Full-automatic pressing equipment and pressing method for detachable plate heat exchanger

A plate heat exchanger, detachable technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve problems such as shortening the production cycle, and achieve the effect of shortening the production cycle, ensuring the inspection accuracy and improving the operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

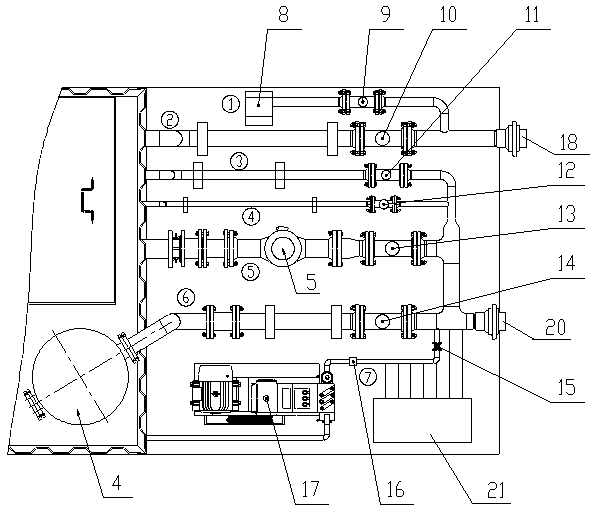

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

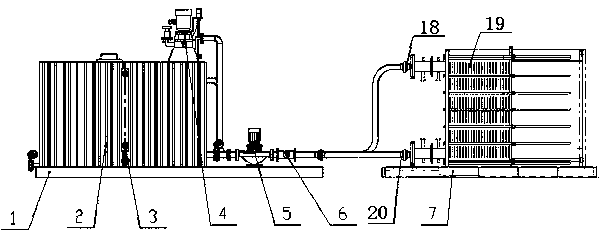

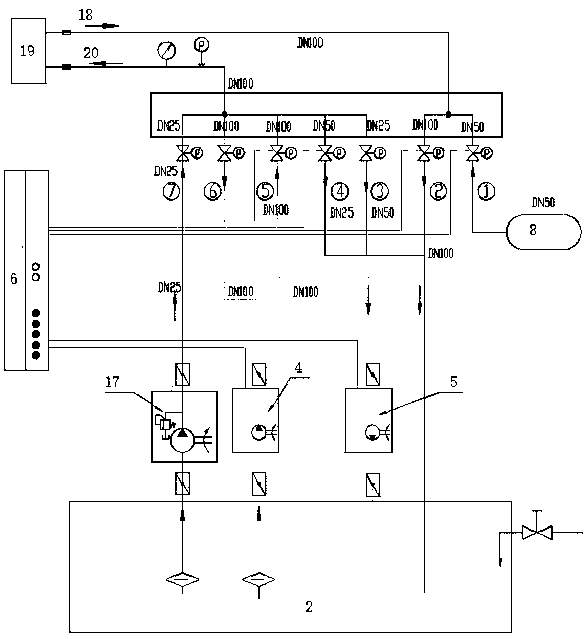

[0020] refer to figure 1 , is a schematic diagram of the external structure of the overall equipment of the present invention, including a base 1, a water tank 2, a magnetic float level gauge 3, an emptying pump 4, a filling pump 5, an electric control system 6, and a water storage skid 7, and a water tank is installed on the base 1 2. Filling pump 5, electric control system 6, what is stored in the water tank 2 is suppressing medium, and the liquid level of suppressing medium is controlled by magnetic float liquid level gauge 3.

[0021] The emptying pump 4 is an unsealed self-controlled self-priming pump, which has the characteristics of temperature resistance and pressure resistance, stable and reliable self-priming performance, long service life, small vibration, low noise, easy disassembly, and easy installation.

[0022] The perfusion pump 5 adopts an anti-corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com