High-efficiency lubricating oil production and purification equipment

A lubricating oil, high-efficiency technology, applied in the field of high-efficiency lubricating oil production and purification equipment, can solve the problems of inconvenient collection and transfer of lubricating oil, inability to initially filter impurities from crude oil, affecting work efficiency, etc., to ensure the effect of secondary distillation, increase Double distillation reflux function, the effect of avoiding oil waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

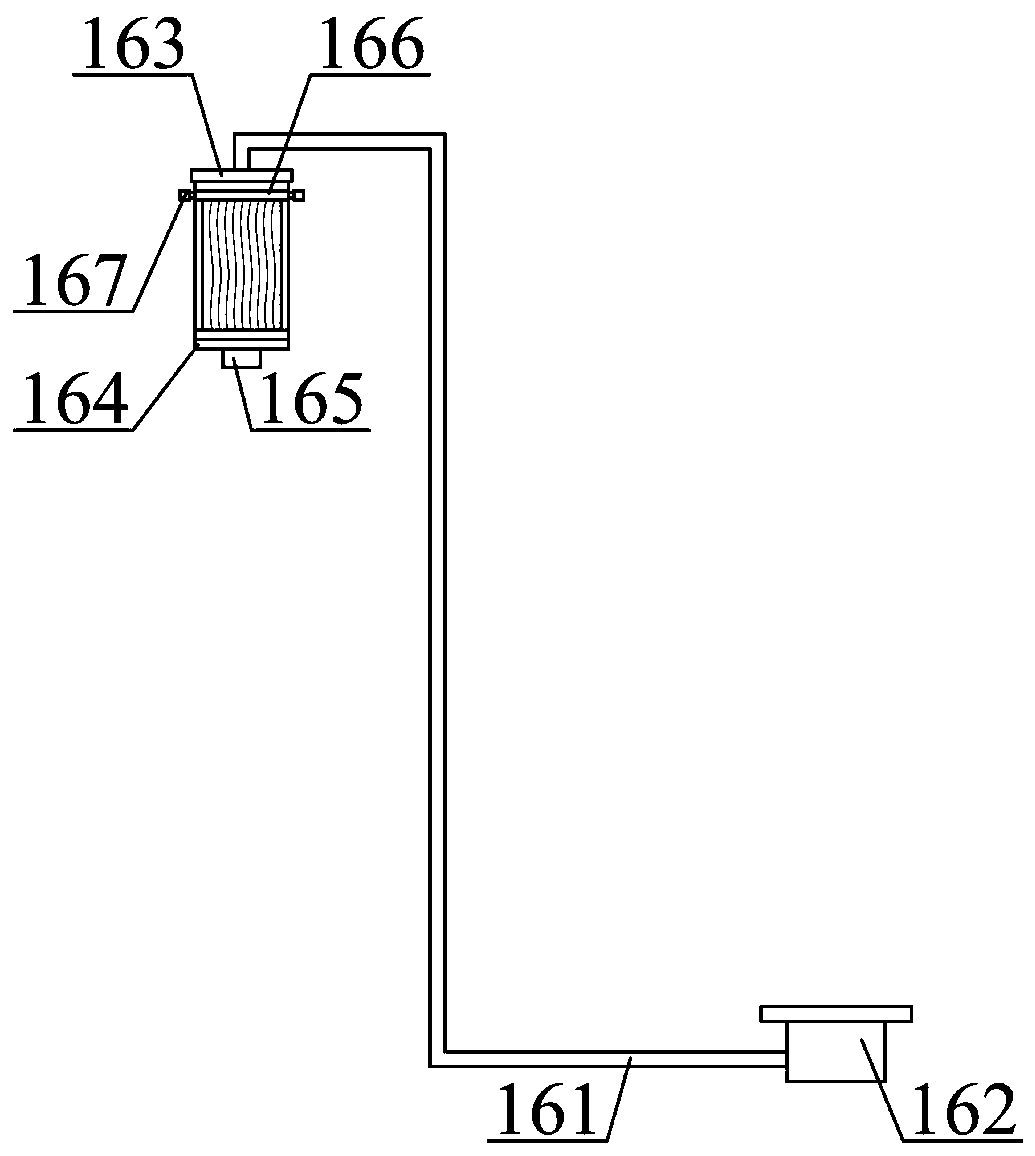

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the high-efficiency lubricating oil production and purification equipment includes agitator 1, distiller 2, heating plate 3, external insulation shell 4, main controller 5, oil suction pump 6, purifier 7, cooling box 8, cooling liquid injection Pipe 9, cooling fluid discharge valve 10, waste oil discharge valve 11, diversion pipe 12, lubricating oil outlet pipe 13, mechanical valve 14, crude oil purification preliminary impurity filter observation box structure 15, crude oil purification after secondary high-efficiency reflux and re-distillation Miscellaneous box structure 16, lubricating oil export collection transfer tank structure 17 and observable disassembly and cleaning discharge floor structure 18, the agitator 1 is bolted to the upper end of the distiller 2; the left and right sides of the distiller 2 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com