Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Guaranteed inspection accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

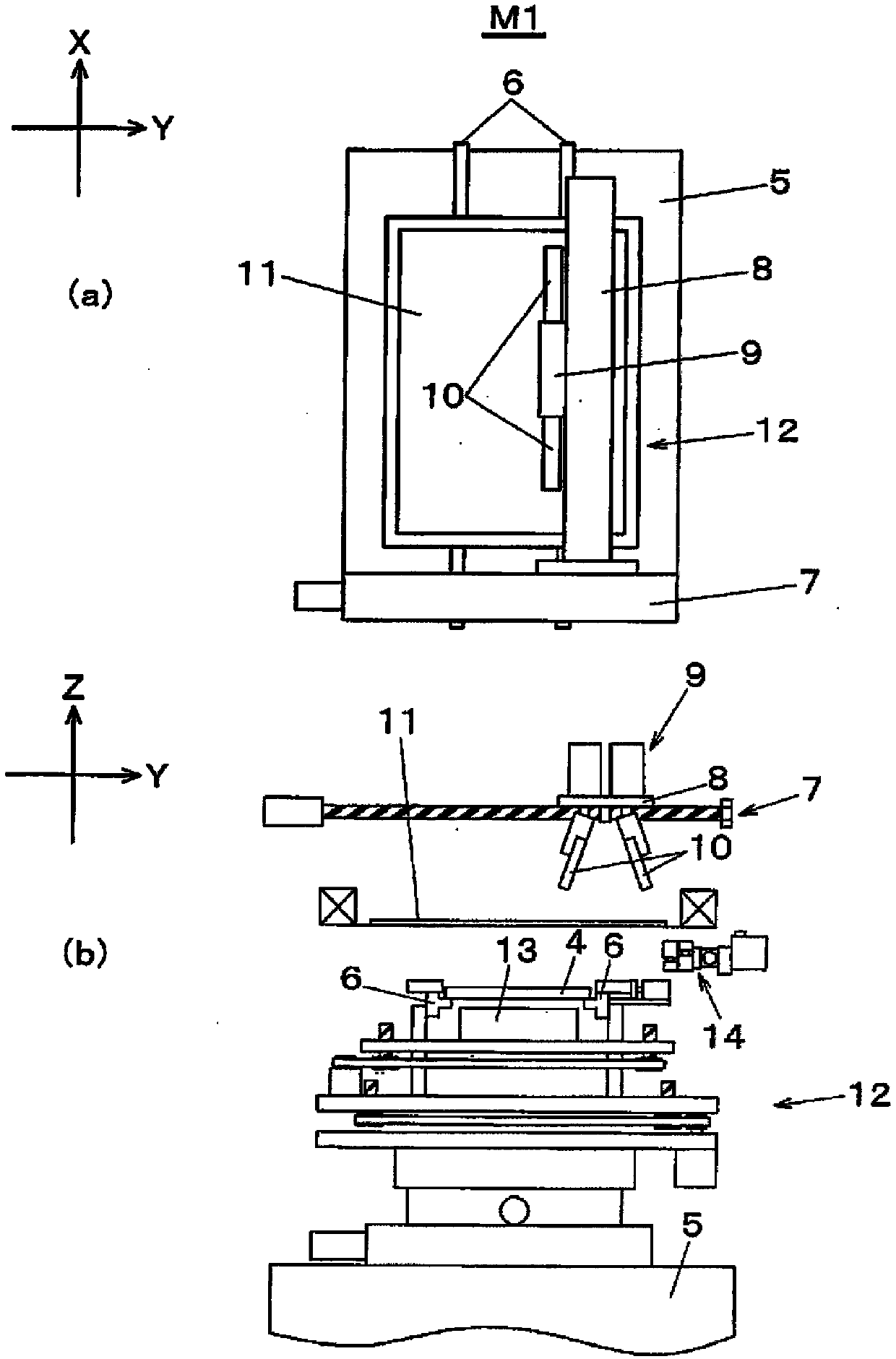

Substrate outer appearance inspection device

ActiveCN101363804AGuaranteed inspection accuracyMaterial analysis by optical meansUsing optical meansColor imageOptical axis

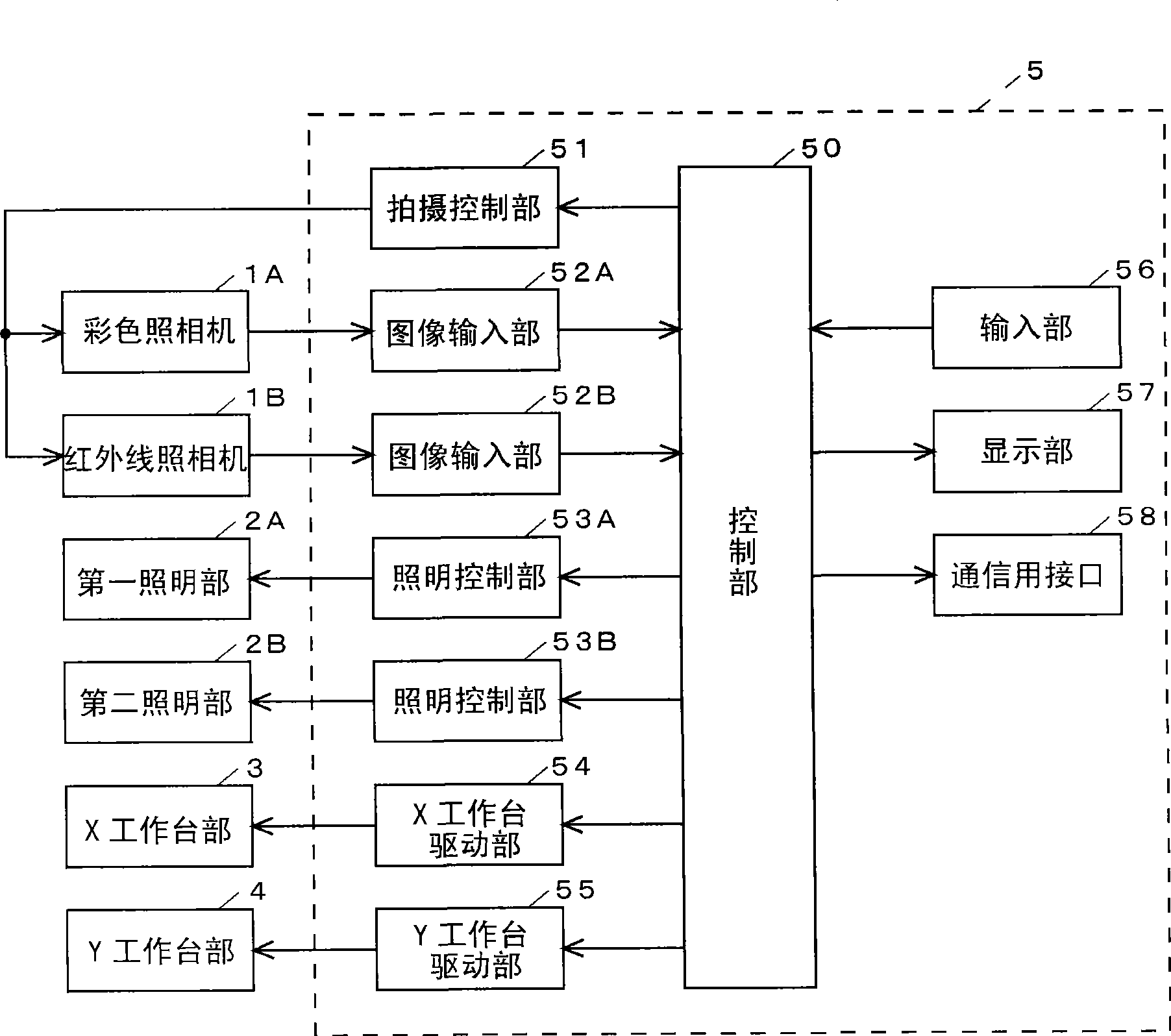

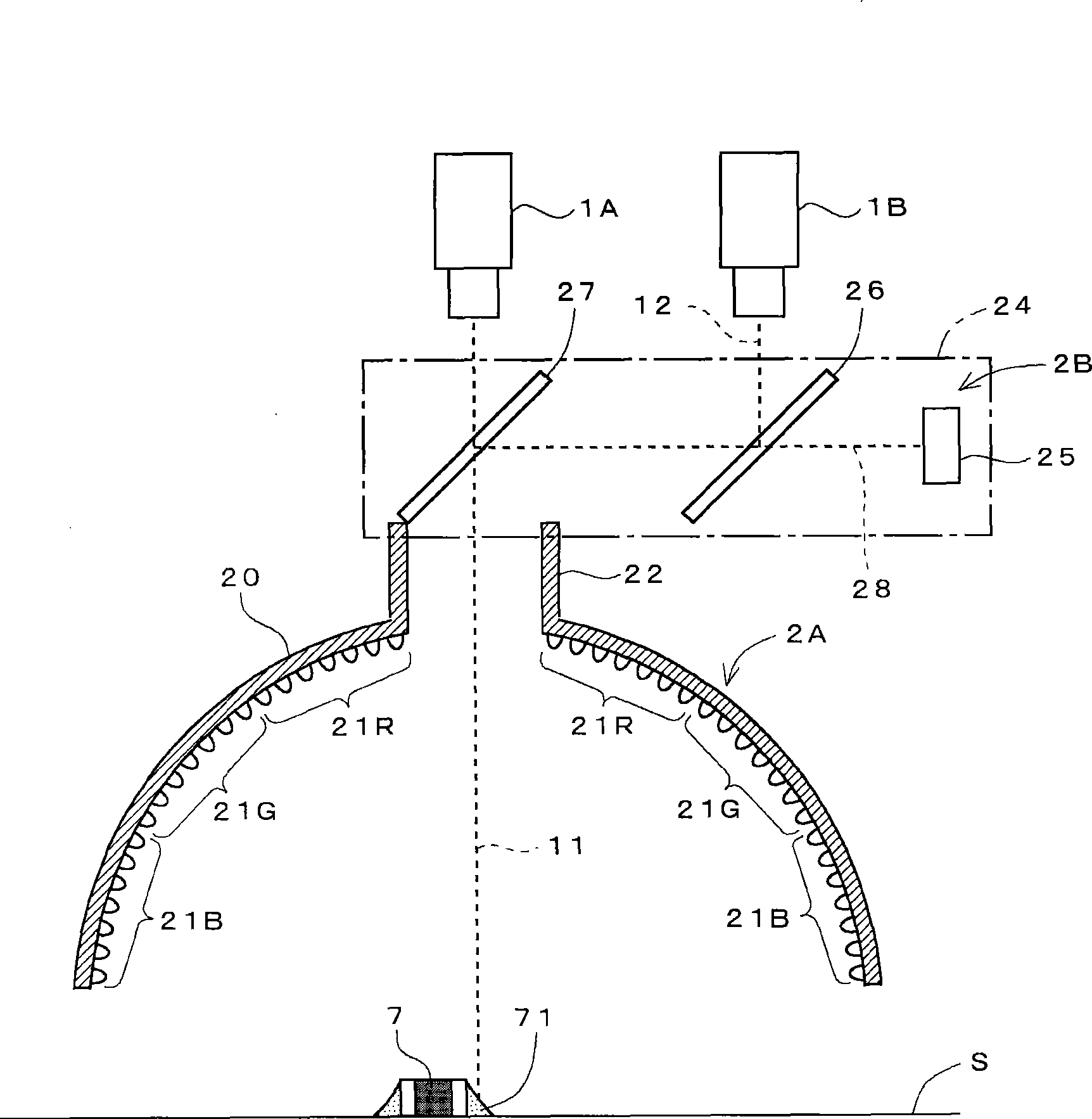

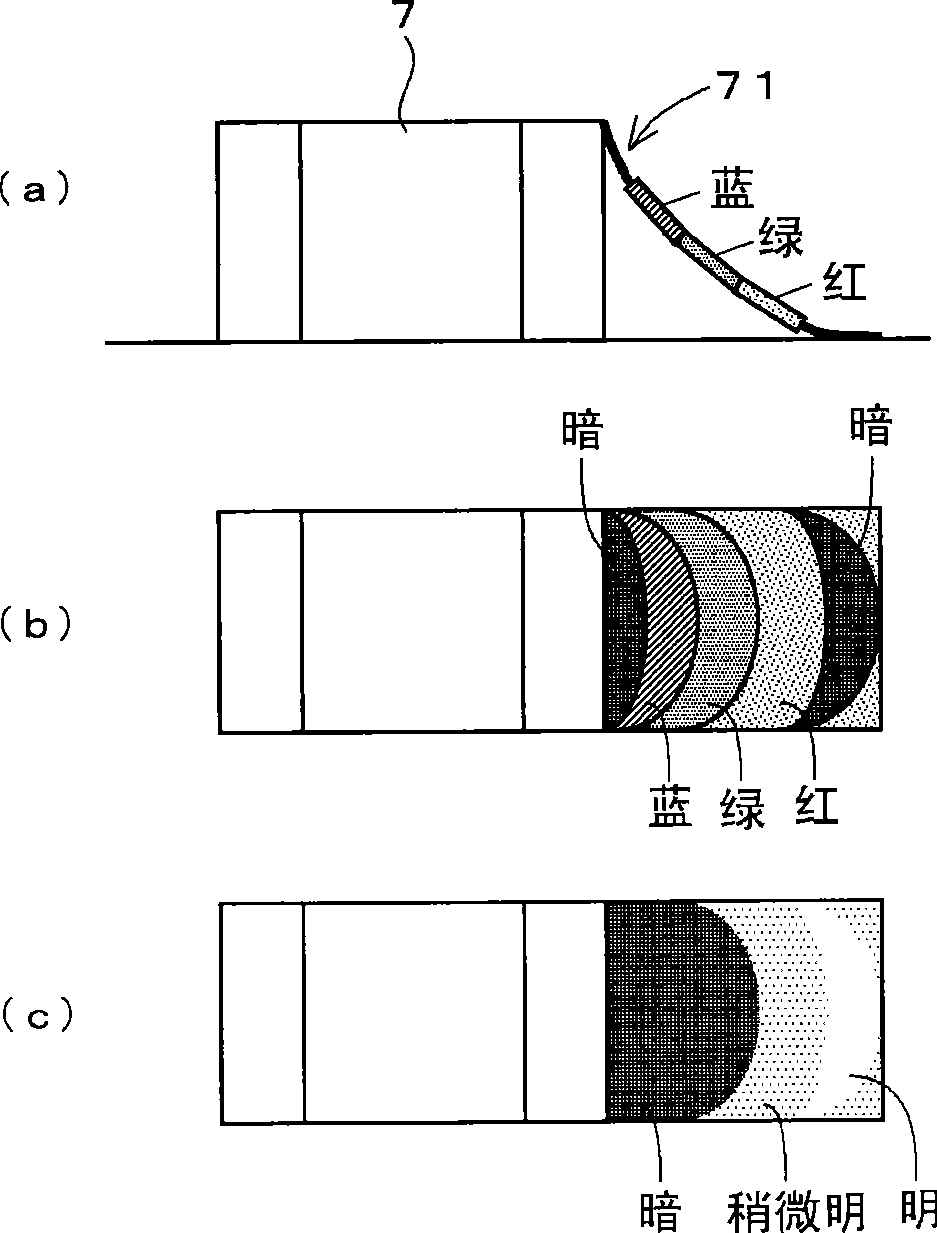

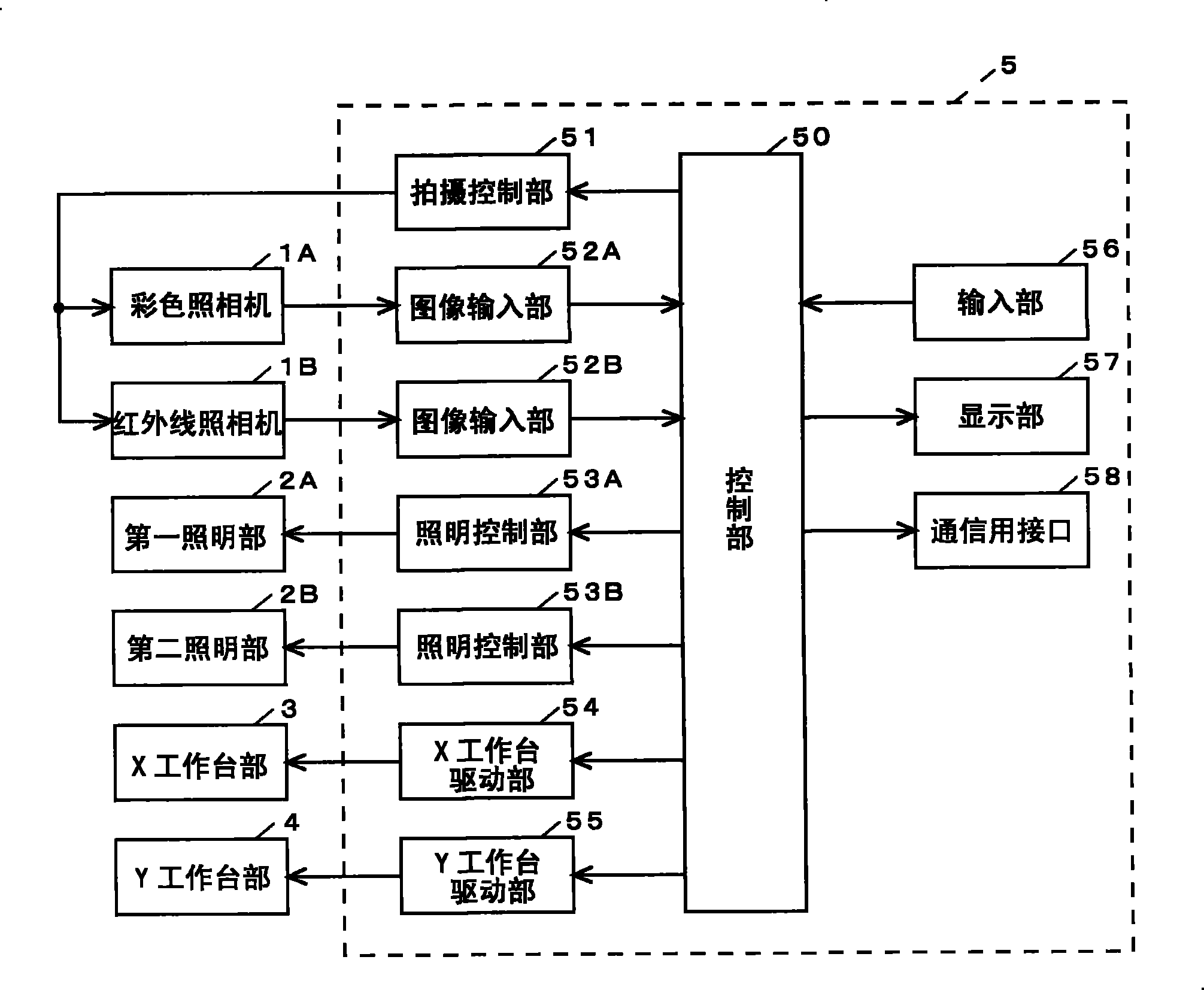

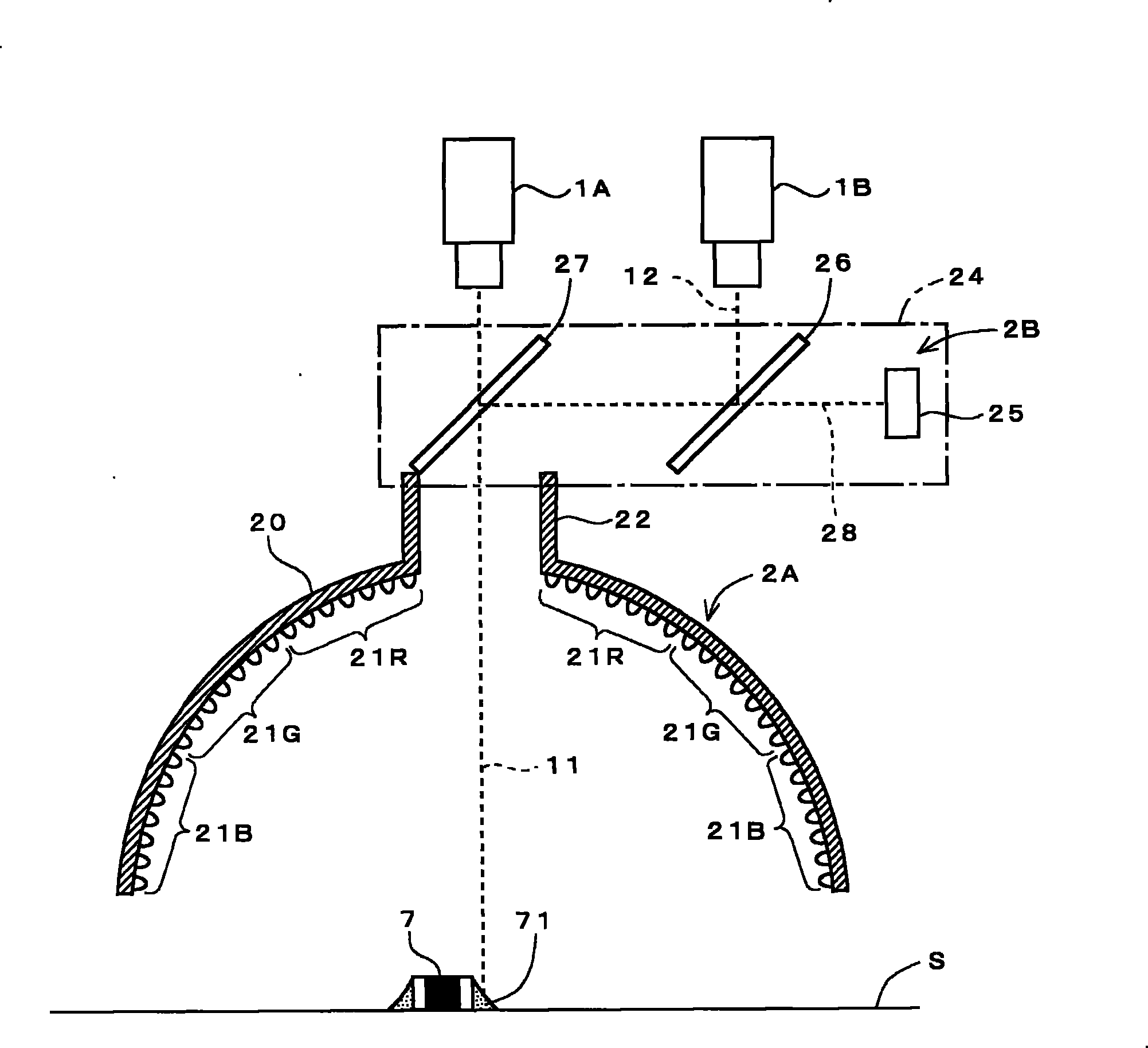

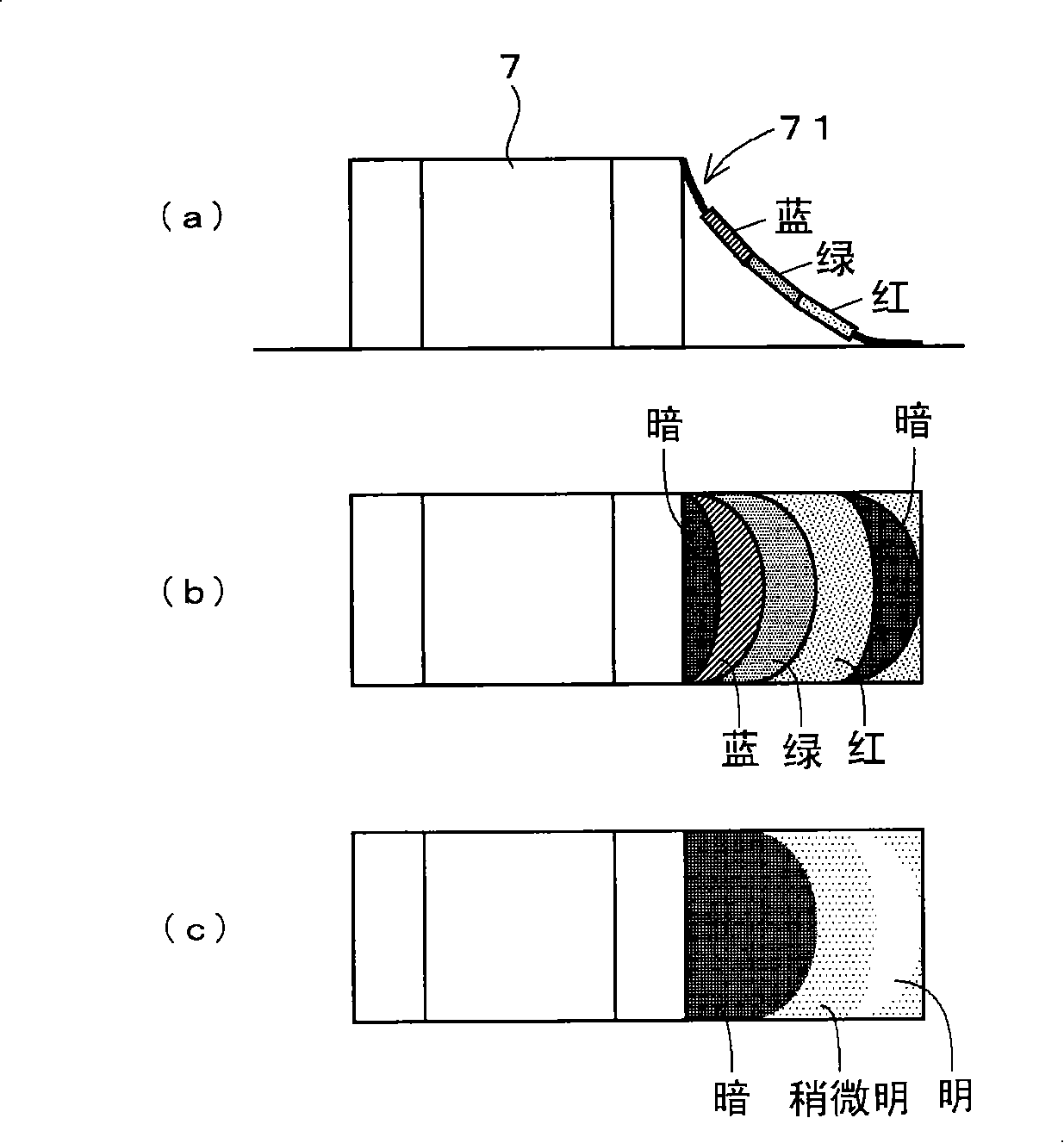

The invention provides a substrate appearance inspection device capable of differentiating solder steep surface and plane surface, which are hard to detect out with colorful high-brightness illumination, and capable of picking-up position out of the solder in white illumination. A colorful camera and infrared camera are arranged above a substrate to make each light receiving faces opposite to the substrate face. A first illumination section respectively irradiating visible lights such as red, green, blue from different directions and a second illumination section irradiating infrared light along light axis of the camera are arranged between the camera and substrate. Color image is formed by reflected light reflected by the incidence substrate of the camera from the first illumination section, shade image is formed by reflected light of camera incidence infrared light. Image of position corresponding to the color image is processed when detecting position out of the welded corner, position corresponding tilt grade of five-grade is determined by using color image and shade image when detecting the welded corner.

Owner:ORMON CORP

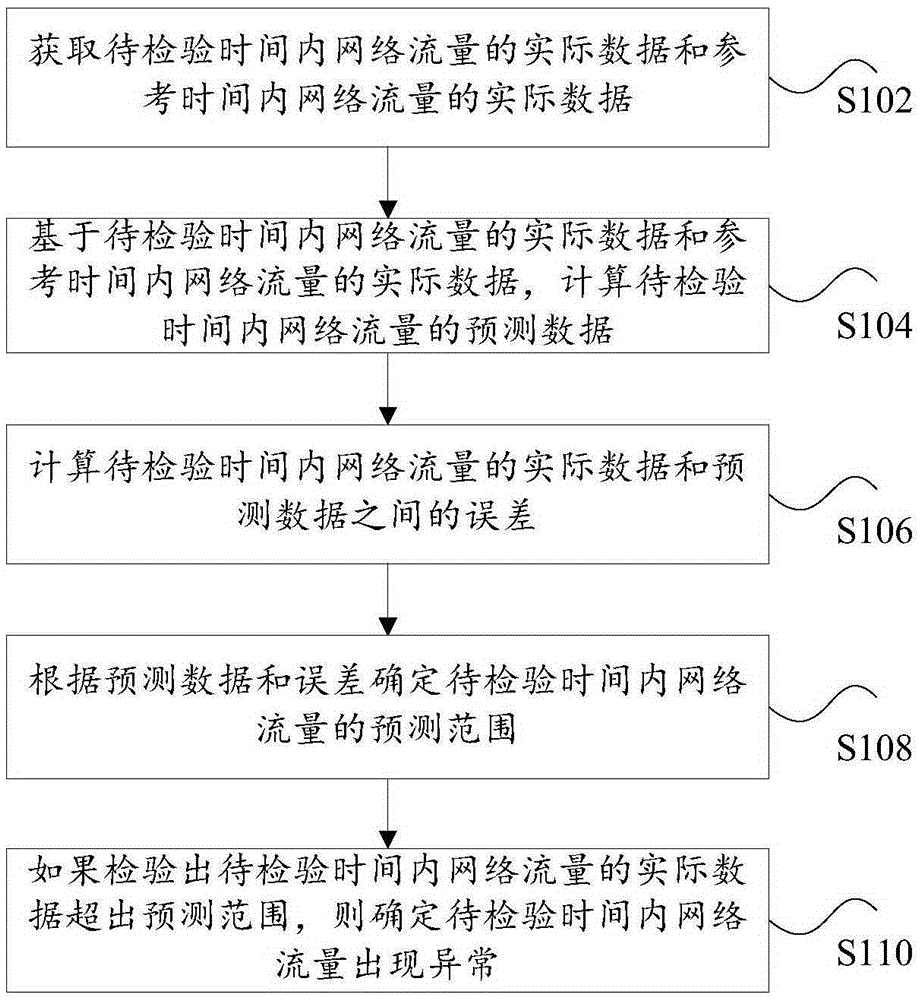

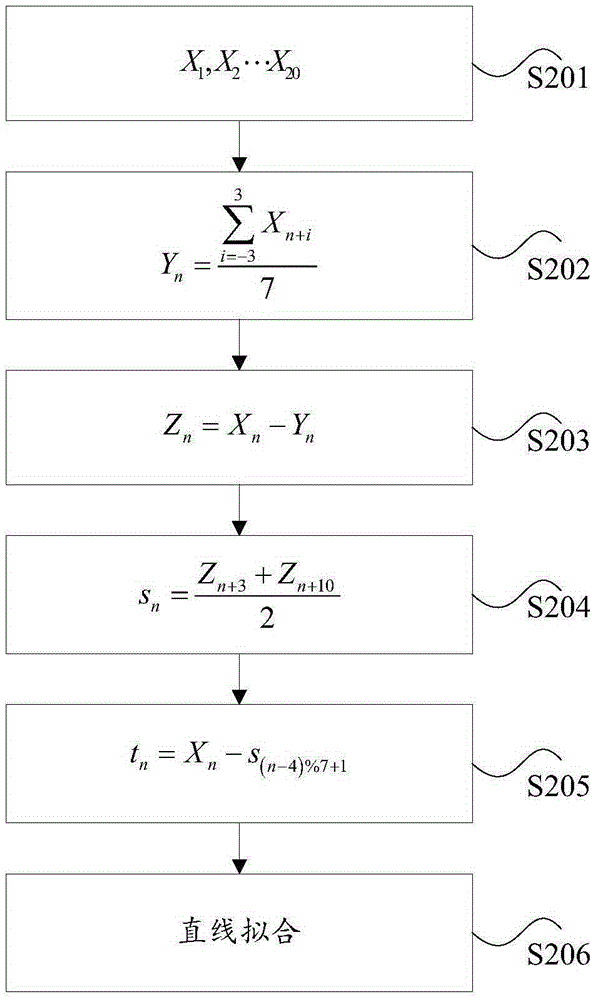

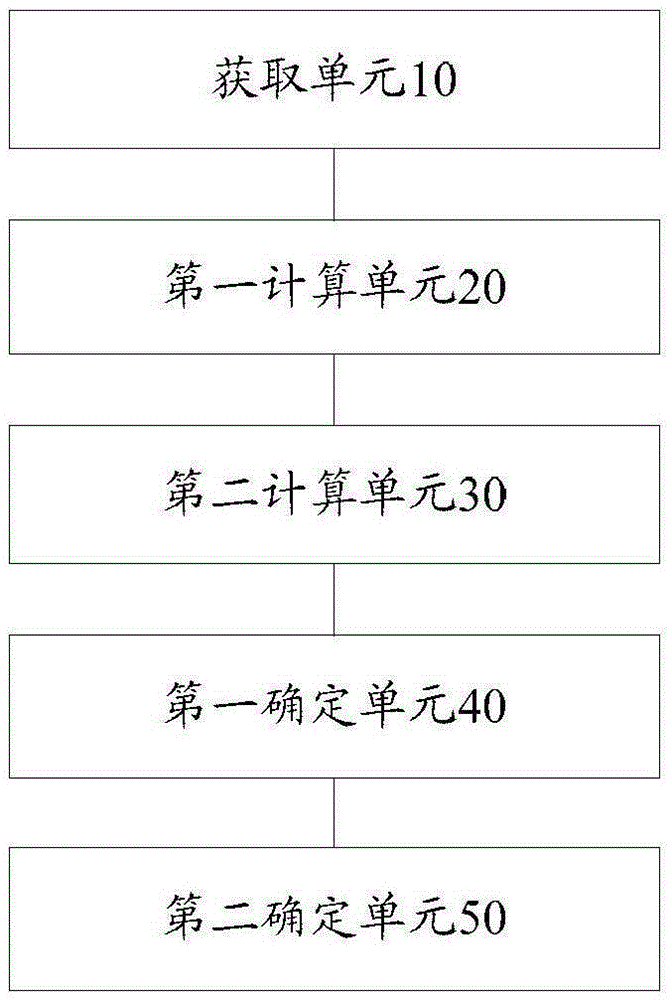

Network traffic checking method and network traffic checking device

ActiveCN106685749ASolve technical problems with low efficiencyAvoid the disadvantages of low inspection speedData switching networksReal-time computingTraffic volume

Owner:BEIJING GRIDSUM TECH CO LTD

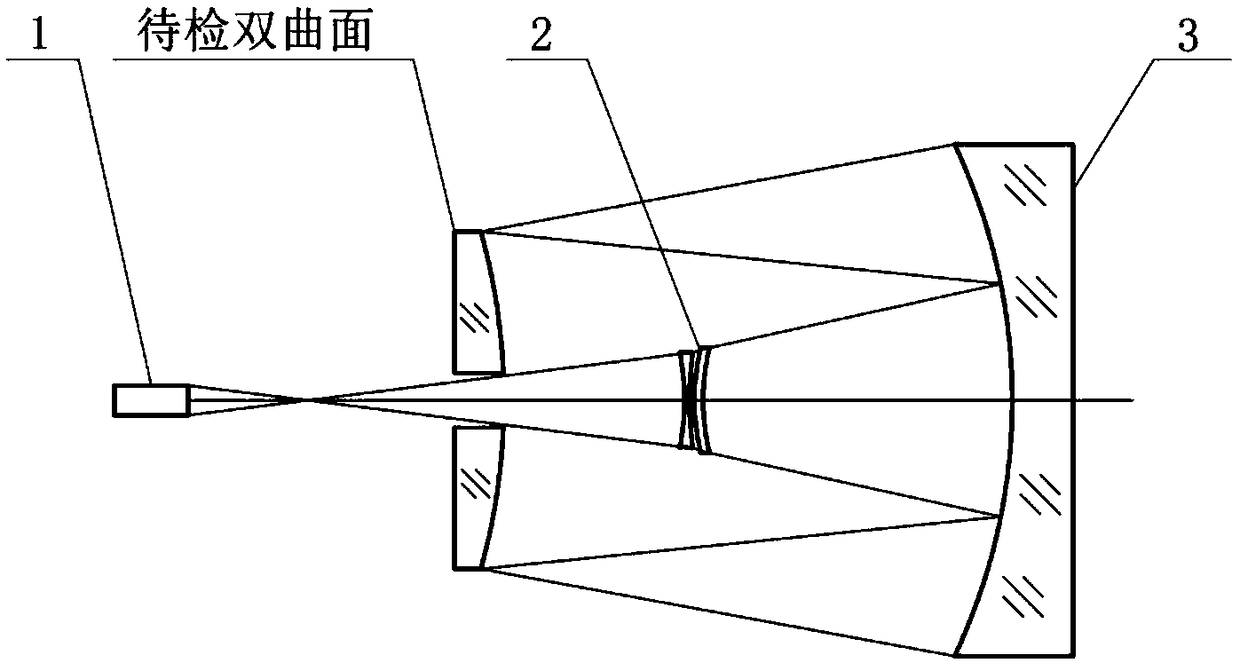

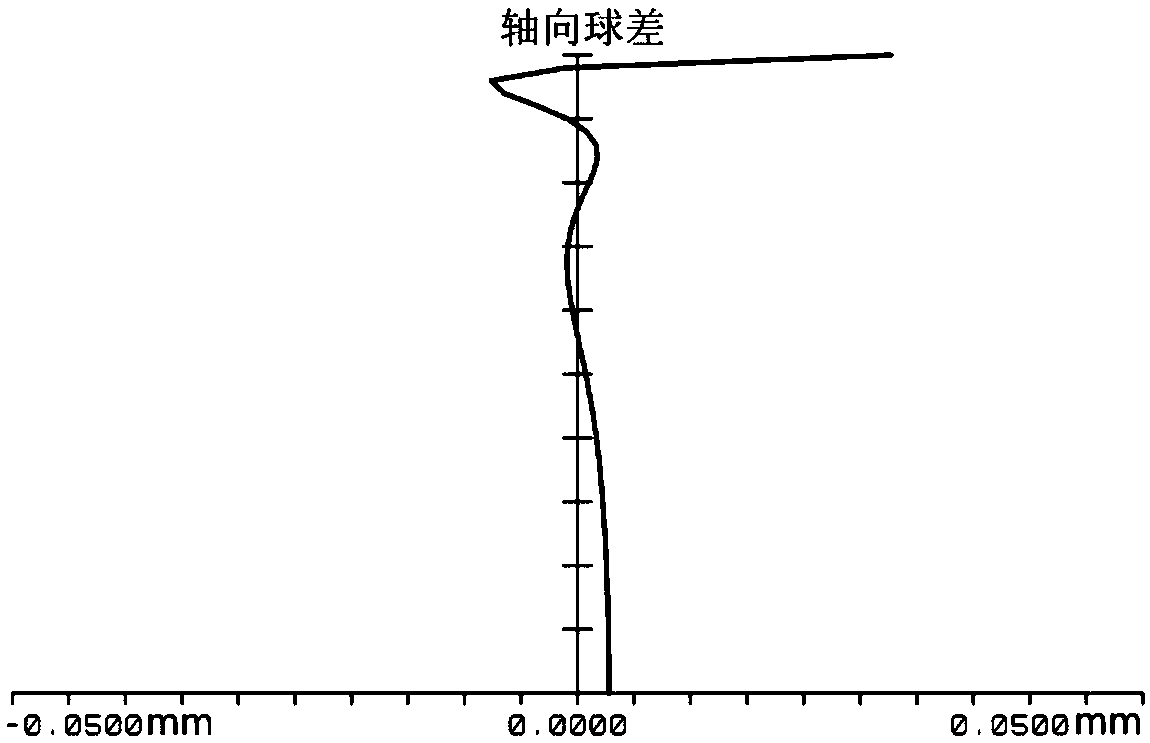

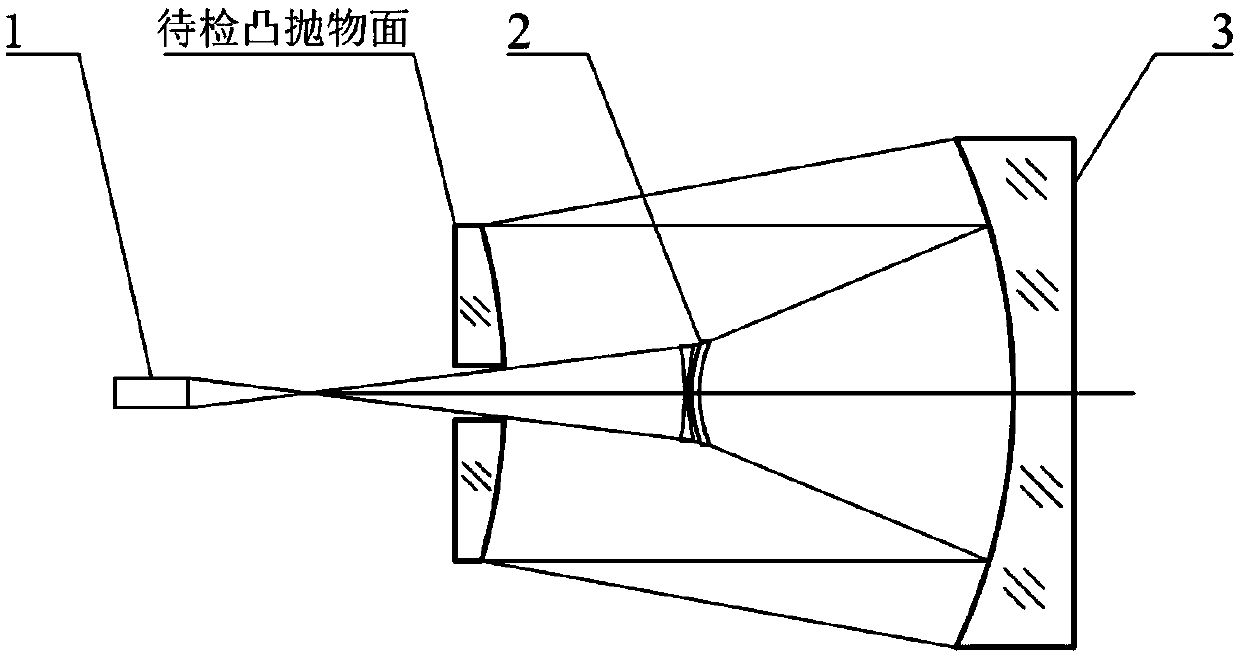

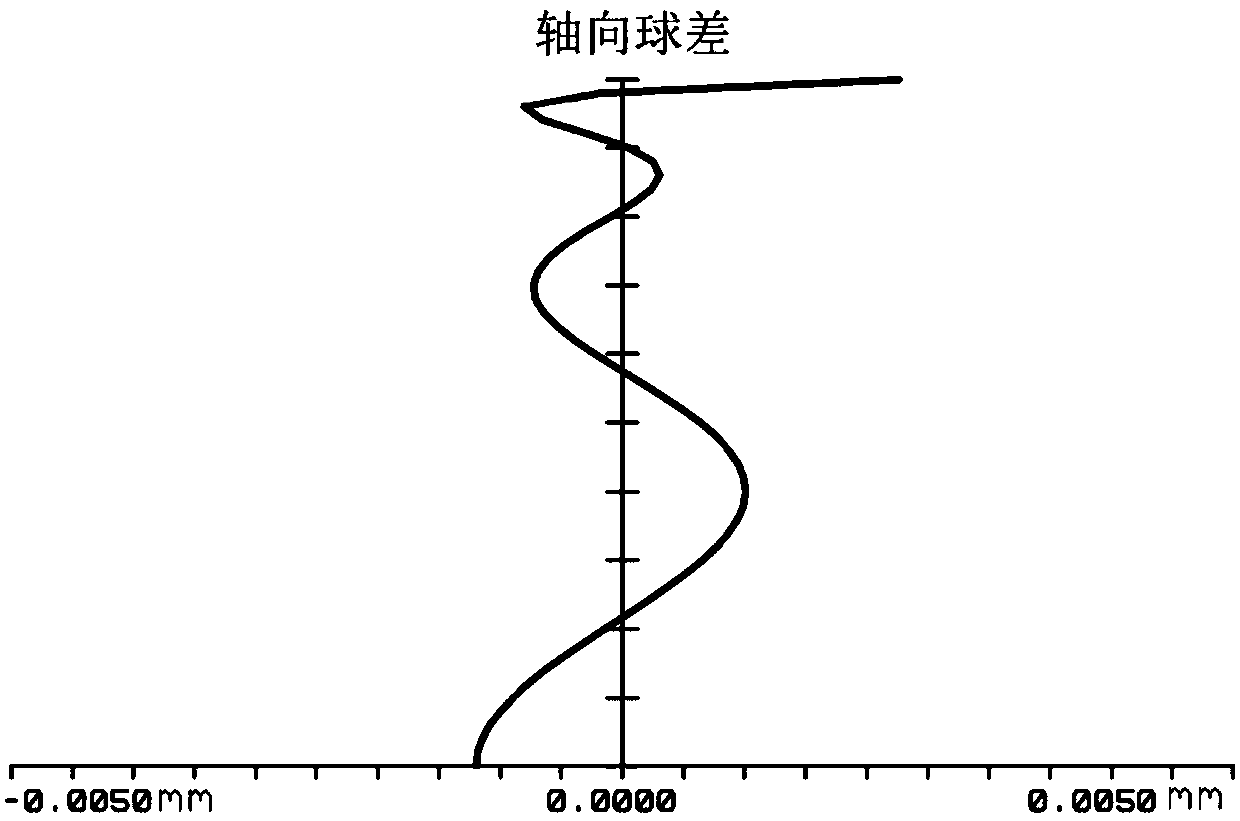

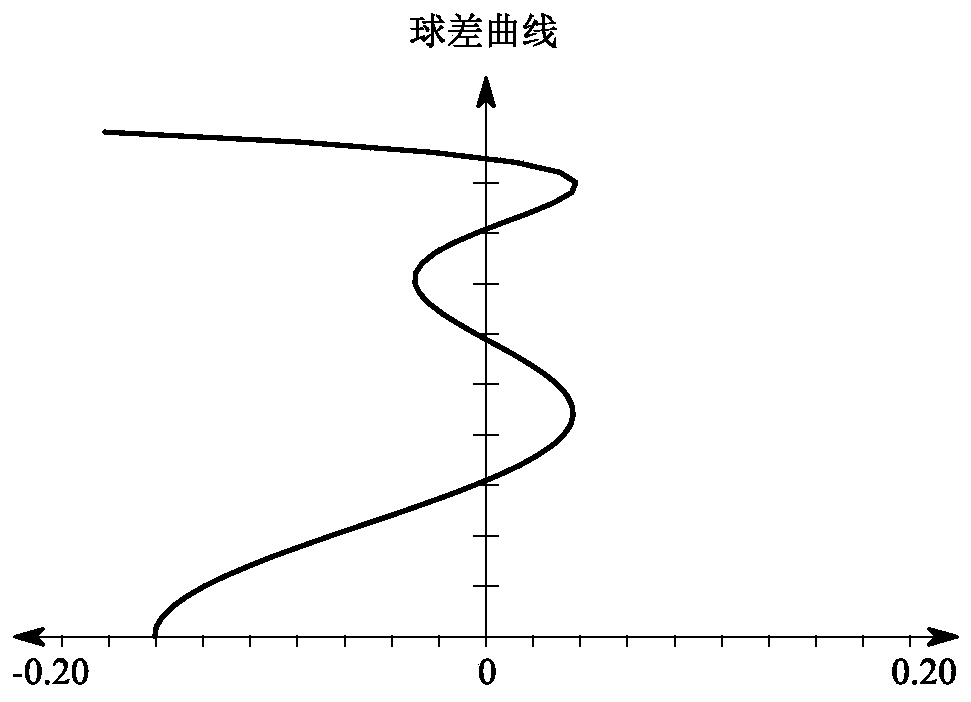

Optical system used for checking extra-large-caliber convex double-curved-surface reflecting mirror

PendingCN109253864ASmall caliberGuaranteed inspection accuracyOptical apparatus testingAstronomyLaser interferometry

The invention discloses an optical system used for checking an extra-large-caliber convex double-curved-surface reflecting mirror. In the system, the center of sphere of a spherical reflecting mirroris positioned on the rear focal point of the convex double-curved-surface reflecting mirror to be checked, and divergent rays emitted from the laser interferometer are injected from the center hole ofthe convex double-curved-surface reflecting mirror to be checked, and are refracted through a compensating lens group to be injected to the spherical reflecting mirror; and the rays reflected from the spherical reflecting mirror are reflected by the reflecting mirror to be checked to reach the spherical reflecting mirror again along a normal direction, and then, the rays are subjected to auto-collimation reflection to return to the interferometer along an original route. By use of the optical system, the high-accuracy checking of the extra-large-caliber convex double-curved-surface reflectingmirror with the caliber of 600mm and above can be realized, and while checking accuracy is guaranteed, the caliber of an auxiliary surface and system length can be reduced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

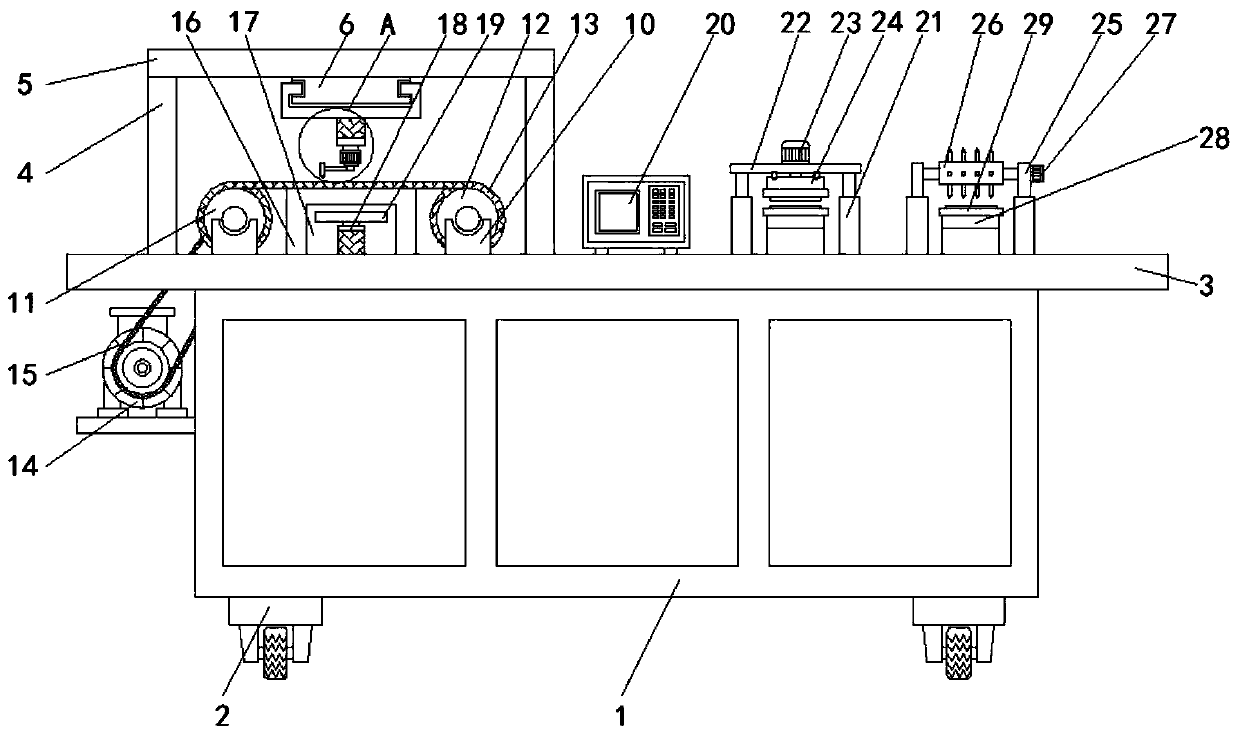

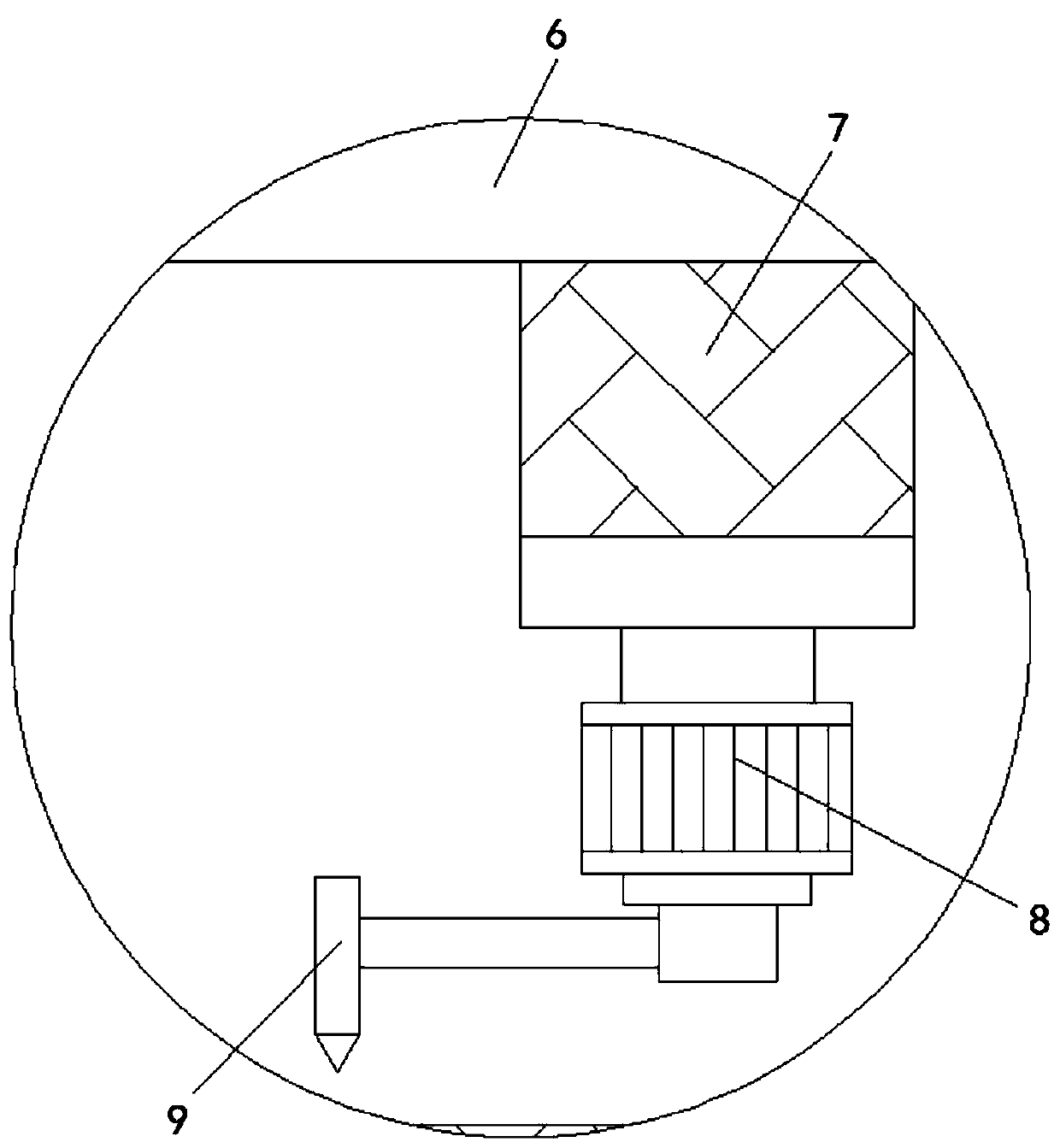

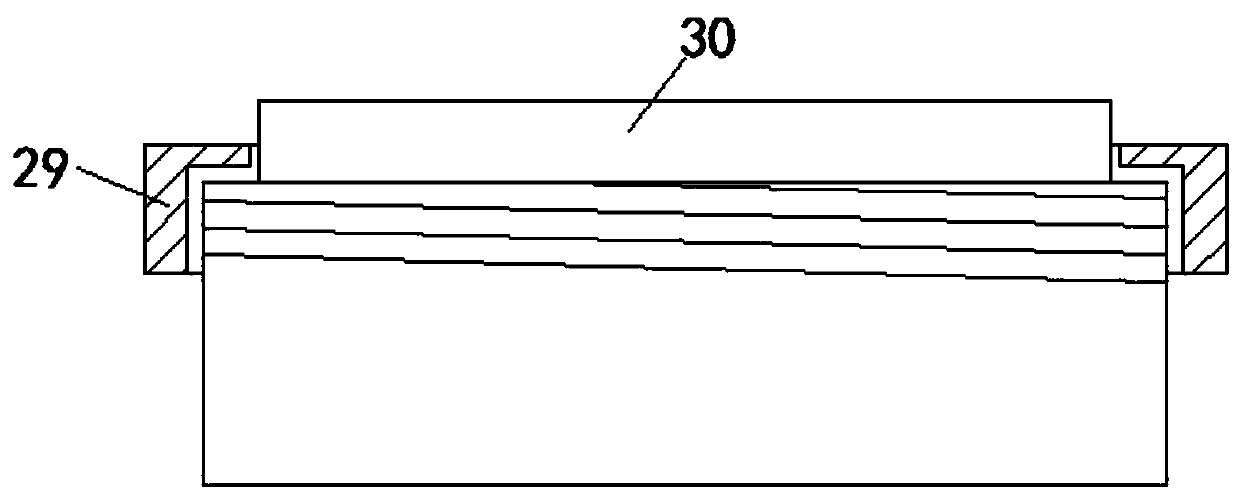

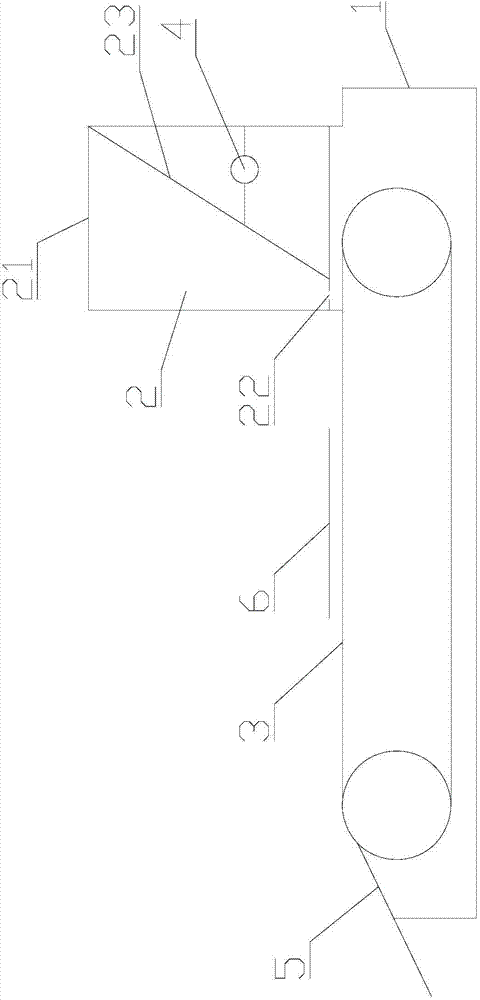

Cloth product surface quality inspection equipment

InactiveCN110926986AGuaranteed inspection accuracyReduce inspection costsInvestigating abrasion/wear resistanceManufacturing engineeringWorkbench

The invention relates to the technical field of cloth product inspection. The invention further discloses cloth product surface quality inspection equipment. Workbench, two wheels are fixedly mountedon each of the left side and the right side of the bottom of the workbench, a panel is fixedly mounted at the top of the workbench, two supporting plates are fixedly connected to the left side of thetop of the panel, the tops of the two supporting plates are fixedly connected with a first top plate, and a Y-axis sliding table is fixedly mounted at the bottom of the first top plate. The inventiondiscloses cloth product surface quality inspection equipment. In the prior art, quality detection is performed on a cloth surface; at present, the wear resistance, pilling resistance, rubbing color fastness and other properties of cloth are generally detected, but an existing detection device can only independently detect one property, so that the detection cost is increased. Meanwhile, a cloth product needs to be sampled before detection, and the problems that at present, manual sampling is generally adopted, randomness is not enough, and the detection result is likely to be inaccurate are solved.

Owner:陕西众策网络科技发展有限公司

Appearance check device and appearance check method

InactiveCN103376061AGuaranteed inspection accuracyGuaranteed Check QualityUsing optical meansHuman errorComputer science

The invention provides an appearance check device and an appearance check method, and check precision and quality can be ensured always by the invention. A shooting apparatus is used to shoot a clamp for correction; based on a measurement value for correction drawn from shot image information, in a correction structure in which a correction handling executor executes data for correction for storing, before displaying production start screen, check screen before production is displayed according to the correction message for correction order. Therefore, execution miss of correction caused by human fault like storage error made by the operators can be reliably prevented, and check precision of the appearance check device can be ensured, and check quality can be ensured.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

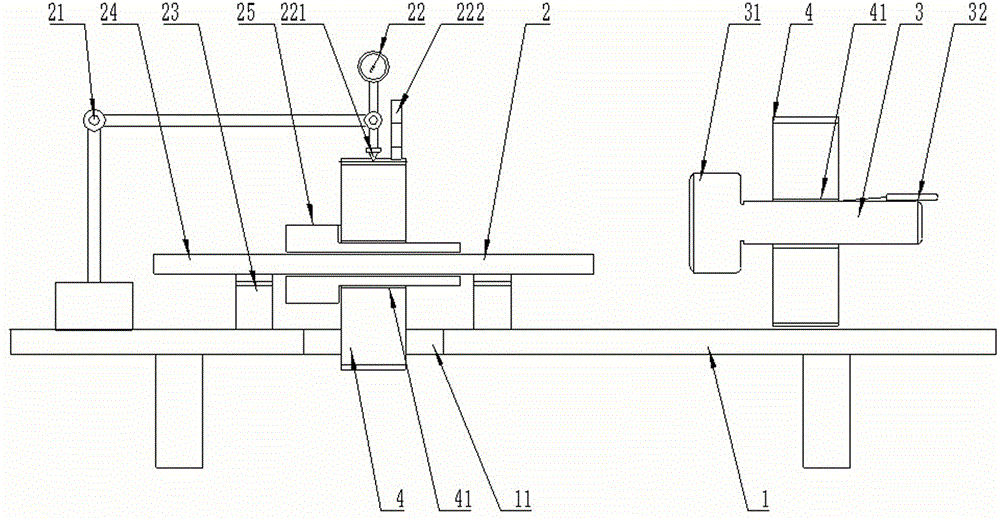

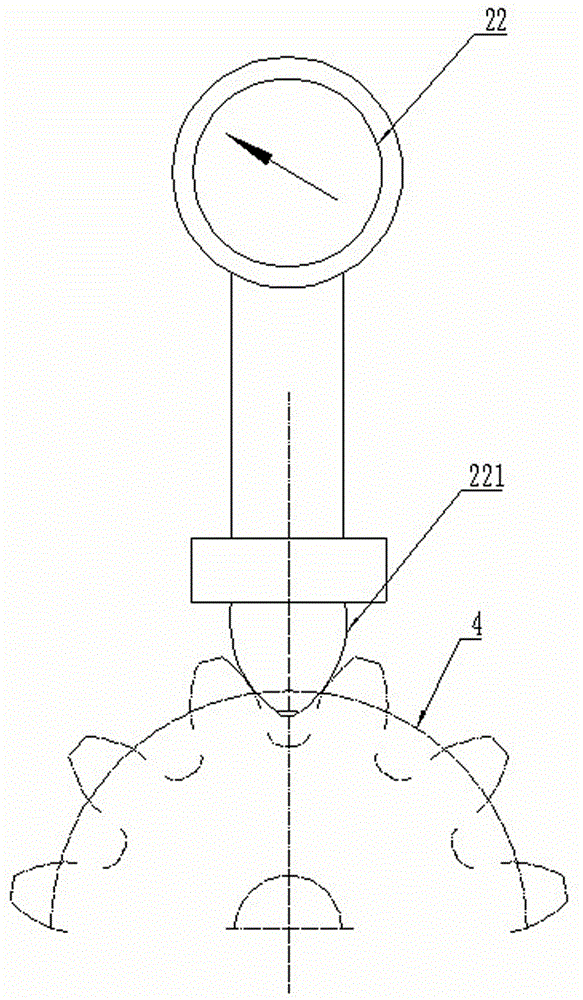

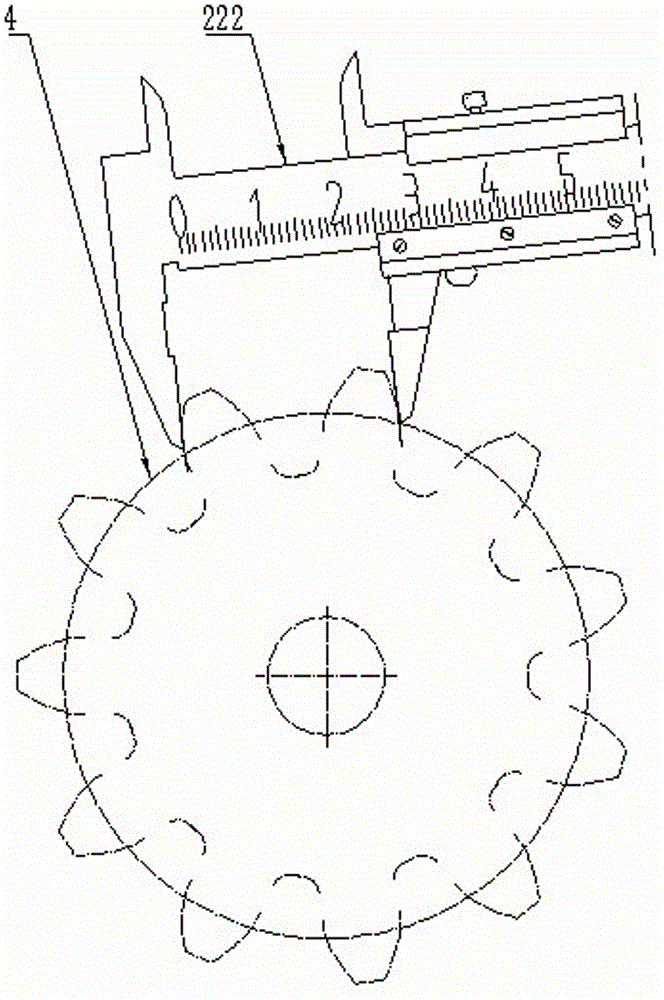

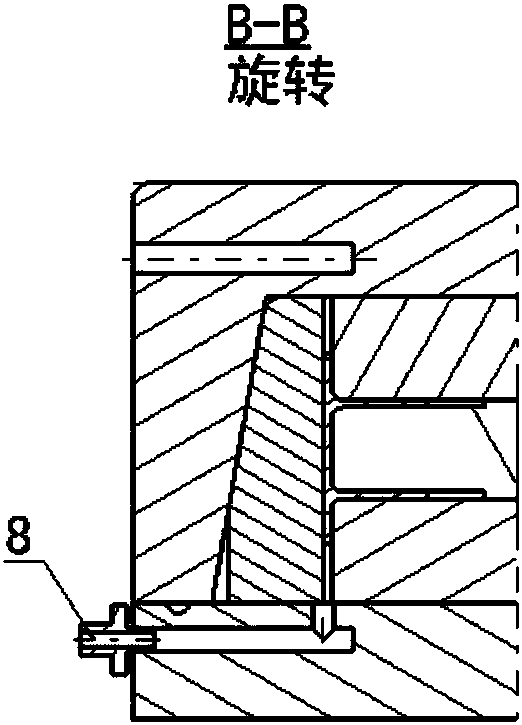

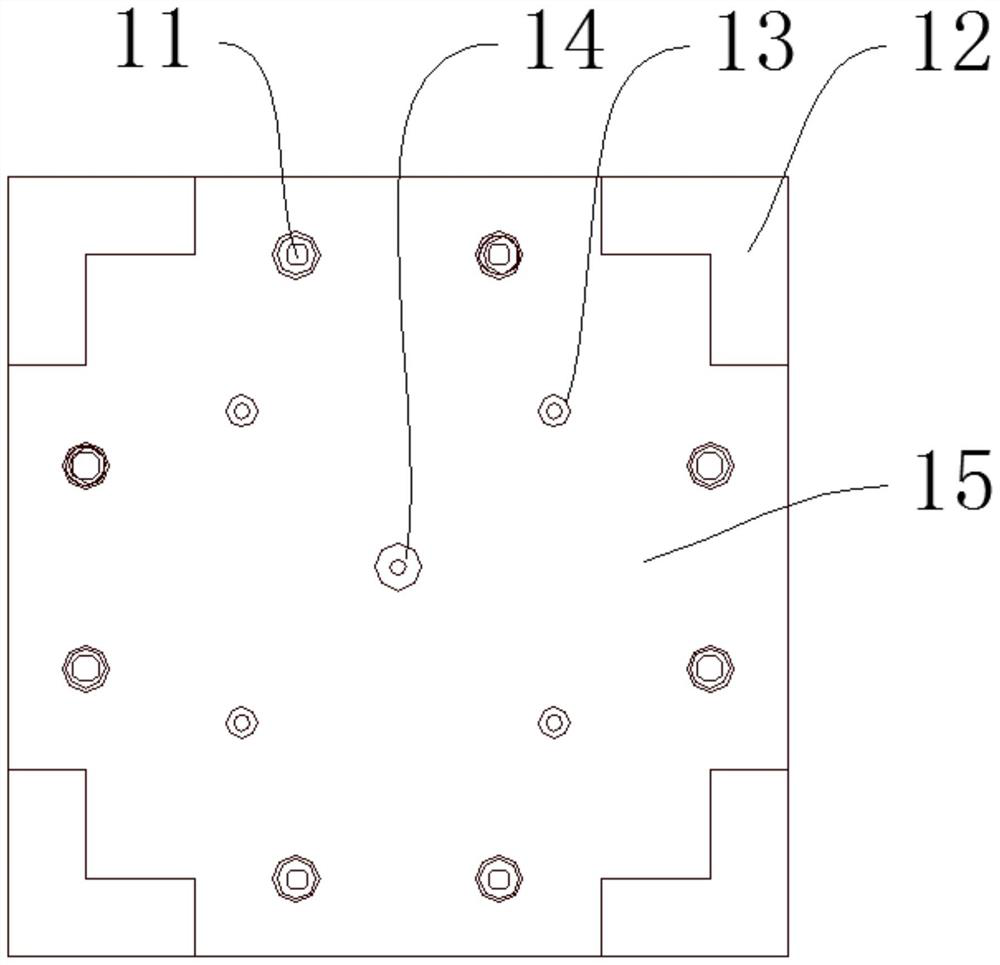

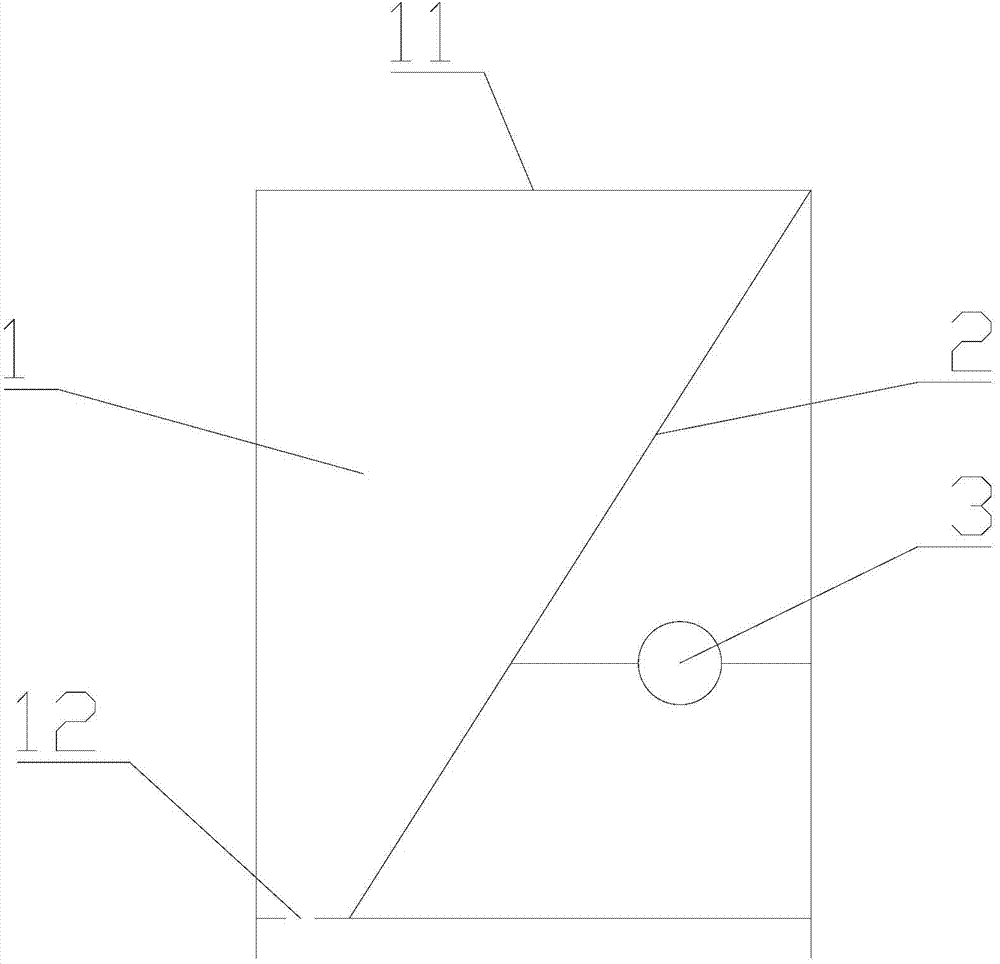

Verifying device for gear of textile machine

InactiveCN104864790ASimple structureEasy to operateMechanical measuring arrangementsEngineeringCalipers

The invention discloses a verifying device for gears of a textile machine. The device comprises a verifying platform. The verifying platform is provided with a tooth calibrating assembly and a hole calibrating assembly. The verifying platform is also provided with a strip-type hole. The tooth calibrating assembly comprises a support and a V-type platform. One end of the support is connected with a dial indicator, and the other end is fixedly arranged on the verifying platform. The V-type platform is provided with a spindle. A positioning sleeve is arranged out of the spindle. The tooth calibrating assembly is also provided with a vernier caliper. The hole calibrating assembly comprises a hole calibrating shaft and a plug gauge. The device is characterized by simple structure, convenient operation, stable and reliable use, and can obviously improve precision of gears of a textile machine.

Owner:ANHUI HUAMAO TEXTILE

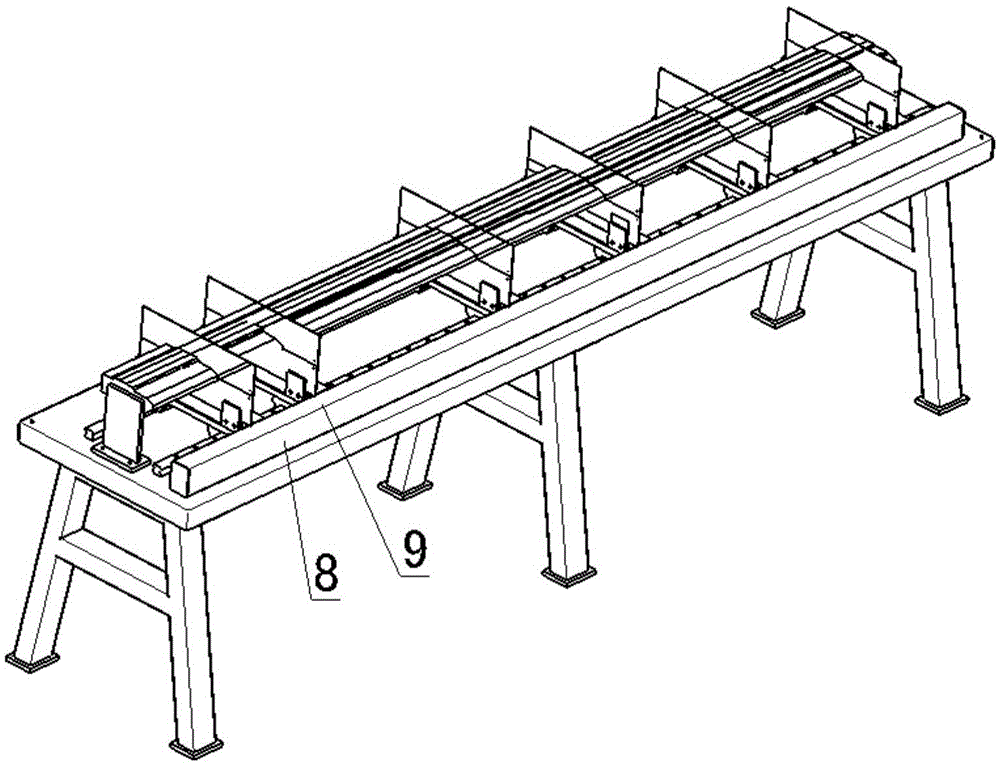

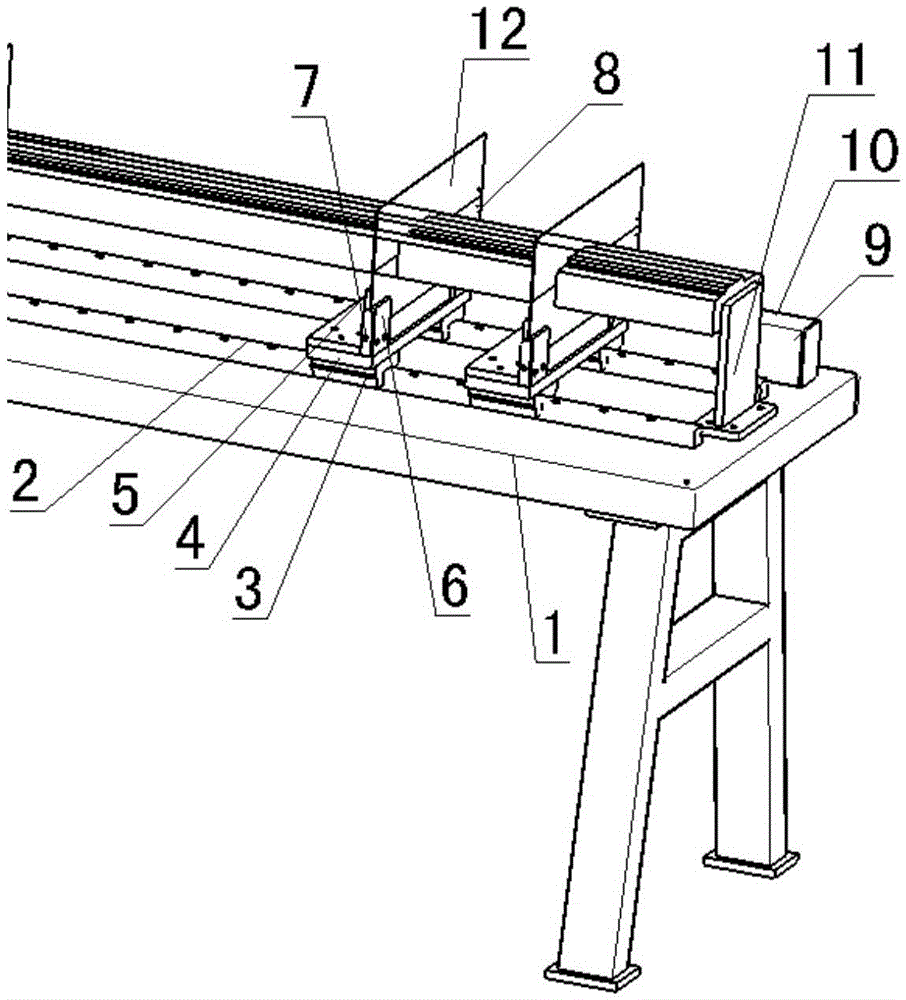

Blade foam integrated inspection device

ActiveCN105547076AGuaranteed inspection accuracyImprove inspection efficiencyMechanical counters/curvatures measurementsEngineeringInspection method

The invention relates to a blade foam integrated inspection device used for shape inspection of blade filling foam and belongs to the helicopter manufacturing field. With the development of batched delivery, the consumption of blade filling foam is increased more and more. According to a traditional manual sample plate inspection method, inspection positions are determined through manual lineation, which causes low efficiency, low accuracy, serious manual influence factors and the like. With the blade foam integrated inspection device of the invention adopted, integrated inspection of blade filling foam can be realized, the reliability of shape inspection can be improved, inspection efficiency is improved, and manual influence factors can be eliminated.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

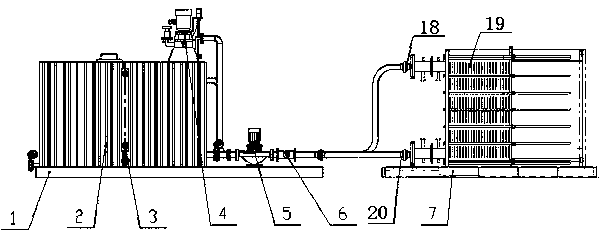

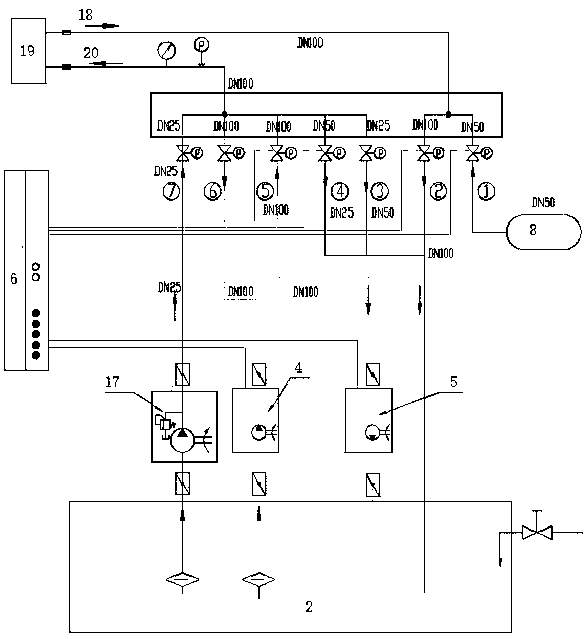

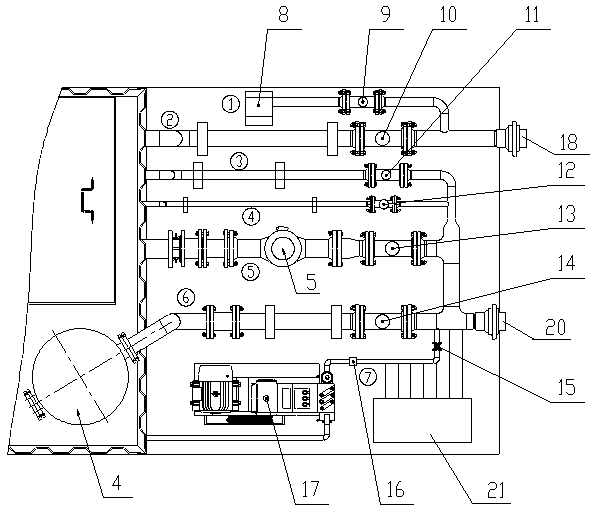

Full-automatic pressing equipment and pressing method for detachable plate heat exchanger

PendingCN110006593AGuaranteed inspection accuracySimple structureFluid-tightness measurement using fluid/vacuumElectrical controlEngineering

The invention discloses full-automatic pressing equipment for a detachable plate heat exchanger and a control method. The equipment comprises a PLC control system and an electric control cabinet controlled by the PLC control system, a plurality of electromagnetic valves are arranged in the electric control cabinet, the electromagnetic valves control first to seventh pipelines respectively to carryout full-automatic pouring, pressurizing, pressure maintaining, pressure releasing, back pumping and drying processes of plate pressure testing, and therefore full-automatic pressurizing testing of the detachable plate heat exchanger is completed. The electric control system is adopted to control opening and closing of the electromagnetic valve and starting and stopping operation of the electricequipment, errors caused by manual operation are greatly reduced, the full-automatic mechanical pressing process is achieved, the productivity is liberated, the production period is shortened, the operation precision is improved, and the detachable plate heat exchanger plate pressure test method is a great leap in the detachable plate heat exchanger plate pressure test technology.

Owner:SHANGHAI LANBIN PETROCHEM EQUIP +1

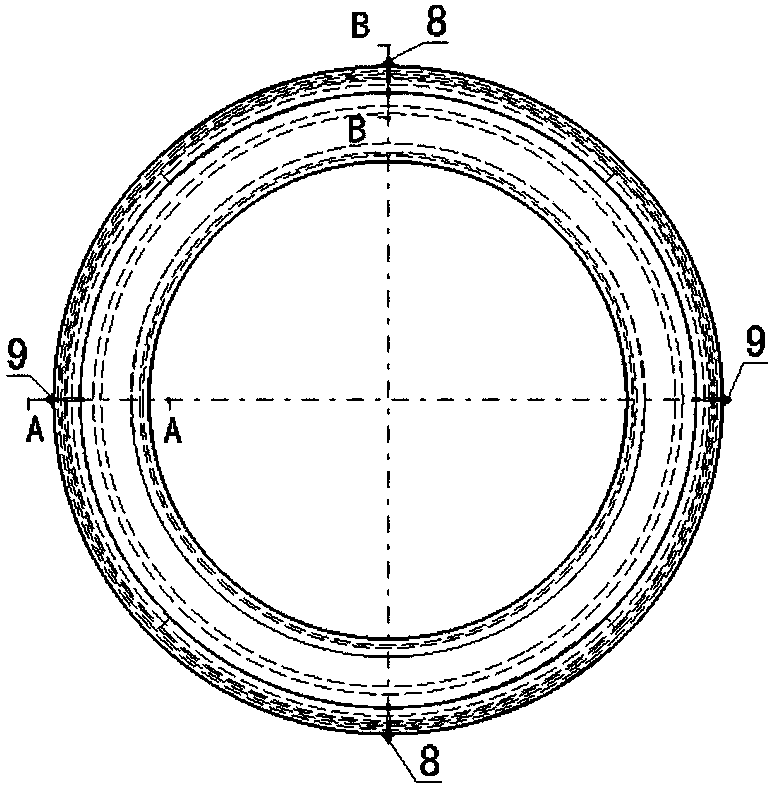

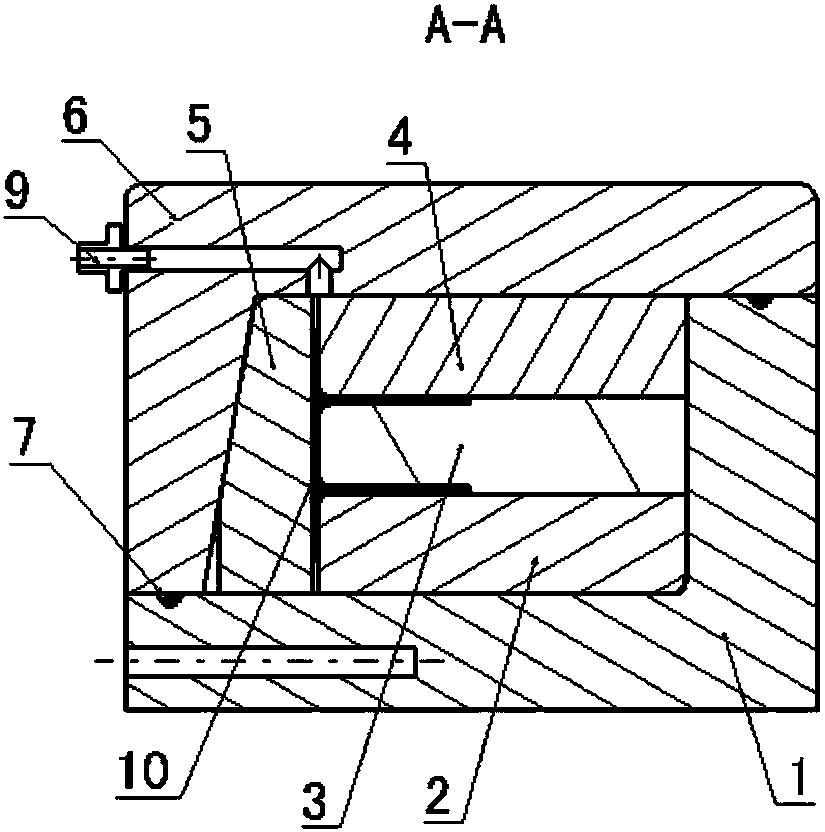

Forming tool and method for annular composite part with section in pi shape

InactiveCN108068362AGuaranteed inspection accuracyImprove inspection efficiencyEngineeringVacuum pumping

The invention belongs to the field of composite material die pressing forming, and particularly relates to a forming tool and method for an annular composite part with the section in a pi shape. According to traditional vacuum bag hot pressing forming, gum deposition will be caused, pressure in sufficient, die assembly is not in place, and therefore part precision is excessively poor. When vacuumbag hot pressing forming is adopted, the heating speed is low, and part deformation is caused. The forming tool comprises a base and a cover plate which are arranged outside and further comprises a lower module, a middle module, an upper module and an outer module which are arranged inside. The outer module is of a sectional annular structure, the other parts are of an integrated annular structure, and an annular pi shaped cavity is formed after the internal modules are combined. A preformed body is formed in advance, the modules are combined with the preformed body, the size precision and surface roughness degree of each end face of products can be effectively ensured, it can be ensured that gum liquid soaks materials at each place through vacuum pumping and pressurized gum infusion ways,and part quality is effectively ensured.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

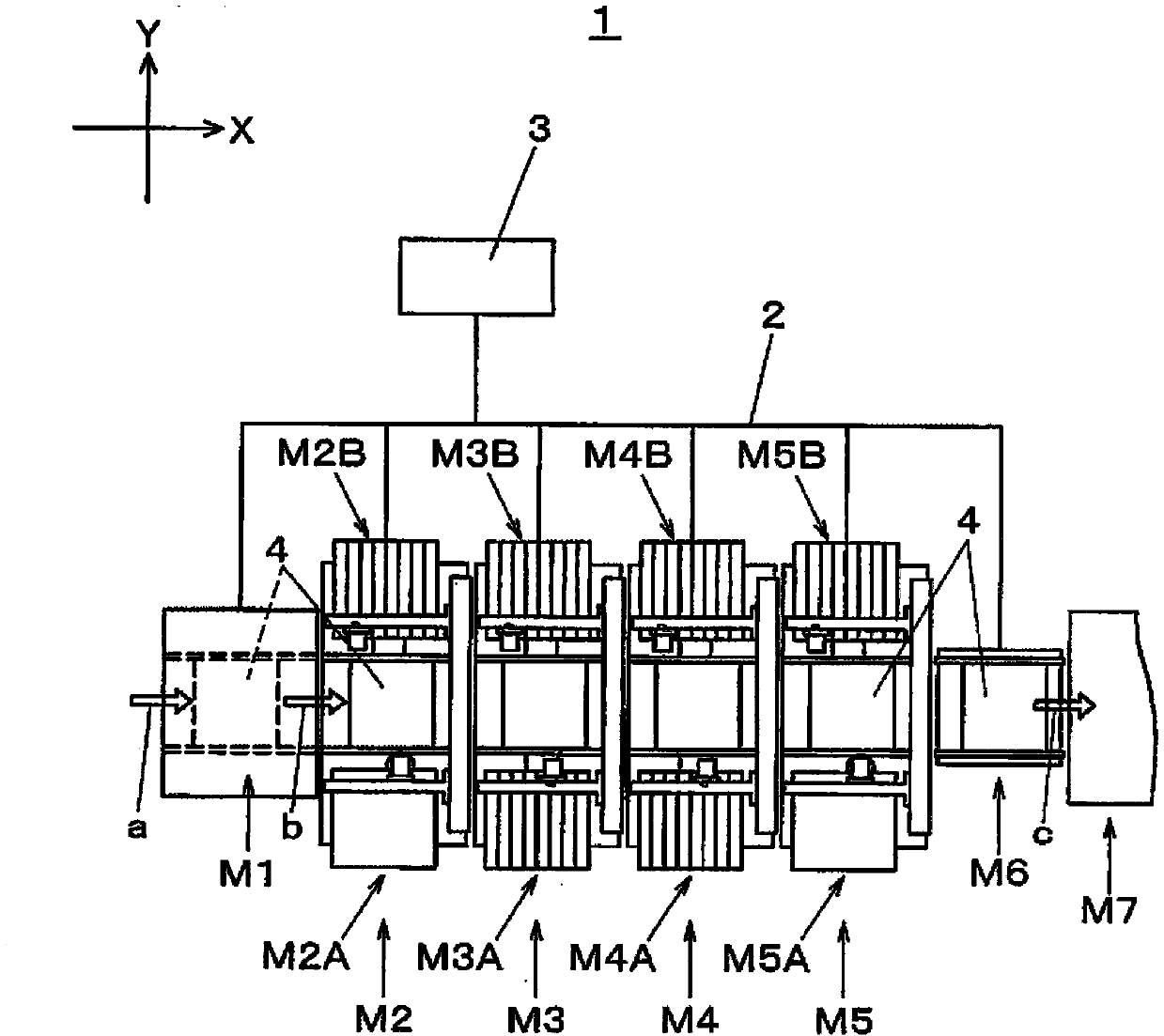

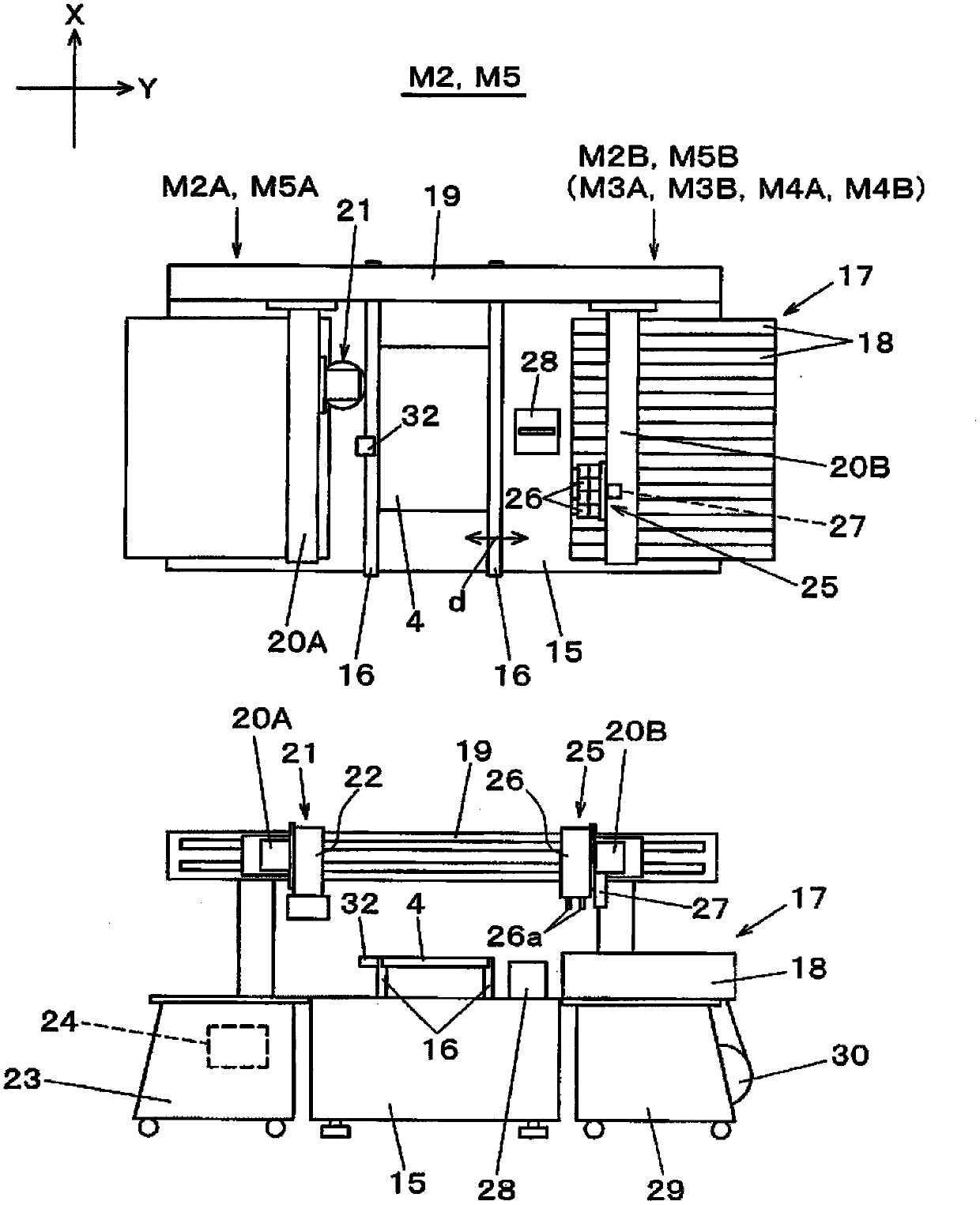

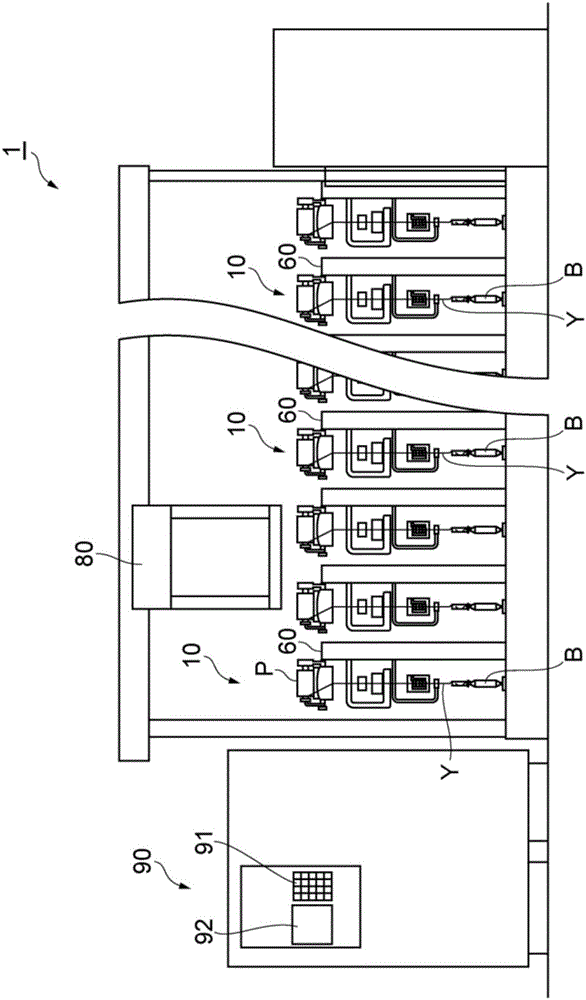

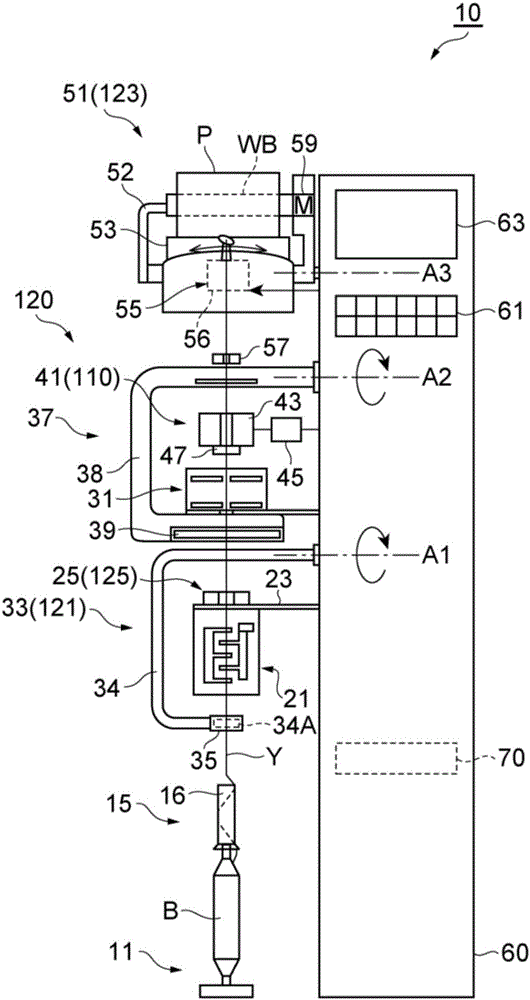

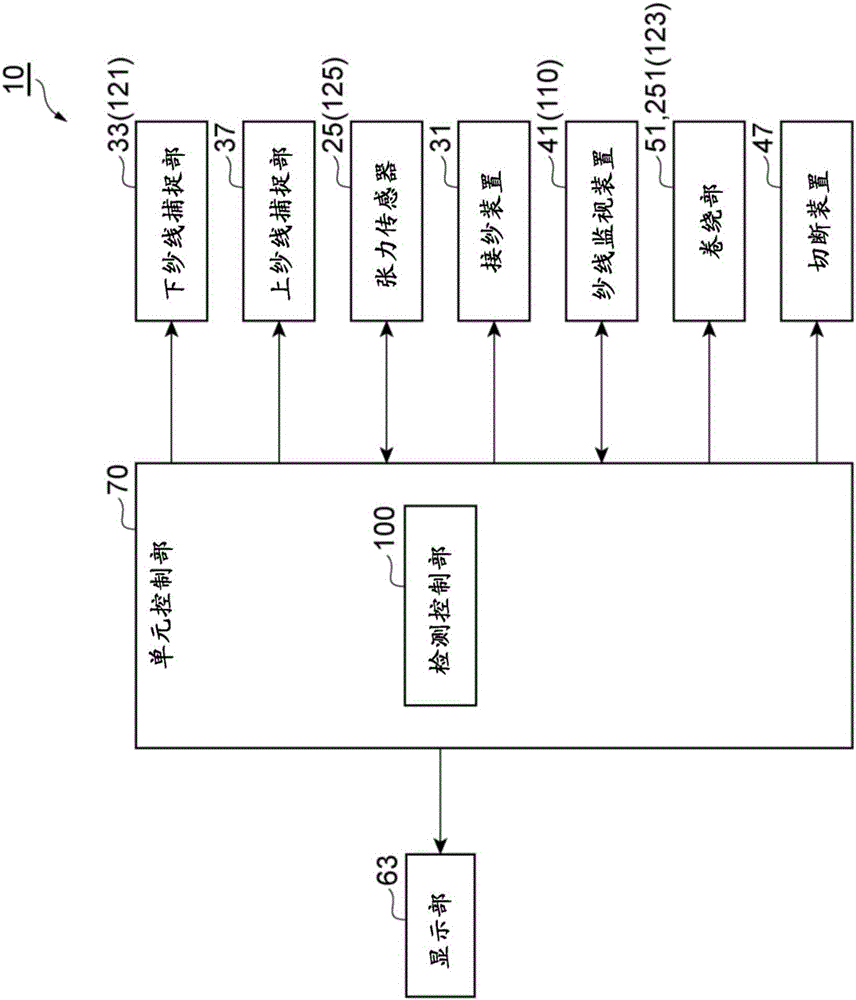

Yarn coiler, automatic winder and splicing portion detection method

ActiveCN105966992AEasy to checkGuaranteed inspection accuracyFilament handlingMaterial analysisYarnPortion size

The invention provides a yarn coiler, an automatic winder and a splicing portion detection method; the winding unit (10) comprises the following elements: a yarn tube support (11) supporting a yarn feeding tube (B), a coiling portion coiling on the yarn (Y) of the yarn feeding tube supported by the yarn tube support, a splicing device (31) arranged between the yarn tube support and the coiling portion so as to splice the yarn on the yarn tube support side and the yarn on the coiling portion, a size obtaining portion (110) obtaining the size of the yarn splicing portion using a splicing unit to splice the yarn, a force obtaining portion (120) obtaining the force of the yarn splicing portion, and a detection control portion having a normal mode and a detection mode, wherein the detection control portion can switch the yarn coiling on the yarn feeding tube so as to form a coil work in the normal mode, and the detection control portion can use the size obtaining portion and the force obtaining portion to obtain the yarn splicing portion size and force, thus outputting a detection value in the detection mode.

Owner:MURATA MASCH LTD

Particle sorting machine

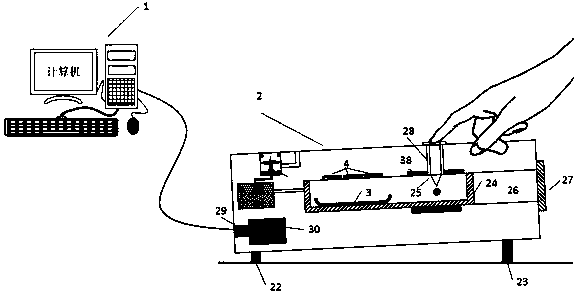

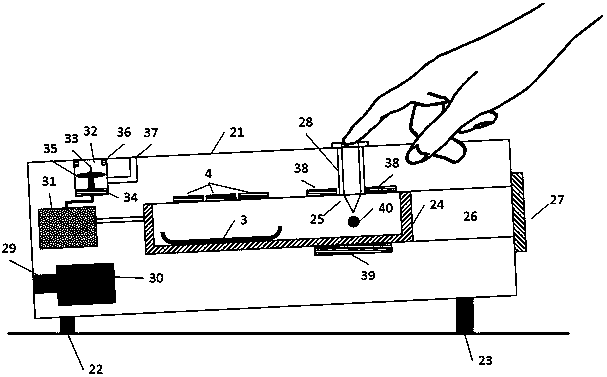

The invention discloses a particle sorting machine. The particle sorting machine comprises a stander, a stock bin, a flattening mechanism and a conveying mechanism, wherein the stock bin, the flattening mechanism and the conveying mechanism are respectively installed on the stander, the stock bin and the flattening mechanism are sequentially arranged along the conveying direction of the conveying mechanism, a feeding opening and a discharging opening are formed in the stock bin, the discharging opening is formed in the bottom of the stock bin, the stock bin is connected with a vibrating mechanism, the flattening mechanism is provided with a horizontal flattening surface, the conveying mechanism is provided with a horizontal working surface, the discharging opening and the flattening surface are respectively arranged above the working surface, and a passage which is used for particles to pass through is formed between the flattening surface and the working surface. By adopting the particle sorting machine, not only can the quantity of the particles be adjusted, but also the scattering state of the particles can be adjusted, the inspection by an inspector can be facilitated, the inspection efficiency can be improved, and the inspection precision also can be guaranteed.

Owner:浙江中科光铭光电股份有限公司

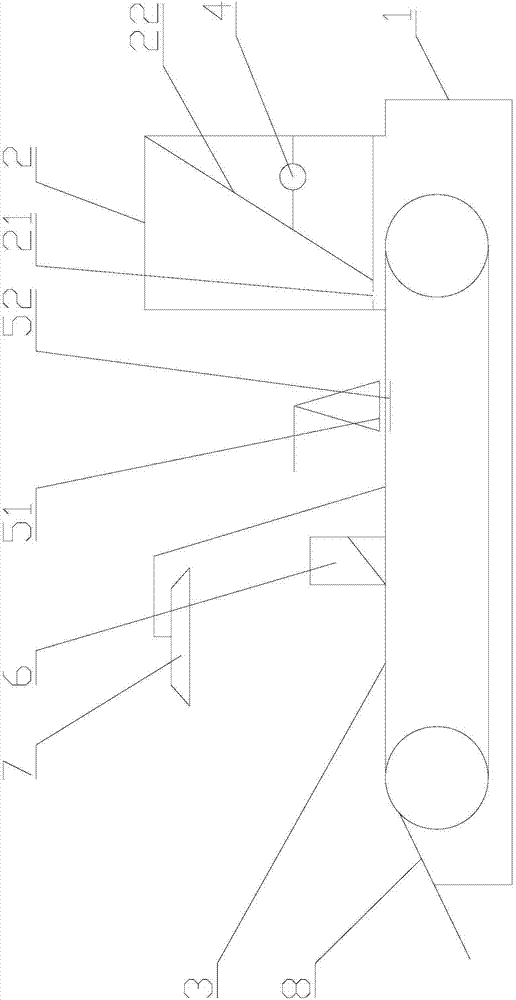

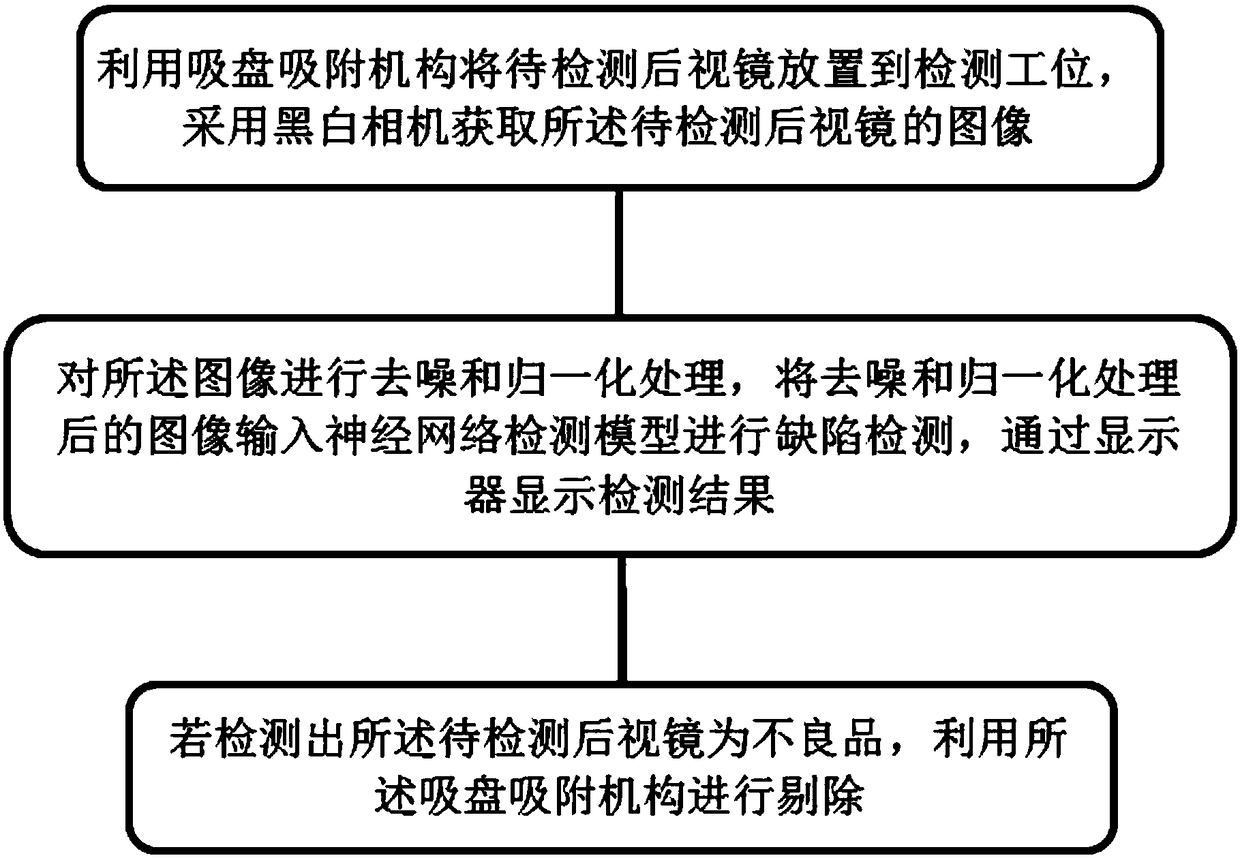

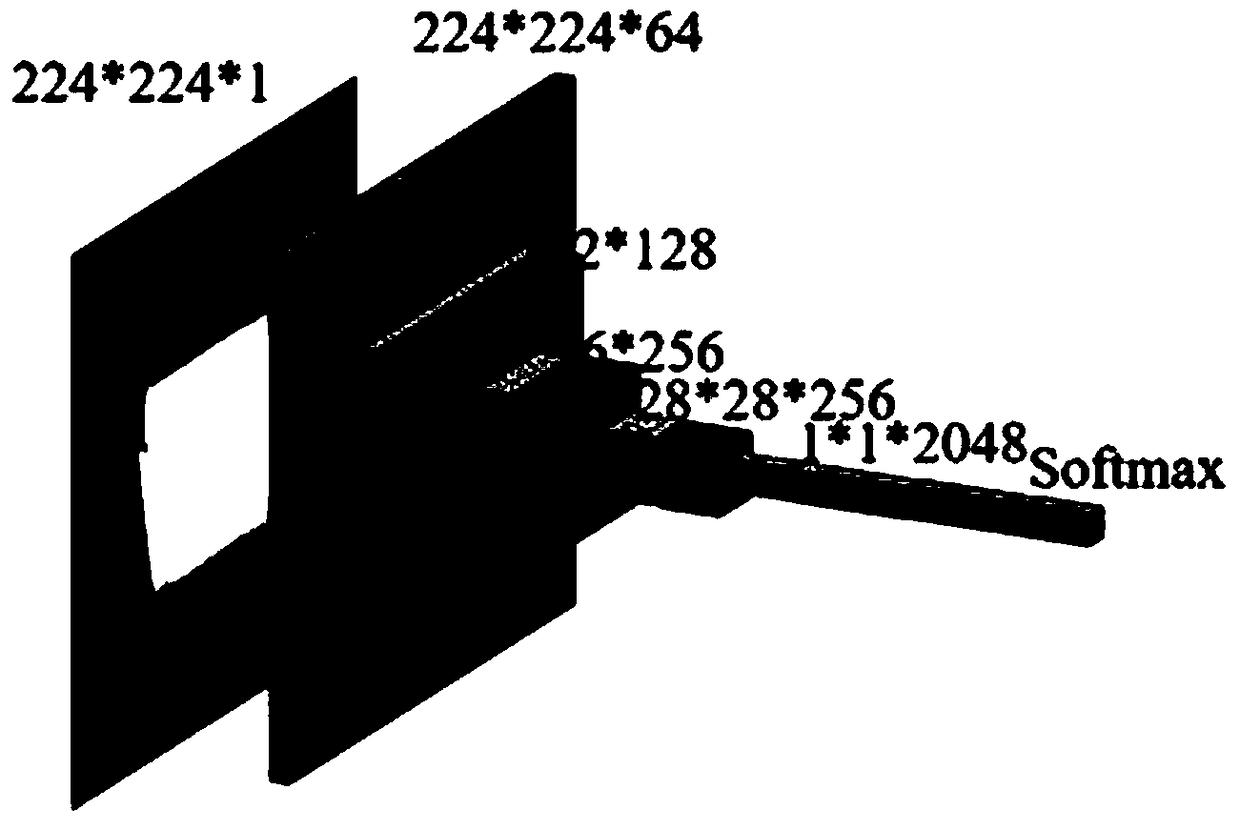

Detecting method for detecting station for edging defect on back layer of rear view mirror

InactiveCN109187549AAvoid secondary pollutionFully automatedOptically investigating flaws/contaminationDisplay deviceComputer vision

The invention belongs to the technical field of intelligent detection and discloses a detecting method for a detecting station for an edging defect on a back layer of a rear view mirror. The detectingmethod comprises the following steps: (1), placing a to-be-detected rear view mirror on the detecting station by using a sucker adsorption mechanism, and acquiring an image of the to-be-detected rearview mirror by using a black-and-white camera; (2), denoising and normalizing the image, inputting the denoised and normalized image to a neural network detection model for defect detection, and displaying a detection result by a display;(3), eliminating the to-be-detected rear view mirror by using the sucker adsorption mechanism if the to-be-detected rear view mirror is detected to be a defective product; and(4), repeating the steps (1)- (3) to detect defects of the next to-be-detected rear view mirror. By using the method disclosed by the invention, the full automation of detection for theedging defect on the back layer of the rear view mirror is realized, the accuracy rate of detection is guaranteed, meanwhile, the detecting efficiency is increased, and the production cost is reduced.

Owner:SHANGHAI UNIV OF ENG SCI

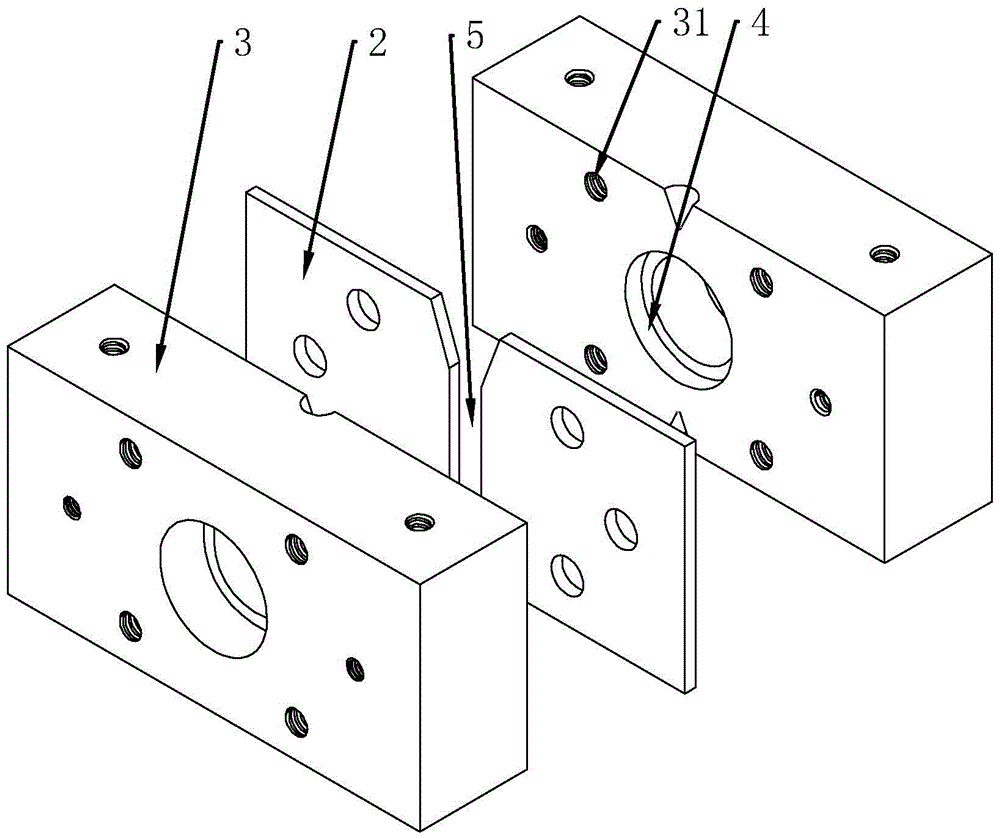

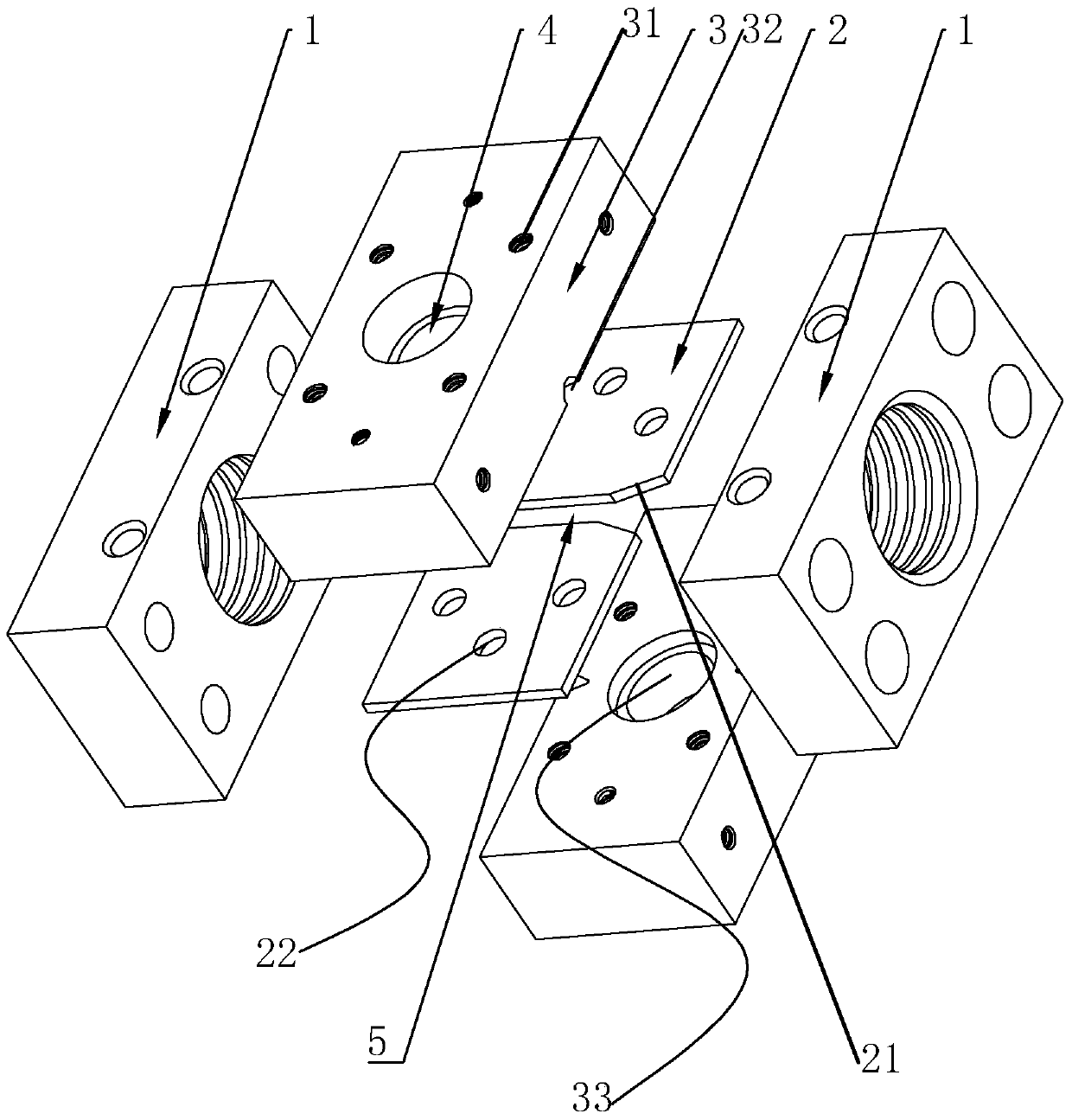

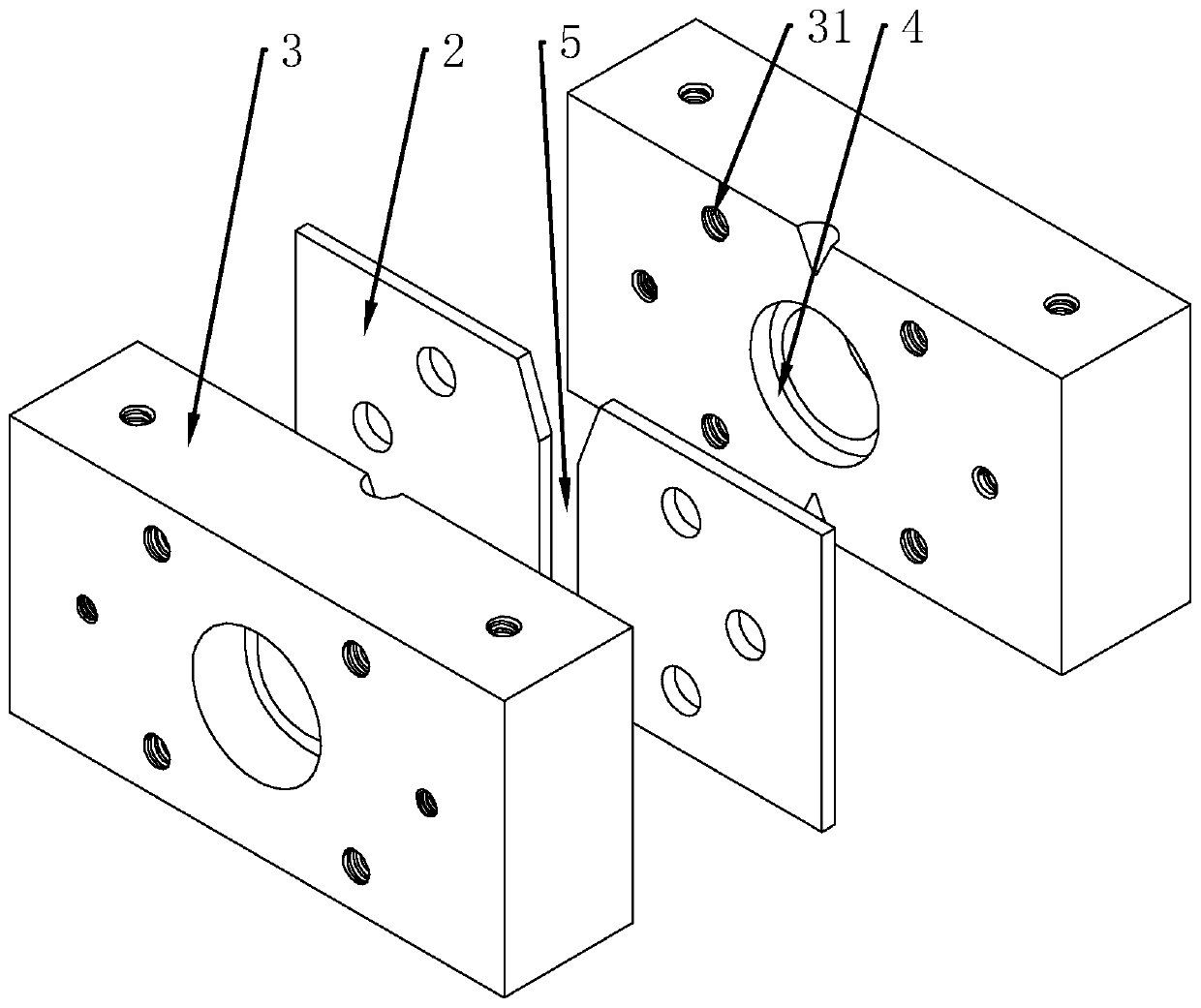

Method for manufacturing check block of insoluble liquid particle detection device and optical sample reservoir

The invention discloses a method for manufacturing a check block of an insoluble liquid particle detection device and an optical sample reservoir, aiming at solving the technical problem in the prior art that a stainless steel plate sealed in the manner of thread splicing and sealant is difficult to reach the pressure-bearing value for ultrahigh pressure detection is solved. According to the technical scheme, the check block in the optical sample reservoir is integrally welded in a special processing form and is wholly embedded into a connecting block, and then is welded again to form the optical sample reservoir for an insoluble liquid particle detector applied to an optical resisting method. The optical sample reservoir with the check block in such arrangement has the highest loading capacity reaching above 400kg and can fully meet the requirement for ultrahigh pressure detection.

Owner:BEIJING LANKE IND & TRADE CO LTD

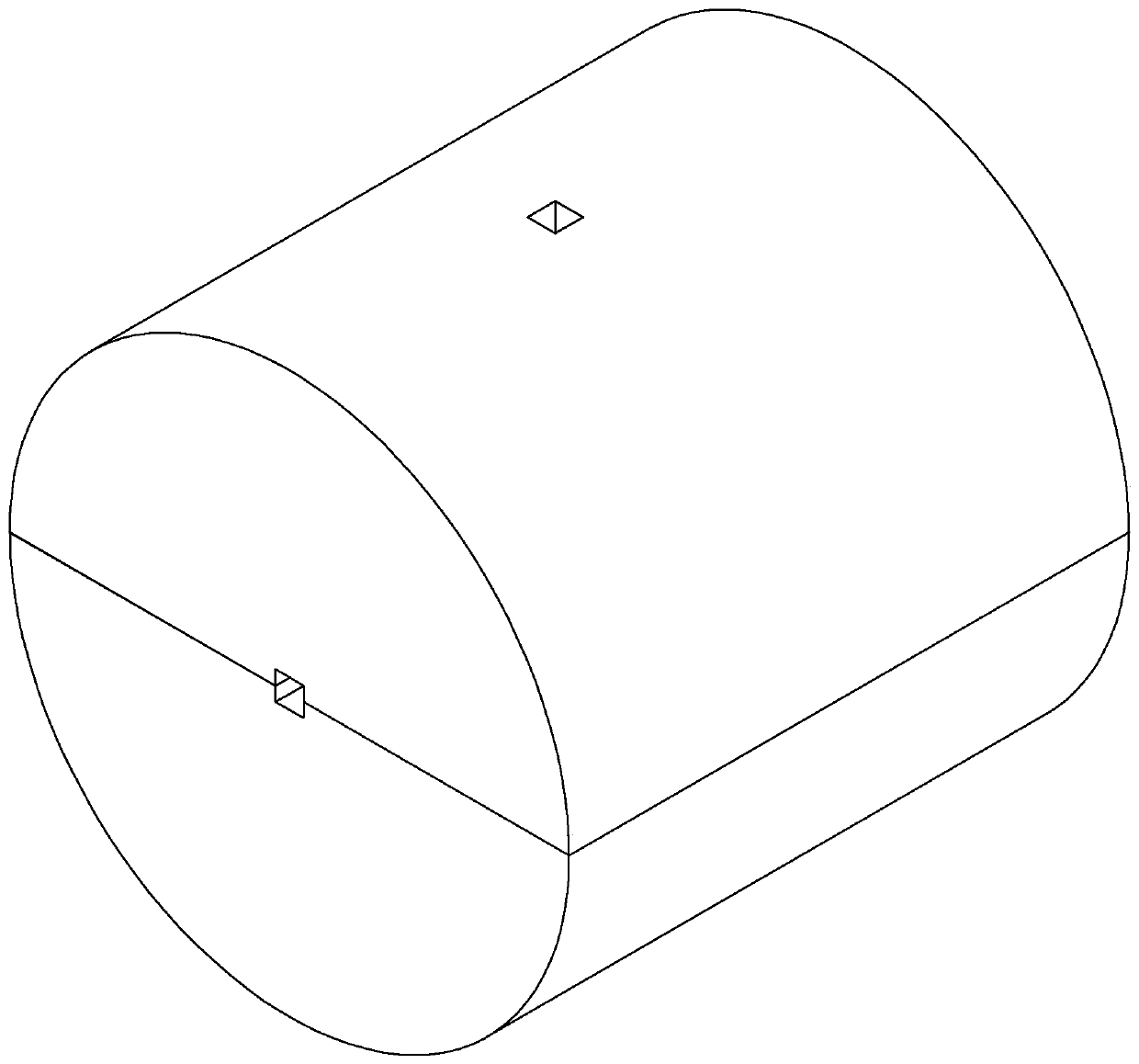

Optical system for checking ultra large diameter convex parabolic mirror

InactiveCN109253865ASmall caliberGuaranteed inspection accuracyOptical apparatus testingAstronomyLaser interferometry

The invention discloses an optical system for checking an ultra large diameter convex parabolic mirror. The detection optical system is composed of a laser interferometer, a compensation lens group, ato-be-detected convex parabolic mirror and a spherical mirror. A sphere centre of the spherical mirror is located on a rear focus of the detected convex parabolic mirror. Divergent light emitted by the laser interferometer is incident from a central hole of the detected convex parabolic mirror and is incident on the spherical mirror through refraction of the compensation lens group. Light reflected by the spherical mirror is incident on the spherical mirror again along a normal direction through reflection of the detected convex parabolic mirror and returns to the laser interferometer according to an original path through self-collimating reflection. The system has the advantages that high precision detection of the ultra large diameter convex parabolic mirrors with diameters of 600mm orabove can be realized, detection precision is ensured, and the diameter of an auxiliary spherical surface and length of the system can be reduced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

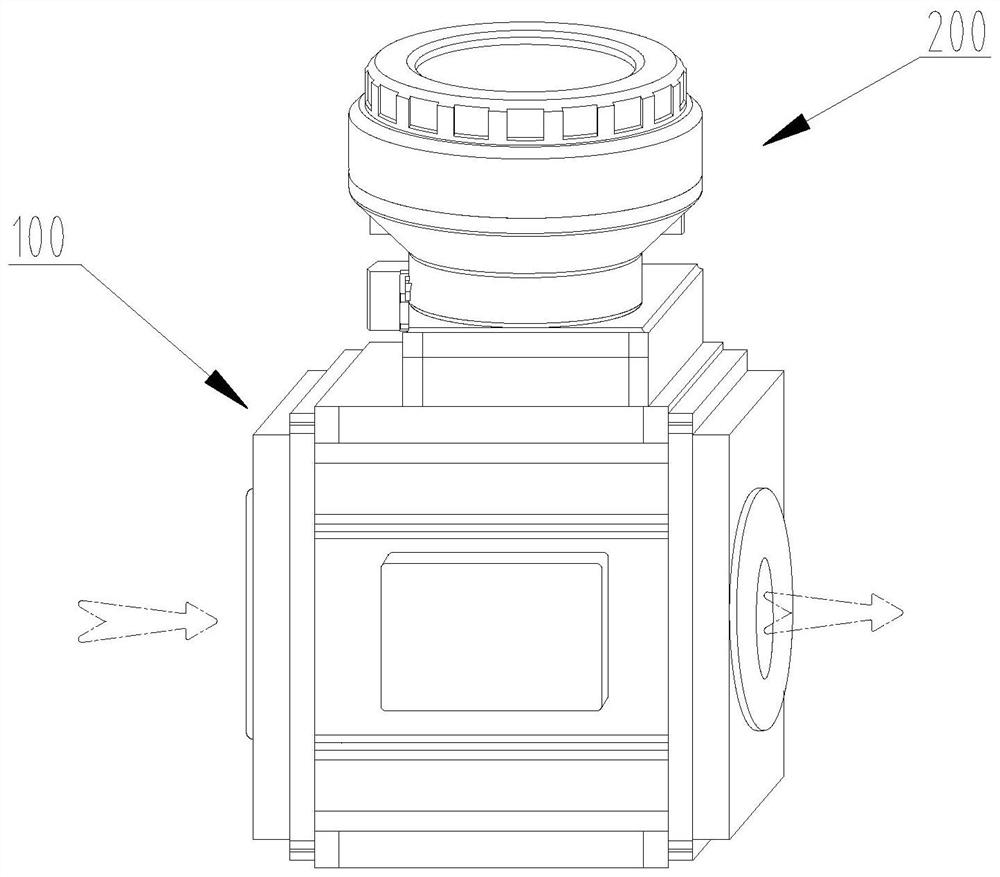

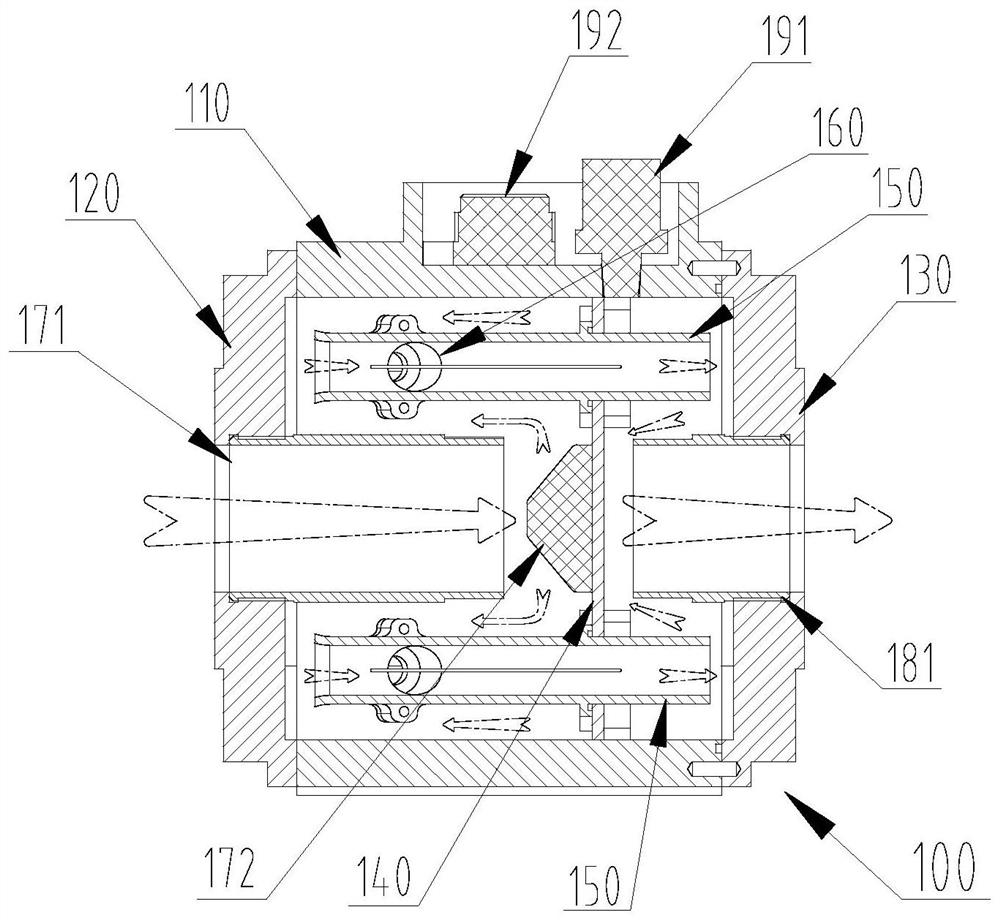

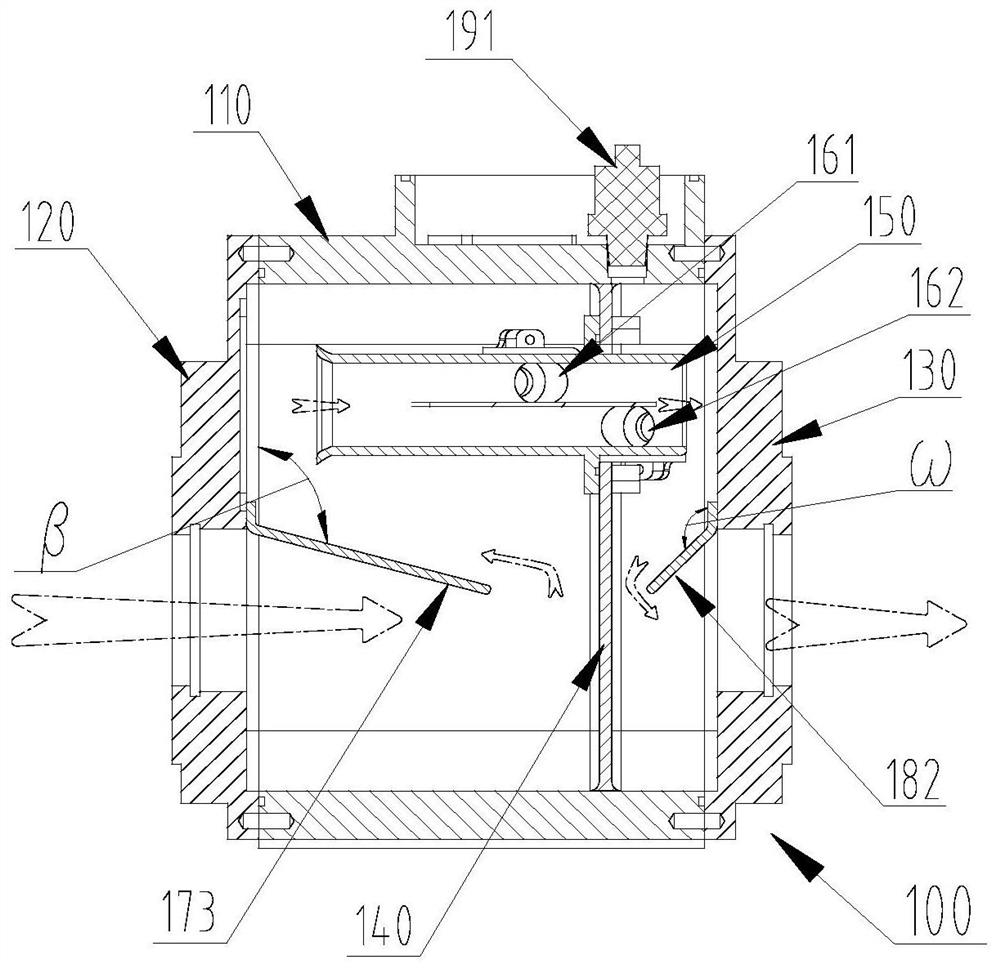

Gas ultrasonic flowmeter

ActiveCN113701834AReduce impactMeet detectionVolume/mass flow measurementVolume meteringUltrasonic sensorStraight tube

The invention discloses a gas ultrasonic flowmeter. A meter body of the gas ultrasonic flowmeter comprises a box body, a front end flange cover with a gas inlet and a rear end flange cover with a gas outlet, one side of the front end flange cover is connected to one end face of the box body, and a gas inlet flow dividing assembly is further arranged in the position, located on the side, of the box body. One side of the rear end flange cover is connected to the other end face of the box body and provided with a gas leading-out component, a partition plate dividing the box body into a gas inlet cavity and a gas outlet cavity is arranged in the box body and located between the gas inlet flow dividing assembly and the gas leading-out component, a hollow measuring pipe section is installed on the partition plate, and the gas inlet end of the measuring pipe section is located in the gas inlet cavity. The gas outlet end of the measuring pipe section is located in the gas outlet cavity, and an ultrasonic transducer pair is installed on the measuring pipe section and used for detecting the flow of gas. A front straight pipe section, a rear straight pipe section and a front flow stabilizer in the prior art are removed, the size of the meter body is effectively reduced, the structure is more compact, installation is more convenient, and the installation requirement of the gas ultrasonic flowmeter in the available space limited area can be met.

Owner:上海中核维思仪器仪表股份有限公司

Substrate outer appearance inspection device

ActiveCN101363804BGuaranteed inspection accuracyMaterial analysis by optical meansUsing optical meansColor imageOptical axis

The invention provides a substrate appearance inspection device capable of differentiating solder steep surface and plane surface, which are hard to detect out with colorful high-brightness illumination, and capable of picking-up position out of the solder in white illumination. A colorful camera and infrared camera are arranged above a substrate to make each light receiving faces opposite to thesubstrate face. A first illumination section respectively irradiating visible lights such as red, green, blue from different directions and a second illumination section irradiating infrared light along light axis of the camera are arranged between the camera and substrate. Color image is formed by reflected light reflected by the incidence substrate of the camera from the first illumination section, shade image is formed by reflected light of camera incidence infrared light. Image of position corresponding to the color image is processed when detecting position out of the welded corner, position corresponding tilt grade of five-grade is determined by using color image and shade image when detecting the welded corner.

Owner:ORMON CORP

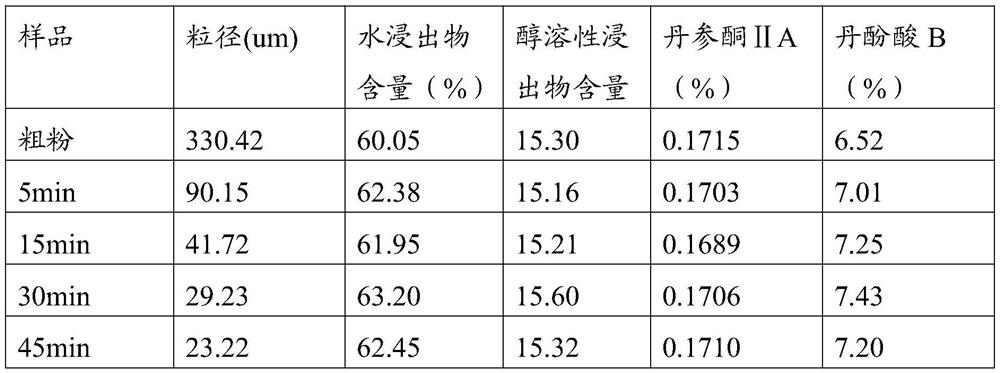

Preparation method and quality detection method of traditional Chinese medicine composition for treating cerebrovascular diseases through meridian rehabilitation method

PendingCN113413413ASave raw materialsEasy to operateNervous disorderComponent separationMedicinal herbsSequela

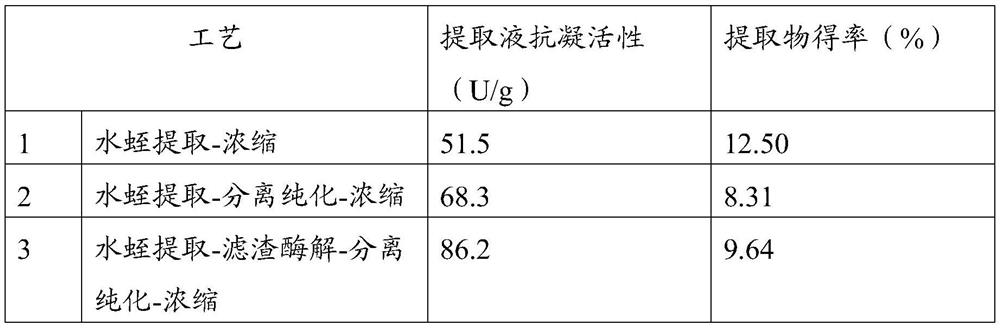

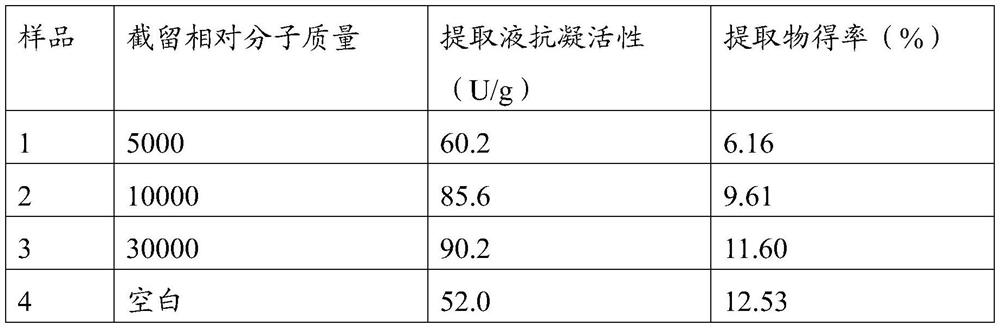

The invention discloses a preparation method and a quality detection method of a traditional Chinese medicine composition for treating cerebrovascular diseases through a meridian rehabilitation method. The steps of filter residue enzymolysis, separation and purification and the like are added on the basis of the original extraction process, so that the defects of the original extraction process are overcome, the loss of bioactive substances is reduced, and the efficacy of the product is improved. A sample is purified by adopting biological pharmaceutical technologies such as ultrafiltration and ion-exchange chromatography, so that the leech extract with high purity and strong biological activity is obtained, and the utilization rate of medicinal materials is improved. The traditional Chinese medicine composition disclosed by the invention is taken as a main material, is supplemented with other products and is combined with a physical therapy of a hyperbaric oxygen chamber, so that the traditional Chinese medicine composition has a very good treatment effect on limb numbness, hemiplegia, facial paralysis, unclear language, water choking and food choking in a recovery period and a sequelae period of cerebrovascular diseases, and has a relatively good curative effect on improving the neurological function of a patient and recovering the action ability; meanwhile, the effect of preventing relapse of cerebrovascular diseases can also be achieved.

Owner:乐泰药业有限公司

Bright spot inspection device for lithium battery diaphragm

ActiveCN105372249AInspection data and strict standardsImprove inspection efficiencyOptically investigating flaws/contaminationBright spotEngineering

The invention belongs to the field of the inspection tool die for the inspection of the bright spot on diaphragm surface in the production of lithium battery diaphragms, and more specifically provides a bright spot inspection device for a lithium battery diaphragm. The device includes a light box with built-in light sources; one surface of the light box is provided with a transparent plate for the light from the light sources to pass through; an unwinding shaft for sleeve arrangement of a diaphragm roll is arranged at one end of the transparent plate, and the axis of the unwinding shaft is parallel to the transparent plate; the unwinding shaft is arranged above the transparent plate; a guide roller is fixed on one end of the transparent plate where the unwinding shaft locates; the axis of the guide roller is parallel to the axis of the unwinding shaft; a gap formed by the guide roller surface and the transparent plate surface forms a passage channel for passing of the diaphragm pressing close the transparent plate surface; and the transparent plate is provided with scales along a direction perpendicular to the axis of the unwinding shaft. The device can effectively avoid the influence of light on the inspection results, realize rapid test operation of a plurality of diaphragm rollers, and greatly improve the inspection efficiency.

Owner:TONGLING JINGNENG ELECTRONICS

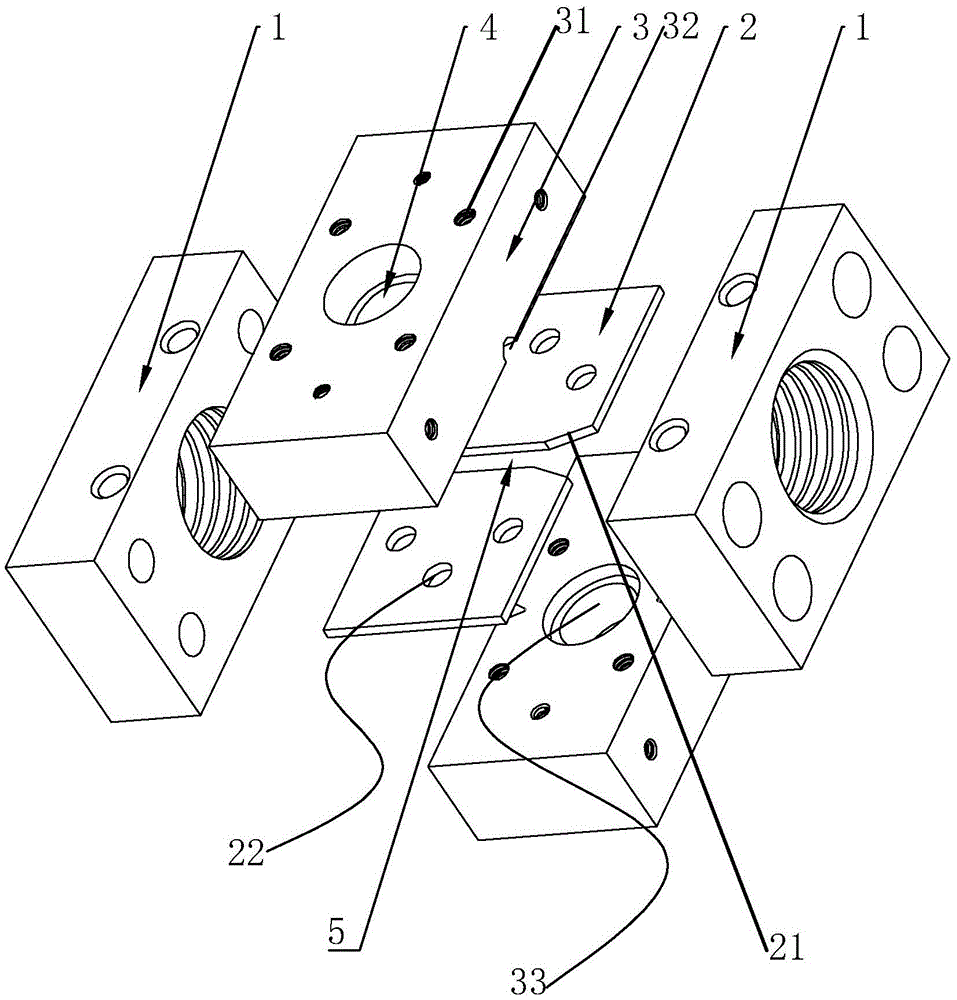

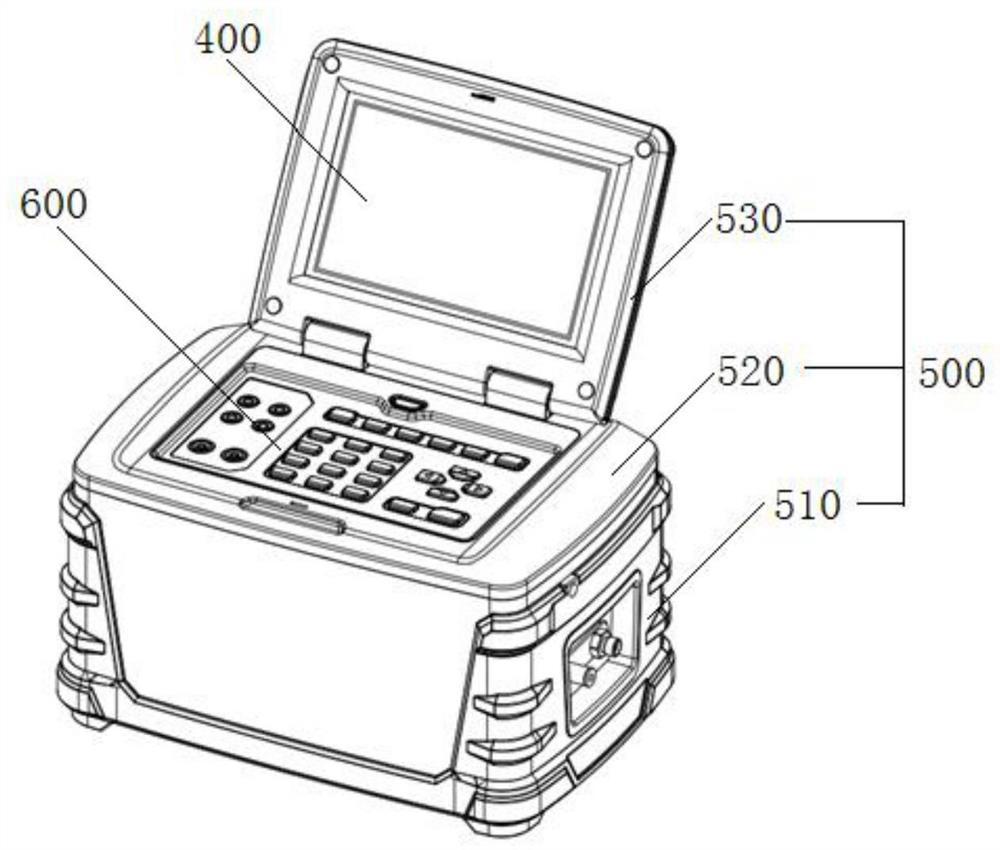

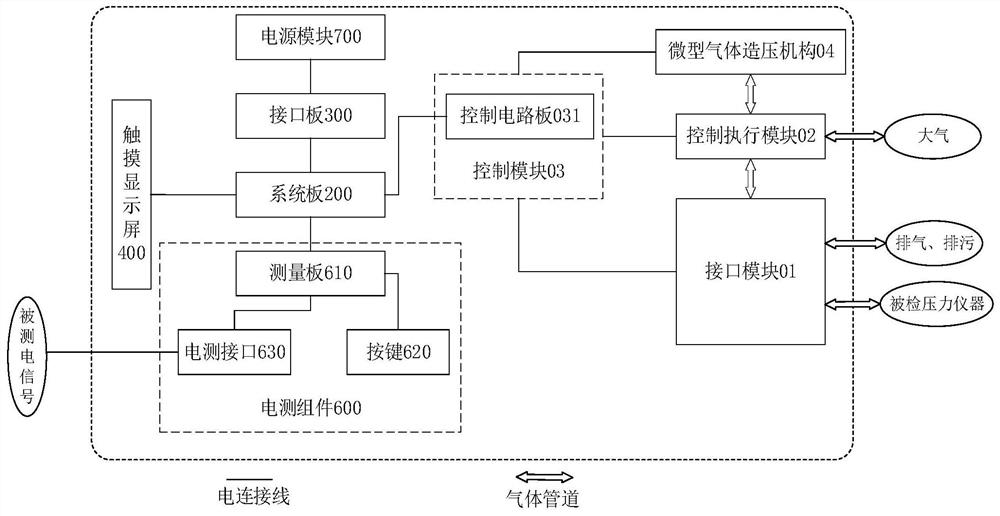

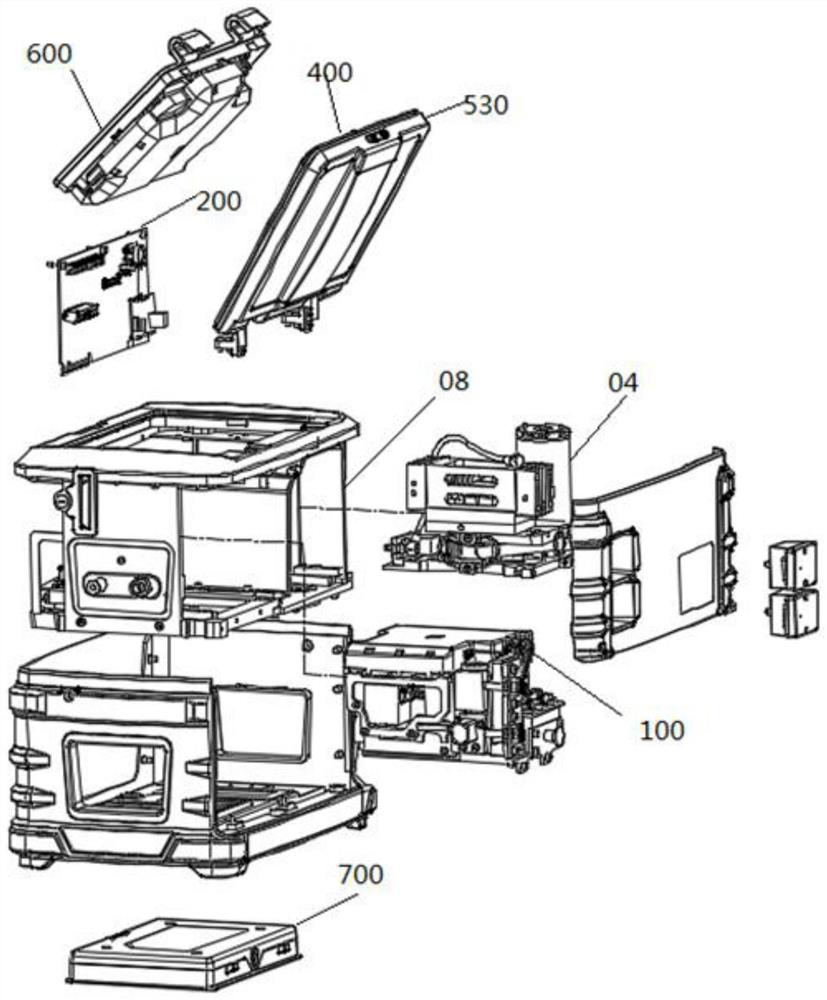

Gas circuit assembly and gas pressure calibrator

PendingCN112304494AReduce connectionsEasy to installFluid pressure measurementFluid pressure control using electric meansControl engineeringAir pump

The invention provides a gas circuit assembly and a gas pressure calibrator. The calibrator comprises a shell, and a gas circuit assembly and a circuit part which are assembled in the shell in a modular manner, the gas circuit assembly comprises a gas pressure control mechanism and a micro gas pressure generating mechanism, the gas pressure control mechanism provides required pressure gas for a detected pressure instrument, and comprises an interface module realizing air channel connection in a plug-in mode, a control execution module and a control module for controlling the interface module and the control execution module, the miniature gas pressure generating mechanism provides positive pressure gas and negative pressure gas for the gas pressure control mechanism and comprises a miniature piston type gas pump serving as the pressure source. The modular design is adopted, all the gas circuit assemblies are assembled in a push-pull mode, and installation and maintenance are convenient; the circuit components are installed in a plug-in mode, the vertical space is fully utilized, and light weight design is adopted so that the whole structure is compact, the size is small, the weightis light, and the calibrator is suitable for on-site verification.

Owner:BEIJING CONST INSTR TECH INC

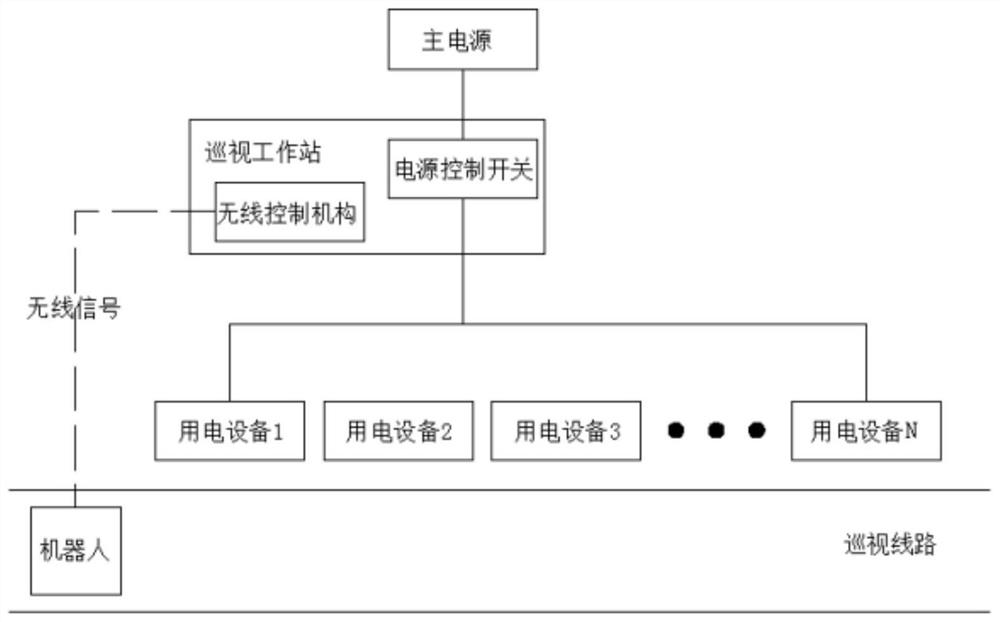

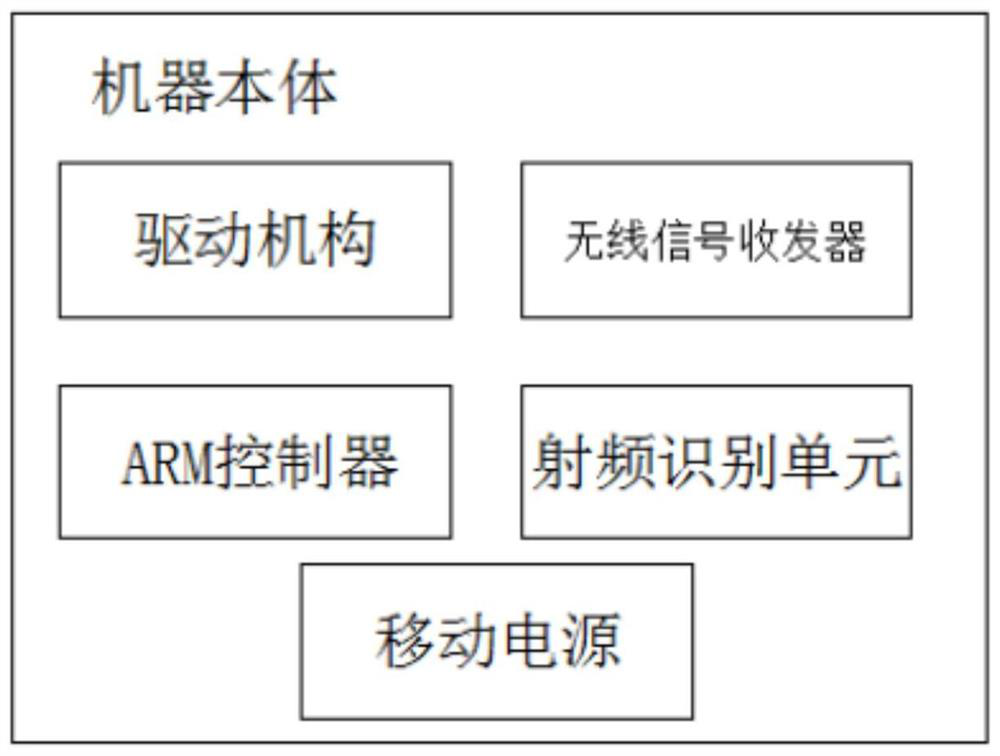

Power equipment uninterrupted patrol system based on digital twinning technology

PendingCN113823013AInspection record specificationReduce labor costsRegistering/indicating working of machinesWireless architecture usageWireless controlStatistical analysis

The invention discloses a power equipment uninterrupted patrol system based on a digital twinning technology, and relates to the technical field of automatic production. The power equipment uninterrupted patrol device based on the digital twin technology comprises a patrol workstation, power equipment, a patrol line and a robot, a wireless control mechanism and a power supply control switch are arranged in the patrol workstation, and the wireless control mechanism is electrically connected with the robot through wireless signals, and the power supply control switch is electrically connected with the electric energy output end of the main power supply. According to the power equipment uninterrupted patrol system based on the digital twin technology, the mobile terminal is used for identifying the electronic tag to achieve patrol management of equipment, statistical analysis of information such as the equipment patrol rate, the omission ratio, the personnel arrival rate and the equipment abnormity, and supervision and inspection of work of patrol personnel, so that patrol records are more standard, and the labor cost is reduced, and the patrol effect is well guaranteed.

Owner:STATE NUCLEAR ELECTRIC POWER PLANNING DESIGN & RES INST CO LTD

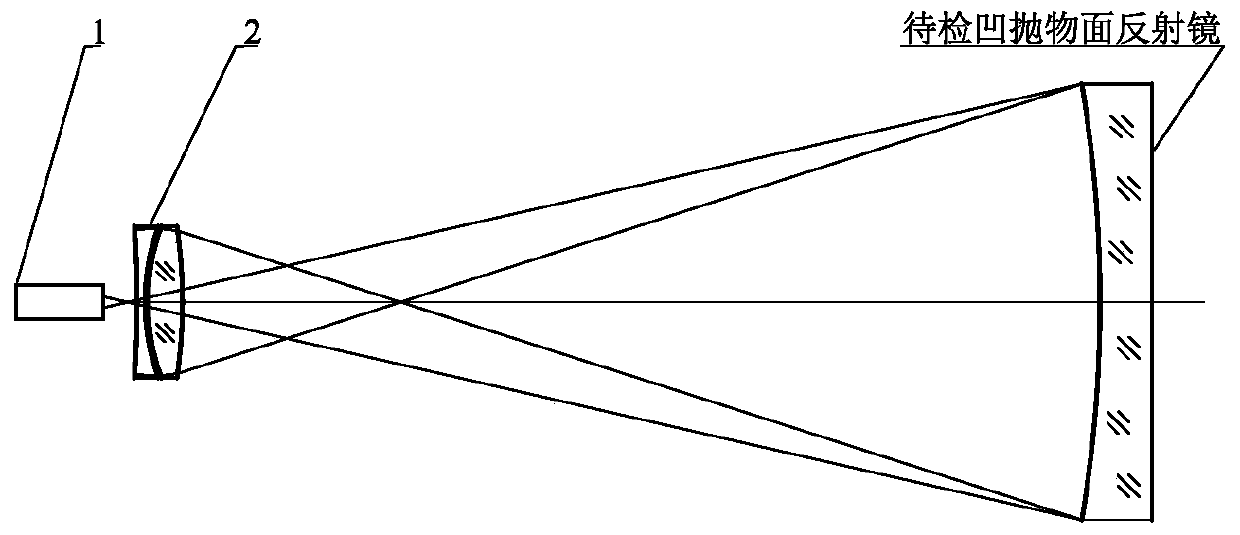

Optical system for inspecting super-large-aperture concave aspheric reflector

PendingCN111458111ASmall caliberEasy to processTesting optical propertiesOptic systemOptical path length

The invention discloses an optical system for inspecting a super-large-aperture concave aspheric reflector. The inspection optical system is composed of a laser interferometer and an auto-collimationcorrection lens group. The auto-collimation correction lens group is located in front of the conjugate rear point of the concave aspheric reflector to be detected. Light emitted by the laser interferometer is refracted and imaged at a conjugate rear point of the concave aspheric reflector to be detected through the auto-collimation correction lens. And the light reflected by the reflector to be detected is imaged at the conjugate front point of the concave aspheric surface to be detected. Reflected light is refracted by the auto-collimation correction lens group, is auto-collimated and reflected on the surface far away from the concave aspheric reflector to be detected, and returns to the interferometer according to the original path. The optical system has the advantages that the opticalsystem can achieve high-precision inspection of the concave aspheric reflector with the ultra-large aperture and the ultra-large relative aperture. Meanwhile, the optical path length of the optical system is short, the caliber of the auto-collimation correction lens group is small, and machining, assembling and adjusting are convenient.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

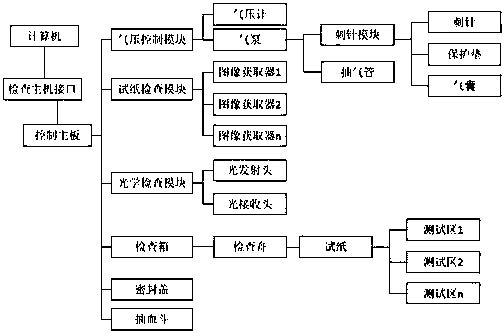

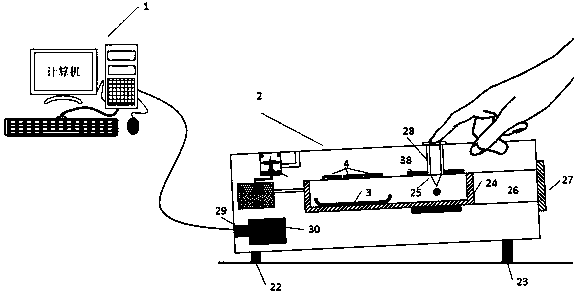

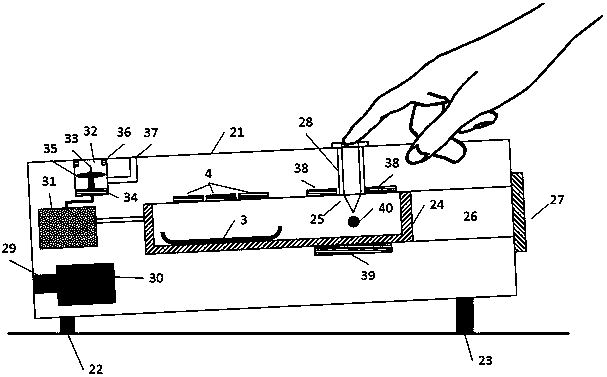

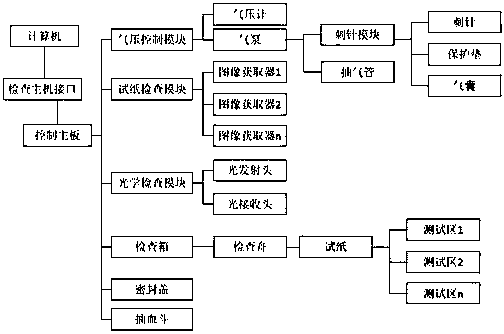

An intelligent finger blood test device for laboratory

ActiveCN109567827BAvoid the inconvenience of self-drawing finger bloodReduce the amount of blood usedMaterial analysis by observing effect on chemical indicatorTransmissivity measurementsBlood drawingUSB

Owner:ANHUI OURUIDA ELECTRICAL APPLIANCE TECH

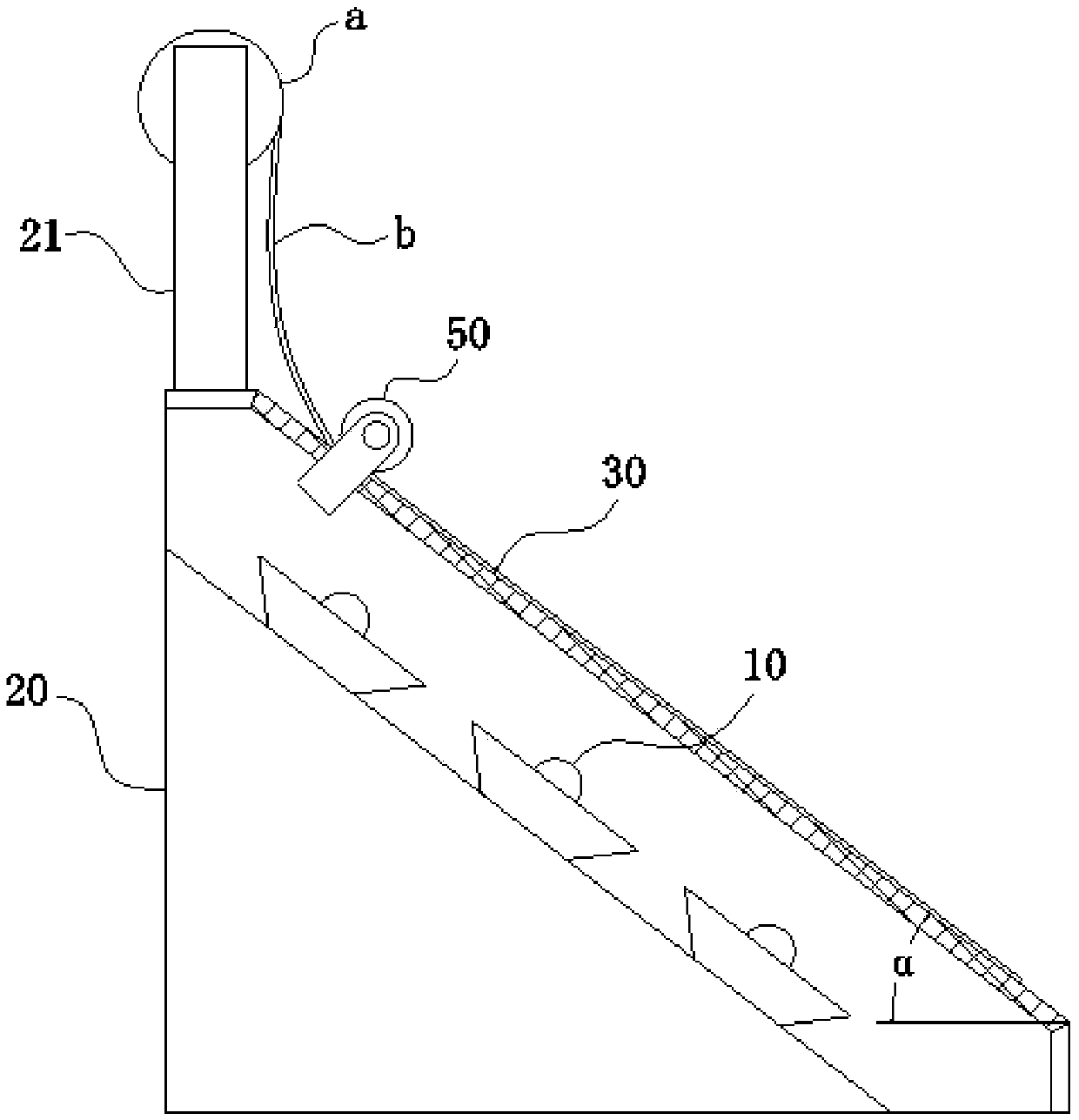

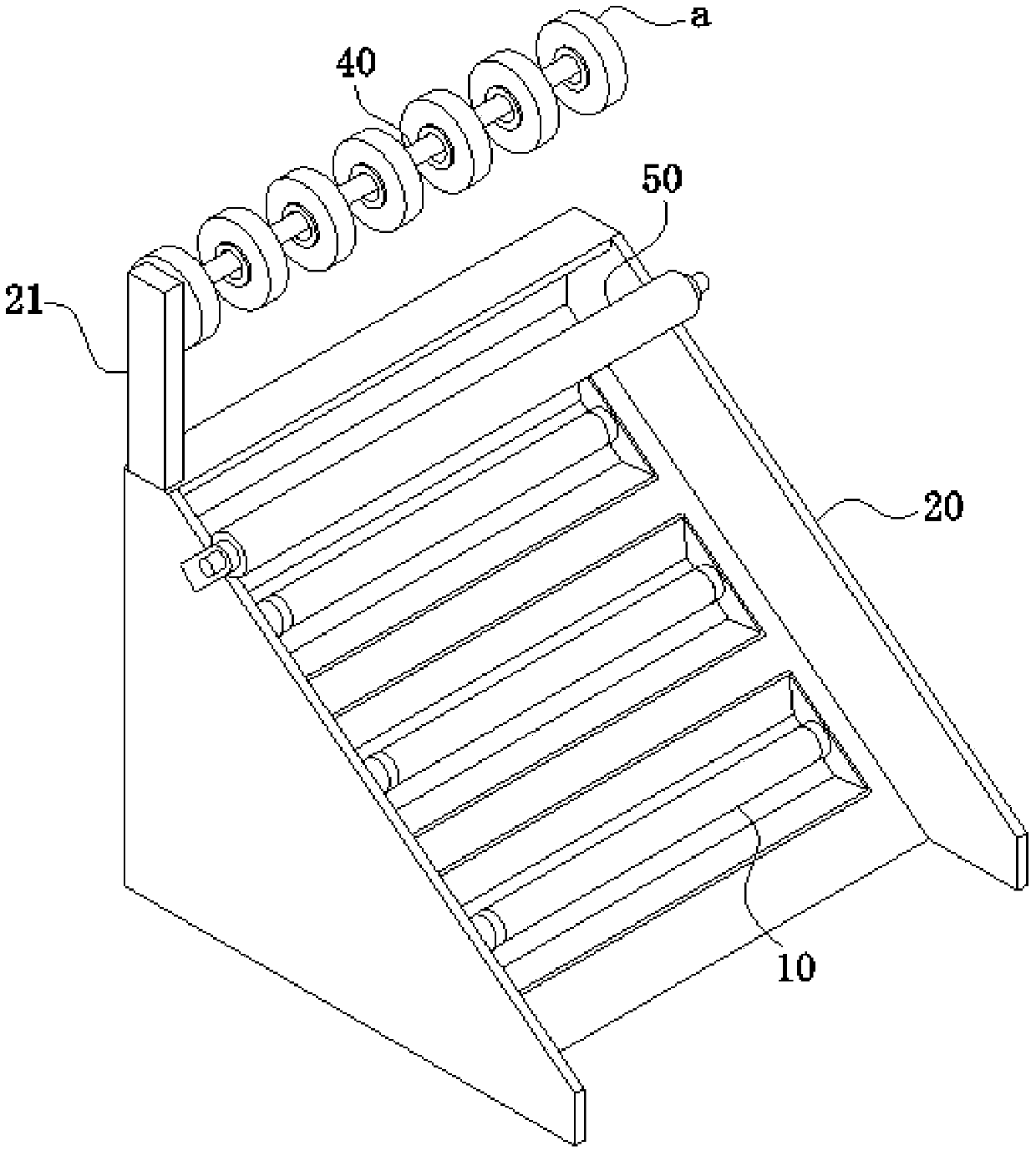

Particle sorting device

InactiveCN104773480ANeatly scatteredConvenient inspectionConveyor partsMechanical engineeringParticle sorting

The invention discloses a particle sorting device. The particle sorting device comprises a stander, a stock bin and a conveying mechanism, wherein the stock bin and the conveying mechanism are respectively installed on the stander, the stock bin is provided with a feeding opening and a discharging opening, the discharging opening is formed in the bottom of the stock bin, the stock bin is connected with a vibrating mechanism, the conveying mechanism is provided with a horizontal working surface, and the working surface is arranged below the discharging opening. Particles are stacked in the stock bin from the feeding opening and fall on the working surface of the conveying mechanism by virtue of the discharging opening, the particles are conveyed by the conveying mechanism to the position of an inspector to be inspected, by controlling the size of the discharging opening, after a given amount of particles drop, the particles can be stuck in the discharging opening, after the dropped particles are inspected, the stock bin is vibrated by virtue of the vibrating mechanism, the particles can drop again, the particles can be quantitatively conveyed to the position of the inspector, the working surface moves relative to the discharging opening, the particles are kept a scattering state on the working surface and are flatly scattered, so that the particles are convenient to inspect by the inspector; moreover, the particles can automatically fall and be dispersed, and the manual stacking and spreading is not needed, so that the inspection efficiency can be improved, and the inspection precision also can be guaranteed.

Owner:浙江中科光铭光电股份有限公司

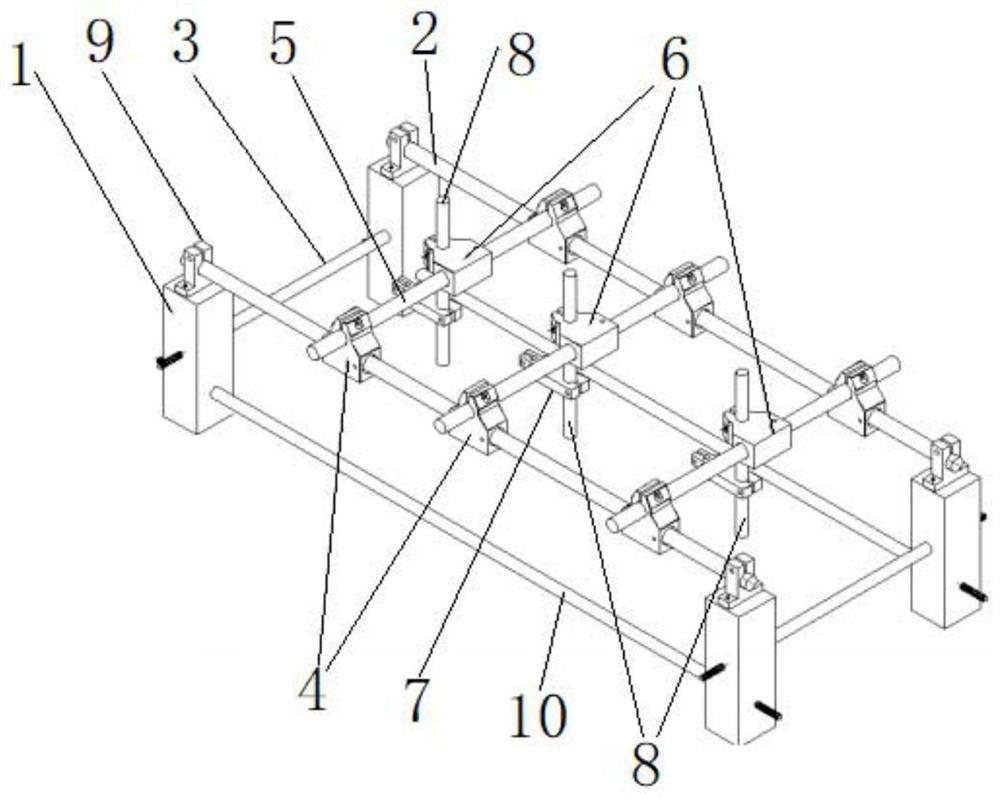

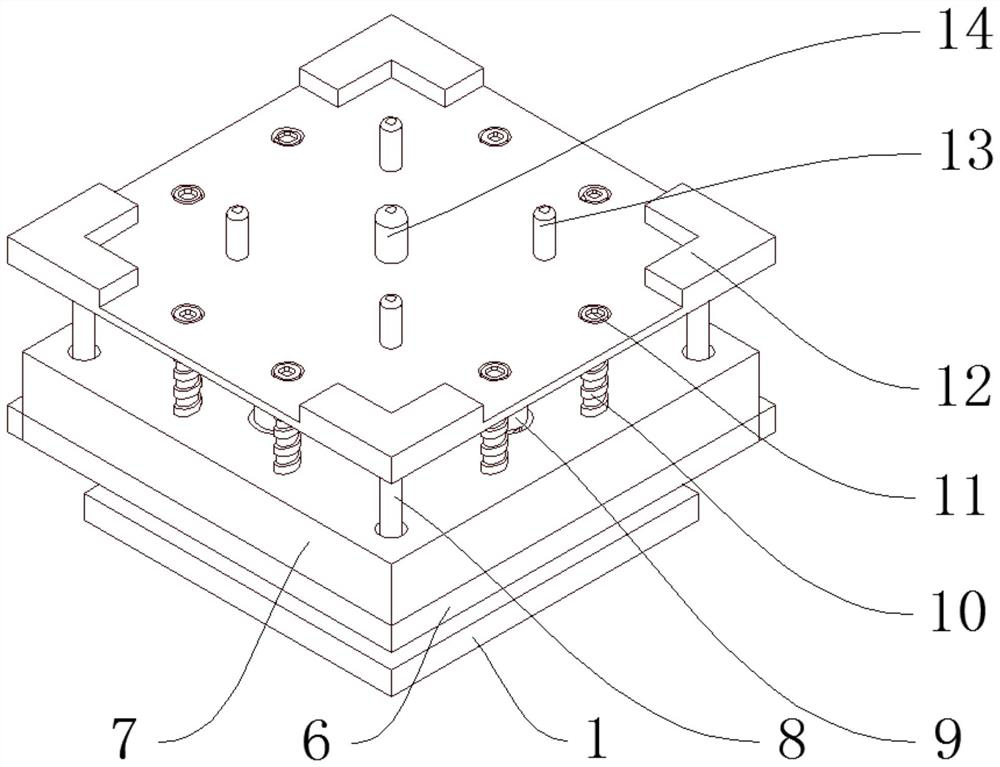

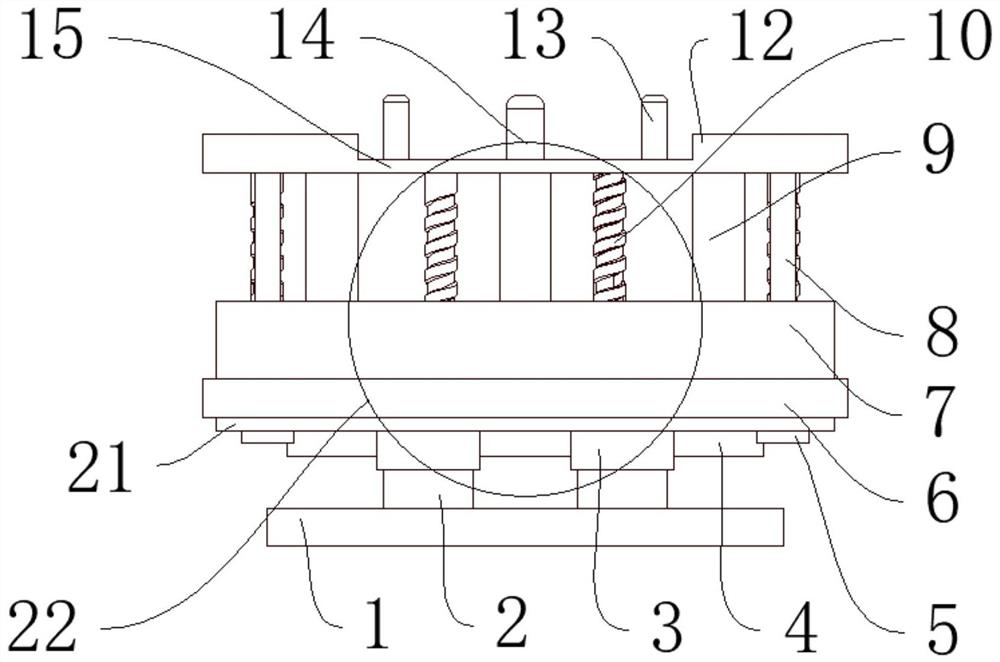

3D curved glass cover plate profile tolerance inspection jig and profile tolerance inspection method

PendingCN113670171AMeet inspection needsImprove general performanceMechanical counters/curvatures measurementsGlass coverEngineering

The invention provides a 3D curved glass cover plate profile tolerance inspection jig applied to the technical field of 3D curved glass, and further relates to a 3D curved glass cover plate profile tolerance inspection method, and according to the 3D curved glass cover plate profile tolerance inspection jig, a left-right movable supporting rod (2) is installed between every two adjacent jig supporting columns (1) in the transverse direction; and a middle supporting rod (3) is installed between every two adjacent jig supporting columns (1) in the longitudinal direction, a plurality of side edge sliding blocks (4) are movably sleeved on each left-right movable supporting rod (2) according to gaps, a middle sliding block (6) is sleeved on each middle sliding rod (5), a clamp (7) is installed on each middle sliding block (6), a measuring meter is installed on each clamp (7). According to the 3D curved glass cover plate profile tolerance inspection jig and the inspection method, the profile tolerance value can be quickly identified, the inspection precision and efficiency of the profile tolerance of the 3D curved glass cover plate are ensured, and unqualified products are prevented from being put into the market.

Owner:芜湖长信新型显示器件有限公司

Method and optical sample cell for manufacturing a test block of a liquid insoluble particle detection device

The invention discloses a method for manufacturing a check block of an insoluble liquid particle detection device and an optical sample reservoir, aiming at solving the technical problem in the prior art that a stainless steel plate sealed in the manner of thread splicing and sealant is difficult to reach the pressure-bearing value for ultrahigh pressure detection is solved. According to the technical scheme, the check block in the optical sample reservoir is integrally welded in a special processing form and is wholly embedded into a connecting block, and then is welded again to form the optical sample reservoir for an insoluble liquid particle detector applied to an optical resisting method. The optical sample reservoir with the check block in such arrangement has the highest loading capacity reaching above 400kg and can fully meet the requirement for ultrahigh pressure detection.

Owner:BEIJING LANKE IND & TRADE CO LTD

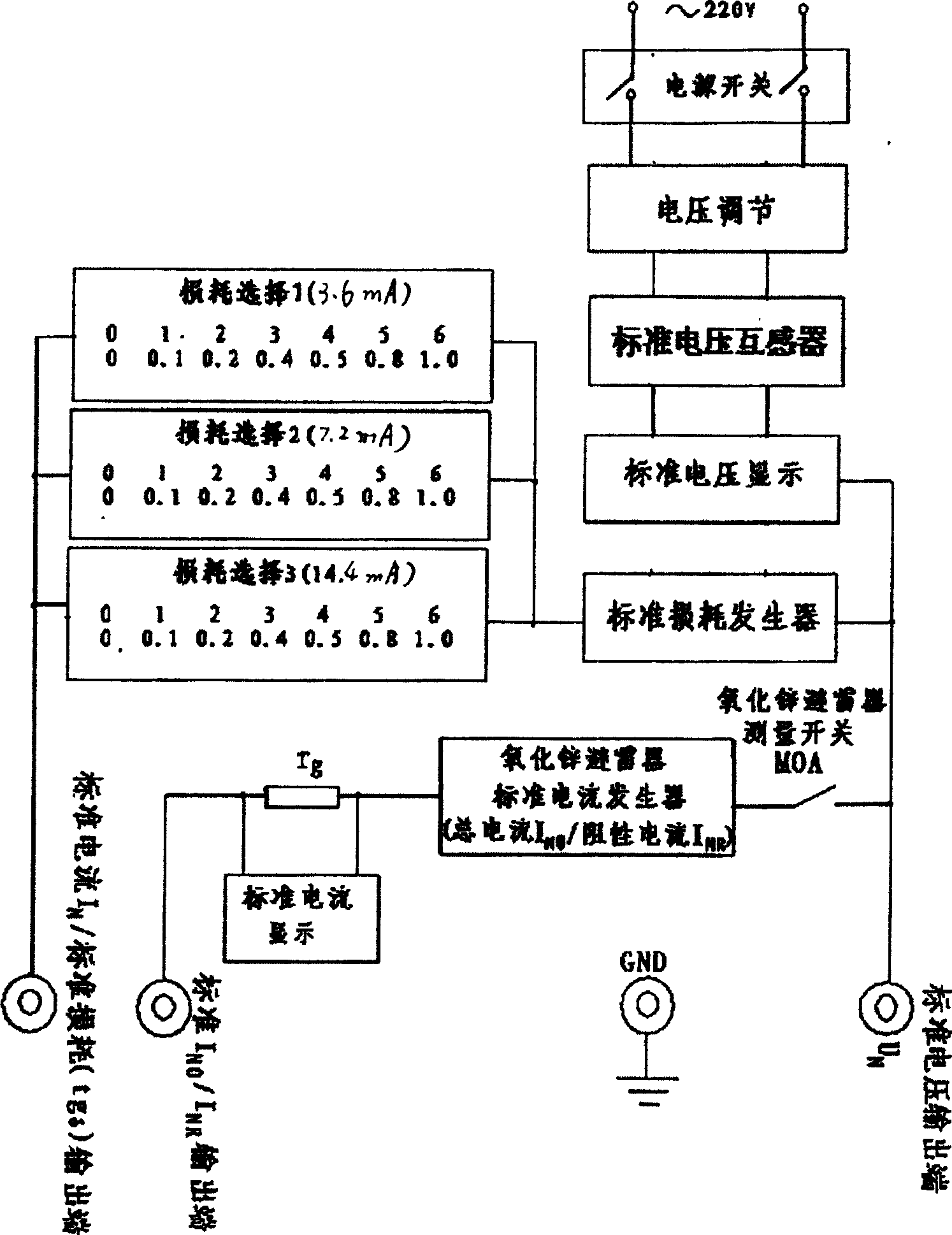

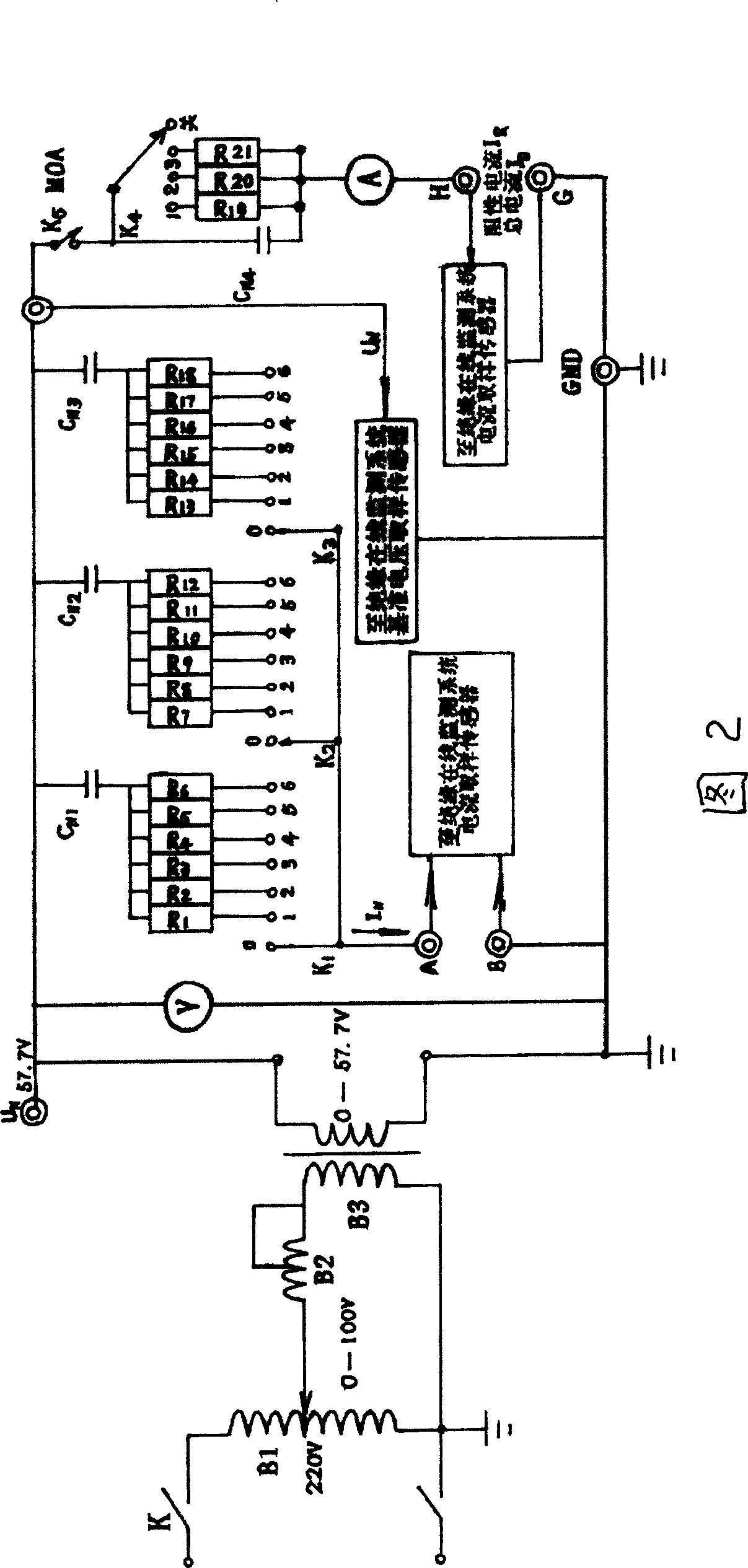

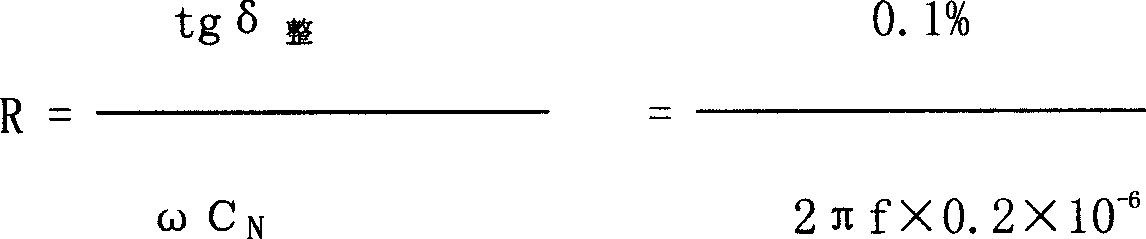

Insulated on-line monitoring system checker of high-voltage electric equipment

InactiveCN100501440CGuaranteed inspection accuracyRealize periodic verificationTesting dielectric strengthCapacitanceMonitoring system

The invention relates to a device for correcting the on-line monitoring system of high voltage electric device insulation. The device comprises a power circuit, a standard loss circuit and a zinc oxide lightning arrester circuit; wherein the standard loss circuit includes three parallel connected standard capacities, 18 resistors and three switches.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

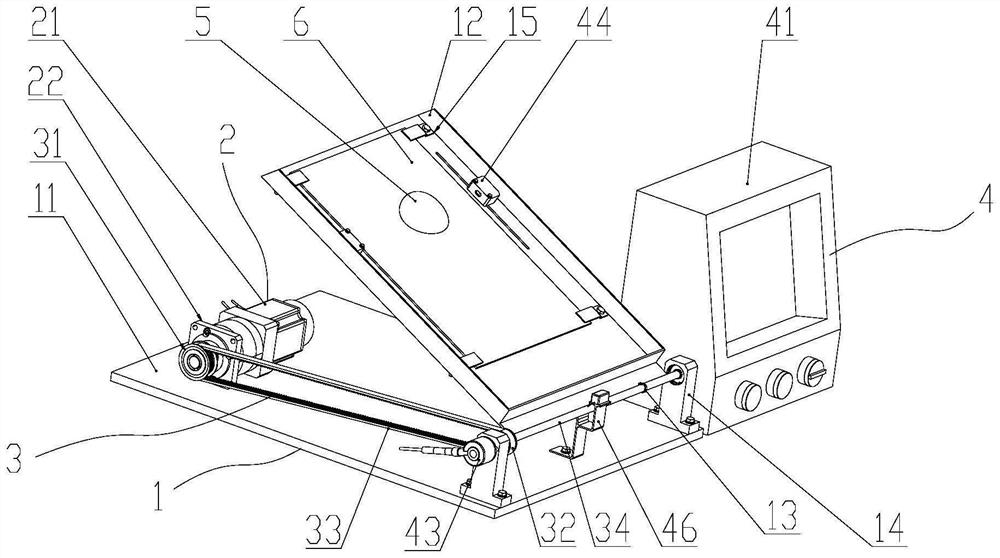

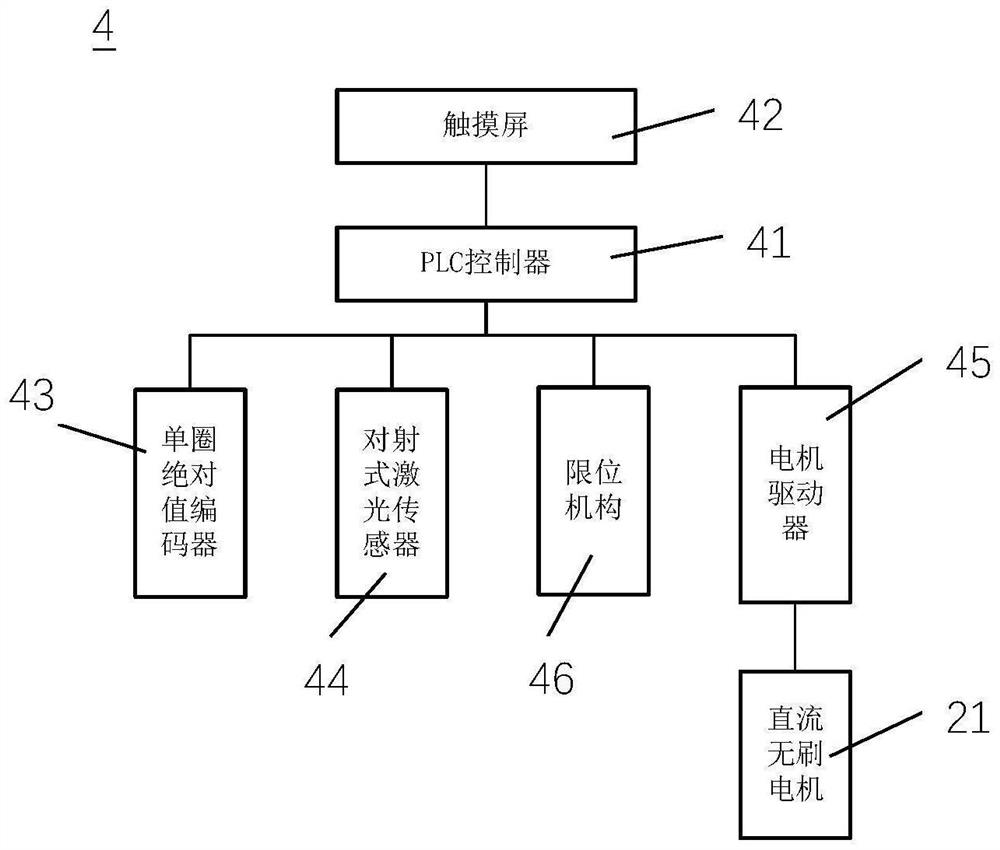

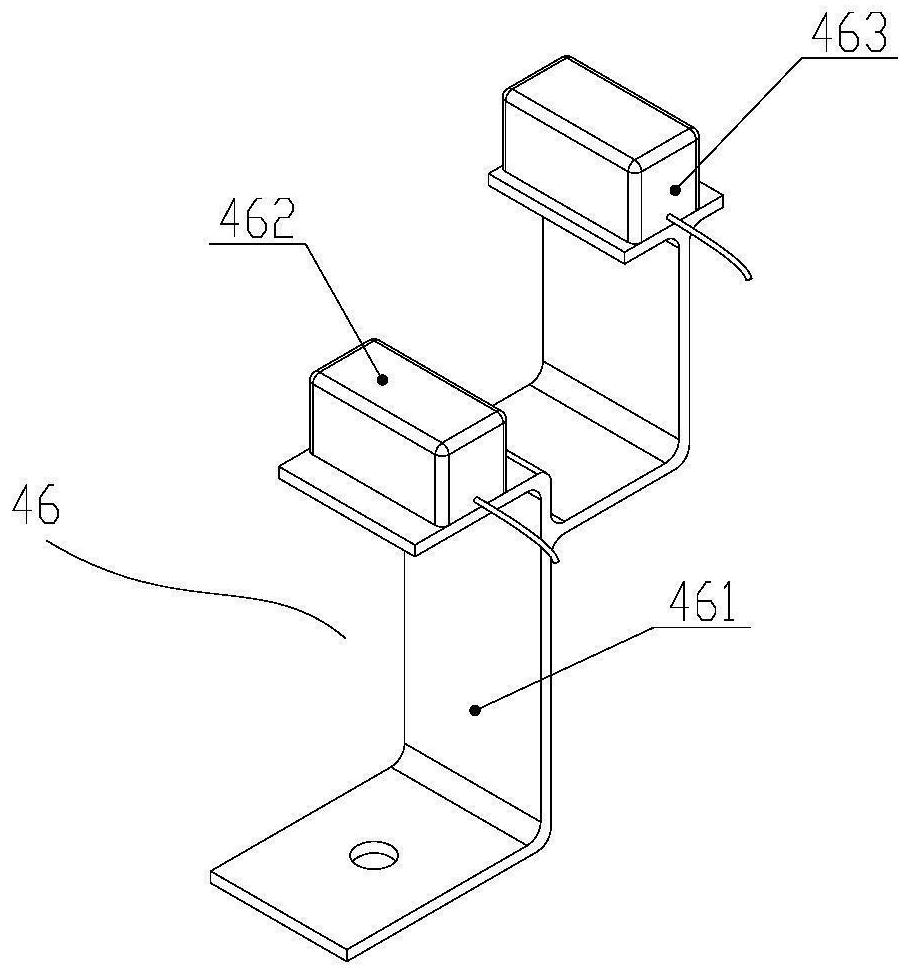

Automatic detection test device and method for static friction coefficient of crop grains

PendingCN114659976ASmooth transmissionIncrease the level of automationUsing mechanical meansMaterial analysisBrushless motorsOptical axis

The invention relates to a crop grain static friction coefficient automatic detection test device and method, and the device comprises a test bench which comprises a pedestal and a test platform, and a tested material and tested crop grains are disposed on the test platform; the driving mechanism comprises a direct-current brushless motor and a speed reducer, the direct-current brushless motor is installed at the rear end of the base, and the speed reducer is connected with the direct-current brushless motor; the transmission mechanism comprises a synchronous belt transmission mechanism and an optical axis, the optical axis is installed at the front end of the base and connected with the speed reducer through the synchronous belt transmission mechanism, and the test platform is connected with the optical axis through a half-split type fixing shaft ring; the control device comprises a controller, a single-ring absolute value encoder, a correlation type laser sensor, a motor driver and a limiting mechanism, the single-ring absolute value encoder is installed at one end of the optical axis, the correlation type laser sensor is installed on the test platform, the motor driver is connected with the direct-current brushless motor, and the limiting mechanism is installed on the base and connected with the optical axis. The invention also provides an automatic detection test method of the device.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Intelligent finger blood examination device for laboratory medicine

ActiveCN109567827AAvoid the inconvenience of self-drawing finger bloodReduce the amount of blood usedMaterial analysis by observing effect on chemical indicatorTransmissivity measurementsBlood drawingUSB

The invention relates to an intelligent finger blood examination device for laboratory medicine. Finger blood is drawn by adopting computer control, and the minimum amount of blood drawing can be automatically determined according to different examination items, so that excess blood drawing is avoided; the invention provides a new finger blood puncture method and a blood drawing method, and uses negative pressure to extract the finger blood, thereby avoiding the problem that patients are inconvenient to draw the finger blood on their own; when the intelligent finger blood examination device isin use, optical examination and test paper examination are sequentially performed after blood drawing, so that the amount of the used blood is reduced, and the examination accuracy can be guaranteed;the invention adopts an air pump to automatically control the puncture of fingers and blood drawing, thereby saving the cost; the device adopted by the invention is connected with a computer, and aninterface is a commonly used USB interface, so that the device is easy to switch over, wide in application, and can be used at home.

Owner:ANHUI OURUIDA ELECTRICAL APPLIANCE TECH

Damping mechanism for condensate water machine

PendingCN112901706AReduce vibrationGuaranteed inspection accuracyNon-rotating vibration suppressionHydraulic cylinderThermodynamics

The invention discloses a damping mechanism for a condensate water machine. The damping mechanism comprises a bottom plate, an installation module and a damping module, wherein the installation module is used for installing the condensate water machine; the installation module comprises a positioning plate, first positioning pins and a second positioning pin; and the damping module is used for reducing working vibration of the condensate water machine. Spring sleeves are arranged, so that damping during strenuous vibration is completed; a rubber shock pad and hydraulic cylinders are arranged, so that shock absorption during slight vibration is completed; and the plurality of positioning pins are arranged, so that the inspection precision is ensured while the vibration is reduced.

Owner:东莞市泰丰空调制冷设备有限公司

Stock bin for sorting particles

InactiveCN104772283AConvenient inspectionNo manual operationGradingEngineeringMechanical engineering

Owner:浙江中科光铭光电股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com