Circumferential falling film distillation tower

A rectification tower and falling film technology, applied in the field of rectification towers, can solve the problems of heat loss in the tower, large temperature difference between inside and outside, and influence on rectification work, and achieve the effect of ensuring rectification effect, uniform transportation, and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

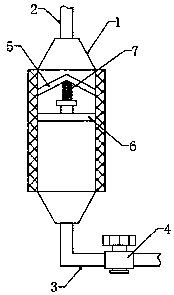

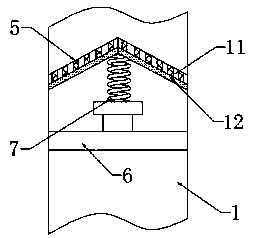

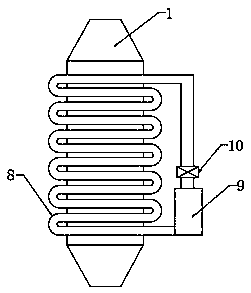

[0018] like Figure 1-3 As shown, the present invention provides a technical solution: a surrounding falling film rectification tower, comprising a tower body 1, a flow dividing mechanism and a heat preservation mechanism, the flow dividing mechanism is installed inside the tower body 1, and the heat preservation mechanism is installed in the tower body 1. Outside the body 1, the upper end of the tower body 1 is installed with a feed pipe 2, the lower end of the tower body 1 is installed with a discharge pipe 3, and the outside of the discharge pipe 3 is installed with a control valve 4. The mechanism includes a splitter plate 5, a limit plate 6 and a return spring 7, the splitter plate 5 is an inclined mechanism, the splitter plate 5 is a double-layer structure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com