3D curved glass cover plate profile tolerance inspection jig and profile tolerance inspection method

A technology of curved glass and profile, which is applied in the direction of mechanical counter/curvature measurement, measuring device, instrument, etc. It can solve the problems that the profile of 3D curved cover plate cannot be measured, cannot adapt to product shape changes, and cannot meet the profile measurement. To achieve the effect of ensuring rapid production, saving costs and reducing cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

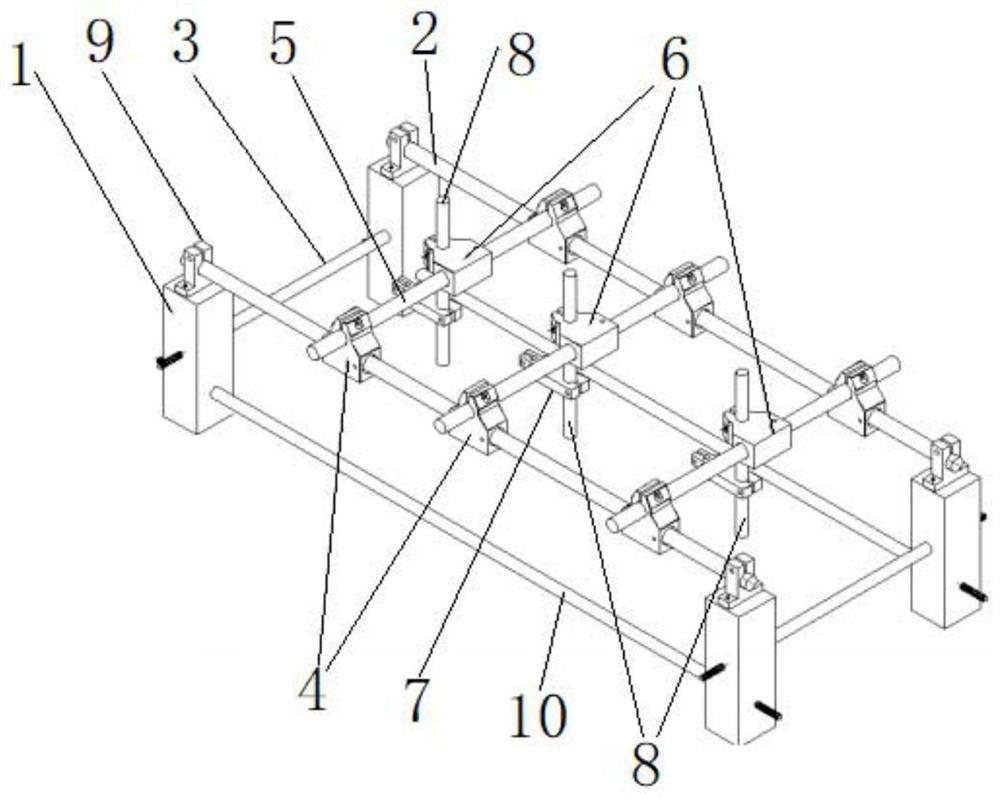

[0027] as attached figure 1 As shown, the present invention is a 3D curved glass cover plate profile test fixture, which includes a plurality of fixture support columns 1, and a left and right movable support rod 2 is installed between each two horizontally adjacent fixture support columns 1, An intermediate support rod 3 is installed between two vertically adjacent fixture support columns 1, and a plurality of side sliders 4 are movable on each left and right movable support rod 2 according to the gap, and one of each left and right movable support rod 2 The middle slider 5 is set between the side slider 4 and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com