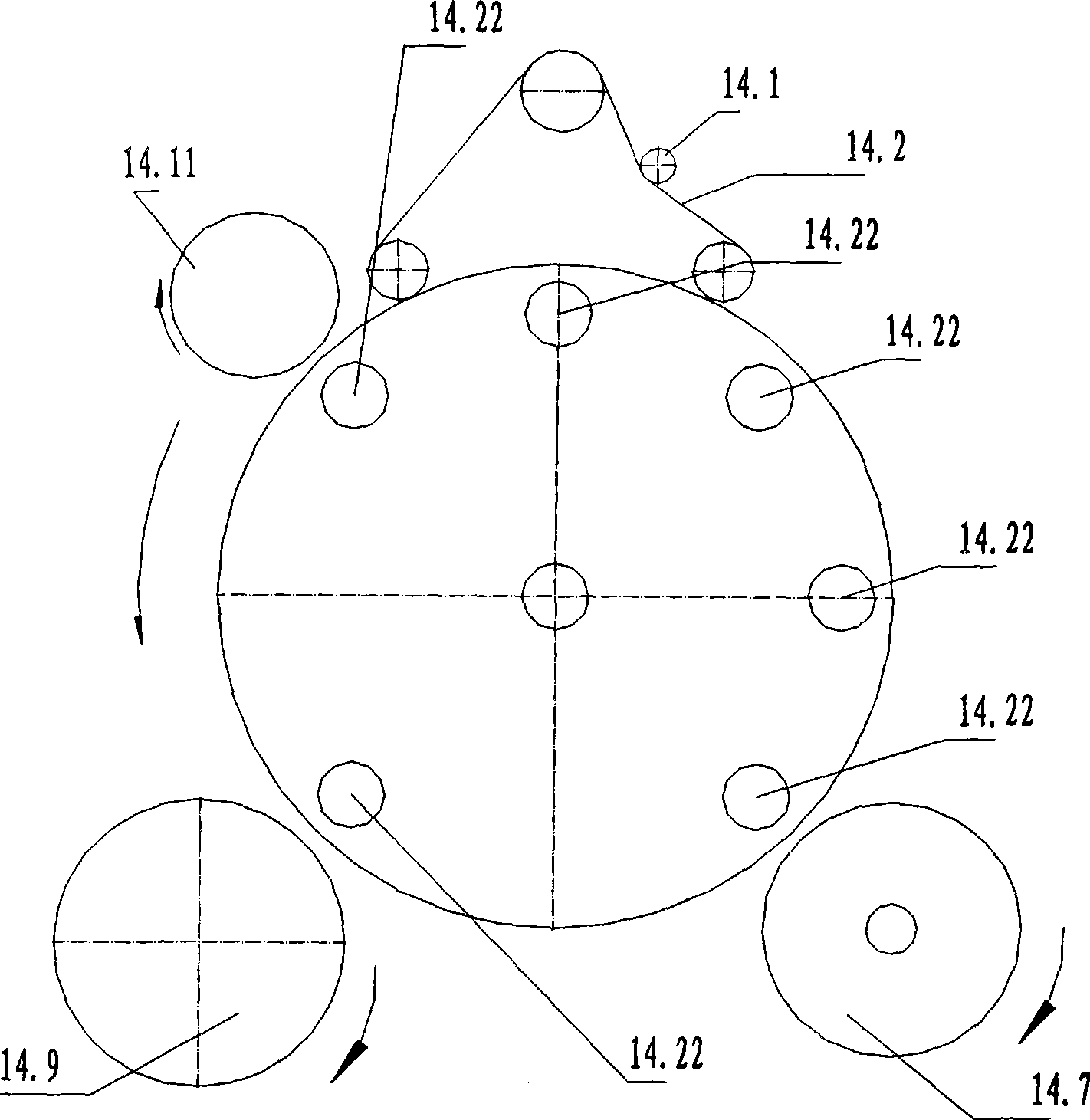

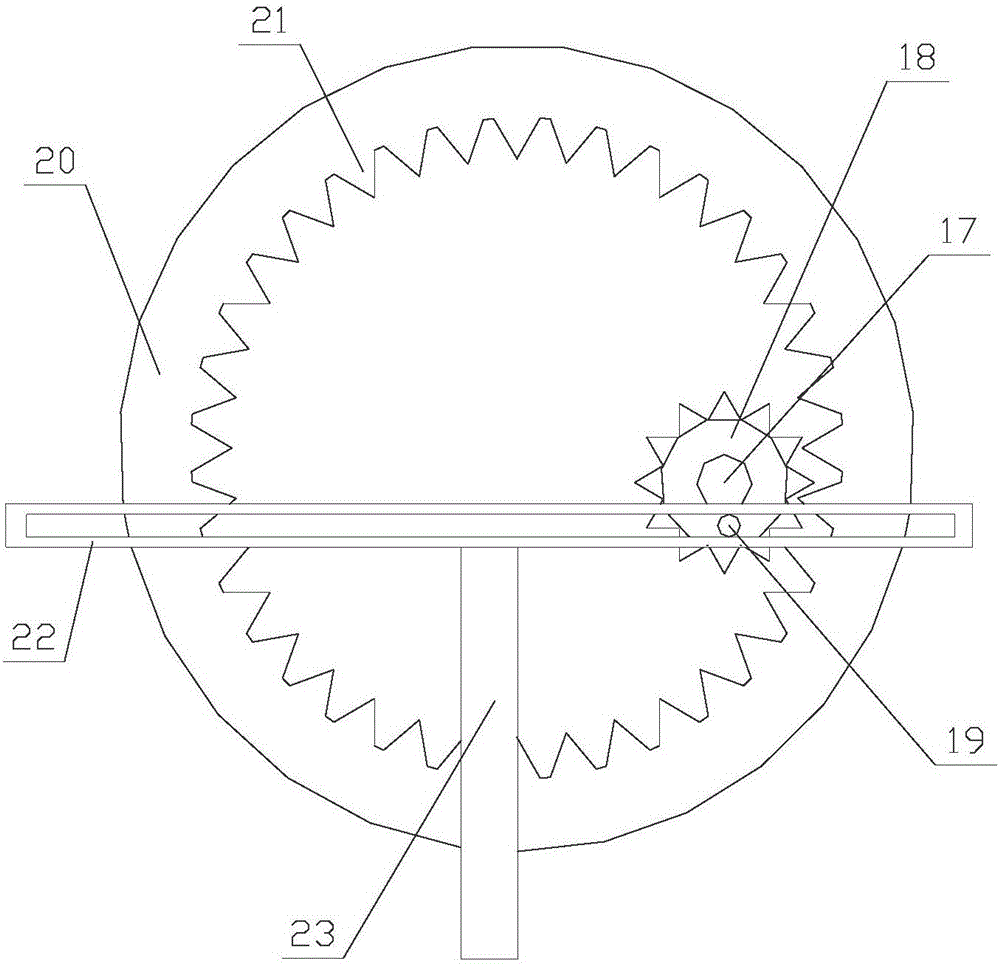

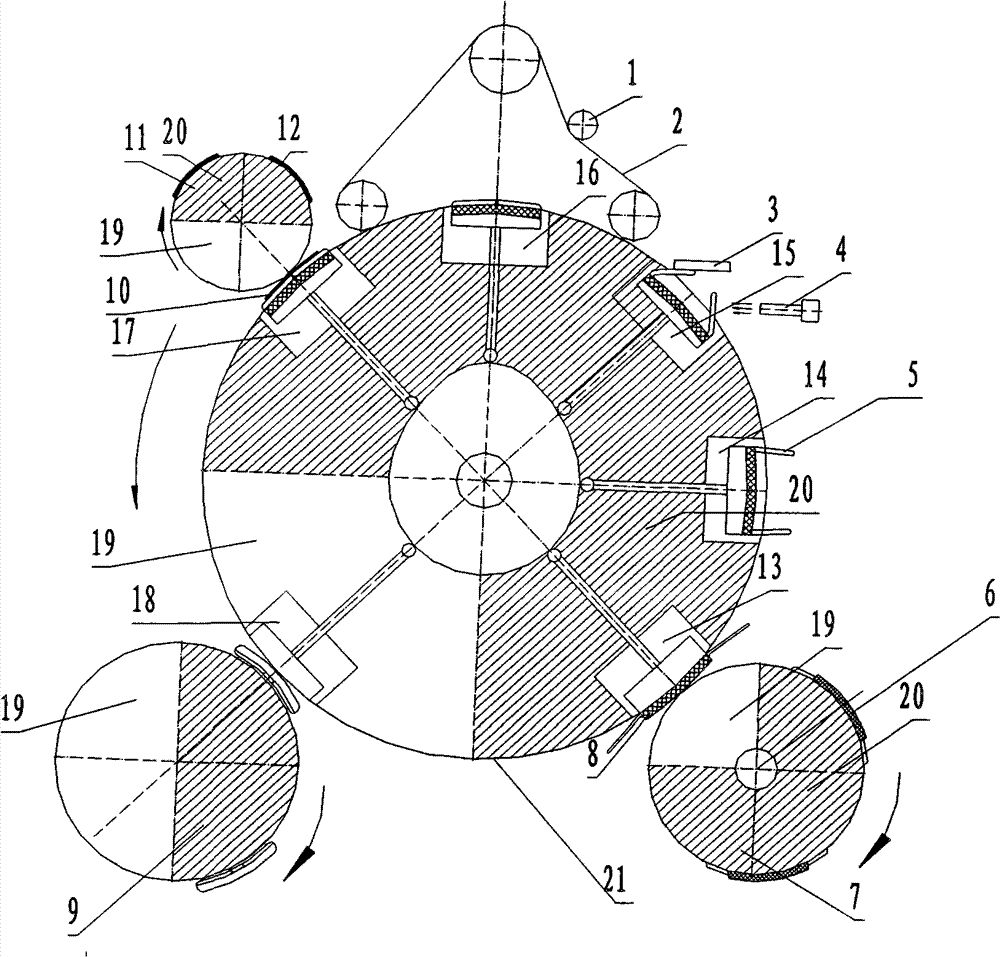

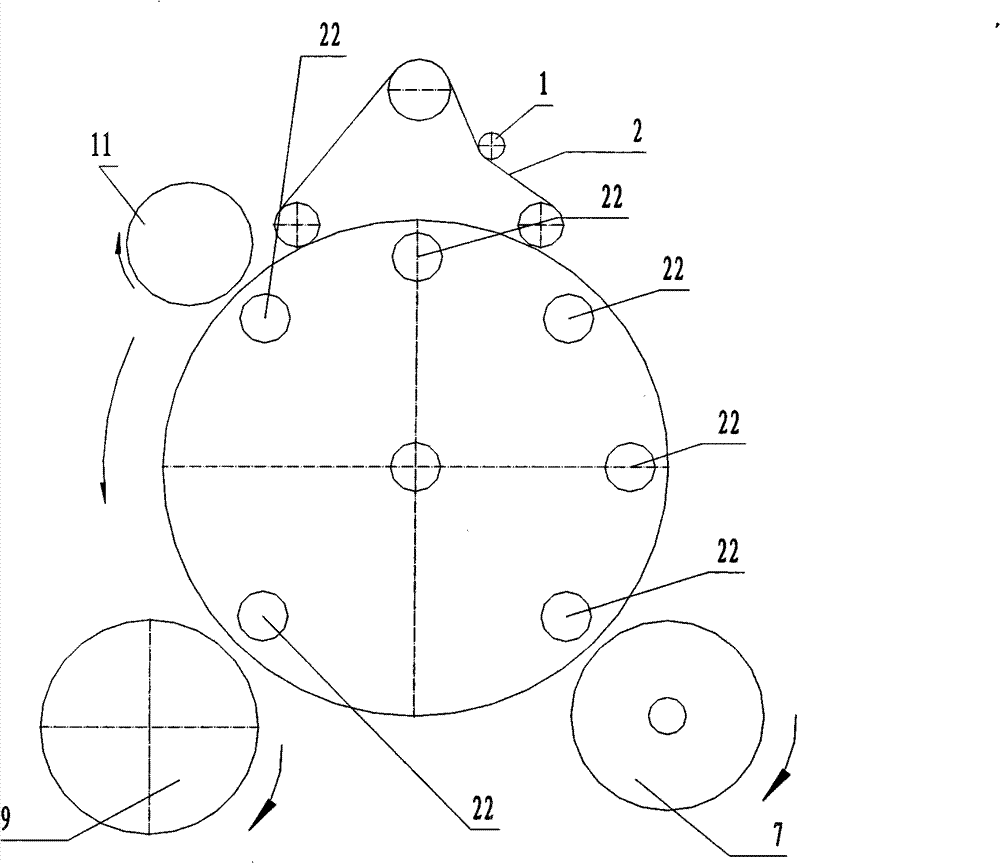

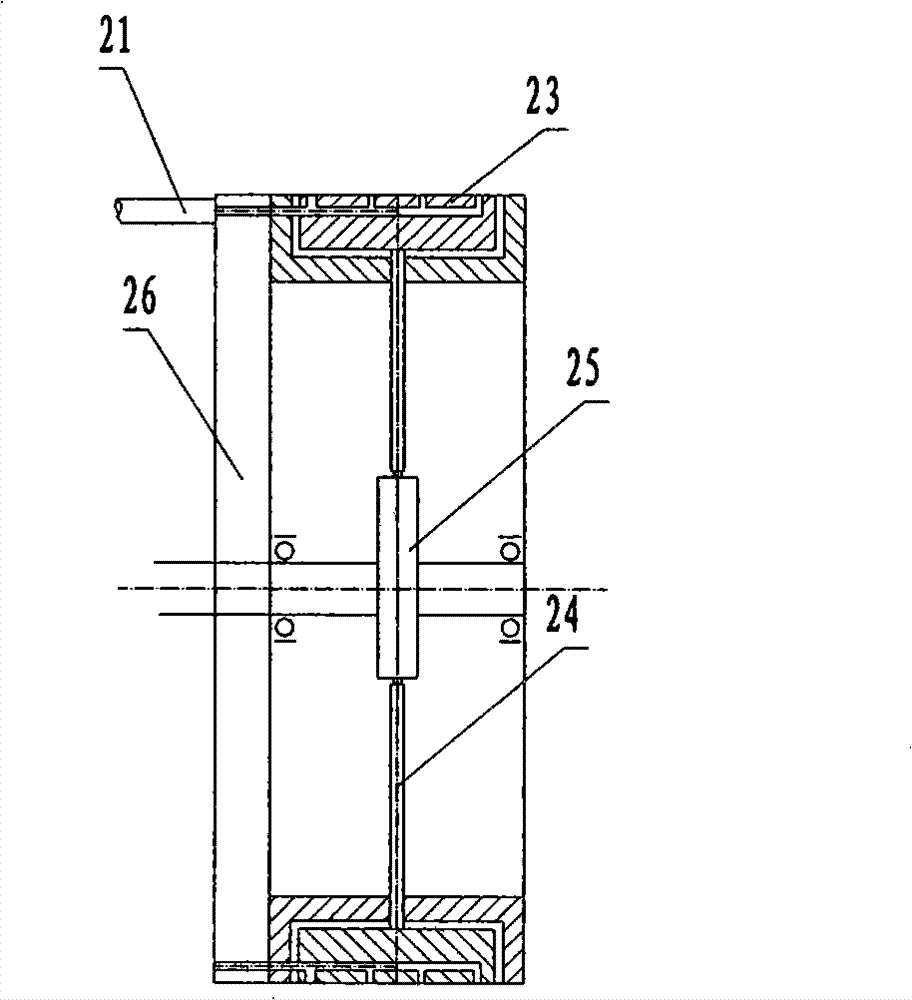

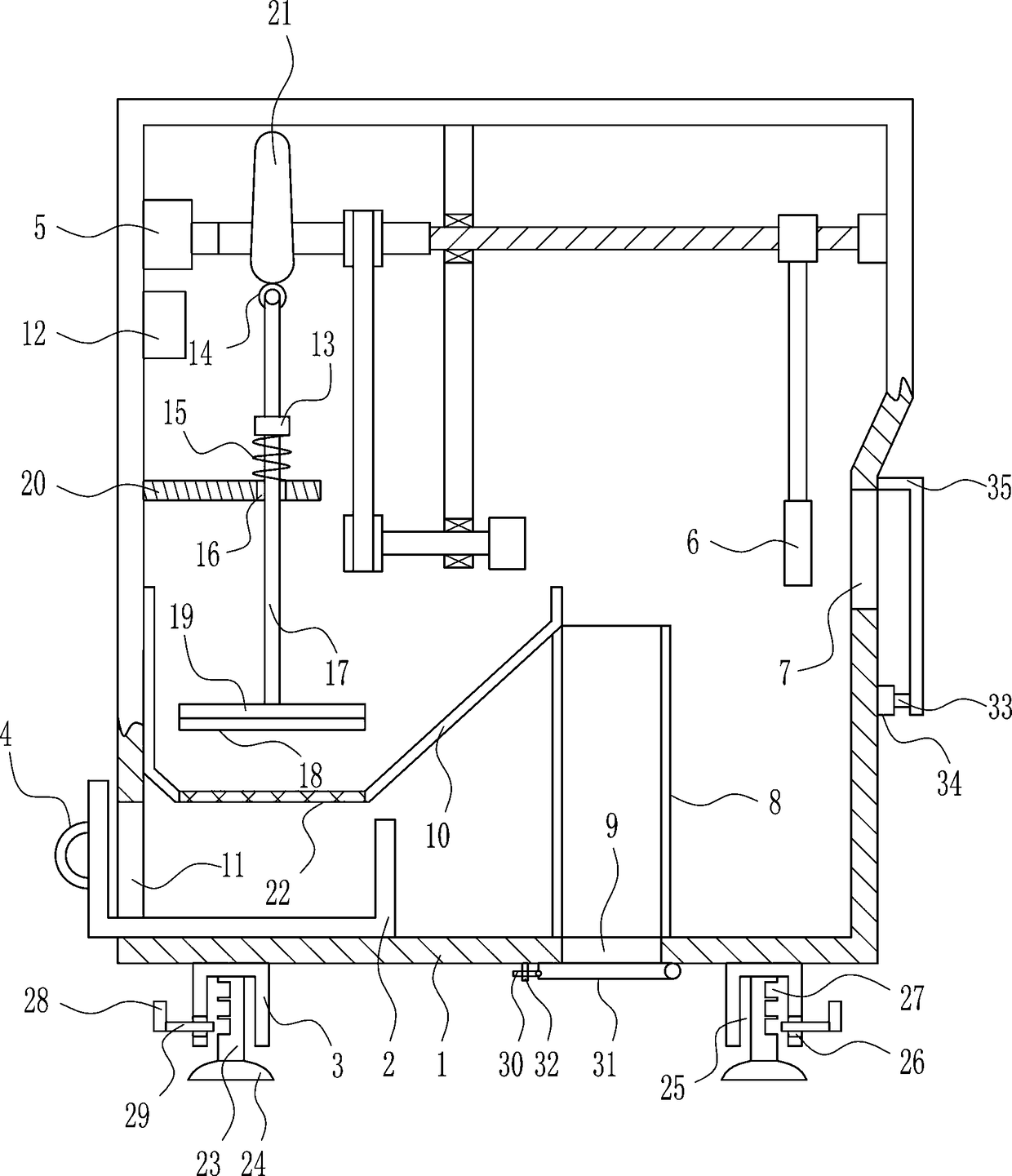

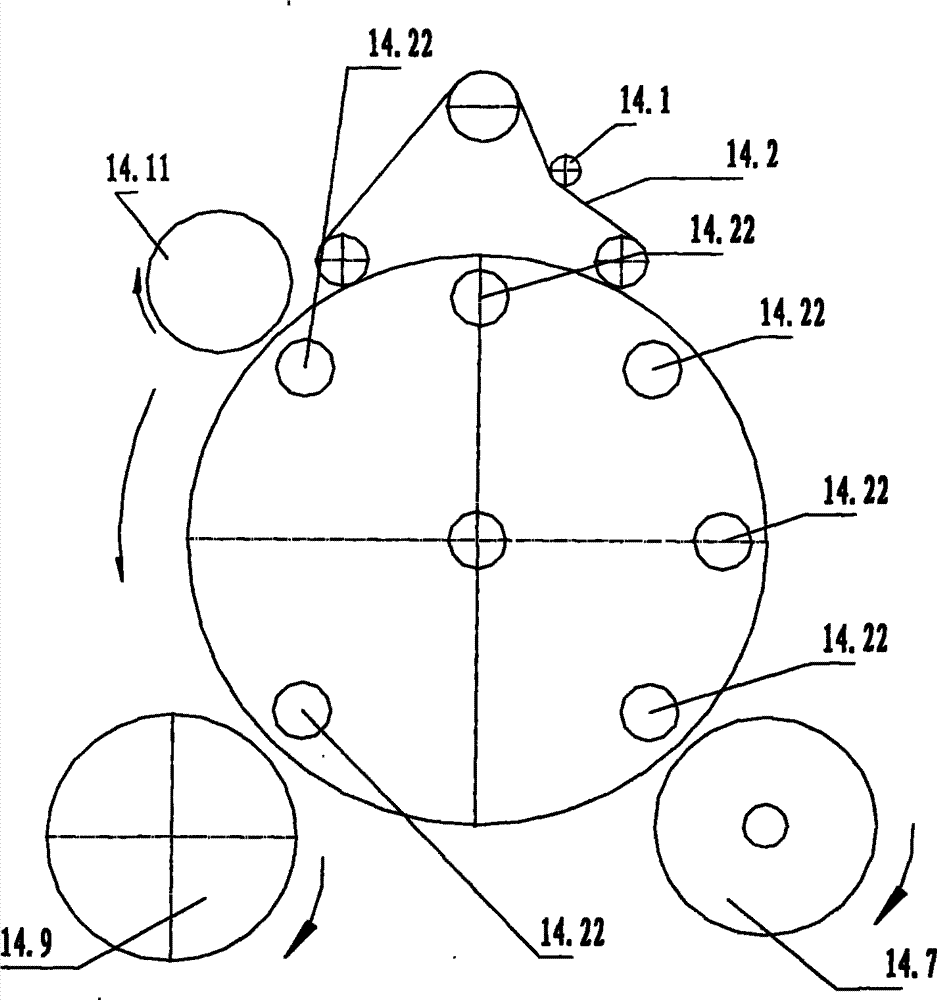

Horizontal preparation method of sanitary napkin with protective wings and device thereof

The invention relates to a method and a device for preparing transverse-output winged sanitary napkins, which belongs to the technical field of sanitary napkins. The method for preparing transverse-output winged sanitary napkins comprises the technological processes of preparing absorbers, compounding basement membrane, cutting finished products and coating with small packs. The technological processes are continuously completed, and the processes of preparing the absorbers, compounding the basement membrane, cutting the finished products adopt a transverse side-by-side die mode for the transverse forming production of products. The preparation device comprises an absorber-preparing mechanism, a basement-membrane compounding mechanism, a finished-product cutting mechanism and a small-packcoating mechanism, wherein an absorber knife rest is sequentially connected with a diversion-groove knife rest, a periphery-sealing knife rest, a switching suction hub, a wing-folding knife rest and a finished-product cutting knife rest; the switching suction hub is provided with a lifting-sliding suction block, a lifting-type connecting rod and a cam; the lifting-sliding suction block is communicated with an air suction port; the lifting-sliding suction block is connected with the cam through the lifting-type connecting rod; and the switching suction hub is tangentially provided with an assorted suction hub and a pressure feed mechanism. The invention has the advantages of simple structure, good product quality, high speed of production lines, capability of greatly saving raw materials and energy, and the like.

Owner:小护士(天津)科技股份有限公司

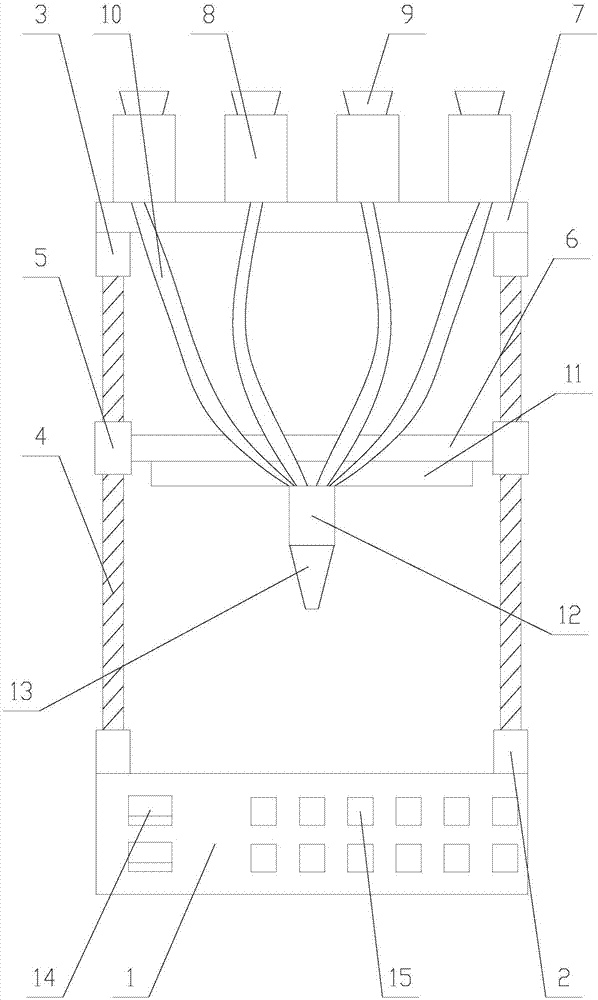

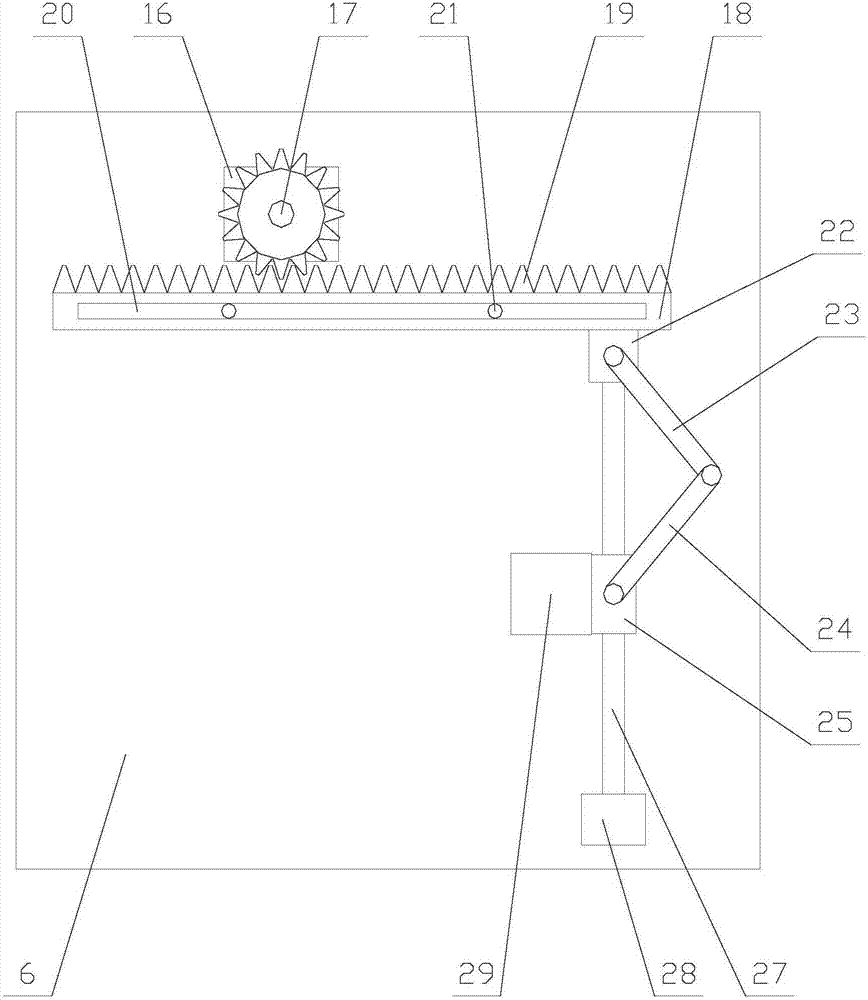

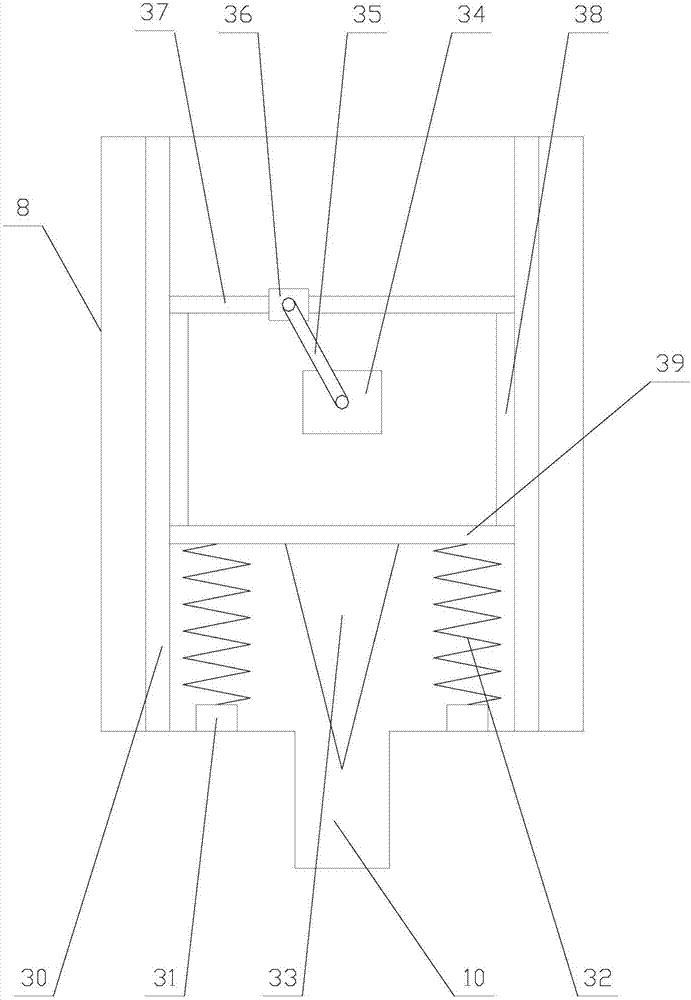

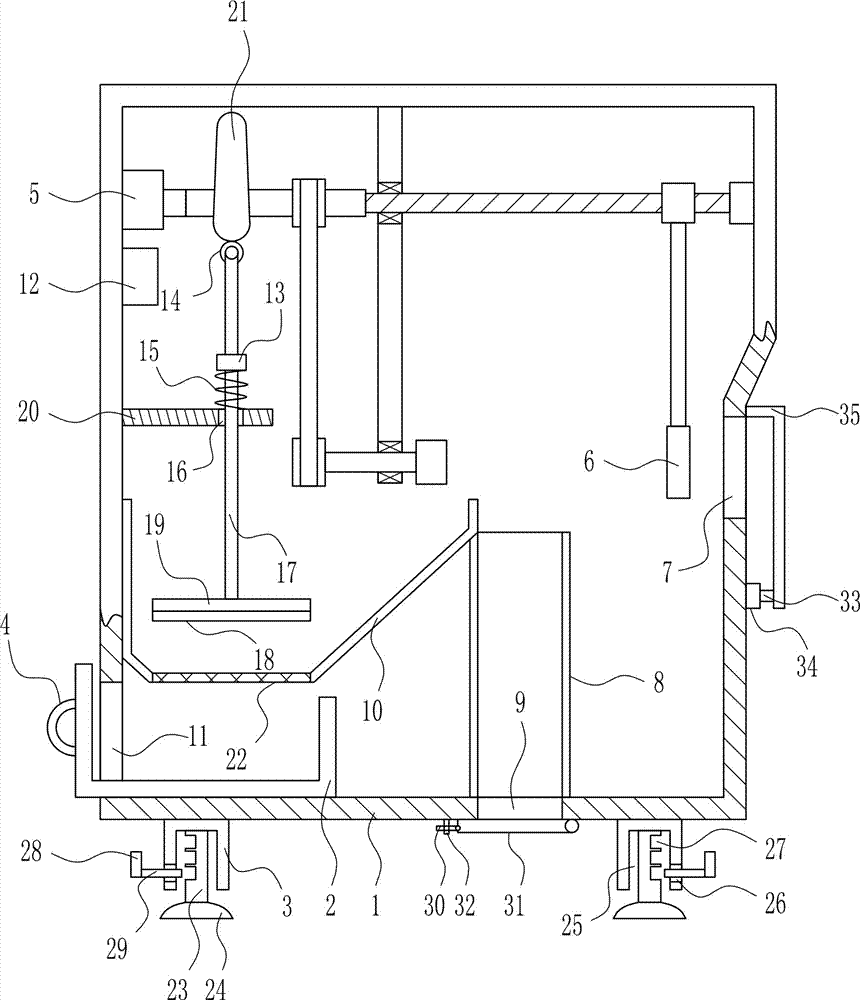

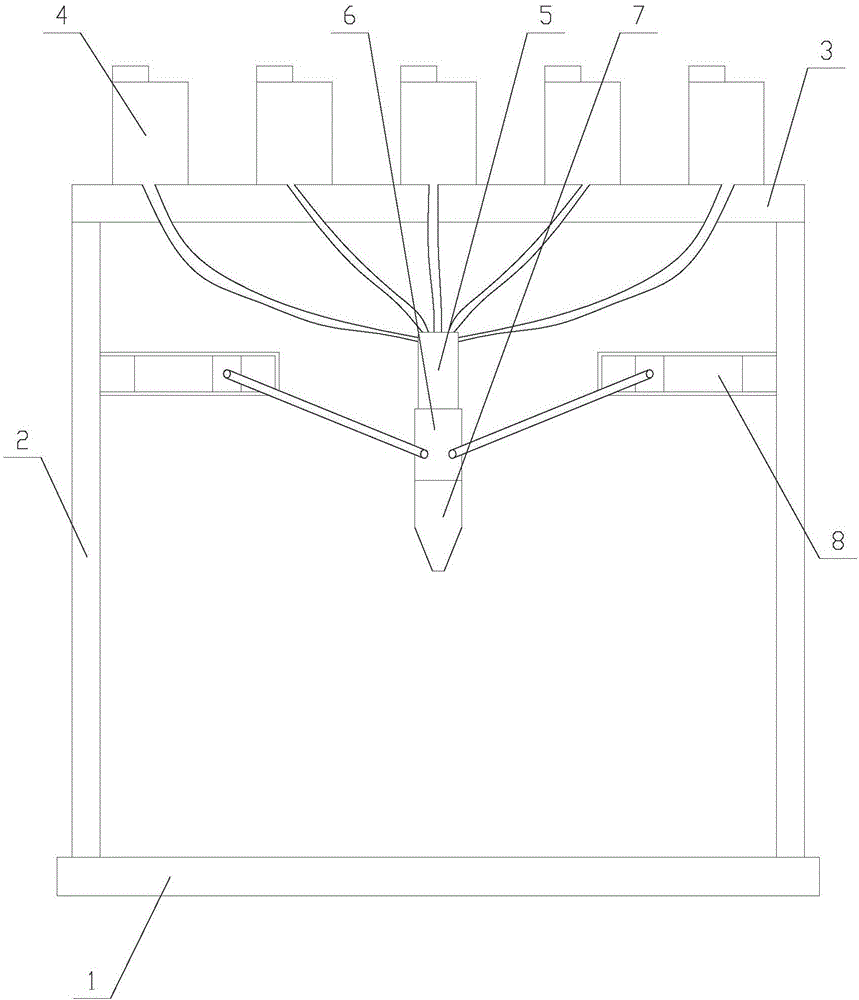

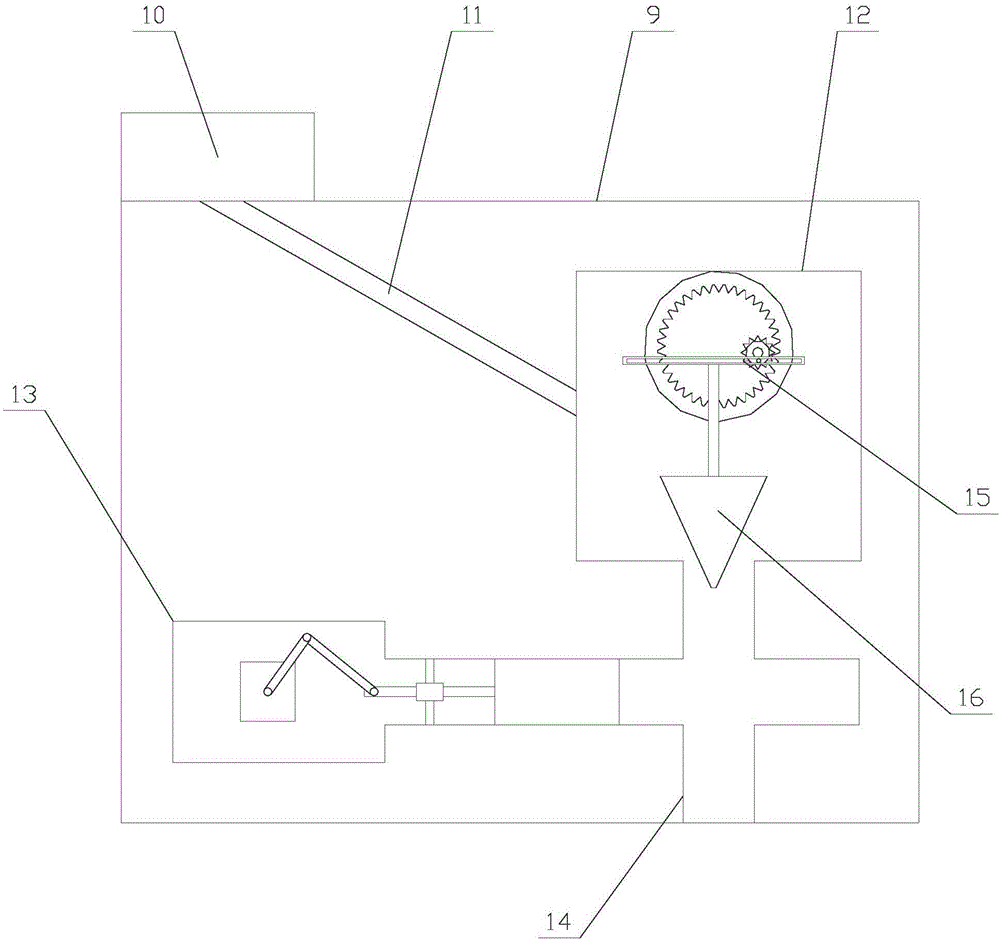

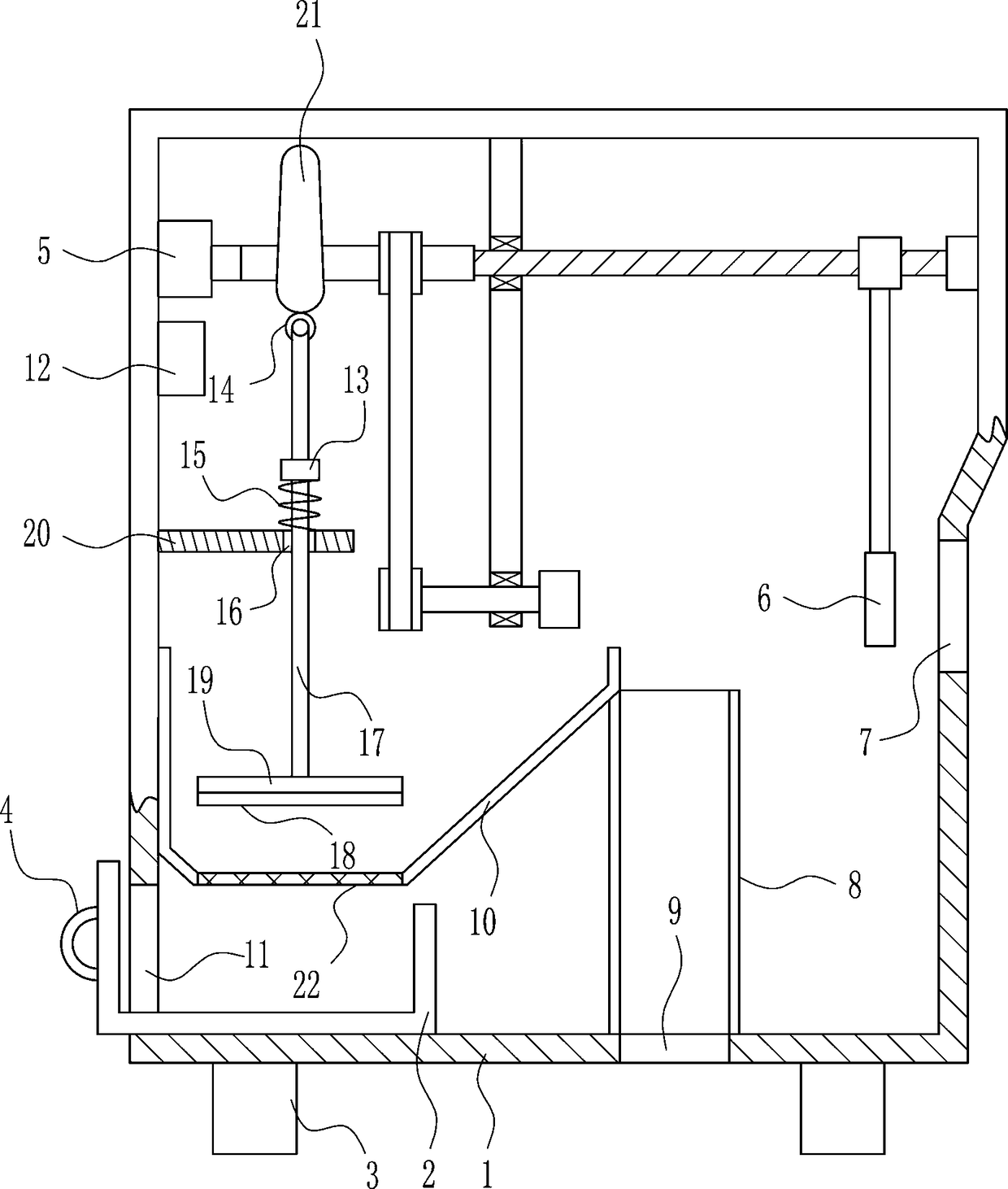

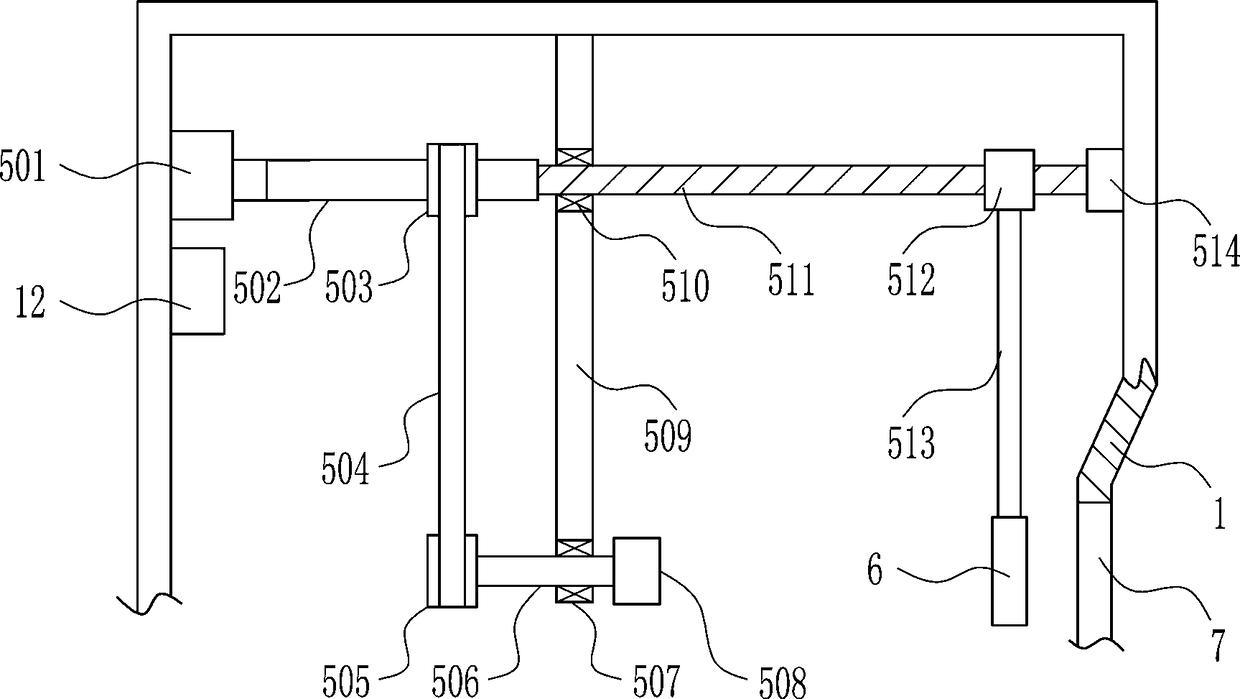

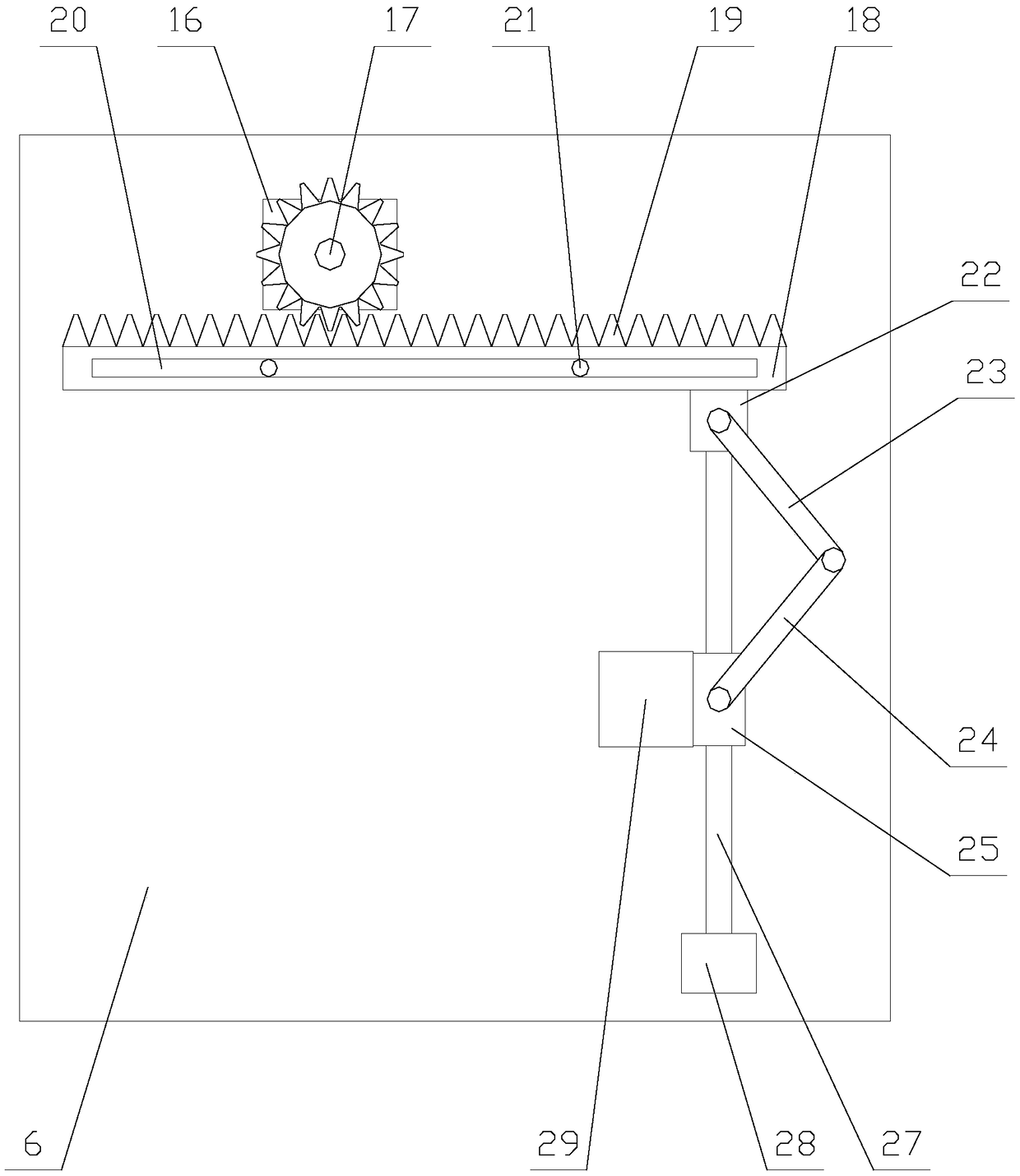

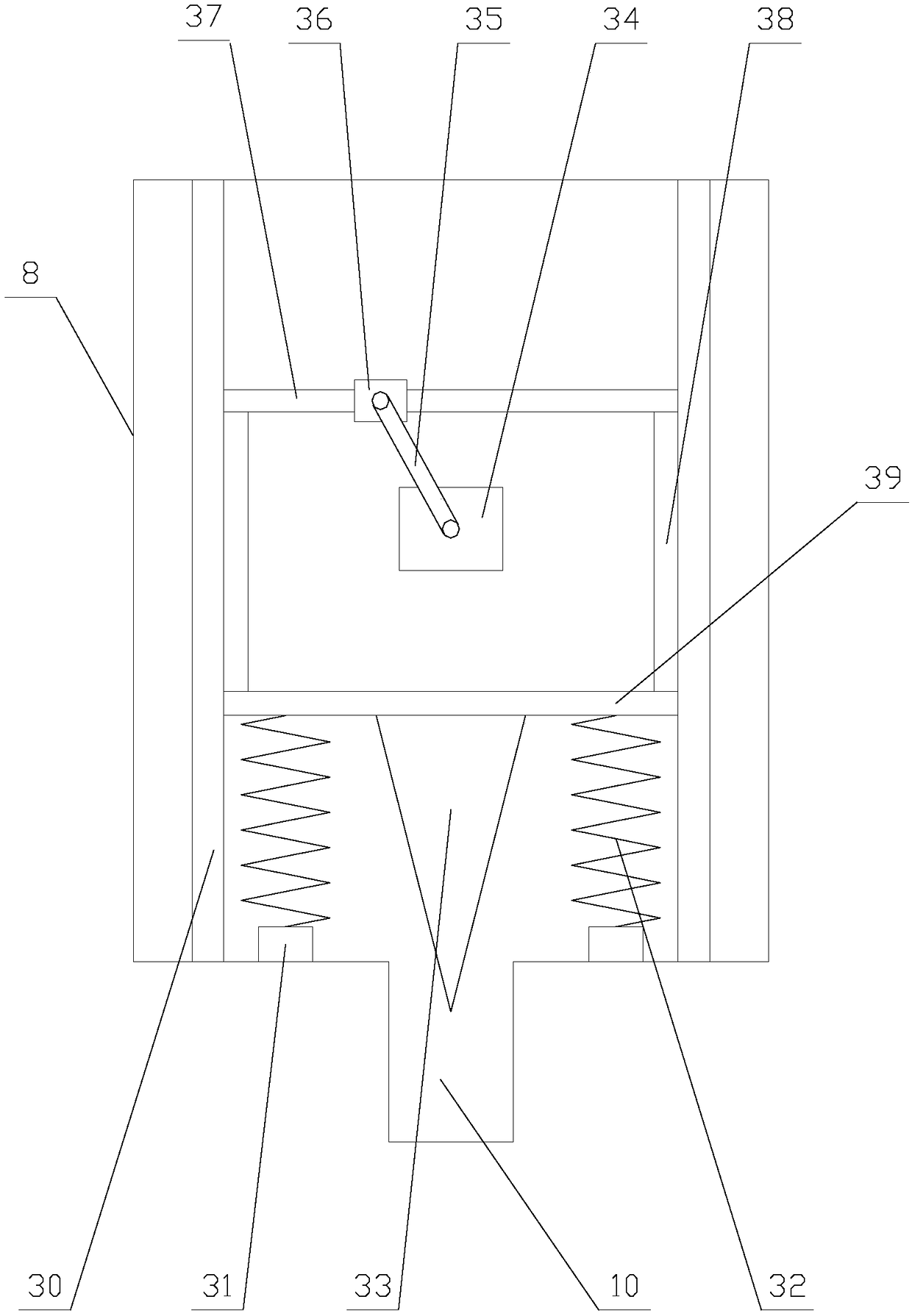

Intelligent 3D printer capable of accurately preparing materials and uniformly mixing materials

ActiveCN106891003AMove preciselyAccurate control of flow rateAdditive manufacturing apparatusIncreasing energy efficiencyProcess engineeringDrive motor

The invention relates to an intelligent 3D printer capable of accurately preparing materials and uniformly mixing materials. The intelligent 3D printer comprises a heating device and a plurality of feeding units, wherein each feeding unit comprises a raw material box; a material control mechanism is arranged in each raw material box; each material control mechanism comprises a speed adjusting block, a fourth driving motor, a third connection rod, a sliding ring, a top rod, a bottom rod and two support rods; two stirring units are arranged in the heating device; each stirring unit comprises a support plate, a fifth driving motor, a fifth driving shaft and a plurality of paddle blades. According to the intelligent 3D printer capable of accurately preparing materials and uniformly mixing materials, the height positions of the speed adjusting blocks are changed by the third driving motors in the raw material boxes; pressure data of a pressure sensor is used as feedback; the speed adjusting blocks can accurately move, so that the material circulating speeds are accurately controlled; the materials are accurately prepared; furthermore, the two stirring units in the heating device are used for fully mixing the materials entering the heating device; the materials and the quality of printed samples are ensured; meanwhile, the practicability of the equipment is further improved.

Owner:都昌西交口腔科技有限公司

Multi-function edging device

InactiveCN106217167AWill not affect normal edging operationNormal edging operation guaranteedEdge grinding machinesGrinding carriagesResource utilizationEngineering

The invention discloses a multi-function edging device. One end of an adjusting arm is movably riveted to a base and can be fixed via a stop bolt; the other end of the adjusting arm is connected with a protective baffle; the protective baffle can be arranged between the eyes of an edging operator and an edging part for shielding by rotationally adjusting the adjusting arm; a sliding groove is formed in the side wall of the base in the circumferential direction; an arc splash plate is close to and fitted to the side wall of the base; the bottom end of the arc splash plate is embedded in the sliding groove, so that the arc splash plate can slide in the circumferential direction of the base; and a magnifying lens extending outwards is also arranged on the adjusting arm, is connected with the adjusting arm through a gooseneck, and can be placed between the protective baffle and a millstone by adjusting the gooseneck. The multi-function edging device is simple in structure and convenient to use, and can effectively prevent edging chippings from splashing all around or even enter the eyes of the edging operator, so that the safety of the edging operator and surrounding materials is guaranteed; and moreover, waste materials can be recycled, so that the resource utilization rate is improved.

Owner:WUHU CHENGDELONG FILTER EQUIP CO LTD

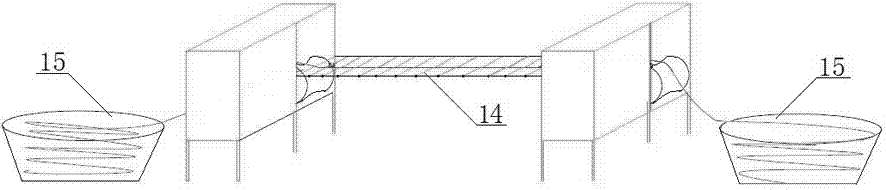

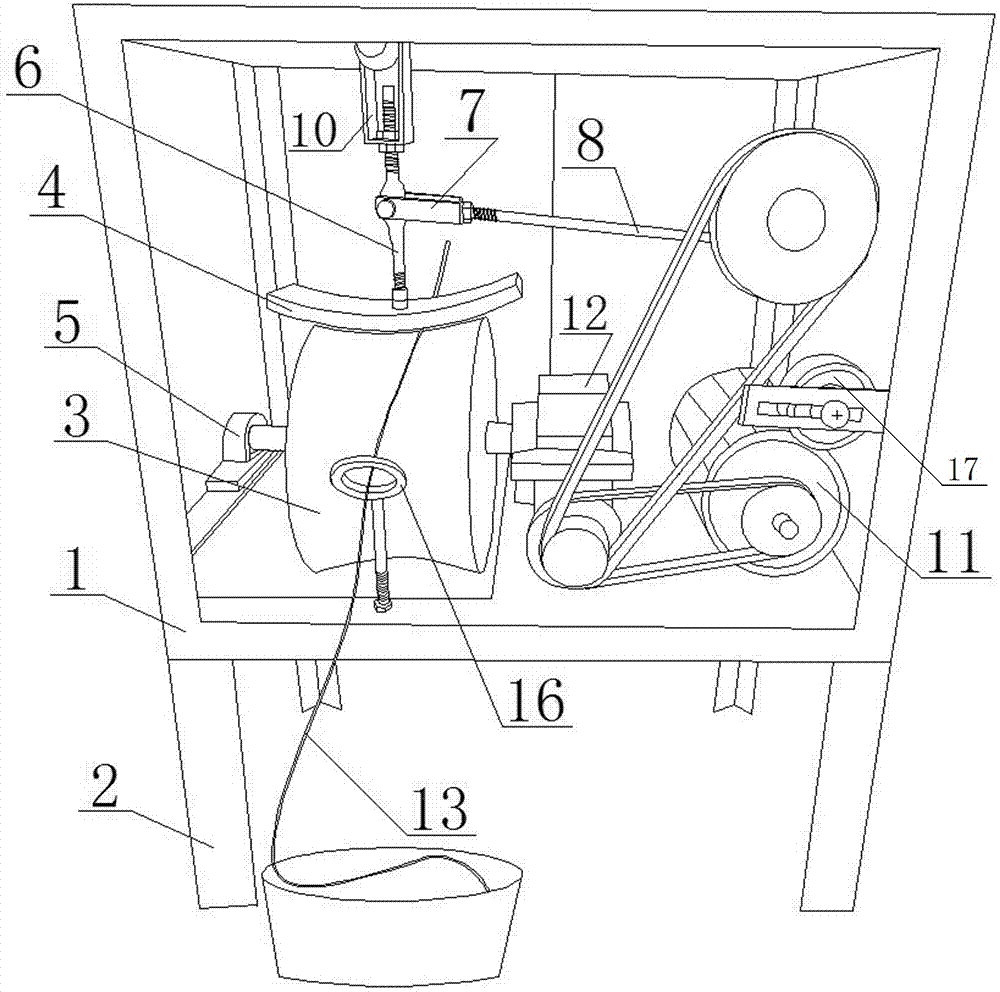

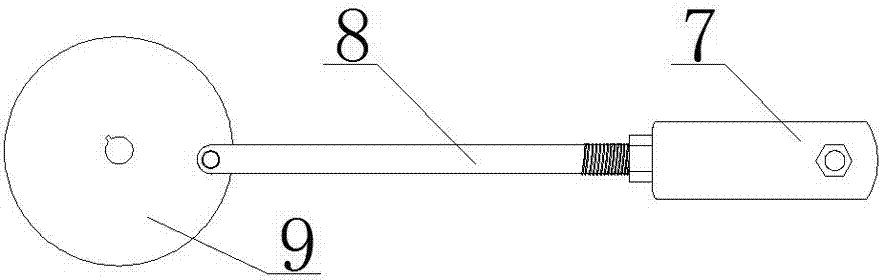

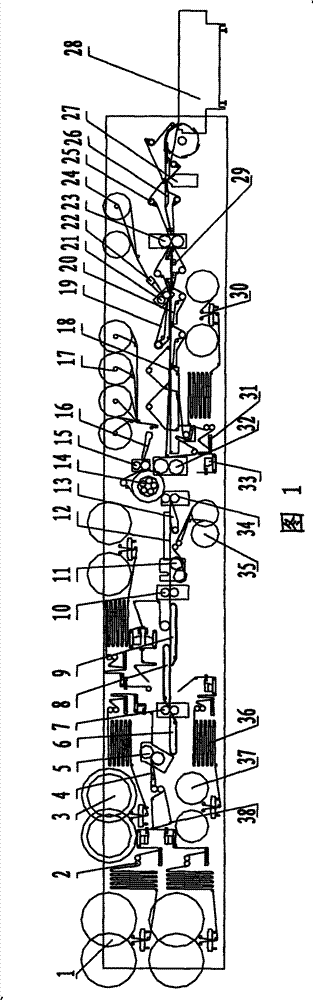

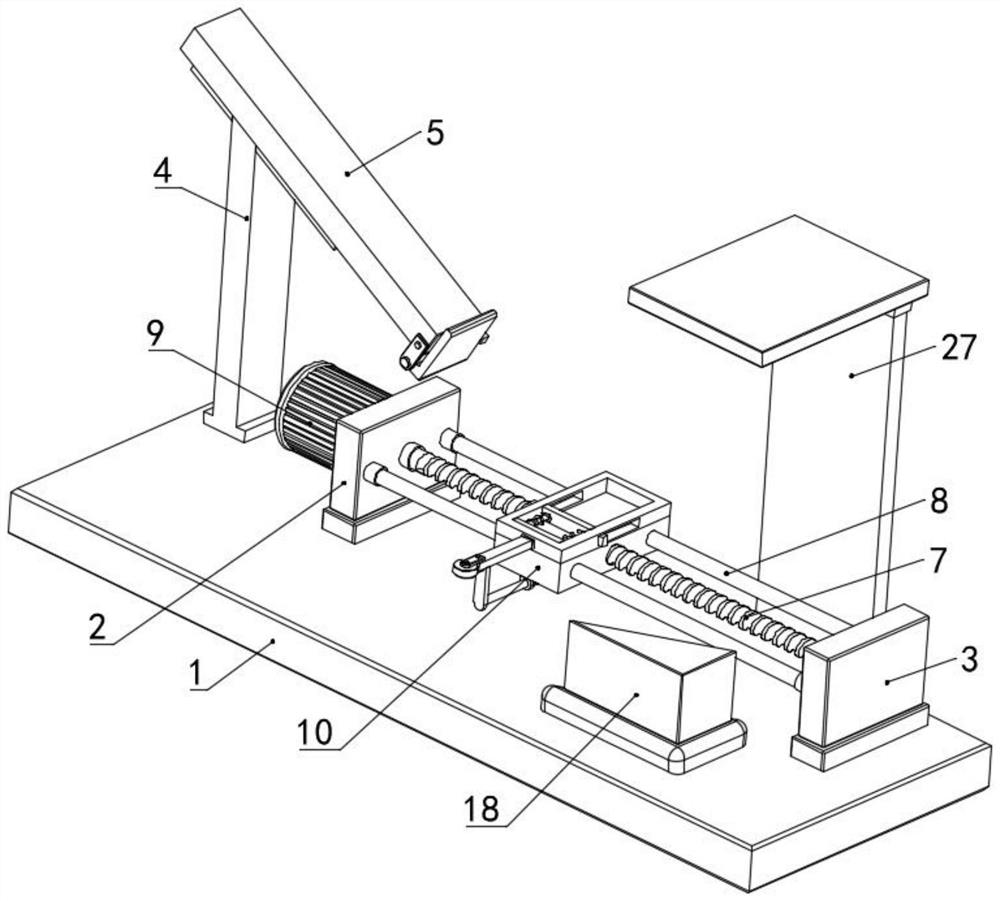

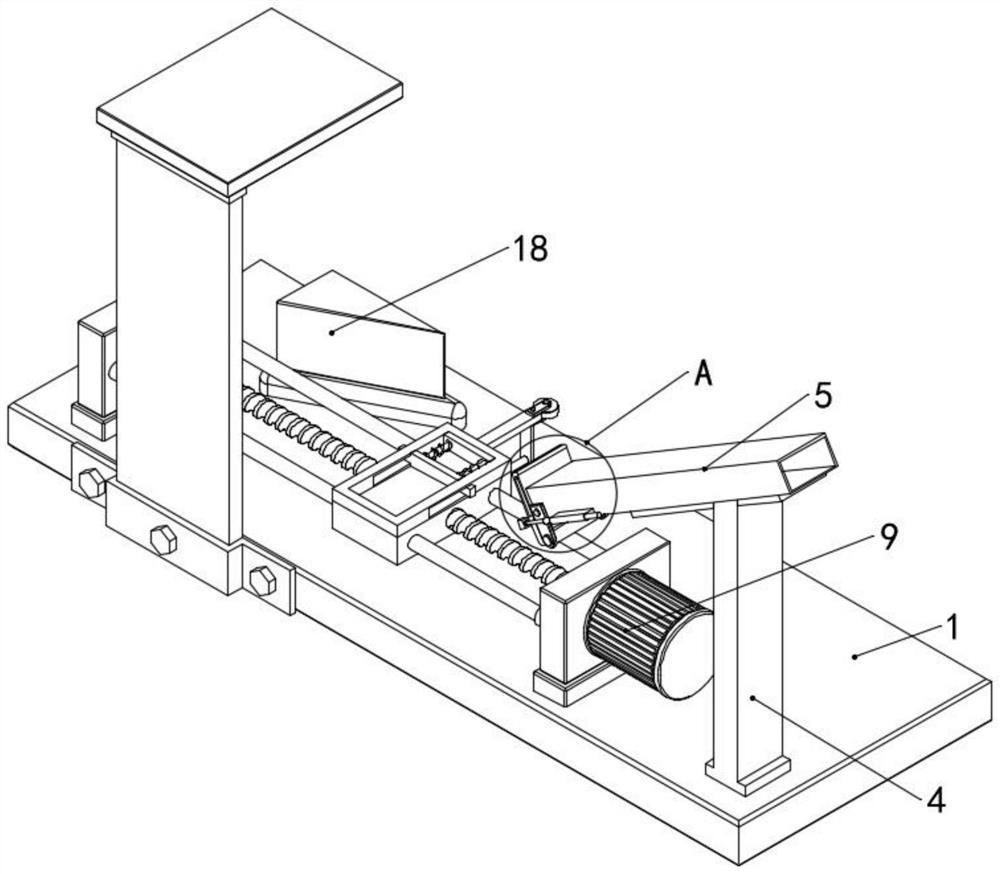

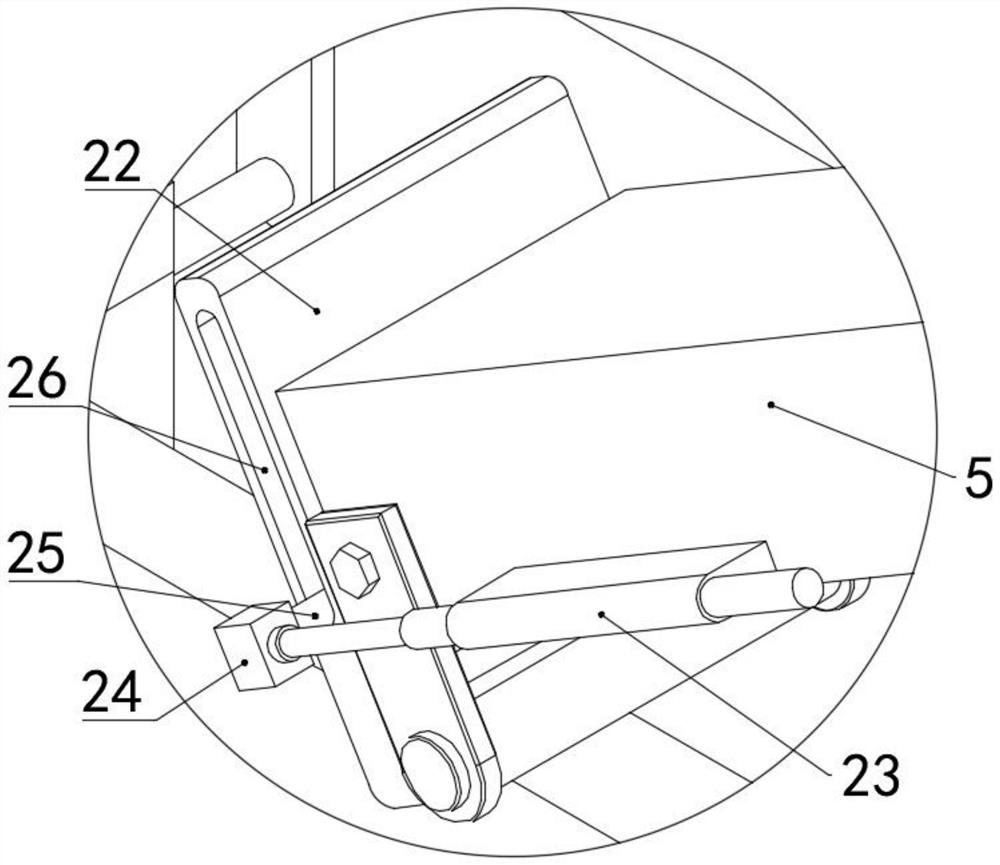

Parallel type imitated handmade noodle twisting and thinning machine and use method

PendingCN107410408AIncrease productivityReduce labor intensityDough shapingReciprocating motionEngineering

The invention discloses a parallel type imitated handmade noodle twisting and thinning machine and a use method. The machine comprises at least two sets of noodle twisting mechanisms, a transmission mechanism and a power mechanism, wherein each noodle twisting mechanism comprises a circumferential concave roller and an arc-shaped twisting board, and the circumferential concave roller rotates; a gap exists between the arc-shaped twisting board and a concave surface of the circumferential concave roller; the arc-shaped twisting board is connected with a suspension rod, the suspension rod is hinged at the top of a frame body, the suspension rod is connected with the transmission mechanism, and the suspension rod and the arc-shaped twisting board are driven by the transmission mechanism to make single pendulum type reciprocating motion along the axial direction of the circumferential concave roller; and the at least two sets of noodle twisting mechanisms are arranged side by side and are connected by virtue of noodle support rollers. The machine disclosed by the invention has the beneficial effects that noodle twisting and thinning links are completed by virtue of machines instead of handwork, so that product specifications are unified; the overall production efficiency of enterprises is improved, and the labor intensity of manual operation is alleviated; the parallel type design is adopted, so that original two twisting and thinning steps are simplified; and the structure is compact, parts are easy to process, and the cost is low.

Owner:GU LANG YI XI TANG WEI YE BIOLOGICAL TECH

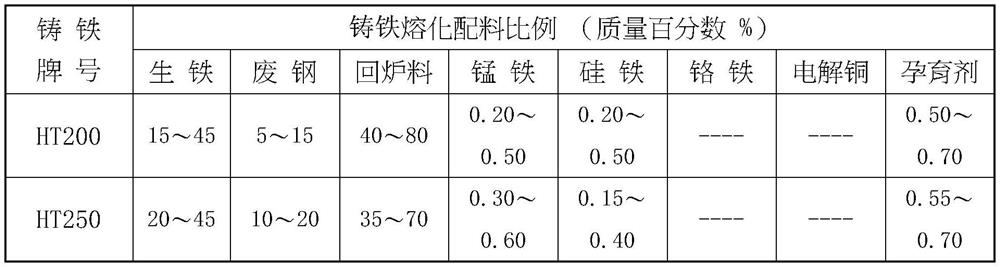

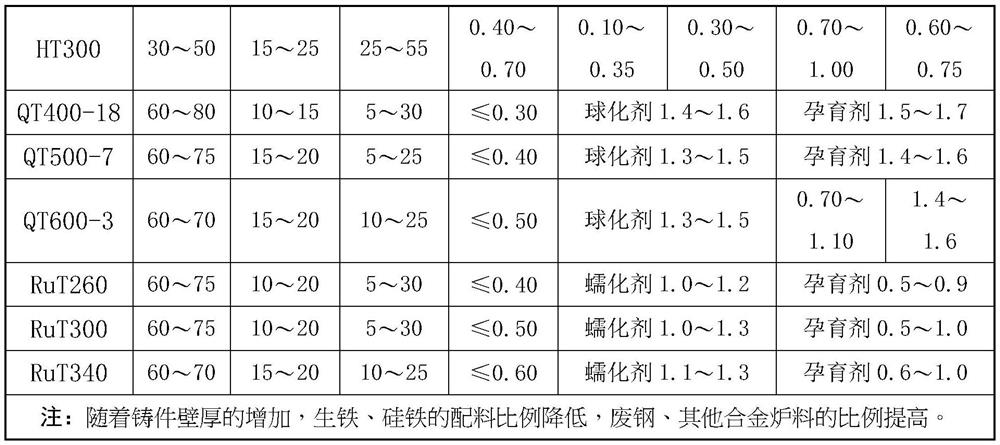

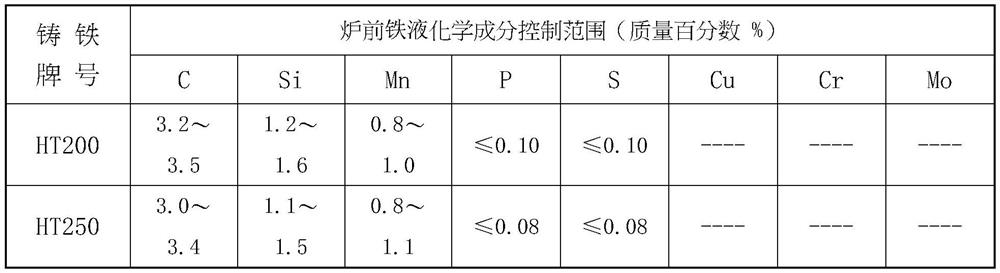

Method for melting heterogeneous cast iron in same intermediate frequency electric furnace

InactiveCN111809014AReduce smelting costEasy to operateProcess efficiency improvementIntermediate frequencyMaterials science

The invention discloses a method for melting heterogeneous cast iron in the same intermediate frequency electric furnace, and belongs to the field of cast iron smelting. The method comprises the following steps of preparing furnace burden, equipment and technical documents; determining melting operation sequences of different material types or different brands of molten iron; determining melting process procedures of first molten iron and other molten iron; preparing materials, charging and heating for melting according to process burdening list requirements; sampling for molten iron chemicalcomposition analysis and adjustment before discharging; determining a burdening process of second molten iron according to specific conditions after discharging and pouring; supplementing the requiredmetal furnace burden into the furnace and heating for melting; performing sampling analysis and component adjustment of the second molten iron, molten iron treatment, discharging and pouring; and repeatedly performing the above steps for melting production and molten iron treatment of next molten iron. According to the method, different material types or different grades of iron castings can be obtained by smelting the molten iron in the same furnace, so that the quality of the castings is effectively stabilized, the qualified rate of the castings is guaranteed, the flow control of productionis conveniently carried out, and the smelting cost of cast iron is reduced.

Owner:HEBEI HUABEI DIESEL ENGINE

Efficient chipping device for rod-like medicines

The invention relates to a chipping device, in particular to an efficient chipping device for rod-like medicines. In order to solve the technical problems, the invention provides the efficient chipping device for rod-like medicines. The efficient chipping device for the rod-like medicines comprises a working box, a collecting slot, bases, a pull ring, a wrapping device, a clamping device, a guide barrel and the like, wherein the left side and the right side of the bottom of the working box are symmetrically equipped with the bases; an inlet is formed in the right wall of the working box; an outlet is formed in the bottom wall of the working box; a through hole is formed in the left lower wall of the working box; the collecting slot is formed in the through hole in a penetrating mode; the pull ring is arranged on the left outer wall of the collecting slot; the wrapping device is arranged on the inner upper portion of the working box; the wrapping device is connected with the clamping device; and the clamping device is positioned at the left side of the inlet. The efficient chipping device achieves the efficient chipping effect, can be used for uniformly cutting the medicines, is convenient to use and store, and can guarantee the textures of the medicines.

Owner:保定澳美医疗器械有限公司

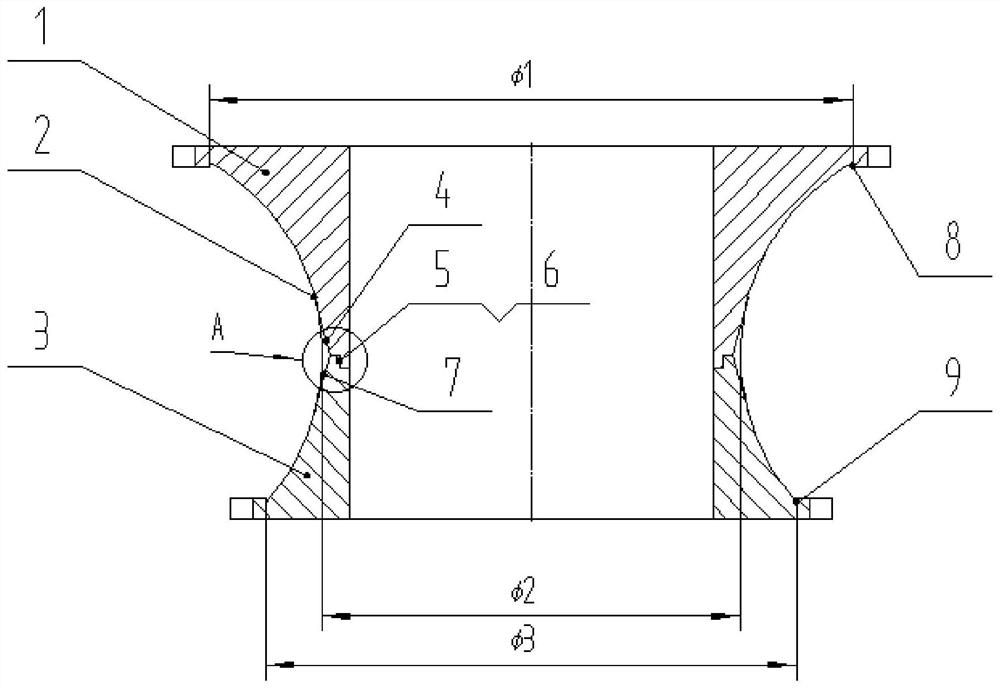

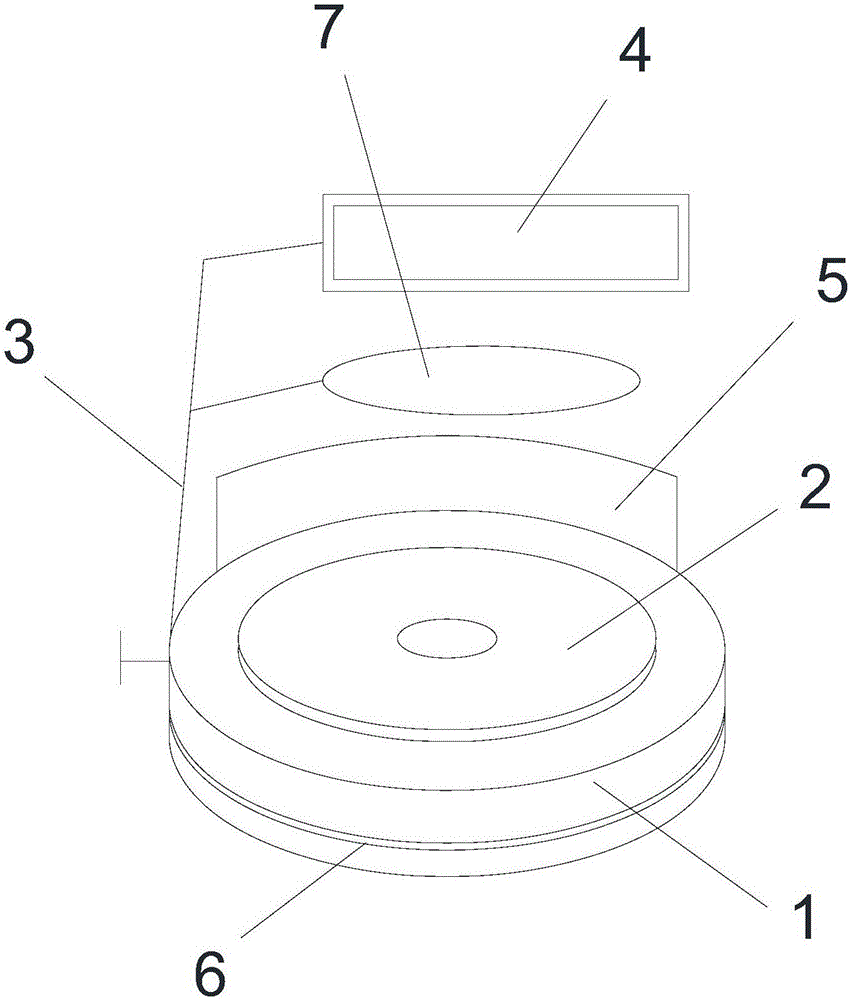

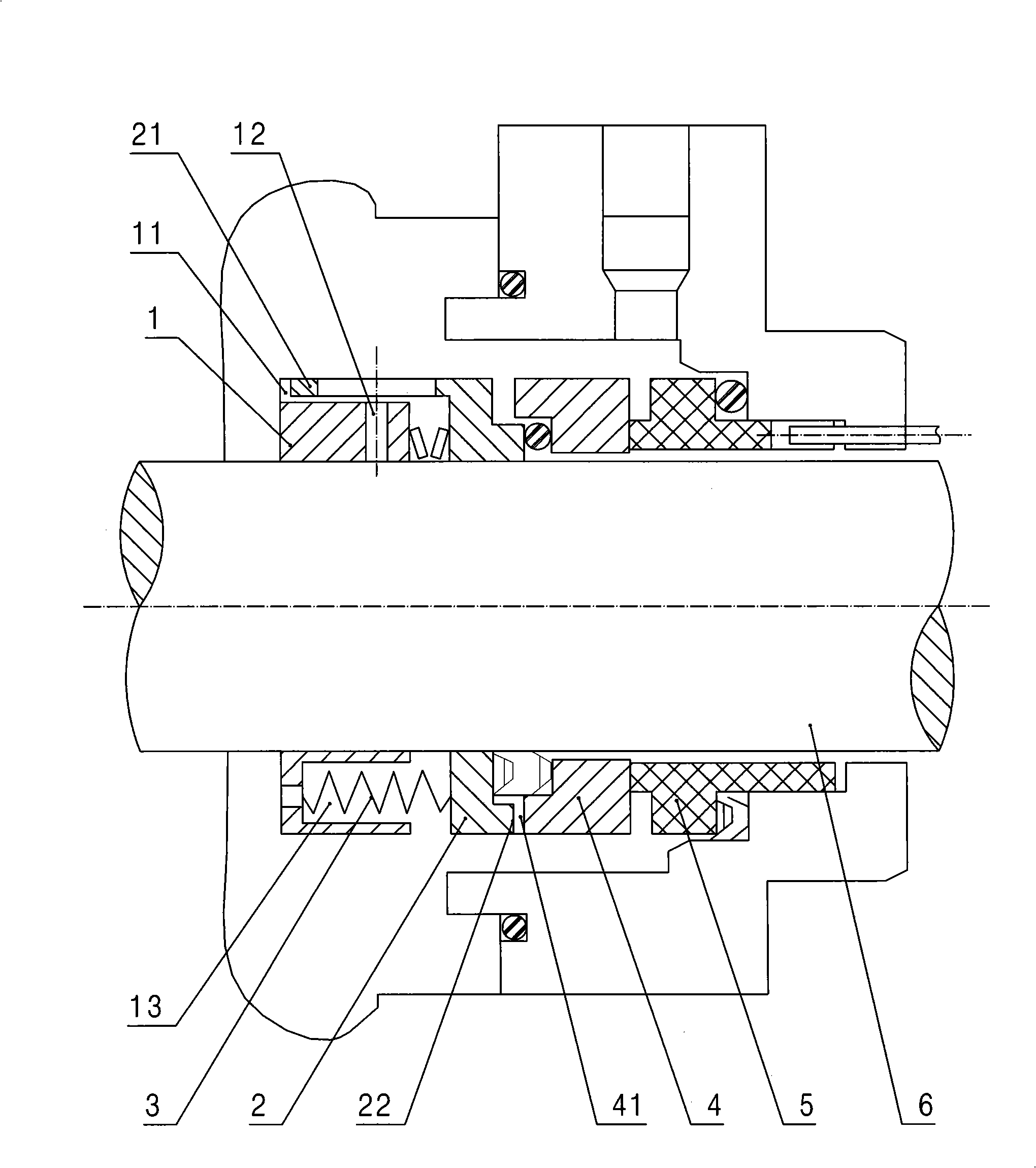

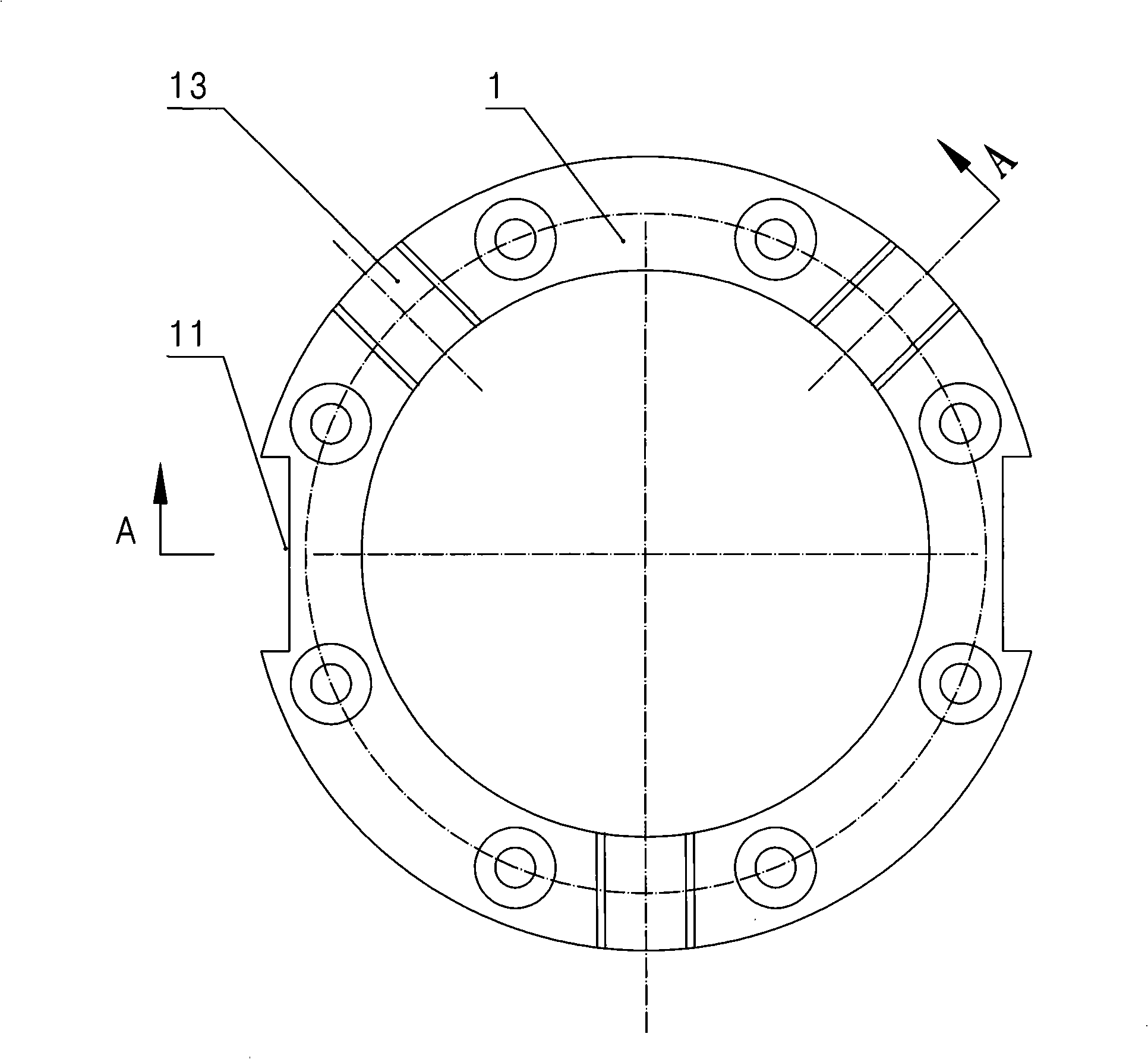

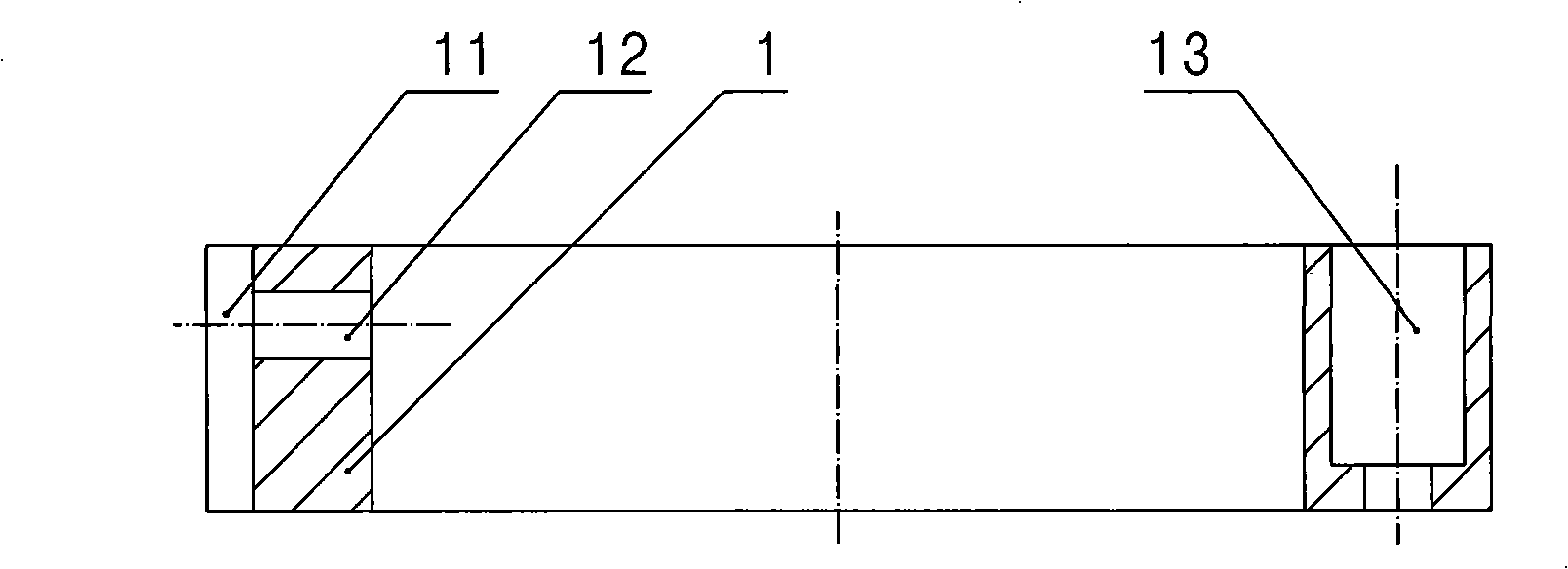

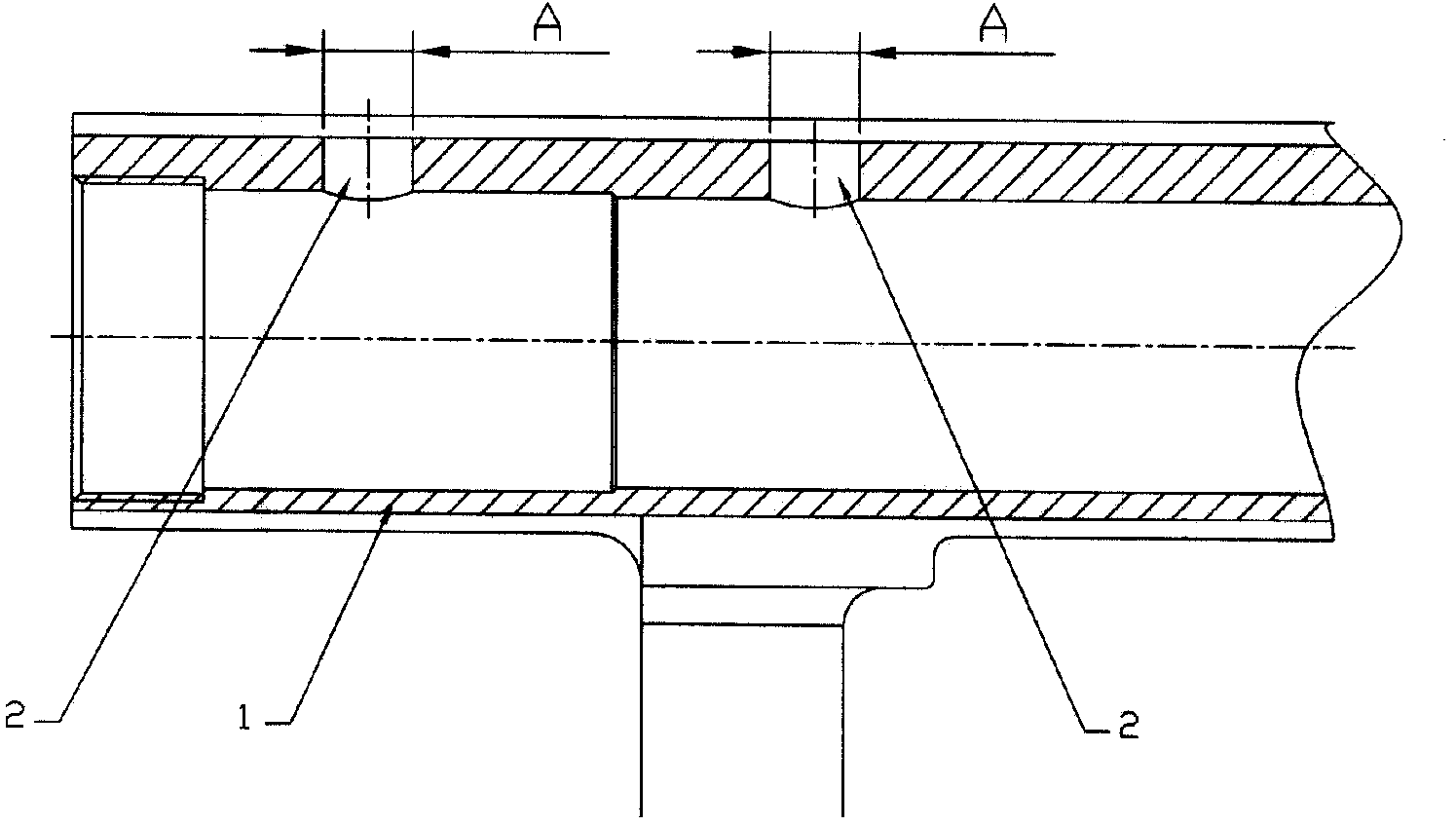

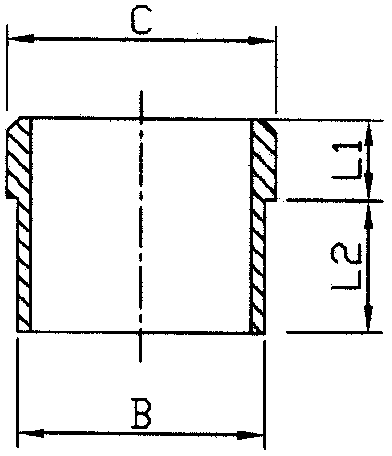

Pressure testing method for small diameter open-mouth connecting pipe of pressure vessel

InactiveCN108548725ALow costGuaranteed MaterialMaterial strength using tensile/compressive forcesThick wallEngineering

The invention discloses a pressure testing method for a small-diameter open-mouth connecting pipe of a pressure vessel, belongs to the field of pressure vessel manufacturing, and solves the difficultyof use of a die for stamping a pressure testing end socket of a small-diameter thick-walled connecting pipe. The pressure testing method is as follows: according to the pressure requirements of equipment pressure testing, the thickness and related dimensions required for the pressure testing end socket are calculated by special calculation software; according to the calculated dimensions, a pressure test tool (1) is directly processed by a lathe; a remaining sheet material in the manufacturing process of the pressure vessel is used as a material for the pressure test tool (1), the thickness of the sheet material is greater than the height of the required pressure testing end socket; the pressure test tool (1) is welded to an open nozzle (2) of the pressure vessel, and is used for flaw detection of attachment welds; after the flaw detection is qualified, pressure resistance tests of the pressure vessel are carried out according to operating procedures. The method does not need the dieto stamp the pressure test tool of the small-diameter open-mouth connecting pipe, waste is utilized, and the method is green and environmentally-friendly, and also ensures the same material. The pressure testing method is suitable for the pressure testing of the small-diameter thick-walled open-mouth connecting pipe, in particular, the open-ended connecting pipe with the inner diameter of phi lessthan or equal to 300 mm, of the pressure vessel.

Owner:LANZHOU LS HEAVY EQUIP

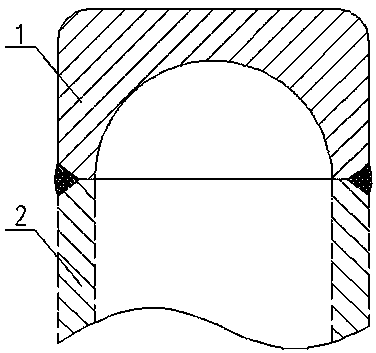

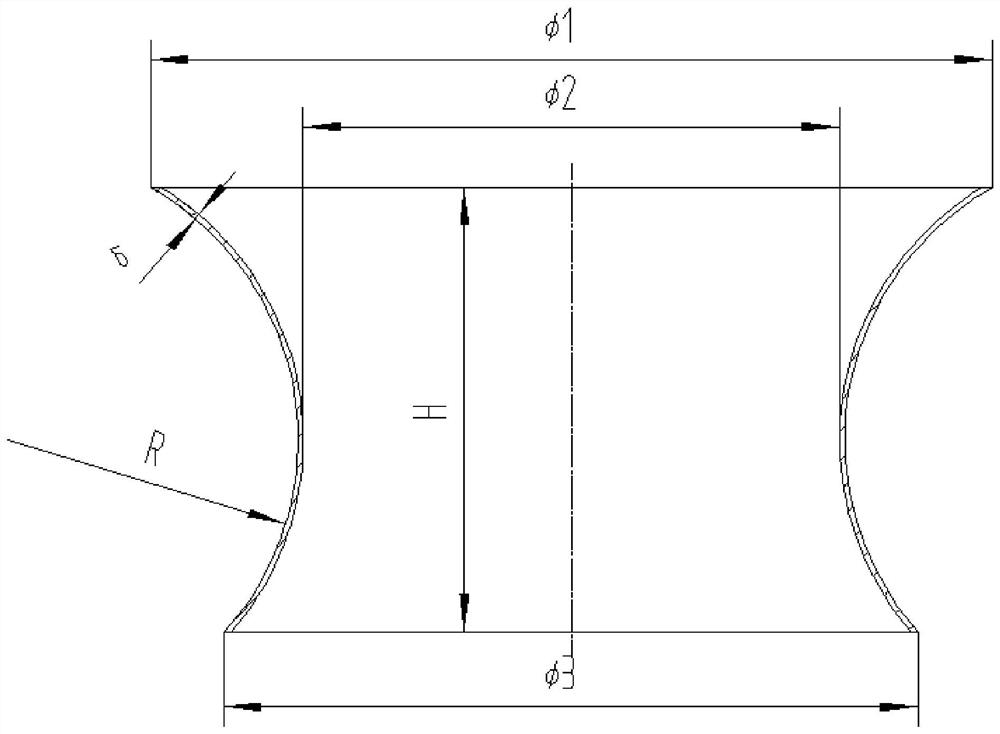

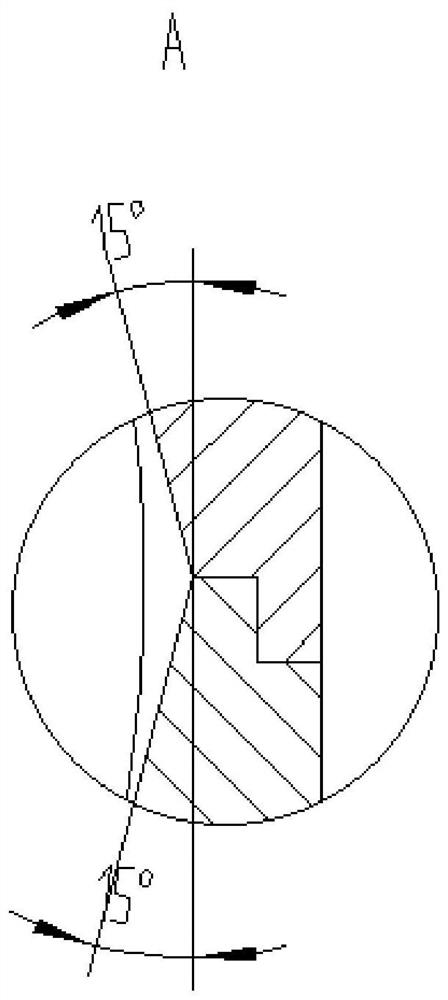

A kind of pressure molding die of fan air inlet and manufacturing method

ActiveCN111299422BAvoid asymmetrical up and down arcsAvoid asymmetryShaping toolsMechanical engineeringIndustrial engineering

The invention provides a pressure molding die for the air inlet of a fan and a manufacturing method thereof, and relates to the field of fan manufacturing. In this way, it is possible to avoid the asymmetry of the upper and lower arcs of the arc section of the air inlet caused by supporting one side of the workpiece alone, and the possibility of cold work hardening and uneven hardness of the material when processing larger sizes. This manufacturing method improves the manufacturing accuracy of the arc section of the air inlet, enables the molding line to meet the design requirements, effectively improves the performance and quality of the product, reduces the manufacturing cost of the arc section of the air inlet, and improves the production efficiency and efficiency of the part. its quality. The compression mold is used in conjunction with the molding method of the fan air inlet. The workpiece is supported by the upper mold and the lower mold to form the arc section of the air inlet. The same curvature of the upper mold arc and the lower mold arc is set to ensure that the air inlet arc section meets Model line requirements.

Owner:WUHAN UNIV OF TECH

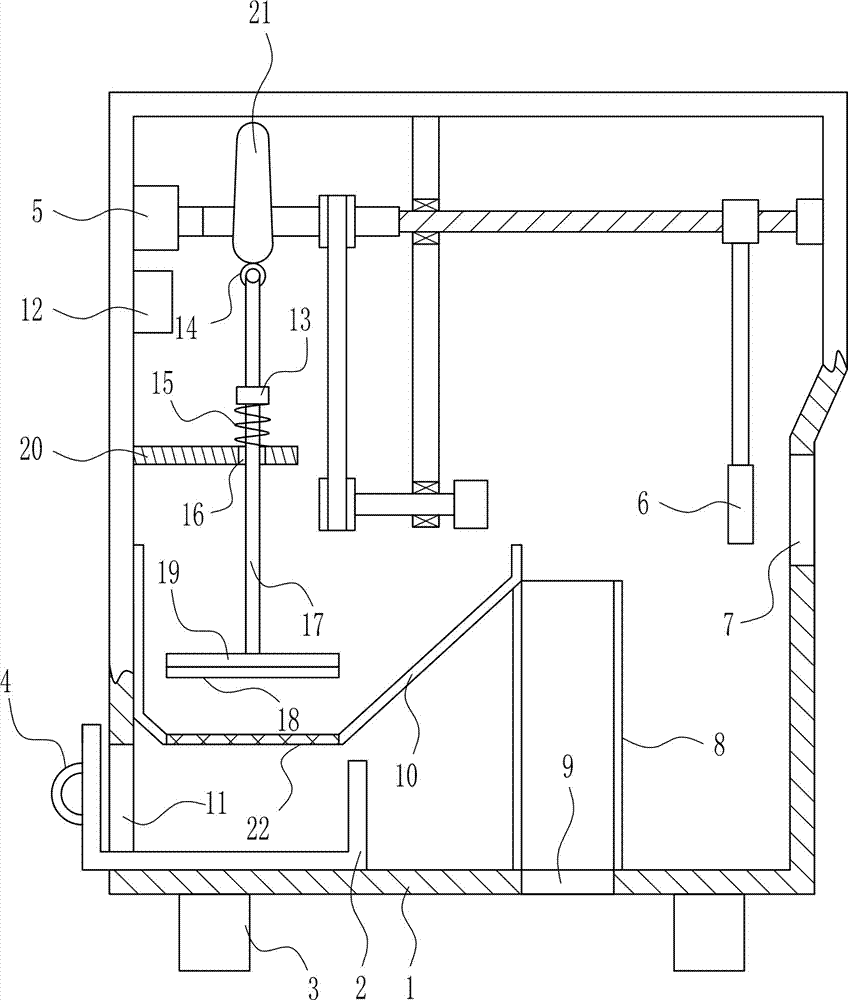

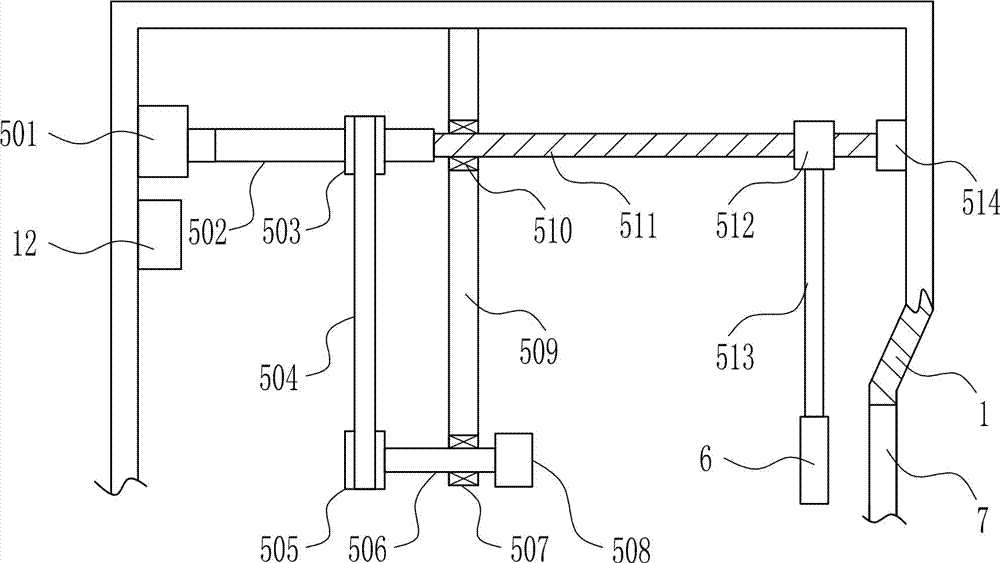

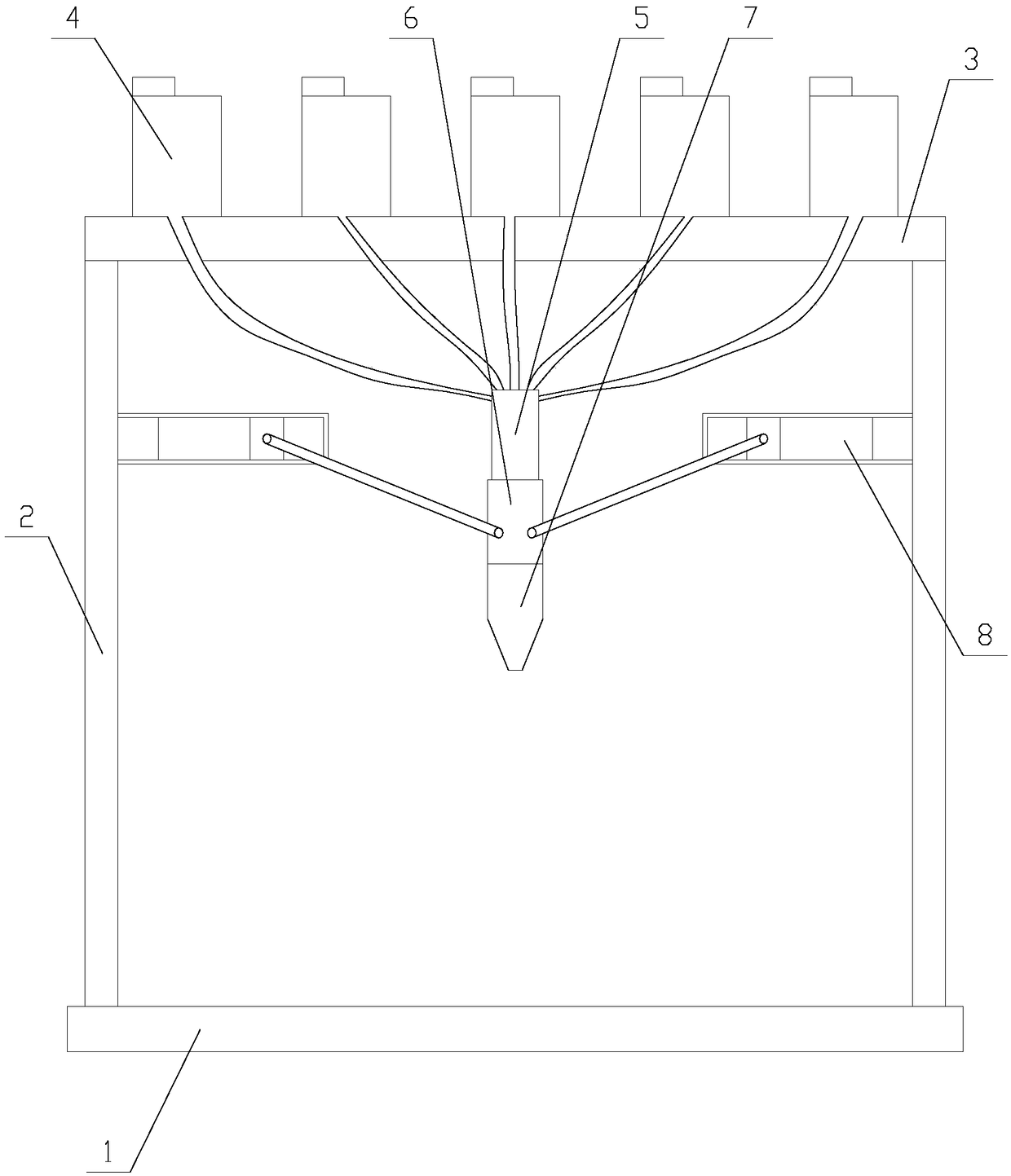

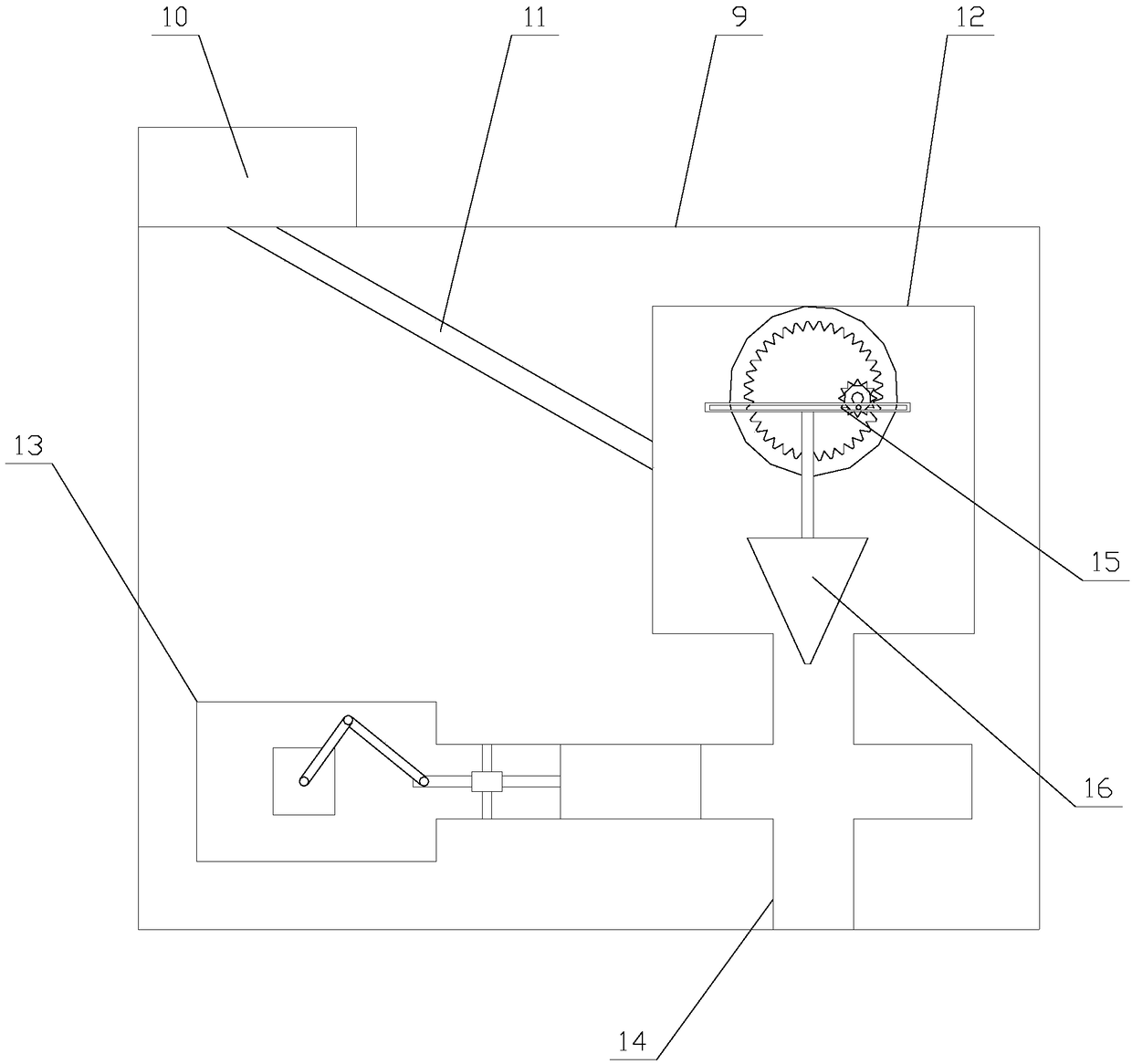

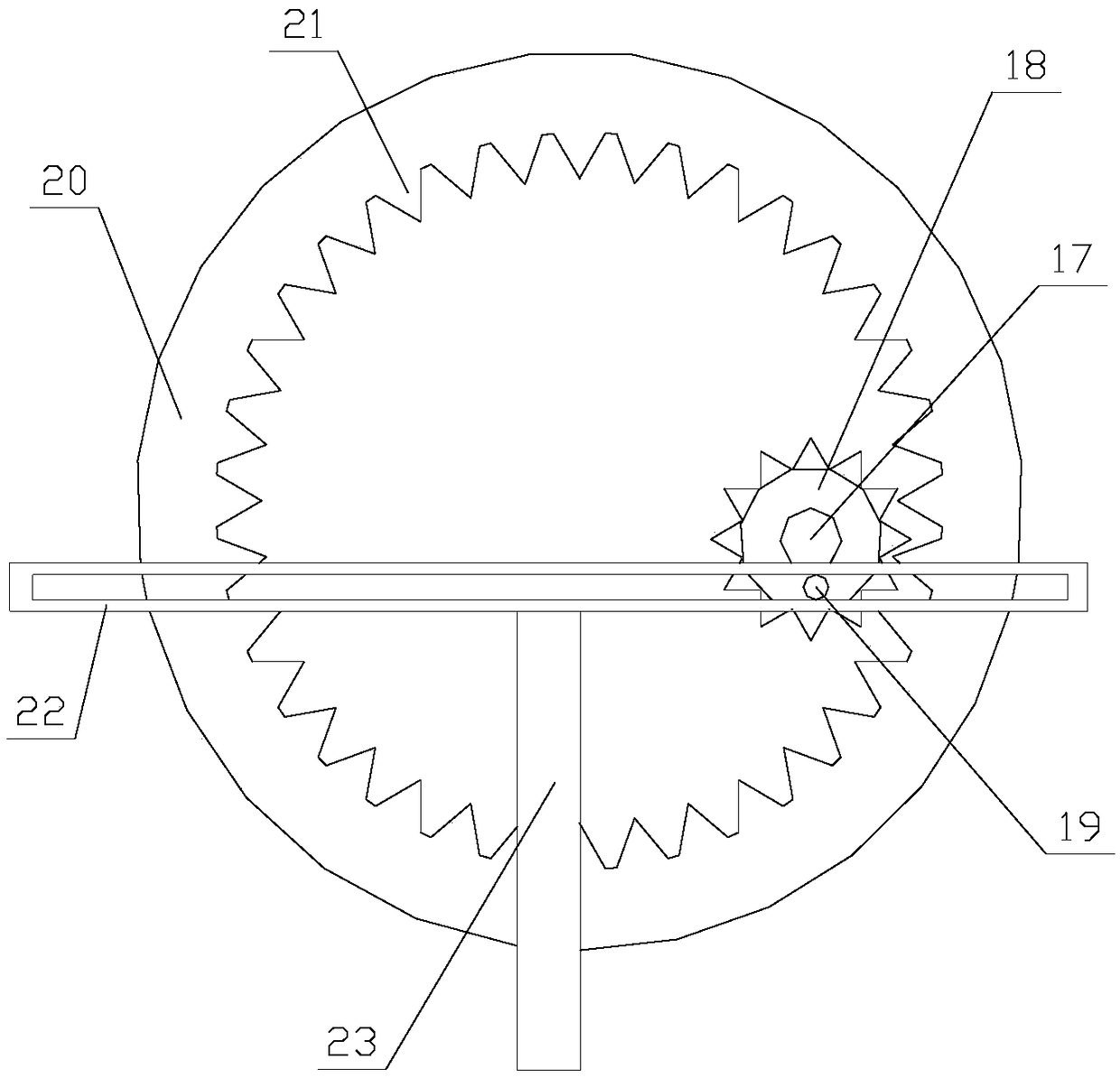

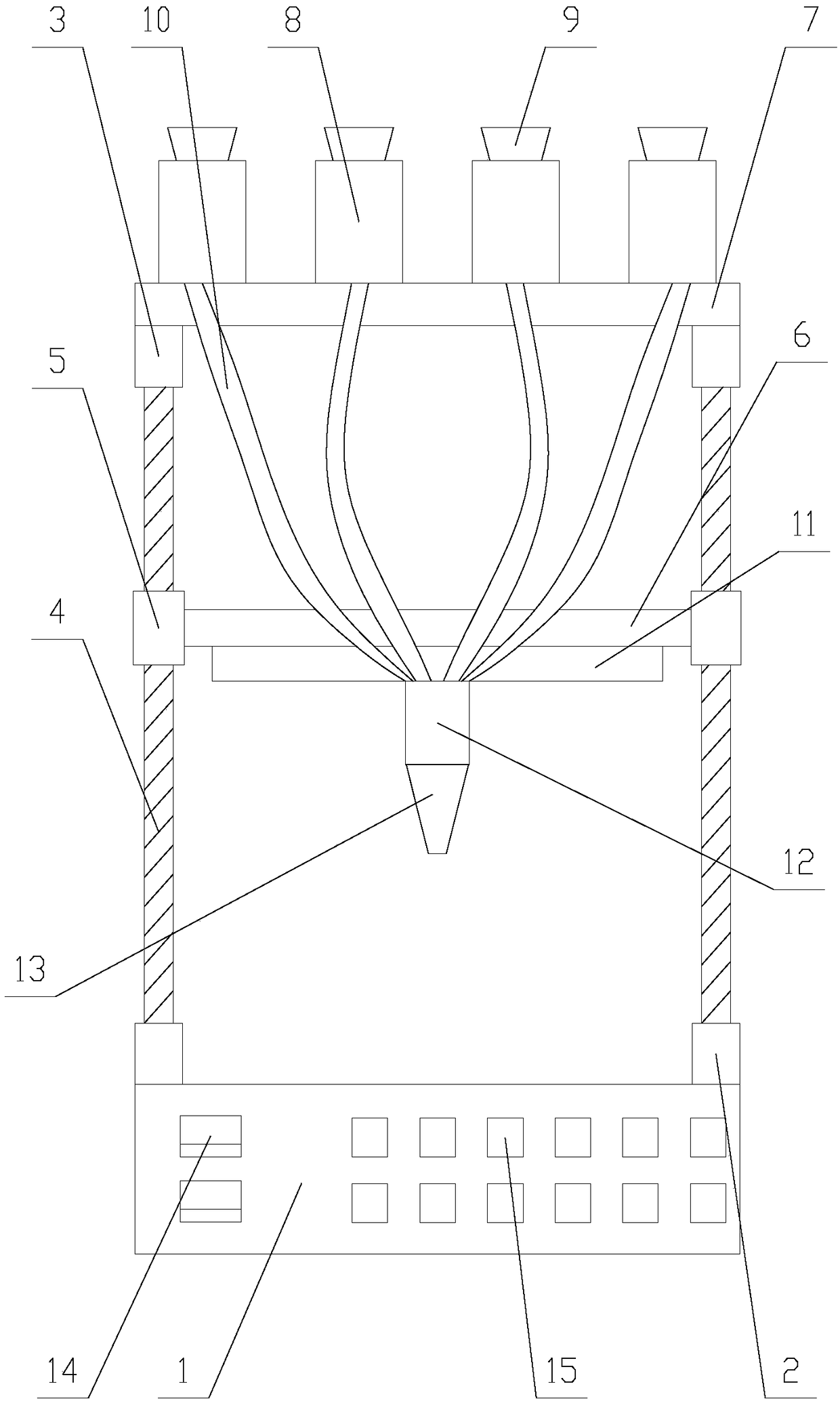

Intelligent 3D printer using various mixed raw materials

ActiveCN106827520ADosage controlChange velocityManufacturing driving means3D object support structuresSprayerEngineering

The invention relates to an intelligent 3D printer using various mixed raw materials. The intelligent 3D printer using the various mixed raw materials comprises a base, a top plate, a stirring box, a heating device, a printing sprayer, two braces and a plurality of feeding mechanisms, wherein the two braces are respectively fixed on two sides of the base; the top plate is erected on the two braces; each feeding mechanism is arranged on the top plate; the stirring box is arranged under the top plate; the heating device is arranged under the stirring box; and the printing sprayer is arranged under the heating device. According to the intelligent 3D printer using the various mixed raw materials, speed regulating blocks are driven to ascend and descend by driving units, the circulation speed of materials in discharging tubes is changed, and then the use amount of the raw materials is controlled. The intelligent 3D printer is simple and convenient, and therefore, the cost of equipment is reduced. Moreover, the various materials in the feeding mechanisms are fully mixed by various mixing units in the stirring box, so that the materials of printed finished products are guaranteed; and the practicability of the printer is improved.

Owner:四川康铭智能装备科技有限公司

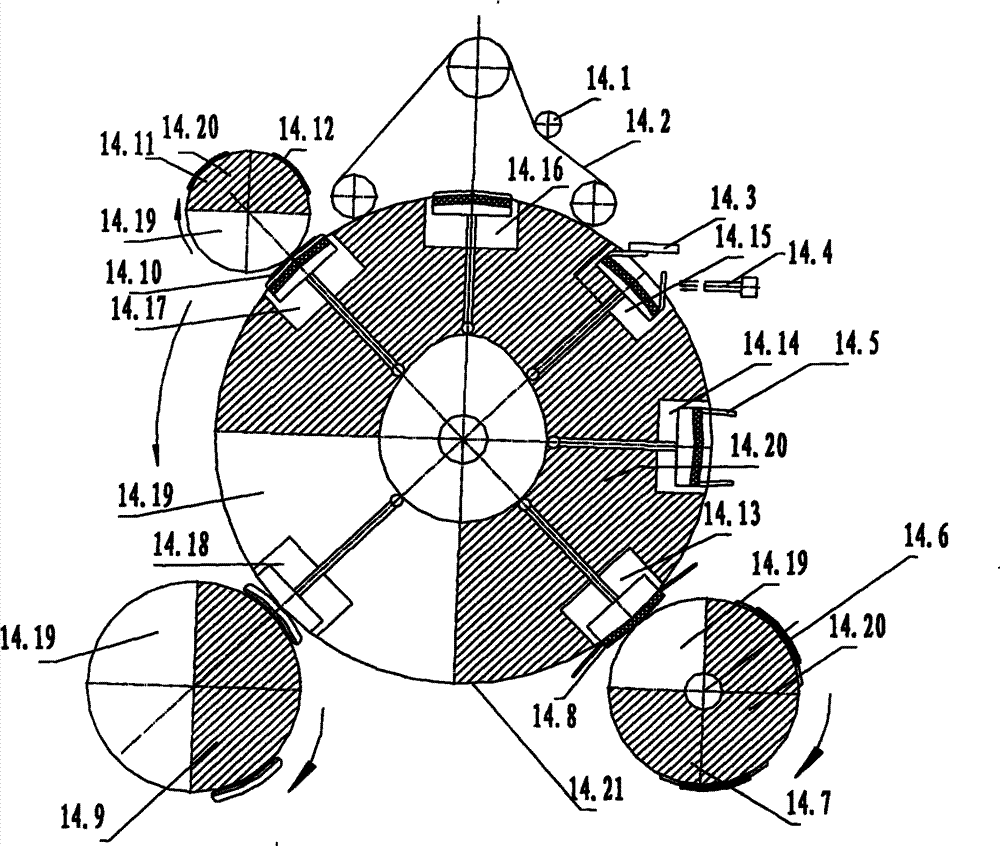

Horizontal device for automatically folding wings of sanitary napkin with protective wings

ActiveCN101485603BAvoid sticky situationsSolve the technical problems of the folded wing processSanitary towelsEngineeringCam

The invention relates to an automatic wing-folding device for transverse-output winged sanitary napkins, which belongs to the technical field of sanitary napkins. The automatic wing-folding device for transverse-output winged sanitary napkins comprises a wing-folding suction hub, and is characterized in that the wing-folding suction hub is provided with a lifting-sliding suction block, a lifting-type connecting rod and a cam; the lifting-sliding suction block is communicated with an air suction port; the lifting-sliding suction block is connected with the cam through the lifting-type connecting rod; a wing-folding area is absorbed to be a negative pressure area when the wing-folding suction hub rotates; a feeding area is an constant pressure area; and the wing-folding suction hub is tangentially provided with an assorted suction hub and a pressure feed mechanism. The device has the advantages of cost reduction, simple structure, reliable performance, convenient operation, flatness andeasy use of the folded wings, high production efficiency, good product quality and the like.

Owner:小护士(天津)科技股份有限公司

An intelligent 3D printer using a mixture of multiple raw materials

ActiveCN106827520BDosage controlChange velocityManufacturing driving means3D object support structuresSprayerEngineering

The invention relates to an intelligent 3D printer using various mixed raw materials. The intelligent 3D printer using the various mixed raw materials comprises a base, a top plate, a stirring box, a heating device, a printing sprayer, two braces and a plurality of feeding mechanisms, wherein the two braces are respectively fixed on two sides of the base; the top plate is erected on the two braces; each feeding mechanism is arranged on the top plate; the stirring box is arranged under the top plate; the heating device is arranged under the stirring box; and the printing sprayer is arranged under the heating device. According to the intelligent 3D printer using the various mixed raw materials, speed regulating blocks are driven to ascend and descend by driving units, the circulation speed of materials in discharging tubes is changed, and then the use amount of the raw materials is controlled. The intelligent 3D printer is simple and convenient, and therefore, the cost of equipment is reduced. Moreover, the various materials in the feeding mechanisms are fully mixed by various mixing units in the stirring box, so that the materials of printed finished products are guaranteed; and the practicability of the printer is improved.

Owner:四川康铭智能装备科技有限公司

A high-efficiency chipping device for rod-shaped medicinal materials

Owner:保定澳美医疗器械有限公司

Production process of medical coconut without additive film

ActiveCN103340758BGuaranteed MaterialProlong the action timeCosmetic preparationsPhysical treatmentBiotechnologyBiochemical engineering

The invention relates to a production process of a medical coconut additive-free diaphragm. A common mask is difficult to meet medical treatment level requirements, the medical coconut additive-free diaphragm is subjected to high temperature high pressure disinfection sterilization treatment at an equivalent level, disinfection sterilization treatment is carried out on the medical coconut additive-free diaphragm by adopting an appropriate medical treatment level irradiation processing manner, microorganism fiber material of the medical coconut additive-free diaphragm and skin friendliness thereof are guaranteed while appearance quality and inherent properties of a processed product are not damaged, essence and nutritional ingredients can be continuously conveyed to each position of skin when the medical coconut additive-free diaphragm is used, and action time of effective ingredients to skin is prolonged, so that the requirements on a medical treatment level mask paster are met.

Owner:海南奈雅生物技术有限公司

Horizontal preparation method of sanitary napkin with protective wings and device thereof

The invention relates to a method and a device for preparing transverse-output winged sanitary napkins, which belongs to the technical field of sanitary napkins. The method for preparing transverse-output winged sanitary napkins comprises the technological processes of preparing absorbers, compounding basement membrane, cutting finished products and coating with small packs. The technological processes are continuously completed, and the processes of preparing the absorbers, compounding the basement membrane, cutting the finished products adopt a transverse side-by-side die mode for the transverse forming production of products. The preparation device comprises an absorber-preparing mechanism, a basement-membrane compounding mechanism, a finished-product cutting mechanism and a small-packcoating mechanism, wherein an absorber knife rest is sequentially connected with a diversion-groove knife rest, a periphery-sealing knife rest, a switching suction hub, a wing-folding knife rest and a finished-product cutting knife rest; the switching suction hub is provided with a lifting-sliding suction block, a lifting-type connecting rod and a cam; the lifting-sliding suction block is communicated with an air suction port; the lifting-sliding suction block is connected with the cam through the lifting-type connecting rod; and the switching suction hub is tangentially provided with an assorted suction hub and a pressure feed mechanism. The invention has the advantages of simple structure, good product quality, high speed of production lines, capability of greatly saving raw materials and energy, and the like.

Owner:小护士(天津)科技股份有限公司

An intelligent 3D printer with precise ingredients and uniform mixing

ActiveCN106891003BMove preciselyAccurate control of flow rateAdditive manufacturing apparatusIncreasing energy efficiencyProcess engineeringDrive motor

The invention relates to an intelligent 3D printer with accurate ingredients and uniform mixing, which includes a heating device and several feeding units. The feeding unit includes a raw material box, and a material control mechanism is arranged in the raw material box. Motor, third connecting rod, slip ring, top rod, bottom rod and two support rods, two stirring units are arranged in the heating device, and the stirring unit includes a support plate, a fifth drive motor, a fifth drive shaft and several paddles . The intelligent 3D printer with precise ingredients and uniform mixing changes the height position of the speed control block through the third drive motor in the raw material box, and the pressure data of the pressure sensor is used as feedback to realize the precise movement of the speed control block, thus accurately controlling the material The circulation speed is fast enough to achieve accurate batching. Not only that, the two stirring units in the heating device fully mix the incoming materials, ensuring the material and quality of the printed samples and further improving the practicability of the equipment.

Owner:都昌西交口腔科技有限公司

Edge grinding device provided with magnifying glass

InactiveCN106392805AWill not affect normal edging operationNormal edging operation guaranteedEdge grinding machinesPortable grinding machinesMagnifying glassEngineering

The invention discloses an edge grinding device provided with a magnifying glass. One end of an adjusting arm is movably riveted to a base and can be fixed through a limiting bolt, and the other end of the adjusting arm is connected with a protective baffle. The protective baffle can be located between the eyes of an edge grinding operator and an edge-grinded piece for sheltering through rotation of the adjusting arm. The side wall of the base is provided with a sliding groove in the circumferential direction. An arc-shaped splash shield is close to and attached to the side wall of the base. The bottom end of the arc-shaped splash shield is embedded in the sliding groove so that the arc-shaped splash shield can slide in the circumferential direction of the base. The adjusting arm is further provided with the magnifying glass extending outwards. The magnifying glass is connected with the adjusting arm through a gooseneck. The magnifying glass can be located between the protective baffle and a grinding disk through adjustment of the gooseneck. The edge grinding device provided with the magnifying glass is simple in structure, convenient to use and capable of effectively preventing edge grinding fragments from splashing around and even splashing to the eyes and guaranteeing the safety of the edge grinding operator and surrounding materials.

Owner:WUHU CHENGDELONG FILTER EQUIP CO LTD

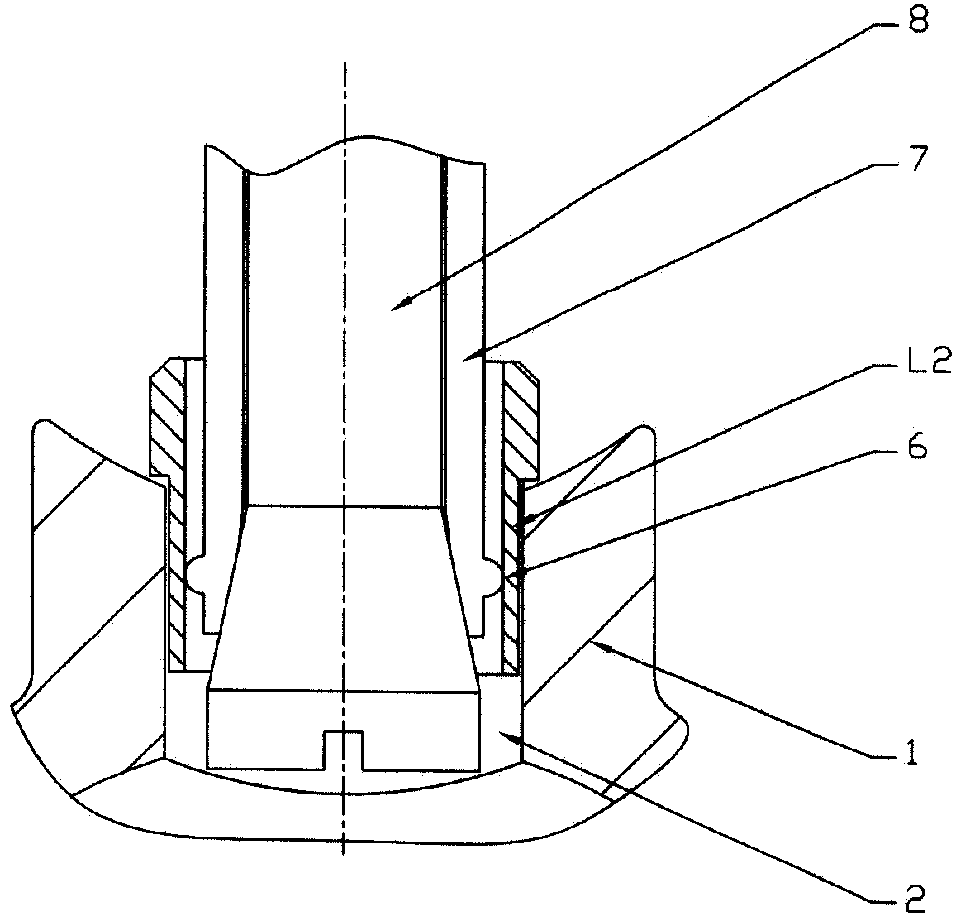

Transmission device for mechanical seal

InactiveCN101349347ASet the structure firmlyEasy to processEngine sealsMechanical engineeringEngineering

Owner:江苏英德利实业有限公司

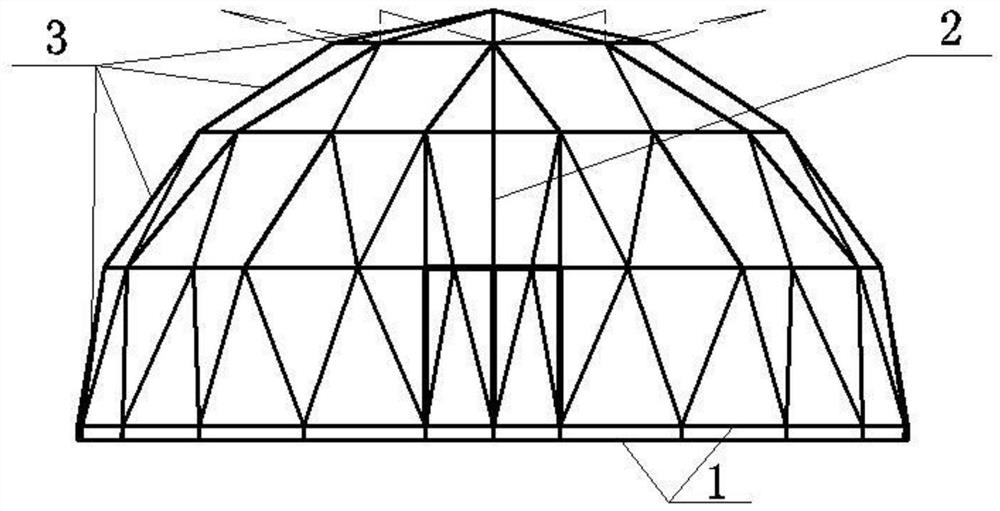

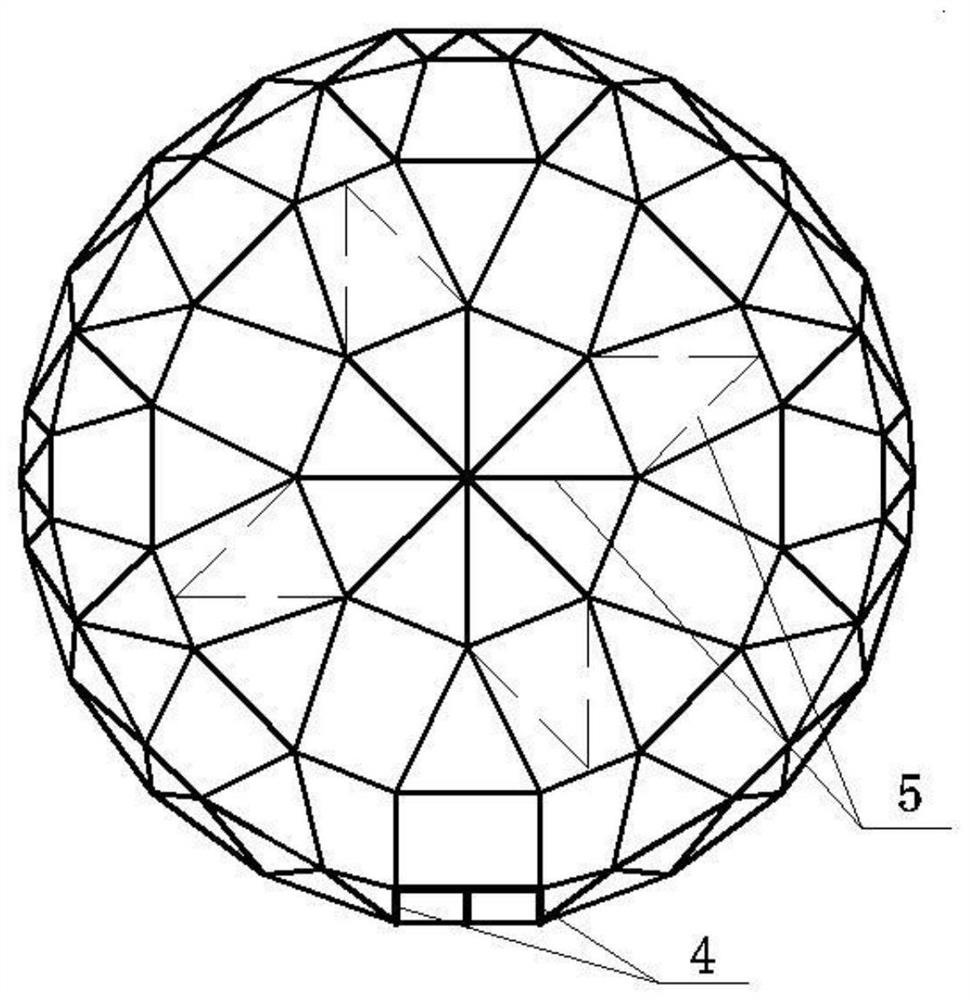

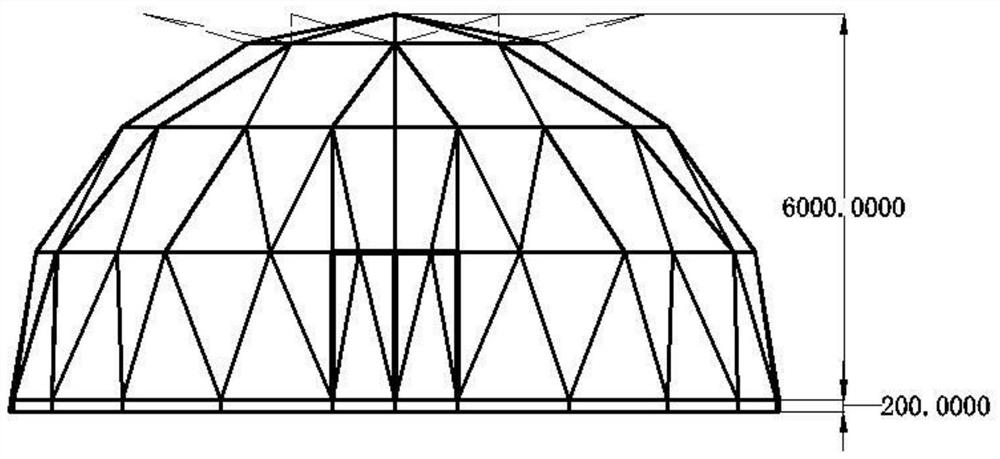

Dome greenhouse skeleton structure imitating gordon euryale leaf veins

InactiveCN113196992AImprove mechanized operation abilityReliable facility environmentClimate change adaptationGreenhouse cultivationGreenhouseSkylight

The invention is applied to the field of greenhouse skeleton structure design, and particularly relates to a dome greenhouse skeleton structure imitating gordon euryale leaf veins. The skeleton structure comprises a ring beam, middle stand columns, main beams, a greenhouse door and skylights, wherein the ring beam divides a circle into 20 equal parts, the stand columns are evenly arranged on each equal part and four quadrant points of the circle, the main beams are arranged above the ring beam, the main beams are divided into four layers and are obtained by quartering a 1 / 4 arc in the vertical direction, the overall structure is a triangular and quadrilateral truss unit, a greenhouse door is arranged between the two vertical main beams in the front view direction of the fourth layer on the upper portion of the ring beam, and four skylights capable of being opened and closed are arranged on the first layer of main beams. By means of the gordon euryale leaf vein structure, the dome greenhouse skeleton structure which is high in strength and high in illumination, saves materials and facilitates mechanical operation is provided, and analysis proves that forked structures and forked angles of the gordon euryale leaf veins not only can transfer the effect of concentrated stress and improve the overall structural strength, but also can save the materials on the premise of ensuring sufficient strength of the greenhouse.

Owner:SHENYANG UNIV

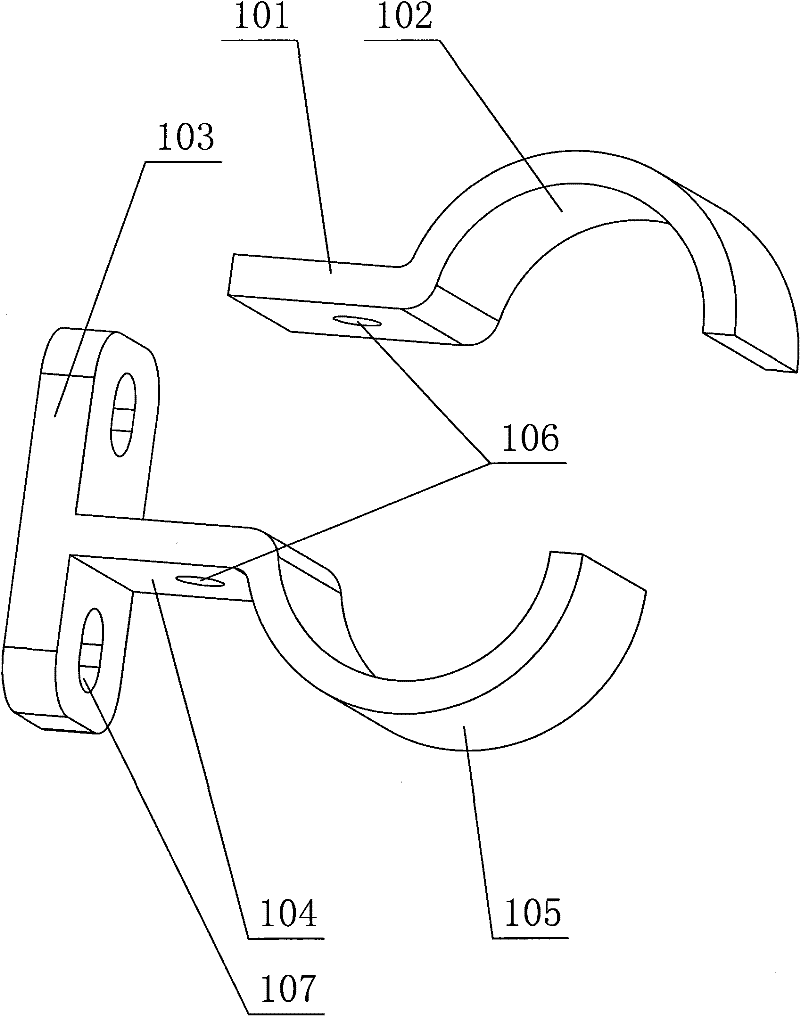

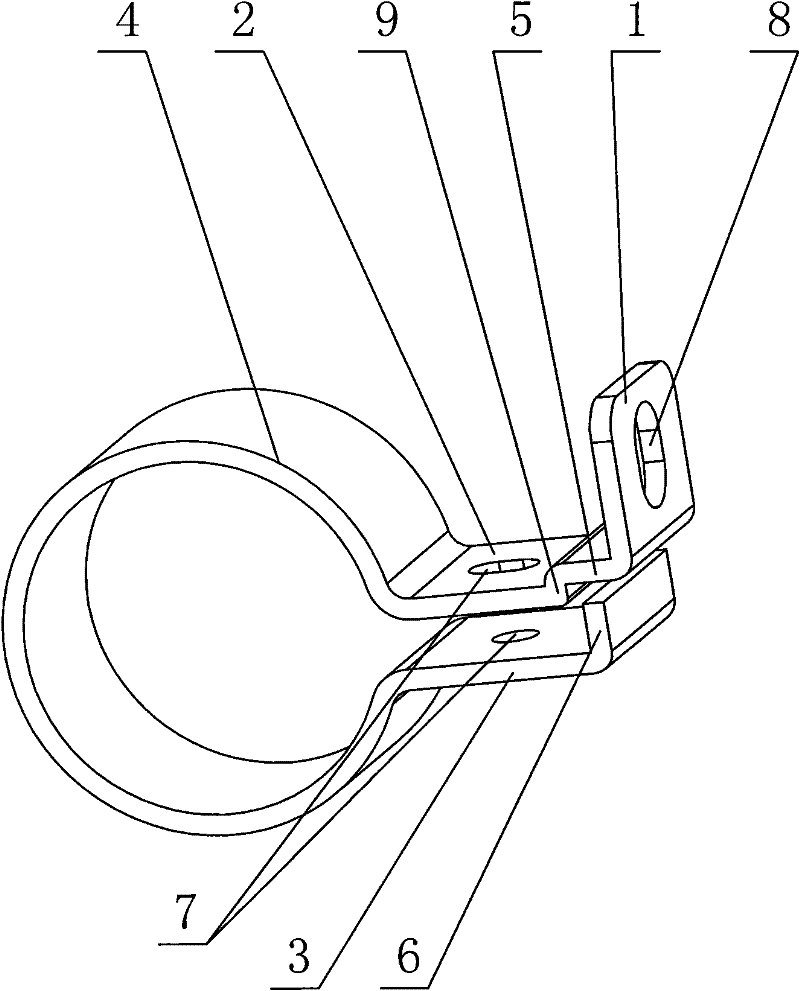

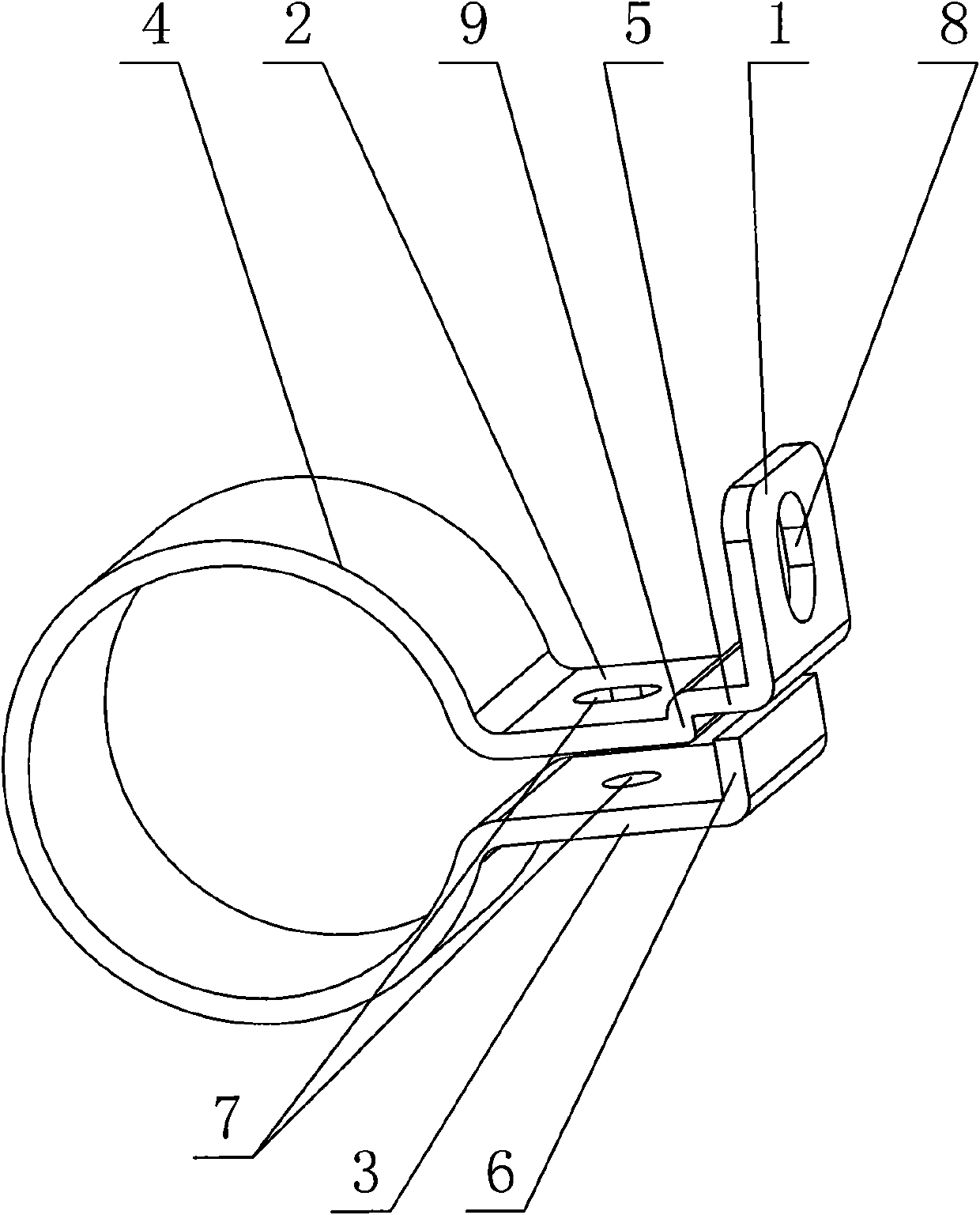

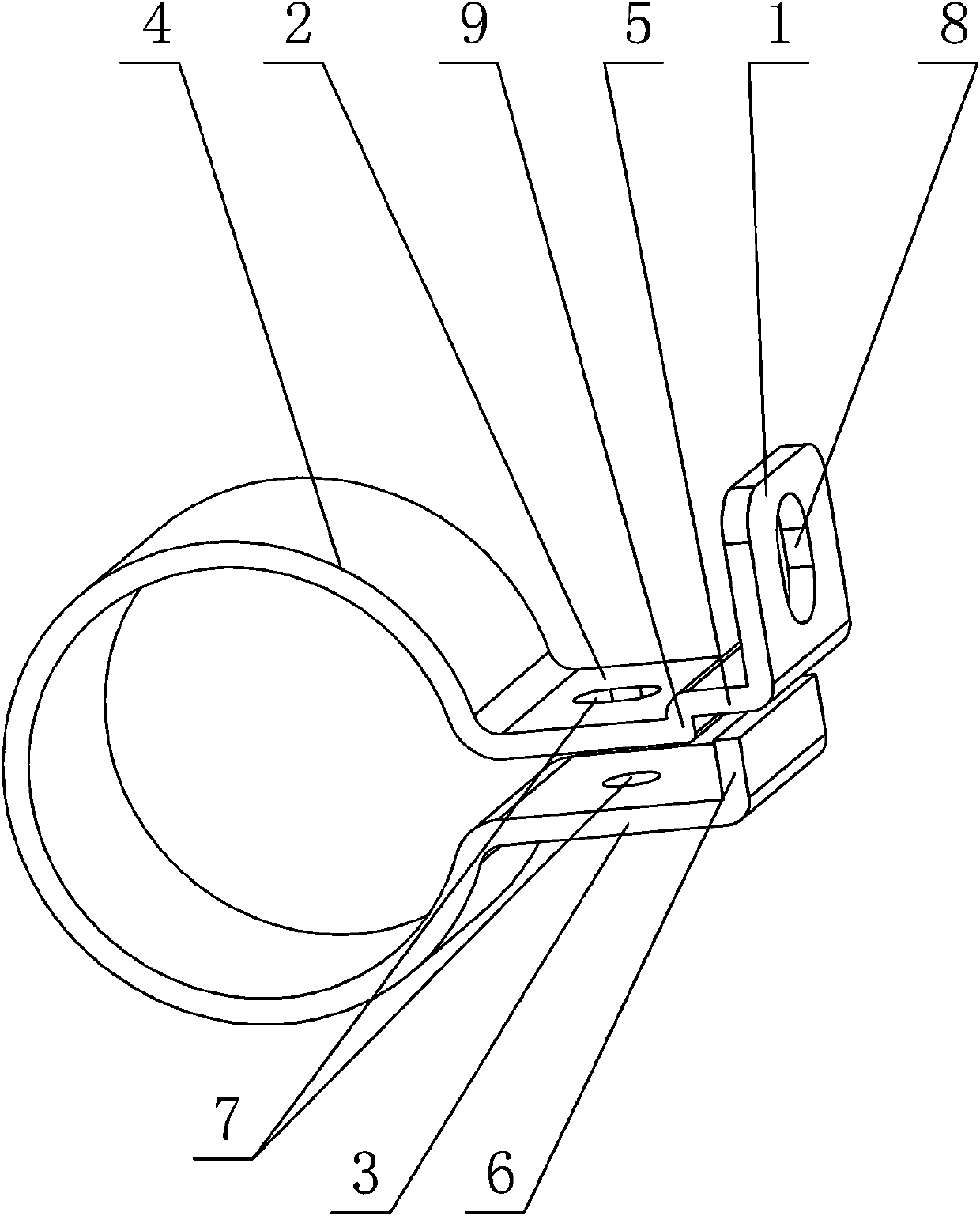

Armrest seat of subway escape and evacuation platform

The invention discloses an armrest seat of a subway escape and evacuation platform, which comprises a fixed seat (1), a first transverse plate (5), a first vertical plate (9), an upper transverse plate (2), a round sleeve (4) with an opening, a lower transverse plate (3) and a lower vertical plate (6), wherein the fixed seat (1), the first transverse plate (5), the first vertical plate (9), the upper transverse plate (2), the round sleeve (4) with the opening, the lower transverse plate (3) and the lower vertical plate (6) are sequentially connected into a whole, the upper end of the lower vertical plate (6) can be tightly abutted against the connected part of the first transverse plate (5) and the first vertical plate (9), holes (7) which have corresponding positions and are used for bolts to penetrate are all arranged on the upper transverse plate (2) and the lower transverse plate (3), an expansion bolt through hole (8) is arranged on the fixed seat (1), and the fixed seat (1), thefirst transverse plate (5), the first vertical plate (9), the upper transverse plate (2), the round sleeve (4) with the opening, the lower transverse plate (3) and the lower vertical plate (6) are all metal parts with the same thickness. The armrest seat has low manufacturing cost.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

Edge polishing device with arc-shaped splash shield

InactiveCN106312732AWill not affect normal edging operationGuaranteed MaterialEdge grinding machinesGrinding/polishing safety devicesDrive motor

The invention discloses an edge polishing device with an arc-shaped splash shield. A through hole is formed in a base along a central axis direction; a rotation shaft is arranged in the through hole; a polishing plate is arranged on the top end of the rotation shaft in a sleeving way; the bottom end of the rotation shaft is connected with a spindle of a drive motor so as to enable the drive motor to drive the polishing plate to rotate by adopting a self-central axis as an axle; one end of an adjusting arm is movably riveted on the base and can be fixed through a stop bolt, and the other end of the adjusting arm is connected with a protecting baffle plate, so that the protecting baffle plate can be shielded between eyes of an edge polishing operator and an edge polishing parts through rotatably adjusting the adjusting arm; a sliding chute is arranged on the side wall of the base along a circumferential direction; the arc-shaped splash shield is close to and fit to the side wall of the base; and the bottom end of the arc-shaped splash shield is embedded in the sliding chute, so that the arc-shaped splash shield can slide along the circumferential direction of the base. The edge polishing device is simple in structure and convenient to use, and can effectively prevent edge polishing chippings from splashing throughout and even splashing into the eyes so as to ensure the safety of the edge polishing operator and peripheral materials.

Owner:WUHU CHENGDELONG FILTER EQUIP CO LTD

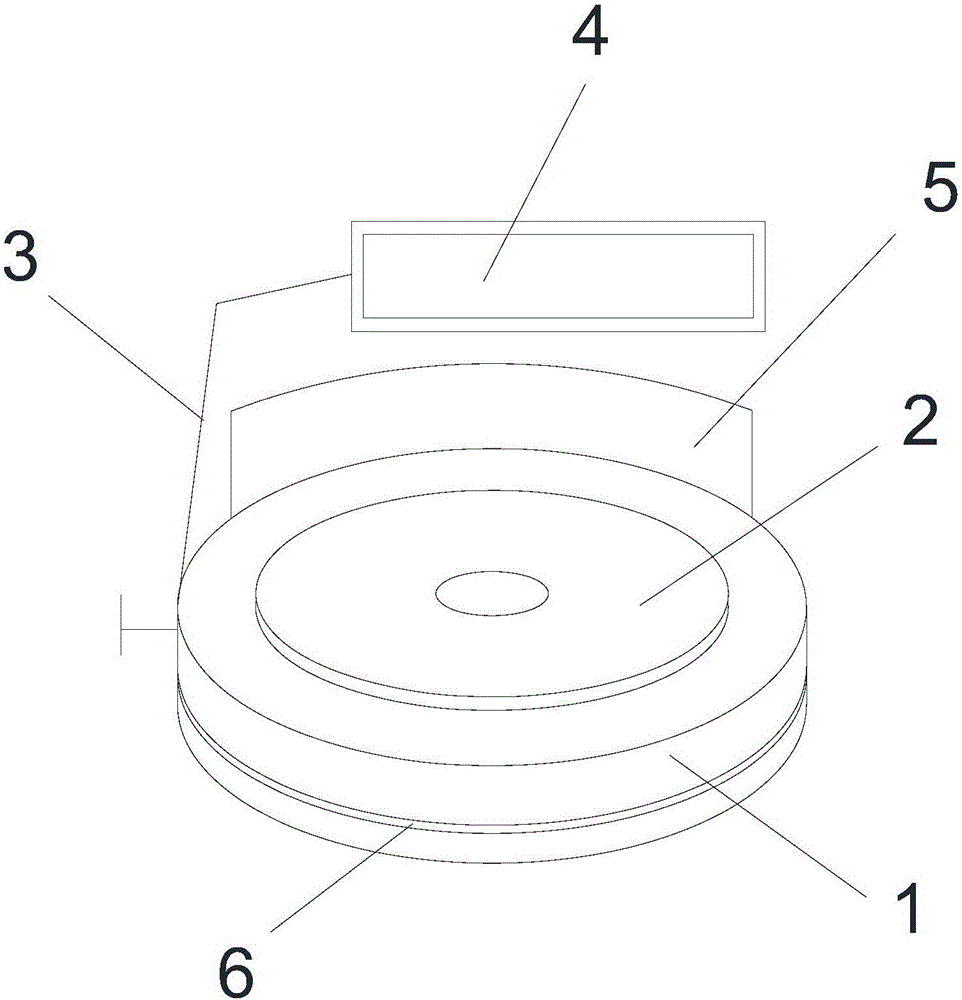

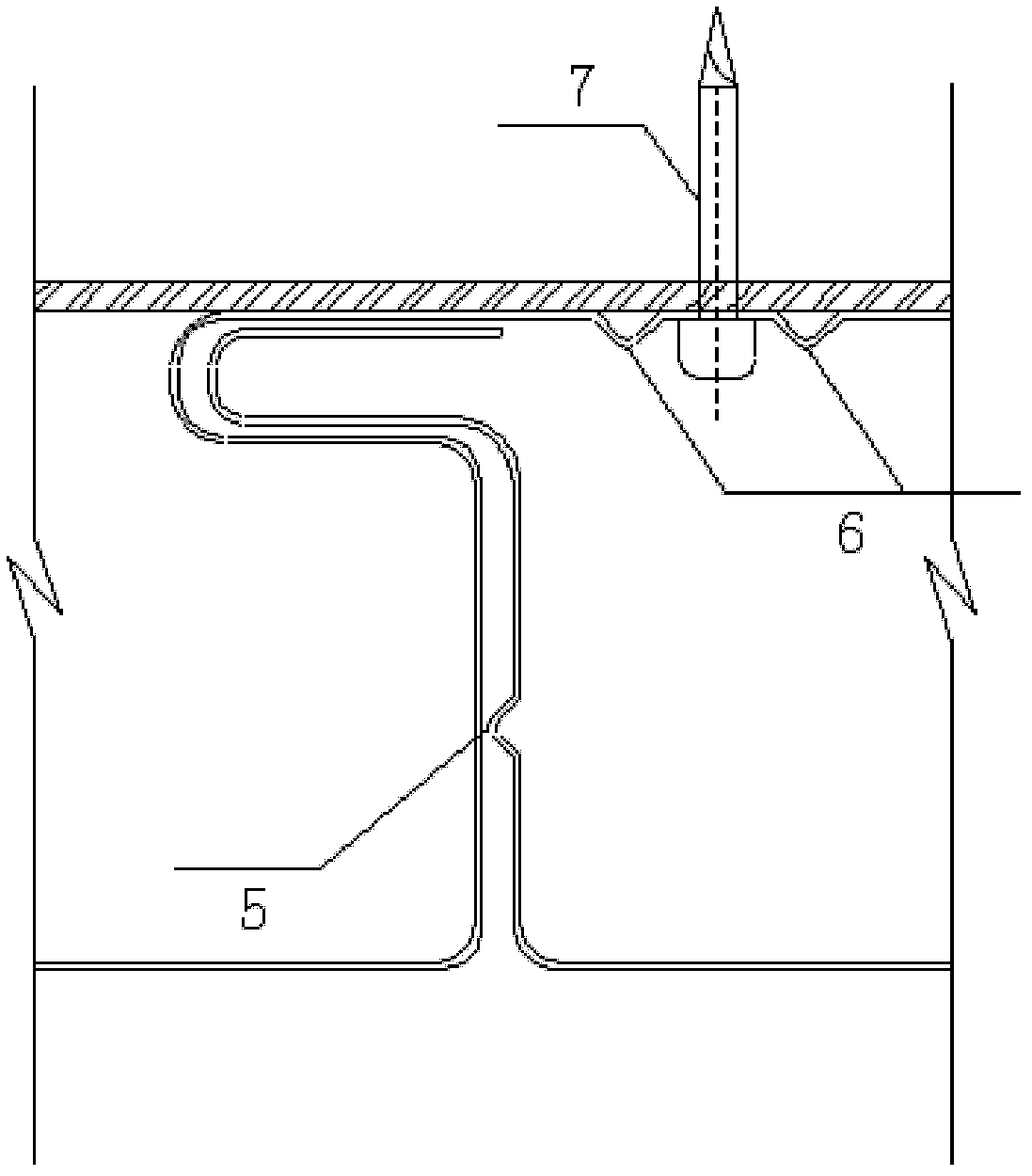

Hidden metal contour plate for building wall face, and manufacturing method thereof

The invention discloses a hidden metal contour plate for a building wall face, and a manufacturing method thereof, and belongs to the technical field of metal contour plates. The metal contour plate is formed by compressing a flat metal base plate by using a forming roll along a straight line; the cross section of the metal contour plate is processed to have a groove profile, and shallow wave troughs are formed on the metal contour plate along the length direction; a concave female buckle edge is formed on one side of the metal contour plate along the length direction, a convex male buckle edge is formed on one side of the metal contour plate along the length direction, and the height and length of the female buckle edge are consistent with those of the male buckle edge; and one metal contour plate is fixed on a purline by a waterproof tapping screw between two female buckle edge side protruded ribs on the female buckle side of the metal contour plate, and the male buckle side of the other metal contour plate is inserted into a groove of the female buckle side to realize mutual meshing, so two metal contour plates are connected in a socket way. The invention has the advantages that the hidden metal contour plate has a flat, straight and attractive appearance, and is fully decorative; and the hidden metal contour plates are connected in a hidden way, so the problems that connection pieces are rusted and water is leaked are avoided.

Owner:BEIJING SHOUGANG CONSTR GROUP

Armrest seat of subway escape and evacuation platform

The invention discloses an armrest seat of a subway escape and evacuation platform, which comprises a fixed seat (1), a first transverse plate (5), a first vertical plate (9), an upper transverse plate (2), a round sleeve (4) with an opening, a lower transverse plate (3) and a lower vertical plate (6), wherein the fixed seat (1), the first transverse plate (5), the first vertical plate (9), the upper transverse plate (2), the round sleeve (4) with the opening, the lower transverse plate (3) and the lower vertical plate (6) are sequentially connected into a whole, the upper end of the lower vertical plate (6) can be tightly abutted against the connected part of the first transverse plate (5) and the first vertical plate (9), holes (7) which have corresponding positions and are used for bolts to penetrate are all arranged on the upper transverse plate (2) and the lower transverse plate (3), an expansion bolt through hole (8) is arranged on the fixed seat (1), and the fixed seat (1), the first transverse plate (5), the first vertical plate (9), the upper transverse plate (2), the round sleeve (4) with the opening, the lower transverse plate (3) and the lower vertical plate (6) are all metal parts with the same thickness. The armrest seat has low manufacturing cost.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

Locking strip and preparation method thereof

The invention belongs to the technical field of cast iron, and particularly relates to a locking strip and a preparation method thereof. The method comprises the following steps: weighing steel scrap and steel pins for subsequent use; starting an electric furnace for smelting and firstly putting the steel scrap into the electric furnace; smelting the steel scrap into liquid by the electric furnace and putting the steel pins to obtain a solution; adding a carbon-increasing agent, a silicon-increasing agent, a dechroming agent, a manganese-increasing agent and an anti-oxidizing agent to regulate internal components of the solution; and carrying out casting molding to obtain the locking strip. The locking strip is prepared from the following materials in percentage by mass (percent): 3.8 to 4.0 percent of carbon, less than or equal to 0.05 percent of phosphorus, 0.14 percent of manganese, less than or equal to 0.1 percent of chromium, 1.8 to 2.0 percent of silicon, less than or equal to 0.03 percent of sulphur, and the balance iron. By adopting waste steel pins as the main raw materials, crude iron is replaced by the waste steel pins, so that the using consumption of the crude iron is reduced, and adjustment after smelting of the electric furnace is carried out and the casting is carried out. The production cost is reduced when the material quality of a casting piece product is ensured, and environment protection and energy conservation effects are achieved.

Owner:赵昆山 +1

Stable type feeding mechanism for welding machining applied to electronic products

PendingCN114310044AHigh precisionGuaranteed materialWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringManufacturing engineering

The invention is applicable to the related technical field of feeding equipment, and provides a stable feeding mechanism for welding processing applied to electronic products, which comprises a base, a first vertical plate and a second vertical plate fixed on the upper part of the base, and a storage box arranged above the base. The bidirectional driving assembly drives the frame body to do linear motion in the horizontal direction, the bidirectional driving assembly works in the forward direction, the frame body does linear motion towards the first vertical plate, and when the frame body reaches the tail end of the stroke, the pneumatic control assembly works and controls the storage box to complete one-time opening and closing action, so that the to-be-welded materials slide into the frame body, and then the to-be-welded materials slide into the frame body. The bidirectional driving assembly works reversely, the frame body and the to-be-welded material move towards the second vertical plate, and in the process, the elastic limiting assembly triggers movement to fix and limit the to-be-welded material in the frame body, so that the to-be-welded material is fixed and limited in the conveying process, and the welding machining precision is effectively improved.

Owner:刘斌

Production process of cold silicone liner

InactiveCN101584507BGuaranteed MaterialGuaranteed styleFibre treatmentGarmentsPolymer sciencePolyamide

Owner:CHANGXING SHIANTE CLOTHING MATERIAL

Connecting structure and connecting method thereof for shell of liquid reservoir and sleeve

InactiveCN104034102AAchieve riveted fixationGuaranteed MaterialRivetsRefrigeration componentsEngineeringAluminium

The invention discloses a connecting structure and a connecting method thereof for a shell of a liquid reservoir and a sleeve. The shell is provided with a circular through hole. The connecting structure is characterized in that the outer diameter of the sleeve comprises a large-diameter section and a small-diameter section, the diameter of the small-diameter section is smaller than that of the through hole, and the small-diameter section is disposed in the through hole. For further completing and complementing the connecting structure, the other technical characteristics are added that the shell and the sleeve are made of aluminum, and a projection portion is sunk in the inner wall of the through hole, the shell is provided with the circular through hole, the outer diameter of the sleeve is divided into the large-diameter section and the small-diameter section, and the diameter of the small-diameter section is smaller than that of the through hole. Since the small-diameter section of the sleeve in clearance fit with the through hole of the shell is provided with the projection portion abutted against the inner wall of the through hole of the shell, the sleeve is fixedly riveted to the shell, and material guarantee is provided for implementation of the connecting structure and the connecting method.

Owner:XINCHANG YUEKE MACHINERY

Preparation method of eight-ingredient wine

PendingCN114410418AMaterial guaranteeQuality assuranceTesting beveragesDigestive systemCoixProcess engineering

The preparation method comprises the following steps: step A, selecting raw materials, taking white spirit as a wine base, and taking red dates, Chinese yams, coix seeds, white hyacinth beans, haws, malt, radish seeds and kudzuvine roots as auxiliary materials; the auxiliary materials are washed and diced for standby application; mixing the backup auxiliary materials to prepare a soaking material; step B, soaking; the wine base is put into a soaking cylinder, the soaking material is put into the wine base to be soaked, and the temperature of the soaking cylinder is kept constant; the wine base forms a base material; step C, filtering and separating; taking out the soaked material from the base material; the preparation method comprises the following steps: adding a base material into a blending tank, filtering the base material, and introducing the obtained to-be-prepared liquid into the blending tank for blending so as to improve the problems that the flavor difference of the prepared wine is large and the uncertain factors of the alcoholic content are obviously increased due to excessive auxiliary materials in the prepared wine and difficult control of the substance distribution of the auxiliary materials.

Owner:粮草仓有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com