Optical system used for checking extra-large-caliber convex double-curved-surface reflecting mirror

A hyperboloid mirror and optical system technology, applied in the field of optical systems for aspheric inspection, can solve the problems of difficult processing, large compensation mirror caliber, and less choice of lens materials, so as to ensure the inspection accuracy and reduce the caliber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the present invention will be further described through the description of the embodiments and the accompanying drawings.

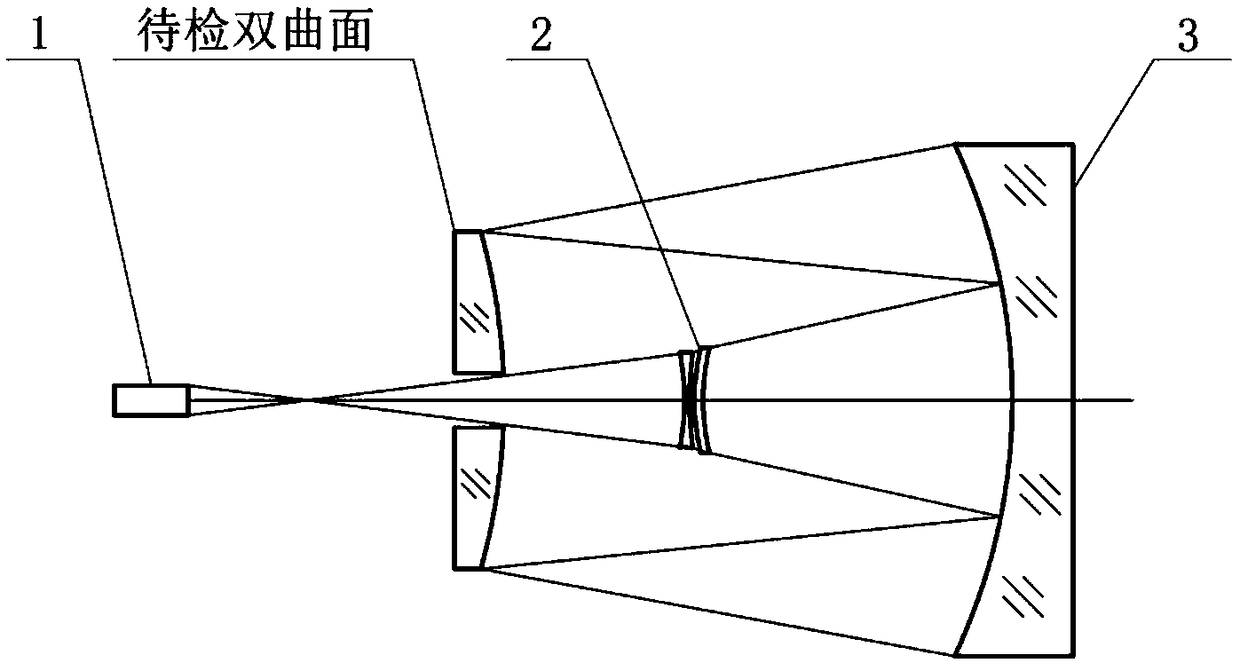

[0013] It is known that the diameter of the convex hyperboloid mirror to be tested is 600 mm, the radius of curvature is 1.8 m, and the eccentricity is 2.25. The optical system for inspecting the hyperboloid is composed of a laser interferometer, a compensation lens group, a convex hyperboloid reflector to be inspected and an auxiliary reflector. The ratio of the caliber of the auxiliary reflector to the caliber of the convex hyperboloid reflector to be inspected is 2, and the ratio of the compensation lens group to the caliber of the convex hyperboloid reflector to be inspected is 0.1.

[0014] In order to reduce the aperture of the auxiliary reflector, it is necessary to reduce the distance between it and the convex hyperboloid reflector to be tested. At the same time, in order to avoid blocking the optical path, the optical path re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com