Method for melting heterogeneous cast iron in same intermediate frequency electric furnace

An intermediate frequency electric furnace and cast iron technology, applied in the field of cast iron smelting, can solve the problems of waste of smelting space, lack of systematic and comprehensive research, inability to guarantee accurate, fast, low-cost cast iron smelting production process and the inherent quality of castings, etc., to achieve quality improvement, Effect of reducing smelting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for smelting heterogeneous cast iron in an intermediate frequency electric furnace in the same furnace, comprising the following steps:

[0025] 1. Prepare charge and equipment:

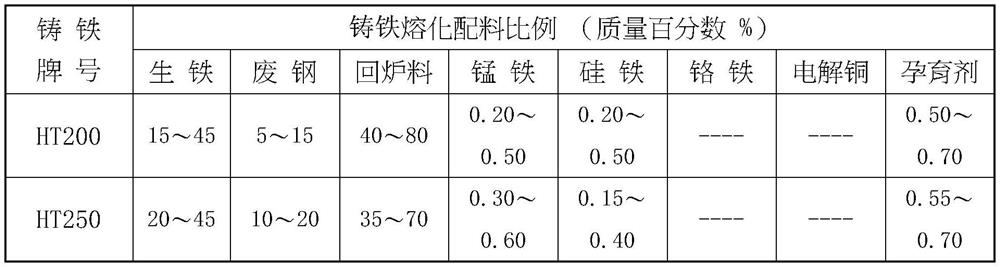

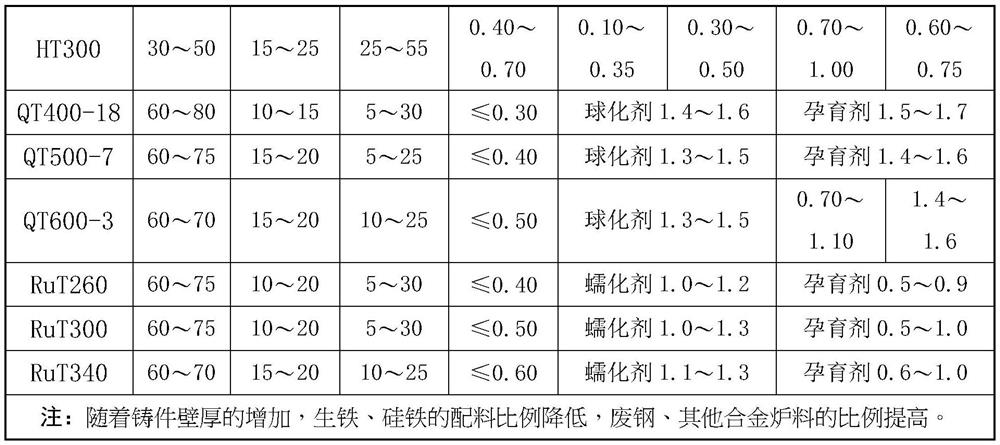

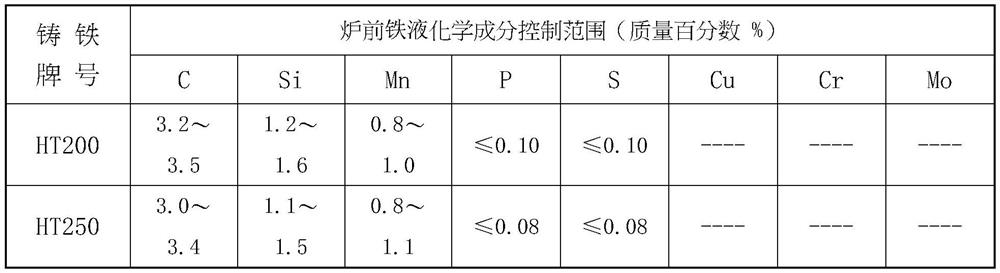

[0026]Prepare various furnace materials such as pig iron, scrap steel, recycled materials, ferroalloys, and auxiliary materials required for cast iron melting production; check and prepare various equipment required for smelting such as intermediate frequency electric furnaces, molten iron treatment packages, cranes, and testing equipment; prepare Various technical documents such as standards, manuals, process regulations, operation instructions, and batching process sheets required for cast iron smelting operations; among them, the return charge refers to the metal charge that is returned to the furnace and used for remelting, generally including homogeneous casting pouring Castings, scrapped castings, and ingots of molten iron remaining from the previous furnace; ferroalloys refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com