Distillation column used for solvent recovery

A distillation tower and solvent technology, applied in the field of solvent recovery distillation towers, can solve the problems of fast rising speed, influence, and low recovery efficiency, and achieve the effect of slowing the rising speed, ensuring the distillation effect, and ensuring the continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

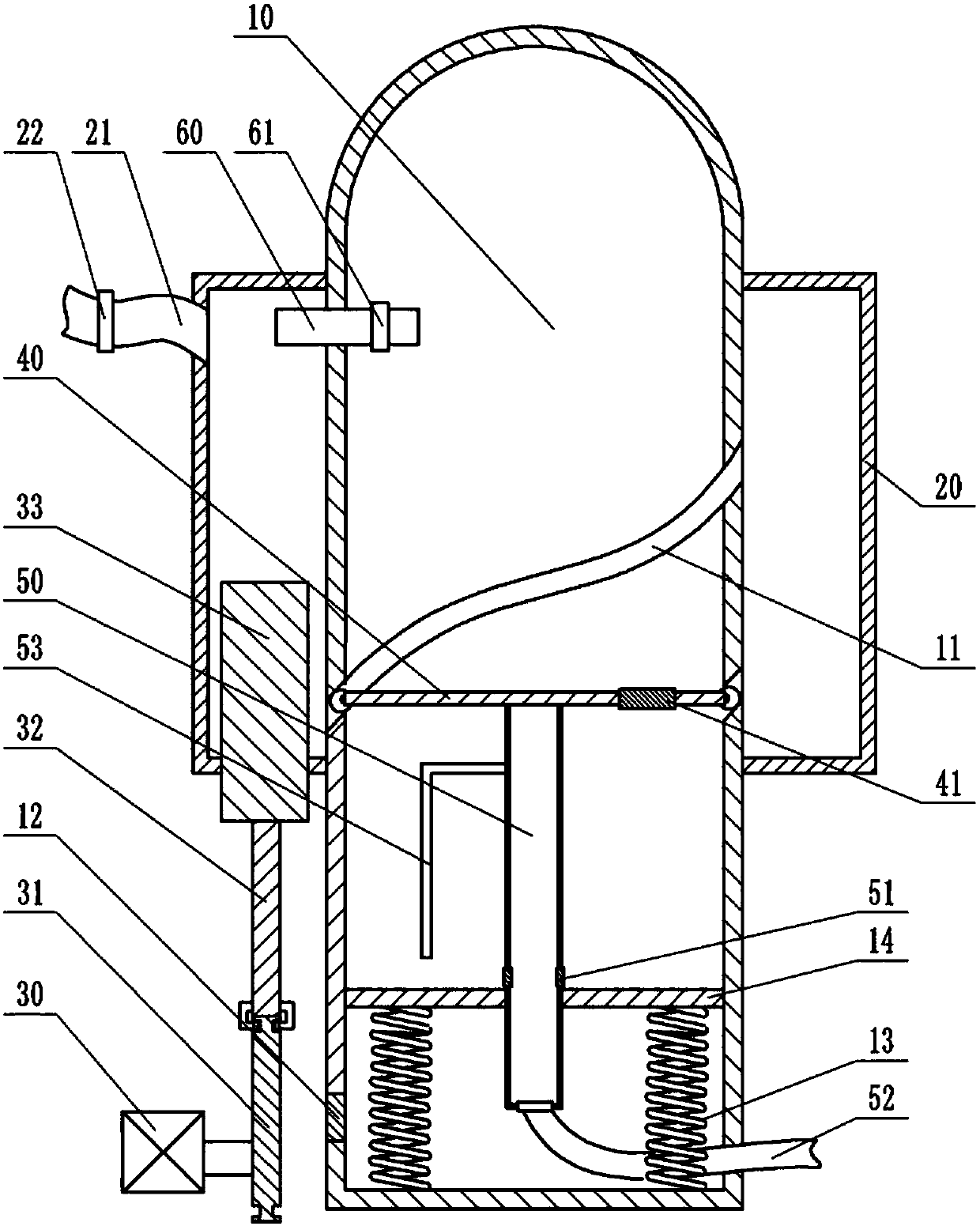

[0024] like figure 1As shown, a rectification device for recovering organic solvents includes a power unit, a distillation tank 10 and a baffle 40 , and the baffle 40 is located in the distillation tank 10 . The lower part of the retort 10 is slidably connected with a partition 14, and a plurality of springs 13 are connected between the partition 14 and the inner wall of the retort 10. The plurality of springs 13 are evenly distributed along the circumference of the partition 14, and the springs 13 are arranged on the partition. The plate 14 has a supporting effect, and when the substance on the dividing plate 14 increases, the spring 13 is compressed, and the dividing plate 14 slides down along the inner wall of the retort 10 . The retort 10 is provided with a one-way door 12 located below the partition 14 , and when the one-way door 12 is squeezed by the liquid in the retort 10 , the one-way door 12 can be opened toward the outside of the retort 10 . The inner wall of the m...

Embodiment 2

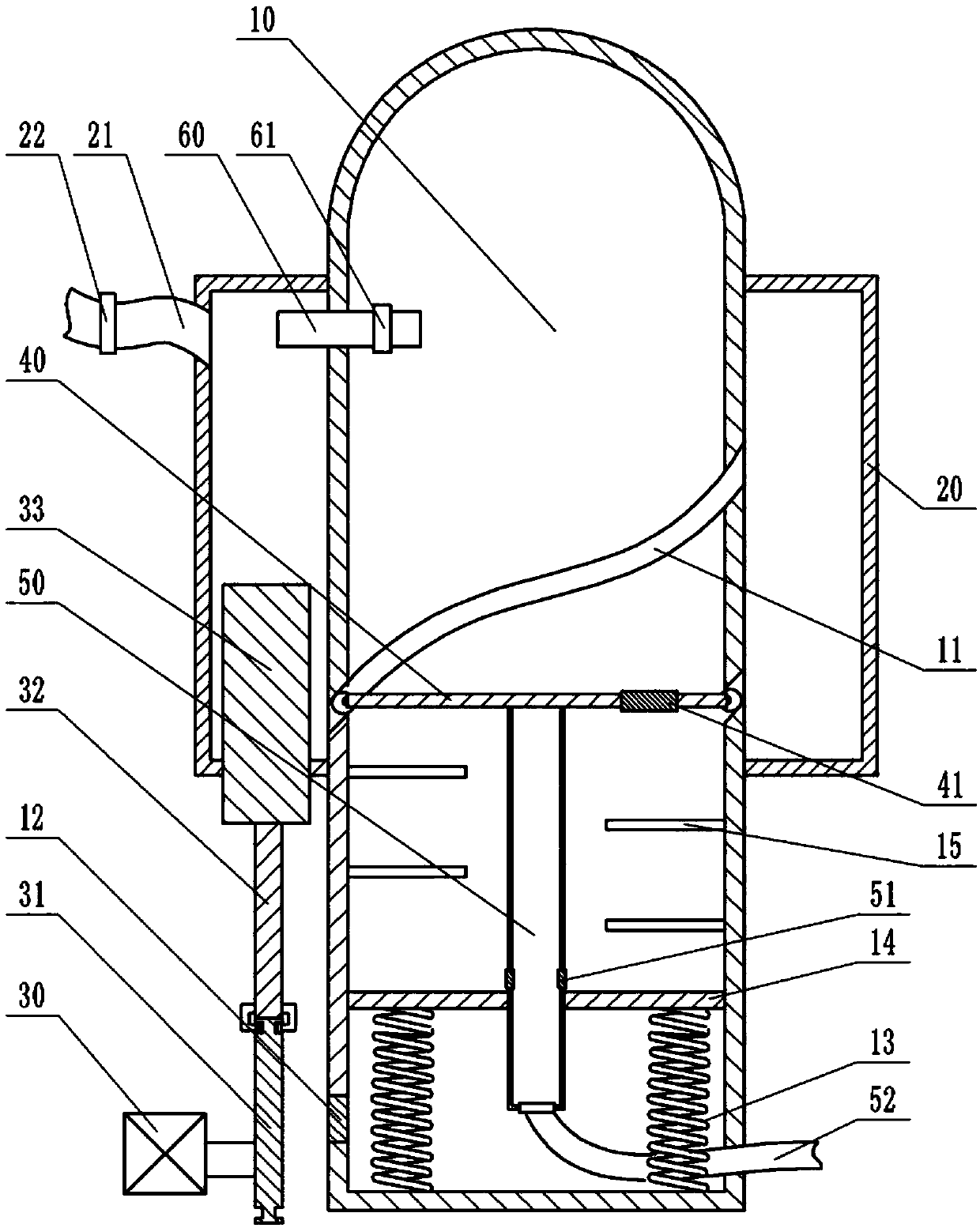

[0027] The difference between this embodiment and embodiment 1 is: as figure 2 As shown, the stirring shaft 53 is not provided on the side wall of the steam pipe 50 ; a plurality of slow flow plates 15 located below the grooves 11 are alternately provided on the inner wall of the distillation tank 10 . The slow flow plates 15 are arranged alternately to form a gas and liquid circulation channel in the distillation tank 10. The heating vapor at the bottom of the distillation tank 10 moves upward along the circulation channel, and the waste solvent falling on the baffle plate 40 flows to the partition along the circulation channel. 14. The setting of the circulation channel increases the movement stroke of the heating steam and the waste solvent, slows down the flow velocity of the heating steam and the reflux liquid, enables the two phases of the vapor and liquid to fully contact for interphase mass transfer, and improves the effect of distillation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com