Method for manufacturing check block of insoluble liquid particle detection device and optical sample reservoir

A manufacturing method and testing block technology, which are applied in measuring devices, particle and sedimentation analysis, particle size analysis, etc., can solve problems such as difficulty in precise control of slit width, restriction of development, and rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

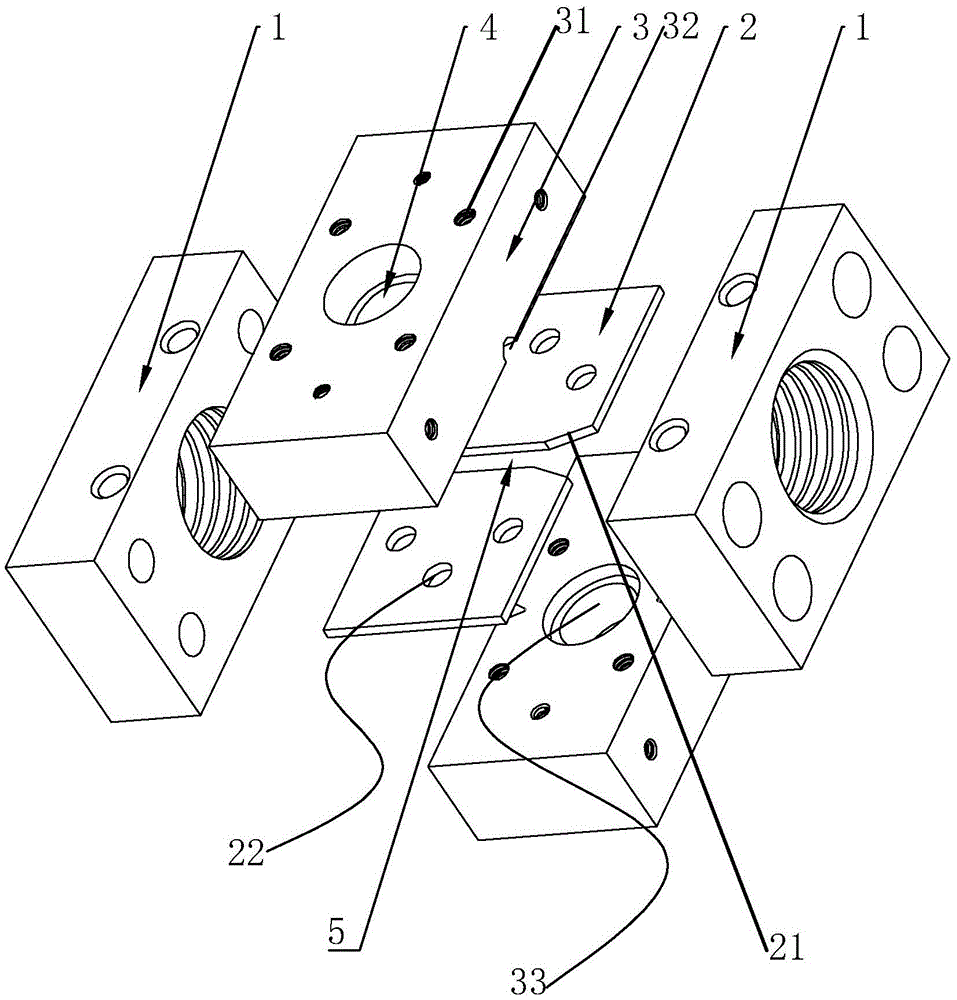

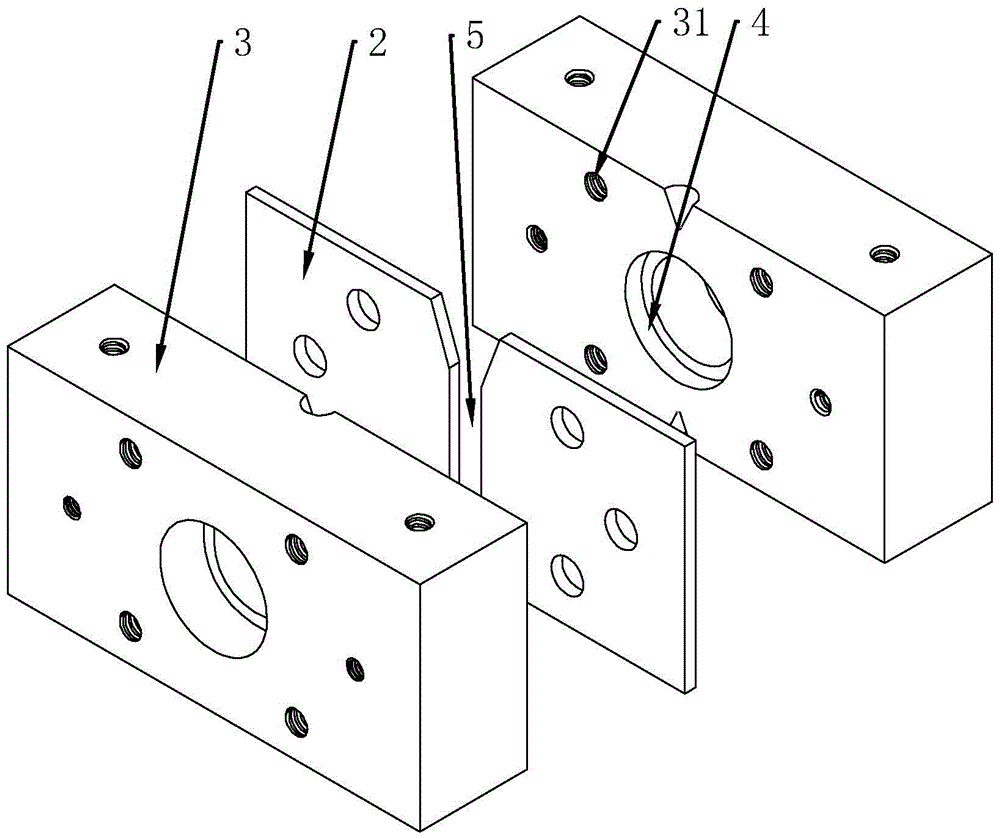

[0061] Process a stainless steel block whose external dimensions are suitable for liquid insoluble particle detection instruments with 316 stainless steel block, and process an embedded groove 63 according to the external dimensions of the test block in the center of this stainless steel block, its structure is as follows Figure 7 shown in . The test block is embedded in the embedded groove 63 and all the joints at the two ends of the connection block 6 are welded and sealed, so that the optical sample cell in this embodiment is formed, and its structure is as follows Figure 8 shown in .

Embodiment 2

[0063] according to Figure 9 with Figure 10 The U-shaped block 65 and the cover plate 66 shown in the form are separately processed to connect the block 6, wherein the U-shaped groove inside the U-shaped block 65 is used to embed the inspection block. When using the split connection block 6 in this embodiment, the process of embedding the test block includes:

[0064] Step 1. Install the inspection block on the U-shaped block 65, and weld all the joints on three sides;

[0065] Step 2. Cover the cover plate 66 on the U-shaped block 62 , and weld around the joint along the U-shaped block 65 and the cover plate 66 .

[0066] The structure of the optical sample cell formed in embodiment 2 is as follows Figure 11 As shown, its airtightness is better than that of embodiment 1, and its reason is that when connecting block 6 in embodiment 1 is welded with inspection block, there are two vertical weld seams 7 less than embodiment 2, and these two passes weld When the manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com