Hidden metal contour plate for building wall face, and manufacturing method thereof

A metal pressing and hidden technology, which is applied in the direction of construction, building construction, covering/lining, etc., to avoid rust, avoid water leakage problems, and easy to control the installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

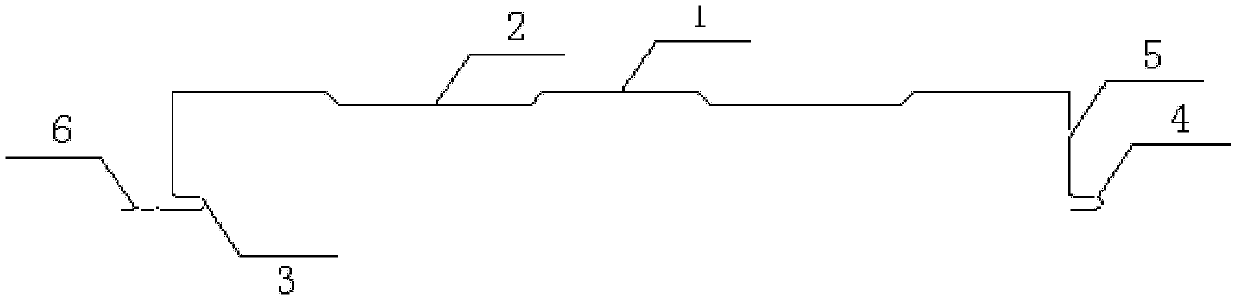

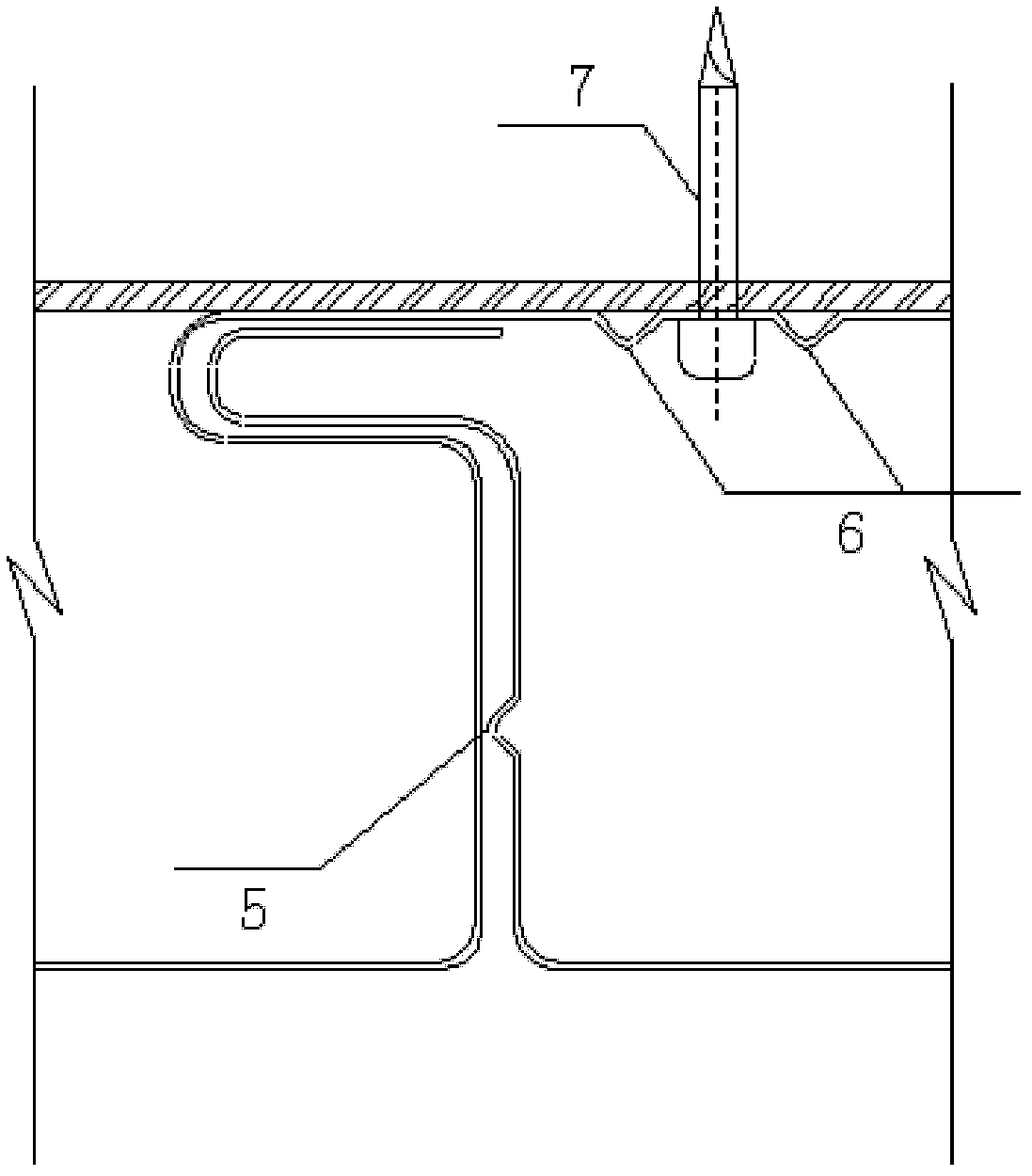

Embodiment 1

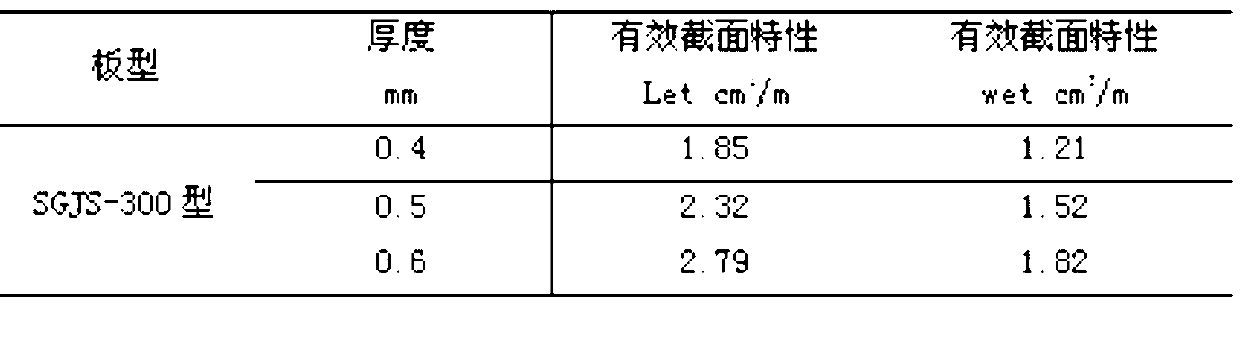

[0031] The metal profiled plate 1 is pressed and formed by a flat metal substrate along a straight line using a forming roller. The metal substrate is a hot-dip galvanized sheet, and the thickness of the metal profiled plate 1 is 0.6mm; the effective width is 300mm, and the expanded width is 457mm. The cross section of the metal profiled plate 1 is processed into a groove shape, and a wave groove 2 is provided along the length direction. The wave height of the wave groove is 39mm; The convex male buckle side 4, the height and length of the female buckle side 3 and the male buckle side 4 are the same, and the height is 3mm. Form plate 1, there are two side convex ribs 6 of the side of the female button on the side 3 of the female button, and one side convex rib 5 of the side of the male button on the side 4 of the male button; two metal profiled plates 1 are connected, and one metal profiled plate Fix the metal profiled plate 1 on the purlin with waterproof self-tapping screws ...

Embodiment 2

[0035]The metal profiled plate 1 is formed by pressing a flat metal substrate along a straight line using a forming roller. The metal substrate is a color-coated plate, and the thickness of the metal profiled plate 1 is 0.8mm; the effective width is 350mm, and the expanded width is 500mm. The cross-section of the profiled plate 1 is processed into a groove shape, and a wave groove 2 is provided along the length direction; the wave height of the wave groove is 45mm, and one side of the metal profiled plate 1 along the length direction is a concave female button edge 3, and the other side is a convex The height and length of the male buckle side 4, the female buckle side 3 and the male buckle side 4 are the same, the height is 5mm, and the connecting line between the center point of the female buckle side 3 groove and the male buckle side 4 convex groove center point is parallel to the metal profile Plate 1, two side ribs 6 of the side of the female buckle on the side 3 of the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com