Particle sorting machine

A particle and sorting technology, which is applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems that the inspection efficiency and inspection accuracy cannot be taken into account at the same time, the inspection is laborious, and the spread is messy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

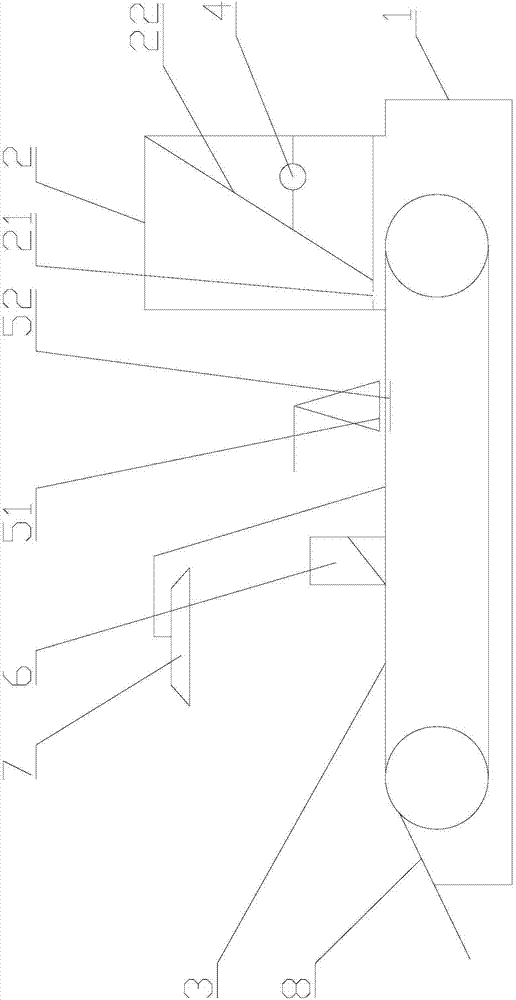

[0014] Such as figure 1 As shown, a sorting particle machine includes a frame 1, a conveying mechanism, a feed bin 2, a vibration mechanism 4, a leveling mechanism, a waste box 6, a lighting lamp 7 and a blanking plate 8, and the conveying mechanism is installed on the frame. The silo, the leveling mechanism, the waste bin and the blanking plate are installed on the frame sequentially along the conveying direction of the conveying mechanism.

[0015] The conveying mechanism has a horizontal working surface 3. In this embodiment, the conveying mechanism is a synchronous belt conveying device. The synchronous belt conveying device includes two synchronous belt pulleys located at the same level and a transmission connection between the two synchronous belt pulleys. Synchronous belt, the upper surface of the synchronous belt is the working surface of the conveying mechanism. Of course, a horizontal support surface can also be directly arranged on the frame, and a cylinder is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com