Manufacturing method for aluminum alloy fine wires

A manufacturing method and technology of aluminum alloy wire, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, electrical components, etc., to achieve the effects of not easy to creep and relax, increase the drawing speed, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

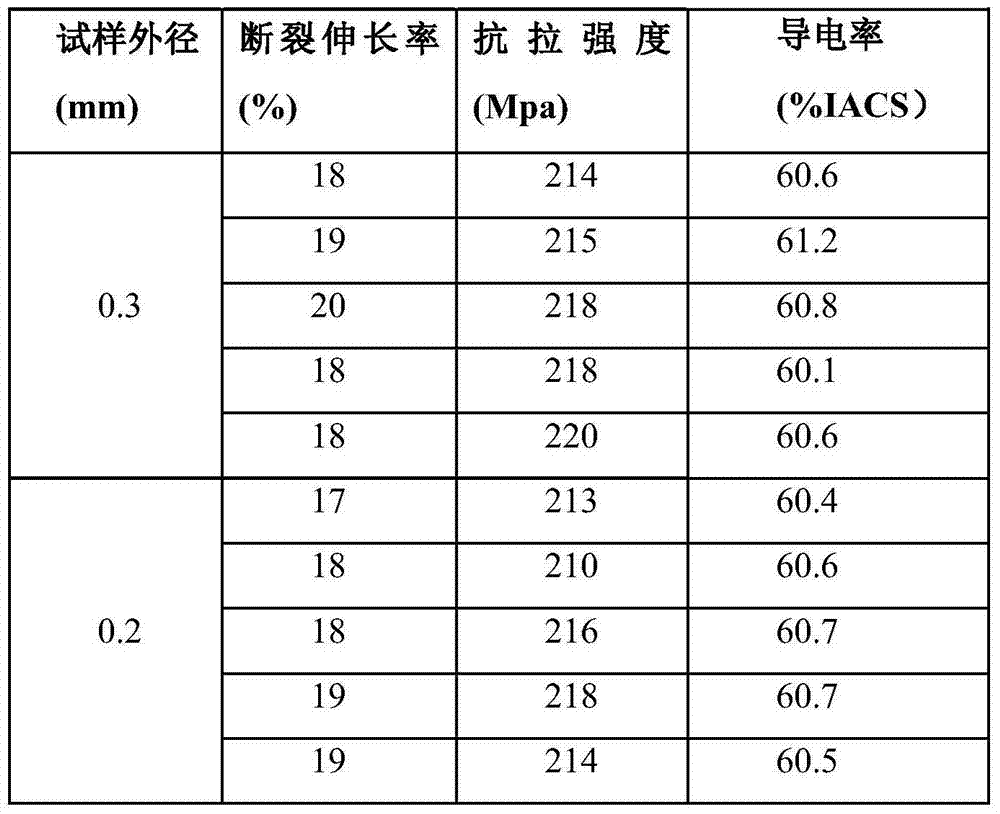

Image

Examples

Embodiment 1

[0039] Embodiment 1 of the present invention provides a method for manufacturing an aluminum alloy filament with a wire diameter of 0.2 mm, comprising the following steps:

[0040] a) Initial drawing: the aluminum alloy rod is drawn and processed into an aluminum alloy wire, and the drawing speed of the drawing process is 30m / s;

[0041] b) Secondary drawing: the aluminum alloy wire obtained in step a) is drawn into an aluminum alloy wire, and the drawing speed of the drawing process is 15m / s;

[0042] c) Three-time drawing: the aluminum alloy wire obtained in step b) is drawn into aluminum alloy filaments, and the drawing speed of the drawing process is 10m / s;

[0043] d) Heat treatment process: the aluminum alloy filament obtained in step c) is subjected to a process of heating-heating-cooling, wherein,

[0044] During the heating process, the aluminum alloy filament is heated to 340°C, and the required heating time is 2 hours;

[0045] During the heat preservation process...

Embodiment 2

[0054] Embodiment 2 of the present invention provides a method for manufacturing aluminum alloy filaments with a wire diameter of 0.2 mm. The same parts as those in Embodiment 1 will not be described in detail, and the differences are as follows:

[0055] Include the following steps:

[0056] a) Initial drawing: the aluminum alloy rod is drawn into an aluminum alloy wire, and the drawing speed of the drawing process is 20m / s;

[0057] b) Secondary drawing: the aluminum alloy wire obtained in step a) is drawn into an aluminum alloy wire, and the drawing speed of the drawing process is 10m / s;

[0058] c) Three-time drawing: the aluminum alloy wire obtained in step b) is drawn to make aluminum alloy filaments, and the drawing speed of the drawing process is 15m / s;

[0059] d) Heat treatment process: the aluminum alloy filament obtained in step c) is subjected to a process of heating-heating-cooling, wherein,

[0060] In the above heating process, the temperature of the aluminum...

Embodiment 3

[0064] Embodiment 3 of the present invention provides a method for manufacturing aluminum alloy filaments with a wire diameter of 0.2 mm. The same parts as those in Embodiments 1 and 2 above will not be described in detail. The differences are:

[0065] Include the following steps:

[0066] a) Initial drawing: the aluminum alloy rod is drawn into an aluminum alloy wire, and the drawing speed of the drawing process is 25m / s;

[0067] b) Secondary drawing: the aluminum alloy wire obtained in step a) is drawn into an aluminum alloy wire, and the drawing speed of the drawing process is 12m / s;

[0068] c) Three-time drawing: the aluminum alloy wire obtained in step b) is drawn into aluminum alloy filaments, and the drawing speed of the drawing process is 12m / s;

[0069] d) Heat treatment process: the aluminum alloy filament obtained in step c) is subjected to a process of heating-heating-cooling, wherein,

[0070] In the above heating process, the temperature of the aluminum allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com