Rotary powder box for steel wire production

A technology of powder box and steel wire, applied in the field of rotating powder box for steel wire production, can solve the problems of uneven surface contamination of steel wire, affecting the tensile performance of steel wire, scratching the surface of steel wire, etc. The effect of increasing the chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

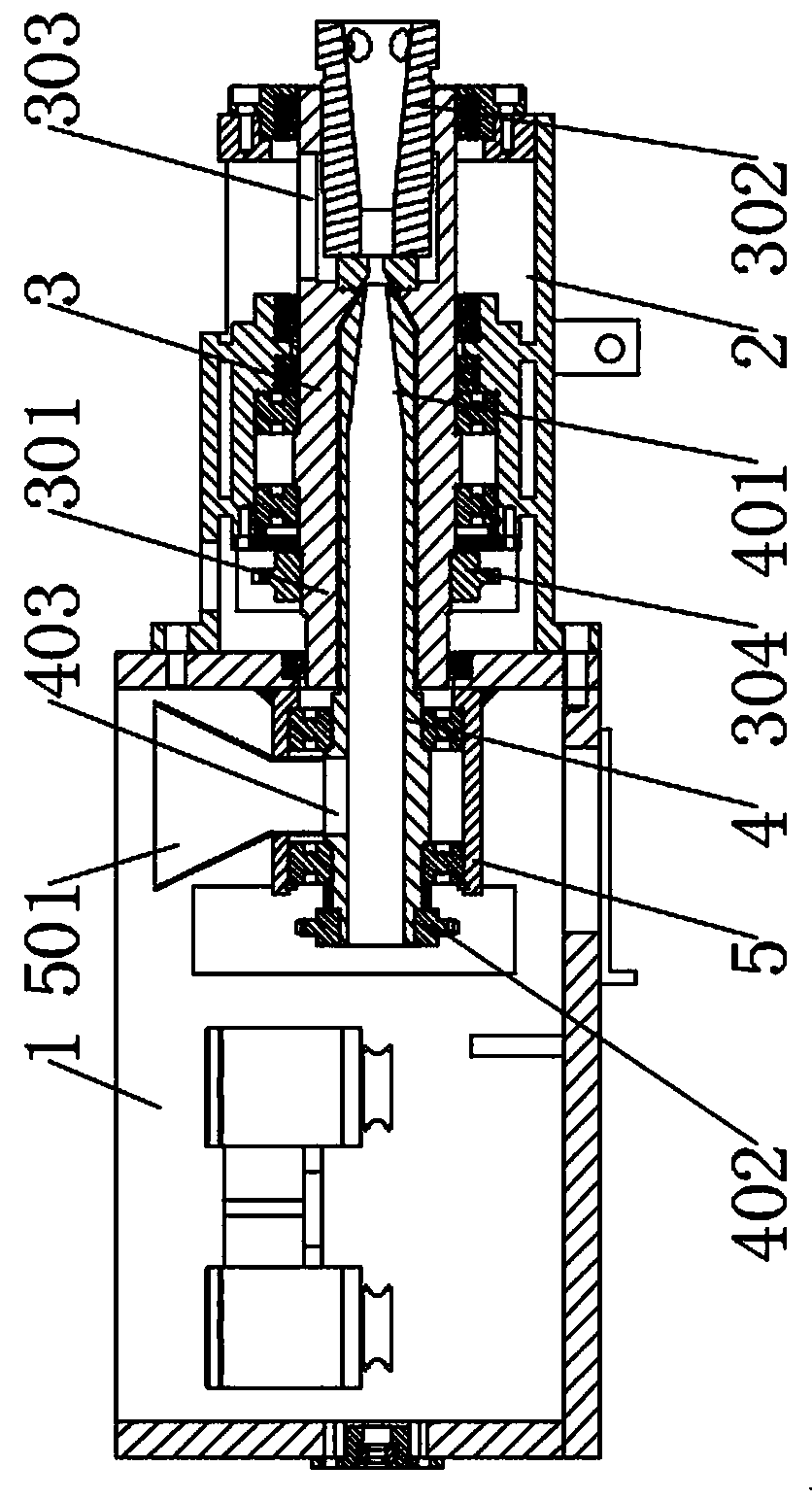

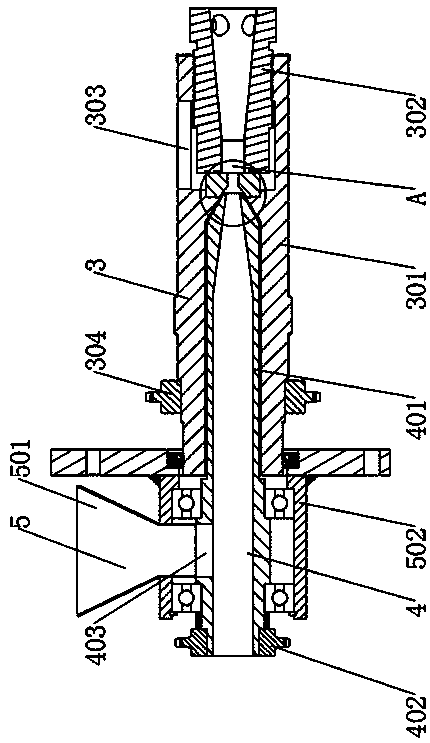

[0026] see Figure 1-5 , the present invention provides a technical solution: a rotary powder box for steel wire production, including a powder box 1 and a water box 2 that are independent of each other and fixedly installed. 3. It includes the first rotating body 301 which is hollow inside and open at both ends. The inside of the first rotating body 301 is coaxially fixed with a drawing die, and the inside of the powder box 1 is horizontally rotated to install a powder storage mechanism 4. And the second rotating body 401 with both ends open, the second rotating body 401 is partially coaxially nested and installed inside the first rotating body 301, the first rotating body 301 and the second rotating body 401 can rotate relatively, the second rotating body 401 is located on the outer peripheral wall of the first rotating body 301 to provide a powder inlet 403 , and the powder inlet 403 communicates with the hollow area inside the second rotating body 401 .

[0027] The insid...

Embodiment approach 2

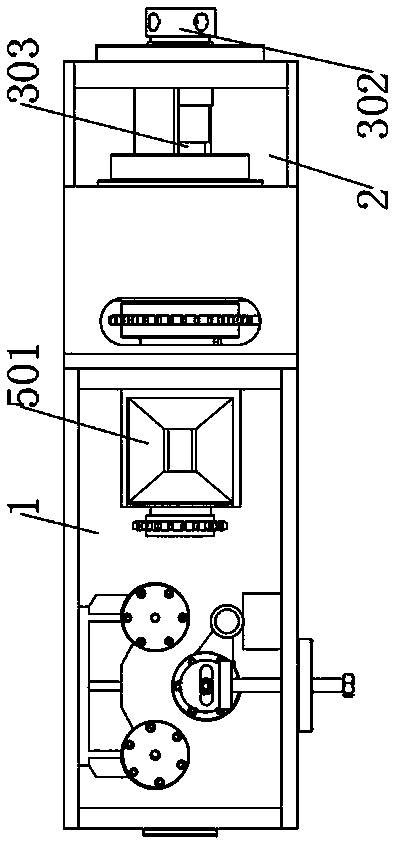

[0039] see Figure 6-7 , the present invention provides a technical solution: a rotary powder box for steel wire production, including a powder box 1 and a water box 2 that are independent of each other and fixedly installed. 3. It includes the first rotating body 301 which is hollow inside and open at both ends. The inside of the first rotating body 301 is coaxially fixed with a drawing die, and the inside of the powder box 1 is horizontally rotated to install a powder storage mechanism 4. And the second rotating body 401 with both ends open, the second rotating body 401 is partially coaxially nested and installed inside the first rotating body 301, the first rotating body 301 and the second rotating body 401 can rotate relatively, the second rotating body 401 is located on the outer peripheral wall of the first rotating body 301 to provide a powder inlet 403 , and the powder inlet 403 communicates with the hollow area inside the second rotating body 401 .

[0040] The insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com