Gas ultrasonic flowmeter

An ultrasonic flowmeter and gas technology, which is applied in the directions of liquid/fluid solid measurement, volume measurement, flow/mass flow measurement, etc., can solve the problem of increasing installation space requirements of the gas ultrasonic flow metering system, and achieve the effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] This embodiment provides a gas ultrasonic flowmeter installed on a gas pipeline for flow detection of gas.

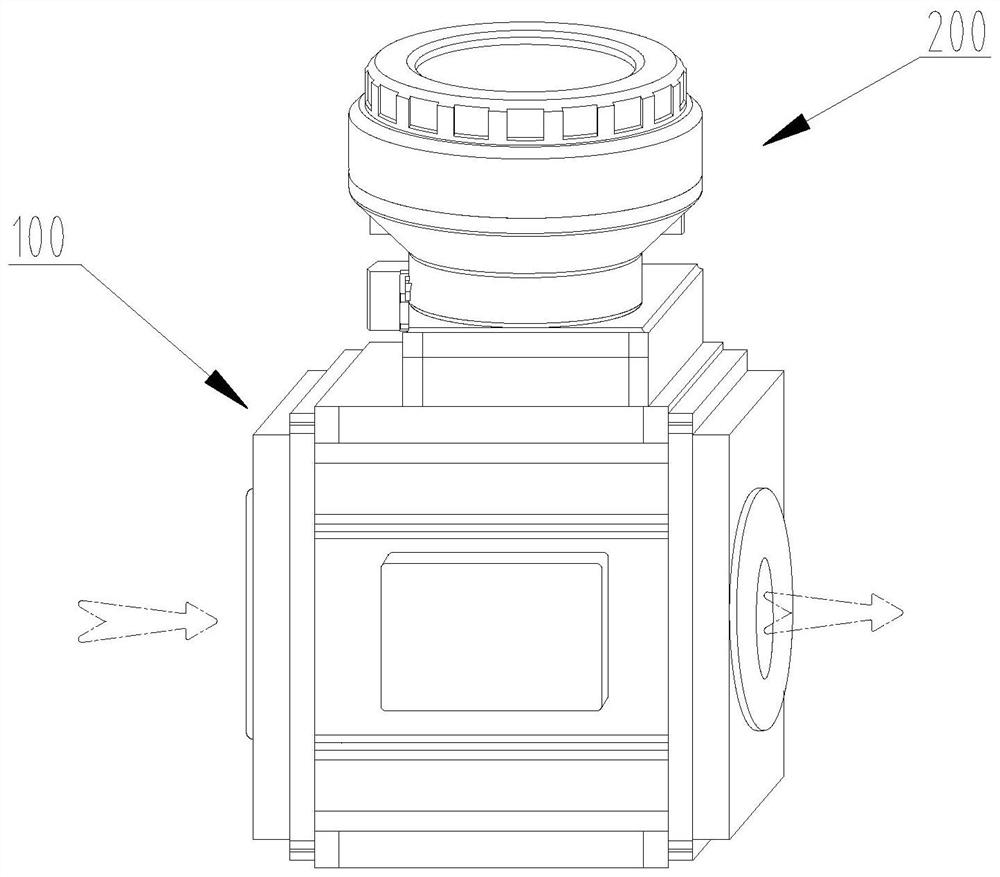

[0082] Such as figure 1 A schematic diagram of a three-dimensional structure of a gas ultrasonic flowmeter provided in an embodiment of the present invention is as follows:

[0083] A gas ultrasonic flowmeter installed on a gas pipeline (not shown in the figure) for flow detection of gas, including a meter body 100, a detection device installed on the meter body 100, the detection device includes a An ultrasonic transducer pair 160 (not shown in the figure) composed of the first ultrasonic transducer 161 and the second ultrasonic transducer 162 for gas flow information.

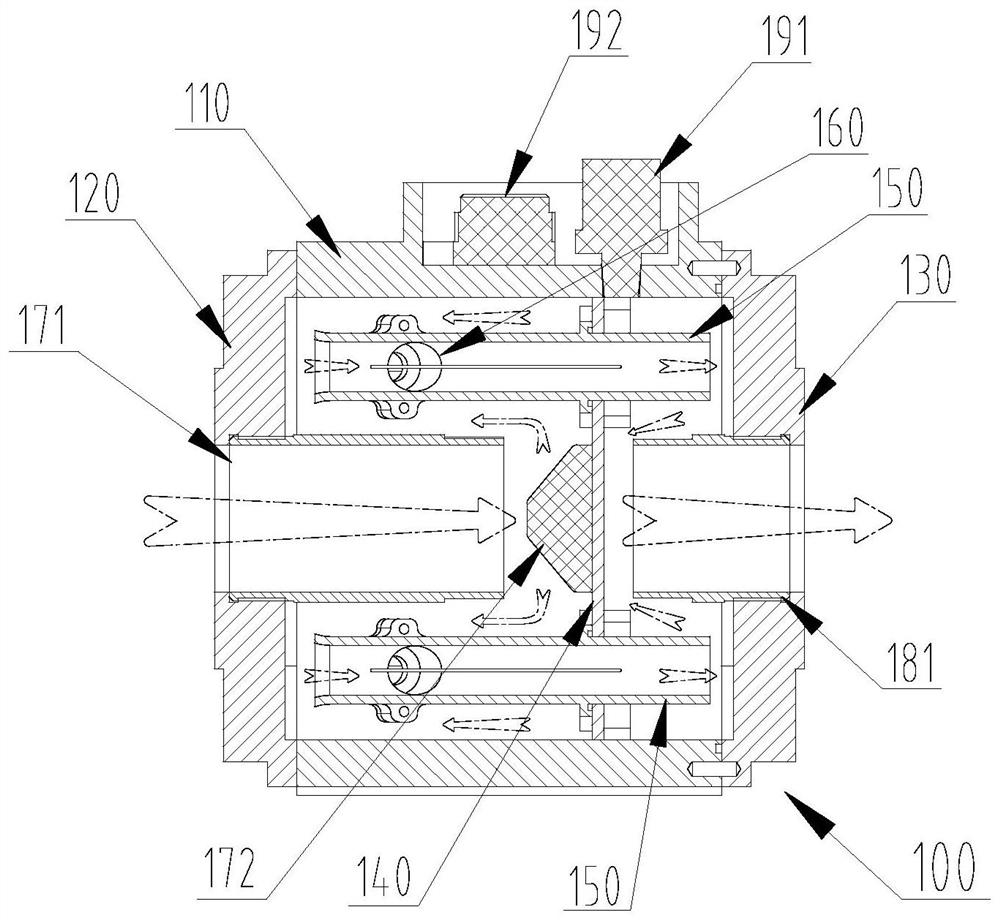

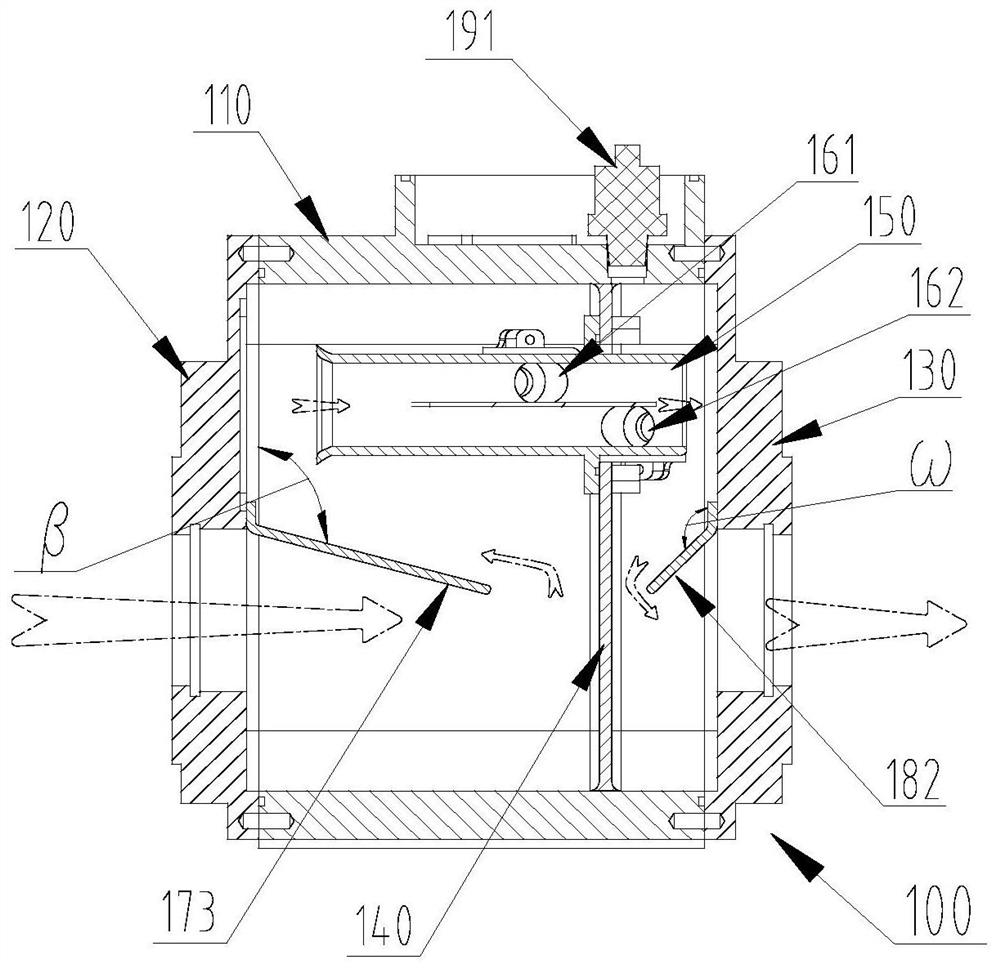

[0084] Such as figure 2 A schematic cross-sectional structural view of the meter body of a gas ultrasonic flowmeter provided by an embodiment of the present invention, image 3 Another kind of gas ultrasonic flowmeter provided by the embodiment of the present invention has a schematic cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com