Method for installing converter body equipment and tooling platform

A technology of equipment installation and platform, which is applied in the manufacture of converters, etc., can solve the problems of manpower and material resources, difficulty in installation of converter body equipment, and low precision, and achieve the effects of improving work efficiency, saving manpower, and improving installation work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention mainly uses a self-made tooling platform to complete the assembly, transportation and installation of the converter body on the platform.

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

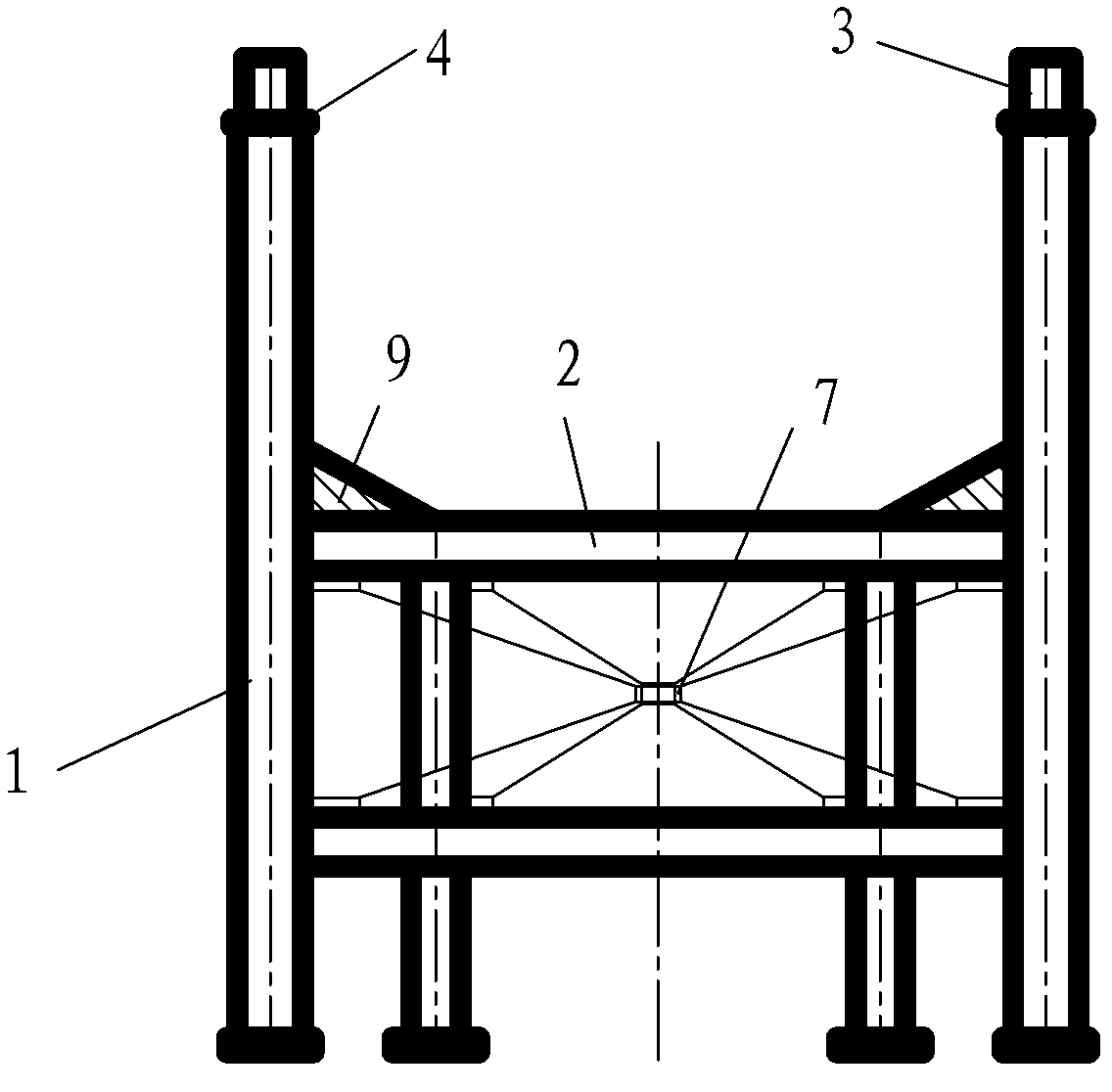

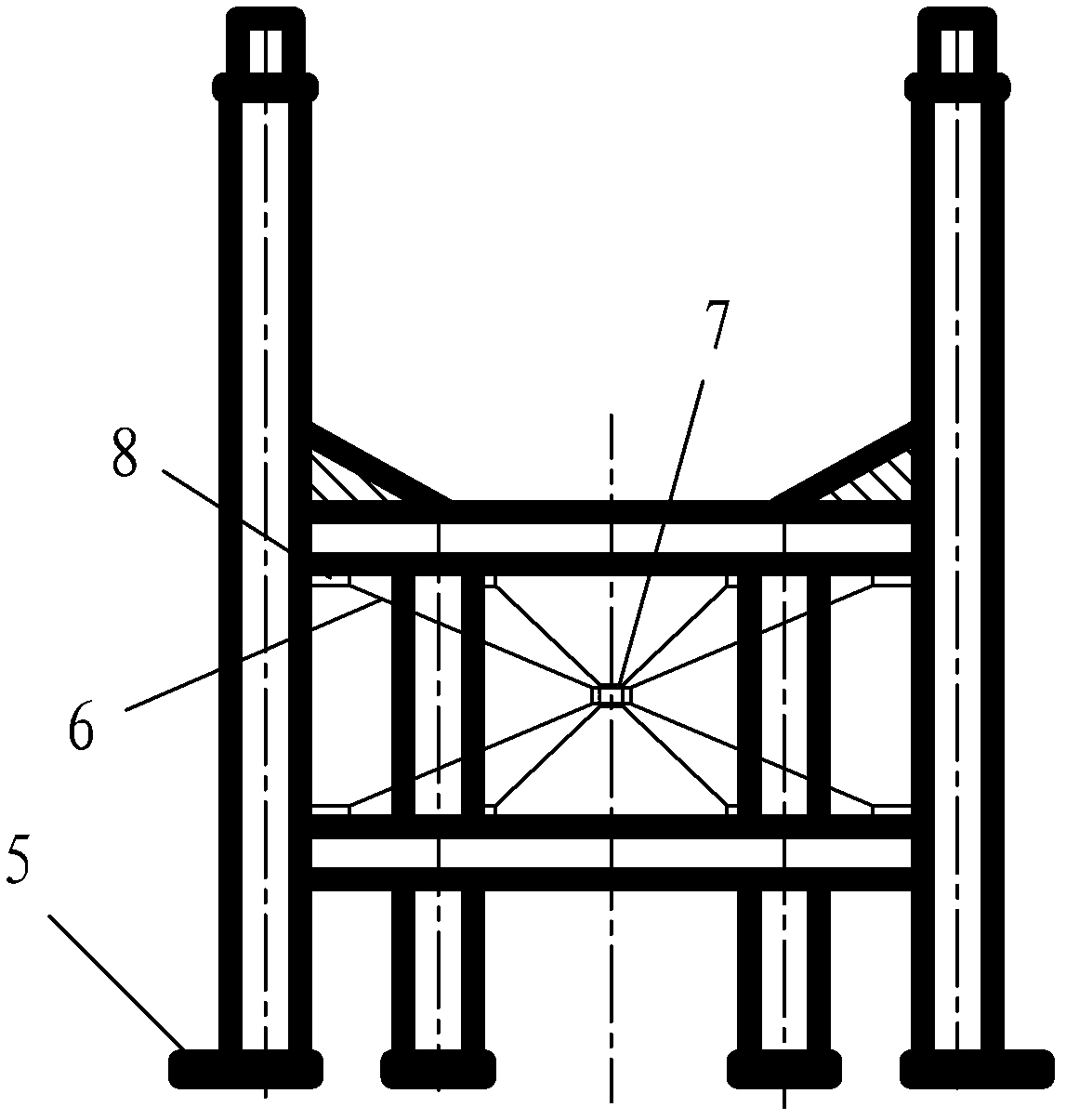

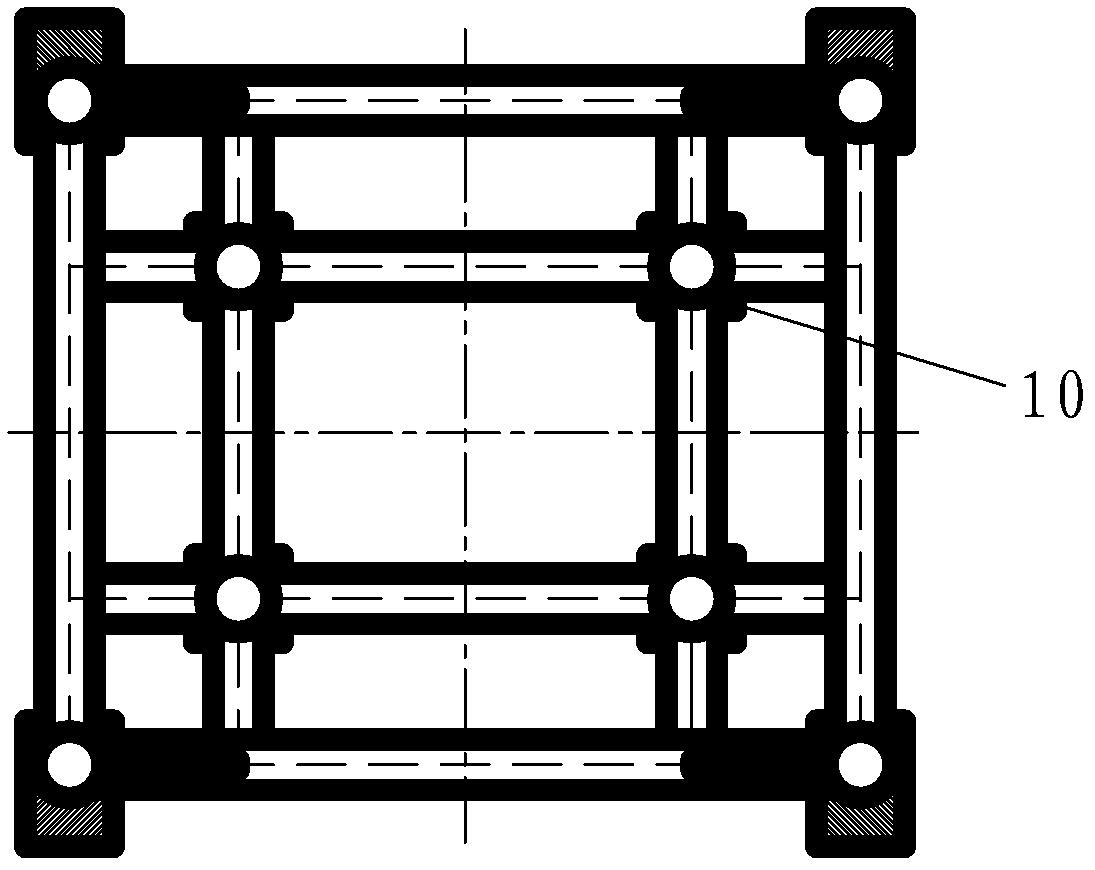

[0028] The tooling platform for installing the converter body equipment of the present invention includes a platform body, and the platform body includes four steel pipe columns 1 on the periphery and four steel pipe columns 1 on the inner circumference. The length of the column is smaller than the four steel pipe columns on the periphery. The bottom end of the steel pipe column 1 is provided with a column support plate 5. The column support plate 5 is a 1000x700x30mm steel plate. There are beams 2, beams 2 are made of 400x400x13x21mm H-shaped steel, one layer per eight, which is the upper and lower layers of the same structure, each layer of beams is arranged in the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com