Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Guaranteed drawing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

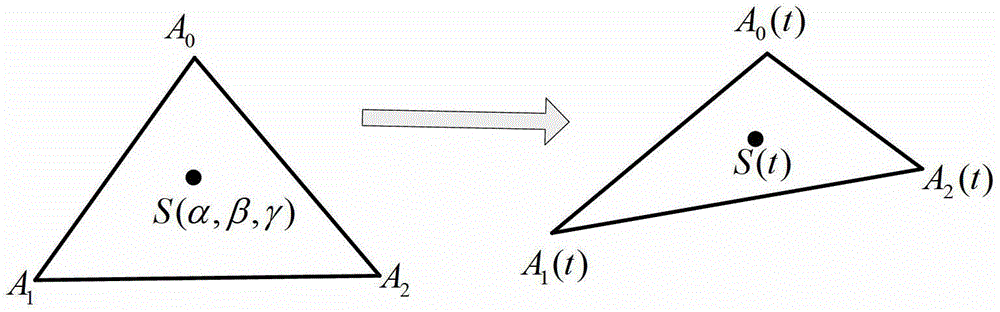

Method for approximately drawing soft shadow of three-dimensional scene

ActiveCN104346831AQuality improvementReduce noise3D-image rendering3D modellingVisibilityComputer graphics (images)

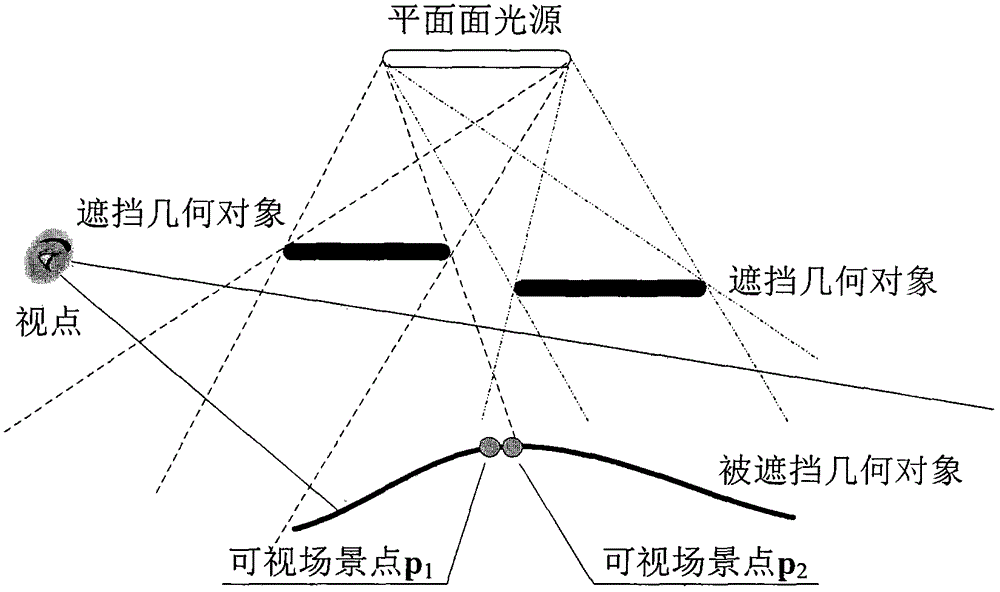

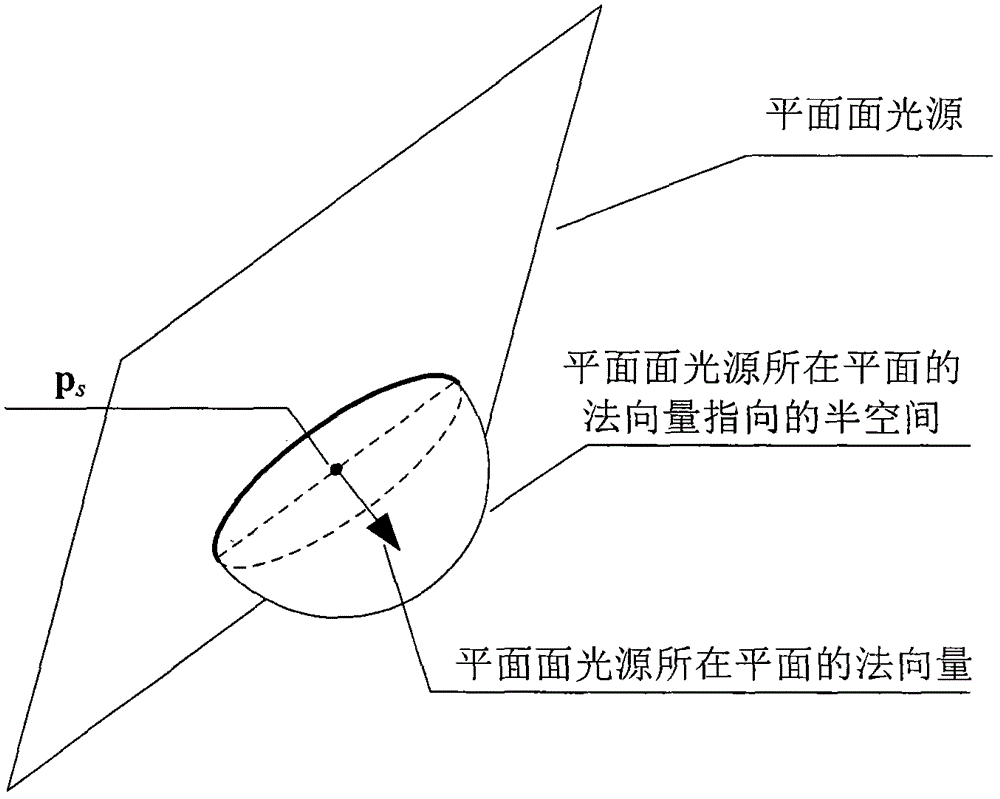

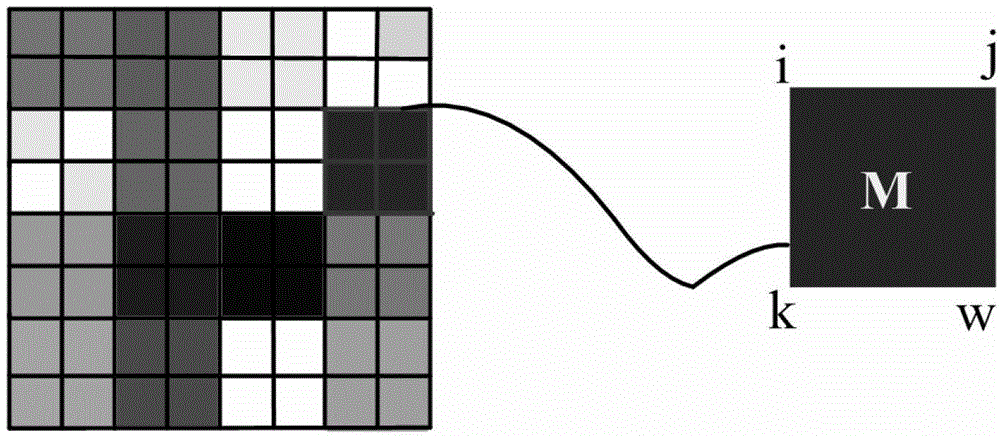

The invention provides a method for approximately drawing a soft shadow of a three-dimensional scene. The method comprises the following steps of estimating planar surface light source visibility in a visible scene area by randomly sampling planar surface light sources, and reducing planar surface light source visibility noise introduced through random sampling by utilizing spatial convolution smooth denoising and filtering; utilizing a ray casting technology, calculating illumination contribution of the planar surface light sources visibility data to a visible scene point according to the obtained planar surface light source visibility data of the visible scene point, finally calculating a color value of the visible scene point based on the illumination contribution, and drawing a three-dimensional scene picture comprising the soft shadow. According to the method, the drawing quality of the three-dimensional scene picture can be ensured, and the drawing speed is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

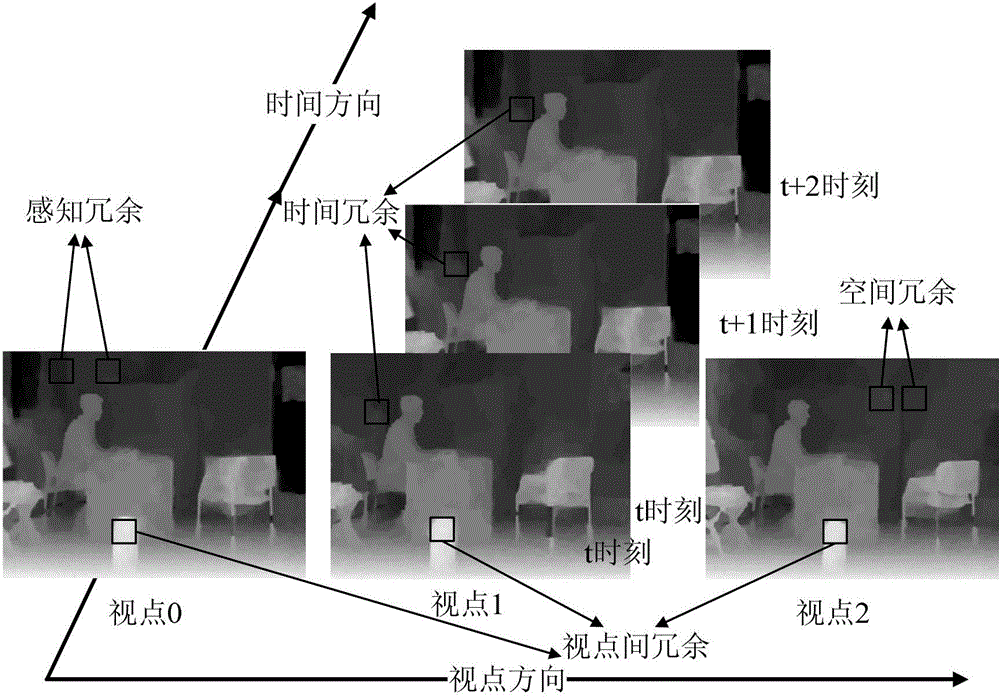

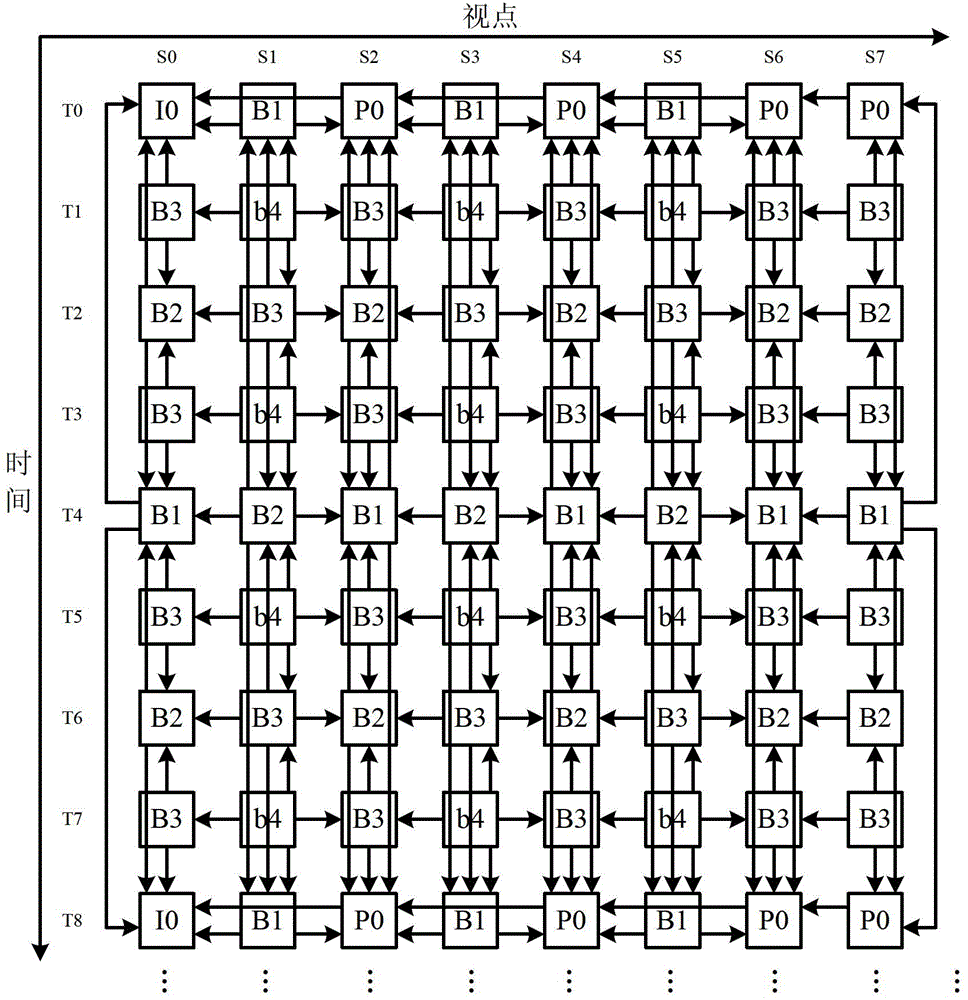

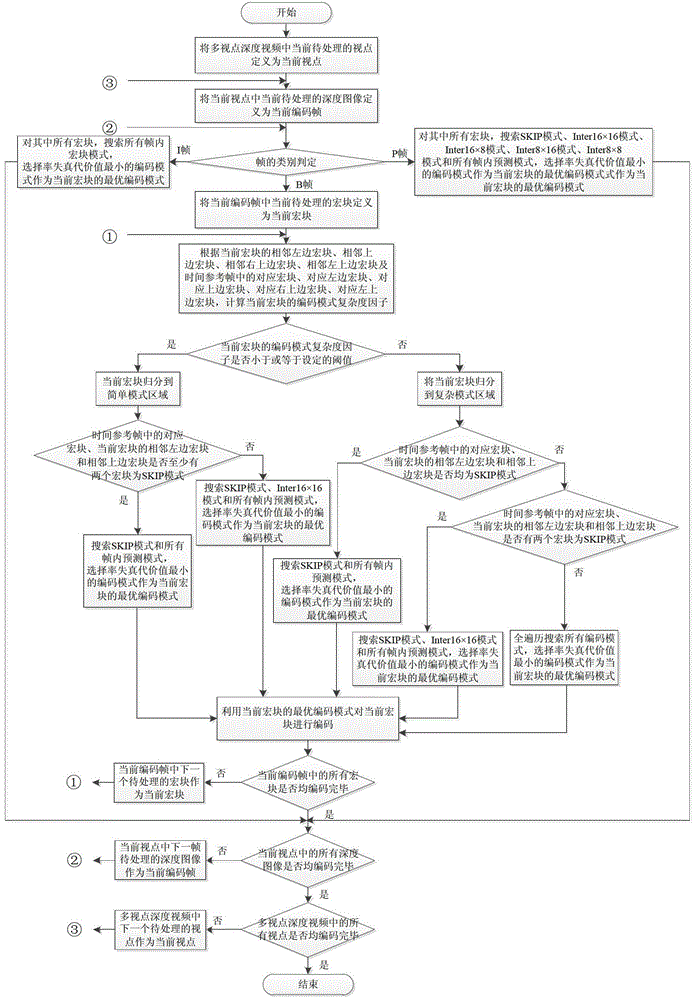

Multi-view depth video fast coding method

ActiveCN103338370ADoes not affect the encoding rateGuaranteed drawing qualityTelevision systemsSteroscopic systemsViewpointsComputation complexity

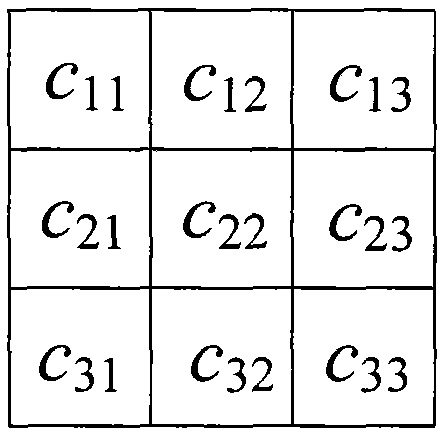

The invention discloses a multi-view depth video fast coding method. A coding mode complexity factor of a macro block is provided; the macro block is attributed to a simple mode zone or a complex mode zone according to the coding mode complexity factor, namely, a depth video is divided into the simple mode zone and the complex mode zone, and different fast coding mode selection strategies are adopted according to different zones; search for simple coding modes is performed for a macro block in the simple mode zone, and search for complex coding modes is performed for a macro block in the complex mode zone; and therefore, little-contributed time-consuming coding mode search in the coding process of a current coding frame can be avoided. As a result, under the premise that virtual viewpoint rendering quality is ensured and the bit rate of depth video coding is not affected, the computation complexity of multi-view depth video coding can be effectively reduced, and the coding time of the multi-view depth video coding can be saved.

Owner:NINGBO UNIV

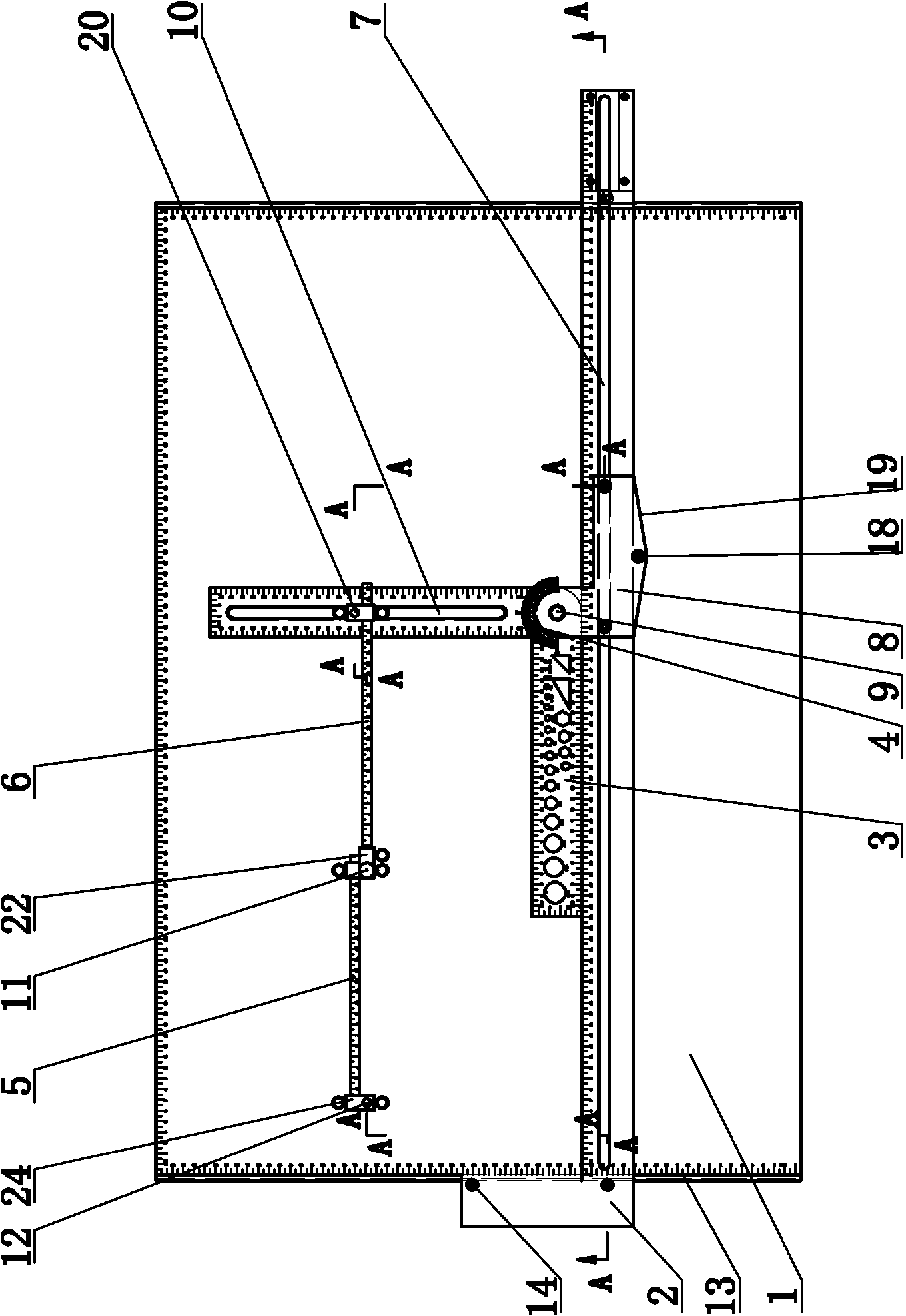

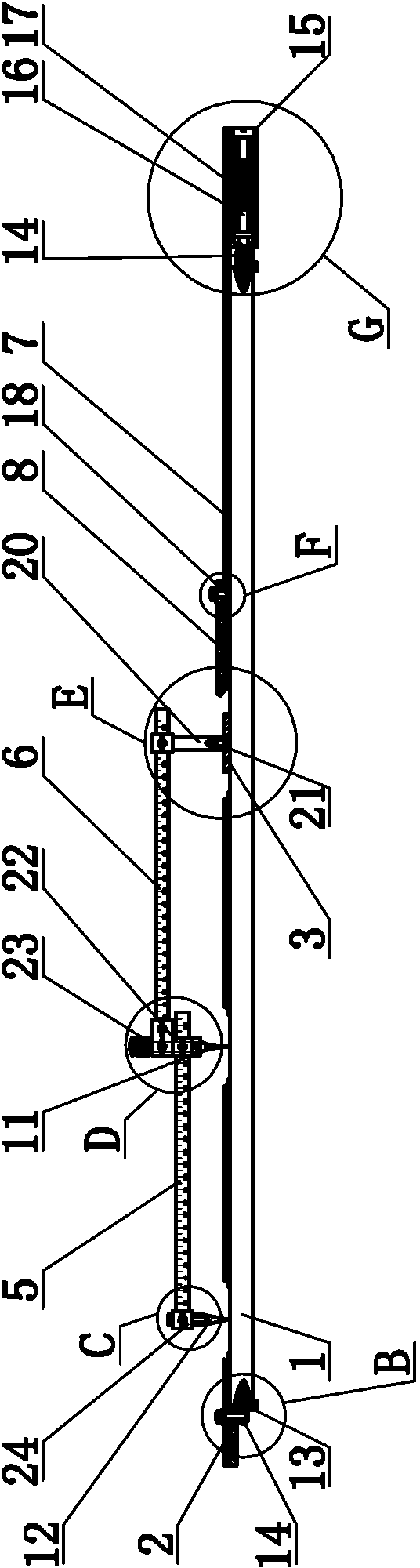

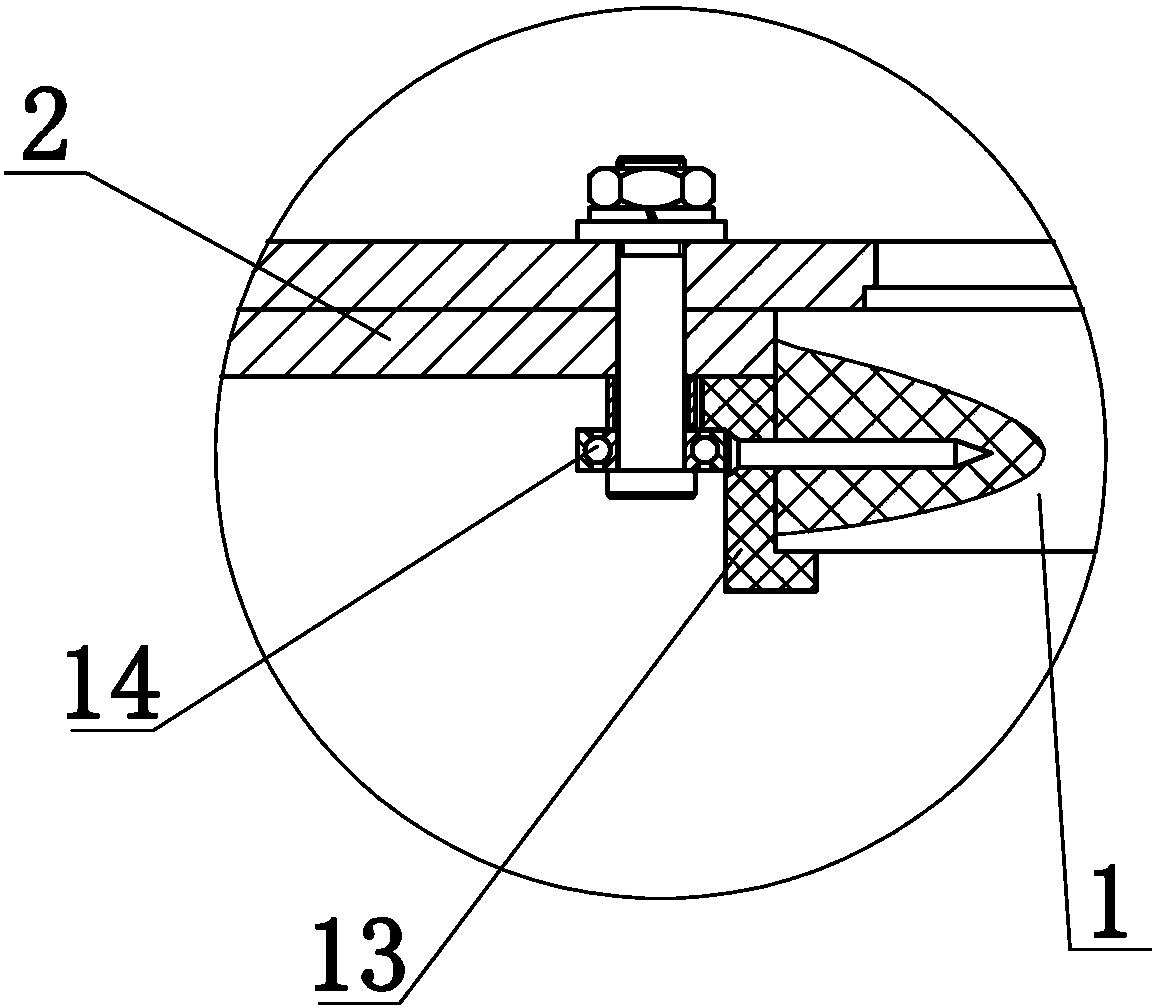

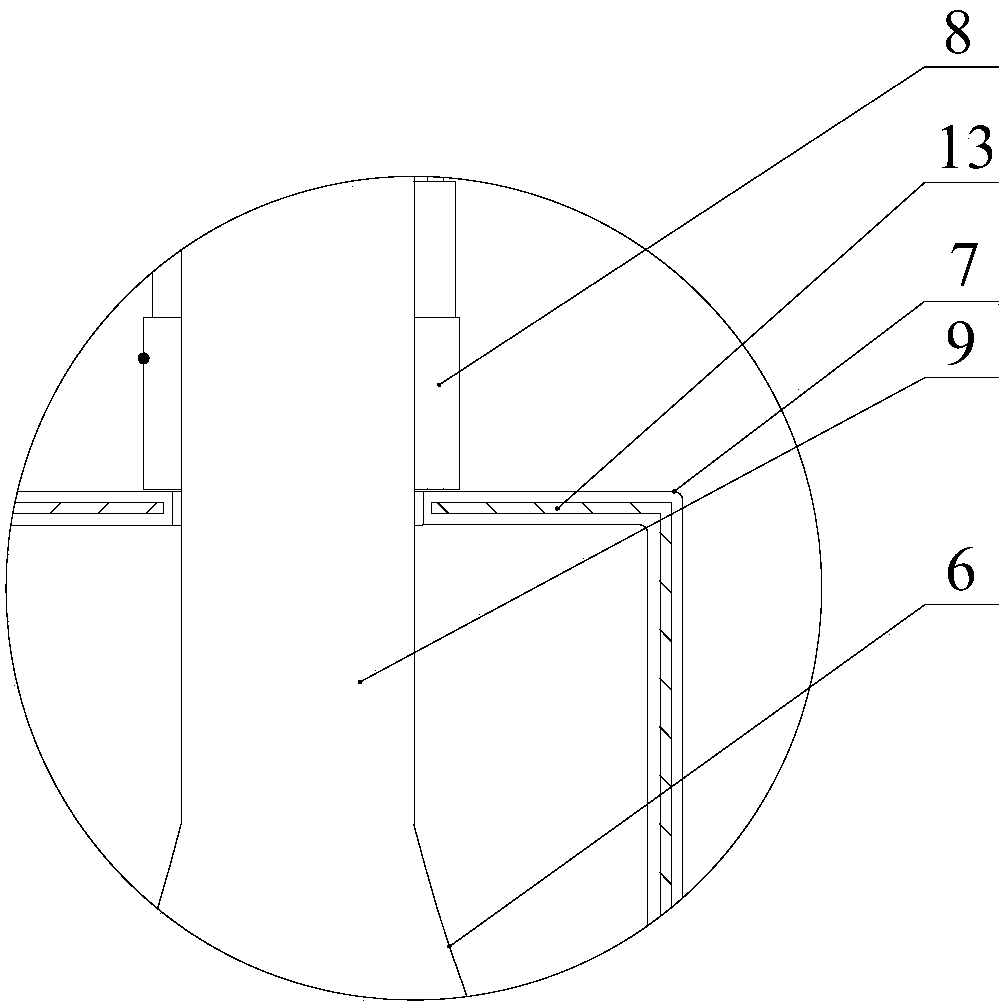

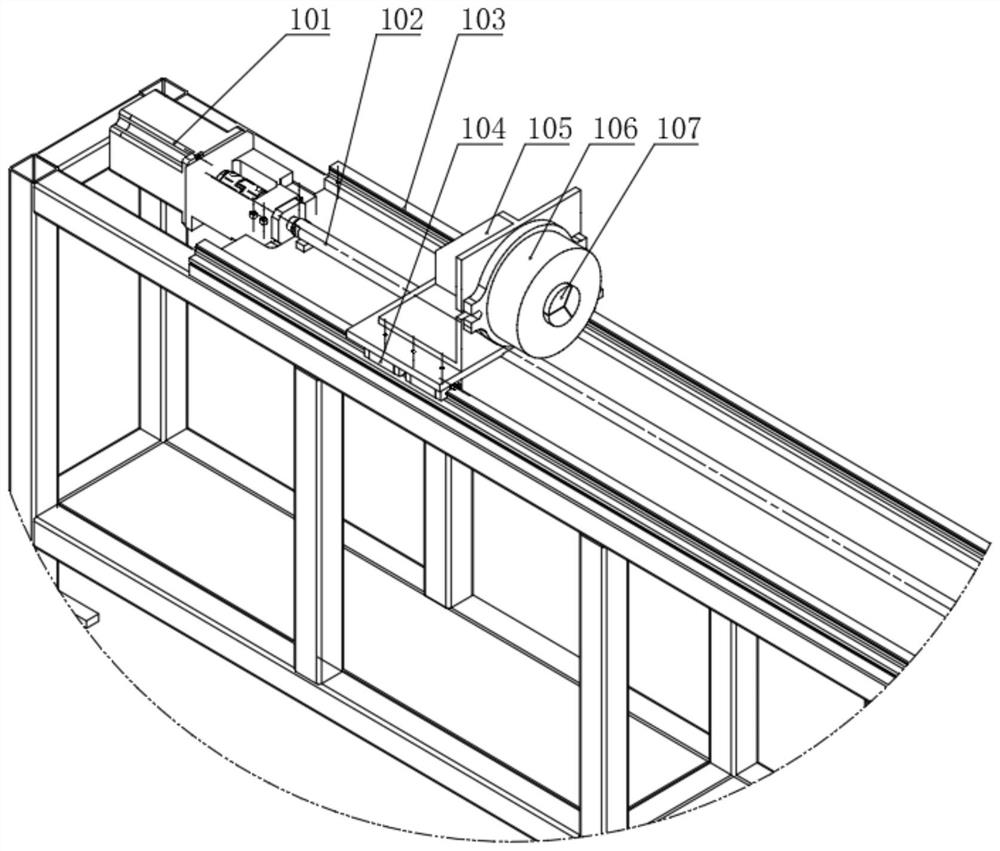

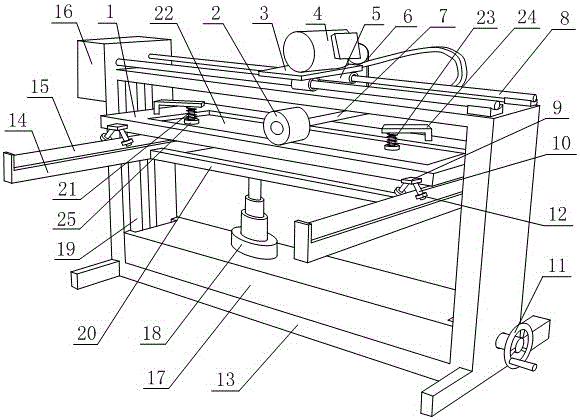

Combined type drawing device of ruler drawing board

The invention relates to a combined type drawing device of a ruler drawing board. The combined type drawing device comprises a T-square, wherein the T-square is arranged on the drawing board and moves up and down along the two sides of the drawing board, a horizontal sliding chute is arranged in the middle of the T-square, an angle measure connecting board moves along the horizontal sliding chute, an angle gauge is arranged at the upper end of the angle measure connecting board, an angle square is connected with the angle gauge through an angle measure rotary shaft, a vertical sliding chute is arranged in one side of the angle square, one end of a supporting ruler moves along the vertical sliding chute, the other end of the supporting ruler is provided with a scriber and connected with one end of a rotating ruler, a pencil is arranged at the other end of the rotating ruler, and a compass is formed by the rotating ruler, the scriber and the pencil. The combined type drawing device combines the drawing board, the T-square, the angle square, the angle gauge, the compass and the like, horizontal lines, vertical lines, straight lines at different angles, circles and others can be drawn, and the drawing device is simple in structure, multifunctional, convenient to carry and capable of effectively improving drawing efficiency and guaranteeing drawing quality and capable of effectively reducing lose possibility.

Owner:HUANGHE S & T COLLEGE +1

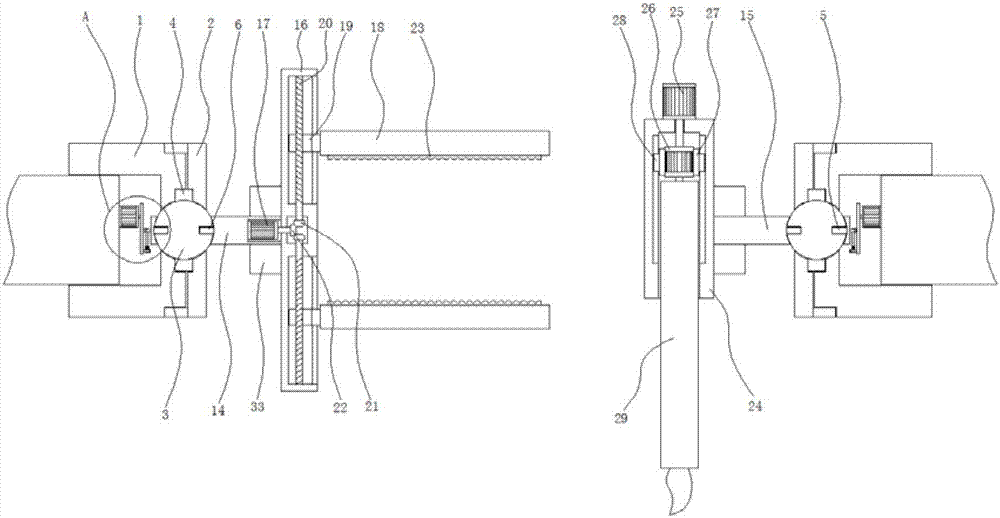

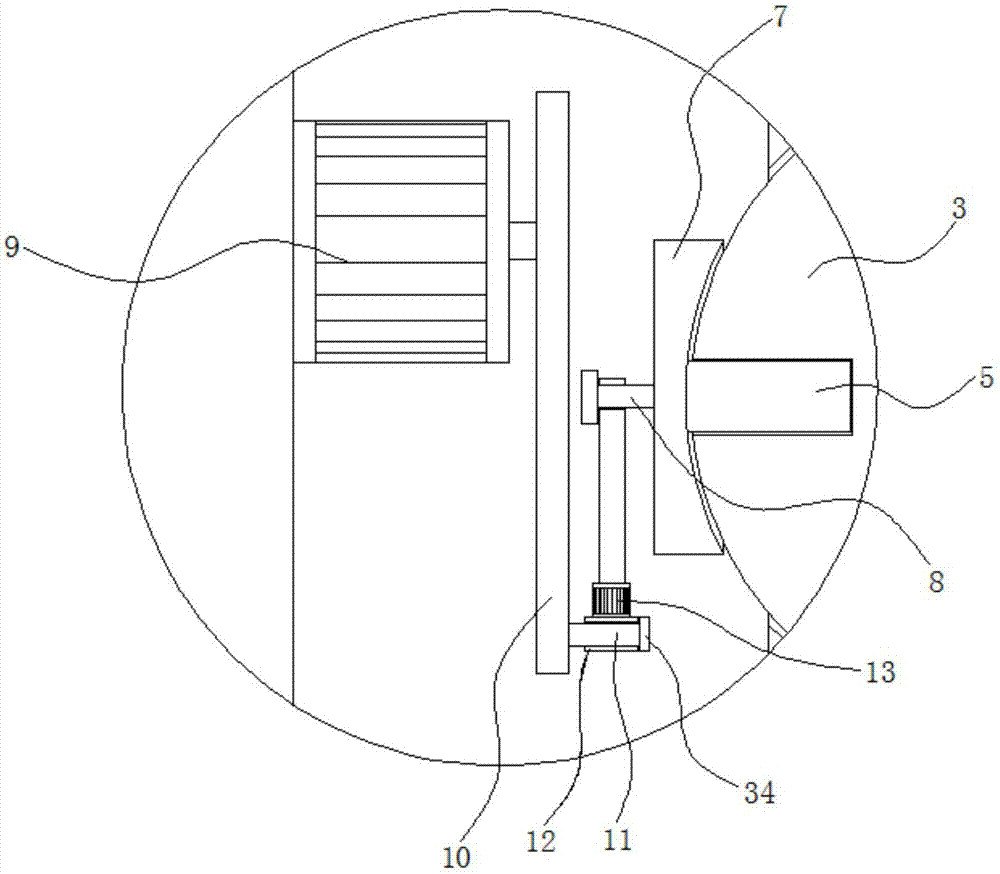

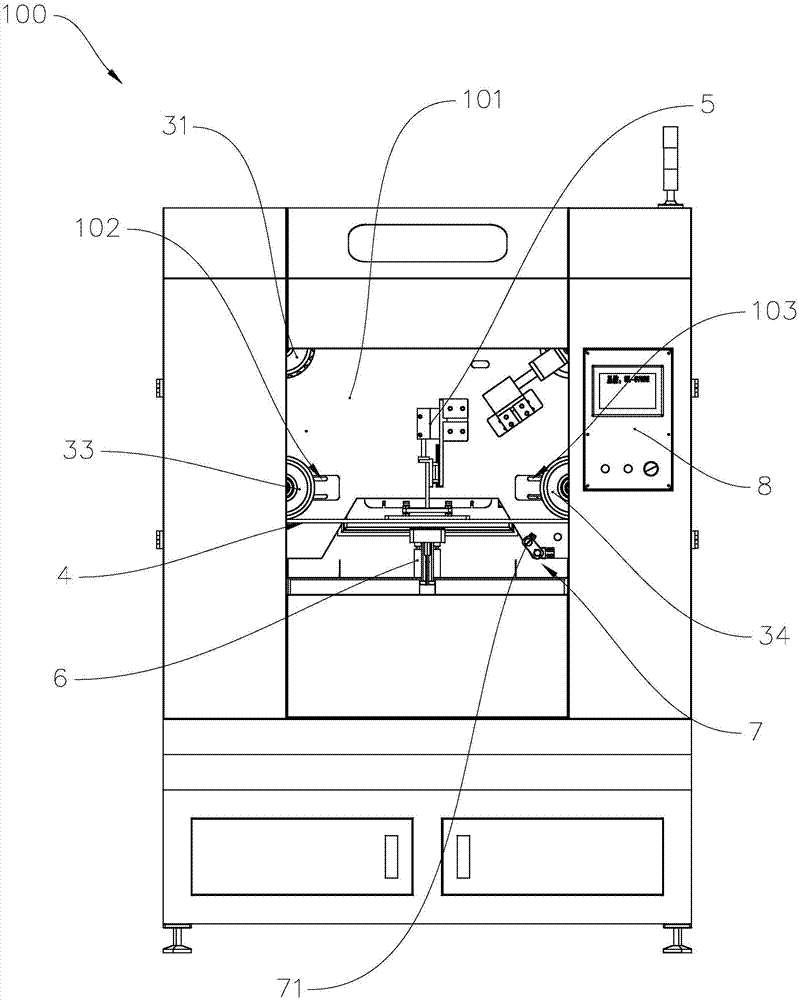

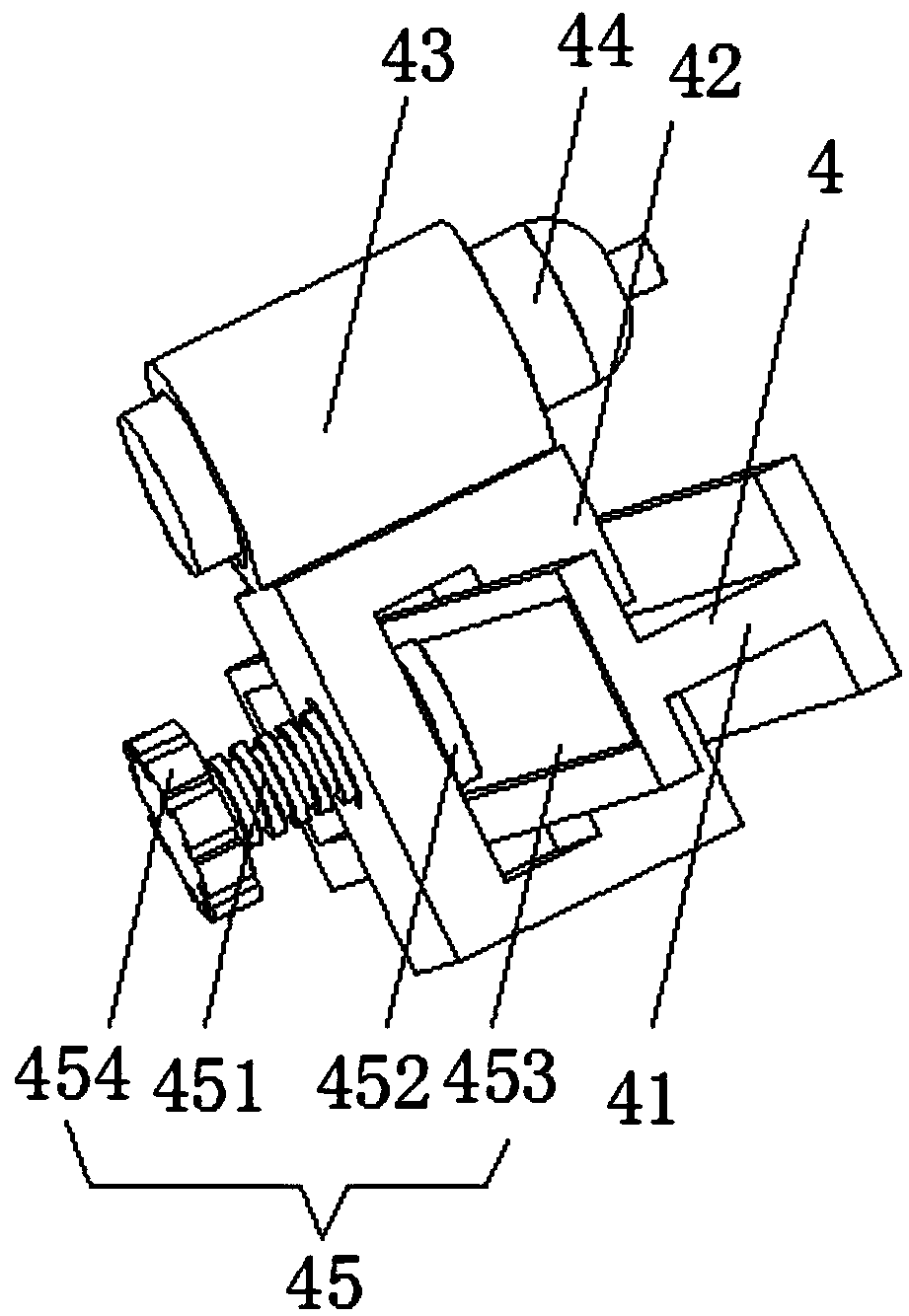

Drawing clamping device for robot

InactiveCN107471223ASmooth rotationThe drive of the rotating motor is convenientOther artistic work equipmentsManipulatorEngineeringDrawing board

The invention discloses a painting clamping device for a robot, which comprises connecting sleeves which are respectively threaded on the ends of two arms of the robot; The outer wall on one side of the arm is provided with an annular connecting groove corresponding to the fixed sleeve, and the fixed sleeve is threadedly connected to the inner wall of the annular connecting groove, and the bottoms of the connecting sleeve and the fixed sleeve are respectively provided with oppositely arranged first fixing grooves. The first fixed port and the second fixed port are provided with a connecting ball, and a friction ring is set on the connected ball, and the inner side walls of the first fixed port and the second fixed port are All are provided with an annular fixing groove corresponding to the friction ring. The invention is simple in structure, easy to use, can stably clamp the drawing board and the paintbrush, and at the same time, it is convenient to control the deflection of the drawing board and the paintbrush, facilitate the smooth progress of drawing, improve the drawing efficiency and ensure the drawing quality.

Owner:重庆胡柚塔文化传播有限公司

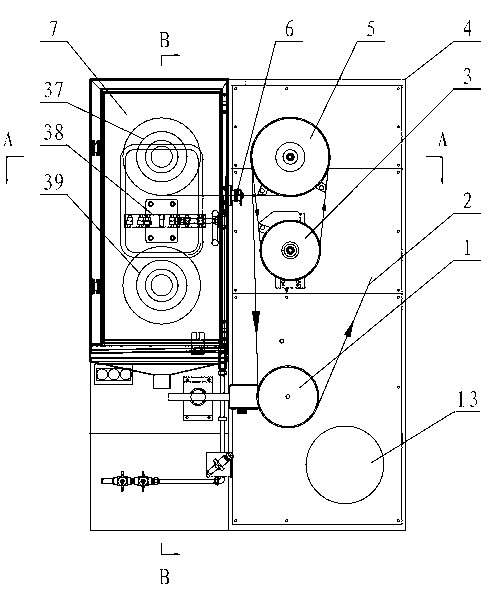

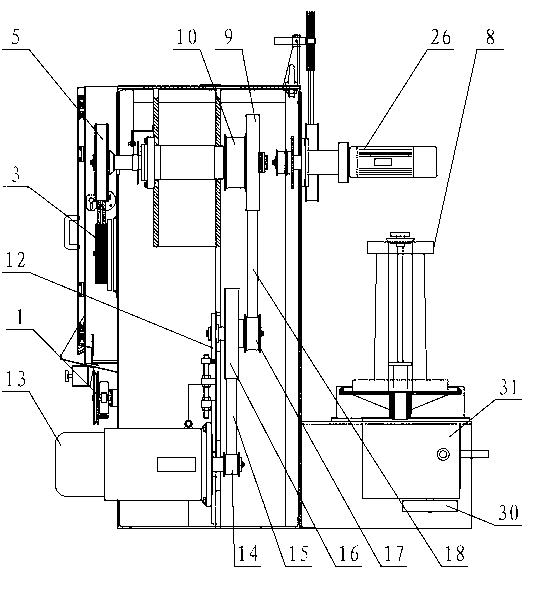

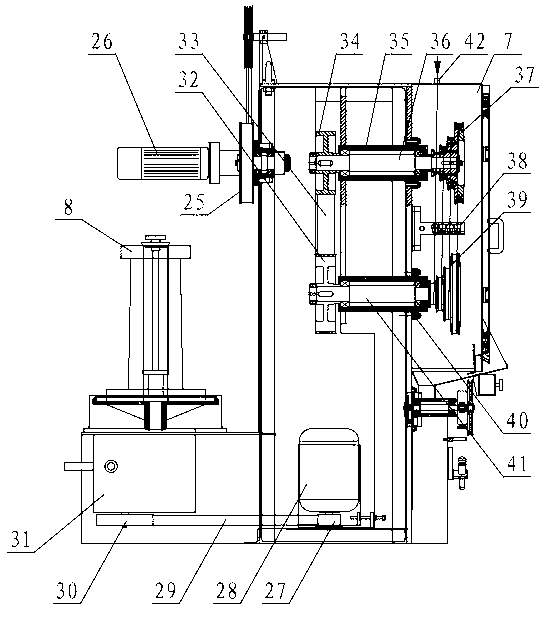

Wire drawing machine

The present invention discloses a wire drawing machine. The wire drawing machine comprises a plurality of wire laying-off devices, a wire drawing device positioned on the rear of the wire laying-off devices, and a wire collecting device positioned on the rear of the wire drawing device. The wire laying-off device comprises a base fixed on the ground, wherein the base is provided with a standing rod, and a reel is arranged on the top of the standing rod. The wire drawing device comprises a plurality of wire drawing capstans for medal wire winding, a plurality of extrusion molds are arranged between the two wire drawing capstans, a plurality of the wire drawing capstans are transmitted through gears, and form transmission connections with a main motor. According to the present invention, the wiring harness is placed on the base of the wire laying-off devices, then the wire is pulled up, such that the medal wire steps across the reel arranged on the top of the standing rod; then the medal wire is wound the wire drawing capstans, and then passes through the extrusion molds, the main motor is started, such that the metal wire moves forwardly and slowly, and finally the stretched metal wire is collected through the wire collecting device; the automation degree of the whole production process is high; the wire drawing machine provided by the present invention has advantages of compact structure, low equipment cost, small land occupation, low energy consumption and uniform wire drawing.

Owner:姜利湘

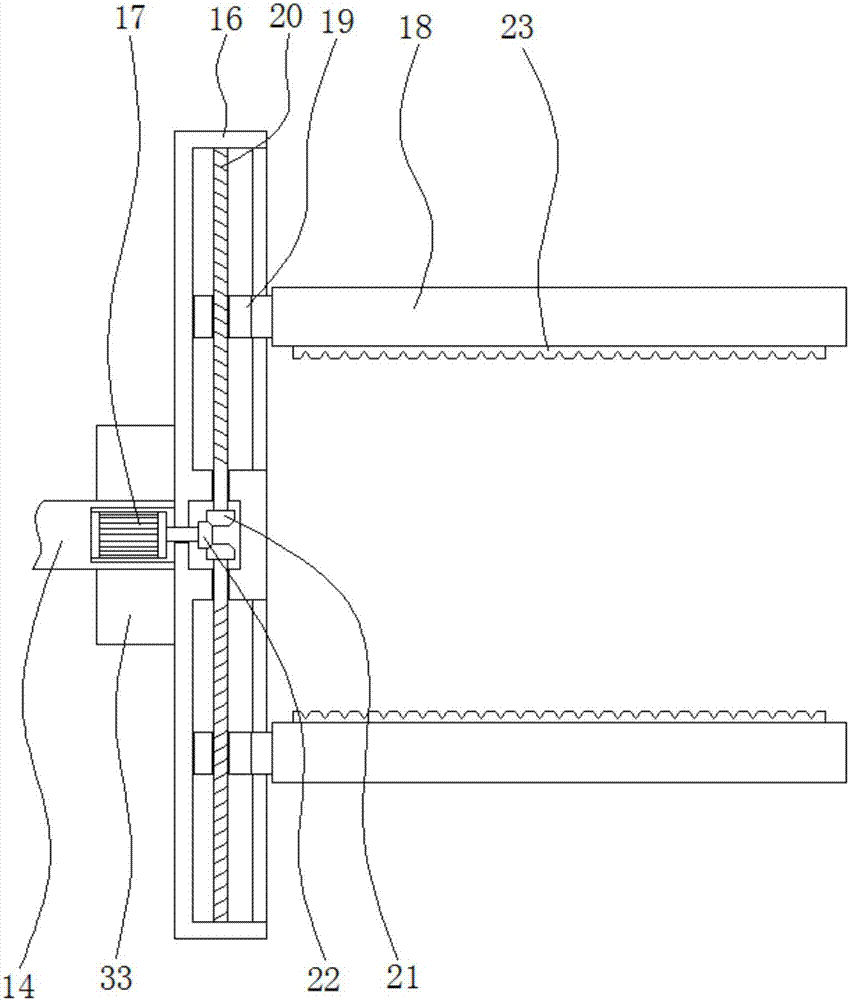

Tension-adjustable extruding and drawing device of drawing frame

The invention discloses a tension-adjustable extruding and drawing device of a drawing frame. The tension-adjustable extruding and drawing device of the drawing frame comprises a base, wherein four first fixing plates are symmetrically welded to the top end of the base; limiting grooves are separately formed in the middles of each two first fixing plates; a first connecting rod is embedded in eachlimiting groove, and toothed plates are separately welded to two ends of each first connecting rod; a second connecting rod is welded between the two toothed plates, and one end surfaces of the two toothed plates are connected with gears in an engaged manner; and a crank is welded to one end surface of each gear, and a rotating rod is arranged between the two gears. The gears, the toothed plates,the cranks, the first connecting rod and the second connecting rod are respectively arranged on the two sides of an extruding roller, so that slivers to be extruded on the two sides of the extrudingroller can be adjusted in different tensioning degrees, the tensioning degrees of the slivers to be extruded on the two sides of the extruding roller are conveniently kept moderate, the extruding effect is good, and the drawing efficiency is improved.

Owner:长兴超特纺织有限公司

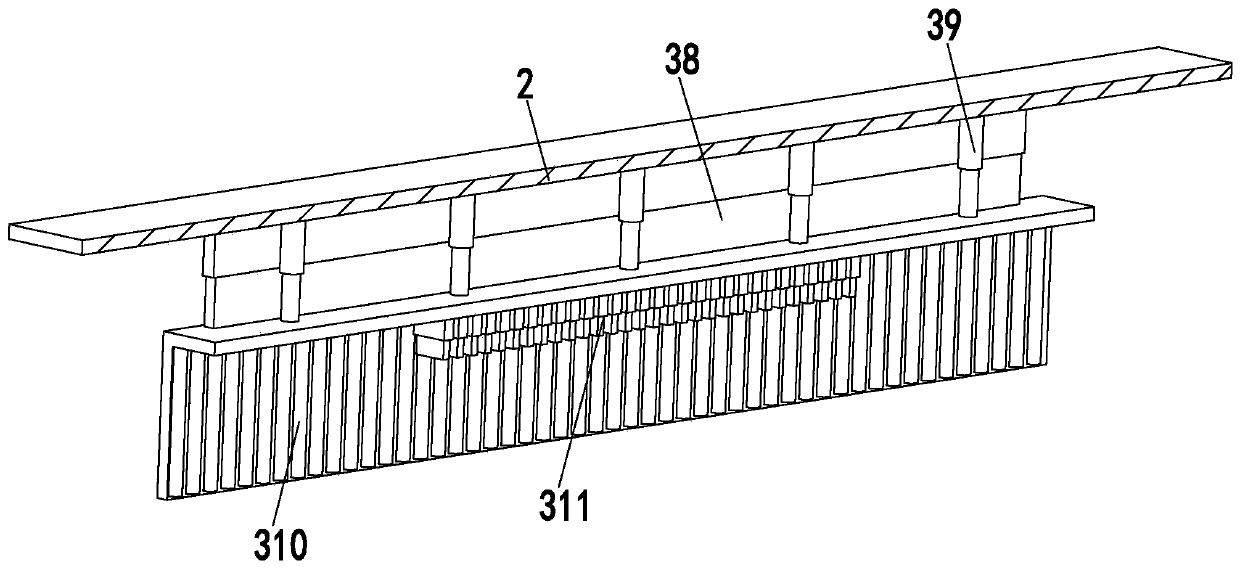

Wire drawing bushing for basalt fiber processing

ActiveCN110698052ADoes not affect the outflow effectGuaranteed drawing qualityGlass making apparatusEngineeringBasalt fiber

The invention relates to the field of basalt fiber processing equipment, and discloses a wire drawing bushing plate for basalt fiber processing. The wire drawing bushing plate for basalt fiber processing comprises a bushing plate shell, a bottom plate, discharge spouts, electrodes, preheating plates and reinforcing ribs; the bottom plate is arranged at the bottom of the bushing plate shell, two opposite electrodes are electrically connected to the two sides of the bottom plate, and the discharge spouts arranged at equal intervals are formed in the bottom of the bottom plate; two preheating plates are arranged in a bushing plate shell; flowing molten liquid is heated by the preheating plates, so that the to-be-drawn molten liquid is uniformly and sufficiently heated; the depth of the bottomplate discharge spouts is also reduced, so that wire drawing work can be carried out conveniently, and it is effectively guaranteed that the to-be-drawn molten liquid located above the bottom plate is sufficiently and evenly heated; the depth of the discharge spouts is small, so that the influence on heat exchange is small, the problem that the discharge spouts are blocked because of crystallization when the temperature of the molten liquid is not high enough is solved without influencing molten liquid flowing out effect, and blocking substances at openings of the discharge spouts are easy toclean.

Owner:太原市鼎泰达建材有限公司

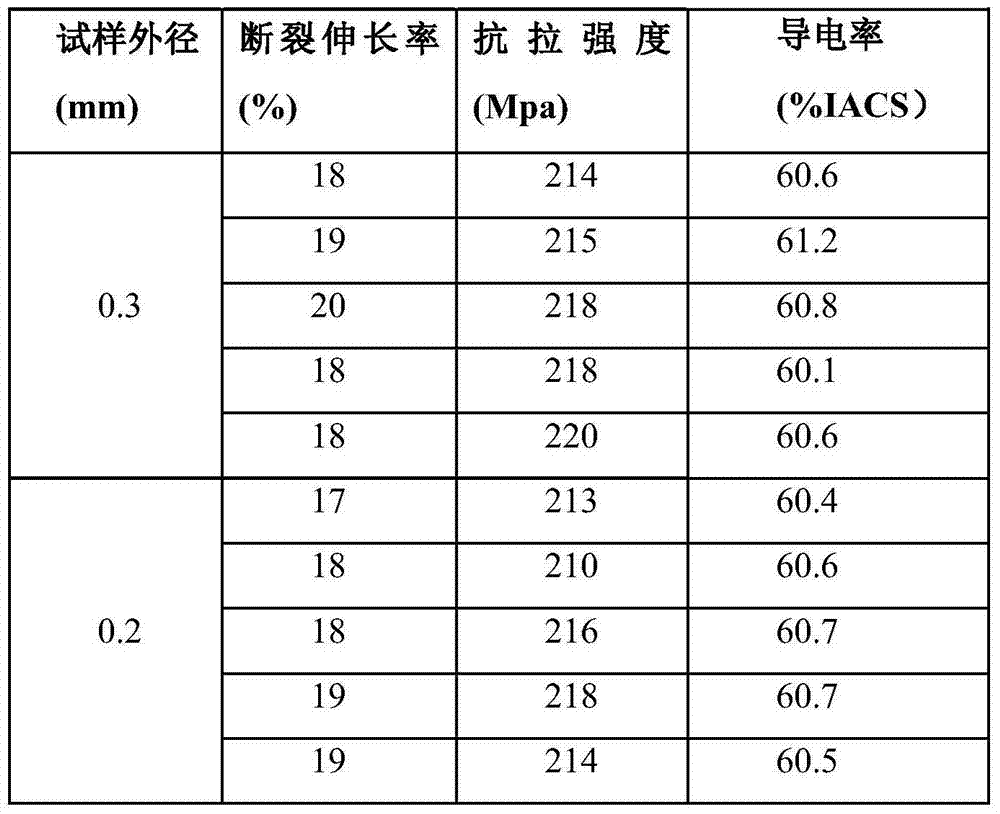

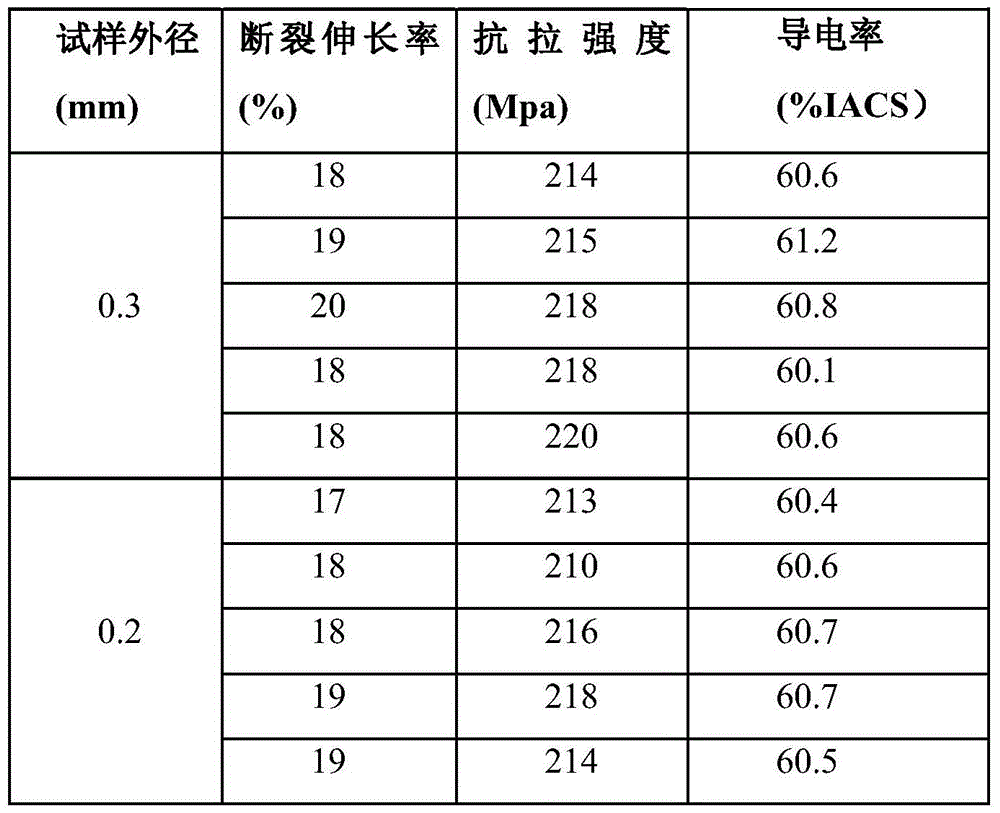

Manufacturing method for aluminum alloy fine wires

InactiveCN104715803AGuaranteed cleanlinessGuaranteed drawing qualityMetal/alloy conductorsCable/conductor manufactureElectrical conductorAluminium alloy

The invention provides a manufacturing method for aluminum alloy fine wires. The manufacturing method for aluminum alloy fine wires includes the following steps of (a) the first time of drawing, wherein an aluminum alloy rod is drawn into an aluminum alloy line, and the drawing speed is 10-40 m / s; (b) the second time of drawing, the aluminum alloy line obtained from the step (a) is drawn into an aluminum alloy wire, and the drawing speed is 5-30 m / s; (c) the third time of drawing, wherein the aluminum alloy wire obtained from the step (b) is drawn into an aluminum alloy fine wire, and the drawing speed is 5-30 m / s; (d) a heat treatment process, wherein the aluminum alloy fine wire obtained from the step (c) is treated according to the process of heating-heat and preservation-cooling. By means of the manufacturing method for aluminum alloy fine wires, aluminum alloy materials can be drawn into single wires with good mechanical performance and anti-fatigue performance, and the single wires meet the requirements of fifth-class / sixth-class conductors in GB / T3956 and can be used as flexible conductors.

Owner:TONGYONG TIANJIN ALUMINUM ALLOY PROD CO LTD

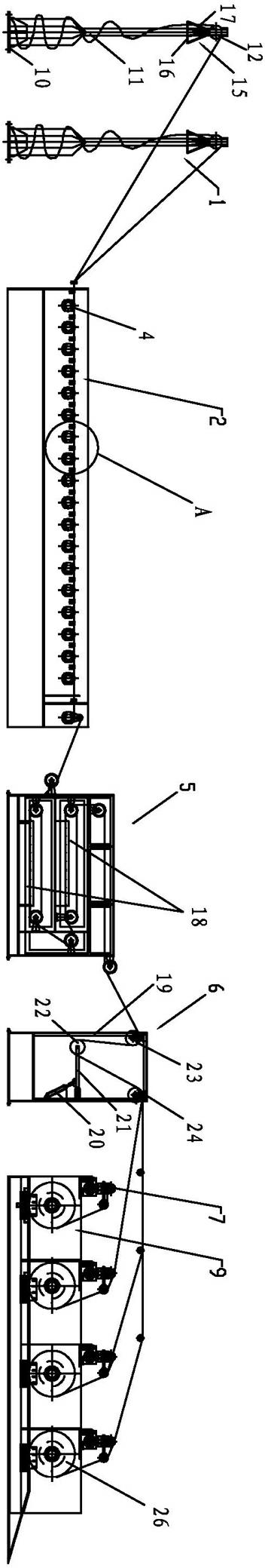

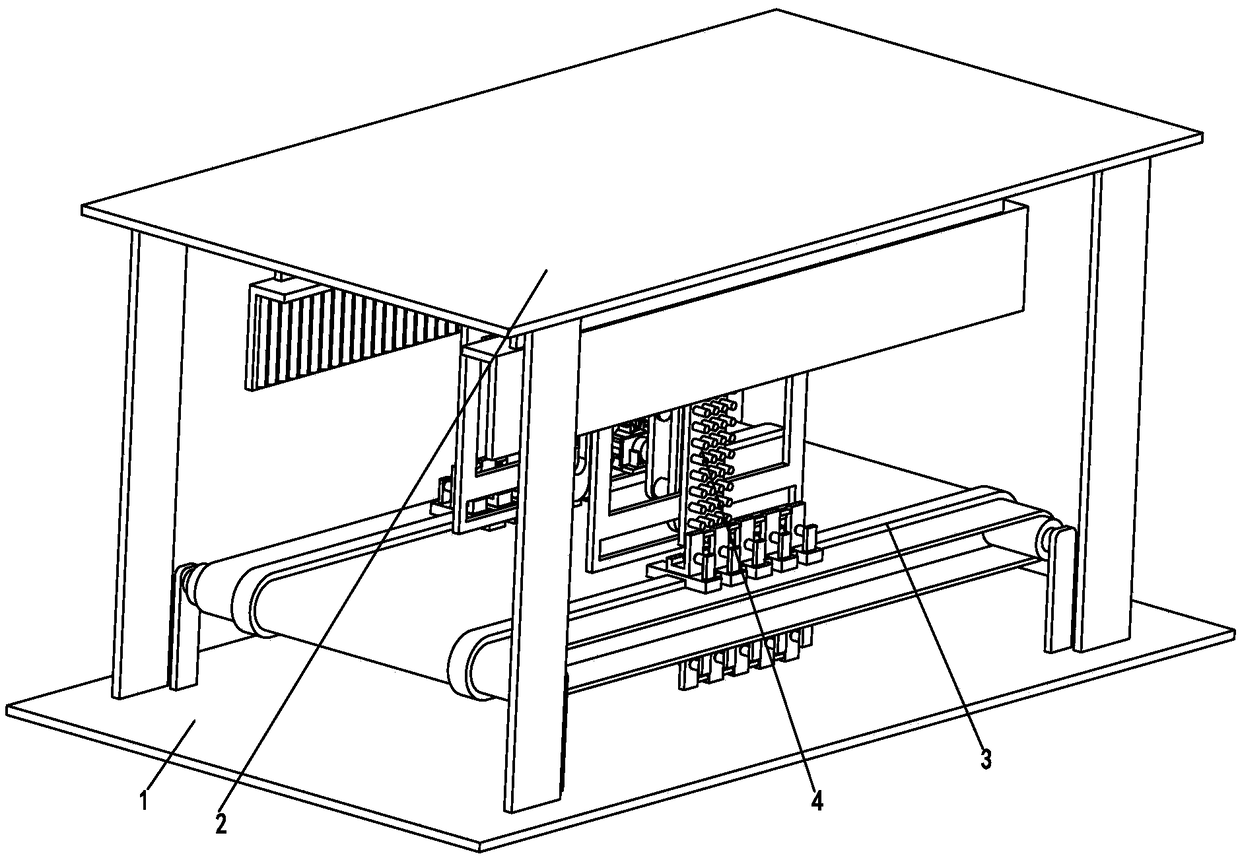

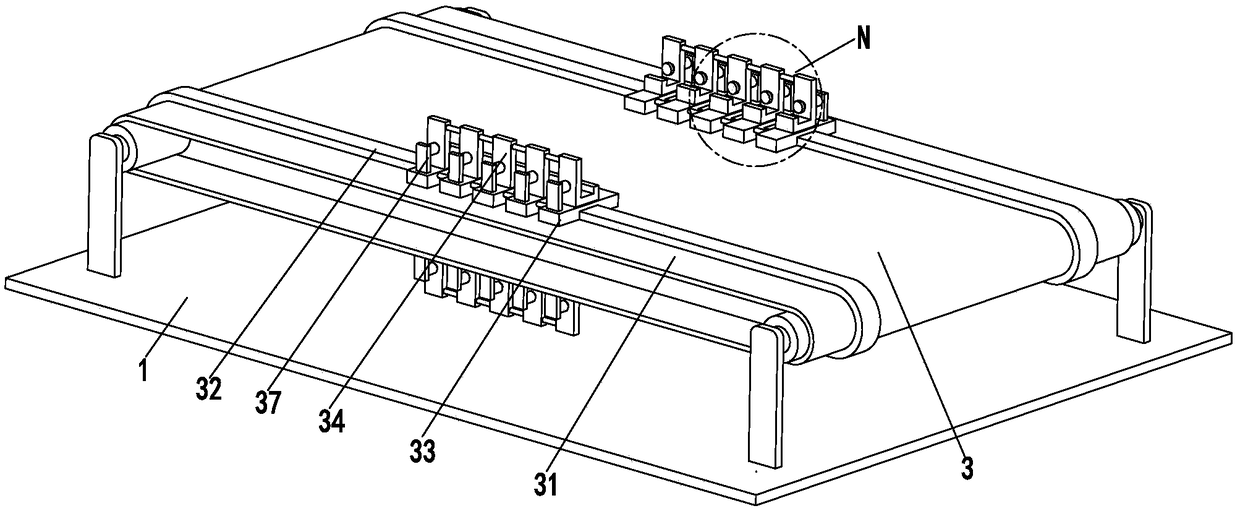

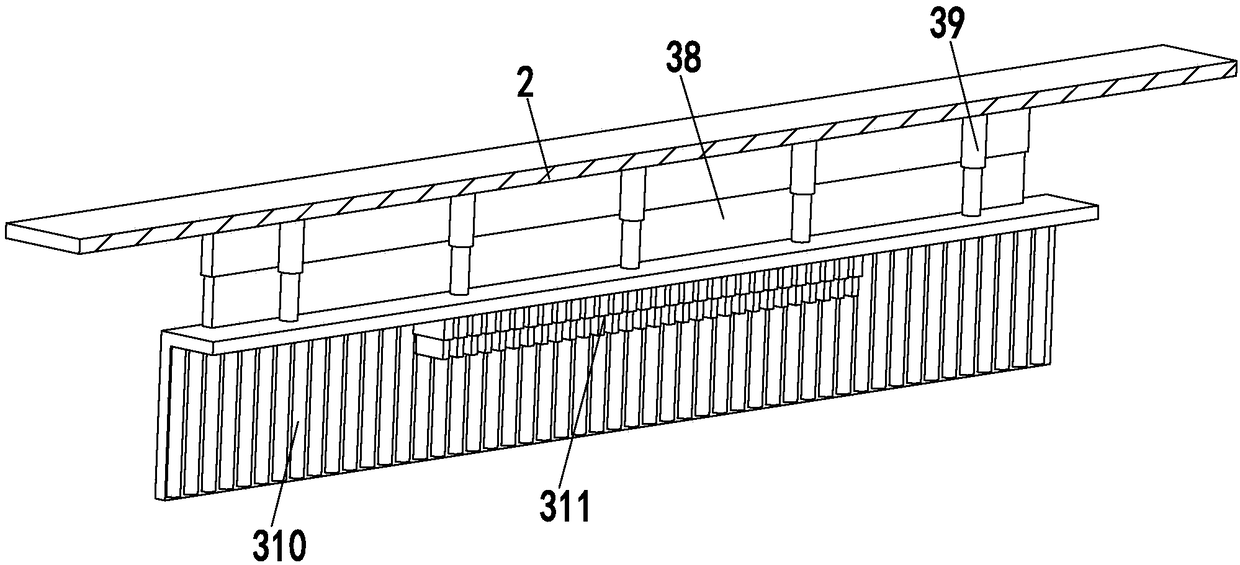

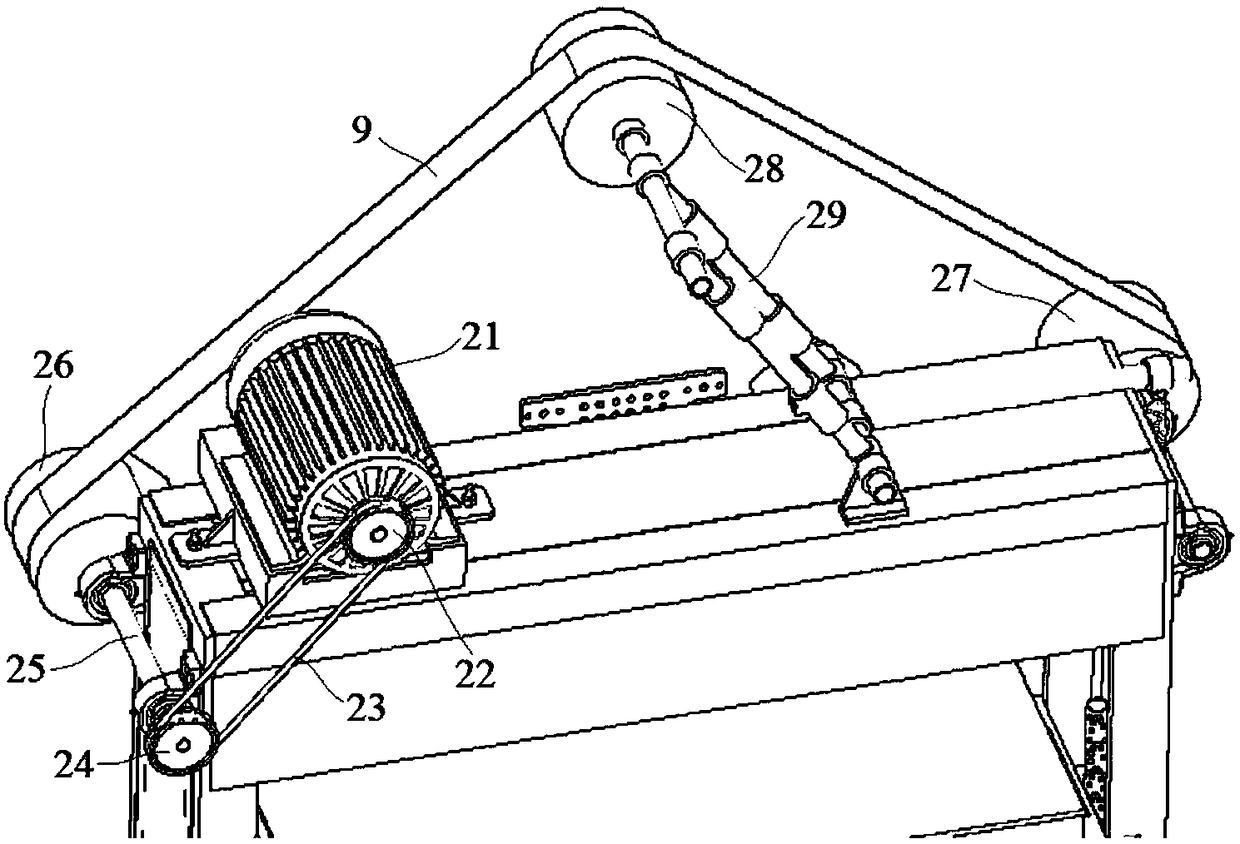

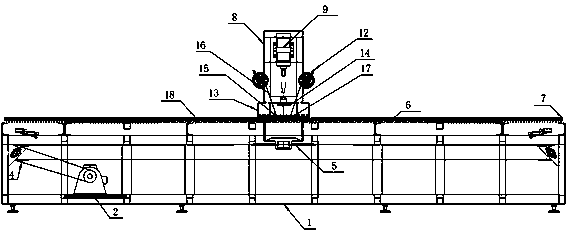

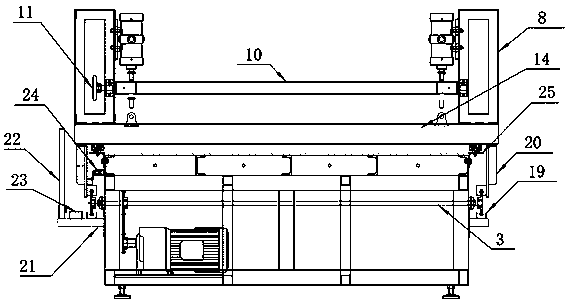

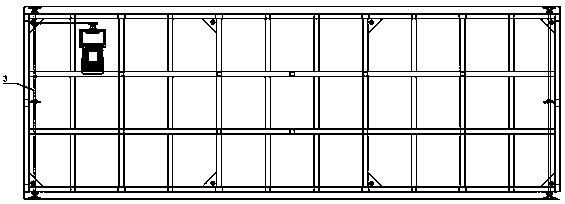

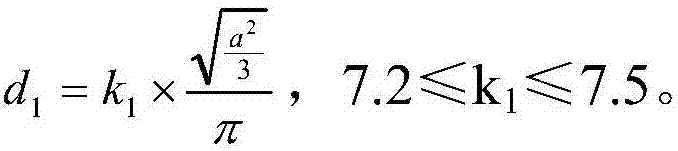

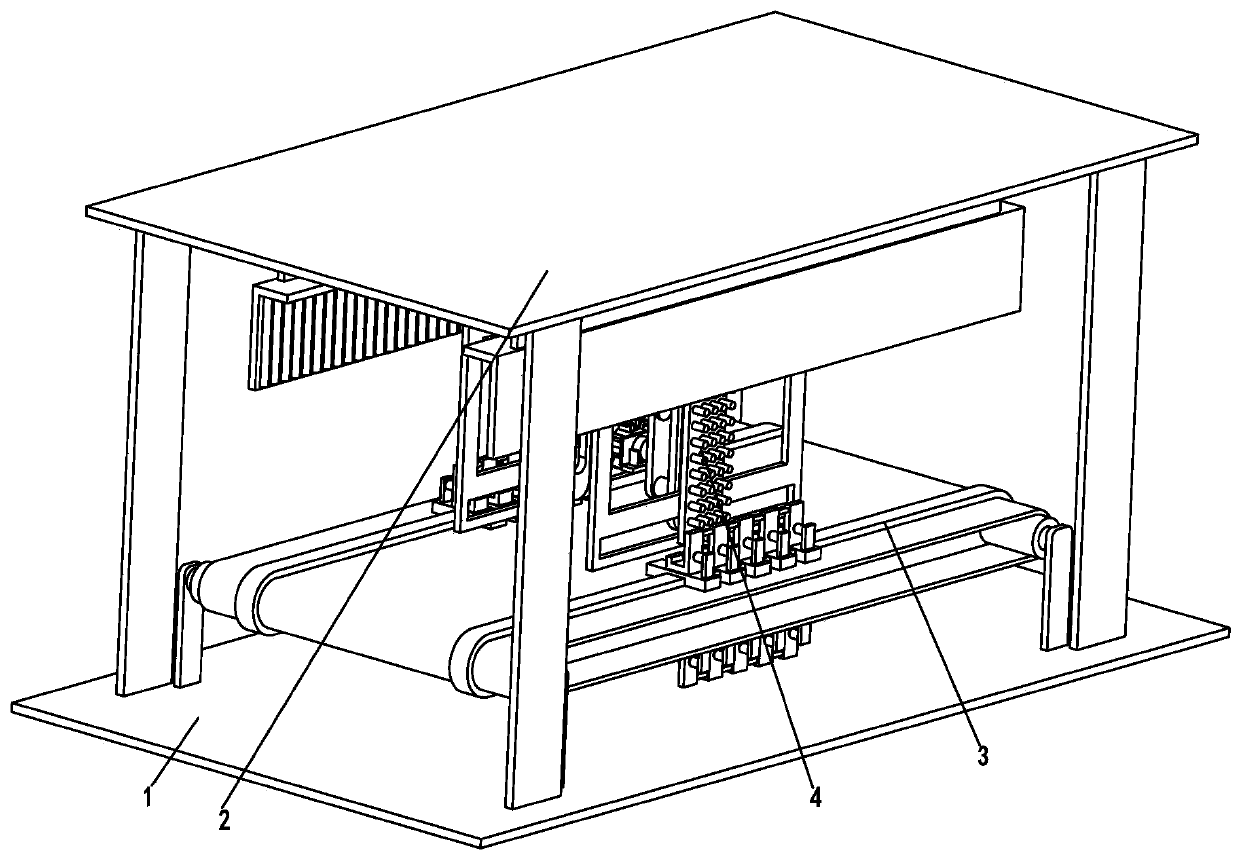

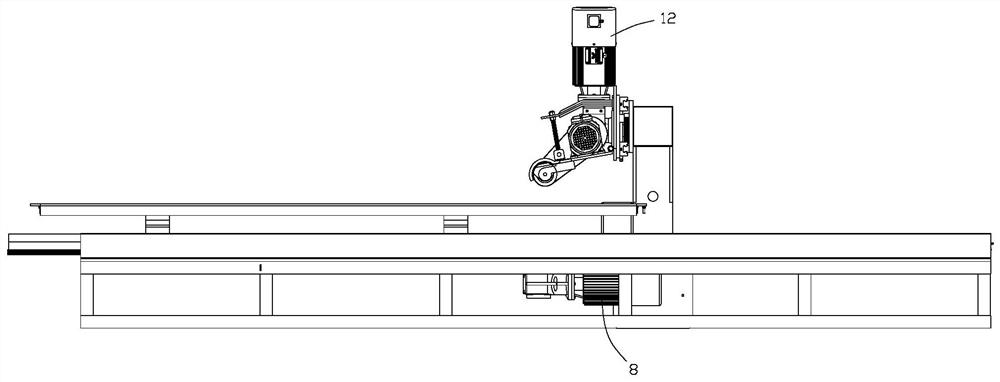

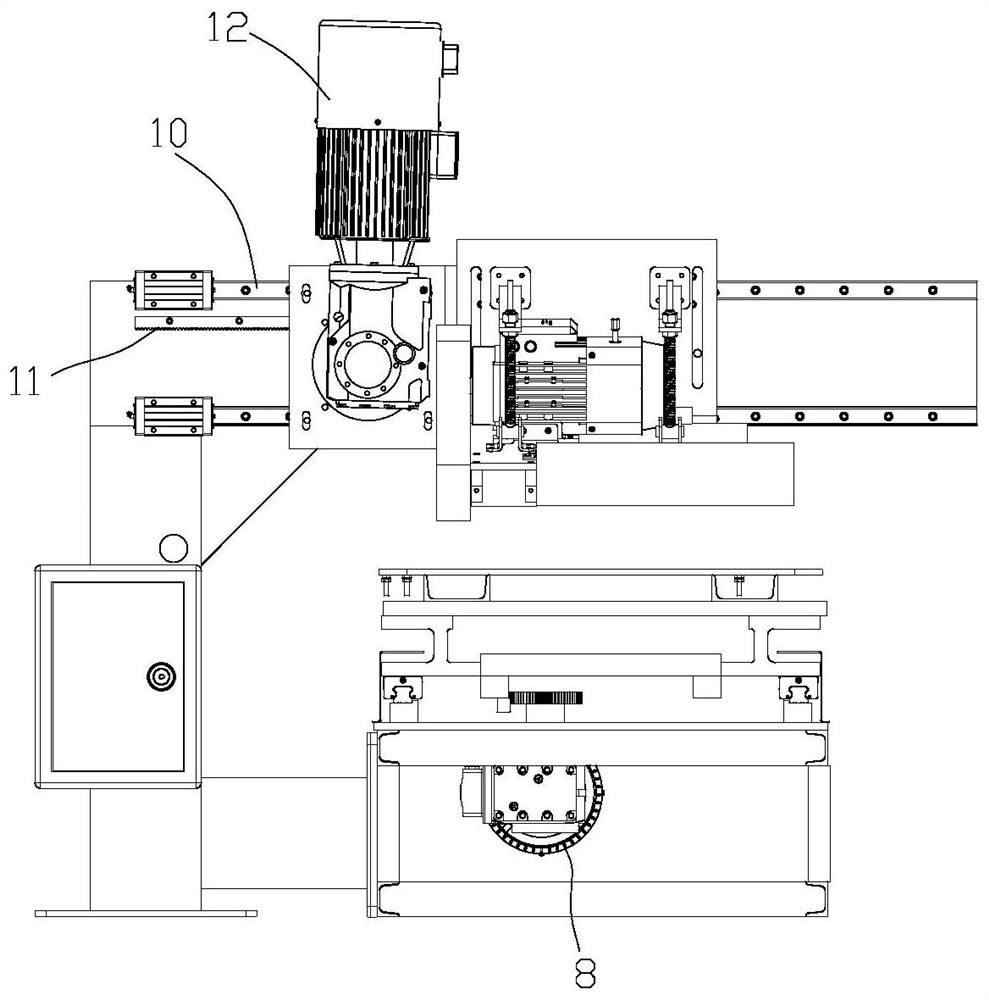

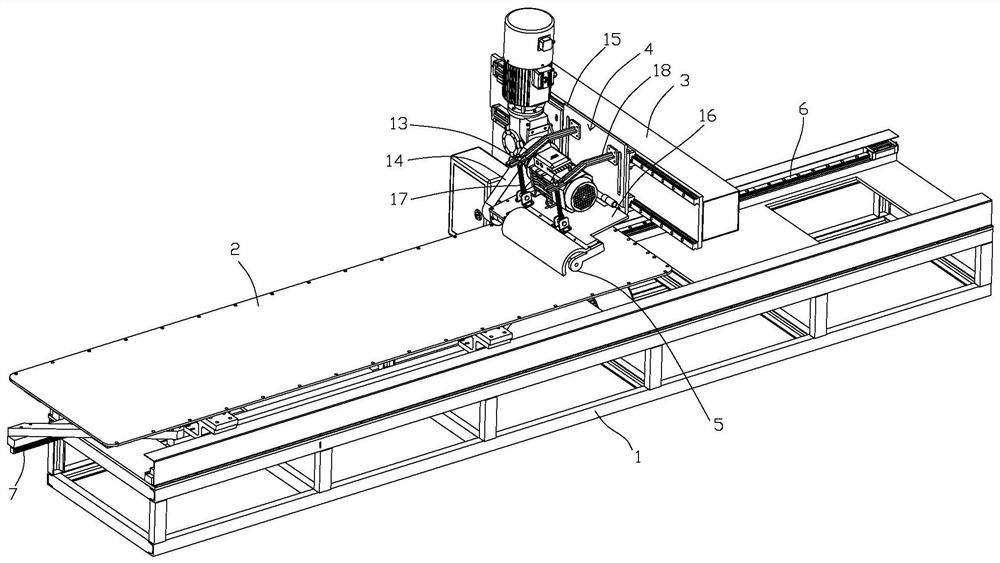

Metal plate wire drawing system and wire drawing technology of system

ActiveCN108857648AImprove work efficiencyImprove stabilityGrinding feedersPlane surface grinding machinesEngineeringMetal

The invention relates to a metal plate wire drawing system and a wire drawing technology of the system. The system comprises a bottom plate, a mounting frame, a conveying device and a wire drawing device, a mounting frame is installed on the bottom plate, and the wire drawing device is arranged on the mounting frame; the conveying device is arranged at the lower end of the wire drawing device, theconveying device is installed on the bottom plate, and the conveying device comprises a workbench, a guide rail, an electric sliding block, a storage frame, an extruding air cylinder, an extruding plate, a fixing plate, a lifting telescopic plate, a lifting air cylinder, an auxiliary frame and a limiting telescopic plate; the wire drawing device comprises a driving mechanism and a wire drawing mechanism. The metal plate wire drawing system can solve the problems that in an existing metal plate wire drawing process, only one metal plate can be processed at a time, the work efficiency is low and the moving stability is poor, the automatic wire drawing function of metal plates can be achieved, and the system has the advantages that two plates can be processed at a time, the work efficiency is high and the moving stability is high.

Owner:广州市高比电梯装饰工程有限公司

Method for approximating soft shadows in 3D scenes

ActiveCN104346831BQuality improvementReduce noise3D-image rendering3D modellingComputer graphics (images)Physics

The present invention provides a method for approximately rendering soft shadows in a three-dimensional scene. This method estimates the visibility of the planar light source in the visible scene area by random sampling of the planar light source, and uses spatial convolution smoothing and denoising filtering to reduce the visibility noise of the planar light source introduced by random sampling; technology, according to the obtained visibility data of the plane light source of the visible scene point, calculate the illumination contribution of the plane light source to the visible scene point, and finally calculate the color value of the visible scene point based on this, and draw a soft Shaded 3D scene footage. The method can improve the drawing speed while ensuring the drawing quality of the three-dimensional scene picture.

Owner:CHANGCHUN UNIV OF SCI & TECH

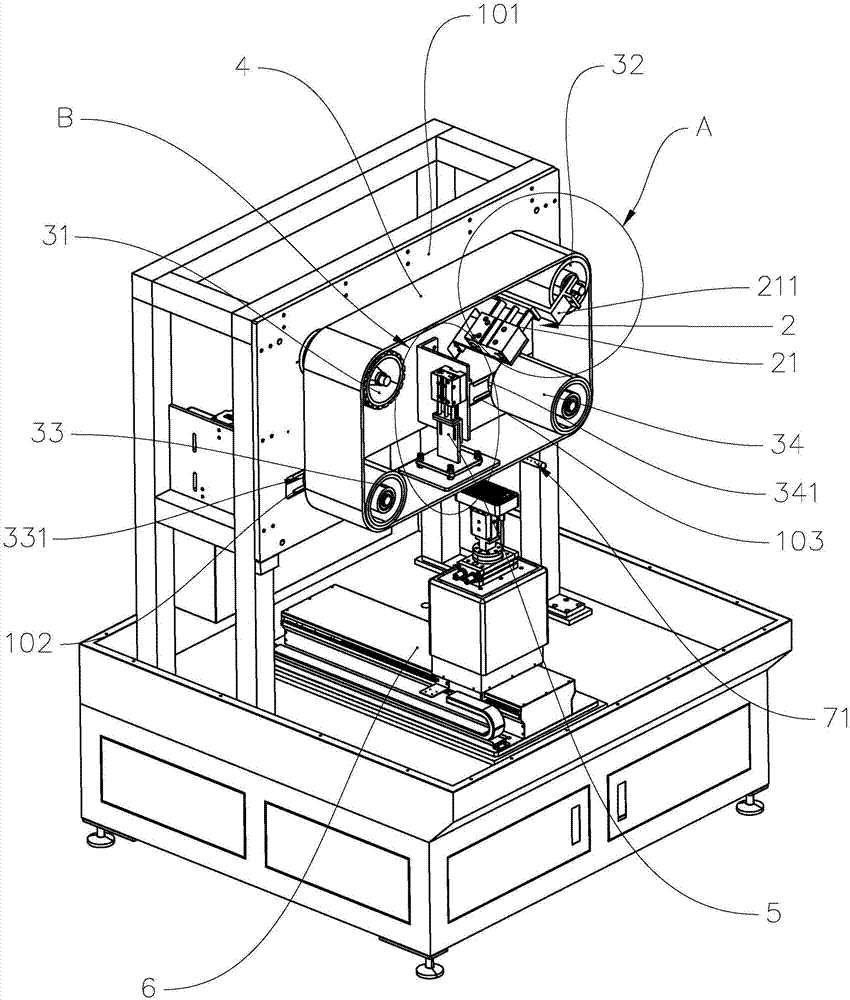

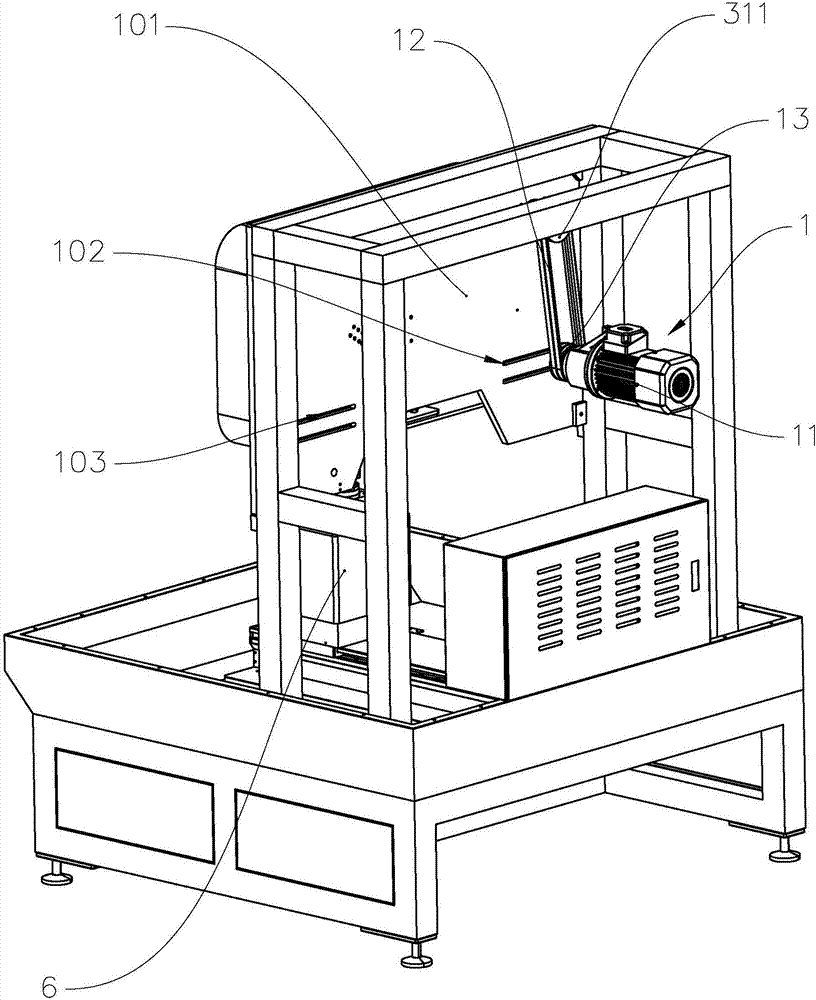

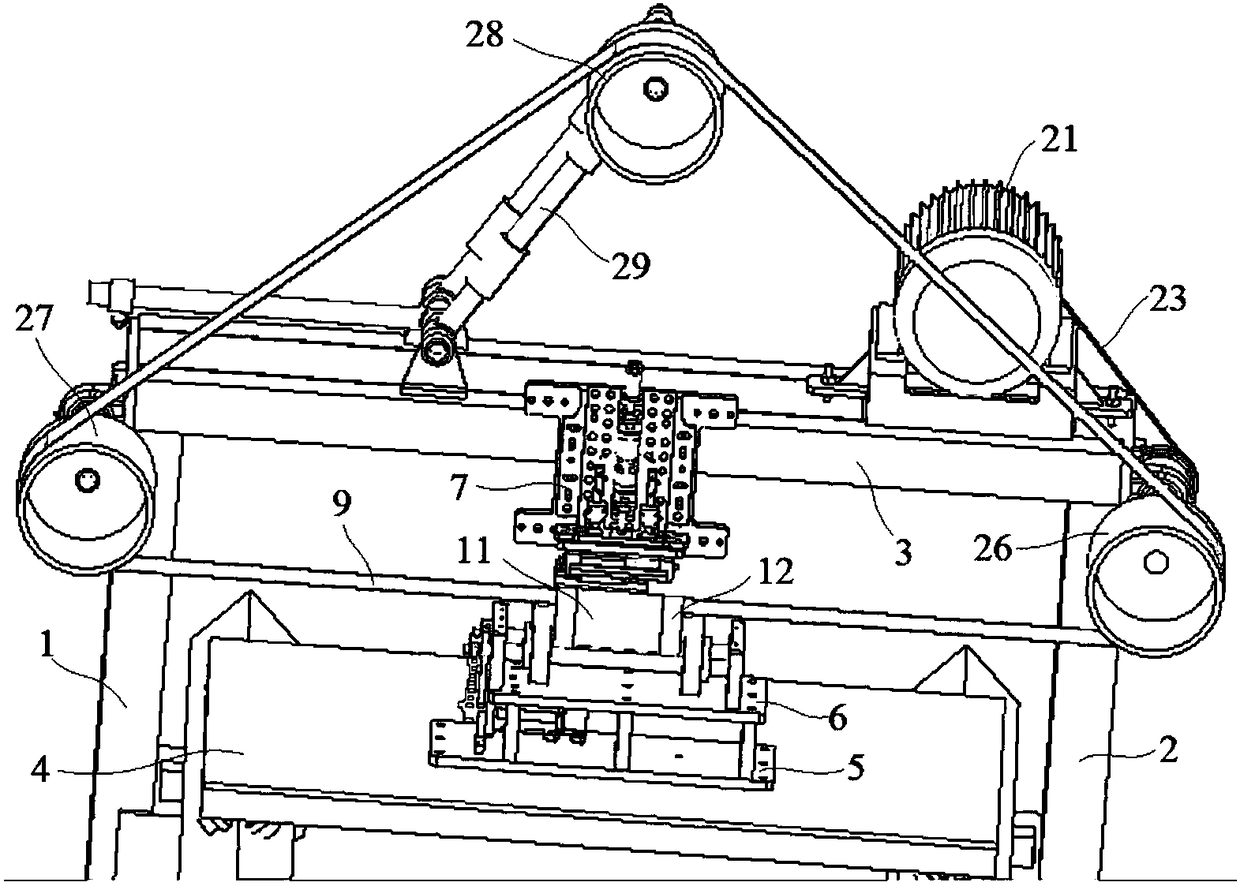

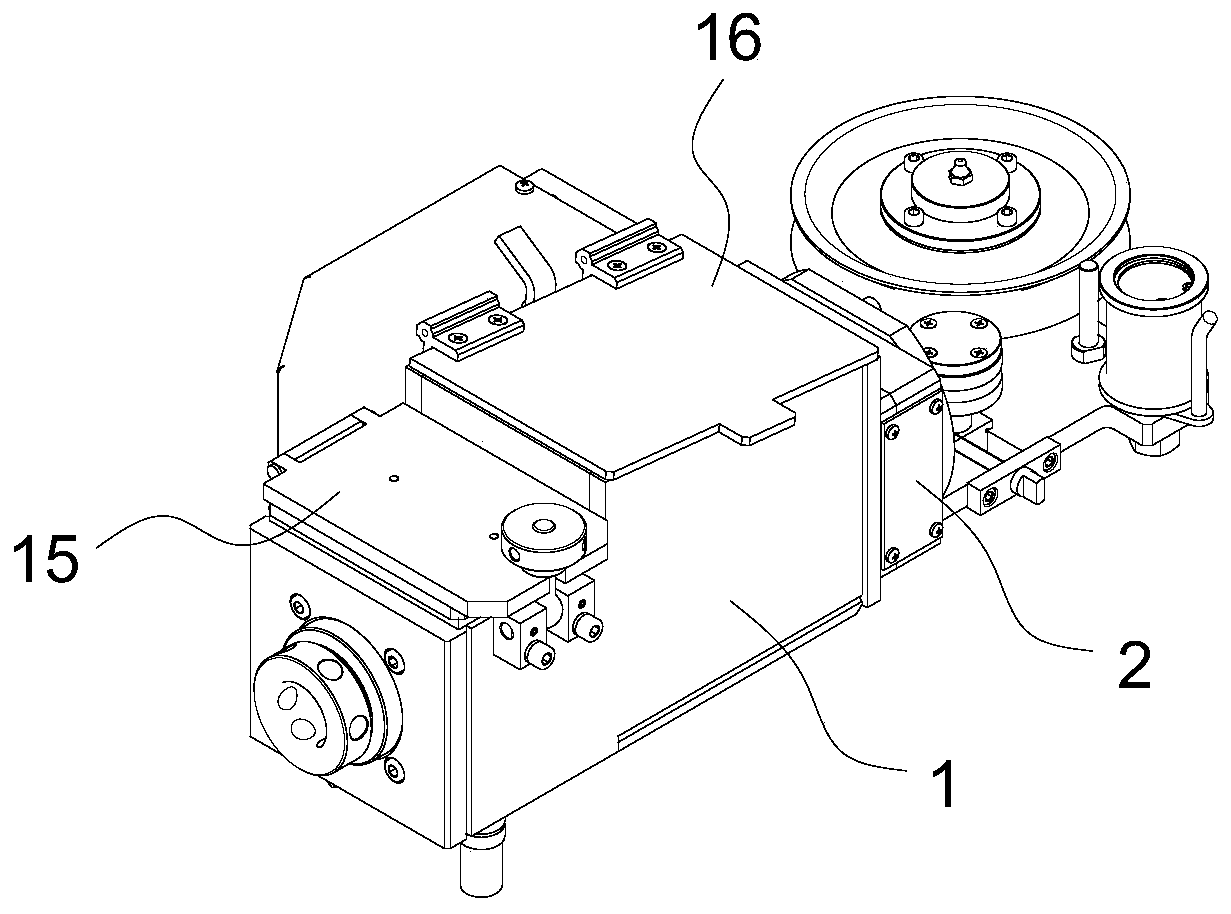

Wire drawing machine and machining method thereof

PendingCN107414640AEnough tensionGuaranteed drawing effectGrinding drivesBelt grinding machinesEngineeringMachine

The invention provides a wire drawing machine and a machining method thereof. The wire drawing machine comprises a machine frame, a first driving mechanism, a second driving mechanism, a plurality of roll shafts, a wire drawing belt, a downward pressing device and a fixture device. The first driving mechanism and the second driving mechanism are fixedly connected with the machine frame. The first roll shaft is connected with the machine frame, and the first driving mechanism drives the first roll shaft to rotate. The second roll shaft is rotationally connected with the second driving mechanism, and the second driving mechanism drives the second roll shaft to move in the axial direction of the second driving mechanism. The third roll shaft is connected with the machine frame. The wire drawing belt is wound on the multiple roll shafts. The downward pressing device comprises a third driving mechanism and a downward pressing assembly. The fixture device comprises a tool fixture, the tool fixture and the downward pressing assembly are located on the two sides of the wire drawing belt correspondingly, the tool fixture is opposite to the downward pressing assembly, and the third driving mechanism drives the downward pressing assembly to push the wire drawing belt towards the tool fixture. The invention further provides the machining method of the wire drawing machine. The wire drawing machine and the machining method thereof have the advantages of being good in wire drawing effect and high in wire drawing quality and wire drawing efficiency.

Owner:珠海桑贝思精密科技有限公司

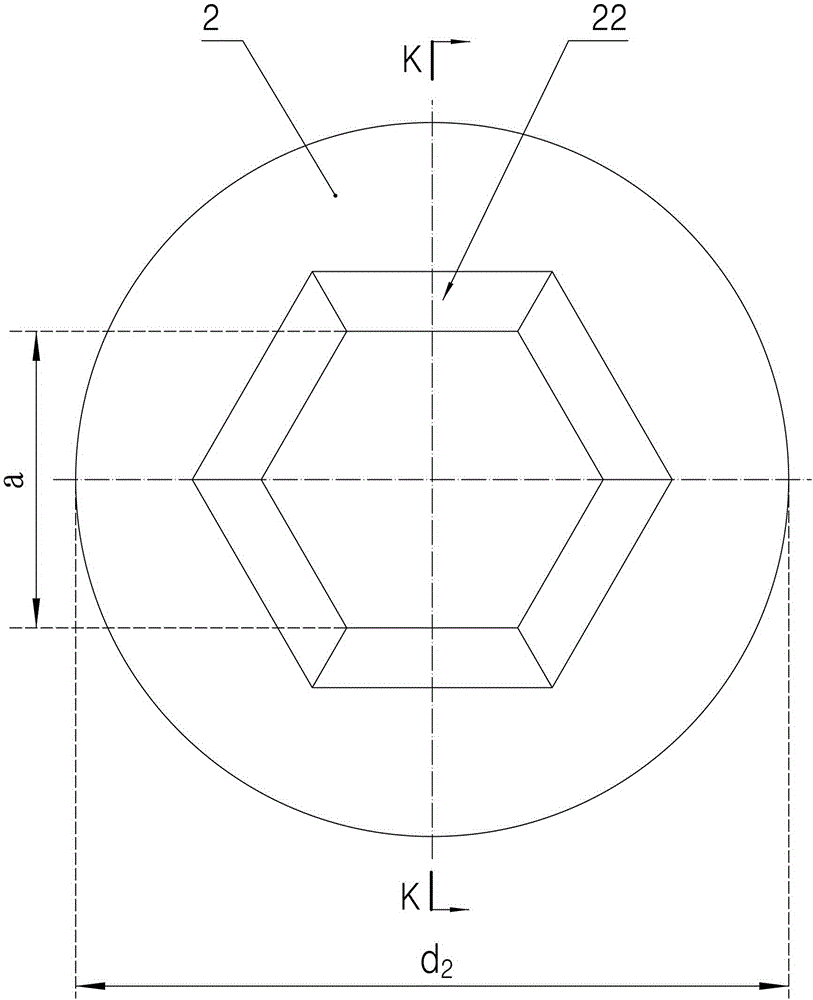

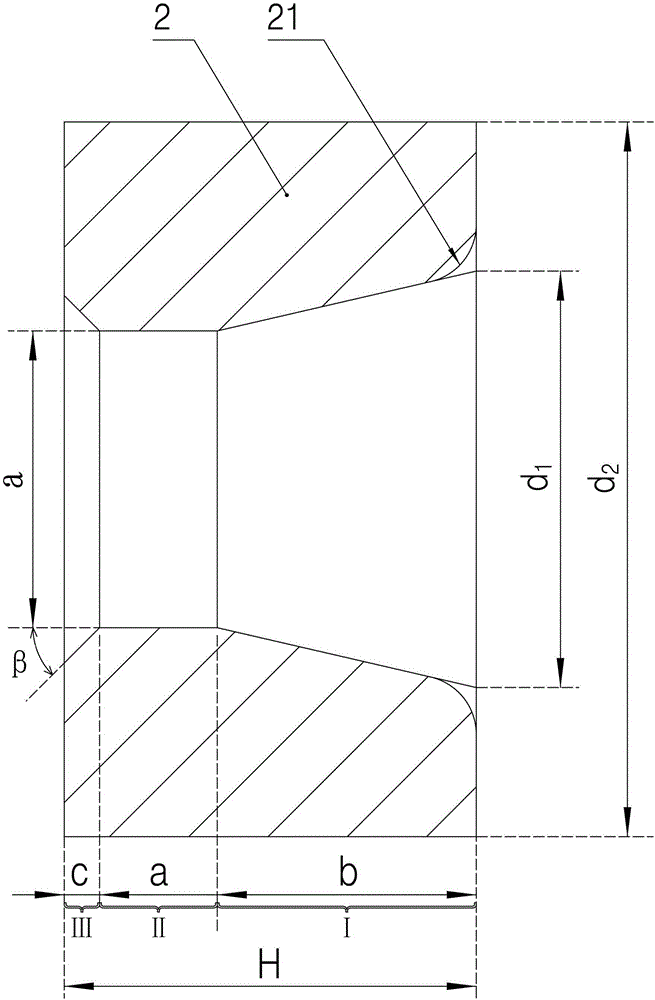

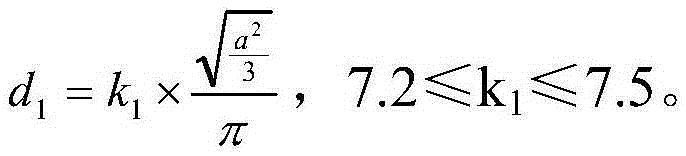

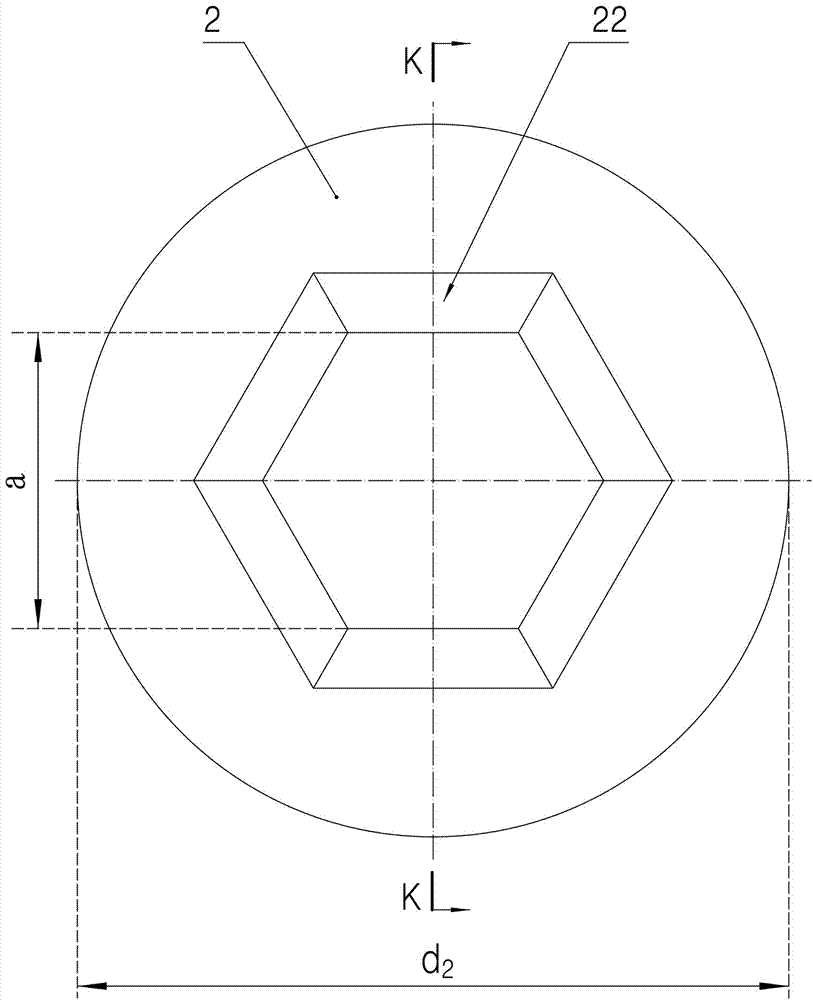

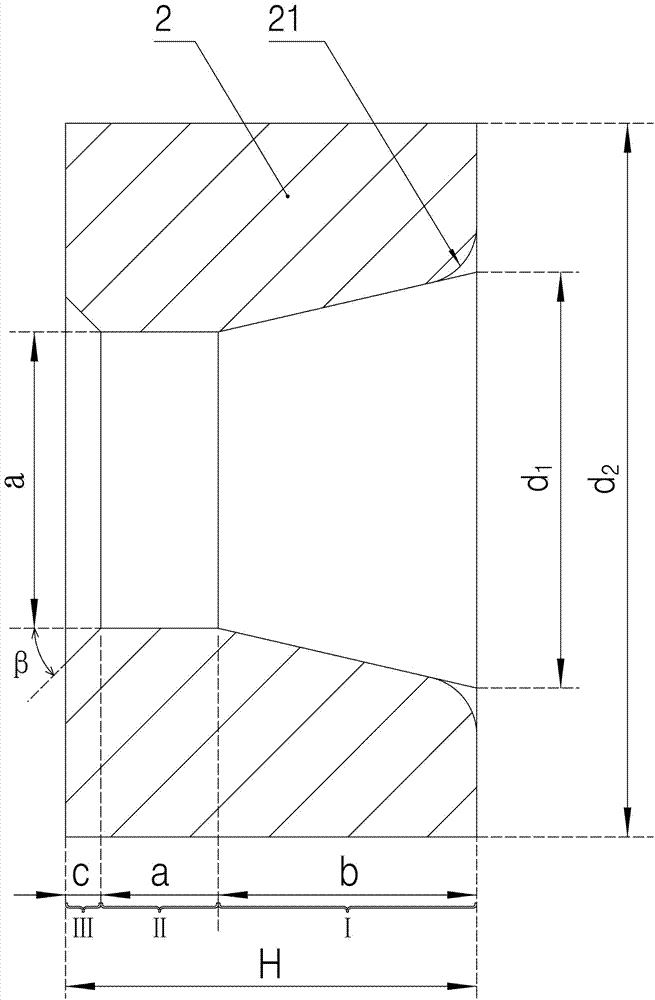

Regular hexagon drawing die

The invention discloses a regular hexagon drawing die. All relevant parameters of an inlet segment of the regular hexagon drawing die can be quantized. The regular hexagon drawing die comprises a drawing die body. The drawing die body is provided with a drawing forming hole which penetrates through the drawing die body. The drawing forming hole comprises the inlet segment and a sizing segment. The sizing segment comprises six flat-straight faces corresponding to six straight sides of a regular hexagon respectively. The distance between each pair of opposite flat-straight faces is a. The inlet segment comprises six leading-in bevels connected with the corresponding flat-straight faces of the sizing segment. Let the distance between the outer edge lines of each pair of opposite leading-in bevels be d1, then d1 is obtained through the formula showed in the specification, and 7.2<=k1<=7.5. The regular hexagon drawing die is used for drawing a circular pipe and a circular bar into a regular hexagon pipe and a regular hexagon bar respectively.

Owner:苏州华创特材股份有限公司

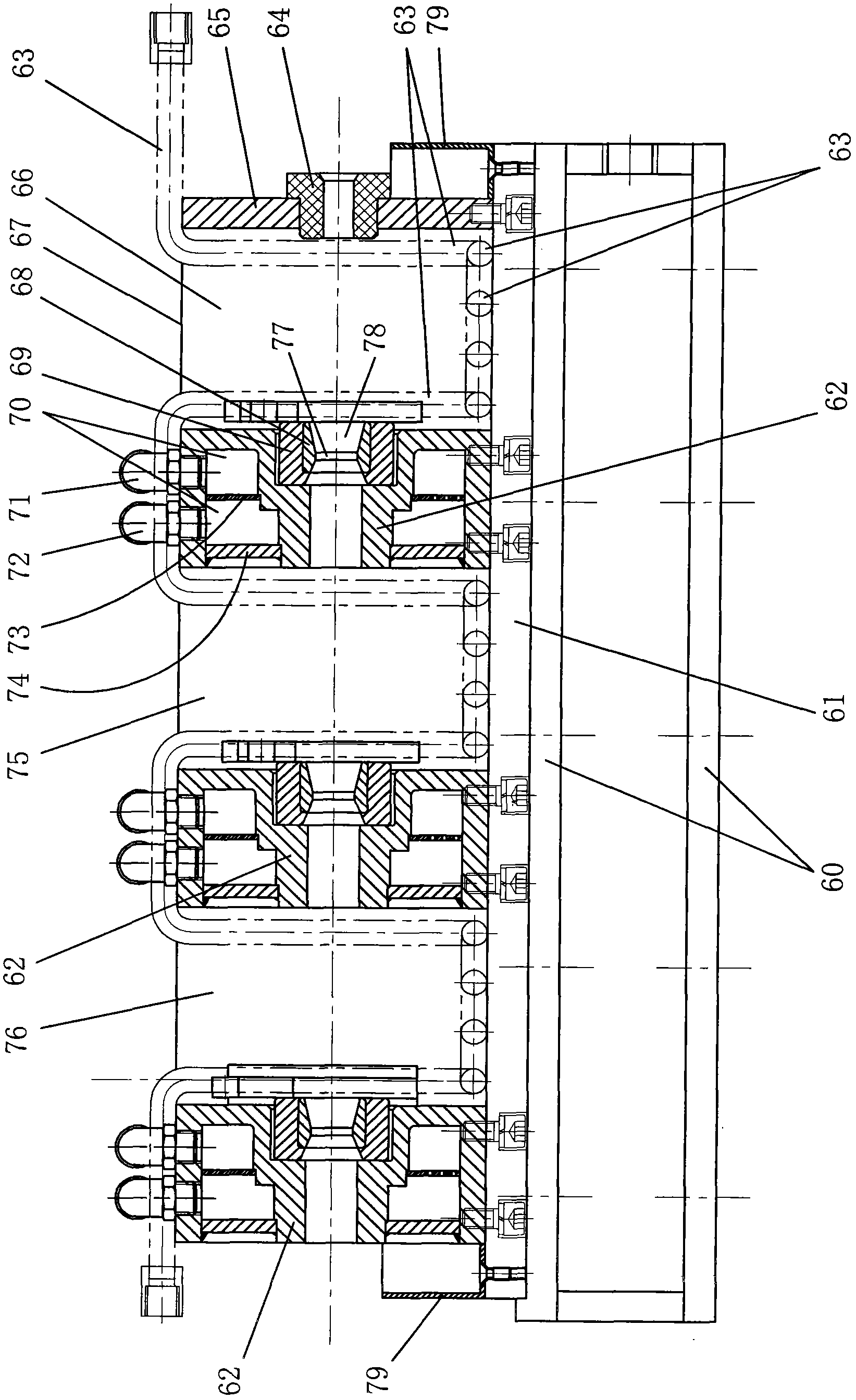

Automatic metal surface treatment device

ActiveCN108177061AAutomatic straight wire drawingGuaranteed drawing qualityGrinding drivesBelt grinding machinesDrive wheelPiston rod

The invention discloses an automatic metal surface treatment device which comprises a left vertical plate, a right vertical plate, a beam plate, a carrier plate, a base plate, a clamp base, a pressing-down mechanism and an abrasive belt. The left vertical plate and the right vertical plate are arranged in parallel. The beam plate is in bridging connection with the left vertical plate and the rightvertical plate. An output shaft of a motor is provided with a driving wheel, the driving wheel is in transmission connection with a driving auxiliary wheel through a belt, an air cylinder is vertically installed on the front surface of an installation plate, a piston rod of the air cylinder is fixedly connected with a pressing-down plate, a middle shaft is sleeved with a left fixing ring and a right fixing ring from the two ends of a supporting sleeve, the left fixing ring and the right fixing ring make close contact with the two end faces of the supporting sleeve correspondingly, and the supporting sleeve is sleeved with a circular pipe which is fixed through the left fixing ring and the right fixing ring. Straight wiredrawing operation of the metal surface can be automatically achieved,wiredrawing straightness, wire flow uniformity and wiredrawing efficiency are improved, the wiredrawing quality of the metal circular pipe is ensured, and the rate of finished products is improved.

Owner:苏州丰川电子科技有限公司

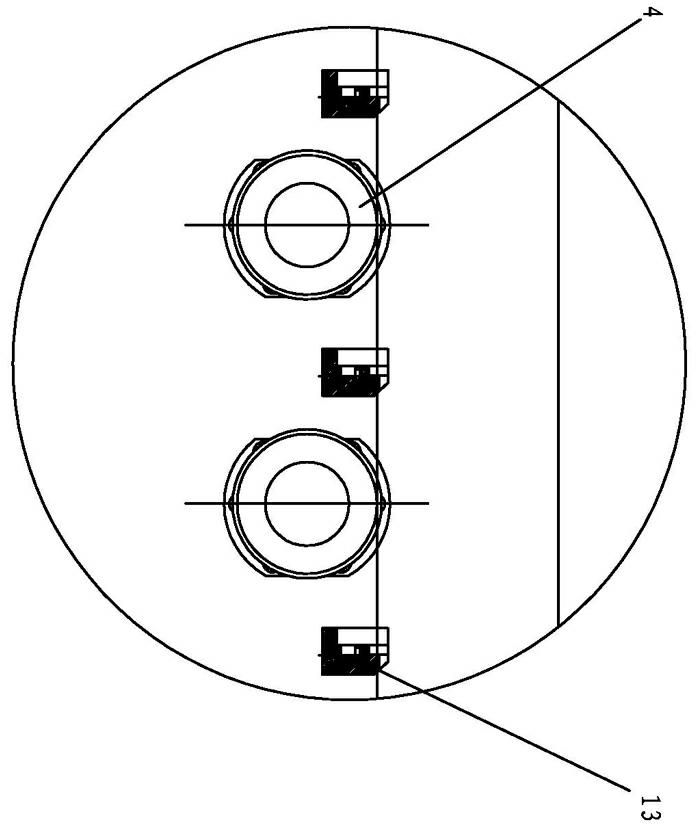

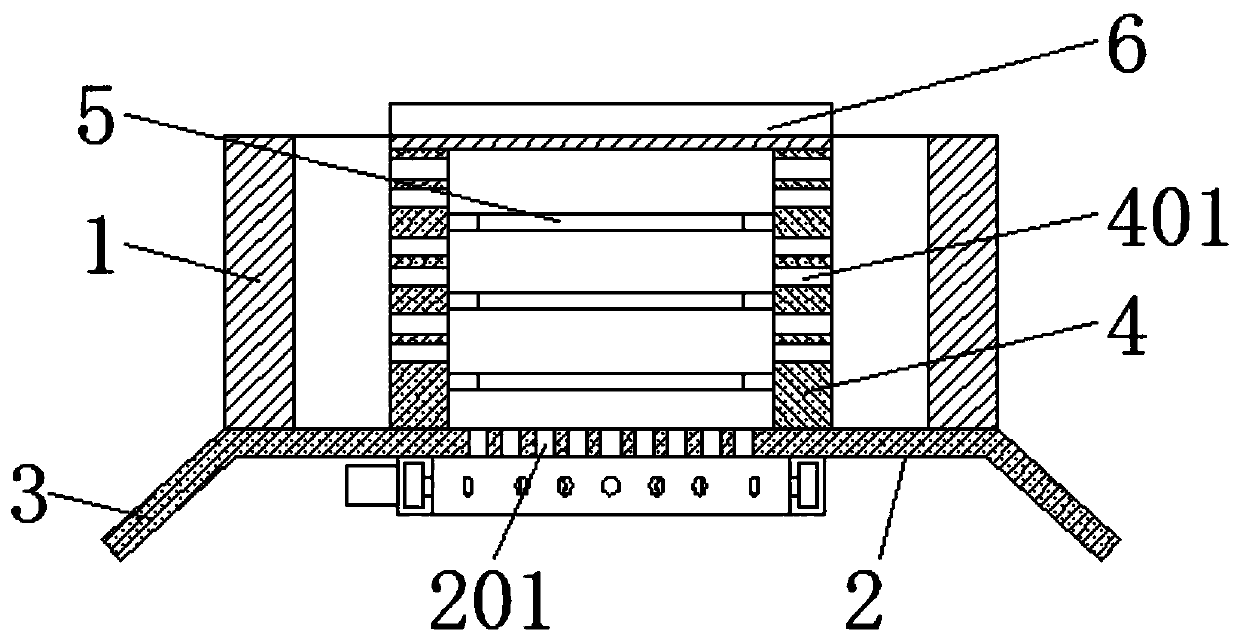

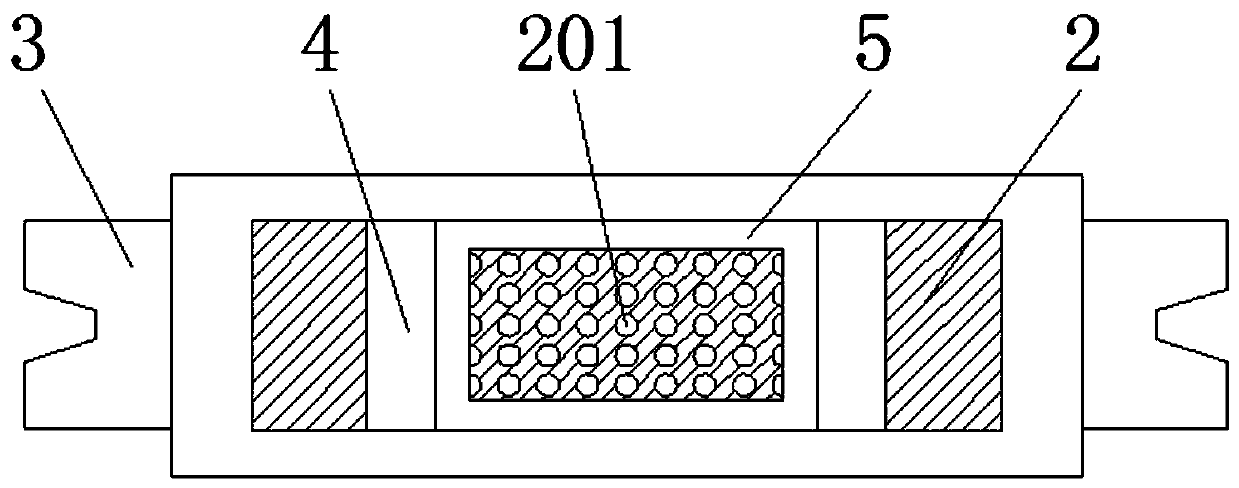

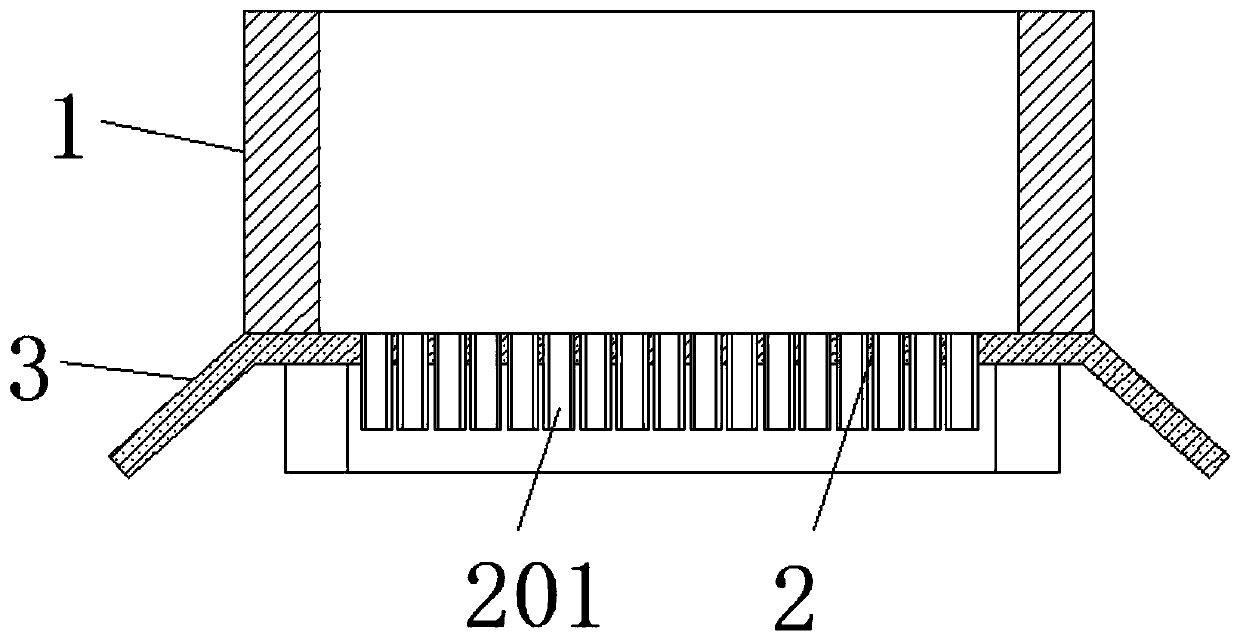

Metal wire drawing die seat device

The invention discloses a metal wire drawing die seat device which comprises a bottom plate. At least two die seats are arranged on the bottom plate; a drawing die is arranged on the front side of a center hole of each die seat; drawing oil cavities are formed between the adjacent die seats and at the front end of the die seat at the most front end; the peripheries of the centers of the die seats are provided with cooling water cavities and are connected with water inlet joints and water return joints; cooling water pipes connected with a cold water supply device are arranged in the drawing oil cavities. The cooling water pipes are arranged in the drawing oil cavities, so that in the operating process, heat of oil is timely taken away by the cold water supply device to effectively cool down drawing oil, viscosity of the drawing oil is ensured and meanwhile, drawing quality is ensured.

Owner:王玉凯

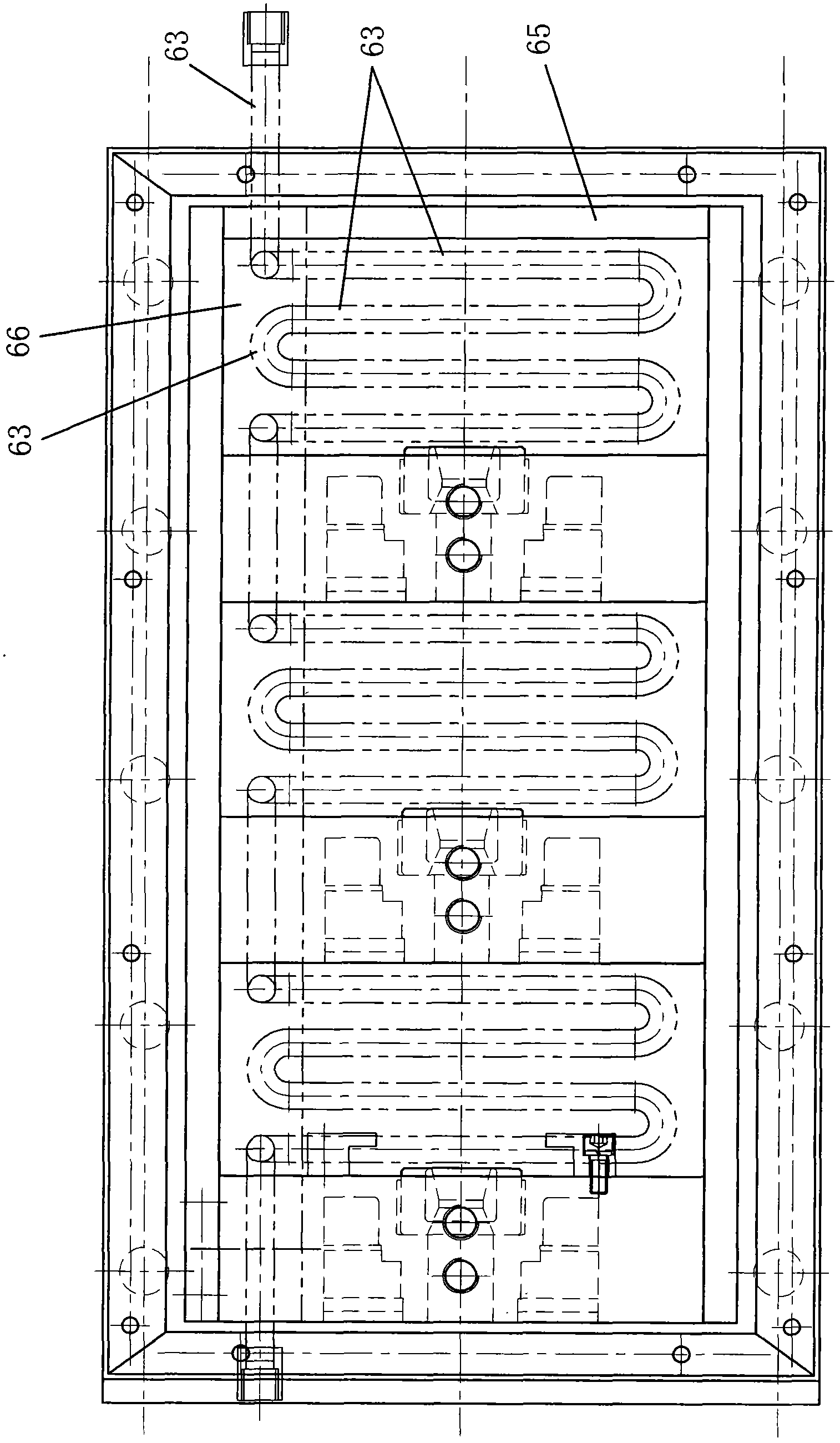

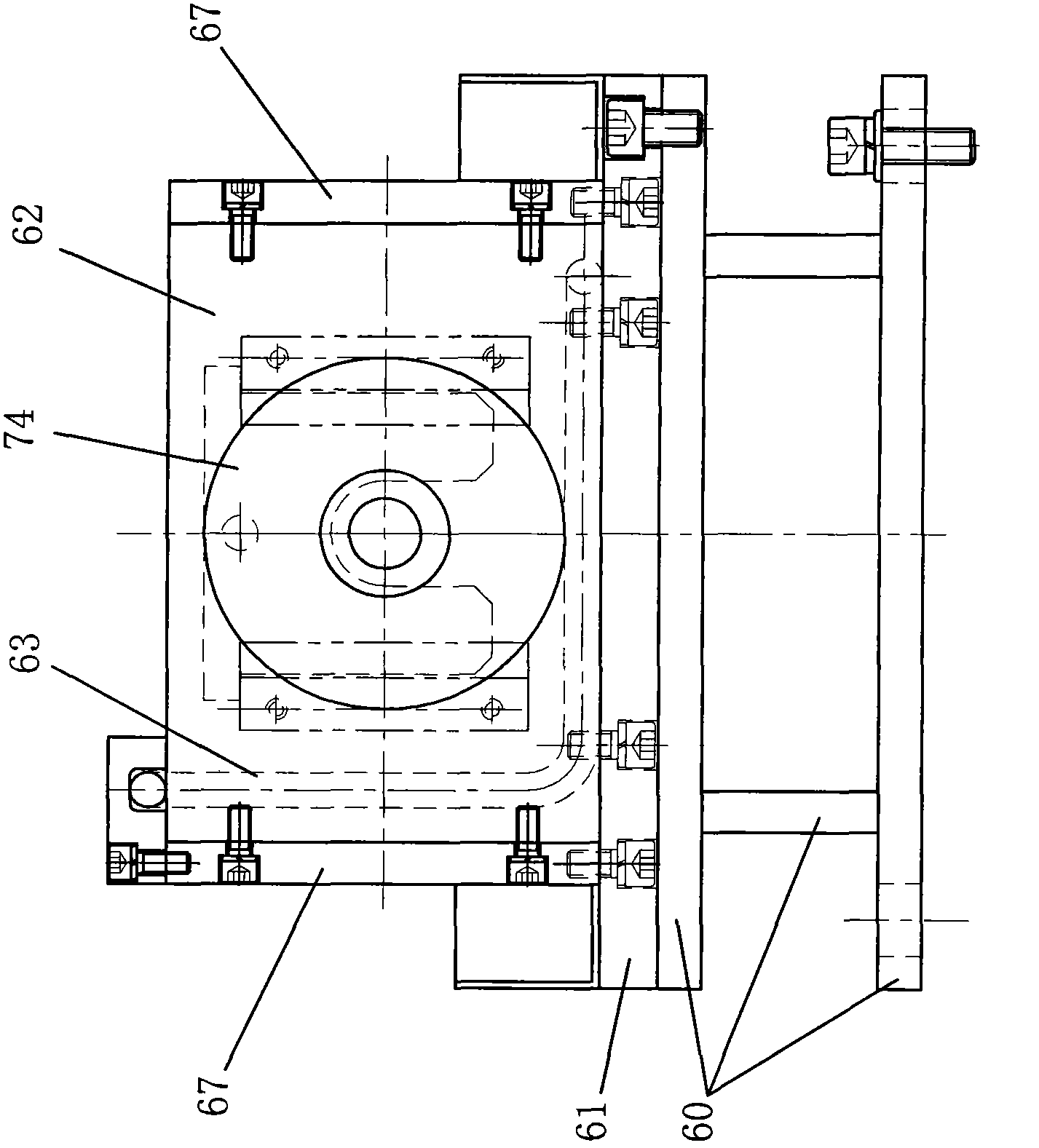

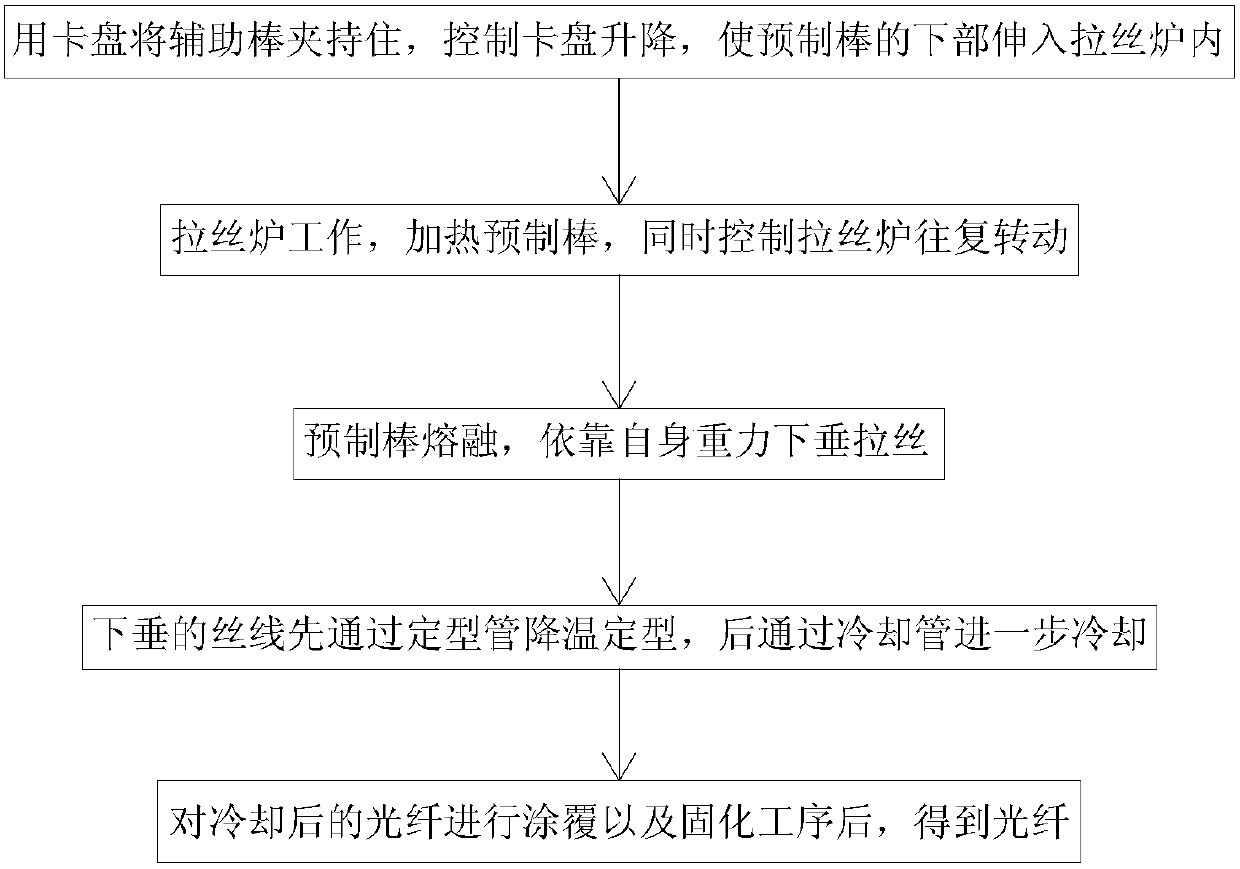

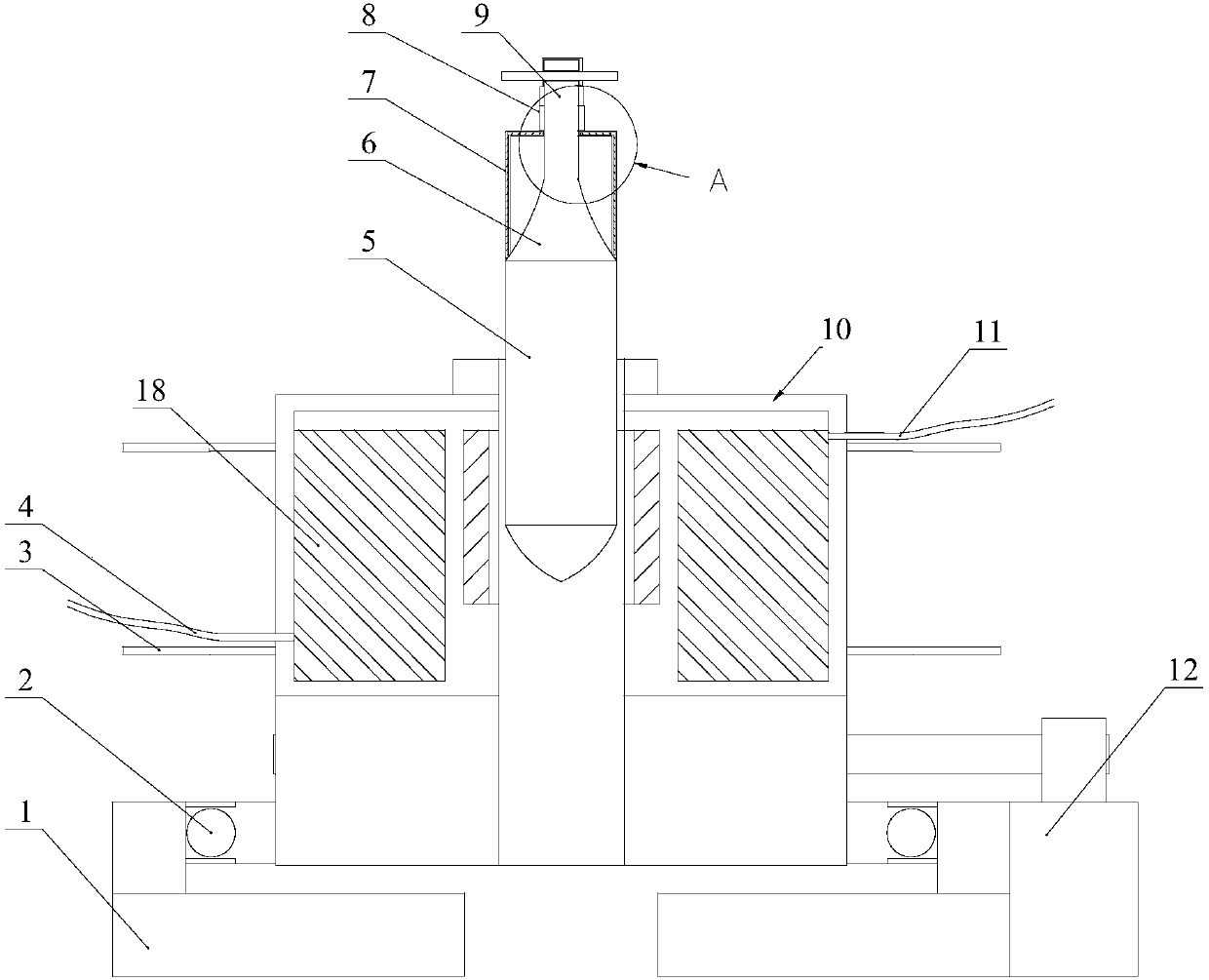

Optical fiber processing technology

ActiveCN105819680BHeating evenlyIncrease profitGlass fibre drawing apparatusEngineeringFiber drawing

The invention discloses an optical fiber processing process. The optical fiber processing process comprises the following steps: 1) clamping an auxiliary rod by a chuck and controlling the chuck to be lifted up and down for enabling the lower part of a prefabricated rod to extend into a fiber drawing furnace; 2) starting the fiber drawing furnace, heating the prefabricated rod, and controlling the fiber drawing furnace to rotate in a reciprocating manner; 3) melting the prefabricated rod and drooping a drawn fiber by self gravity; 4) shaping the drooped fiber by cooling through a shaping pipe, and further cooling the fiber through a cooling pipe; and 5) coating and solidifying the cooled optical fiber to obtain an optical fiber. According to the processing process, the fiber drawing furnace is controlled to rotate in the reciprocating manner, so that the prefabricated rod can be guaranteed to be heated uniformly in a circumferential direction and the fiber drawing quality is ensured.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

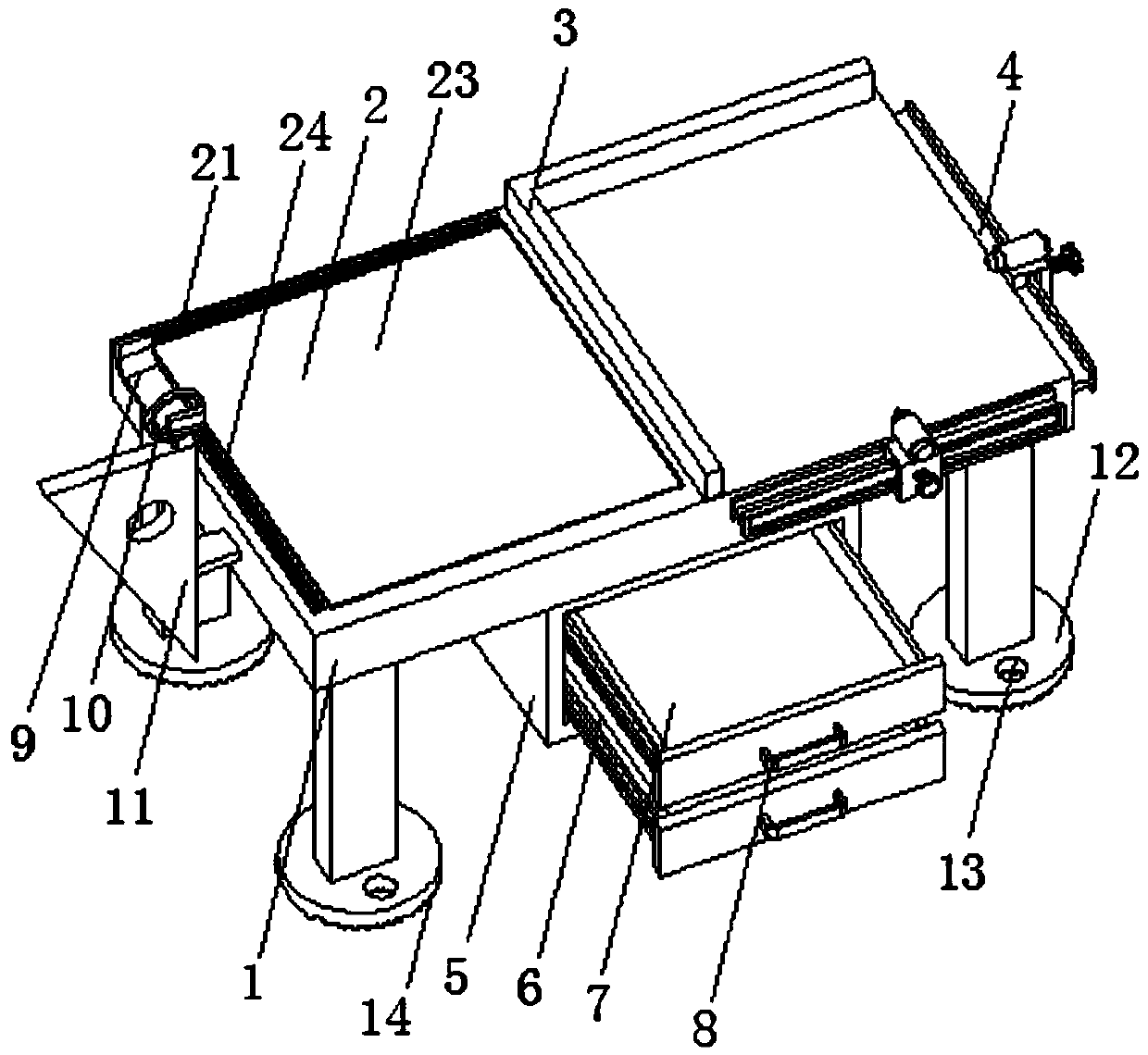

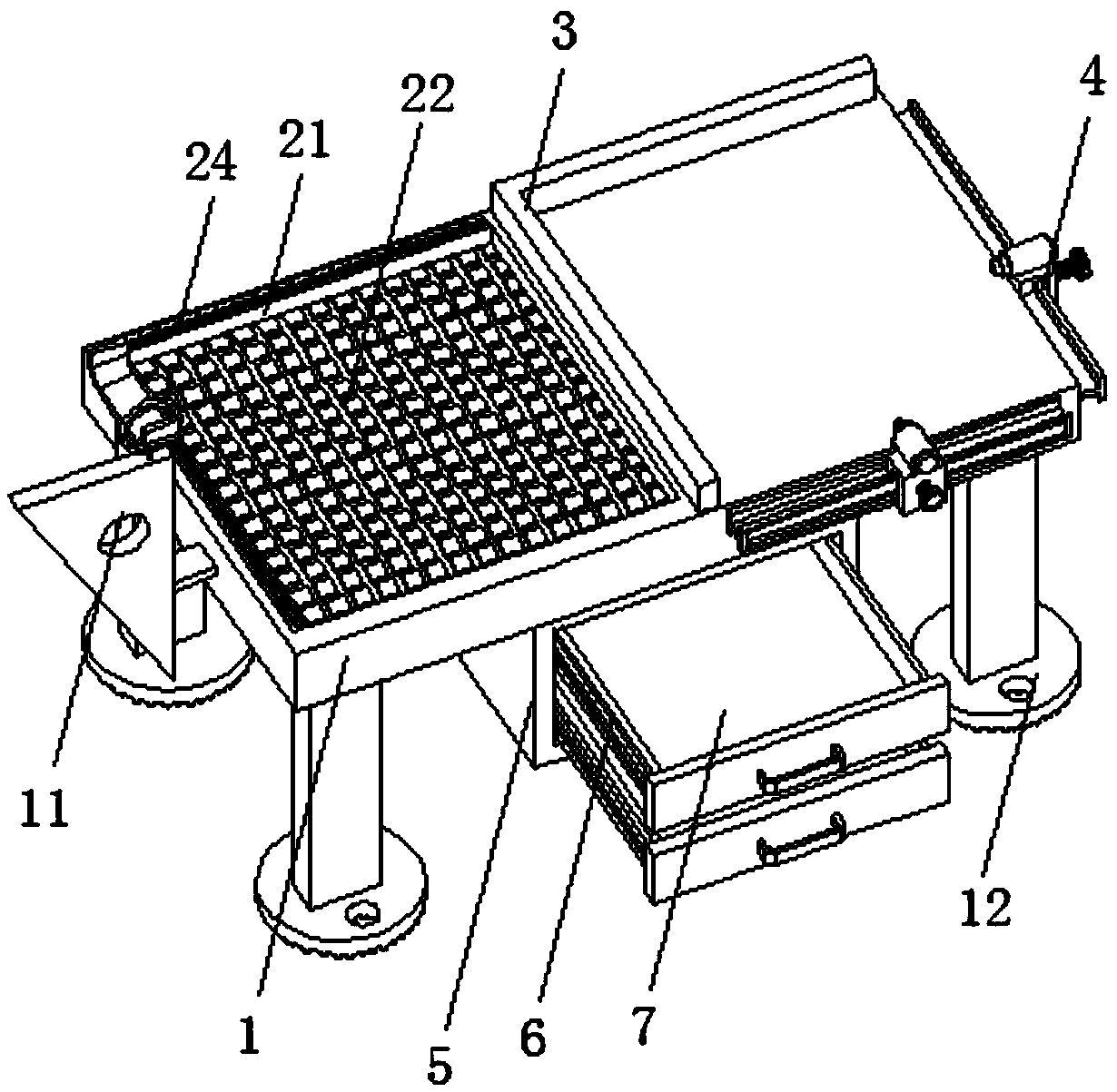

Special drawing desk for mathematics teaching

The invention discloses a special drawing desk for mathematics teaching. The drawing desk comprises a desk body, wherein a first drawing device is arranged at the left side of the upper end of the desk body; an L-shaped developing plate is arranged in the middle of the upper end of the desk body; the right end of the L-shaped developing plate is aligned with the right end desktop of the desk body;the front and rear ends of the L-shaped developing plate are aligned with front and rear end desktops of the desk body; second drawing devices are arranged at the right side and the front side of thedesktop of the desk body; a toolkit is arranged at the lower end of the middle of the desktop of the desk body; sliding rails are symmetrically arranged on the left and right sidewalls of the interior of the toolkit; and the sliding rails are slidingly connected to groove sliding blocks at two sides of the toolkit. The special drawing desk for mathematics teaching is simple in structure, firm infixing, convenient to use in storage and hanging and greatly convenient for users; and moreover, in accordance with demands, accurate datum positioning of mathematics drawing can be achieved by virtueof the first drawing device and the second drawing devices, so that teachers' and students' burden on drawing can be relieved, drawing quality can be guaranteed and using efficiency of the special drawing desk can be improved.

Owner:王子帆

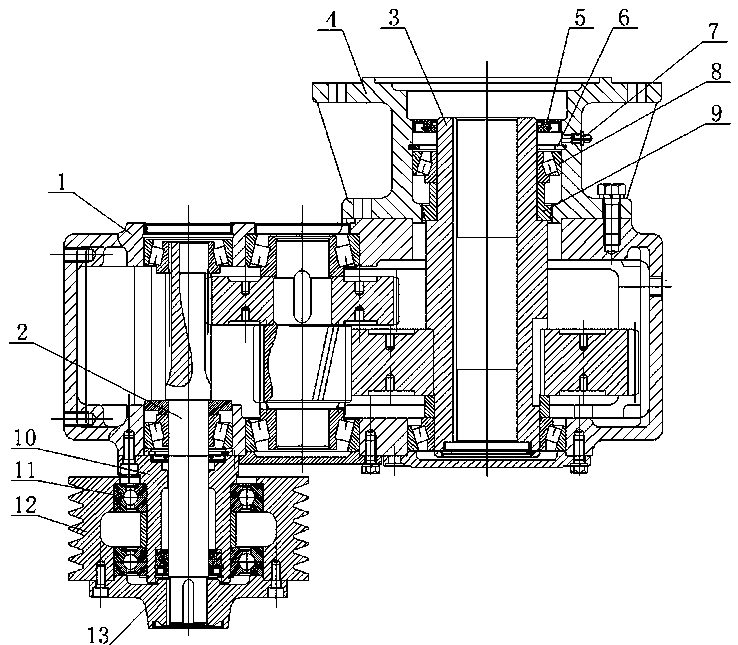

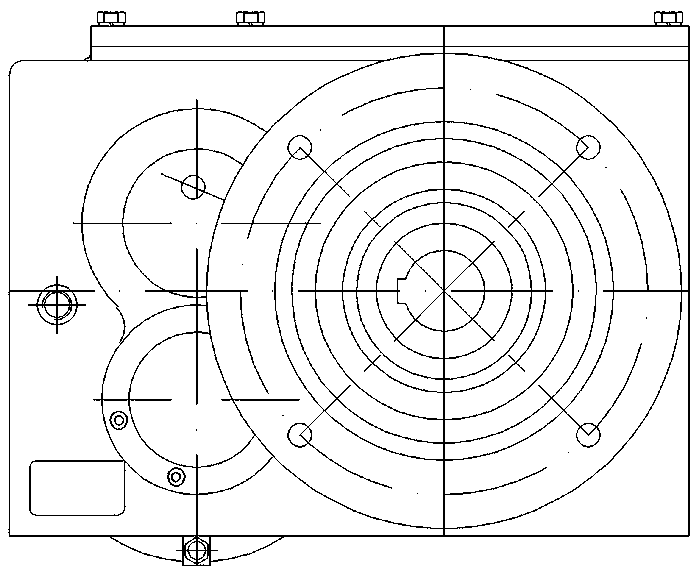

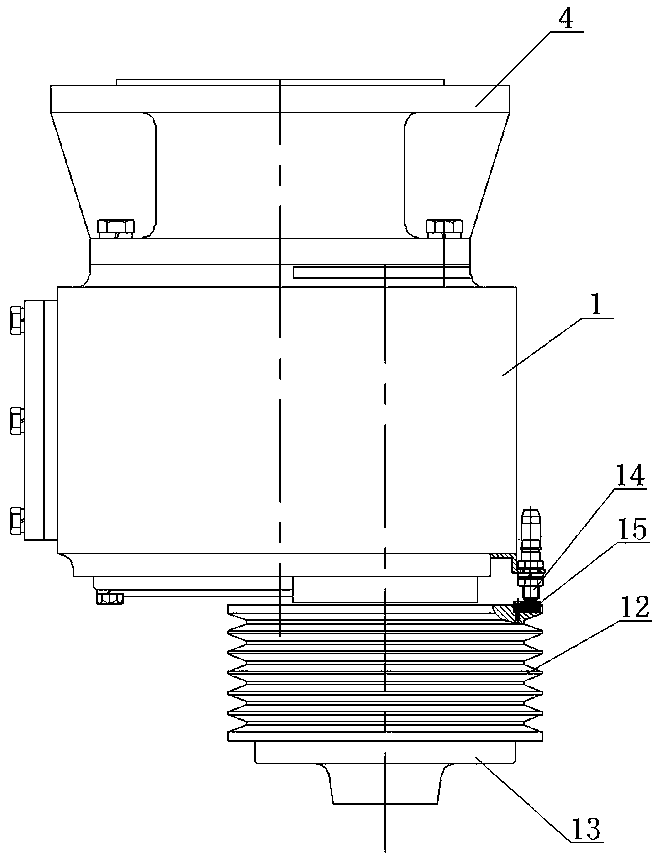

Direct feed type wiredrawing speed reducer

PendingCN110454565AStrong impactImprove transmission efficiencyGearingGear lubrication/coolingReducerFlange

The invention discloses a direct feed type wiredrawing speed reducer. The direct feed type wiredrawing speed reducer comprises a box body, a vertically-arranged input shaft and a vertically-arranged output shaft. The input shaft drives the output shaft through gear reduction. The direct feed type wiredrawing speed reducer is characterized in that the upper shaft end of the output shaft is rotationally supported by a rolling cone bearing arranged in an inner hole of a connecting flange, the upper shaft end of the output shaft is supported by the connecting flange to be higher than the top of the box body, the connecting flange is fixedly mounted on the top of the box body, the upper end face of the outer ring of the rolling cone bearing is axially limited through a retaining ring for a hole, a sealing ring for sealing the shaft end of the output shaft is arranged above the retaining ring for the hole, a grease injection opening is formed in the portion, between the sealing ring and therolling cone bearing, of the wall of the inner hole of the connecting flange, the inner hole of the connecting flange shrinks at the position of a lower port and is provided with an oil blocking ring,and the oil blocking ring is fixedly mounted on the outer circle of the output shaft. Both the input shaft and the output shaft can bear higher impact force, the upper shaft end of the output shaft is closer to a wiredrawing part, the stability of wiredrawing work is improved, and the direct feed type wiredrawing speed reducer has a speed measuring function.

Owner:ZHEJIANG TANHON DRIVING MACHINE

Multifunctional die box

PendingCN110756604AStir wellImprove utilization efficiencyDrawing diesMechanical engineeringMaterials science

The invention provides a multifunctional die box. A box body and a stirring mechanism are included. The box body is provided with a powder cavity. A groove bottom plate is arranged at the bottom of the powder cavity and is a half circular pipe. An opening of the groove bottom plate is arranged upwards. The box body is provided with a die supporting sleeve, and the die supporting sleeve is providedwith a conical hole. The stirring mechanism is fixedly connected with the box body and comprises a stirring rod. The rotation axis of the stirring rod coincides with the center line of the groove bottom plate. A plurality of first scrapers are arranged on the stirring rod at intervals. The bottom faces of the first scrapers are in clearance fit with the inner circle face of the groove bottom plate. A second scraper is arranged at the front end of the stirring rod and provided with a scraping face, and the scraping face and the hole wall of the conical hole are in clearance fit. The multifunctional die box is provided, through the arrangement of the semicircular groove bottom plate and the stirring mechanism which are matched, lubricating powder at the bottom of the powder cavity can be sufficiently stirred, the lubricating powder utilization efficiency is improved, the lubricating powder usage amount is reduced, and cost is saved.

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

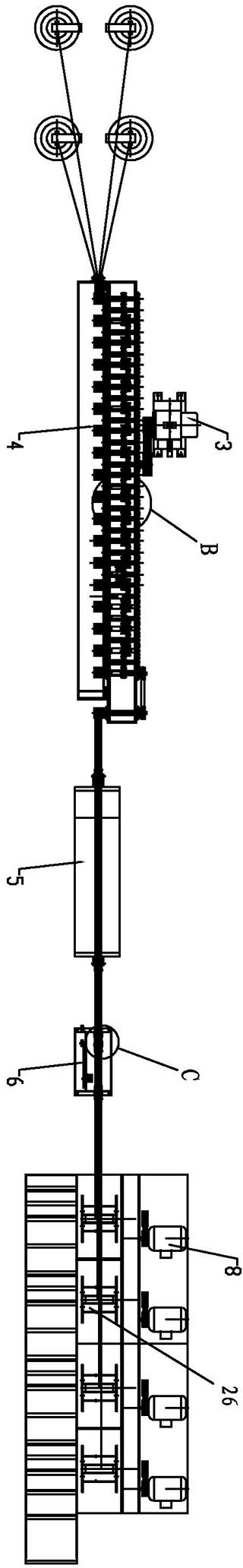

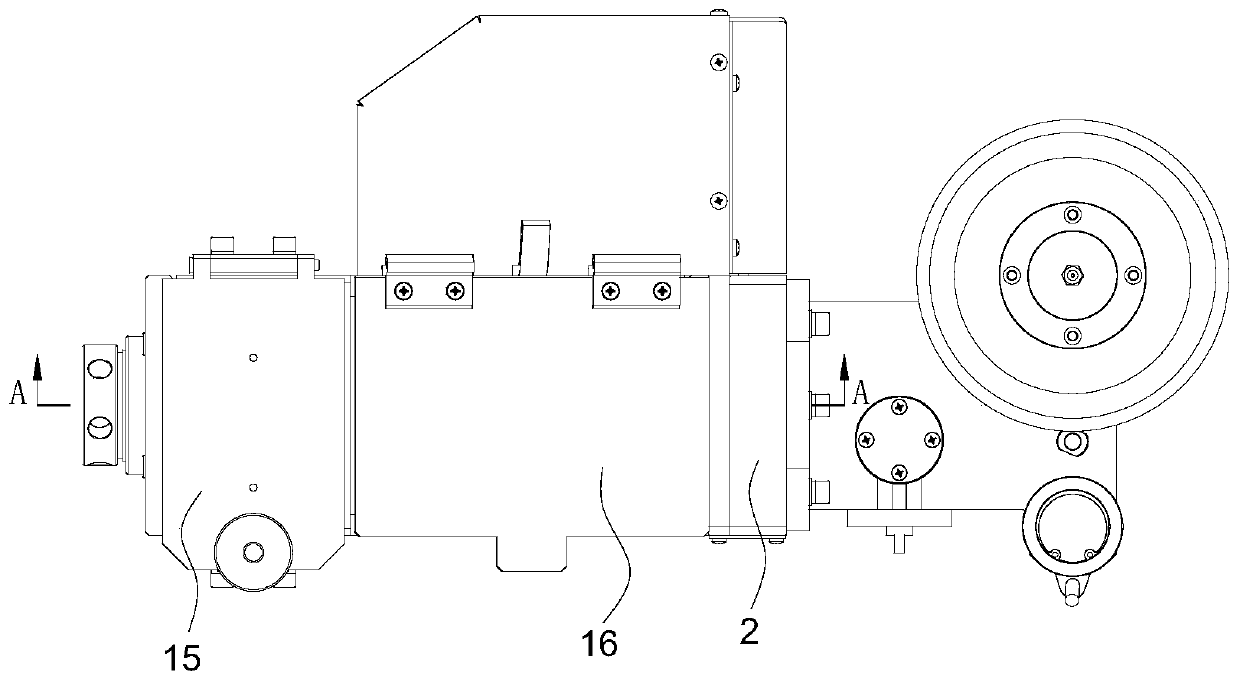

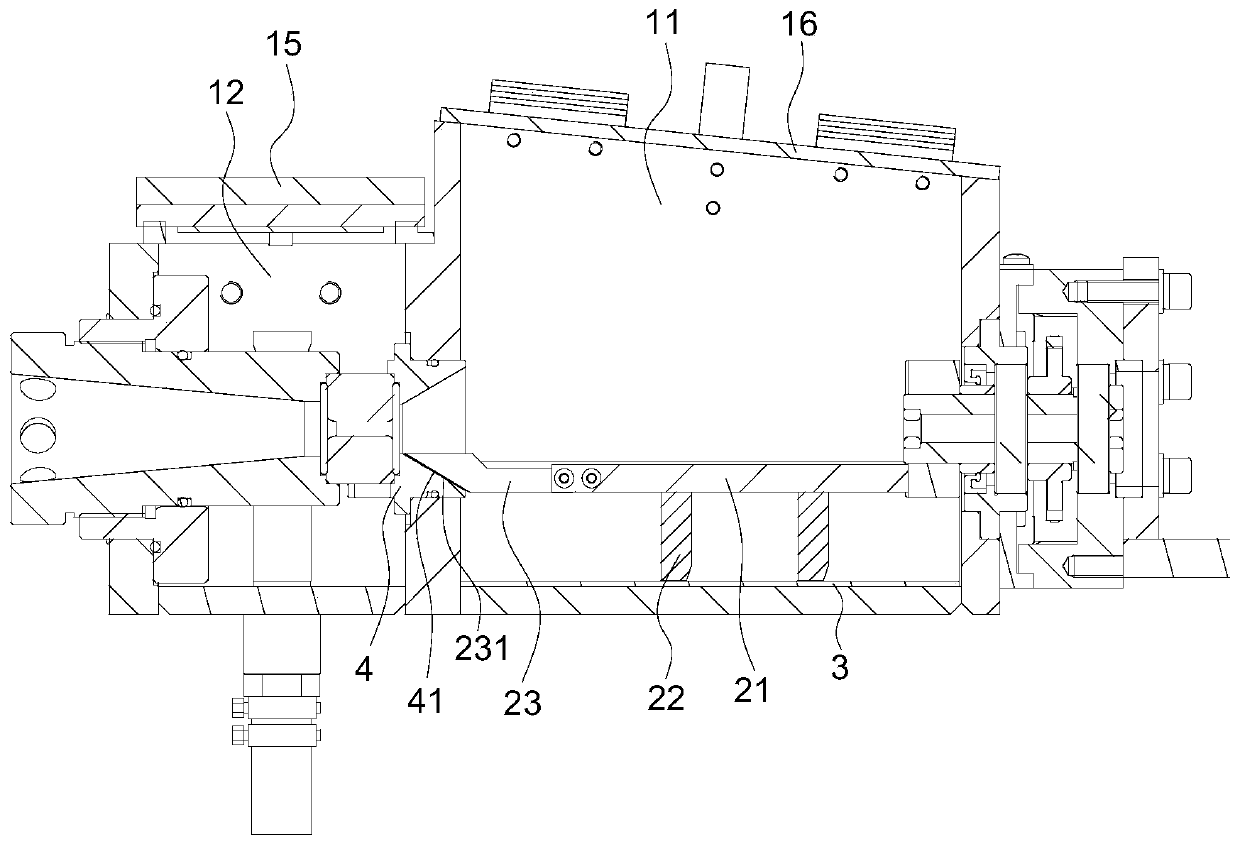

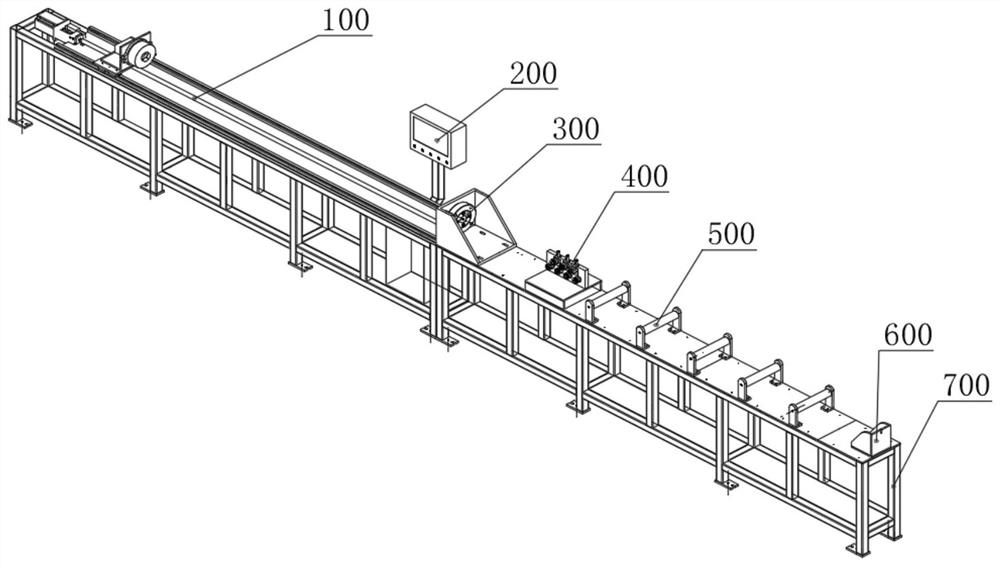

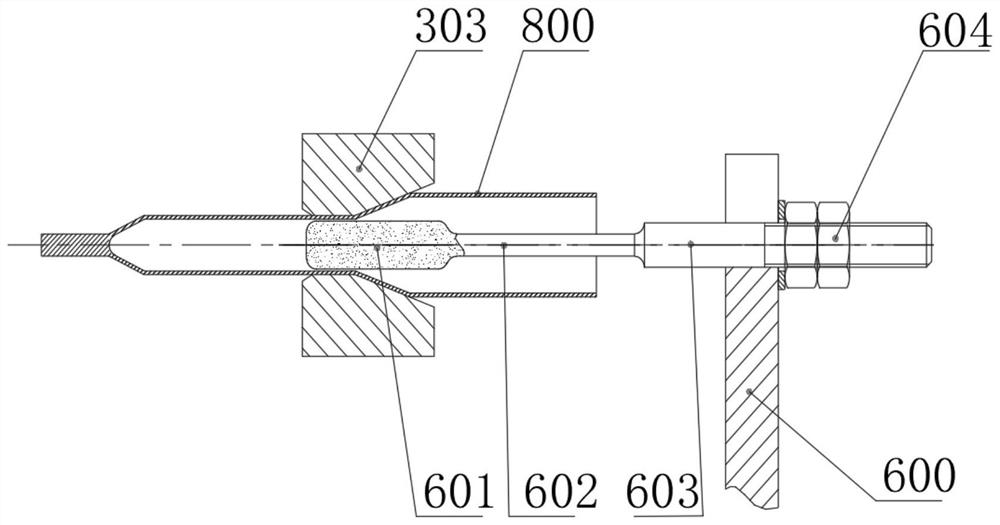

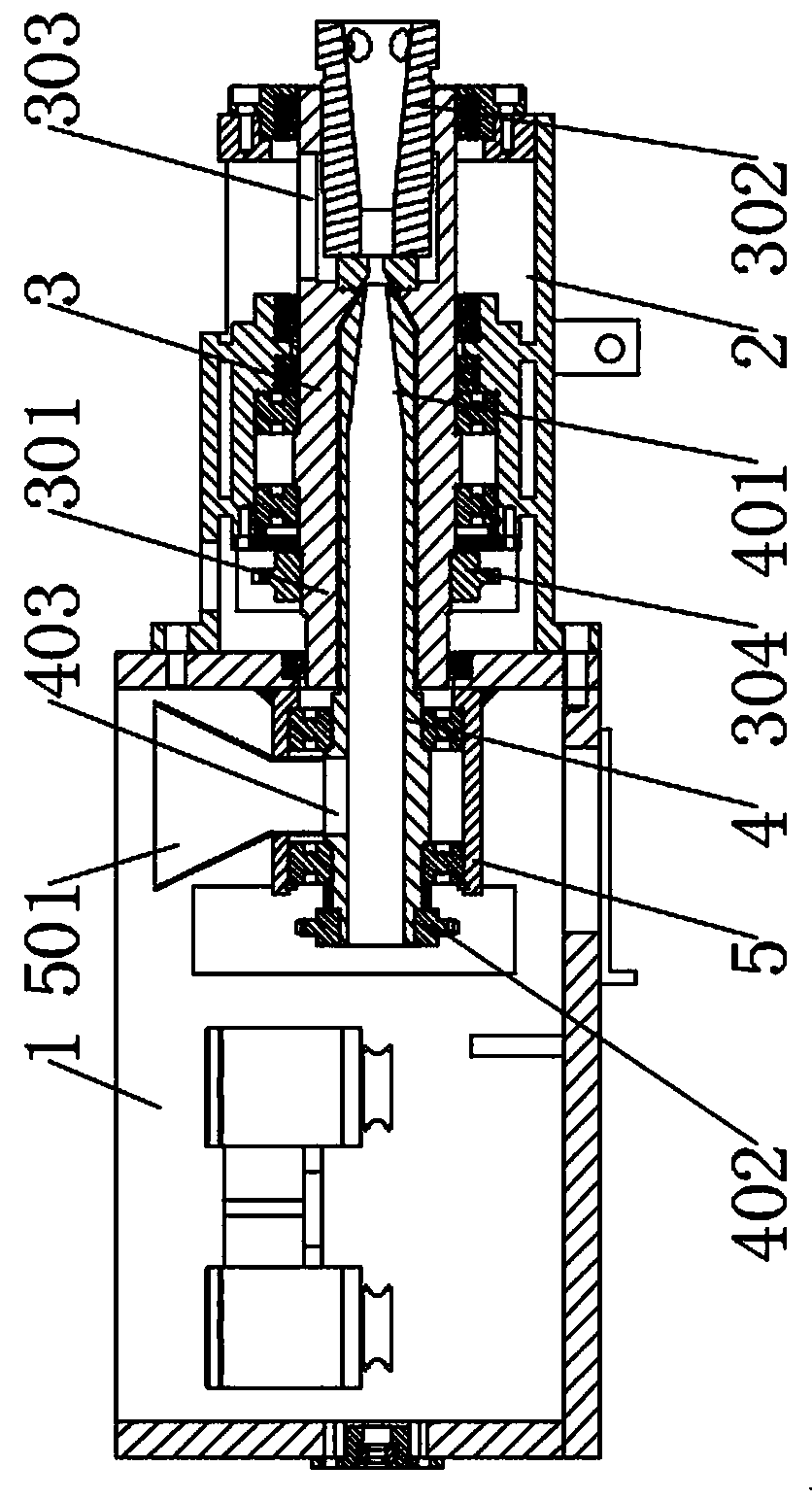

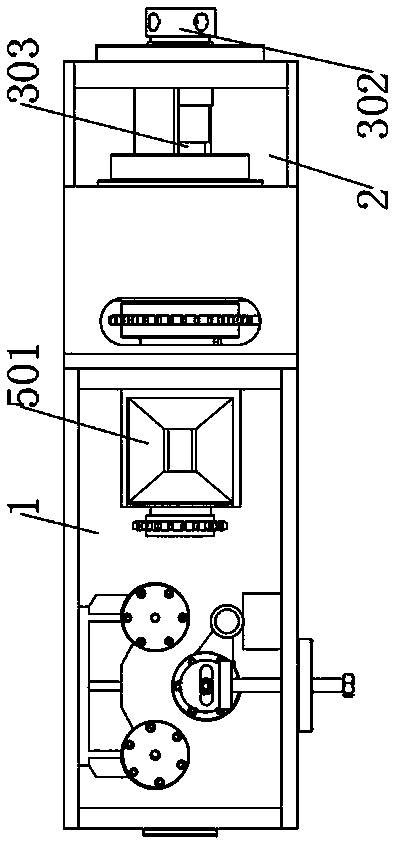

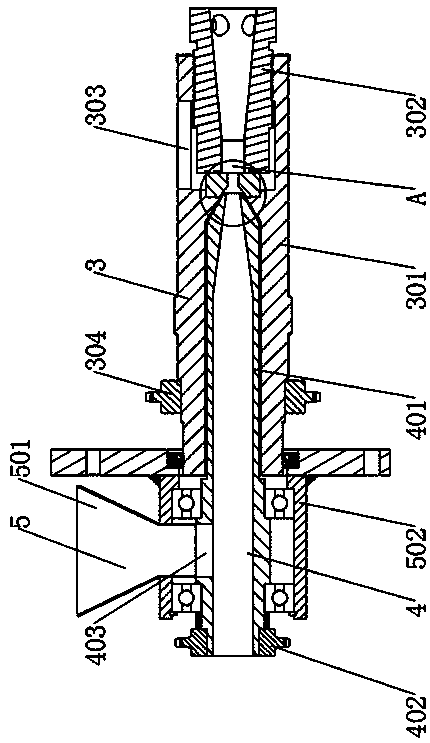

Special drawing equipment for stainless steel cross pipe

PendingCN113275400AGuaranteed drawing qualityGuaranteed straightnessWire straightening devicesDrawing diesMetallurgyElectrical control

The invention discloses special drawing equipment for a stainless steel cross pipe. The equipment comprises a traction mechanism and an electrical control box which are arranged on a rack, and further comprises a core head positioning mechanism, a supporting mechanism, a straightening mechanism and a die and die holder assembly which are sequentially arranged on the rack in the drawing direction; the core head positioning mechanism is used for positioning and adjusting the position opposite to the die and die holder assembly; the supporting mechanism is used for supporting the stainless steel pipe and a core head; the straightening mechanism is used for straightening the stainless steel pipe to keep concentric with the die and die holder assembly and pressing the stainless steel pipe in the drawing process; and the die and die holder assembly is used for finely adjusting the straightness of the stainless steel special-shaped pipe. According to the drawing equipment, the stainless steel pipe can be straightened in advance through the straightening mechanism, it is guaranteed that the stainless steel pipe can be kept concentric with a drawing die all the time in the drawing process, drawing is more stable, meanwhile, the stainless steel pipe is pressed through pressing wheels, and the phenomenon of oscillation caused by overlong extension of the rear part in the drawing process can be prevented.

Owner:新乡龙鑫精密模具制造有限公司

Environment-friendly high-efficiency wire drawing lubricant with controllable viscosity

ActiveCN103952226AAdjustable viscosityStable emulsificationLubricant compositionDimethyl siloxaneStearate

The invention relates to a wire drawing lubricant, and specifically relates to an environment-friendly high-efficiency wire drawing lubricant with controllable viscosity. The wire drawing lubricant comprises, by weight, 20-25 parts of palm oil, 15-18 parts of glyceryl trioleate, 1-2 parts of zine stearate, 2-3 parts of oleic triglycolate, 1-2 parts of polyisobutylene, 6-8 parts of Tween-80, 1-2 parts of bentonite, 1-2 parts of polydimethylsiloxane, 4-5 parts of an auxiliary agent, and 800-1000 parts of deionized water. According to the invention, the viscosity of the wire drawing lubricant is controlled and adjusted by adding the polyisobutylene and the palm oil in the wire drawing lubricant, and is maintained at a proper level within a relatively wide temperature range; and by combining polyisobutylene and the palm oil with other raw materials, the wire drawing lubricant has good lubricity and stable emulsifiability in a high temperature environment, and is not liable to foam, thereby being suitable for long-time storage. The wire drawing lubricant has the advantages of environment friendship, low toxicity, high wire drawing quality, low power consumption in production and capability of providing aid in producing smooth, clean and anti-corrosion wires.

Owner:ANHUI LEESOV IND

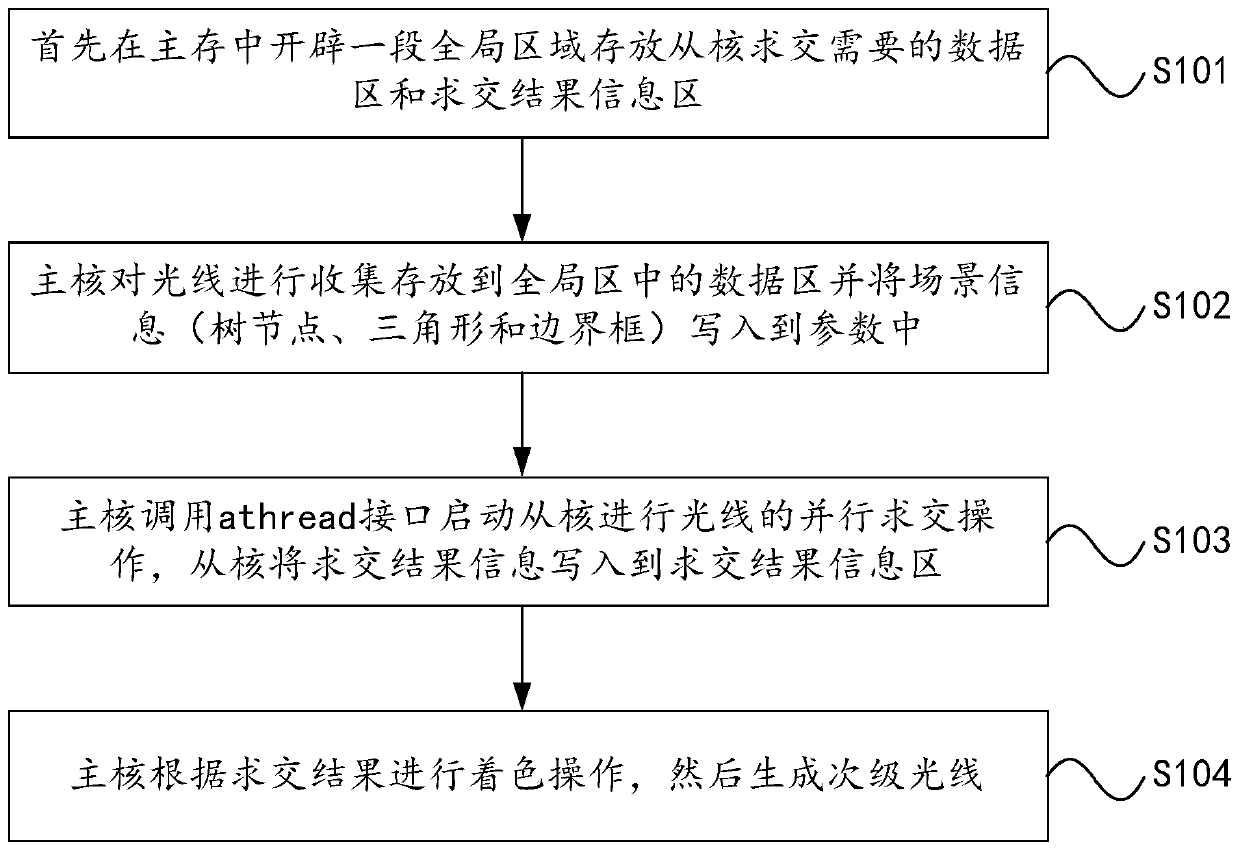

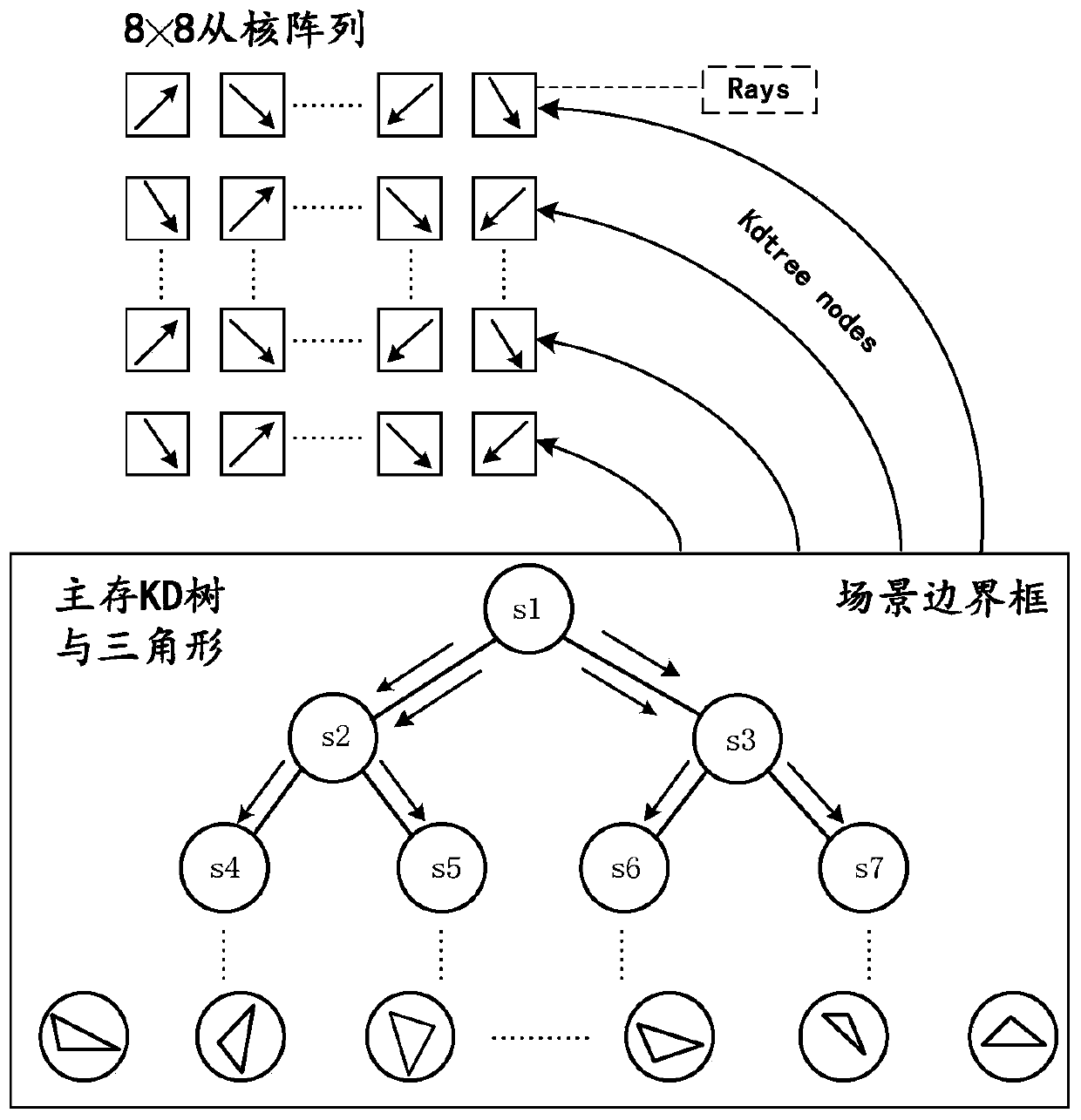

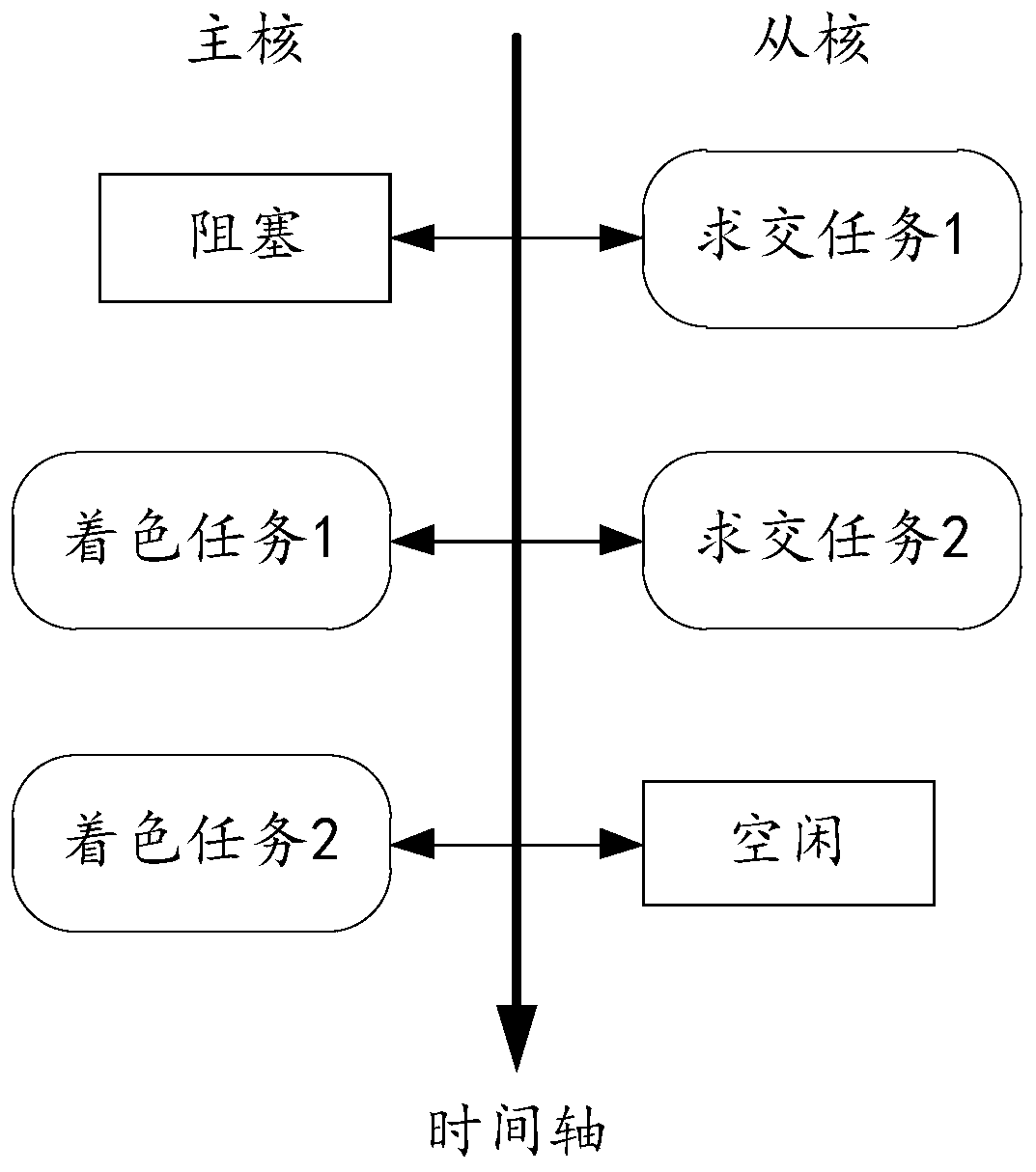

Light parallel intersection method based on many-core processor and optical path tracking system

InactiveCN111402388AShorten the timeGuaranteed drawing quality3D-image renderingComputer hardwareEngineering

The invention discloses a light parallel intersection method based on a many-core processor and an optical path tracking system. The method comprises the steps: opening a global data area used for storing sampling light rays in a main core, performing light ray parallel intersection on the sampling light rays from a core, storing intersection results in the global data area, performing coloring operation by the main core according to the intersection results, and calculating the integral value of the sampling light rays on a light path; separating light intersection and coloring operations from each other; calculating a time ratio of light intersection to coloring operation; dividing the task load of the two; synchronously carrying out the second part of light intersection executed in theslave core and the first part of coloring operation executed in the master core, so the memory of the slave core is fully utilized, the intersection efficiency is effectively improved by utilizing a parallel light intersection mode, the total time of an optical path tracking algorithm is reduced, and the intersection accuracy can be ensured, thereby guaranteeing the drawing quality of an image.

Owner:SHANDONG UNIV

Straight-grain wire drawing machine

PendingCN108620994AGuaranteed to be verticalVertical uniformGrinding machine componentsBelt grinding machinesElectric machineryWave form

The invention discloses a straight-grain wire drawing machine. The machine comprises a machine frame main body, one side of the bottom of the machine frame main body is provided with a motor through amotor bottom plate, guide rails are arranged on the upper end face of a guide rail pair support, the lower end face of a grinding head fixing frame is mounted on the guide rails in a sliding mode, anair cylinder fixing frame is arranged on the upper end face of the grinding head fixing frame, and a lifting air cylinder is installed on the air cylinder fixing frame; an abrasive belt is connectedon an abrasive belt winding and unwinding shaft in a winding mode, abrasive cloth is arranged on the lower end face of the abrasive belt, and the abrasive belt passes through the lower side of a pressing roller; and a working platform is arranged on the upper end face of the machine frame main body, and guide rail baffles are arranged at the positions, located on the outer sides of the guide rails, of the two ends of the working platform. According to the straight-grain wire drawing machine, a grinding head is driven to move through a transmission chain, vibration cannot be generated in the movement process, so that the situation that shock grains are generated on straight grains, and then a wave form and the color difference are formed is avoided, the straight grains of a metal plate areensured to be perpendicular and uniform, the arranged abrasive belt winding and unwinding shaft can be used for updating the abrasive cloth for wire drawing in real time, so that the wire drawing quality is ensured.

Owner:李耀坤

A regular hexagonal drawing die

The invention discloses a regular hexagon drawing die. All relevant parameters of an inlet segment of the regular hexagon drawing die can be quantized. The regular hexagon drawing die comprises a drawing die body. The drawing die body is provided with a drawing forming hole which penetrates through the drawing die body. The drawing forming hole comprises the inlet segment and a sizing segment. The sizing segment comprises six flat-straight faces corresponding to six straight sides of a regular hexagon respectively. The distance between each pair of opposite flat-straight faces is a. The inlet segment comprises six leading-in bevels connected with the corresponding flat-straight faces of the sizing segment. Let the distance between the outer edge lines of each pair of opposite leading-in bevels be d1, then d1 is obtained through the formula showed in the specification, and 7.2<=k1<=7.5. The regular hexagon drawing die is used for drawing a circular pipe and a circular bar into a regular hexagon pipe and a regular hexagon bar respectively.

Owner:苏州华创特材股份有限公司

A metal plate wire drawing processing system and the wire drawing process of the system

ActiveCN108857648BRealize the function of automatic wire drawingImprove work efficiencyGrinding feedersPlane surface grinding machinesEngineeringMetal sheet

The invention relates to a metal plate wire drawing system and a wire drawing technology of the system. The system comprises a bottom plate, a mounting frame, a conveying device and a wire drawing device, a mounting frame is installed on the bottom plate, and the wire drawing device is arranged on the mounting frame; the conveying device is arranged at the lower end of the wire drawing device, theconveying device is installed on the bottom plate, and the conveying device comprises a workbench, a guide rail, an electric sliding block, a storage frame, an extruding air cylinder, an extruding plate, a fixing plate, a lifting telescopic plate, a lifting air cylinder, an auxiliary frame and a limiting telescopic plate; the wire drawing device comprises a driving mechanism and a wire drawing mechanism. The metal plate wire drawing system can solve the problems that in an existing metal plate wire drawing process, only one metal plate can be processed at a time, the work efficiency is low and the moving stability is poor, the automatic wire drawing function of metal plates can be achieved, and the system has the advantages that two plates can be processed at a time, the work efficiency is high and the moving stability is high.

Owner:广州市高比电梯装饰工程有限公司

A system to improve the stability of stainless steel wire drawing

ActiveCN104607476BStable and effective contactGuaranteed drawing qualityEngineeringStainless steel wire

The invention discloses a system for improving the stability of stainless steel wire drawing. A supporting platform is arranged in a supporting frame, a limiting frame is arranged below the supporting platform, the supporting platform is concave inwards to form an installation groove, the supporting platform is provided with a supporting arm, the supporting arm is provided with a compression spring, a compression column is arranged in the compression spring and provided with a compression disk, a hydraulic tank is arranged in the supporting frame, and a multi-stage telescopic arm is arranged in the hydraulic tank; a connecting plate is arranged between limiting plates, the supporting frame is provided with a guide column, through grooves are formed in the limiting plates, limiting columns are arranged above the limiting plates, the supporting platform is provided with an installation plate, an installation shaft is arranged below the installation plate, and a bearing is sleeved on the installation shaft. The system can timely adjust the wear and tear of a wire drawing brush in a wire drawing process, so that the wire drawing brush is always in stable and effective contact with a panel to be subjected to wire drawing, the position of a stainless steel plate is firmly fixed, and the wire drawing quality of the panel is guaranteed.

Owner:ZHONGSHAN WANXIONG KITCHEWARE MFG CO LTD

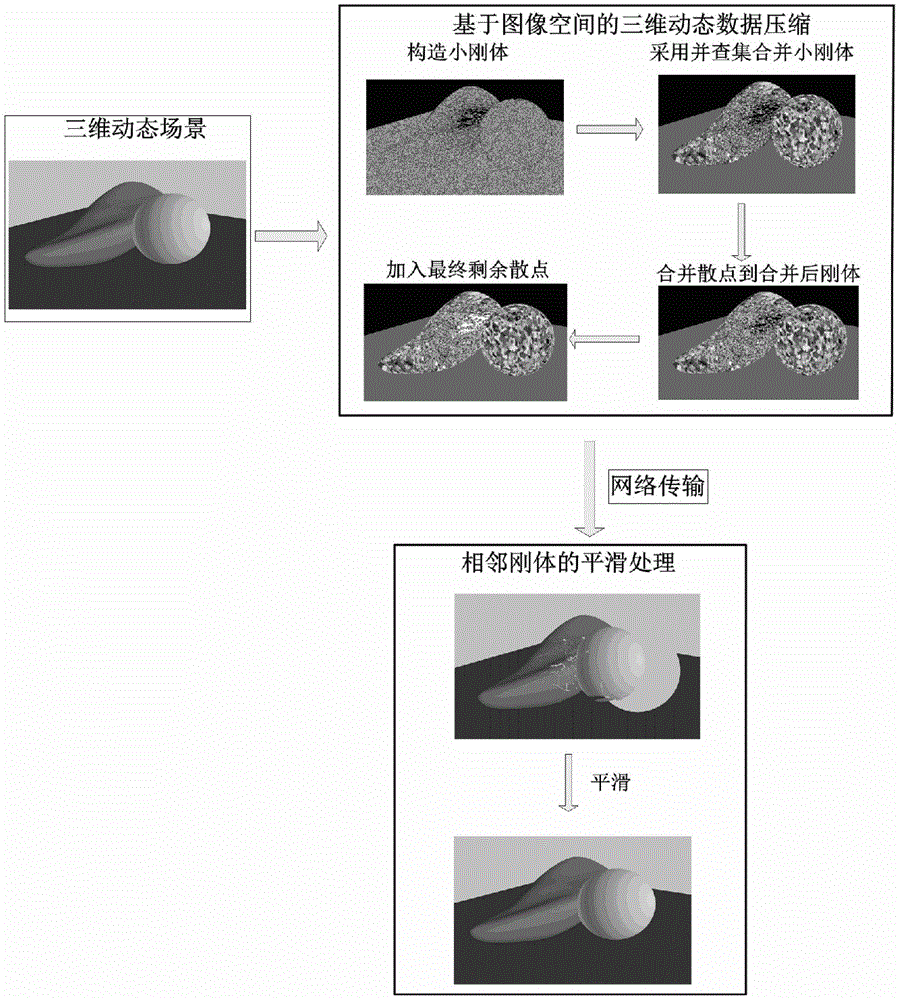

A 3D Dynamic Data Compression and Smoothing Method Based on Image Space

InactiveCN103116897BIncrease the compression ratioGuaranteed drawing qualityImage codingDigital video signal modificationData compressionViewpoints

The invention provides a three-dimensional dynamic data compression and a smoothing method based on image space. The three-dimensional dynamic data compression and the smoothing method based on image space include compressing a sampling point which is projected on a server-side based on the image space, firstly calculating space position of the sampling point at a certain internal, then conducting cluster compression on a motion track to greatly improve data compression rate, conducting smoothing process on a transition area between a client-side and an adjacent rigid body, eliminating gaps between the adjacent rigid body when compression rate is overlarge, and enabling the server-side to transmit dynamic data when the compression rate is overlarge. In a traditional method of interactive three-dimensional figure visualization, when a client-side viewpoint parameter changes, the server-side needs to redraw and transmit a figure with novel viewpoint, and frequent changes of the client-side viewpoint lead to overlarge data transmission amount. The compression of the sampling point motion track can be finished in the image space, GPU parallel calculation characters can be well utilized, rapid and compact compression of the three-dimensional dynamic scene data can be achieved, and limit on a network broadband can be reduced.

Owner:BEIHANG UNIV

A kind of manufacturing method of aluminum alloy thin wire

InactiveCN104715803BGuaranteed cleanlinessGuaranteed drawing qualityMetal/alloy conductorsCable/conductor manufactureElectrical conductorMaterials science

Owner:TONGYONG TIANJIN ALUMINUM ALLOY PROD CO LTD

Stainless steel product surface automatic wire drawing equipment

PendingCN113649895AAutomatic wire drawing realizationControllable drawing speedGrinding carriagesGrinding drivesEngineeringCivil aviation

The invention discloses stainless steel product surface automatic wire drawing equipment. The stainless steel product surface automatic wire drawing equipment comprises a rack, a wire drawing placement platform, a cross beam and a wire drawing mechanism, the wire drawing placement platform is arranged on the rack and can move along the length direction of the rack, and the wire drawing placement platform is used for placing a stainless steel product to be wiredrawn; the cross beam is arranged in the width direction of the rack; the wire drawing mechanism is arranged on the cross beam and can move along the cross beam, the wire drawing mechanism comprises a wire drawing roller, and the wire drawing roller carries out wire drawing process treatment on the stainless steel product to be wiredrawn on the wire drawing placement platform. According to the stainless steel product surface automatic wire drawing equipment, large civil aviation stainless steel products such as check-in and security inspection equipment can be wiredrawn; automatic wire drawing is achieved, the wire drawing speed can be controlled, and the wire drawing quality is guaranteed.

Owner:MEISHAN DEXIN AVIATION EQUIP

Rotary powder box for steel wire production

The invention discloses a rotary powder box for steel wire production. The rotary powder box comprises a powder box and a water box which are independent of each other and are fixedly mounted. A moldcore fixing mechanism is horizontally and rotationally mounted in the water box and comprises a first rotary body, wherein the interior of the first rotary body is hollow, and openings are formed in the two ends of the first rotary body. A wire drawing mold is coaxially and fixedly mounted in the first rotary body. A powder storage mechanism is horizontally and rotationally mounted in the powder box and comprises a second rotary body, wherein the interior of the second rotary body is hollow, and openings are formed in the two ends of the second rotary body. The second rotary body is partiallyand coaxially embedded and mounted in the first rotary body. The first rotary body and the second rotary body can rotate relatively. By means of the rotary powder box for steel wire production, the powder storage mechanism is rotated, so that inside powder constantly rolls, powder caking is avoided, powder has two motion modes of axial pulling and rotating relative steel wires, it is guaranteed that the surfaces of the steel wires are stained with powder evenly, and drawing quality is guaranteed.

Owner:河南巨力钢丝绳制造有限公司

Wire drawing and taking up device for enamelling machine

InactiveCN102496417BEnsure stabilityGuaranteed drawing qualityInsulating conductors/cablesWire rodElectric machinery

The invention discloses a wire drawing and taking up device for an enamelling machine. The wire drawing and taking up device comprises a take-up motor, a take-up capstan motor and a wire drawing motor, wherein the output end of the take-up motor is connected with a rotating shaft of a take-up reel through a driving device; the output end of the take-up capstan motor is connected with a rotating shaft of a take-up capstan through a driving device; a wire spool of the take-up capstan is connected with a wire spool of the take-up reel through an enamelled wire; the output end of the wire drawingmotor is sequentially connected with a first belt pulley, a second belt pulley and a rotating shaft of a wire drawing capstan through the driving device; and the enamelled wire is sequentially connected with wheel surfaces of an upper wire-drawing cone pulley, a wire-drawing die carrier, a lower wire-drawing cone pulley, the wire drawing capstan, a wire return wheel and a guide pulley of a tension control device of the wire drawing capstan. According to the wire drawing and taking up device disclosed by the invention, the wire drawing capstan and the take-up capstan are respectively independent; the wire drawing capstan is controlled by adopting tension; the take-up capstan is separately driven by using the motor; and the wire-drawing speed or the take-up speed can be changed by adjustingthe rotating speed of the motor according to the production requirement, thereby ensuring the quality of finished wires.

Owner:无锡市梅达电工机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com