Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Guaranteed distillation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

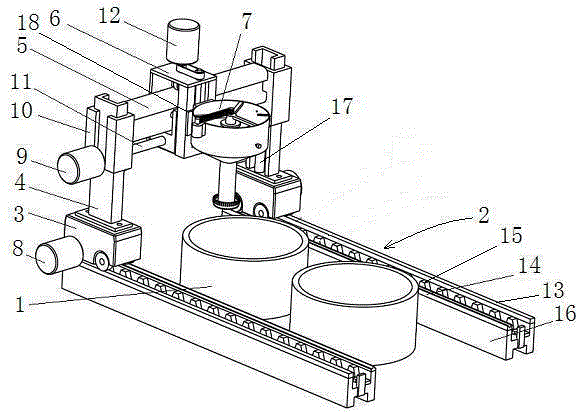

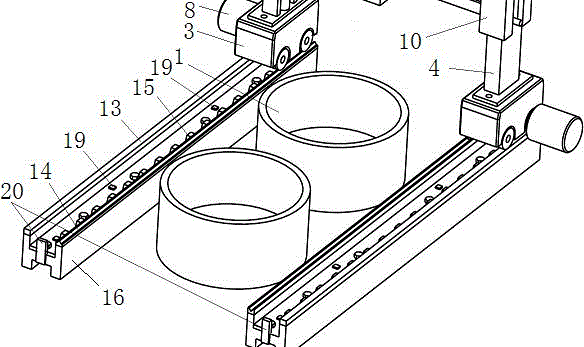

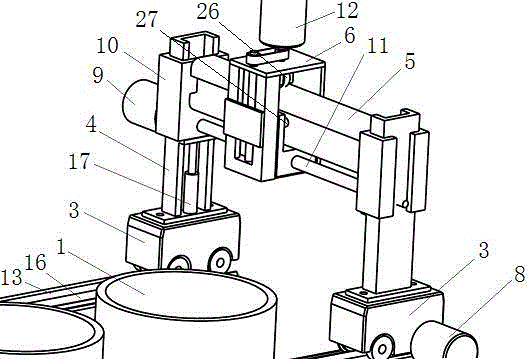

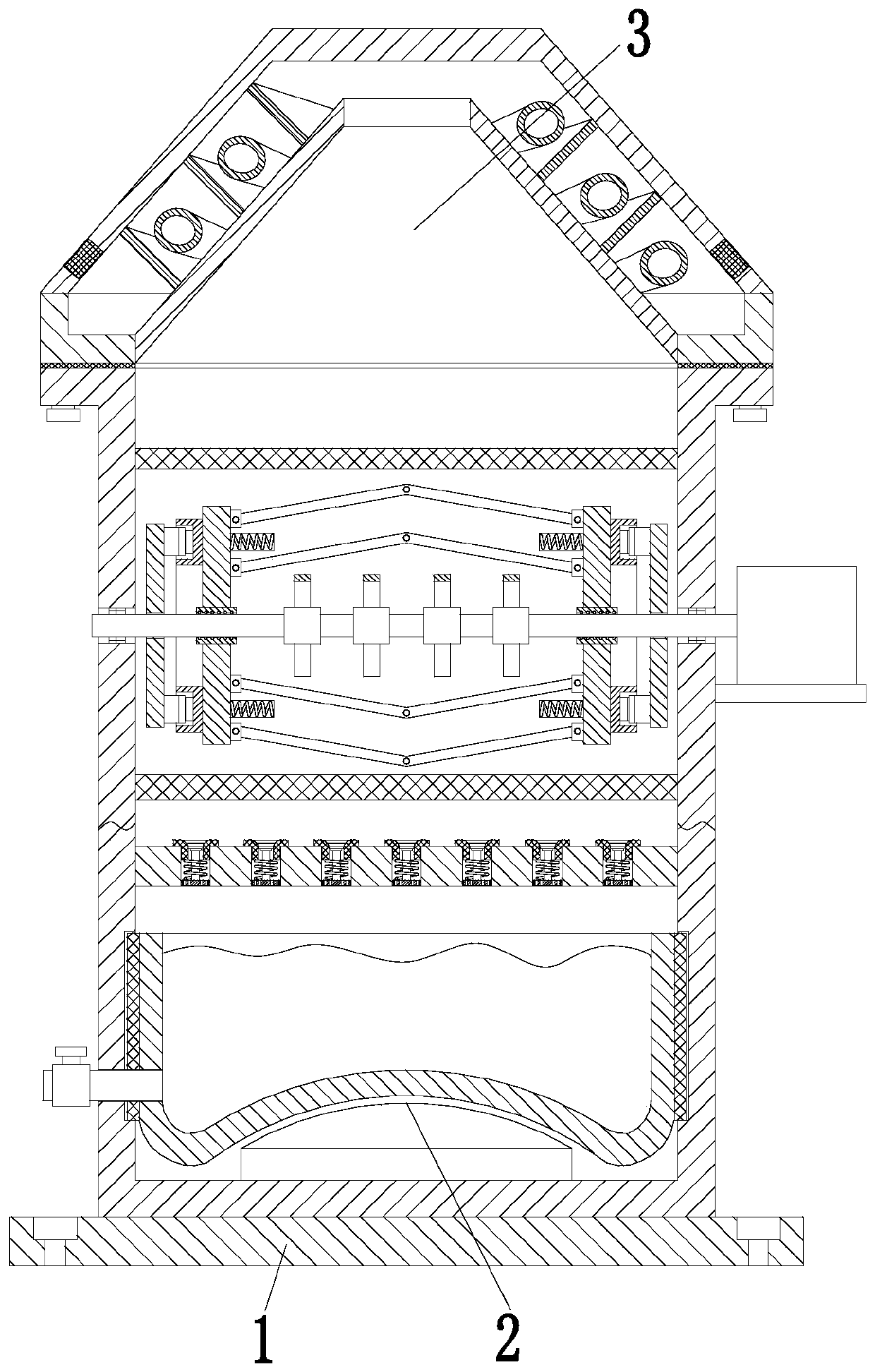

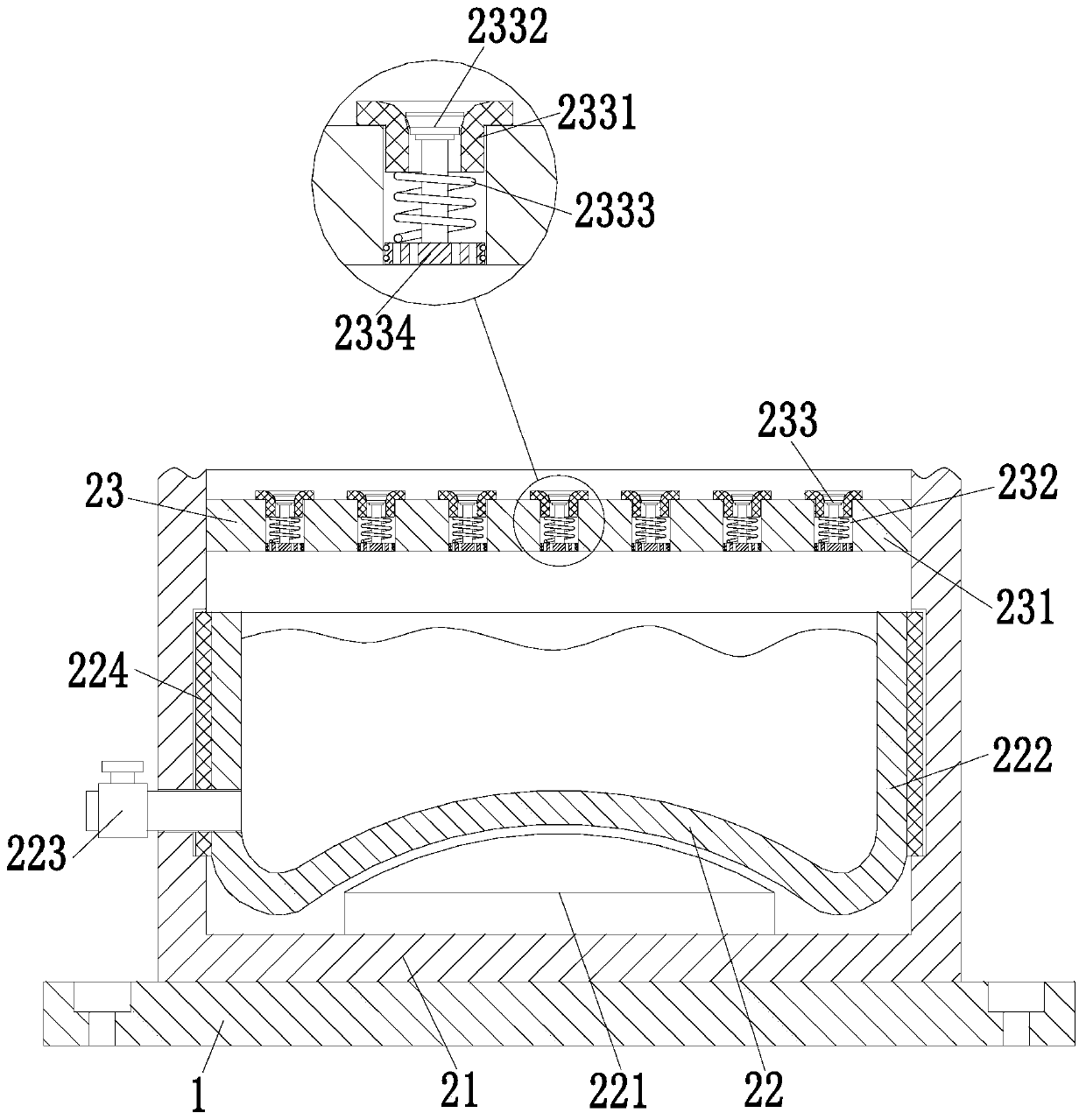

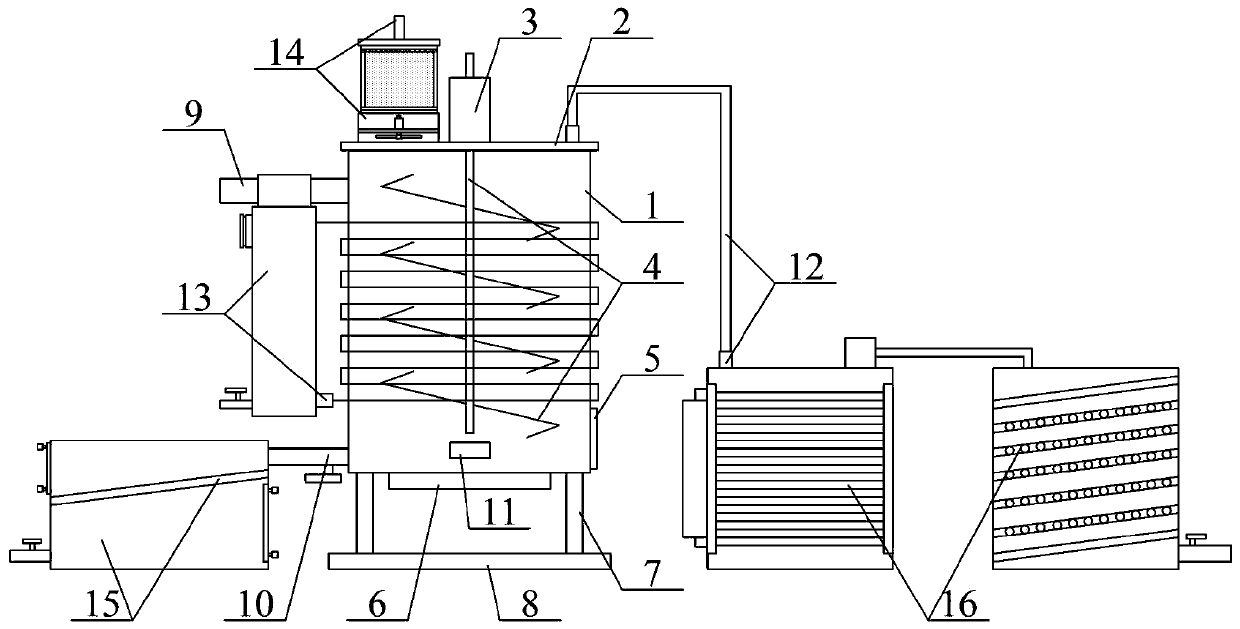

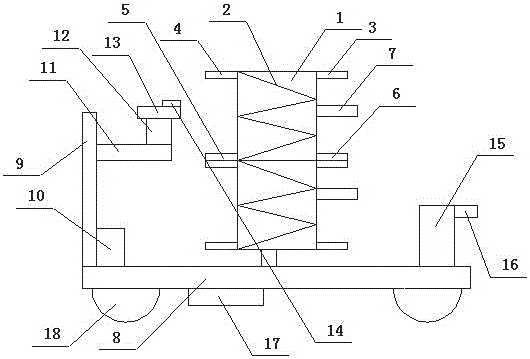

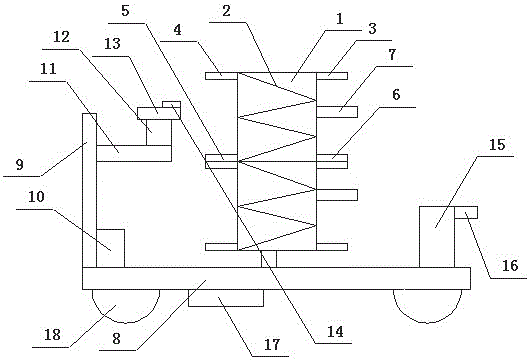

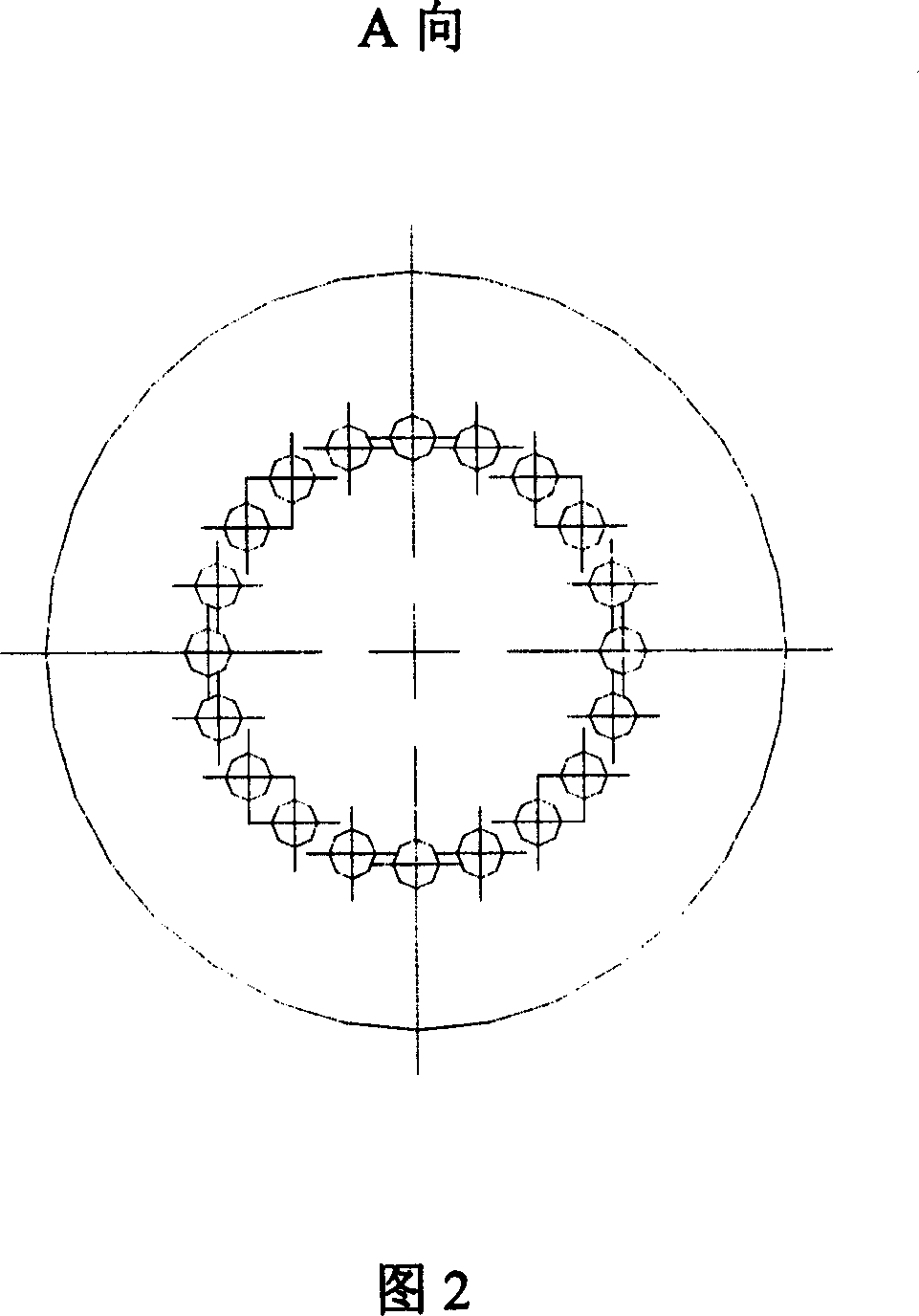

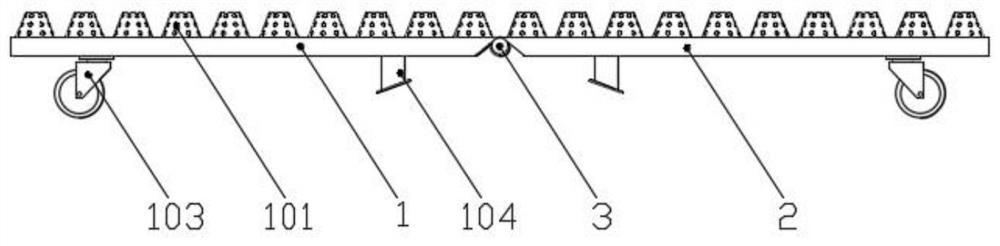

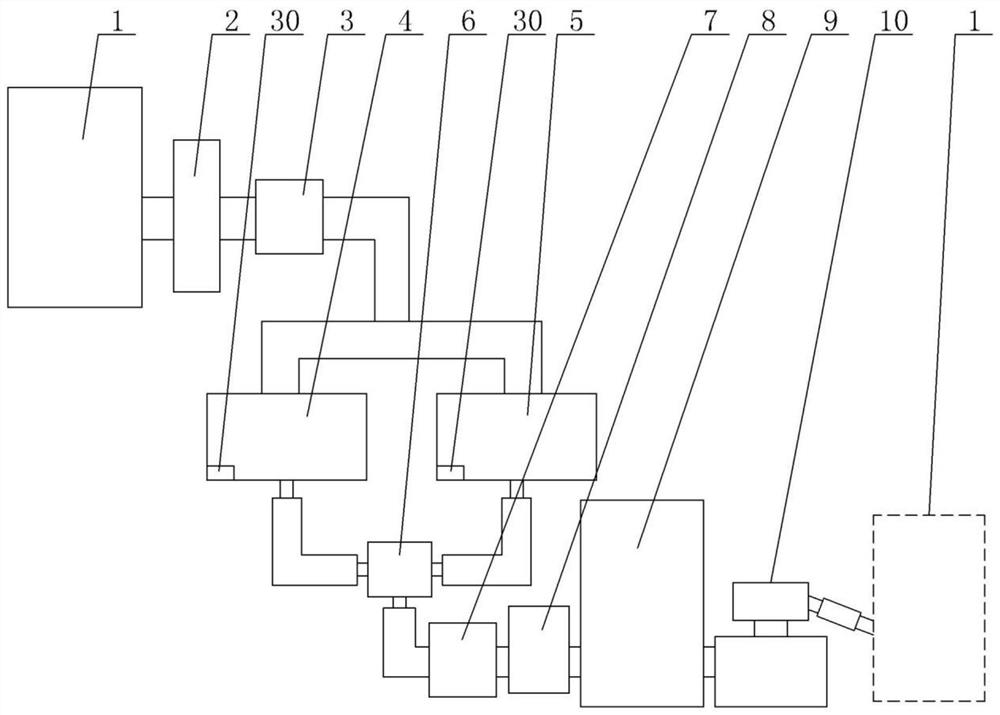

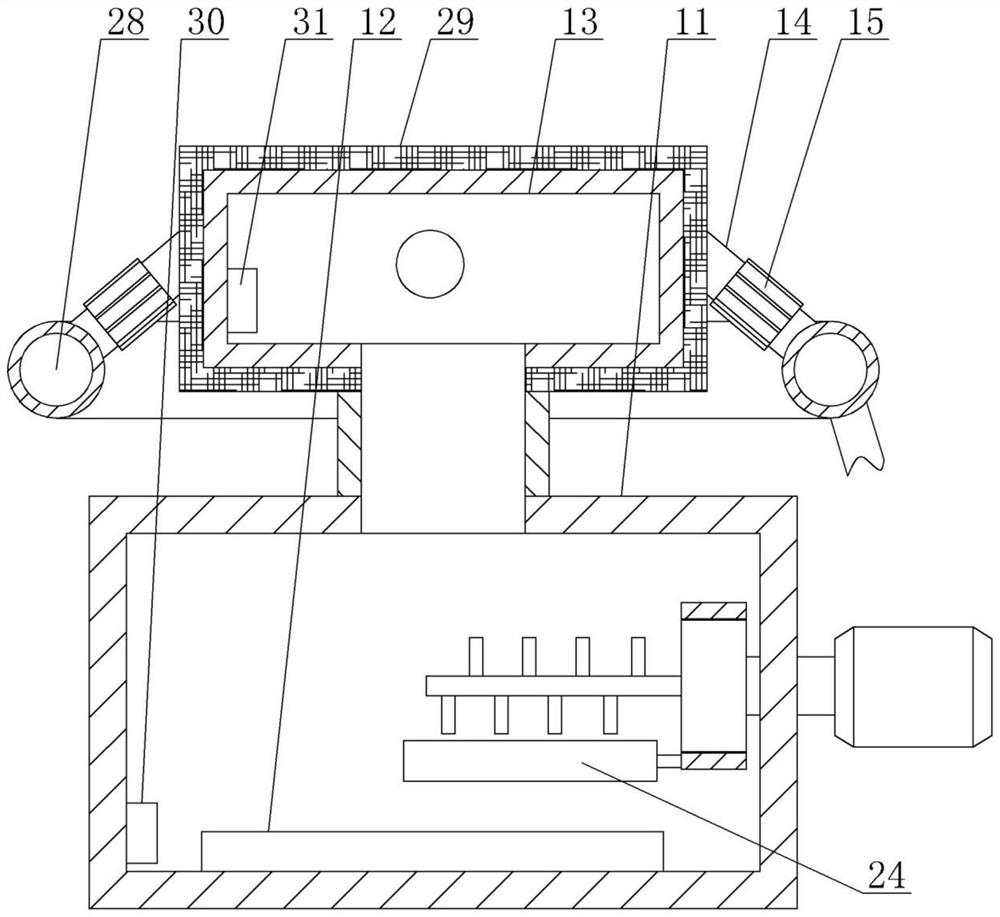

Gantry fermented grain automatic loading machine and loading method

InactiveCN104816954AIncrease loading capacityLower performance requirementsConveyorsAlcoholic beverage preparationSteam pressureControl system

The invention discloses a gantry fermented grain automatic loading machine. The gantry fermented grain automatic loading machine comprises a gantry fermented grain loading robot, a fermented grain loading execution mechanism, a binocular vision identifying system and a control system, wherein the gantry fermented grain loading robot consists of two horizontal guide rails, two stand columns, a cross beam and a ram; the fermented grain loading execution mechanism is mounted on the ram; and the binocular vision identifying system comprises a steam running identification thermal infrared imager and a height identification thermal infrared imager, whose output ends are connected to an input end of the control system. The gantry fermented grain loading robot is excellent in loading capacity, and the performance requirement of the robot can be reduced, so that the equipment cost investment is reduced; the guide rails consisting of a flat guide rail, a V-shaped guide rail and a rack composition are adopted to bear the position deviation caused by slight displacement generated in the fermented grain loading motion process, so that the material distributing and feeding accuracy is guaranteed, and the distilling effect is improved; and the binocular vision identifying system is adopted to obtain the material surface temperature distribution and height, so that fermented grains are uniform to prevent the air way blockage and the steam pressure, and the distillation effect is guaranteed.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

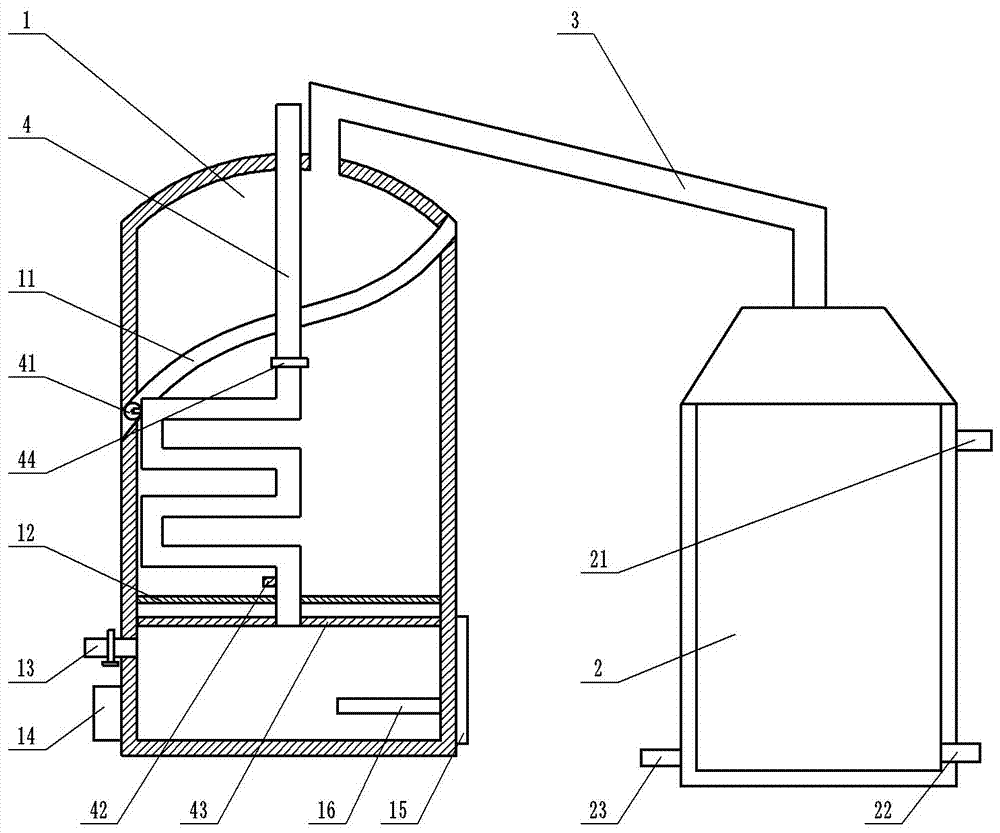

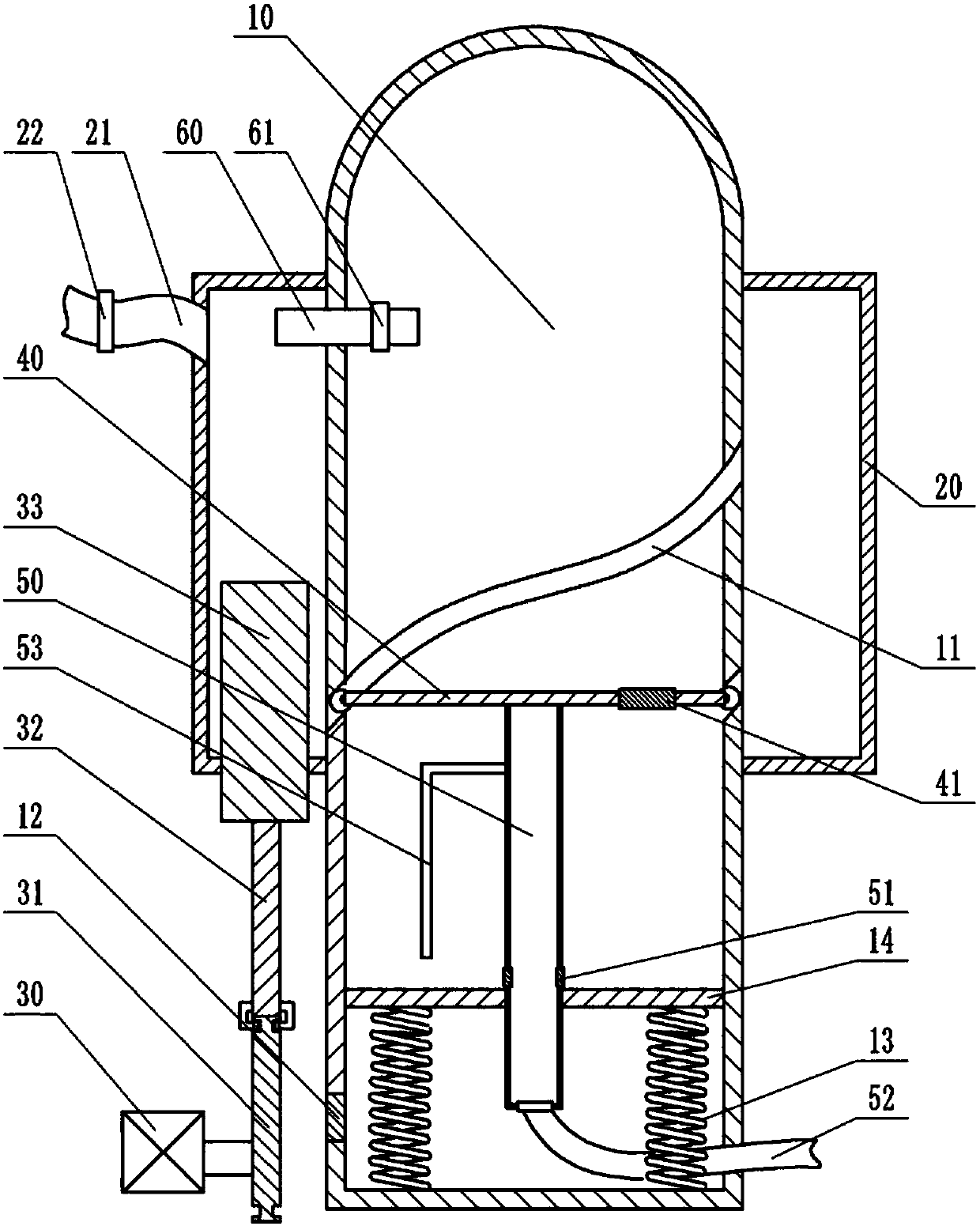

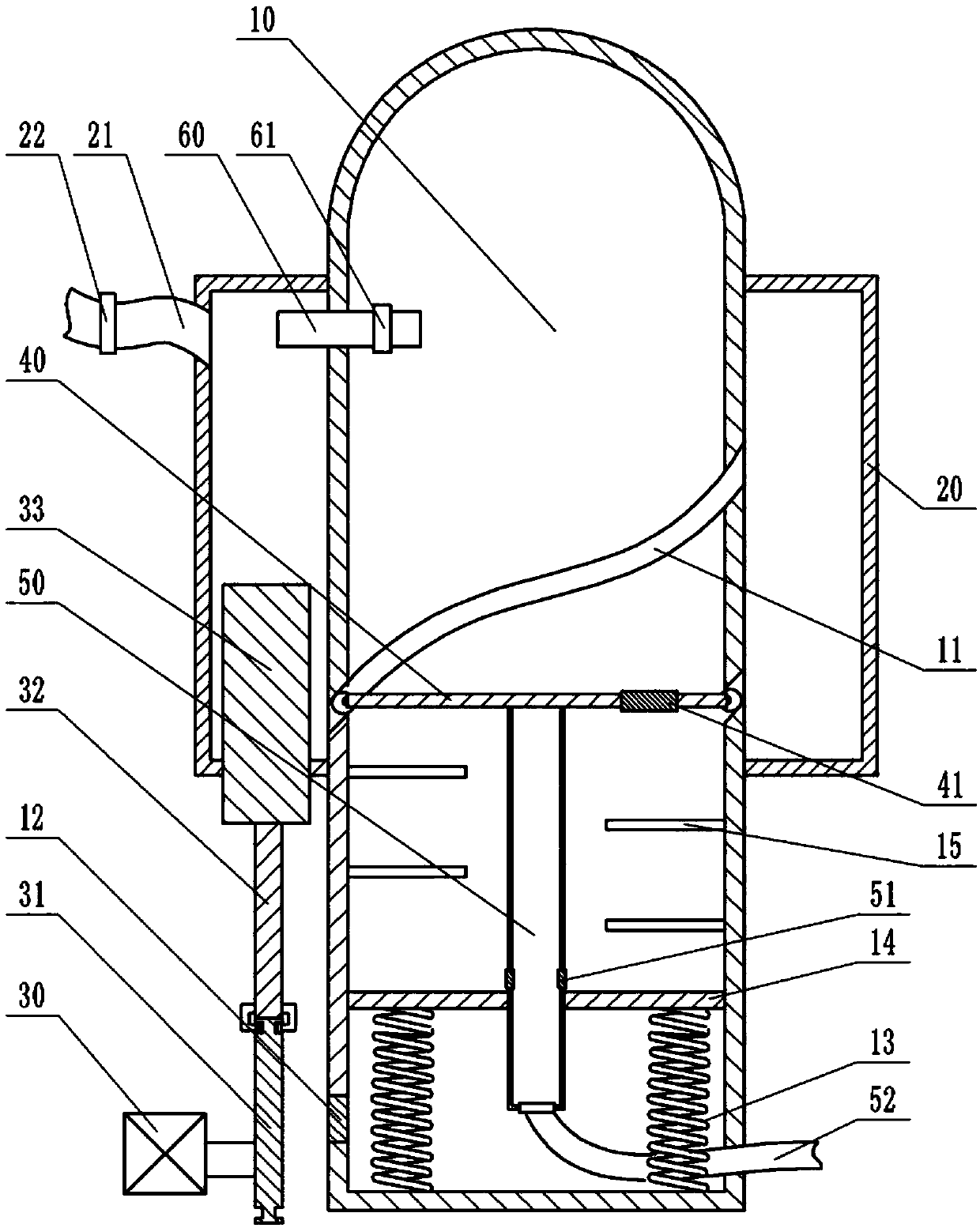

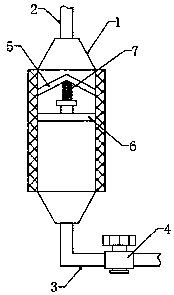

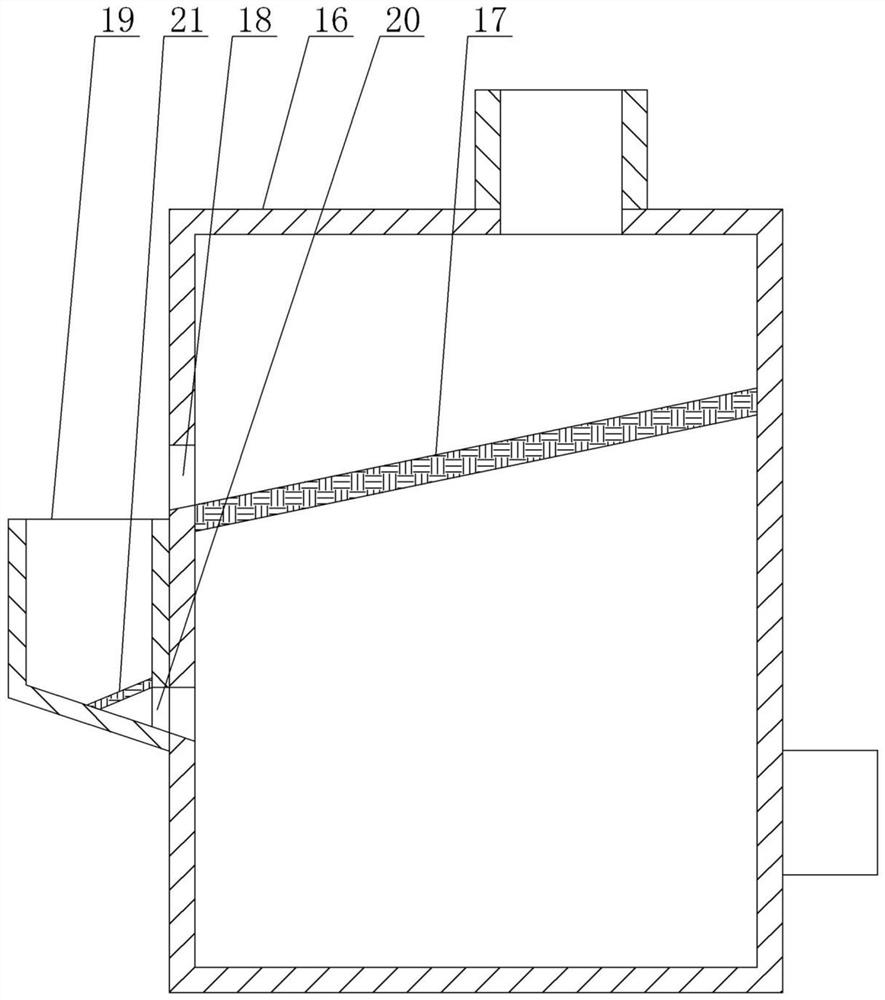

Baijiu brewing device

InactiveCN106867849AEnsure no direct contactQuality impactAlcoholic beverage preparationEngineeringDistillation method

The invention belongs to the technical field of preparation of alcoholic beverages in a distillation method, and particularly discloses a Baijiu brewing device. The Baijiu brewing device comprises a distillation retort, a gas introduction pipeline and a condensation apparatus, wherein one end of the gas introduction pipeline is communicated with the upper portion of the distillation retort, and the other end is communicated with the condensation apparatus; a partition plate is installed in the distillation retort, and a heating apparatus is arranged at a portion positioned below the partition plate in the distillation retort; and the Baijiu brewing device also comprises a steam pipeline with a bent middle portion, and a pressure valve is arranged in the steam pipeline; two free ends of the steam pipeline are positioned on a same straight line, one end of the steam pipeline is connected to the center of the upper portion of the distillation retort in a sliding manner, and the other end is connected to the center of the partition plate in a sliding manner; a spiral groove is formed on the inner wall of the distillation retort above the partition plate, and the steam pipeline is provided with a rolling ball; and the lower end of the steam pipeline is connected with a pushing plate, and the steam pipeline penetrates through the pushing plate. The technical scheme is adopted to distill Baijiu, and the original fermented liquid can be stirred when Baijiu is distilled, so that the original fermented liquid is uniformly heated, and the distillation effect can be ensured.

Owner:贵州省仁怀市茅台镇永泰酒业股份有限公司

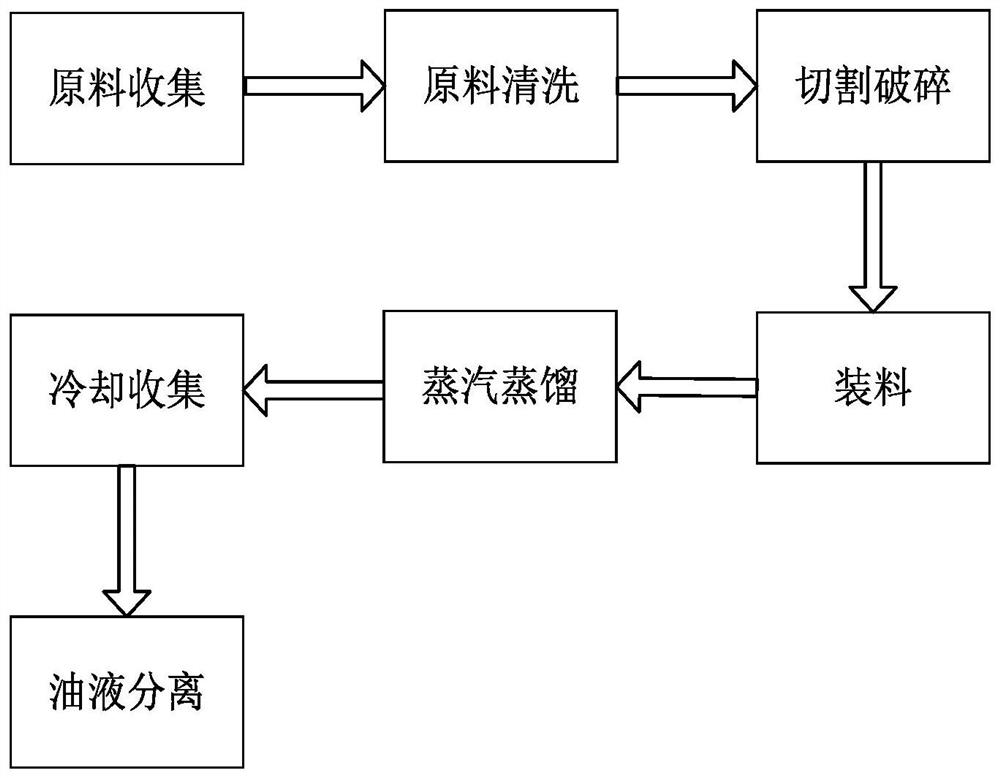

Plant essential oil distillation preparation method

ActiveCN111349520APrevent falling backReduce wasteEssential-oils/perfumesProcess engineeringIndustrial engineering

The invention relates to a plant essential oil distillation preparation method. An adopted device comprises a bottom plate, a distillation device and a cooling device, the bottom plate is of a rectangular structure, mounting holes are uniformly formed in the bottom plate, the distillation device is mounted in the middle of the upper end of the bottom plate, and the cooling device is mounted at theupper end of the distillation device. The device can solve the problems that when existing equipment performs distillation processing on plant essential oil; plant raw materials cannot be overturnedand shifted; raw materials are generally stacked together, hot steam is difficult to completely contact with raw materials; the distillation effect of essential oil in raw materials is poor, the extraction efficiency is low, and when the existing equipment is used for condensing plant essential oil, hot steam cannot be rapidly cooled, so that the condensation effect of mixed steam is poor, the essential oil is prone to losing along with water vapor, and then the plant essential oil is prone to being wasted are solved.

Owner:珠海水信生物科技有限公司

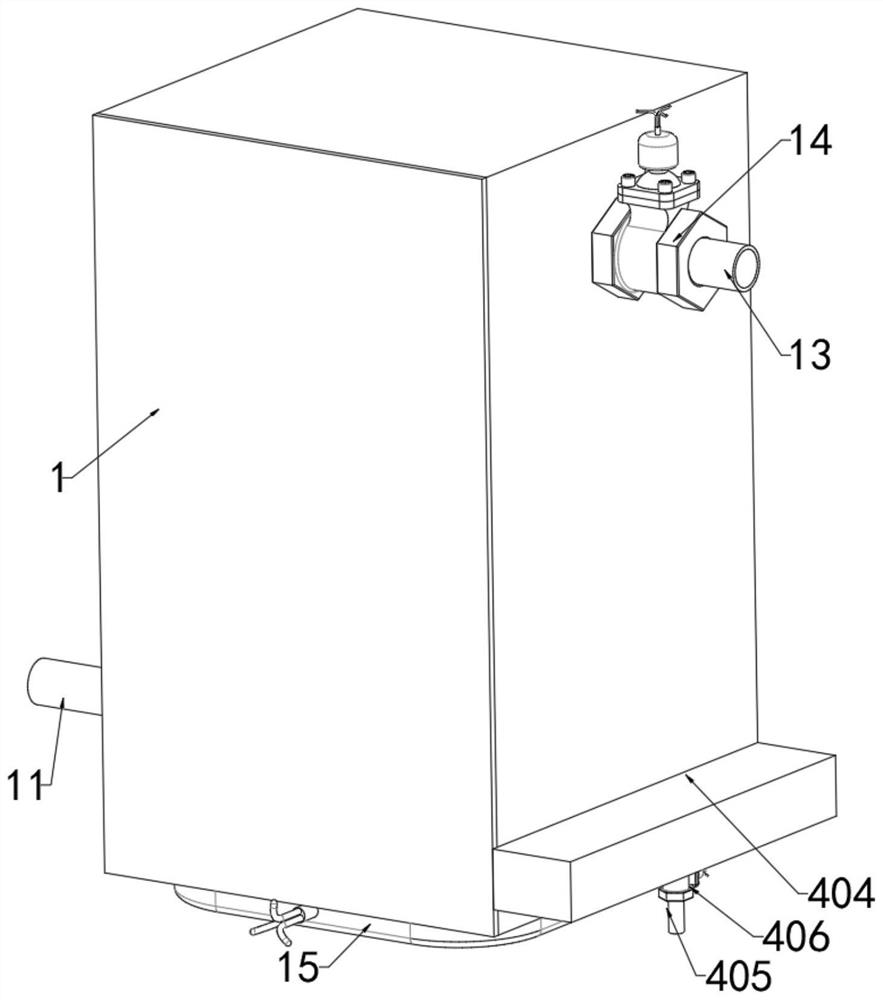

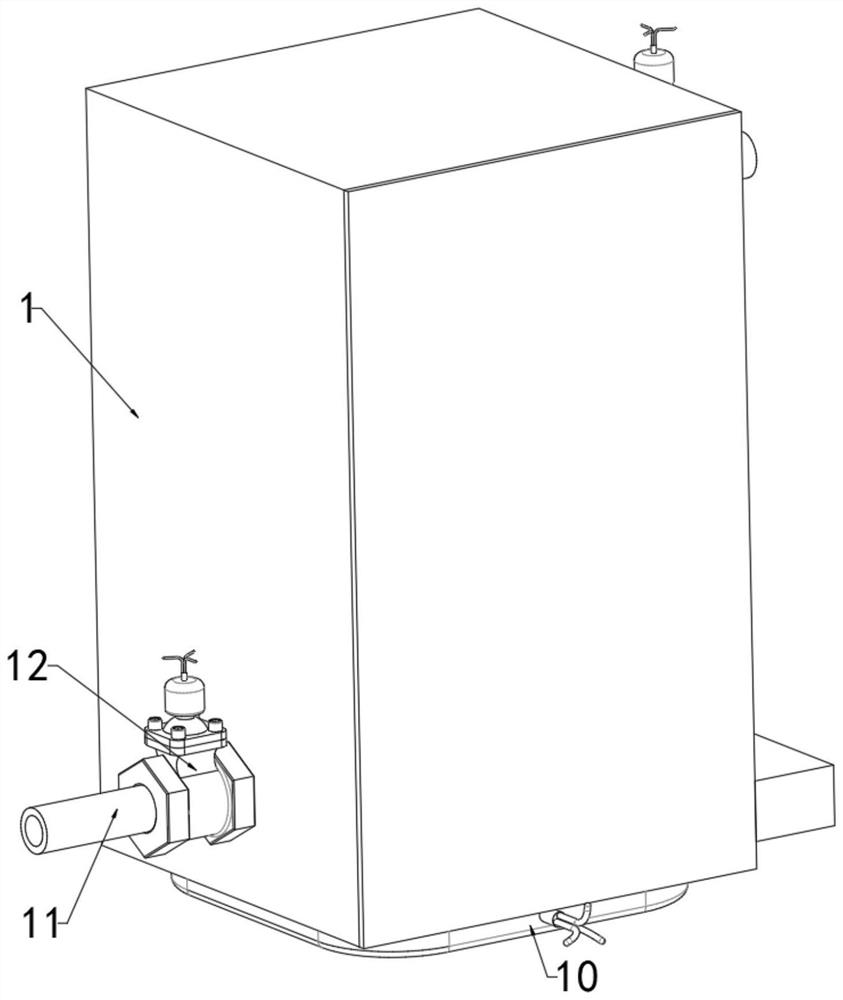

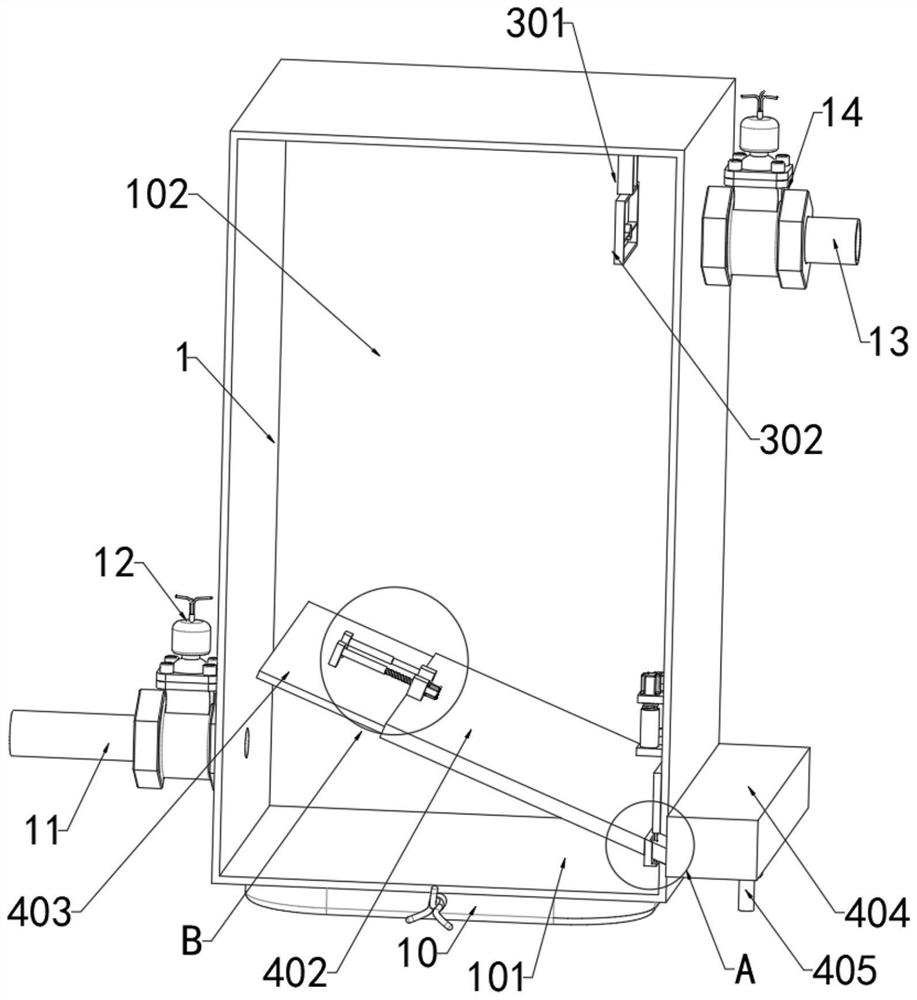

Energy-saving distillation device of multifunctional lubricating oil production equipment

InactiveCN111589179AAvoid wastingSave resourcesDispersed particle separationEnergy recuperation in distillationWater storage tankOil production

The invention provides an energy-saving distillation device of multifunctional lubricating oil production equipment. The device comprises a distillation tank, a tank cover, a stirring motor, an auger,a control panel, a heater, support legs, a fixed base, a lubricating oil guide pipe, an oil discharge pipe with a valve, a temperature sensor and an air guide pipe, and the upper end of the distillation tank is in threaded connection with the tank cover. A waste heat heating water storage tank, a hollow hanging seat, a water injection cover, a drain valve, a circulating pump and a waste heat waste-free reutilization heating circulating pipe are arranged, thus facilitating resource saving, and avoiding waste of thermal energy resources; when the heater is used for heating the distillation tank, heat is dissipated and the waste heat waste-free reutilization heating circulating pipe can be heated; at this time, water in the waste heat heating water storage tank is continuously sucked out through the circulating pump, circulating heating is continuously conducted through the waste heat waste-free reutilization heating circulating pipe, heat recycling work can be conducted, resource wasteis avoided, energy is saved, environmental friendliness is achieved, and no pollution is caused.

Owner:苑昀辉

Preparation method for alkyl alcohol amine

ActiveCN105085282AHigh reactivityHigh selectivityOrganic compound preparationAmino-hyroxy compound preparationAlkaneAlcohol

The invention discloses a preparation method for alkyl alcohol amine. The preparation method comprises the following steps: (1) feeding alkyl amine and a reaction promoter alkanolamine into a reaction kettle for stirring and mixing; (2) adding epoxy alkane for synthesis, wherein the feeding molar ratio of epoxy alkane for synthesis to alkyl amine is higher than the theoretical reaction molar ratio; (3) after the feeding is finished, carrying out heating and pressurization; (4) carrying out heat preservation conversion rate to obtain a crude product; (5) conducting continuous distillation on the crude product to separate out alkyl alcohol amine. During the preparation, alkanolamine is primary alkanolamine or secondary alkanolamine. Compared with the prior art, the preparation method provided by the invention adopts the technical scheme that alkanolamine is taken as the reaction promoter instead of water as a catalyst, so that the conversion rate of alkyl amine can reach 99.0% in general, the highest conversion rate can reach 99.9%, and the highest recovery rate of alkyl alcohol amine can reach 99.8%. Therefore, the preparation method provided by the invention has the advantages of being high in raw material conversion rate and recovery rate.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

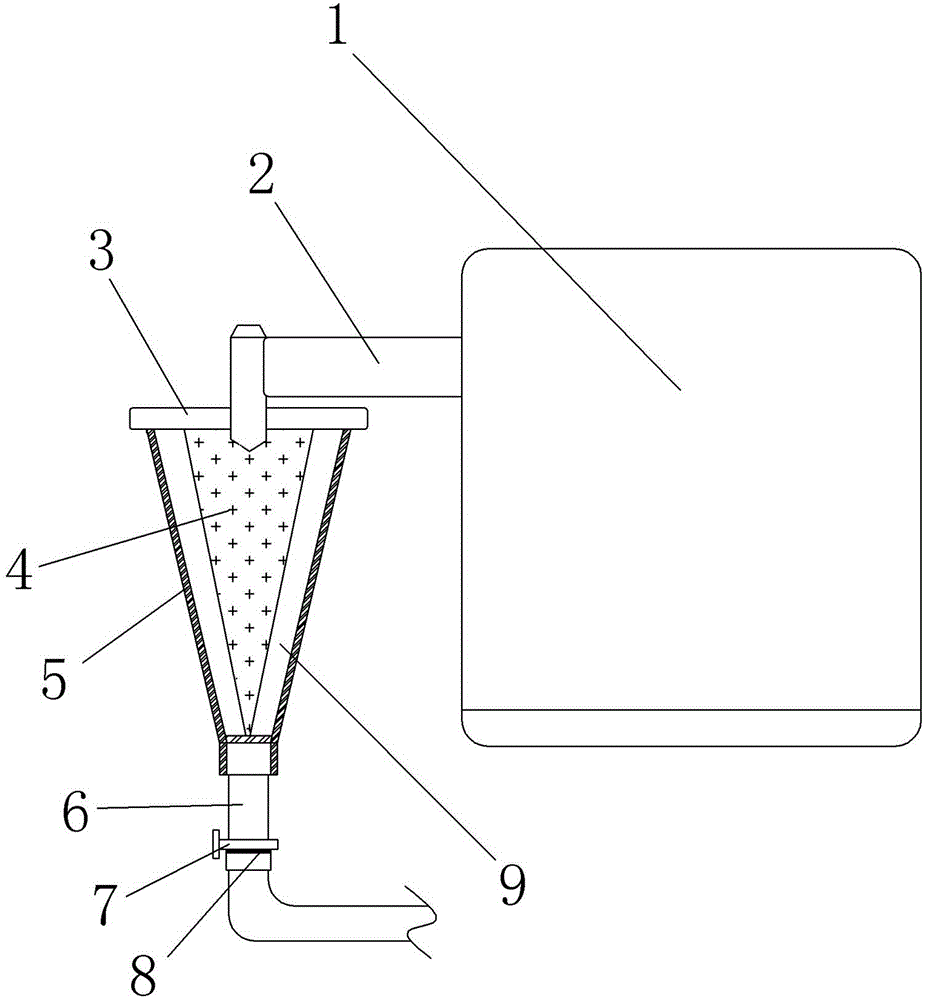

Steam back-flow preventer for brewing machine

InactiveCN104357302APrevent backflowIncrease flow rateAlcoholic beverage preparationProcess engineeringCheck valve

The invention relates to the technical field of brewage, and particularly relates to a steam back-flow preventer for a brewing machine. The steam back-flow preventer comprises a liquor steam pipeline which is connected with the upper part of a distillation device, and is connected with a conical shell, wherein the section of one end, far from the liquor steam pipeline, of the conical shell is gradually reduced; a cavity is formed inside the conical shell; a cushion layer is arranged on the inner wall of the conical shell; the cavity is filled with the absorption cotton; the other end of the conical shell is connected with a diversion pipe; and a check valve is arranged on the diversion pipe. The steam back-flow preventer for the brewing machine has the effects of preventing liquor steam from flowing back and guaranteeing the distilling effect.

Owner:重庆星湖茶酒厂

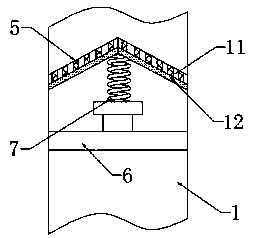

Distillation column used for solvent recovery

InactiveCN107551588AFully contactedGood for interphase mass transferDistillation separationUniversal jointDistillation

The invention belongs to the technical field of solvent recovery, and more specifically discloses a distillation column used for solvent recovery. The distillation column used for solvent recovery comprises a distillation tank, a power unit, and a spoiler; a separating plate is slidingly arranged in the lower part of the distillation tank; springs are arranged between the separating plate and theinternal wall of the distillation tank; the distillation tank is provided with a single-way door below the separating plate; the internal wall at the middle part of the distillation tank is provided with a plurality of spiral grooves; the spoiler is connected with rolling balls via hinge joint; a pressure valve is arranged on the spoiler; a steam pipe is fixedly arranged on the lower surface of the spoiler; the side wall of the steam pipe is provided with a first single-way valve; the lower end of the steam pipe is connected with a corrugated pipe through a universal joint; the side wall of the distillation tank is provided with a material storage sandwich layer; a feed pipe is arranged in the material storage sandwich layer; a second single-way valve is arranged on the feed pipe; the power unit is used for driving waste solvent in the material storage sandwich layer to move into the distillation tank through the feed pipe. The distillation column is used for solvent recovery, is capable of reducing gas rising speed, ensuring distillation effect, and increasing product quality.

Owner:重庆天穗环保科技有限公司

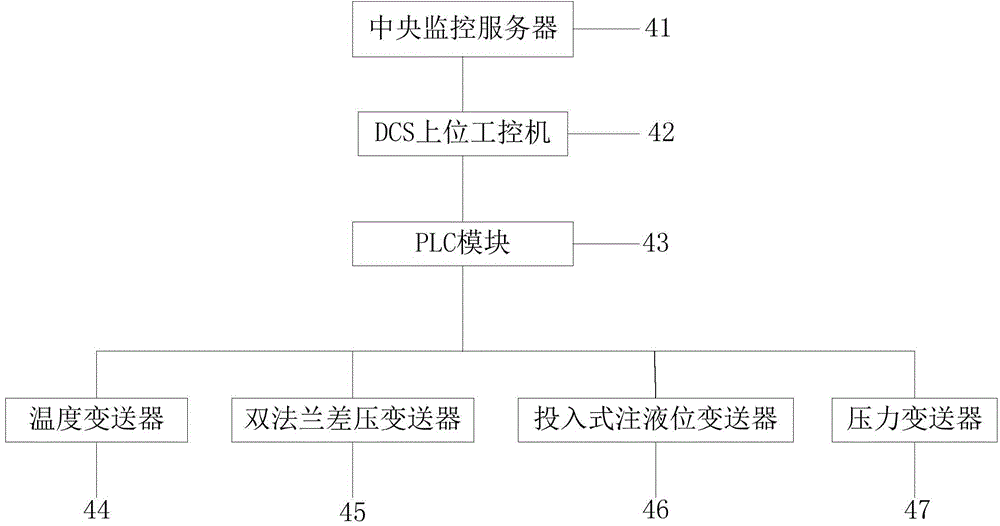

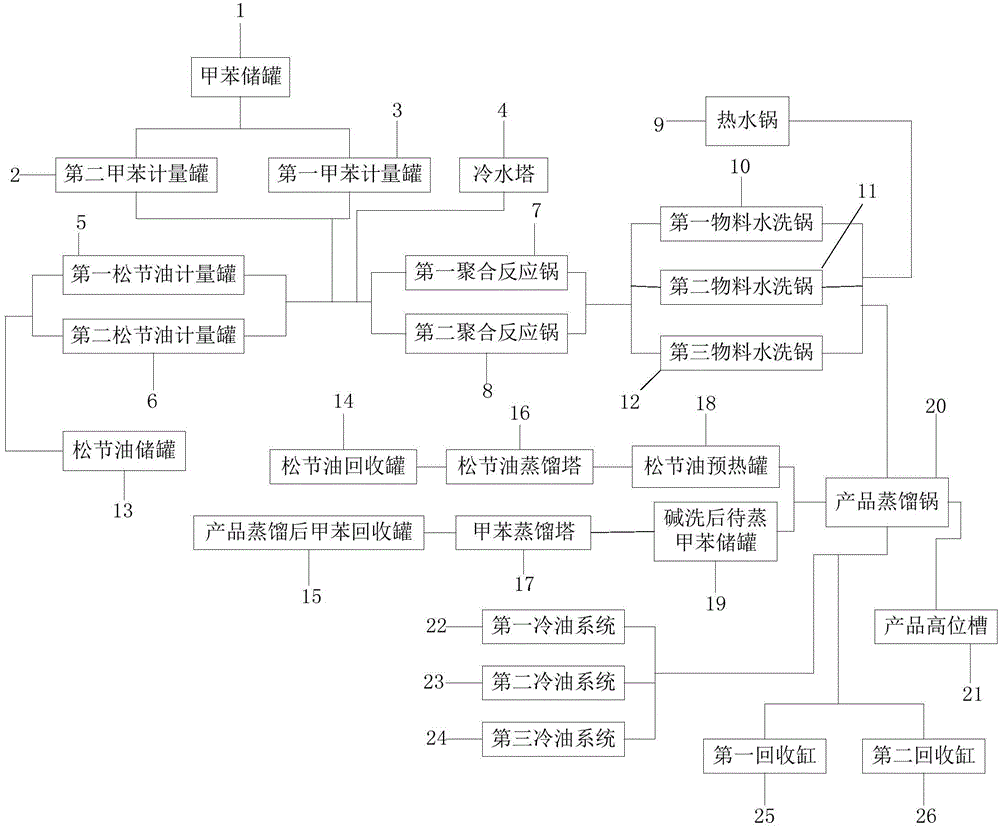

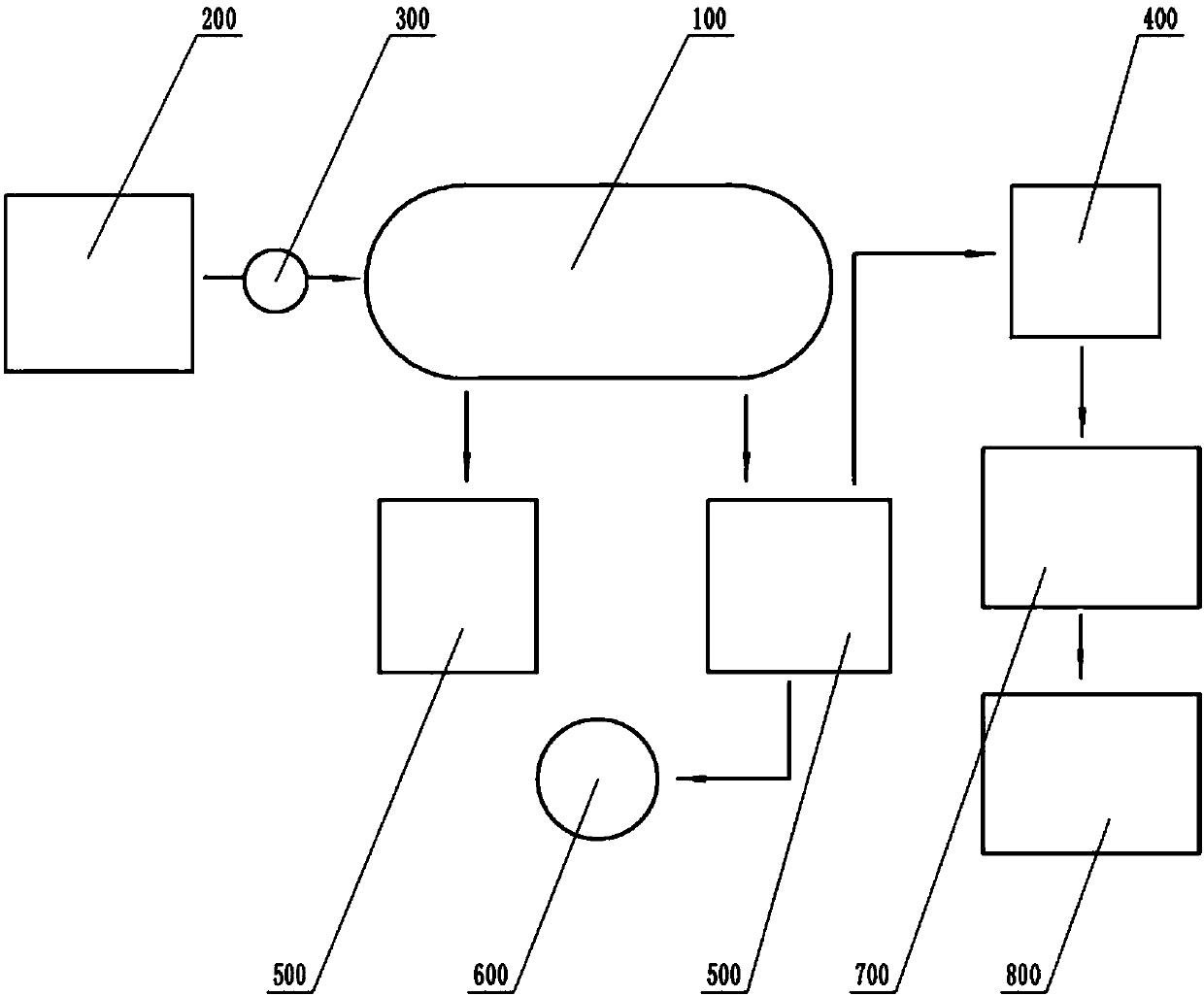

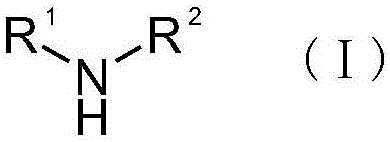

DCS redundancy control system for foodstuff grade terpenes resin production line

InactiveCN104898586AIncrease yieldAchieve separationTotal factory controlProgramme total factory controlDistillationControl system

The invention relates to the control technology field and particularly relates to a DCS redundancy control system for the foodstuff grade terpenes resin production line. The DCS redundancy control system for the foodstuff grade terpenes resin production line comprises a central monitor server, a DCS upper industrial computer, and a PLC module which are connected successively. The PLC module is connected to a temperature transmitter, a double-flange differential pressure transmitter, a throw-in type liquid level transmitter and a pressure transmitter. The DCS redundancy control system for the foodstuff grade terpenes resin production line solves the extra polymer produced through the polymerization process, improves the yield, realizes the effective separation of the high / low polymer and the catalysis residue, solves the problems of the water volume of the hot water supply system and the super high energy consumption materials, solves the explosion caused by the overreaction in the polymerization procedure, solves the no good distillation effect in the toluene distillation process and hard control in the reaction process, guarantees the product distillation effect and improves the product yield rate.

Owner:GUANGXI TIANNENG TECH CO LTD

High-efficiency lubricating oil production and purification equipment

InactiveCN111575051AGood for preliminary filtrationGuaranteed purityTreatment with plural serial refining stagesLubricant compositionWaste oilVALVE PORT

The invention provides high-efficiency lubricating oil production and purification equipment. The high-efficiency lubricating oil production and purification equipment comprises a stirrer, a distiller, a heating sheet, an outer heat preservation shell, a main controller, an oil suction pump, a purifier, a cooling box, a cooling liquid injection pipe, a cooling liquid discharge valve, a waste oil discharge valve, a flow guide pipe, a lubricating oil eduction pipe and a mechanical valve. According to the invention, a crude oil purification buffer hopper, an inlet pipe and oil outlet pipe, an adsorption sheet and movable bolts, a cleaning plate, an observation window and a crude oil primary filter screen are arranged, so preliminary impurity filtering of crude oil is facilitated, and distillation effect is ensured; the crude oil is introduced into the crude oil purification buffer hopper through the inlet pipe, impurities are filtered through a crude oil primary filter screen, the filtering condition is observed through the observation window, so that cleaning can be conducted conveniently; meanwhile, iron impurities in crude oil can be adsorbed in an auxiliary mode through the adsorption sheet, so that the purity of the crude oil can be guaranteed; impurities in the crude oil primary filter screen and the crude oil purification buffer hopper can be cleaned by loosening the movable bolts and taking down the cleaning plate, the operation is convenient, and the filtering effect is guaranteed.

Owner:苑昀辉

Circumferential falling film distillation tower

InactiveCN110404284AEfficient deliveryEfficient processFractional distillationDistillationEngineering

The invention discloses a circumferential falling film distillation tower, comprising a tower body, a shunt mechanism and an insulation mechanism. The shunt mechanism is installed in the tower body, the insulation mechanism is installed on the outside of the tower body, the upper end of the tower body is provided with a feed pipe, the lower end of the tower body is provided with a discharge pipe,and the external of the discharge pipe is provided with a control valve; the shunt mechanism comprises a shunt plate, a limit plate and a reset spring; the limit plate is installed in the internal position of the power body, and the reset spring is installed between the limit plate and the shunt plate; the insulation mechanism comprises a coiled tube, a heating bin and a booster pump; and one endof the heating bin is connected with the booster pump through a pipeline, and the output end and the input end of the heating bin are respectively connected with the two ends of the coiled tube. The distillation tower has the advantages that the feed of the tower body can be shunted rapidly, the insulation effect of the tower body is good through the insulation mechanism set up, and the influenceof the large temperature difference between the inside and outside of the tower body and the loss of heat in the tower on the distillation work is avoided.

Owner:南京颐维环保科技有限公司

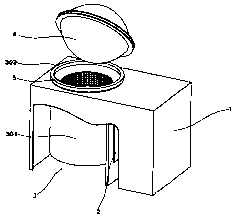

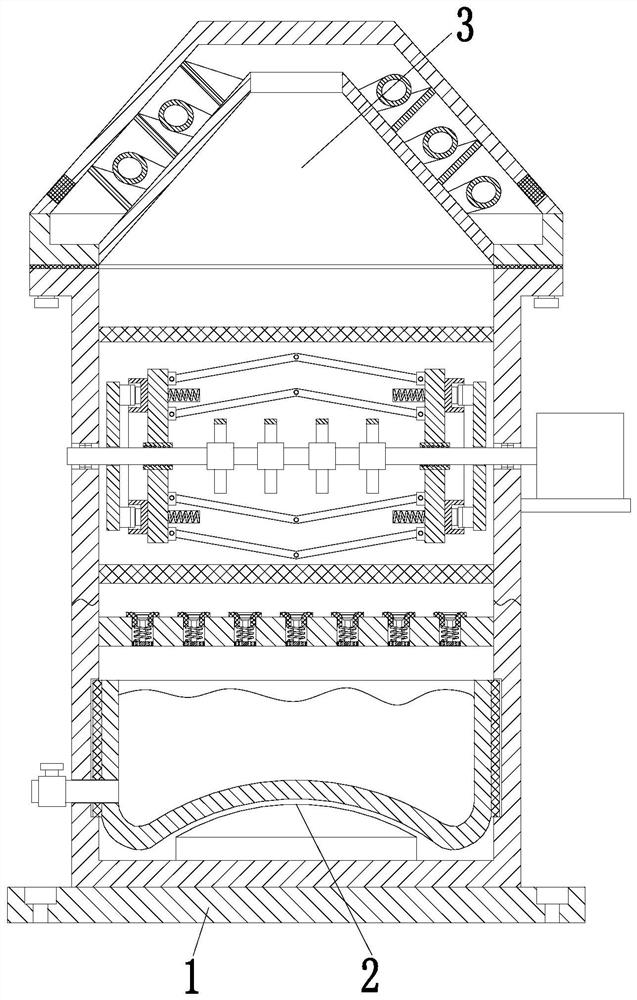

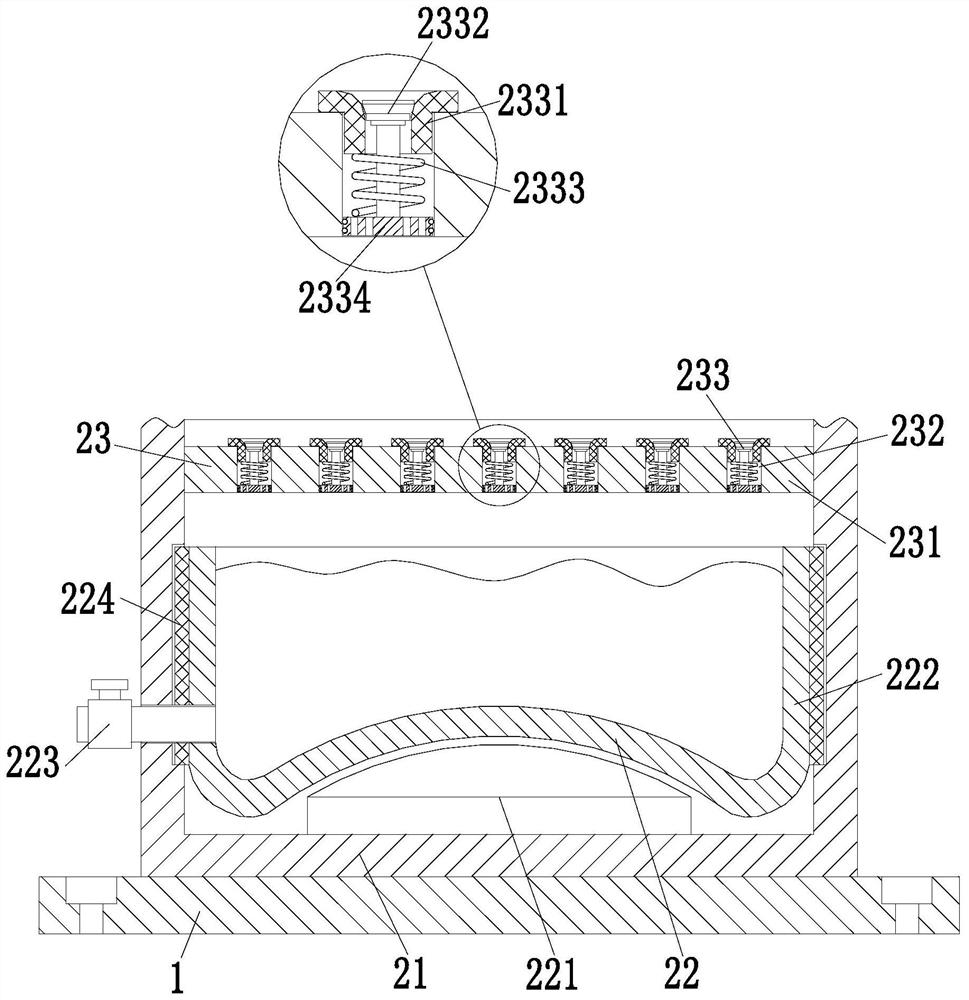

Plant extract distillation device

PendingCN109771978AReduce consumptionSimple structureDistillation regulation/controlRubber ringDistillation

The invention provides a device for distilling a plant and extracting an essence thereof. The device comprises a casing, a control portion, a heating portion, and a cooling portion, wherein the heating portion is arranged in the casing, and the cooling portion is hinged to the casing above the cooling portion; the cooling portion is disposed opposite to the heating portion, a sealing rubber ring is disposed on the heating portion at a position in contact with the cooling portion, the bottom surface of the cooling portion is of a spherical protrusion-like structure protruding downward, and a receiving cylinder is disposed in the center of the heating portion opposite to the center of the cooling portion. The overall structure is simple; the sealed space composed of the heating portion and the cooling portion enables the distillation operation to be implemented in the same space, thereby maximizing the distillation effect; the structure is reasonable, the bottom surface of the cooling portion is of an arc-shaped structure, and the evaporated essence cooled by the cooling portion slides down to the lowest point along the bottom surface and falls into the receiving cylinder, so that the structure of the device is simplified to the greatest extent while the distillation effect is ensured.

Owner:付其芝

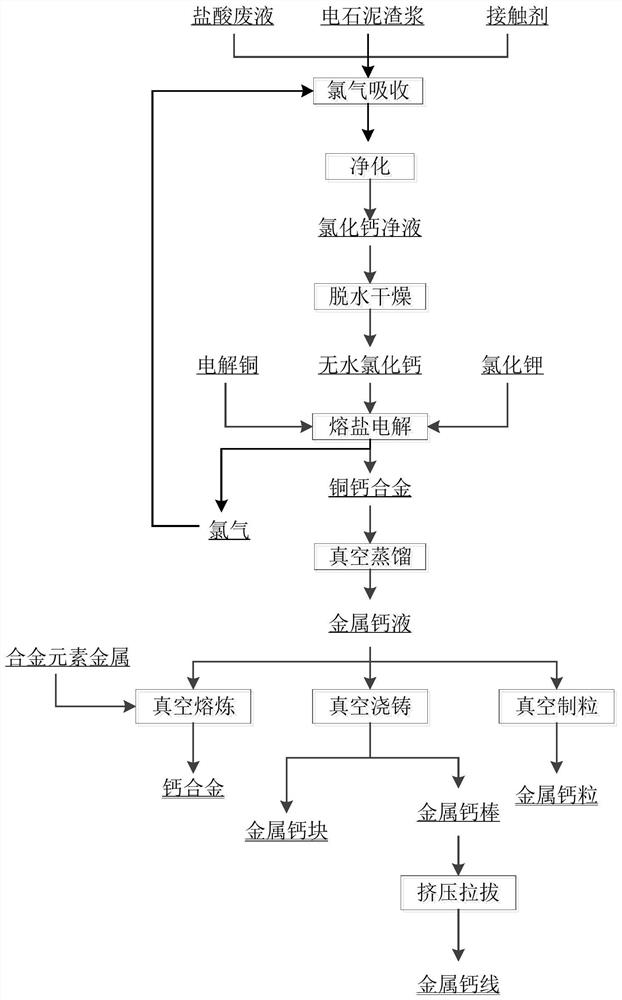

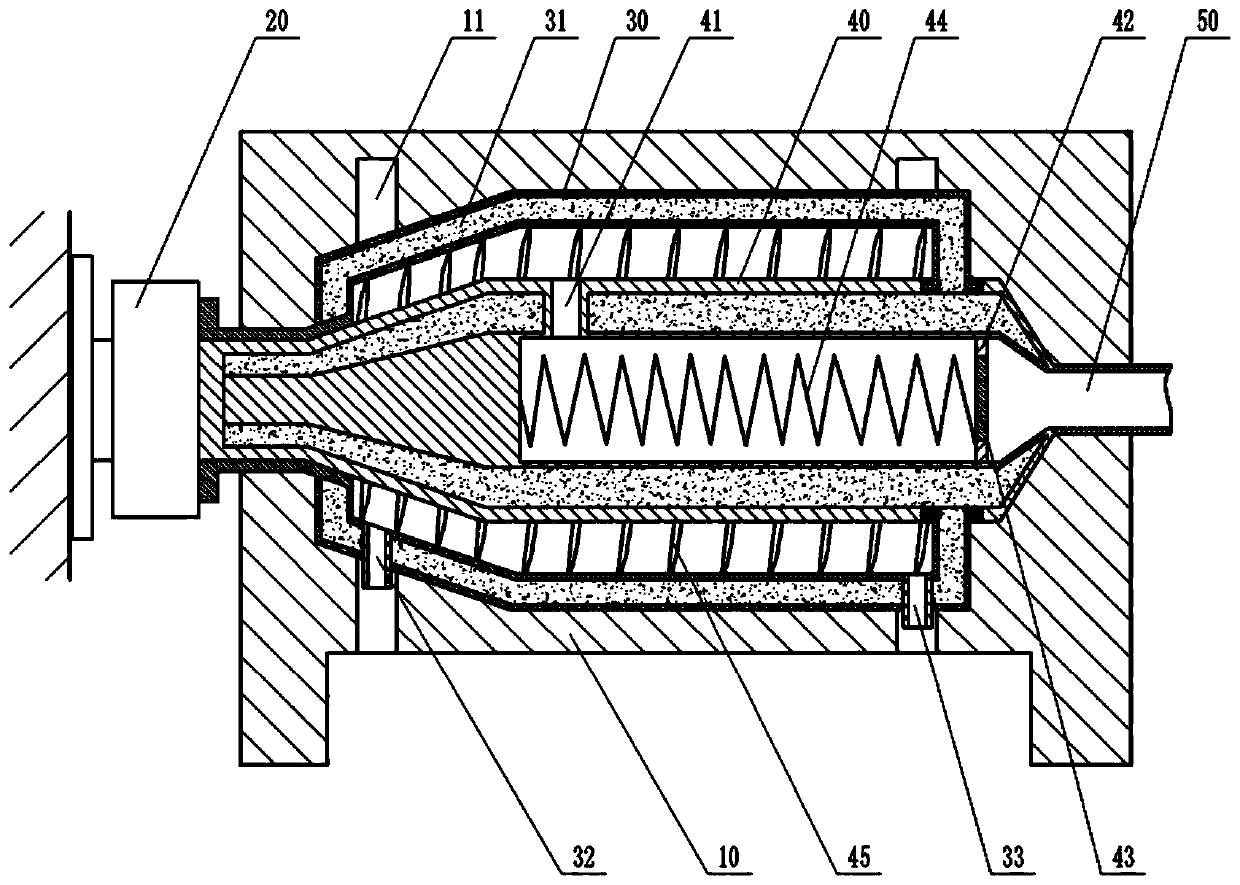

Waste solvent recycling device

ActiveCN107551590AFully heatedEfficient evaporationCentrifugal force sediment separationDistillation in rotating vesselsSpiral bladeDistillation

The invention belongs to the technical field of solvent recycling, and more specifically discloses a waste solvent recycling device. The waste solvent recycling device comprises a raw material feedingunit, a distillation unit, and a condensation unit; the distillation unit comprises a pedestal, a rotating cylinder, a spiral barrel, and a differential mechanism; the side wall of the rotating cylinder and the side wall of the spiral barrel are provided with sandwich layers; the spiral barrel is rotatingly arranged in the rotating cylinder; the sandwich layer on one end of the rotating cylinderis communicated with the sandwich layer of the spiral barrel; the rotating cylinder is rotatingly arranged on the pedestal; one end of the rotating cylinder is designed to be tapered, and the other end is designed to be cylindrical; the external wall of the spiral barrel is provided with spiral blades; one end of the spiral barrel is connected with a feed pipe; a doctor blade is arranged in the spiral barrel in a sliding manner; a pressure valve is arranged on the doctor blade; the spiral barrel and the doctor blade are connected via a spring; the spiral barrel is provided with a discharge hole; one end of the rotating cylinder is provided with a solid output pipe, and the other end is provided with a gas liquid outlet pipe. The waste solvent recycling device is used for recycling waste solvent; in distillation treatment, adhesion of colloid materials onto the internal wall of the distillation unit is avoided, and influences on normal operation of distillation are avoided.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

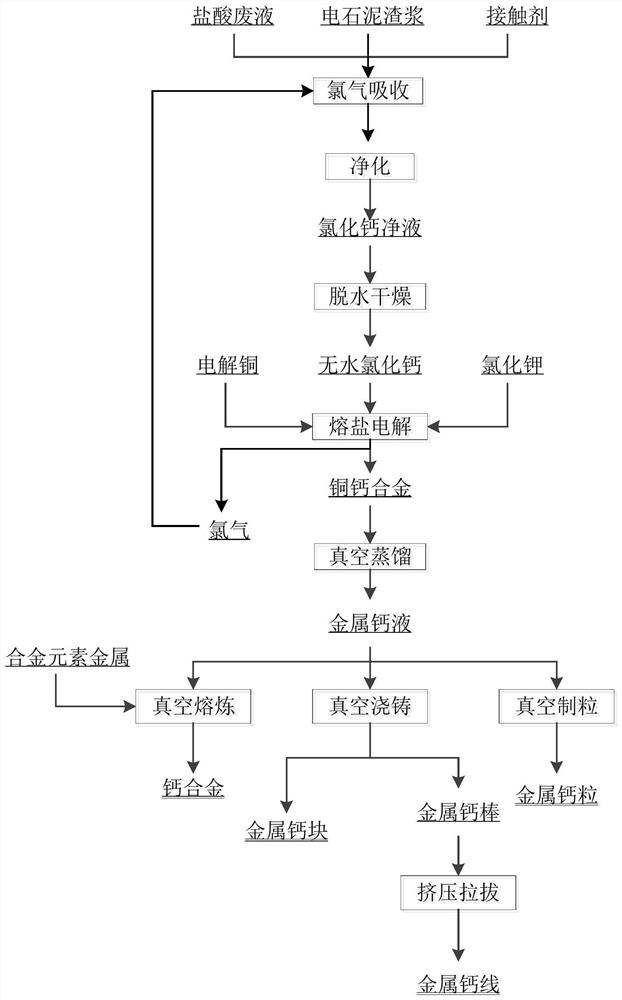

Calcium metal production process

ActiveCN111621812AAchieve recyclingSave energyElectrolysis componentsChemical industrySludgePolyvinyl chloride

The invention relates to a calcium metal production process. The process comprises the following steps that S1, calcium carbide sludge slurry and hydrochloric acid waste liquid in a process for producing polyvinyl chloride through a chlor-alkali acetylene method serve as raw materials to be added into a contact agent to prepare calcium chloride mother liquor; S2, the calcium chloride mother liquoris subjected to drying and granulating to from anhydrous calcium chloride; S3, the anhydrous calcium chloride is added with potassium chloride and electrolytic copper and then is subjected to electrolyzing in an electrolytic cell to obtain a copper-calcium alloy and chlorine, wherein the chlorine is returned to the step S1 to react with the calcium carbide sludge slurry to generate calcium chloride mother liquor; and S4, the obtained copper-calcium alloy is added into a vacuum distillation furnace for distillation in a heat preservation state, and the calcium metal is purified under the protection of inert gas. According to the calcium metal production process, the waste calcium carbide sludge slurry in the chlor-alkali industry serves as a raw material to produce the calcium metal, the energy is saved, the consumption is reduced, and the purity of the calcium metal is high.

Owner:鄂尔多斯市欣欣宸瑞高纯材料有限公司

Calcium metal production process

ActiveCN111621812BAchieve recyclingSave energyElectrolysis componentsChemical industryDistillationPolyvinyl chloride

The invention relates to a calcium metal production process, comprising: S1, calcium chloride mother liquor prepared by adding calcium chloride mother liquor after adding calcium carbide mud slurry and hydrochloric acid waste liquid in the process of producing polyvinyl chloride by chlor-alkali acetylene method as raw materials; The mother liquor is dried and granulated to become anhydrous calcium chloride; S3, adding the anhydrous calcium chloride to potassium chloride and electrolytic copper for electrolysis in an electrolytic cell to obtain copper-calcium alloy and chlorine gas, and the chlorine gas is returned to step S1 to be mixed with The calcium carbide mud slurry is reacted to generate calcium chloride mother liquor; S4, adding the obtained copper-calcium alloy to a vacuum distillation furnace for distillation under heat preservation, and purifying metallic calcium under the protection of an inert gas. The invention relates to a calcium metal production process using waste calcium carbide mud slurry in the chlor-alkali industry as a raw material to produce calcium metal, which saves energy and reduces consumption, and the calcium metal has higher purity.

Owner:鄂尔多斯市欣欣宸瑞高纯材料有限公司

Waste Solvent Recycling Unit

ActiveCN107551590BFully heatedEfficient evaporationCentrifugal force sediment separationDistillation in rotating vesselsSpiral bladeProcess engineering

The invention belongs to the technical field of solvent recycling, and more specifically discloses a waste solvent recycling device. The waste solvent recycling device comprises a raw material feedingunit, a distillation unit, and a condensation unit; the distillation unit comprises a pedestal, a rotating cylinder, a spiral barrel, and a differential mechanism; the side wall of the rotating cylinder and the side wall of the spiral barrel are provided with sandwich layers; the spiral barrel is rotatingly arranged in the rotating cylinder; the sandwich layer on one end of the rotating cylinderis communicated with the sandwich layer of the spiral barrel; the rotating cylinder is rotatingly arranged on the pedestal; one end of the rotating cylinder is designed to be tapered, and the other end is designed to be cylindrical; the external wall of the spiral barrel is provided with spiral blades; one end of the spiral barrel is connected with a feed pipe; a doctor blade is arranged in the spiral barrel in a sliding manner; a pressure valve is arranged on the doctor blade; the spiral barrel and the doctor blade are connected via a spring; the spiral barrel is provided with a discharge hole; one end of the rotating cylinder is provided with a solid output pipe, and the other end is provided with a gas liquid outlet pipe. The waste solvent recycling device is used for recycling waste solvent; in distillation treatment, adhesion of colloid materials onto the internal wall of the distillation unit is avoided, and influences on normal operation of distillation are avoided.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

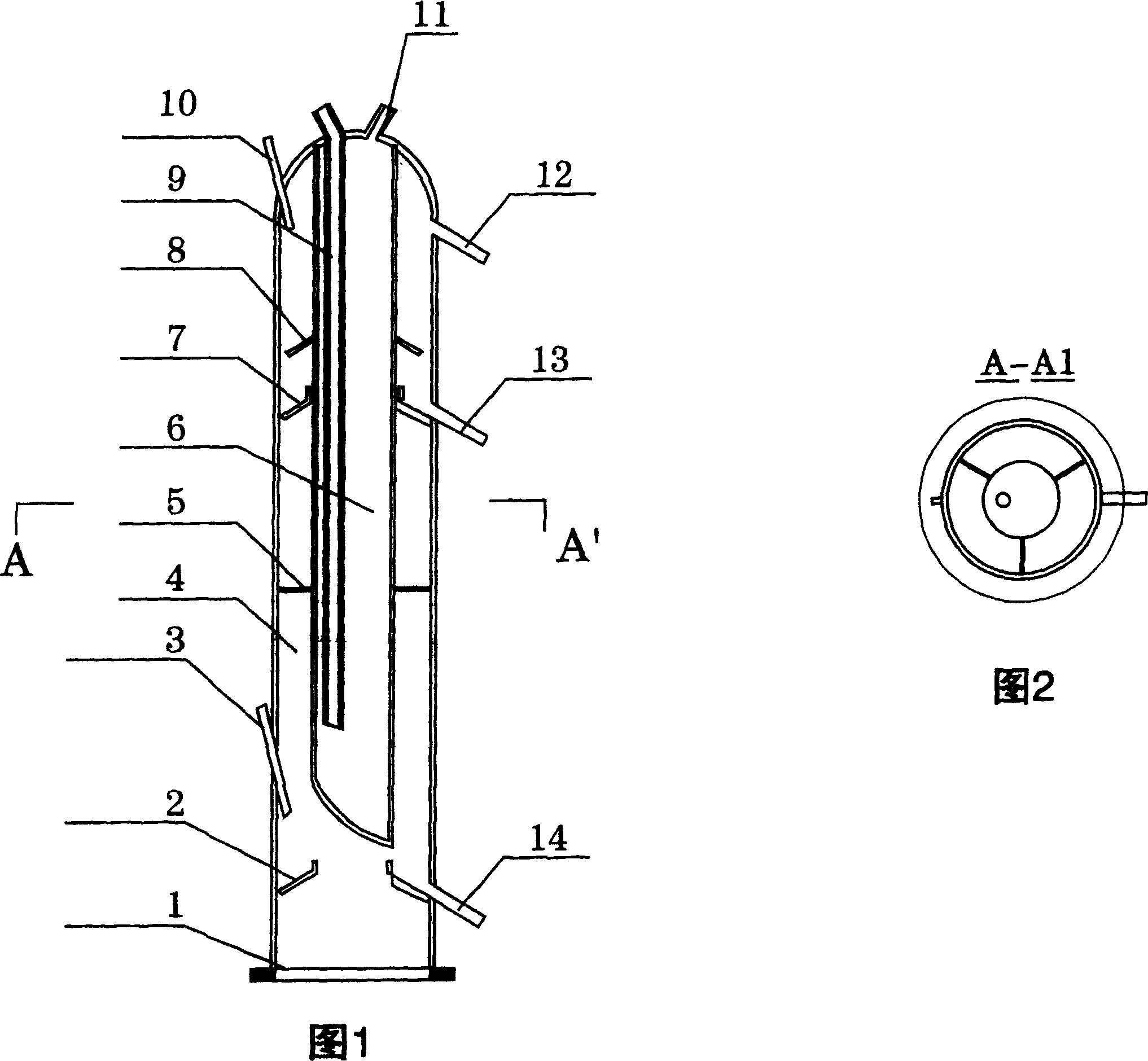

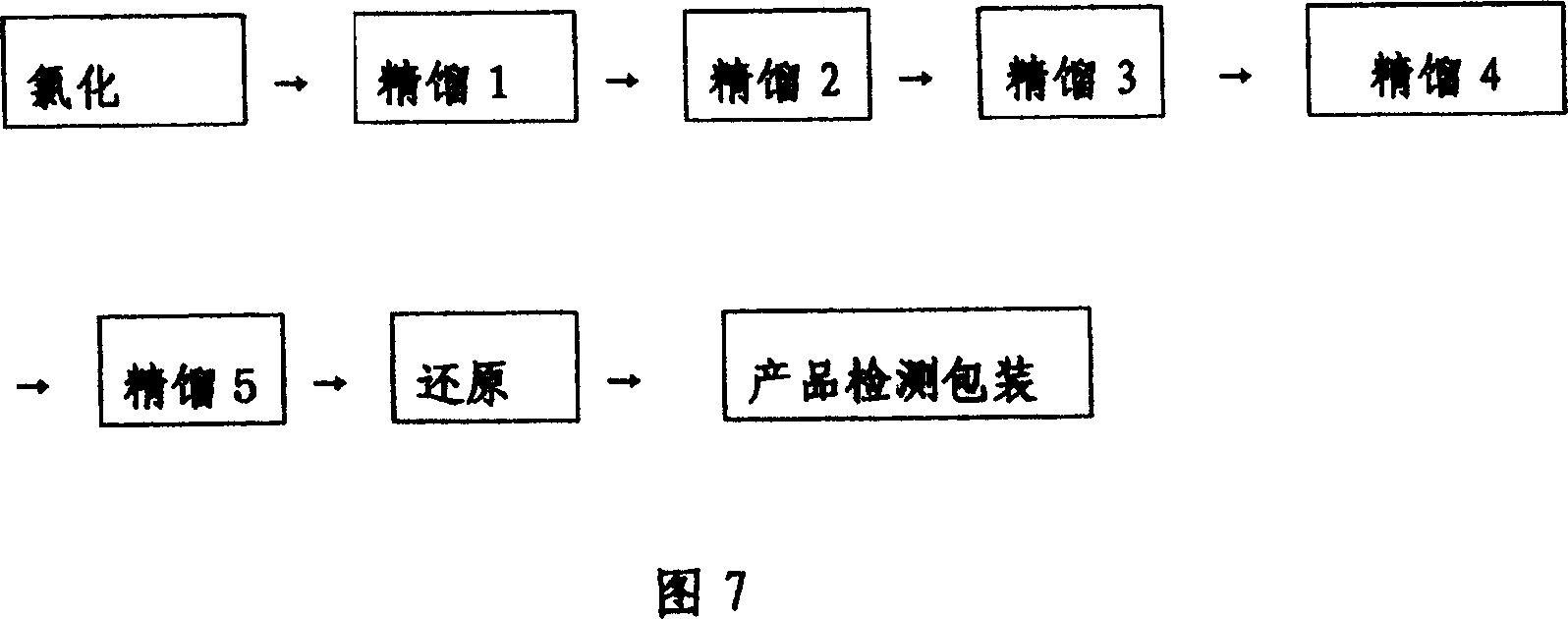

Metal antimony purifying method and apparatus

InactiveCN1325674CGuaranteed distillation effectImprove efficiencyAntimony compoundsProcess efficiency improvementHydrogenAntimony pentachloride

This invention discloses metal antimony purifying method and its mechanism. The method is to fill the industrial antimony in the chlorination tower; lead chlorine in the middle of the tower, heat at the 1 / 3 lower part of the tower to decompose antimony pentachloride; chloride and the superfluous mental blocks in the tower react to create antimony trichloride. The antimony trichloride in the storage tank automatically flows to re-boiling equipment and steam to go into rectification 1; through reflux control valve adjust flow amount of antimony trichloride and reflux amount, and the antimony trichloride goes into the re-boiler of rectification 2; the lower output mouth of the rectification tower arch is connected by the channel with the material interface of the storage tank that has two outputting mouths connected with the computation tank of reductive tank and re-boiler of sub-grade rectification system by the tube. The upper outputting mouth is connected with the residue tank by the pipeline; orderly connect the multi-grade rectification tower and continuously bring in the superfluous hydrogen and revert it and get 99.999%, 99.9999% and 99.99999% metal antimonies.

Owner:云南省通海大方科技有限公司

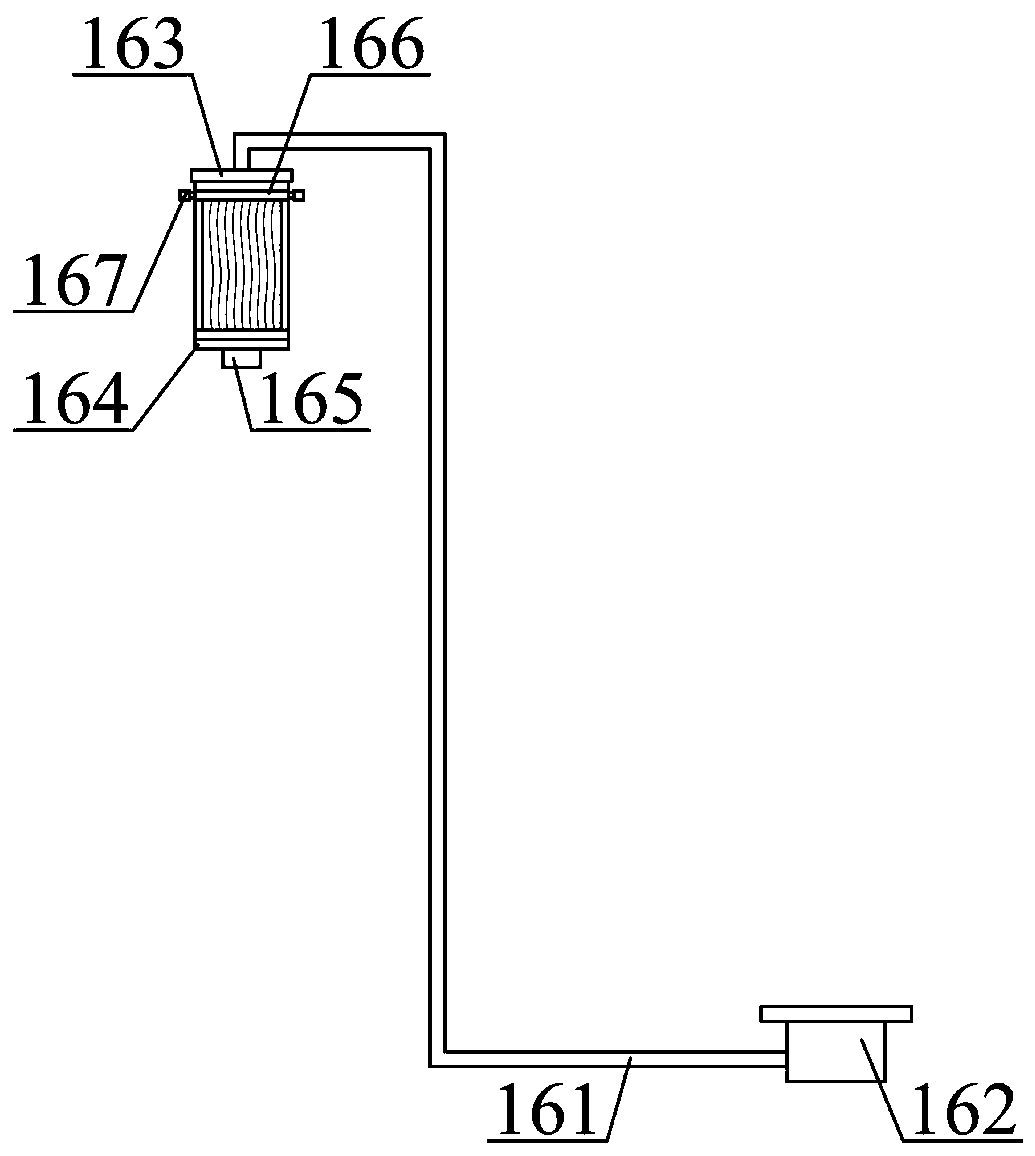

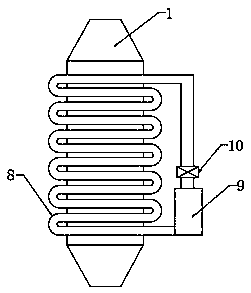

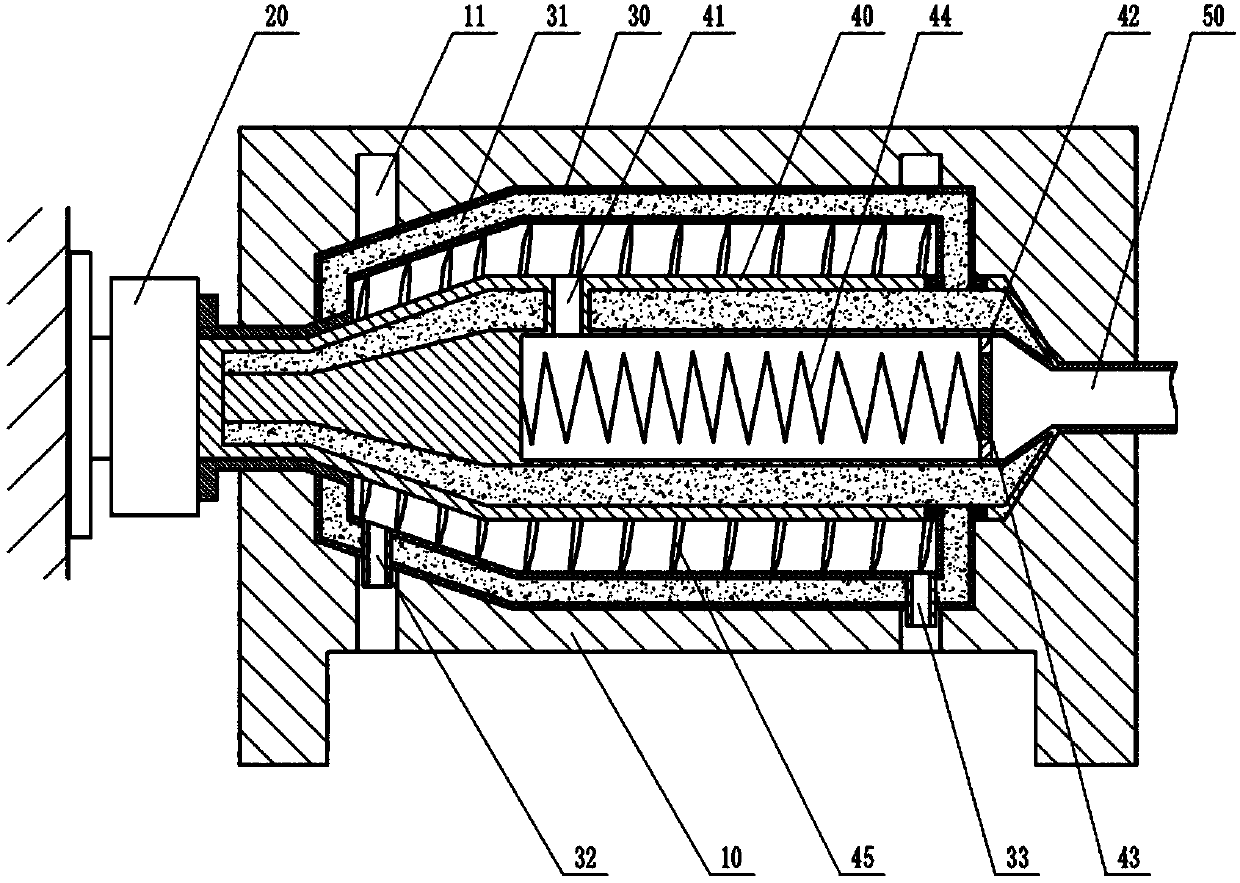

Liquid distillation and cooling all-in-one machine

ActiveCN105091632BEasy to detectGuaranteed distillation effectStationary tubular conduit assembliesHeat exchange apparatusDistillationEngineering

The invention discloses a liquid distilling and cooling all-in-one machine. The liquid distilling and cooling all-in-one machine comprises a plurality of coolers sequentially arranged from top to bottom. Heat exchange pipes are arranged in the coolers. The positions, close to the tops, of the side faces of the coolers are provided with cooling liquid inlet pipes and liquid inlet pipes connected with the heat exchange pipes respectively. The positions, close to the bottoms, of the side faces of the coolers are provided with cooling liquid outlet pipes and liquid outlet pipes respectively. The liquid outlet pipes of the previous coolers are connected with the liquid inlet pipes of the next coolers, and the cooling liquid outlet pipes of the previous coolers are connected with the cooling liquid inlet pipes of the next coolers. Water inlet pipes are arranged in the middles of the side faces of the coolers. The liquid distilling and cooling all-in-one machine can carry out distillation conveniently, and cooling efficiency can be improved.

Owner:巨野众悦香料有限公司

Recycling method of waste solvent in automobile industry

ActiveCN107619146BHeating evenlyReduce moisture contentOrganic compound preparationDispersed particle separationXylyleneSteam pressure

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

Liquid distilling and cooling all-in-one machine

ActiveCN105091632AEasy to detectExpand the scope of useStationary tubular conduit assembliesHeat exchange apparatusEngineeringDistillation

The invention discloses a liquid distilling and cooling all-in-one machine. The liquid distilling and cooling all-in-one machine comprises a plurality of coolers sequentially arranged from top to bottom. Heat exchange pipes are arranged in the coolers. The positions, close to the tops, of the side faces of the coolers are provided with cooling liquid inlet pipes and liquid inlet pipes connected with the heat exchange pipes respectively. The positions, close to the bottoms, of the side faces of the coolers are provided with cooling liquid outlet pipes and liquid outlet pipes respectively. The liquid outlet pipes of the previous coolers are connected with the liquid inlet pipes of the next coolers, and the cooling liquid outlet pipes of the previous coolers are connected with the cooling liquid inlet pipes of the next coolers. Water inlet pipes are arranged in the middles of the side faces of the coolers. The liquid distilling and cooling all-in-one machine can carry out distillation conveniently, and cooling efficiency can be improved.

Owner:黎清弟

System for removing sodium hydroxide during hexamethylenediamine production, and removal method thereof

InactiveCN107652188AImprove positionReduce sodium hydroxide contentAmino compound purification/separationHexamethylenediamineDistillation

The invention provides a system for removing sodium hydroxide during hexamethylenediamine production. A method for carrying out precipitating separation removal through using the density difference between the sodium hydroxide and the hexamethylenediamine is adopted, a crude hexamethylenediamine feeding tube of an original device is extended, the position of a hexamethylenediamine discharging tubeis elevated, and a sodium hydroxide separation tank is arranged, so the sodium hydroxide can be removed in a crude hexamethylenediamine tank, the content of the sodium hydroxide entering a rectifyingsystem is reduced, the purifying effect of a rectifying tower is guaranteed, and the running cycle is prolonged.

Owner:HENAN SHENMA NYLON CHEM

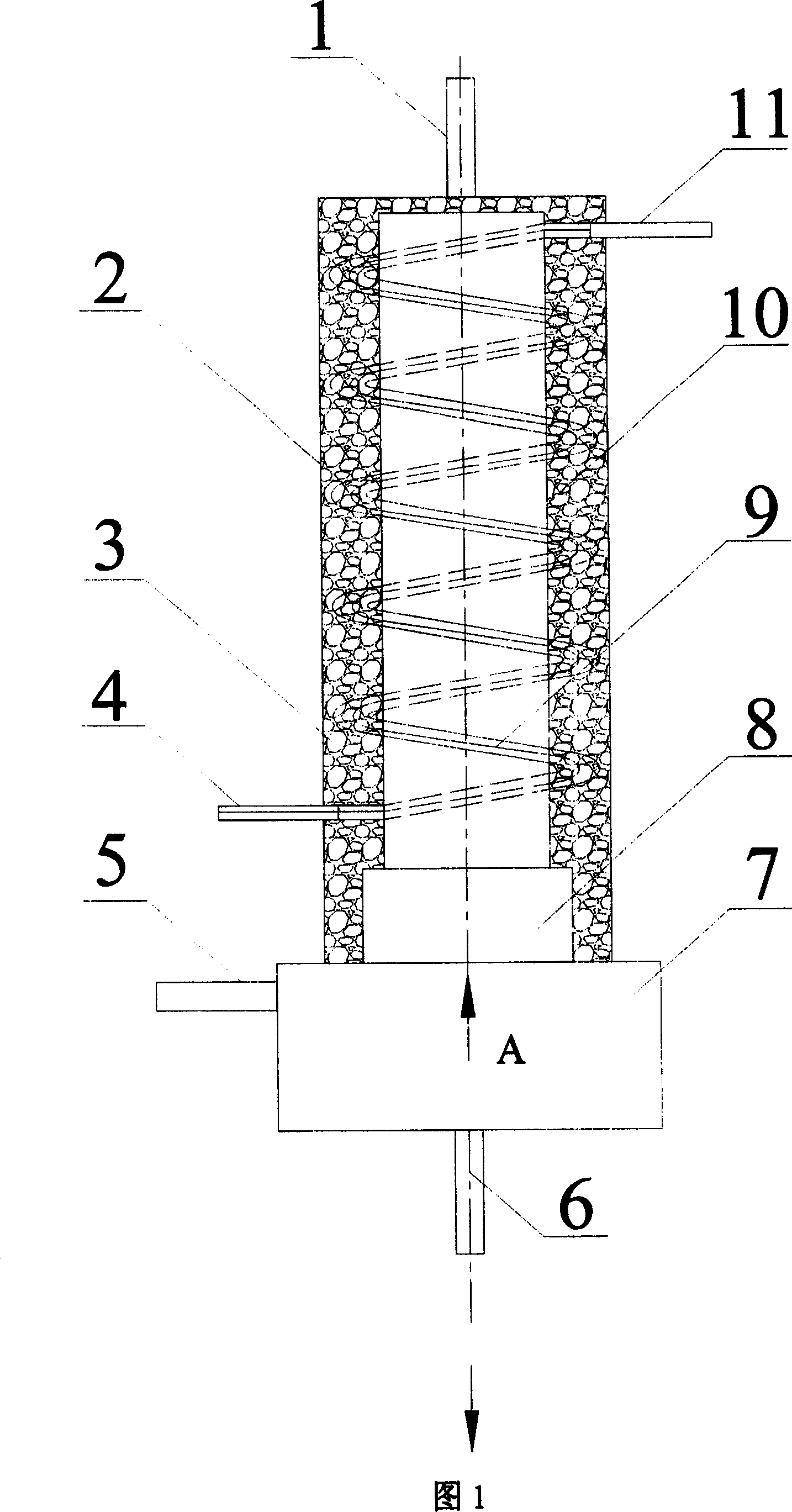

Campact bushing type packed tower

InactiveCN100353129CReduce the overall heightGuaranteed distillation effectSolidificationLiquefactionVapor–liquid separatorFractionation

The present invention discloses a compact double-pipe type filled tower. It possesses the successively-connected fractionation tower body lower internal core and fractionation tower body upper internal core, on the fractionation tower body upper internal core a condenser is set, the exterior of said fractionation tower body upper internal core and condenser is equipped with a fractionation tower body external cover, on the side surface of said fractionation tower body external cover are fixed a condenser outlet tube and a condenser inlet tube which are respectively close to lower end and upper end of said fractionation tower body upper internal core, the upper end of said fractionation tower body external cover is equipped with gas outlet tube, its lower end is equipped with a gas-liquid separator, and the cavity enclosed with the fractionation tower body upper internal core and lower internal core, external cover of fractionation tower body and top end of gas-liquid separator is filled with filling material.

Owner:ZHEJIANG UNIV

A kind of plant essential oil distillation preparation method

ActiveCN111349520BPrevent falling backReduce wasteEssential-oils/perfumesThermodynamicsProcess engineering

Owner:珠海水信生物科技有限公司

A kind of preparation method of alkanolamine

ActiveCN105085282BHigh reactivityHigh selectivityOrganic compound preparationAmino-hyroxy compound preparationAlkaneAlcohol

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

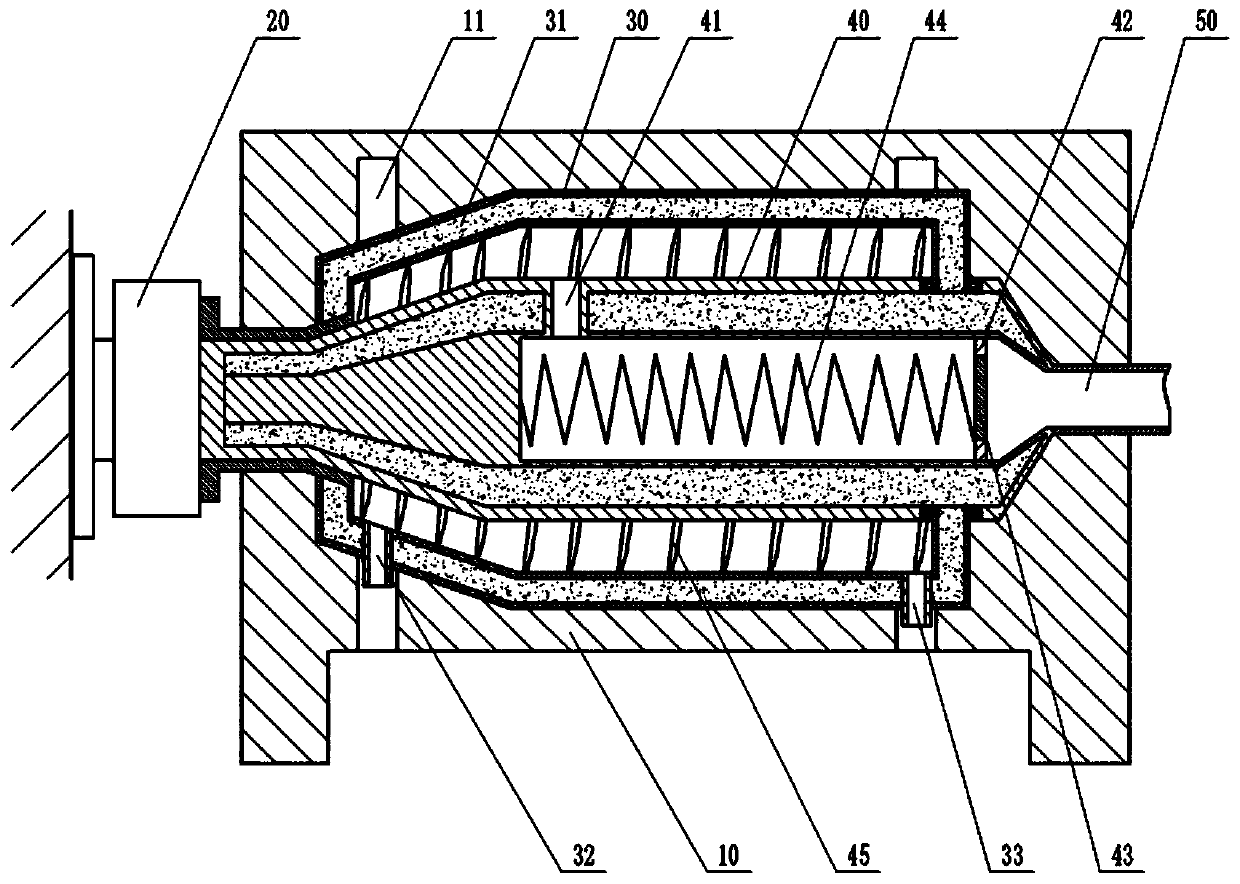

Propylene hydration reaction system for preparing isopropanol

ActiveCN113522178BImprove the effect of hydration reactionHigh yieldOrganic compound preparationHydroxy compound separation/purificationHydration reactionVapor–liquid separator

The invention discloses a system for preparing isopropanol through propylene hydration reaction. The reactor communicates with a gas-liquid separator through a pipeline A, the gas-liquid separator communicates with a dehydration tower through a pipeline B, and the gas-liquid separator communicates with a propylene supply through a pipeline C. The air pipe is connected, the dehydration tower is connected with the purification tower through the pipeline D, the dehydration tower is connected with the pure water supply pipe through the pipeline E, the purification tower is connected with the heat exchanger through the pipeline F, and the pipeline G of the heat exchanger is connected with the pipeline D through the pipeline H, The purification tower communicates with the extraction tank through a pipeline I, the extraction tank is connected with a pipeline J, the extraction tank is connected with a pipeline K, and the pipeline K is connected with the purification tower, and each pipeline is provided with its own valve. It can be seen from the above structure that in the system for preparing isopropanol by propylene hydration reaction of the present invention, the mixed gas after the reaction is condensed by a condenser, the propylene in the mixed gas is separated, and the pure water in the condensed mixture is separated by a dehydration tower, and finally The isopropanol in the mixture is purified and collected through a purification tower.

Owner:JIANGSU XINHUA CHEM +1

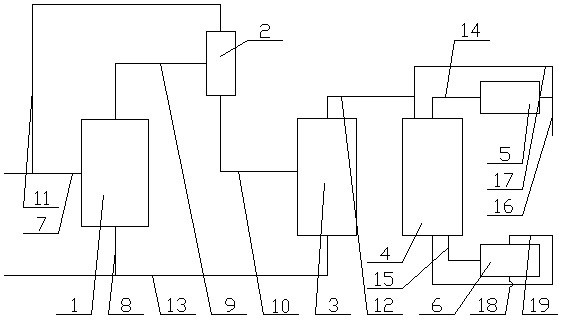

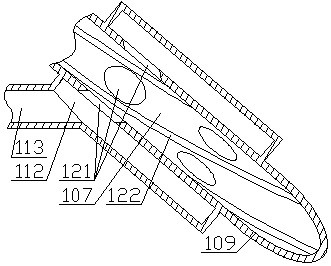

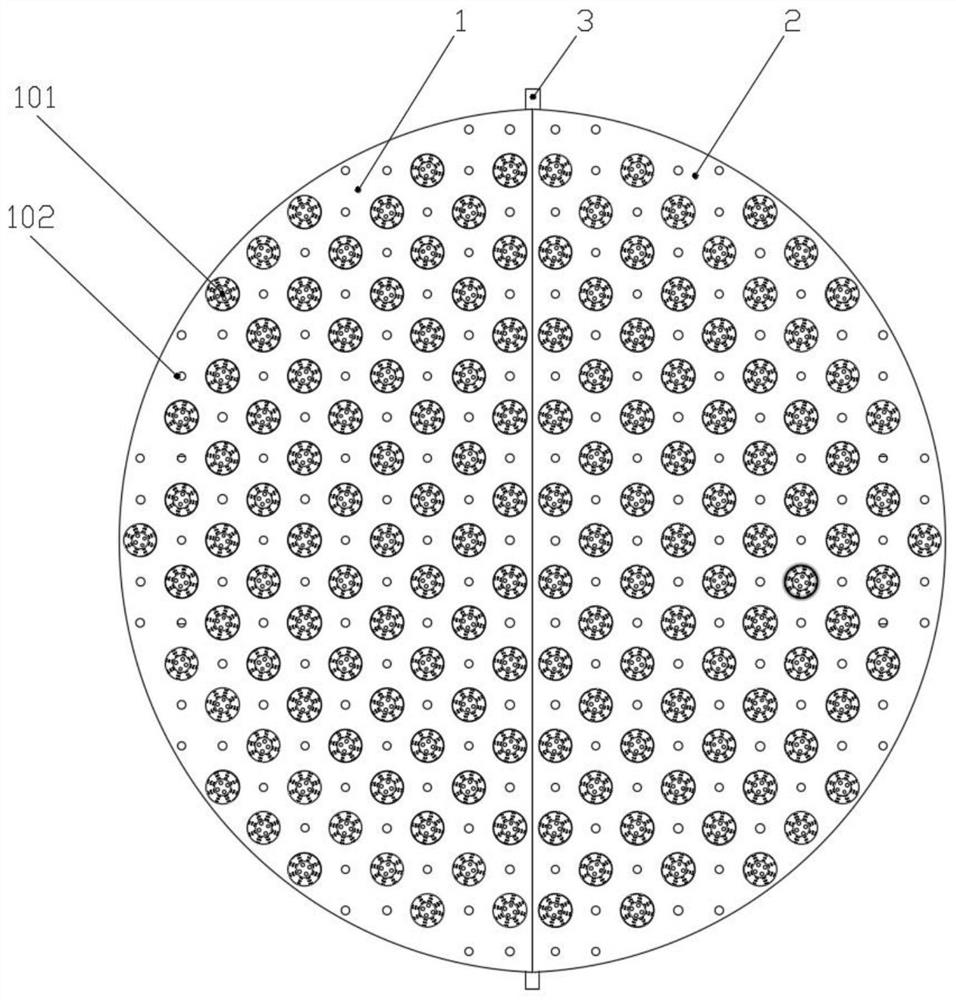

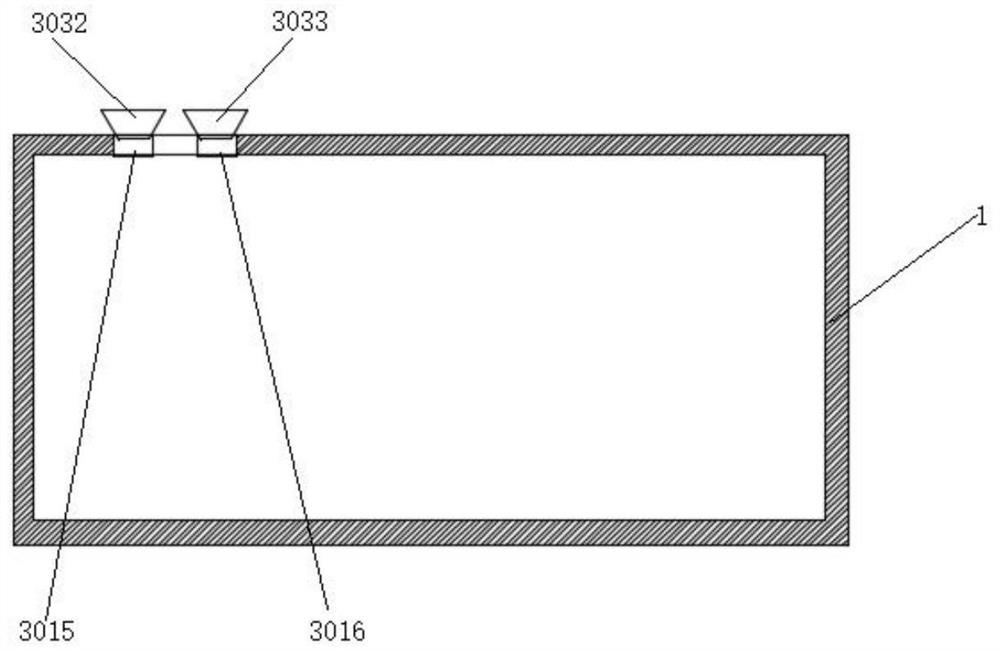

Steamer bottom structure of wine steamer for steaming Maotai-flavor wine

PendingCN111909821APrevent channelingAvoid dead material (dead angle) problemsAlcoholic beverage preparationButt jointEngineering

The invention provides a steamer bottom structure of a wine steamer for steaming a Maotai-flavor wine, and belongs to the technical field of wine brewing. The structure comprises a round steamer bottom, wherein the steamer bottom is formed by butt joint of a first steamer bottom and a second steamer bottom which are semicircular and symmetrically arranged, the first steamer bottom and the second steamer bottom are mutually hinged through a hinge shaft arranged along a symmetrical center line, cone frustums and round holes are distributed in the upper surfaces of the first steamer bottom and the second steamer bottom, the cone frustums are of hollow structures, air inlet holes penetrating the first steamer bottom and the second steamer bottom are formed in the bottoms of the cone frustums,and air outlet holes are distributed in the upper inclined surfaces of the cone frustums. The defects of material leakage, channeling, dead corners and the like of an existing steamer bottom are avoided.

Owner:MOUTAI INST

Filtering and distilling equipment for fine chemical organic synthesis

ActiveCN114470828AGuaranteed accuracyAchieve hybridDistillation regulation/controlChemical industryThermodynamicsOrganic synthesis

The invention relates to the technical field of distillation equipment, in particular to filtering distillation equipment for fine chemical organic synthesis. Filtering and distilling equipment for fine chemical engineering organic synthesis comprises a box body, the box body comprises a distilling area and a condensing area, the side wall of the distilling area is fixedly connected with a feeding pipe, the side wall of the feeding pipe is provided with a first electromagnetic valve, the side wall of the condensing area is fixedly connected with a discharging pipe, the side wall of the discharging pipe is provided with a second electromagnetic valve, and the second electromagnetic valve is arranged on the side wall of the second electromagnetic valve. A heating plate is arranged at the bottom of the distillation area, and a temperature detection assembly and a mixing assembly are arranged at the top of the box body. Compared with the prior art, the filtering and distilling equipment for fine chemical organic synthesis has the beneficial effects that steam can be dispersed and mixed, the accuracy of temperature detection of the temperature sensor is ensured, meanwhile, the stroke of the steam during flowing is increased, so that the distilling effect is ensured, impurities are conveniently collected and treated, and the filtering and distilling equipment is more energy-saving and environment-friendly.

Owner:重庆化工职业学院

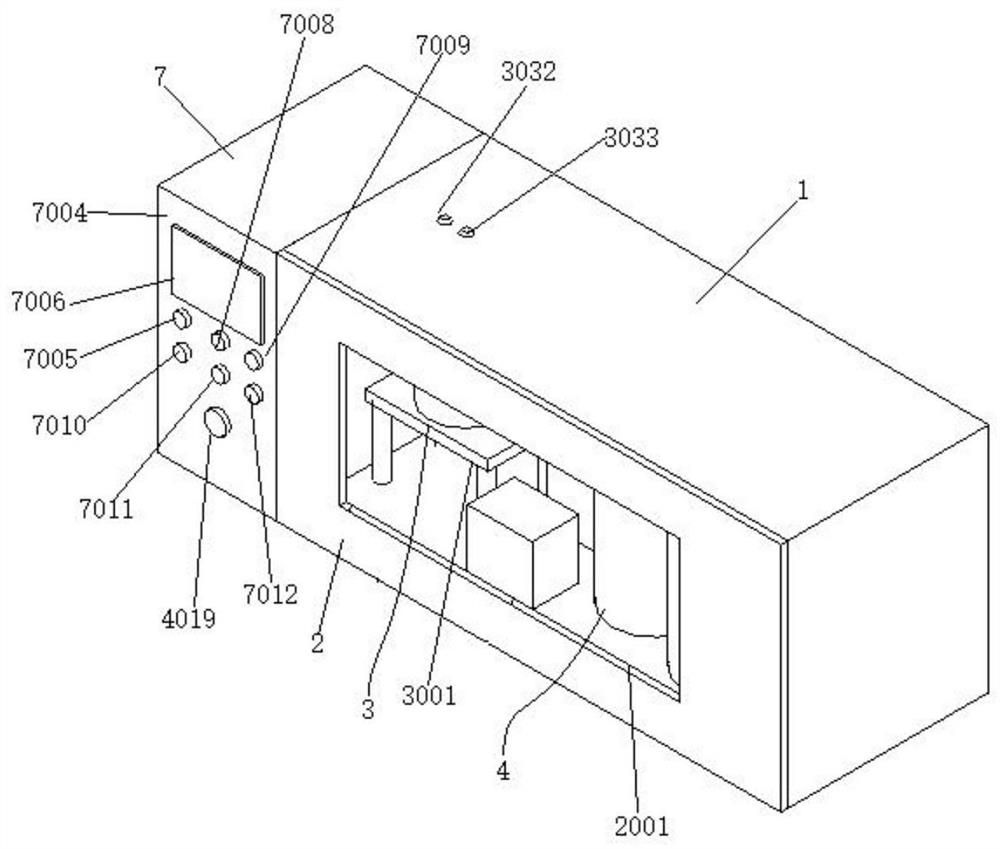

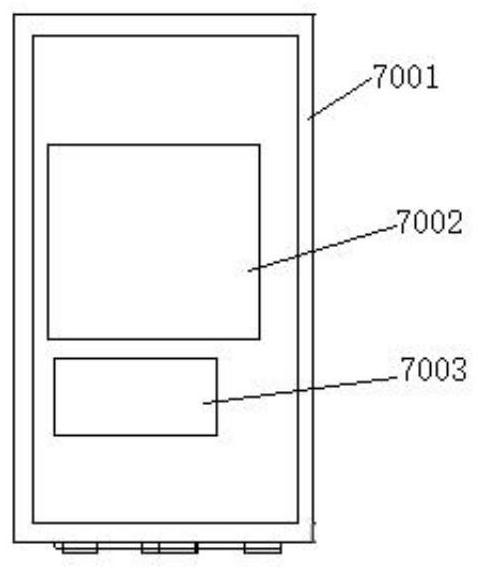

Device for detecting volatile phenol in water

InactiveCN112098399ASimple structureEasy to operateMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationEmbedded systemSingle chip

The invention discloses a device for detecting volatile phenol in water. The device comprises a box body, a box door, and a stripping distillation module, a mixed reaction module and a detection analysis module which are arranged in the box body, the box body is rotationally connected with the box door through hinges; the device for detecting volatile phenol in water further comprises a control module, the control module comprises a control box, a single-chip microcomputer processor, a memorizer and a control panel device, the control box is arranged on one side of the box body, the single-chip microcomputer processor and the memorizer are both arranged in the control box, the control panel is arranged on the outer side wall of the control box, and the control panel comprises a detection switch and a display screen. The display screen is used for displaying the concentration of the sample tested by the detection analysis module. The device for detecting volatile phenol in water is simple in structure and convenient to operate, the labor intensity of workers is relieved, and the detection efficiency and accuracy are greatly improved.

Owner:安洲源(上海)环境科技有限公司

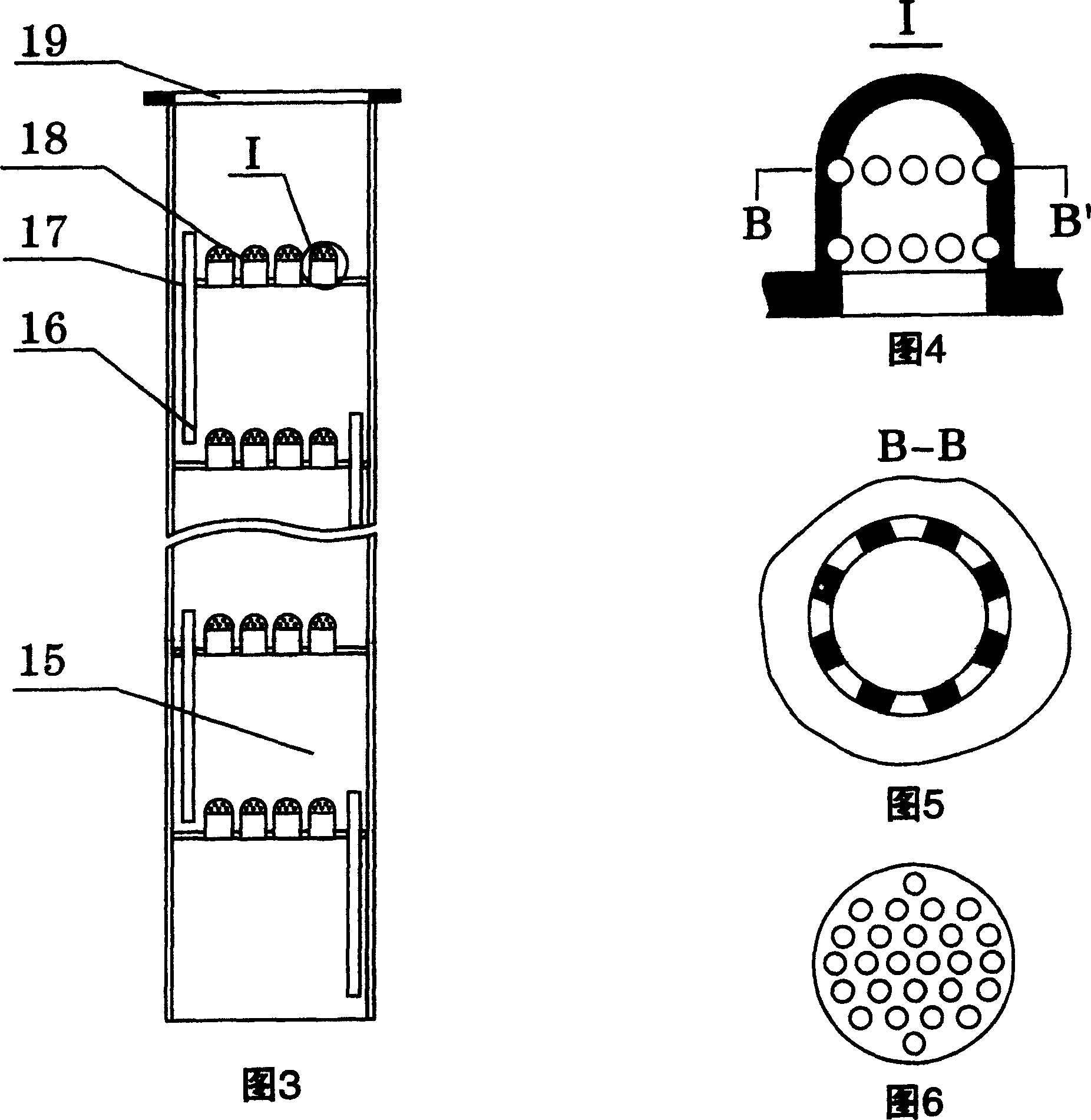

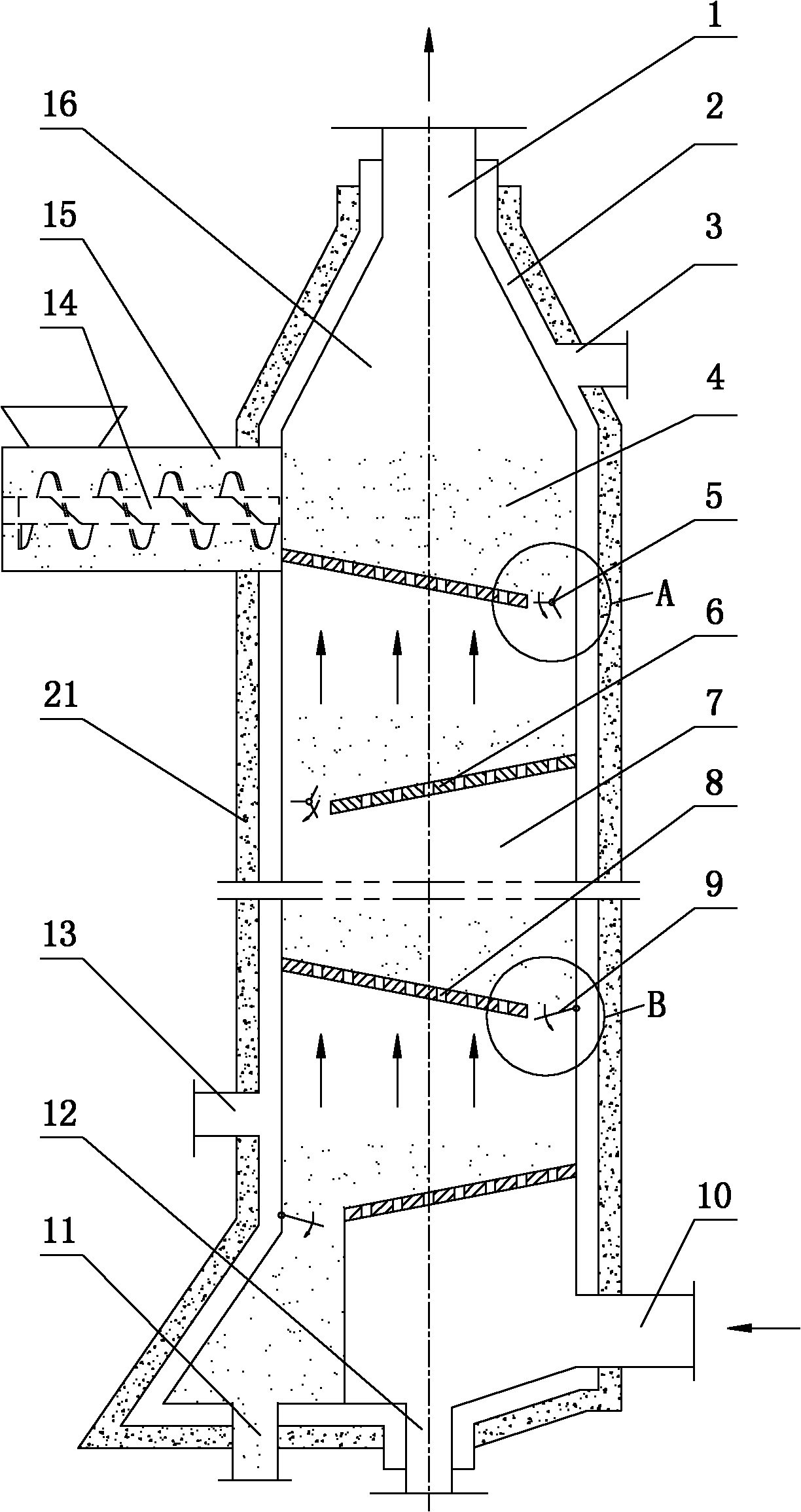

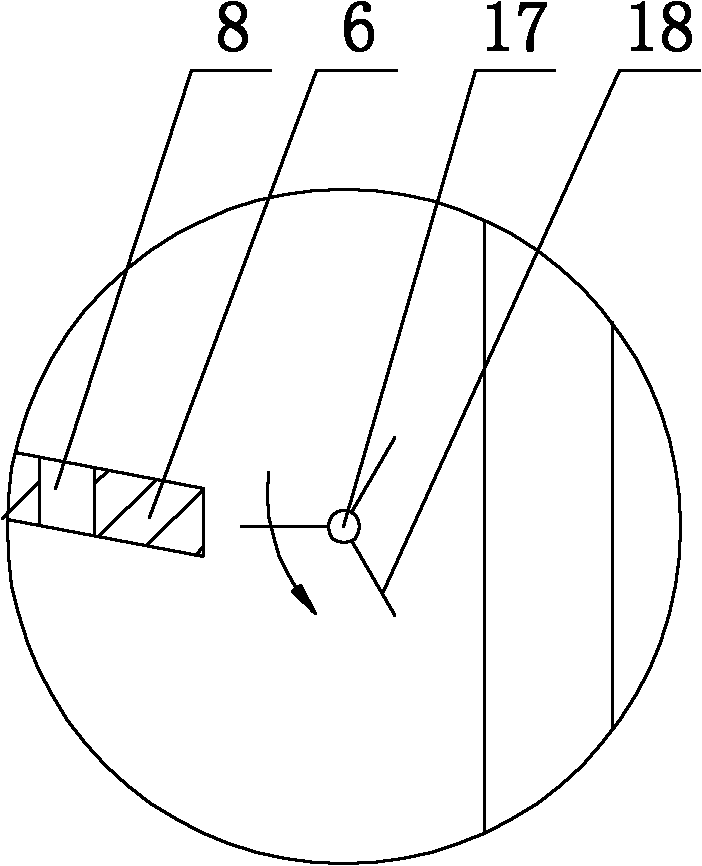

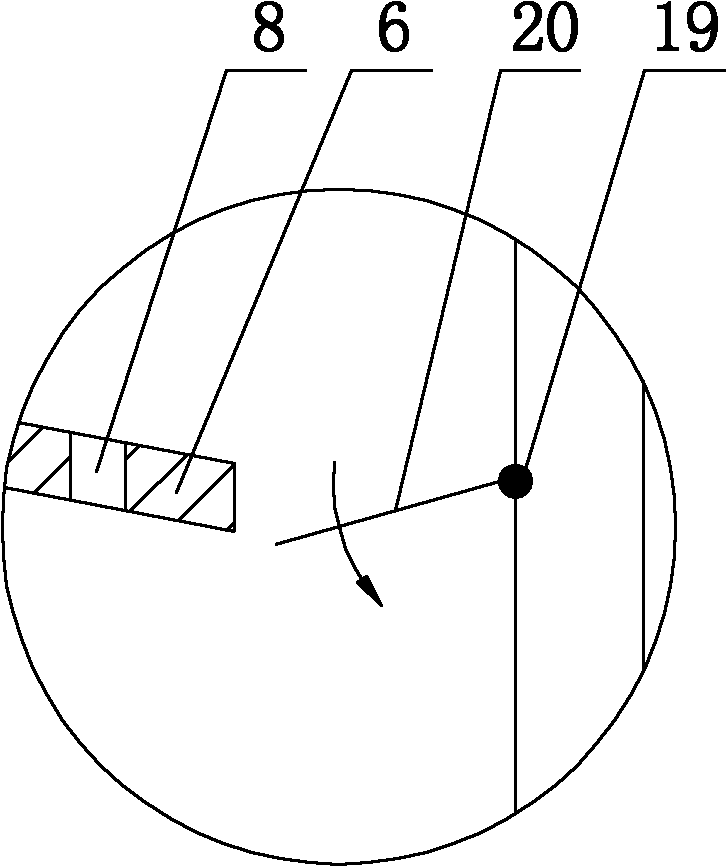

Multilayer fluidized solid continuous distillation column

ActiveCN102335520BLow in ethanolIncreased heat and mass transfer intensitySteam distillationSlagDistillation

The invention relates to a multilayer fluidized solid continuous distillation column which comprises a column body, a mixed steam outlet at the top of the column body, a feed inlet at a sidewall of the upper part of the column body, a superheated steam inlet at a sidewall of the lower part of the column body, and a slag outlet and a cleaning liquid outlet at the bottom of the column body. A set of gas distribution plates are staggerly installed at intervals on the internal wall of the column body between the feed inlet and the slag outlet, and included angles between the set of gas distribution plates and a horizontal plane are adjustable; each gas distribution plate is provided with steam pores; places of the column body corresponding to side edges of bottom ends of gas distribution plates are all provided with a material blanking control unit. The distillation column provided in the invention has the advantages of simple construction, convenient operation, great treatment capacity and a high degree of automation; multilayer gas distribution plates arranged in the distillation column allow a ferment material to be fluidized or periodically fluidized in the process of distillation, which enables rapid and high efficiency continuous distillation technology to be realized, and therefore, the multilayer fluidized solid continuous distillation column provided in the invention is update equipment for existing solid distillation columns.

Owner:TIANJIN UNIV OF SCI & TECH

Automatic water changing device in medicine detector

PendingCN111960595ARealize automatic water changeEasy to change waterTreatment involving filtrationWater/sand/air bathsWater bathsWater storage tank

The invention discloses an automatic water changing device in a medicine detector, and mainly relates to the field of medicine detection. The device comprises a water storage tank, a preheating tank,a water adding pump, a beaker and a water bath which are sequentially connected through pipelines, the beaker and the water bath are communicated with a three-way valve through a pipeline; a remainingconnector of the three-way valve is connected with a water discharging pump, one side of the water discharging pump is connected with a filtering device through a pipeline, one side of the filteringdevice is connected with a collecting tank through a pipeline, one side of the collecting tank is connected with a distilling device through a pipeline, and the distilling device is connected with a water storage tank through a pipeline. The device has the beneficial effects that pure water is obtained through the distillation device and then sent into the water storage tank, more standby water sources do not need to be carried, repeated utilization of waste water after an experiment can be achieved, and the device is convenient to use for experiments on a rapid detection vehicle.

Owner:北检(北京)检测技术研究院

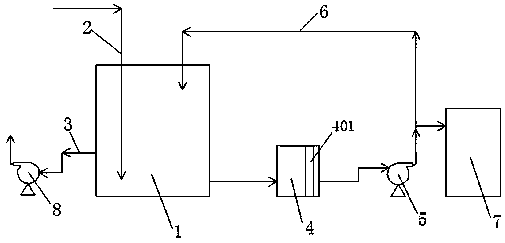

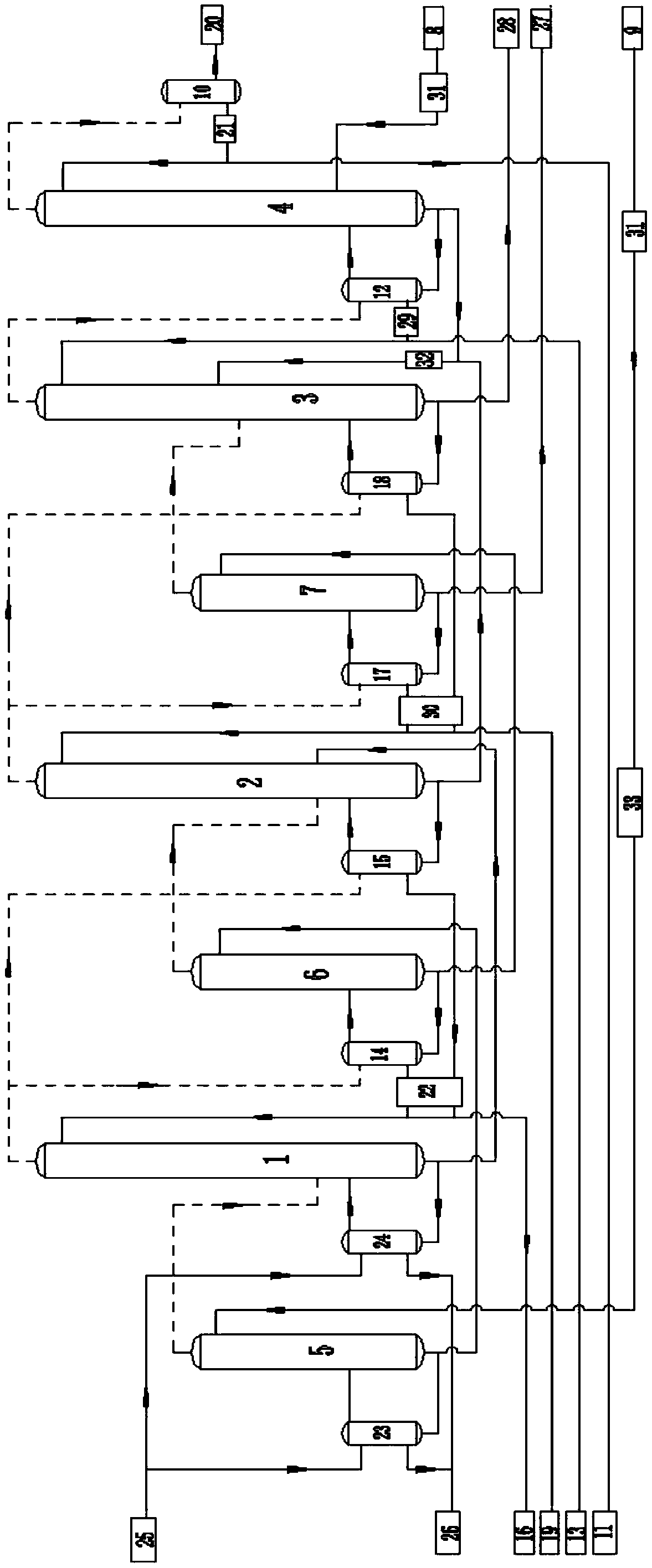

Quadruple-effect solvent recovery energy-saving system and method

PendingCN110841320AAvoid foamingGuaranteed distillation effectOrganic compound preparationEvaporator accessoriesAlcoholProcess engineering

The invention discloses a quadruple-effect solvent recovery energy-saving system. The system comprises a first-effect recovery tower, a second-effect recovery tower, a third-effect recovery tower, a fourth-effect recovery tower, a first-effect evaporation tower, a second-effect evaporation tower, a third-effect evaporation tower, a first mother liquor raw material tank and a second mother liquor raw material tank. The method for recovering alcohol by using the system comprises the following steps: separately distilling the first mother liquor and the second mother liquor, and carrying out low-temperature distillation on the first mother liquor foamed by high-temperature distillation through the fourth-effect recovery tower and the third-effect recovery tower and distilling the second mother liquor which does not foam after high-temperature distillation through the first-effect evaporator, the first-effect recovery tower, the second-effect evaporation tower, the second-effect recovery tower, the third-effect evaporation tower and the third-effect recovery tower. Foaming in the distillation process is avoided, and meanwhile, the energy consumption in post-treatment on the waste liquid is reduced.

Owner:肥城金塔酒精化工设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com