Pressure testing method for small diameter open-mouth connecting pipe of pressure vessel

A pressure vessel, small diameter technology, applied in the direction of using stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve problems such as difficulties and poor control of forming dimensions, and achieve simple methods, convenient operations, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further illustrate the present invention in conjunction with accompanying drawing.

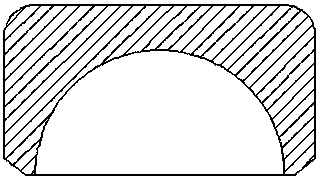

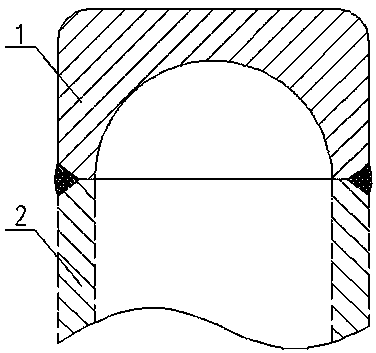

[0013] The pressure test method of the small-diameter open pipe of the pressure vessel: according to the pressure requirements of the equipment pressure test, use special calculation software to calculate the thickness and related dimensions of the pressure test head; according to the calculated size, directly process the pressure test tooling with a lathe 1, such as figure 1 As shown; the material of the pressure test tooling uses the remaining sheet material in the process of pressure vessel manufacturing, and the thickness of the sheet material should be greater than the height of the required pressure test head; the pressure test tooling 1 is welded on the open nozzle 2 of the pressure vessel ,Such as figure 2 As shown, flaw detection is carried out on the connecting weld seam; after the flaw detection is qualified, carry out the pressure test of the pressure vessel according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com