Digital profile grinder

A grinding machine and curve technology, which is applied in the field of digital curve grinding machines, can solve the problems of inability to quantify, low precision, and inability to form at one time, so as to avoid the deviation of human identification, the transmission mechanism is simple, and the detection accuracy is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

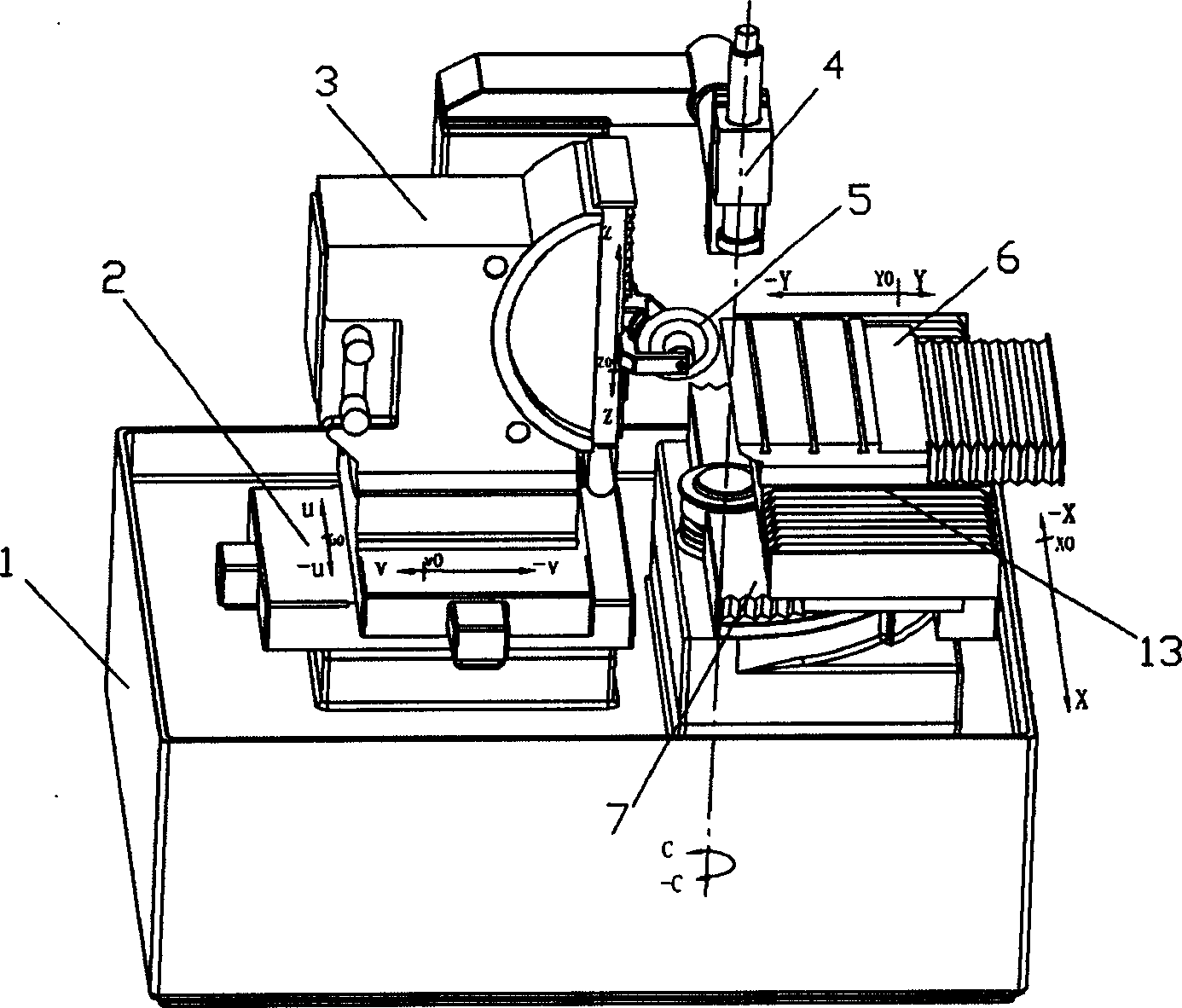

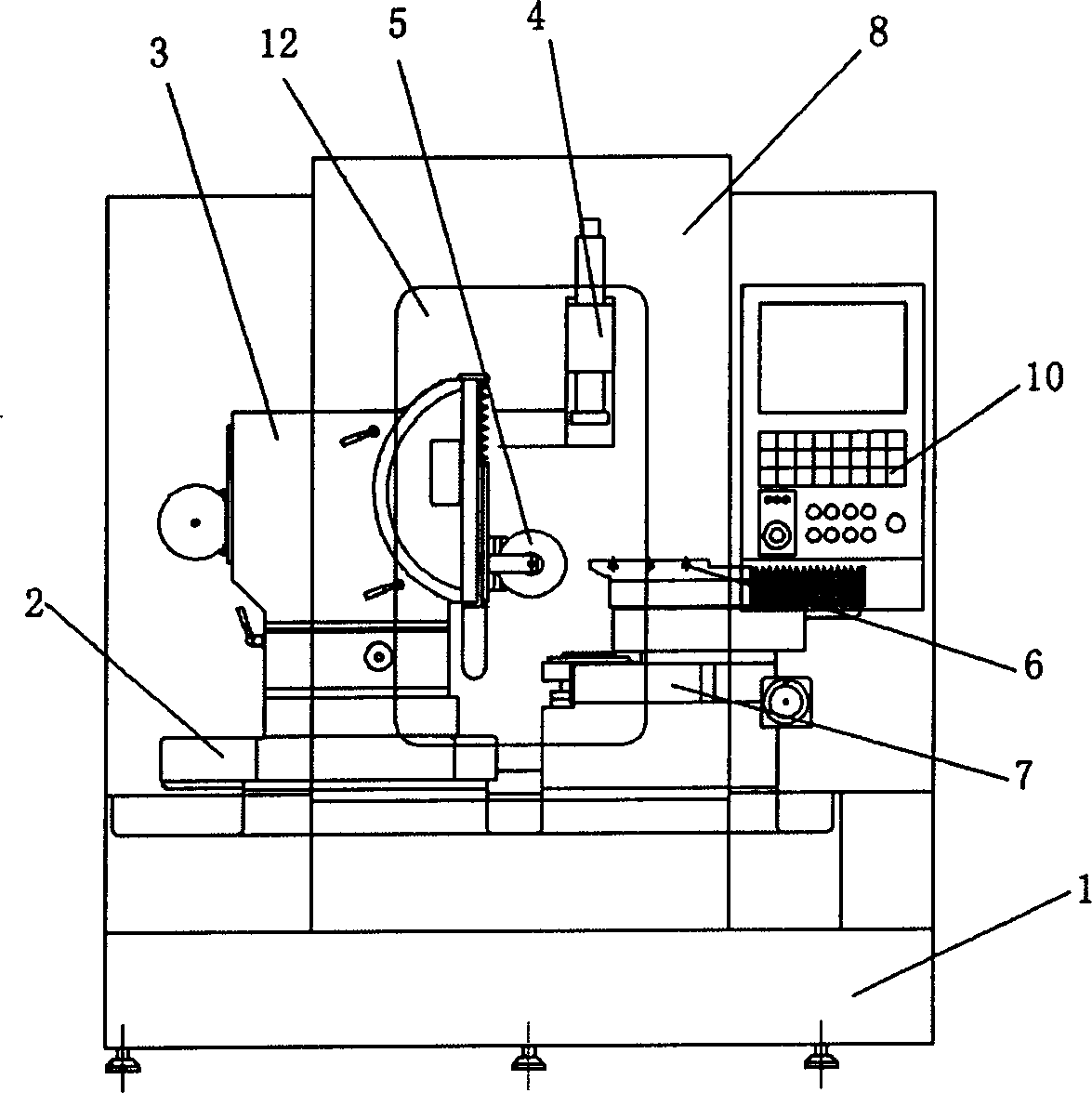

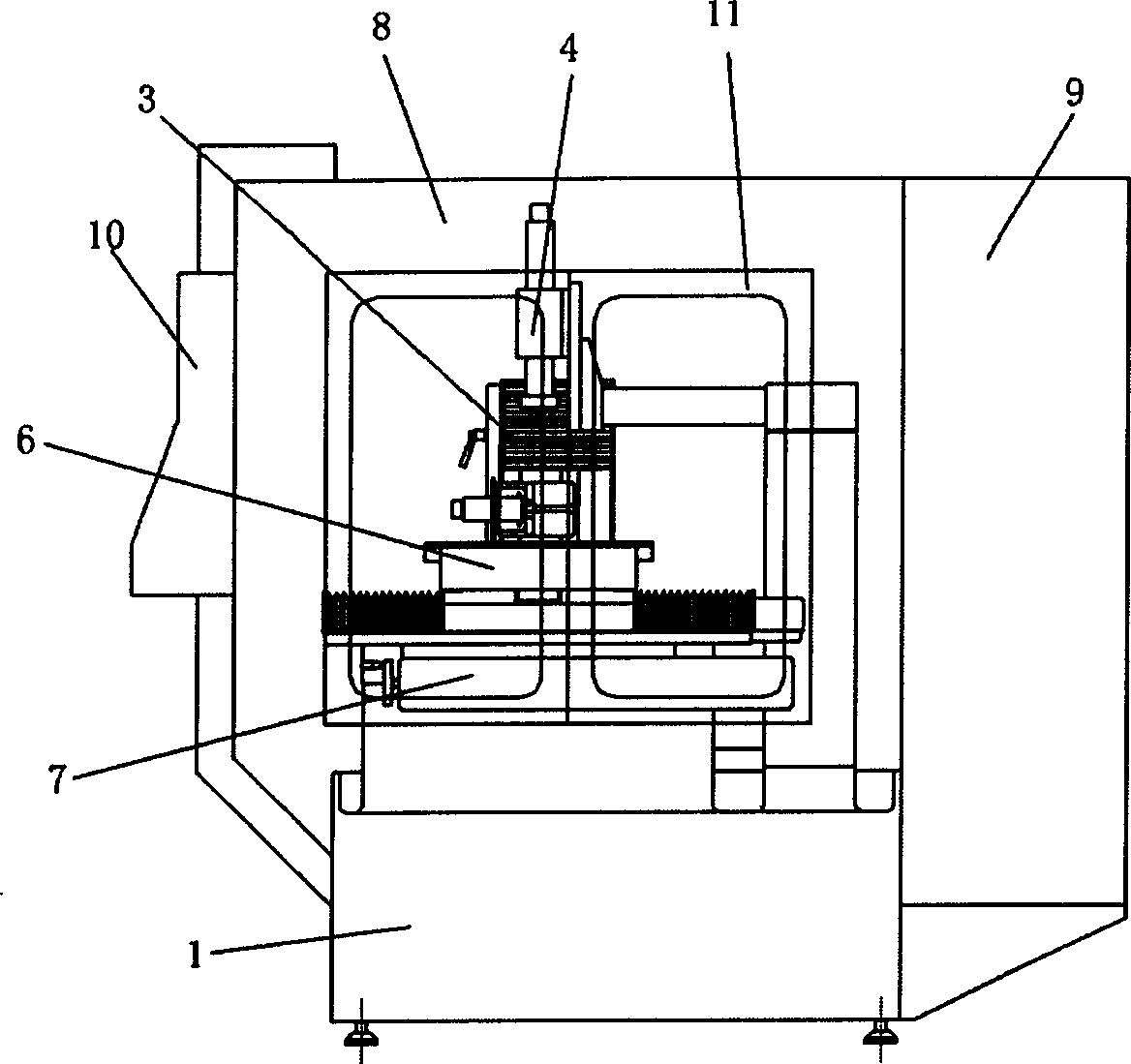

[0026] like Figures 1 to 3 As shown, the digital curve grinder consists of two parts, the main machine and the auxiliary machine station. The main machine is a fully enclosed structure, the right side of the bed 1 is a multi-functional workbench 6, the left side is a grinding wheel frame 3 and a sliding seat 2, the upper part is a CCD detection system 4, and the electric cabinet 9 is located at the back of the main machine and is integrated with the main machine; The auxiliary machine station has a vacuum device, a cooling device, an air balance and a brake control station, etc., which are flatly integrated. It is convenient for transportation, installation and debugging.

[0027] The fully enclosed cover 8 adopts a splicing type, and the panels of each cover are connected to each other and fixedly connected to the main machine; the front right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com