Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Good resistance to segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

C30 self-compacting concrete prepared from recycled aggregate and preparation method thereof

The invention is applicable to the field of building materials, and provides C30 self-compacting concrete prepared from recycled aggregate and a preparation method thereof. The concrete comprises the following raw materials: cement, reclaimed sand, the recycled aggregate, coal ash, fine-grinding mineral powder, an additive and water which are in the weight ratio of 1: (3.01 to 3.43): (3.46 to 3.76): 0.74: 0.27: 0.015: (0.80 to 0.87) according to the weight of the cement, wherein the water-binder ratio is 0.397 to 0.43. Therefore, the prepared C30 self-compacting concrete is good in filling ability, clearance passing ability, segregation resistance and stability and is easy to construct. In addition, the cost of the concrete is lowered greatly.

Owner:北京元泰达环保科技有限公司

Self-compacting concrete

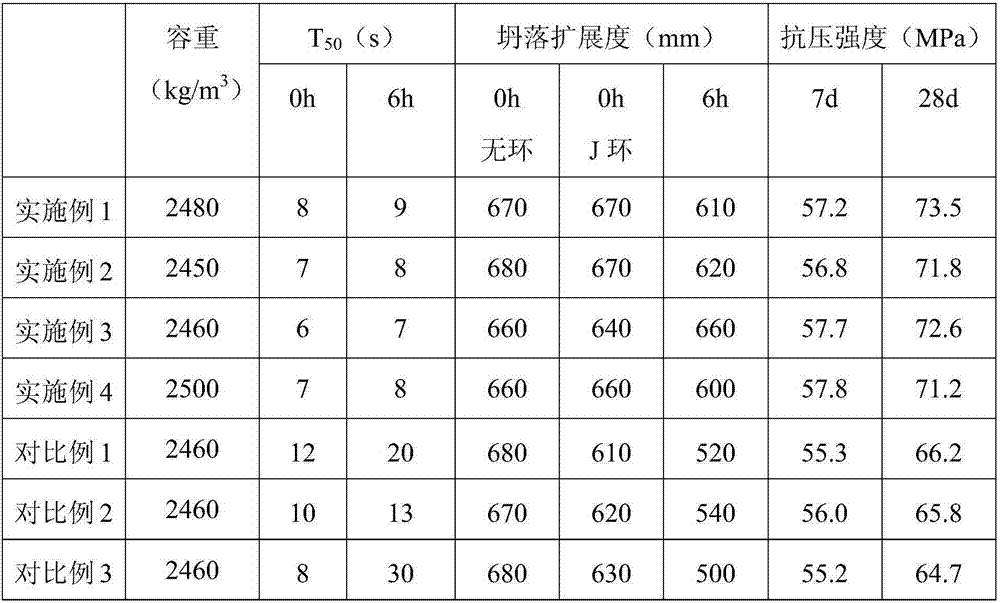

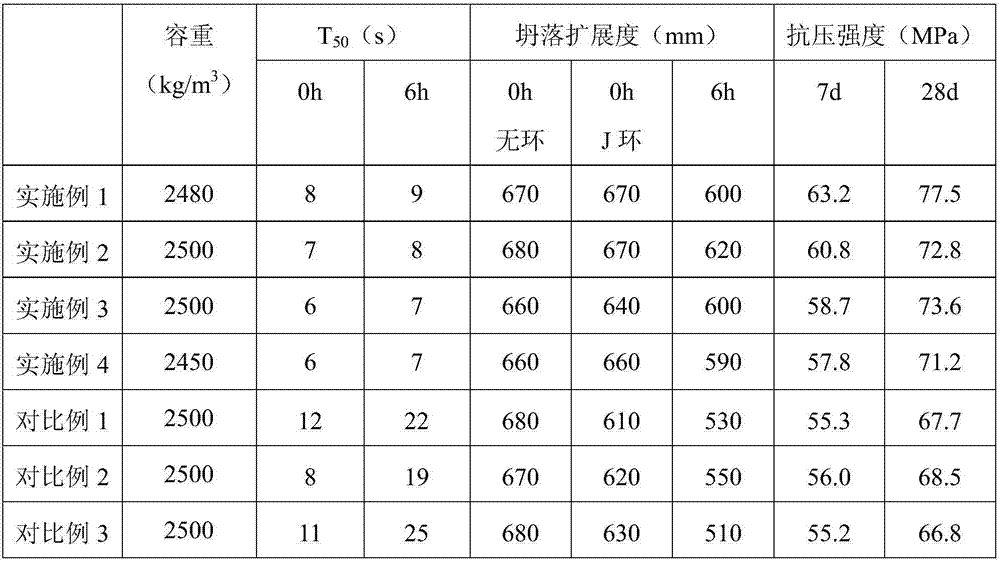

The invention discloses a self-compacting concrete and belongs to the technical field of concrete. The self-compacting concrete comprises the following components in parts by weight: 350-400 parts of cement, 54-80 parts of coal ash, 52-60 parts of slag powder, 50-62 parts of expanding agent, 9-13 parts of silica powder, 748-800 parts of mixed sand, 948-1020 parts of macadam, 140-165 parts of drinking water, 0-10 parts of compound additive and high-performance additive being 1-2% of the binding material in mass fraction. The concrete acquired according to the invention has excellent self-compacting property, fluidity, collapse prevention, cohesiveness and separation resistance, and meanwhile, a test proves that the compressive strength after 7 days is about 57MPa and the compressive strength after 28 days is about 70MPa, so that the concrete provided by the invention has higher compressive strength.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

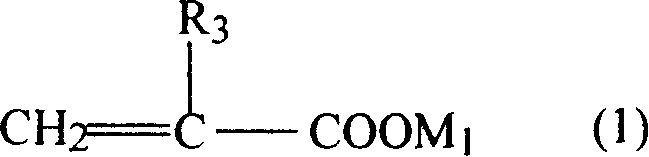

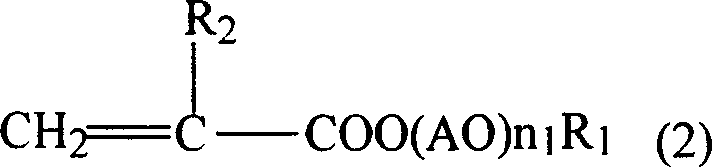

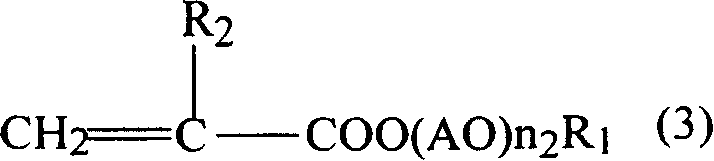

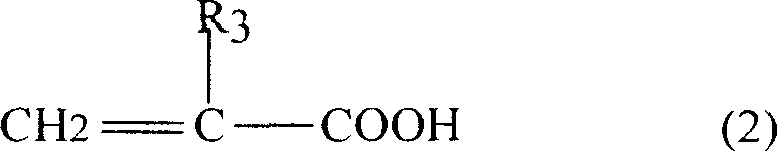

Multifunctional carboxylic-acid comb-shape graft copolymer concrete superplasticizer

The multifunctional super concrete plasticizing agent of carboxylic acid comb grafting copolymer is prepared through the water free radical copolymerization of the following monomers: monomer A with the general expression I in 10-40 wt%, monomer B with the general expression II in 30-70 wt%, monomer C with the general expression III in 10-50 wt%, monomer D with the general expression IV in 3-15 wt%, monomer F with the general expression VI in 0-15 wt%, and reactive defoaming agent E in 0.2-2 wt% of the sum of foregoing five kinds of monomer. The present invention can reduce the shrinkage of concrete, and has good adaptability on cement and admixture material, good dispersivity and slump maintaining performance, high weeping resistance and resolution resistance, small pumping drag, product yield near 100 % and no waste produced in the production process.

Owner:JIANGSU SOBUTE NEW MATERIALS

Self-compacting non-shrinkage concrete-filled steel tube

The invention discloses a self-compacting non-shrinkage concrete-filled steel tube, belonging to the technical field of concrete. The self-compacting non-shrinkage concrete-filled steel tube is prepared from the following components in parts by weight: 360-400 parts of cement, 53-100 parts of coal ash, 15-35 parts of ground slag, 50-80 parts of a compound expansion agent, 700-770 parts of mixed sand, 1040-1070 parts of gravel, 150-160 parts of drinking water and a high performance admixture, wherein the amount of the high performance admixture accounts for 1.7-1.8% of the total mass of a cementing material by mass percent. The self-compacting non-shrinkage concrete-filled steel tube provided by the invention has good self-compacting property, expansibility, fluidity, slump loss resistance,cohesiveness, segregation resistance and higher compression strength; furthermore, the expansion process and strength of concrete-filled steel tube are synergistically developed.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Self-compaction fair-faced concrete with strength grade of C50

The invention discloses self-compaction fair-faced concrete with the strength grade of C50 used for a stiffness concrete structure, belonging to the field of concrete. The mixed proportion comprises 335kg / m<3> cement, a 110kg / m<3> complex mineral additive, 40kg / m<3> coal ash, 850kg / m<3> fine aggregate sand, 910kg / m<3> coarse aggregate and additive PCA; the water-binder ratio is 0.32, the sand ratio is 48%, the dosage replacement rate of the mineral additive is 29% and the water-powder ratio is 0.82; in the unit volume of concrete, the stone occupies 31%, the sand occupies 32.5%, the stone porosity is 36.5%, the rubber powder occupies 19%, the water occupies 15.5% and the gas content is 2%. The self-compaction fair-faced concrete has the effect that the mobility, the segregation resistance and the self fallibility of the concrete meet the requirement, the appearance and colour of the molded concrete are substantially in consistency with little bubbles and dispersion. The self-compaction fair-faced concrete is simple to operate and is particularly suitable for constructing fair-faced concrete of a vertical or inclined stiffness concrete structure with dense steel bars.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Carboxylic acids graft copolymer concrete strengthening agent

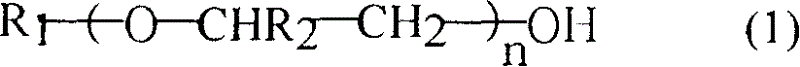

This invention is a carboxylic acids graft copolymer concrete bao tan agent. The procedures are that 1) single alkyl polyether or double hydroxy group polyether and their compound said by general formula (1) is grafting reacted to generate big monomer a with C=C with dyadic unsaturated carboxylic acid or anhydride in condition of acid catalyst. 2) Compound an and monomer b is compounded copolymerized with weight ratio is 70-90% and 3-30%. This invention can greatly improve the slump constant loss of traditional naphthalene system water reducing agent, and improve its dispersibility at the same time. Coagulation time of concrete doesní»t prolong, it has good plastic keeping effect to medium and low slump constant concrete or big degree of fluidity concrete. It has good adaptability to other high efficiency water reducing agent. Good degree of fluidity keeping ability is on it whether coordinated with traditional naphthalene system water reducing agent or melamine system water reducing agent or new style polyocarboxy acid system dispersibility. There is no three wastes during its procedure.

Owner:JIANGSU SOBUTE NEW MATERIALS

High-density self-compacted concrete and preparation method

The invention discloses high-density self-compacted concrete and a preparation method. The high-density self-compacted concrete consists of the following components in percentage by mass: 15-32% of a cementing material, 20-35% of aggregates, 20-42% of sand, 3-12% of expanded vermiculite, 0.1-0.8 percentage of a water reducing agent, 0.04-0.5% of a thickening agent, 0.2-1.5% of a thixotropy lubricant, 0.08-0.8% of straw fiber and 10-25% of water. The preparation method comprises the following steps: stirring the cementing material, the straw fiber and the thickening agent needed for preparation for 3-6 minutes, sequentially adding the water, the water reducing agent and the thixotropy lubricant needed for preparation, and continuously stirring the mixture for 5-10 minutes so as to obtain a slurry mixed material; B, adding the aggregates, the sand and the expanded vermiculite into the slurry mixed material obtained in the step A, and stirring the mixture for 3-6 minutes, thereby obtaining the high-density self-compacted concrete. By adopting the high-density self-compacted concrete, properties of concrete can be effectively improved, a mixture can be relatively good in flowability and caking properties, and the high-density self-compacted concrete has the characteristics of being relatively good in anti-separation properties, tensile resistance, anti-cracking properties, self-filling properties, gap through properties, size stability and the like.

Owner:CHINA MCC17 GRP

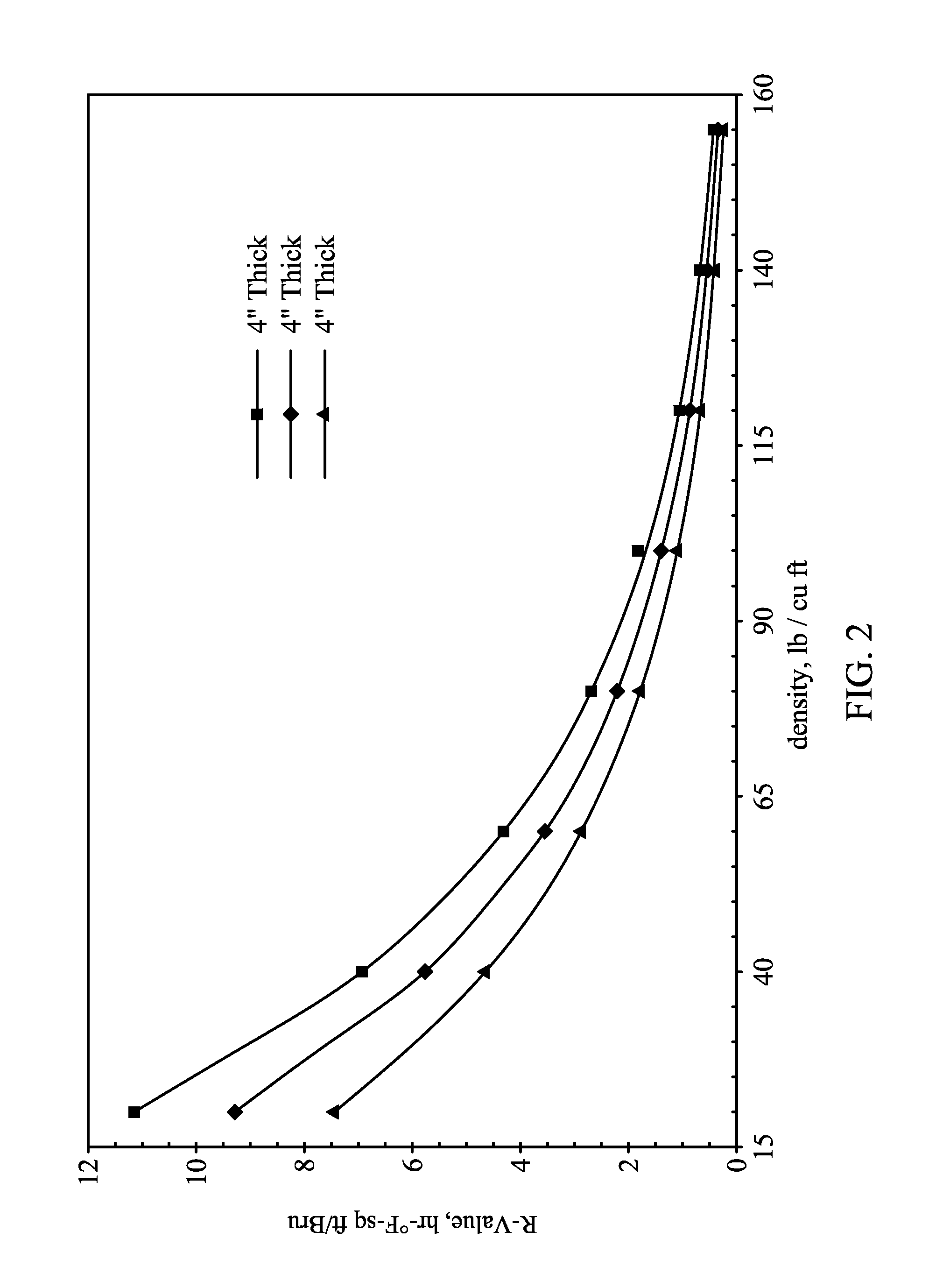

Low-density high-strength concrete and related methods

ActiveUS20160060169A1Low densityRaise the ratioSolid waste managementControl apparatusHigh strength concreteDensity ratio

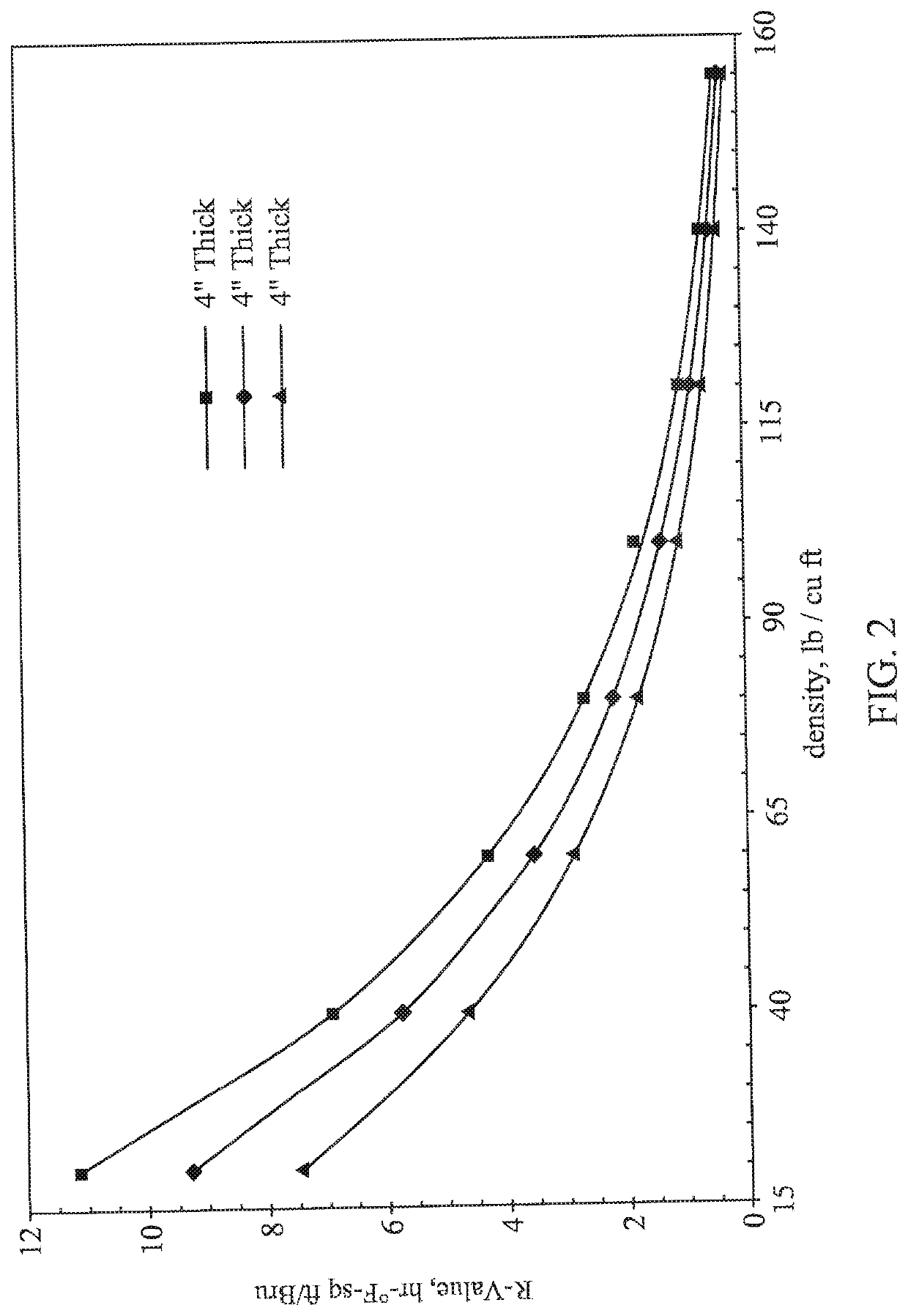

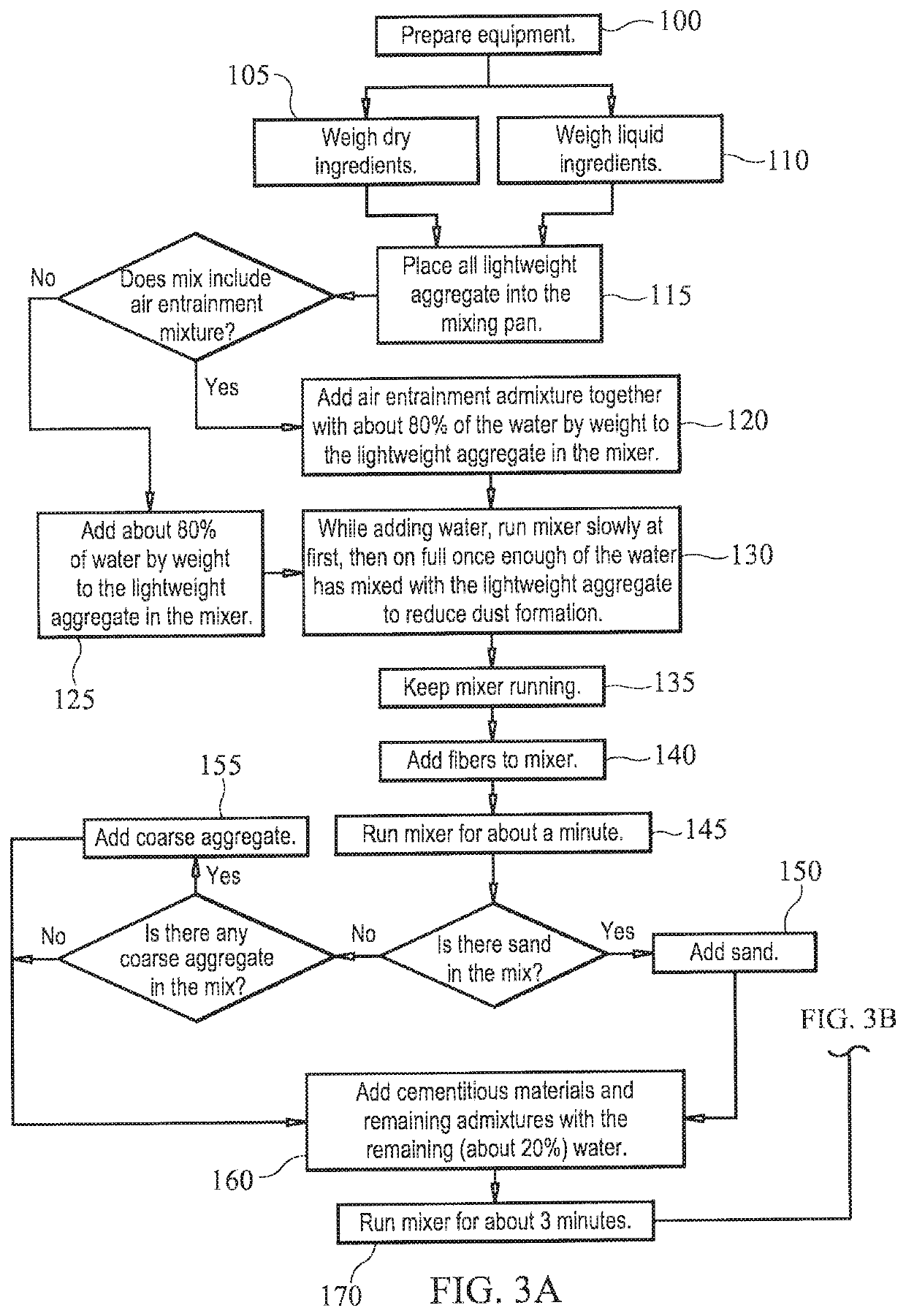

A low-density, high-strength concrete composition that is both self-compacting and lightweight, with a low weight-fraction of aggregate to total dry raw materials, and a highly-homogenous distribution of a non-absorptive and closed-cell lightweight aggregate such as glass microspheres or copolymer polymer beads or a combination thereof, and the steps of providing the composition or components. Lightweight concretes formed therefrom have low density, high strength-to-weight ratios, and high R-value. The concrete has strength similar to that ordinarily found in structural lightweight concrete but at an oven-dried density as low as 40 lbs. / cu.ft. The concrete, at the density ordinarily found in structural lightweight concrete, has a higher strength and, at the strength ordinarily found in structural lightweight concrete, a lower density. Such strength-to-density ratios range approximately from above 30 cu.ft / sq.in. to above 110 cu.ft / sq.in., with a 28-day compressive strength ranging from about 3400 to 8000 psi.

Owner:SEBASTOS TECH

Self-compacting high-performance concrete and preparation method thereof

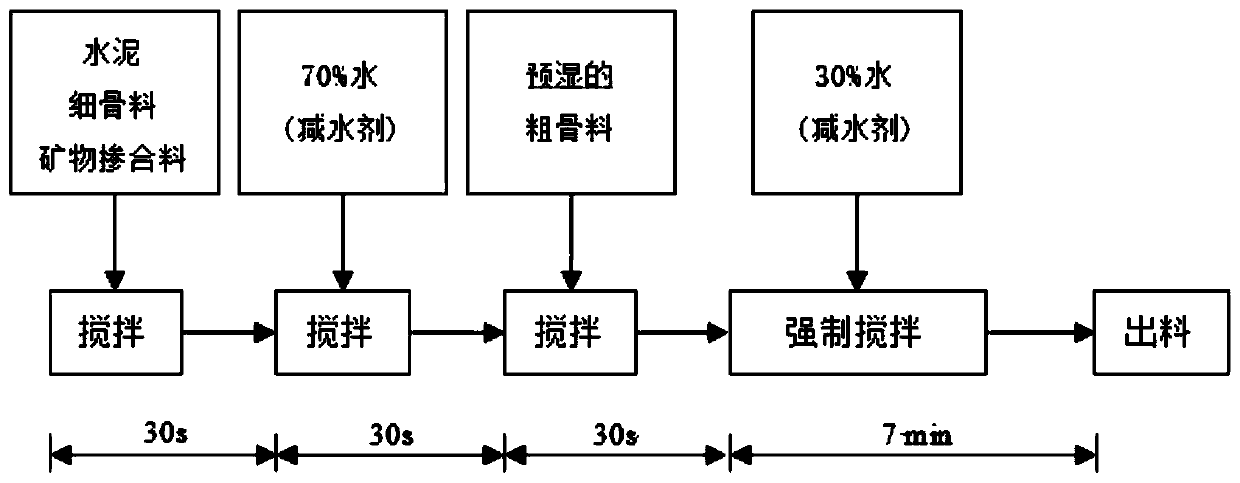

The invention discloses a self-compacting high-performance concrete and a preparation method thereof. The concrete is prepared from the following raw materials by weight: a gelling material, fine aggregate, coarse aggregate, water, polypropylene fiber, a nanometer photocatalysis material, an expanding agent and a high-efficiency water reducer. The preparation method comprises the following steps: step 1, preparation of the nanometer photocatalysis material: (1) with chitosan as a matrix, subjecting chitosan and chloropropylene oxide to cross-linking modification so as to obtain cross-linked chitosan and mixing the cross-linked chitosan with active carbon fiber so as to obtain a mixed loading material; (2) preparing nanometer titanium dioxide sol by using a sol-gel method; and (3) mixing the nanometer titanium dioxide sol with the loading material prepared in (1) and carrying out ultrasonic vibration so as to the nanometer photocatalysis material; and step 2, weighing the gelling material, fine aggregate and polypropylene fiber in a weight ratio, stirring the weighed materials in a forced stirrer for 40 s, then adding the coarse aggregate, water, the nanometer photocatalysis material, the expanding agent and the high-efficiency water reducer and continuing stirring for 90 s so as to obtain the self-compacting high-performance concrete.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

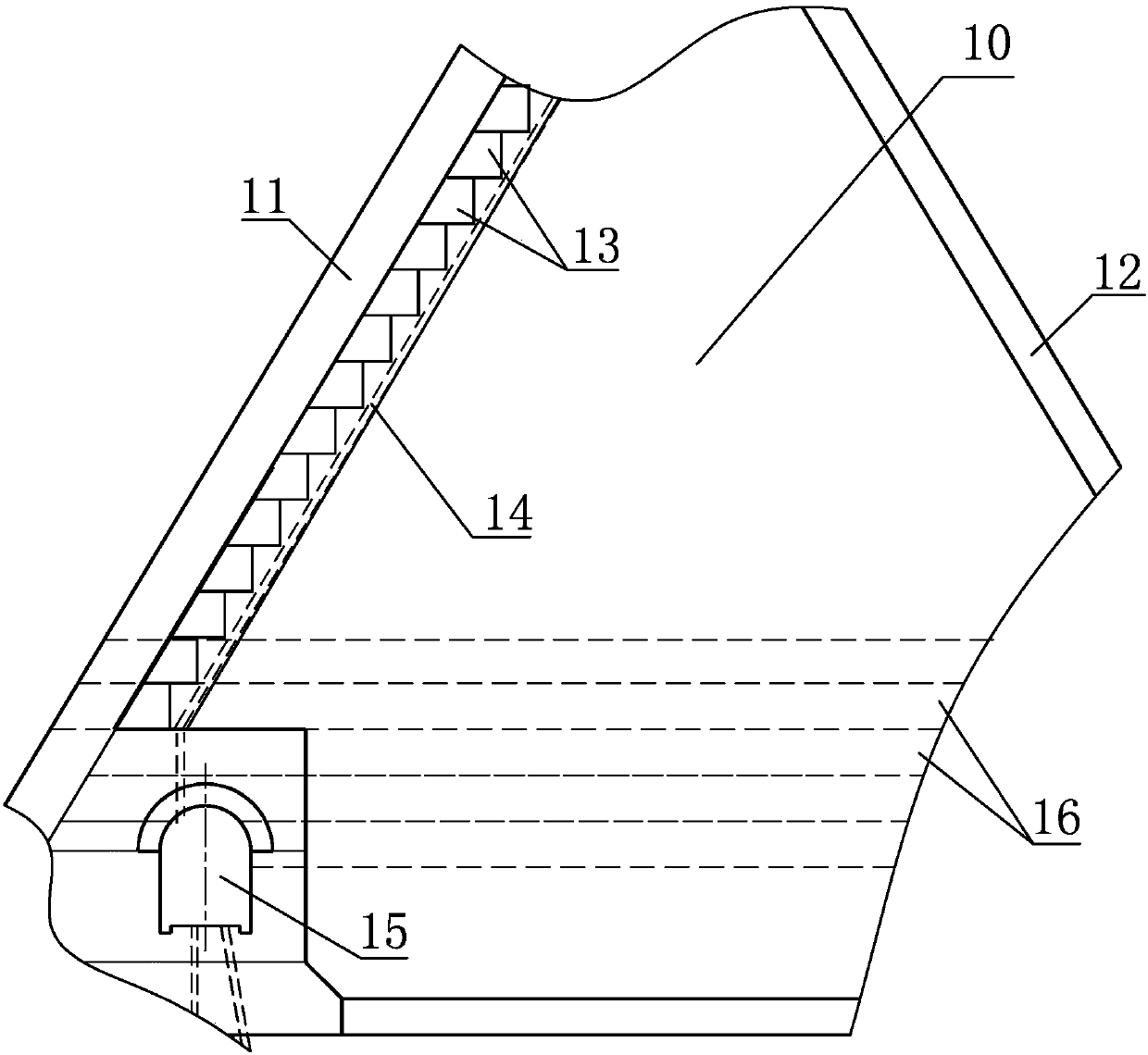

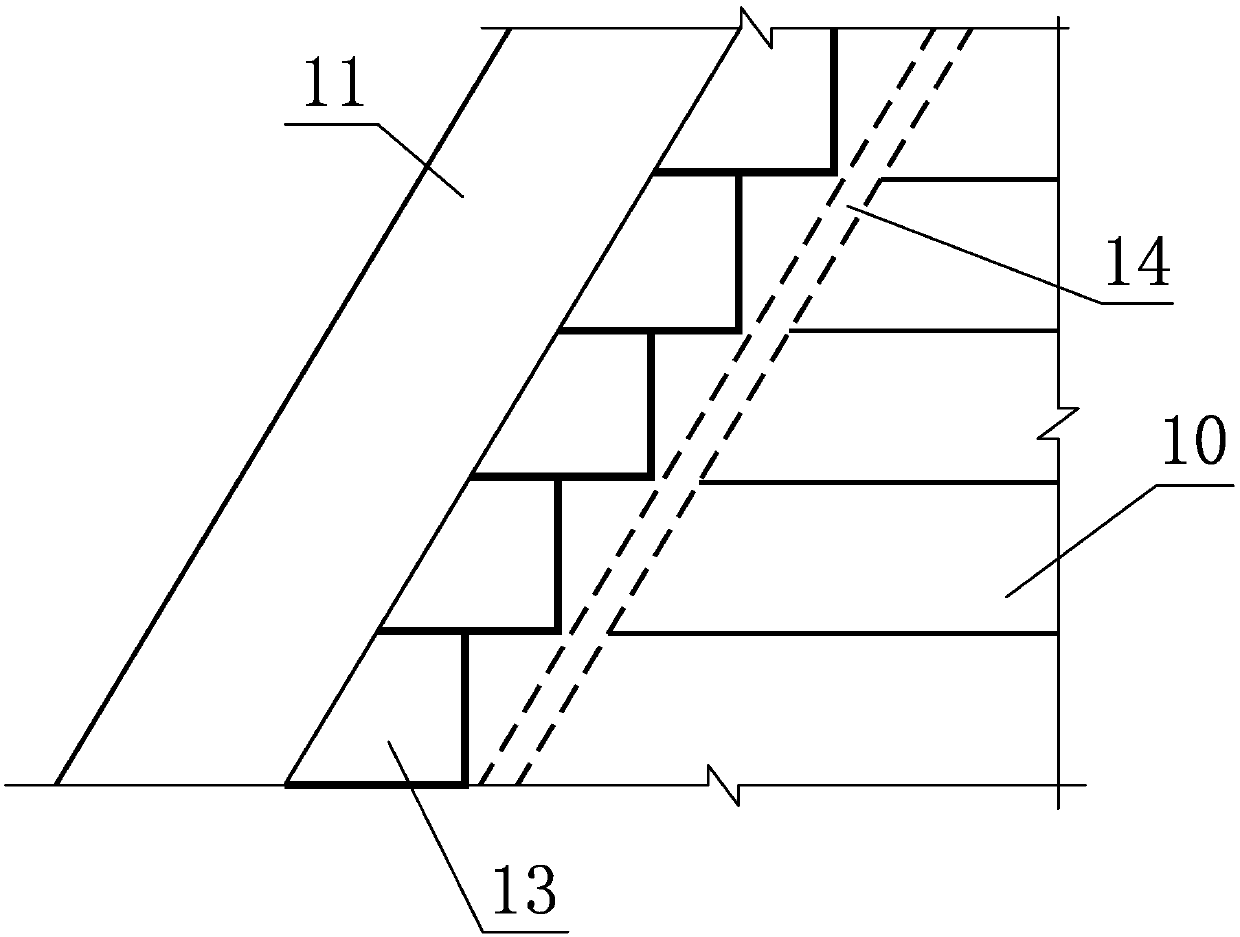

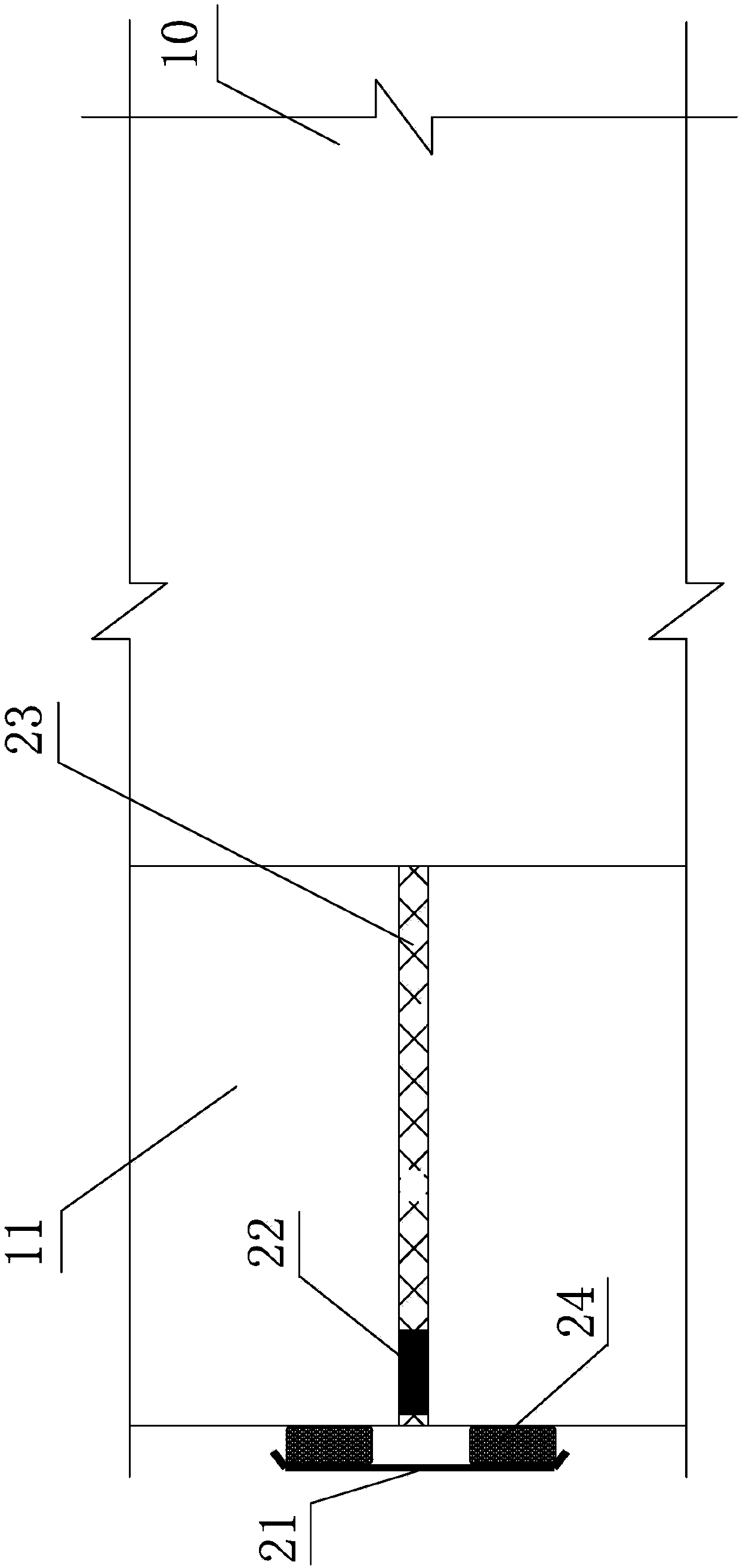

Impermeable drainage system for cement-sand-gravel dam

PendingCN108049370ARich design methodEasy constructionBarrages/weirsClimate change adaptationEngineeringSlurry

The invention provides an impermeable drainage system for a cement-sand-gravel dam. The impermeable drainage system is provided with an upstream impermeable layer and a drainage layer, wherein the upstream impermeable layer is arranged on the upstream of the cement-sand-gravel dam and covers the whole upstream dam face in a laminating manner, the upstream impermeable layer is cut into a pluralityof blocks by transverse seams in the axis direction of the dam, water-stop structures are arranged at the transverse seam positions, at least one part of each water-stop structure is arranged on the surface of the upstream impermeable layer, the upstream impermeable layer is made of slurry-adding vibrating cement sand gravels or slurry enriching cement sand gravels, the drainage layer is arrangedon the downstream side of the upstream impermeable layer of the cement-sand-gravel dam and is adjacent to the upstream impermeable layer, and drainage pipes are arranged on the downstream side of thedrainage layer in the axis direction of the dam and drain leakage water penetrating the upstream impermeable layer. According to the impermeable drainage system, the cement-sand-gravel dam is more economical and environmentally friendly, and meets higher engineering design requirements for compressive strength larger than 20 MPa, anti-freeze strength meeting F300 and impervious strength larger than W10, construction is convenient and fast, the dam body impermeable effect and the dam inner drainage effect can be improved effectively, and the design method of the cement-sand-gravel dam is perfected.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +3

High-concentration crumb rubber modified asphalt and preparation method thereof

ActiveCN102558886AEasy to useReduce absorptionBuilding insulationsHigh concentrationPretreatment method

The invention relates to high-concentration crumb rubber modified asphalt and a preparation method thereof, and belongs to the field of modified asphalt for road construction. Aiming at the problems that the dosage of crumb rubber is not high enough in the traditional crumb rubber modified asphalt technology, and secondary pollution and high energy consumption exist in the wet method modification, the invention adopts a crumb rubber pretreatment method to prepare modified crumb rubber, and then the modified crumb rubber and a reinforcing agent are mixed with asphalt to prepare the high-concentration crumb rubber modified asphalt with a high-speed shearing method, and the filler content of the modified crumb rubber can reach more than 50 parts. The crumb rubber modified asphalt is simple in preparation technology, high in the dosage of the crumb rubber, superior in performance and high in cost performance, and has significant social meaning and environmental protection value.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

Lightweight self-compacting concrete and preparation method thereof

InactiveCN103553450AEfficient and stable productionDoes not involve miningWork performanceUltimate tensile strength

The invention discloses lightweight self-compacting concrete comprising the components of cement, limestone powder, calcined expanded clay, sintered shale ceramic sand, an air-entraining agent, a thickener, a viscosity regulator, a water-reducing agent, and water with a ratio of (450-550): (20-70): (750-900): (100-300): (1-30): (1-30): (0.1-2): (5-15): (170-210). The invention also discloses a preparation method of the concrete. The method has the advantages that: calcined expanded clay and sintered shale ceramic sand are adopted as aggregates, and the performance of the lightweight concrete is regulated by adding the air-entraining agent, the thickener, the viscosity regulator, and the water-reducing agent, such that various working performances satisfy the requirements of self-compacting concrete. The concrete has good anti-segregation performance, excellent pumping performance, self-compacting performance, and high strength. With the viscosity regulator, the production of the lightweight self-compacting concrete is more stable and efficient. Also, natural sand is not adopted as the aggregate, such that sand and gravel mining is not involved in the production, and environment-protection significance is provided.

Owner:JIANGSU MINGHE GRP

Recycled self-compacting concrete and preparation method thereof

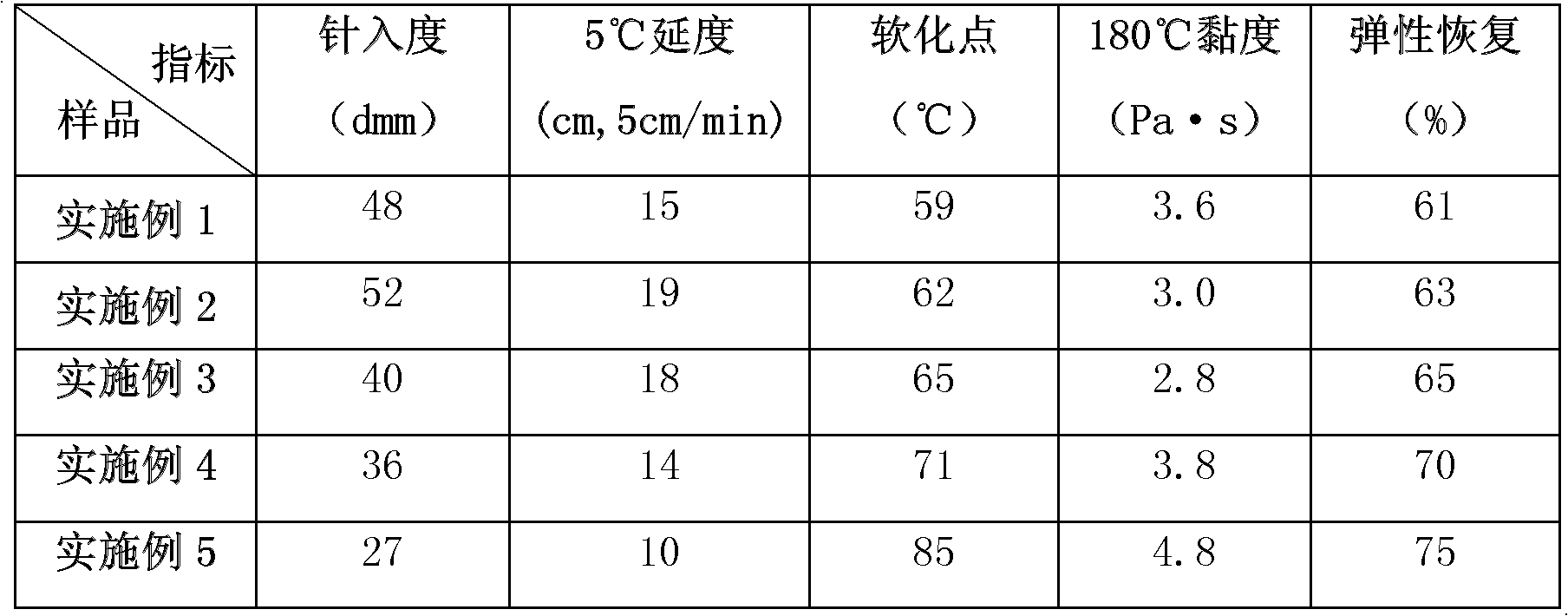

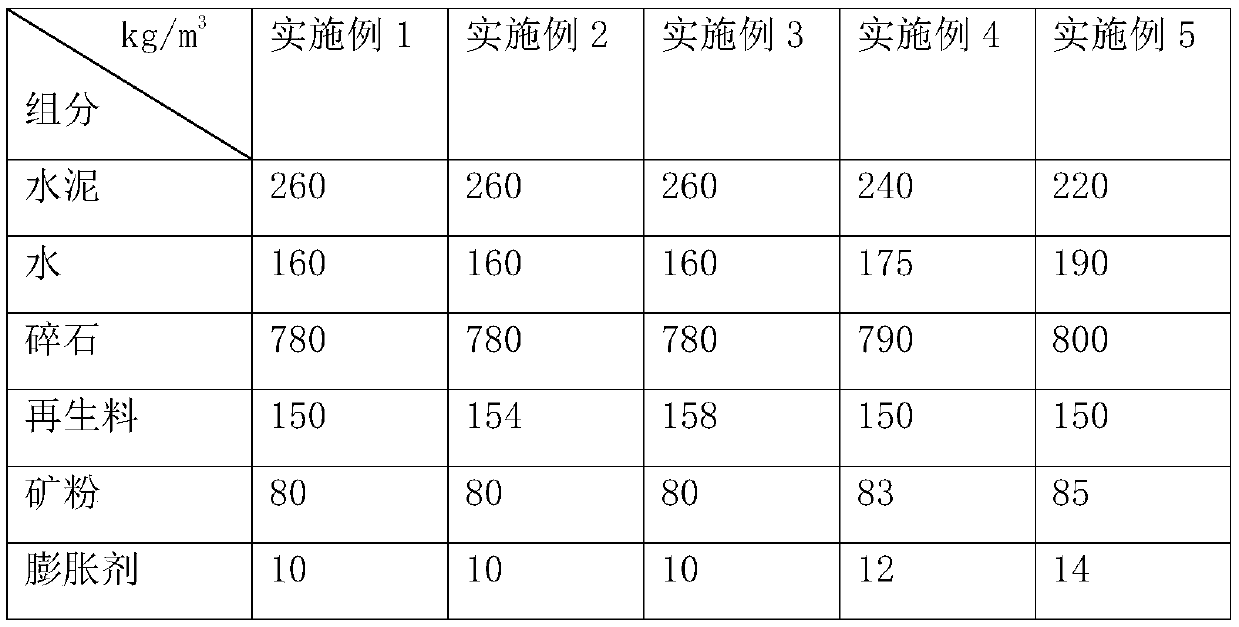

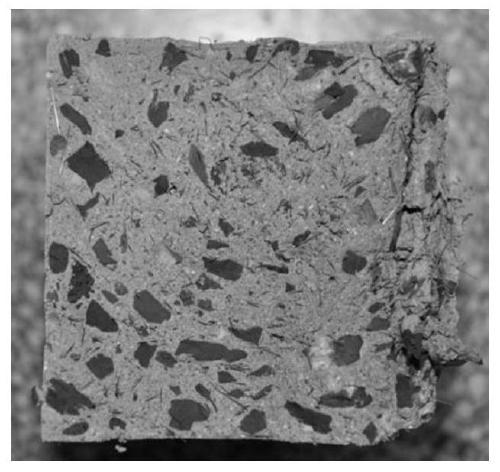

The invention discloses recycled self-compacting concrete and a preparation method thereof. The recycled self-compacting concrete comprises the following components in parts by weight: 220 to 260 parts of cement, 160 to 190 parts of water, 780 to 800 parts of broken stone, 150 to 158 parts of a recycled material, 80 to 85 parts of mineral powder, 10 to 14 parts of an expanding agent, 720 to 750 parts of sand, 3 to 7 parts of a water reducer, 2 to 10 parts of a viscosity modifier and 110 to 117 parts of coal ash; and the recycled material comprises the following components in parts by weight: 20 to 40 parts of iron tailings, 10 to 20 parts of building waste and 20 to 30 parts of steel slag powder. The recycled self-compacting concrete disclosed by the invention has the advantages of high flowing property, filling property and segregation resistance, and the wastes of steel slag and iron tailings are utilized sufficiently.

Owner:西安新意达建筑制品有限公司

Self-compacting fiber toughened lightweight aggregate concrete and preparation method thereof

The invention discloses self-compacting fiber toughened lightweight aggregate concrete and a preparation method thereof. The concrete consists of water, cement, fly ash, silica fume, coarse aggregate,sand, a water reducing agent, steel fibers and polypropylene fibers, has the advantages of being lightweight, high in strength and durability, excellent in crack resistance, great in fluidity and volume stability, capable of achieving automatic compacting and the like, overcomes the defect that the lightweight aggregate concrete is likely to cause brittle failure, and meanwhile can flow compactlyduring pouring; additional vibration is not needed, and the problems of light aggregate floating, vibration segregation and the like in lightweight aggregate concrete are avoided. The self-compactingfiber toughened lightweight aggregate concrete can be widely applied to large-size, super-high-rise and large-span building structures.

Owner:CHANGAN UNIV

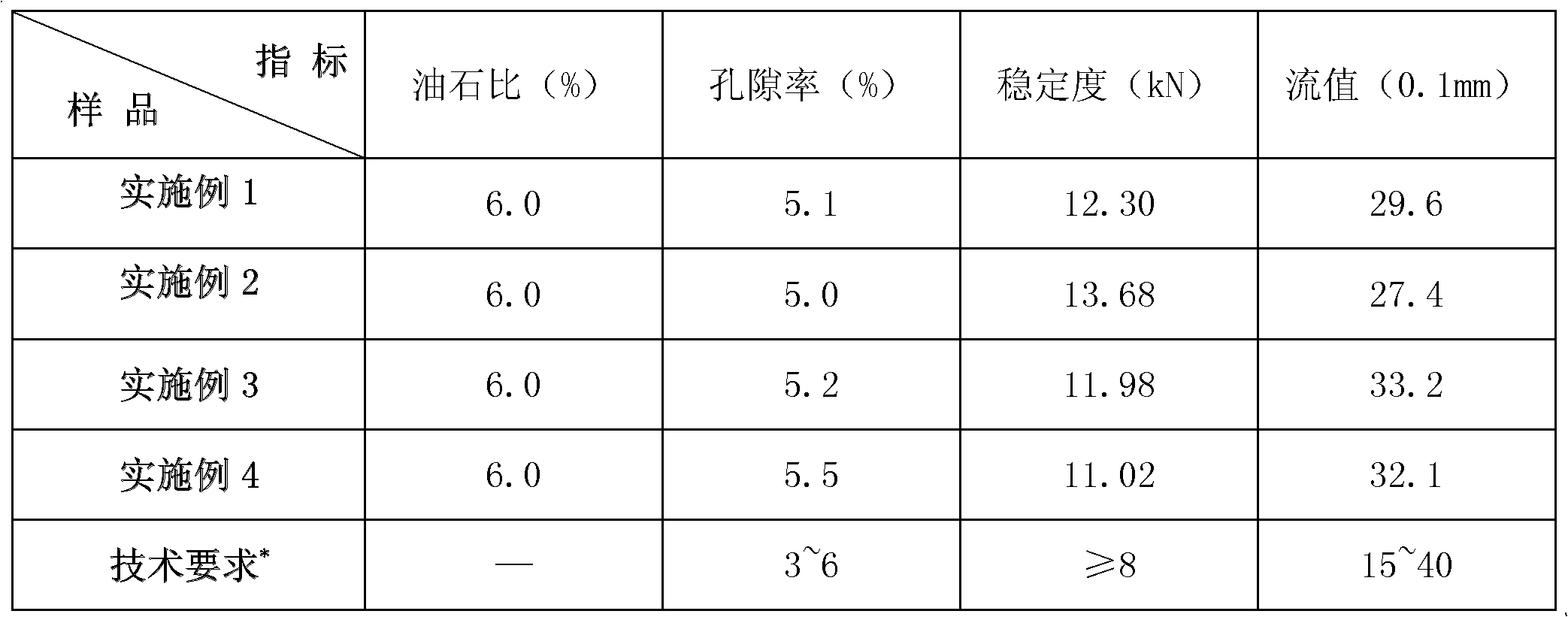

High-concentration rubber powder modified asphalt mixture and preparation method thereof

The invention relates to a high-concentration rubber powder modified asphalt mixture and a preparation method thereof, belonging to the field of road construction asphalt mixtures. A rubber powder pretreatment method is adopted for preparing modified rubber powder against the problems that the using quantity of a conventional rubber powder modified asphalt technology is not high enough, and secondary pollution and high energy consumption exist in wet-process modification, the modified rubber powder and a reinforcing agent are mixed with asphalt and stone to prepare the high-concentration rubber powder modified asphalt mixture, and the filling amount of the modified rubber powder is above 50 parts. The preparation process of the modified asphalt mixture is simple, the using quantity of therubber powder is large, the performances are excellent and the performance-price ratio is high so as to have important social significance and environment-friendly value.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

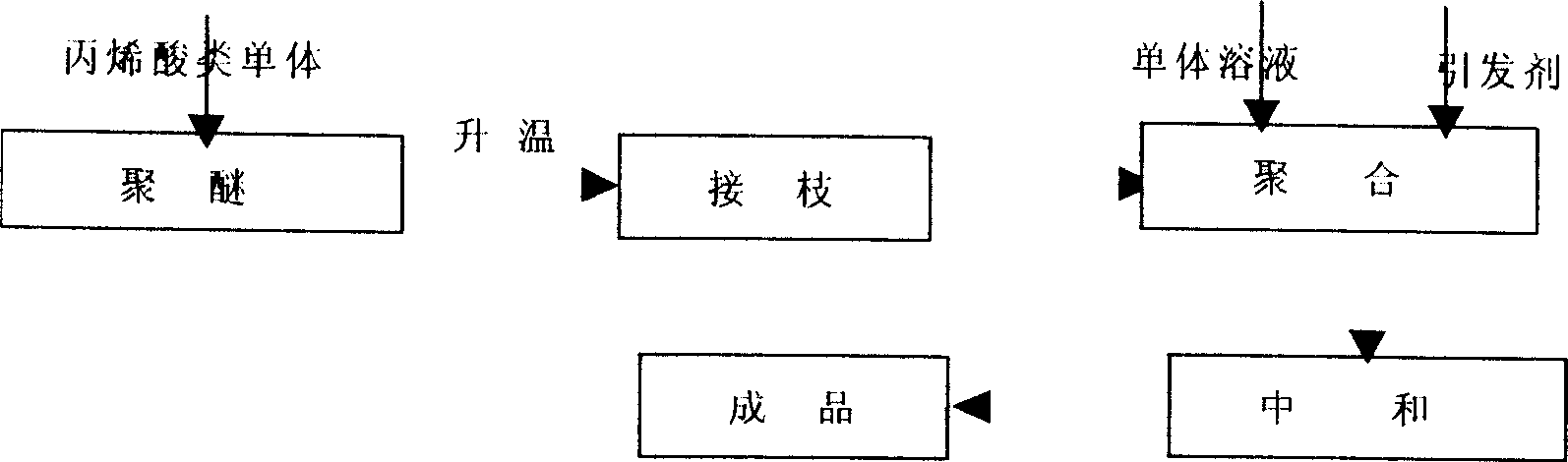

Preparation method of grafted copolymer and air-entraining and slump-retaining polycarboxylate concrete water reducer

The invention belongs to the technical field of concrete admixtures in chemical building materials, and particularly relates to a preparation method of a grafted copolymer and an air-entraining and slump-retaining polycarboxylate concrete water reducer. The air-entraining and slump-retaining polycarboxylate air-entrained concrete efficient water reducer is synthesized by the following steps: introducing a double bond in the process of preparing a macromonomer with reaction activity through utilization of polyoxyalkylene ether monomers; copolymerizing a product obtained from the former step and carboxylic acid monomers and allylsulfonate monomers in a solution so as to introduce a long side chain. The preparation technology is very simple; the reaction condition is easy to control; industrial three wastes are not generated in the production process; the solvent can be recycled after being recovered; and the solvent recovery rate reaches 98%-100%, so that the economic benefits are ensured; and the environmental pollution is avoided.

Owner:山东天汇科技有限公司

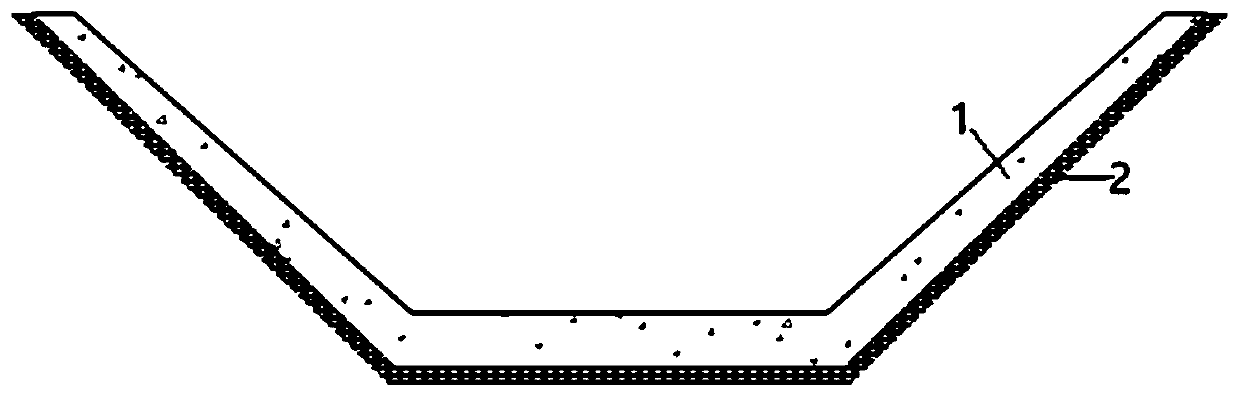

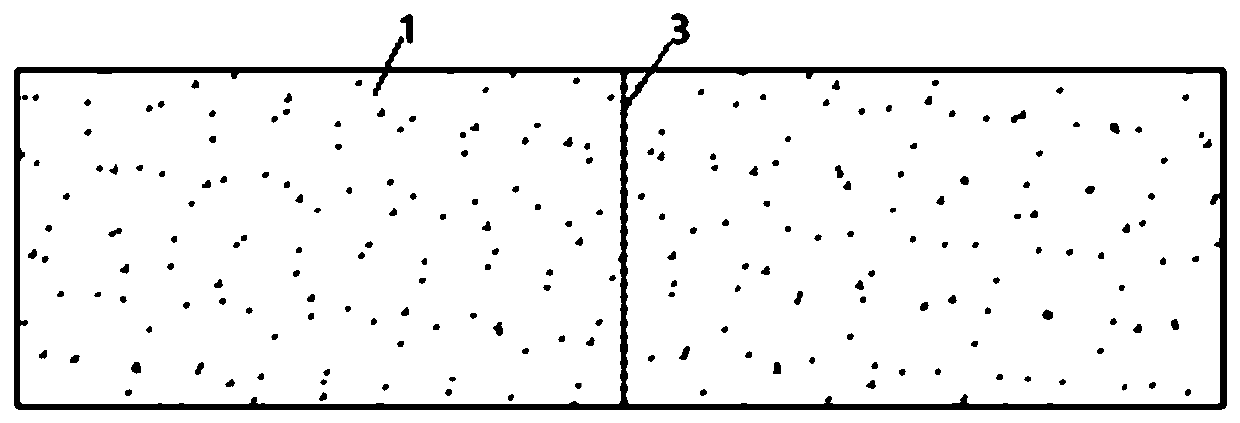

Self-compaction rubber concrete canal lining and preparation method therefor

ActiveCN110698127AImprove ductilityImprove impermeabilityArtificial water canalsFreeze thawingStructural engineering

The invention relates to a self-compaction rubber concrete canal lining and a preparation method therefor. The self-compaction rubber concrete canal lining comprises a canal lining main body, whereinthe canal lining main body is prepared from self-compaction rubber concrete. The lining material provided by the invention can be used for effectively improving high brittleness and low compliance ofthe conventional concrete linings and effectively improving the ductility, impervious waterproofing performance, salt corrosion resistance, freeze-thaw resistance and surrounding soil mass deformationadaptability of lining structures. In addition, the lining material can be filled and compacted in a lining die without bumping down in a poured-in-place process, so that construction steps are simplified, and the schedule of construction is accelerated. The self-compaction rubber concrete canal lining provided by the invention has better popularization and application prospects.

Owner:CHINA AGRI UNIV

Fiber self-dense concrete composition, sound barrier and manufacture method thereof

The invention discloses a fiber self-compact concrete composition, composite sound covolume adsorbing and separating barrier and preparing method with front end of inner cavity of sound barrier as sound adsorbing material cavity and back part as air pad cavity, which comprises the following parts: cement, sand, water, polycarboxylic dehydragent, glass fiber and polypropylene fibre with rate at 1: (1-1.5) : (0.3-0.4) : (0.0056-0.0066) : (0.005-0.015) : (0.0005-0.0015).

Owner:杨志强

Low-density high-strength concrete and related methods

A low-density, high-strength concrete composition that is both self-compacting and lightweight, with a low weight-fraction of aggregate to total dry raw materials, and a highly-homogenous distribution of a non-absorptive and closed-cell lightweight aggregate such as glass microspheres or copolymer polymer beads or a combination thereof, and the steps of providing the composition or components. Lightweight concretes formed therefrom have low density, high strength-to-weight ratios, and high R-value. The concrete has strength similar to that ordinarily found in structural lightweight concrete but at an oven-dried density as low as 40 lbs. / cu.ft. The concrete, at the density ordinarily found in structural lightweight concrete, has a higher strength and, at the strength ordinarily found in structural lightweight concrete, a lower density. Such strength-to-density ratios range approximately from above 30 cu.ft / sq.in. to above 110 cu.ft / sq.in., with a 28-day compressive strength ranging from about 3400 to 8000 psi.

Owner:SEBASTOS TECH

Formula and application method for filling cementing material

InactiveCN108147684AStrong cementing abilityHigh filling strengthCement productionSlagFlexural strength

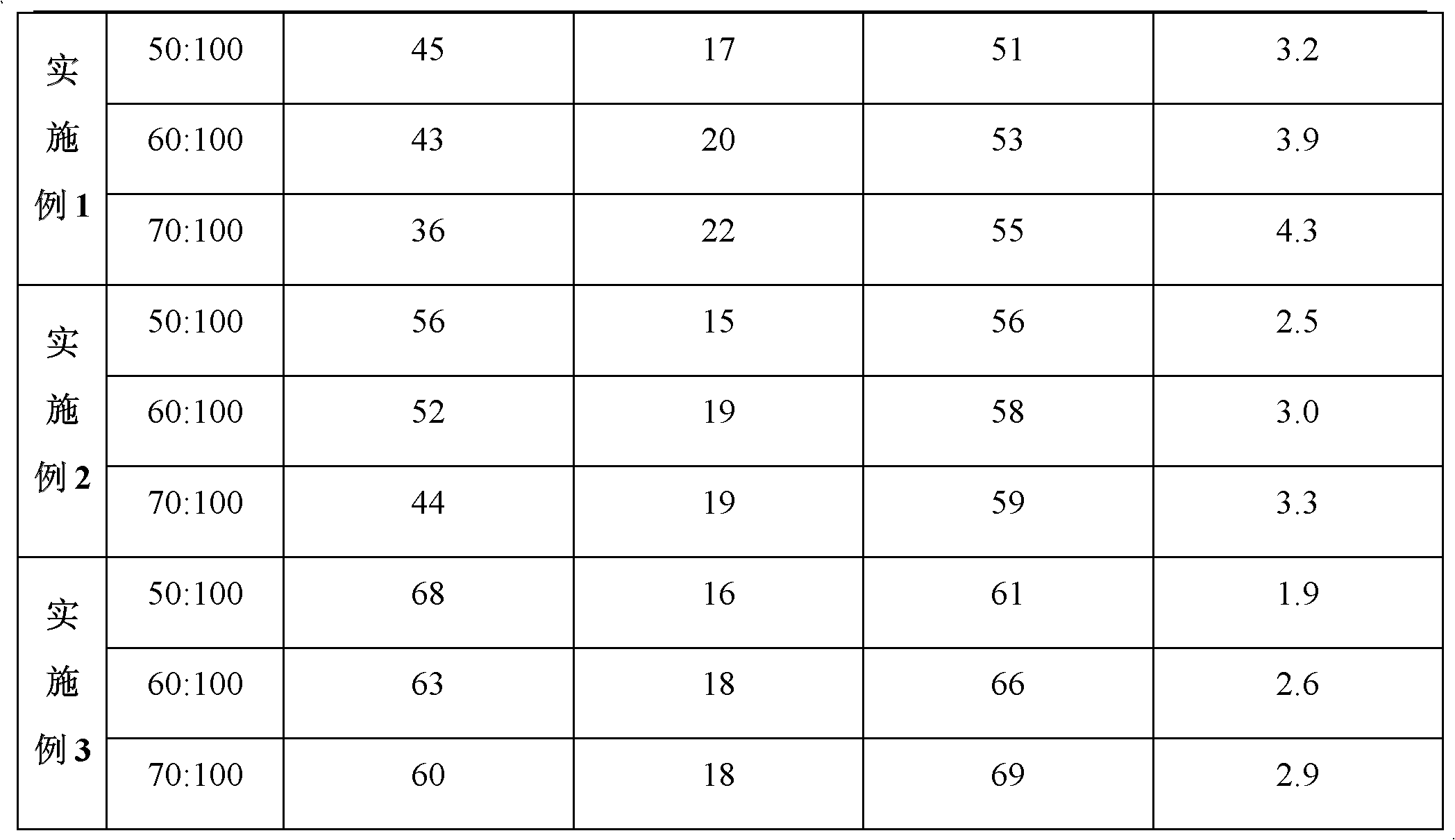

The invention discloses a formula and application method for a filling cementing material. The formula for the filling cementing material adopts slag and other active materials as raw materials, and main chemical components of the formula comprise SiO2, Al2O3, Fe2O3, CaO, MgO and SO3; the formula comprises the following specific raw materials of: 80.2% of the slag, 15.01% of cement clinker, 3.63%of gypsum, 0.65% of solid sodium silicate and 0.51% of an early strength agent. The formula has the following advantages that the filling strength is high, the mortar strength of the cementing material is high, and after tests are conducted, flexural strength, compressive strength and the like can reach standards of P.O 42.5 ordinary cement; it is shown by actual application results that the cementing material has strong cementation ability for fine-grained tailings, and when the same cement-sand ratio and filling concentration are adopted, the filling strength of the filling cementing material is 40-60% higher than that of ordinary cement.

Owner:临沂会宝岭铁矿有限公司

High-strength non-shrinkage concrete master batch

The invention relates to a construction material, in particular to a high-strength non-shrinkage concrete master batch, and aims to solve the problems that: the conventional concrete production process is relatively complex and has high technical threshold; the conventional material is not suitable to be purchased and stored on a large scale because the strength of the conventional material is influenced by storage time and storage environment; and the produced product has poor high fluidity under the condition of high viscosity, and can generate segregation phenomenon when the proportion of the water is larger. The technical scheme adopted by the invention to solve the technical problems is that: mixing 9.5 percent of high-efficiency water reducing agent melamine, 76.1 percent of UEA swelling agent, 0.6 percent of antifoaming agent, 0.6 percent of methyl cellulose ether, 12.2 percent of calcium formate and 1.0 percent of subdivisible emulsion powder; sufficiently and uniformly stirring the mixed materials; grinding the obtained product in a ball grinding mill; and selecting the ground particles of which the particle diameter is controlled to between 5 and 10mu m as the master batch. The master batch is used together with portland cement, fast setting and hardening cement, sulphoaluminate early strength cement and quartz sand to produce various concretes with different application.

Owner:CHINA MCC 2 GRP CO LTD

High-concentration modifying rubber powder and preparation method thereof

ActiveCN102604180AGood elasticityStay flexiblePlastic recyclingBuilding insulationsPre treatmentHigh energy

The invention relates to a high-concentration modifying rubber powder and a preparation method of the high-concentration modifying rubber powder, belonging to the field of modified asphalts for road building. According to the problems that the rubber powder using amount is not large in the existing technology of rubber powder for modifying the asphalt, and the secondary pollution and the high energy consumption exist in wet modification, a rubber pre-processing method is adopted to prepare the modifying rubber powder, and when the modifying rubber powder and the asphalt are mixed together through a high-speed shearing method to prepare the high-concentration rubber powder modified asphalt, the filling amount of the modifying rubber powder is more than 50 parts. The preparation process of the modifying rubber powder is simple, the rubber powder using amount is large, the performance is excellent, the cost performance is high, and the high-concentration modifying rubber powder has important social significance and important environmental-protection value.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

Method for producing potassium salt mine cemented filling material by utilizing graded tailing salt

The invention provides a method for producing a potassium salt mine cemented filling material by utilizing graded tailing salt, and belongs to the technical field of mining engineering and resource comprehensive utilization. The method comprises the following main steps: drying and screening tailing salt; preparing three different grades of aggregates according to different flowability requirements, wherein a proportion control range of the tailing salt to halogen liquid to a cementing agent is that the potassium salt mine tailing salt to the halogen liquid to the cementing agent is equal to (53 percent to 74.5 percent) : (30 percent to 45 percent) : (0.5 percent to 5 percent); stirring the components in the proportion and evenly mixing to prepare the potassium salt mineral cemented filling material. By using the differently graded potassium salt mine tailing salt, the loss degree of the flowability of the filling material along with time is regulated to adapt to different conveying distances and underground filling production; after the filling material is conserved for 28 days, the compressive strength can be up to 0.5MPa to 2.0MPa. According to the method disclosed by the invention, the problems that wastes such as the potassium salt mine tailing salt and the halogen liquid are difficult to treat and comprehensive utilization is difficult are comprehensively solved; by adjusting the grading of the tailing salt, the potassium salt mine cemented filling material has better conveying performance, the segregation resistant capability of the filling material also can be improved, and the mining efficiency of filling milling is improved.

Owner:SINO AGRI INT POTASH CO LTD

Low-density high-strength concrete and related methods

ActiveUS10759701B1Low densityRaise the ratioSolid waste managementCement productionPolymer scienceMicrosphere

A low-density, high-strength concrete composition that is lightweight and self-compacting or non-self-compacting, with a low weight-fraction of aggregate to total dry raw materials, and a highly-homogenous distribution of a non-absorptive and closed-cell lightweight aggregate such as glass microspheres or copolymer polymer beads or a combination thereof, and the steps of providing the composition or components. Lightweight concretes formed therefrom have low density, high strength-to-weight ratios, and high R-value. The concrete has strength similar to that ordinarily found in structural lightweight concrete but at a lower density, such as an oven-dried density as low as 40 lbs. / cu.ft. Such strength-to-density ratios range approximately from above 30 cu.ft / sq.in. to above 110 cu.ft / sq.in., with a 28-day compressive strength ranging from about 3400 to 8000 psi.

Owner:SEBASTOS TECH

Self-compacting concrete applicable to joint section of steel structure concrete composite beam

The invention discloses self-compacting concrete applicable to the joint section of a steel structure concrete composite beam. The concrete is prepared from the following components in parts by mass:100 to 150 parts of water, 450 to 500 parts of cement, 50 to 55 parts of a mineral admixture, 675 to 725 parts of fine aggregate, 1000 to 1100 parts of coarse aggregate, 5 to 10 parts of a high-performance polycarboxylate superplasticizer and 50 to 55 parts of a composite expanding agent, wherein the cement is ordinary Portland cement with a grade of 42.5 or above; the mineral admixture is fly ashwith a grade of national standard I or above; the fine aggregate is natural medium sand or machine-made sand; the coarse aggregate is broken stone with a particle size of 5-25 mm; the water reducingrate of the high-performance polycarboxylate superplasticizer has to be 25% or above. According to the invention, automatic compaction and no shrinkage of concrete in the joint section of a hybrid beam are realized; and the concrete has stable working performance and mechanical performance, and can be applied to concrete structure construction under occasions like construction space is narrow, only self-compaction concrete pouring can be adopted and concrete can only be conveyed from the outer side.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

Fair-faced concrete and preparation method thereof

InactiveCN112341076ASimple manufacturing methodEasy to operate and controlAggregate (composite)Metal-organic framework

The invention discloses fair-faced concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 30-40 parts of cement, 15-25 parts of volcanicash, 3-6 parts of nano hybrid hyperbranched polymer HB-SiO2, 75-85 parts of silica sand, 85-95 parts of coarse aggregate, 3-5 parts of basalt fibers, 1-3 parts of graphene oxide fibers, 7.5-8.5 partsof a composite additive, 15-20 parts of water, 1-3 parts of a carboxyl metal organic framework, 1-3 parts of zirconium citrate and 2-5 parts of zinc oxide nanofibers. The invention also provides a preparation method of the fair-faced concrete. The fair-faced concrete provided by the invention is better in comprehensive performance, higher in compressive strength and flowability, lower in bleedingrate, better in durability, environmental protection property and decorative effect, very good in appearance, smooth in surface and less in pores.

Owner:韩昌龙

Highway concrete with thermal insulation effect and good durability

The invention discloses highway concrete with thermal insulation effect and good durability. Raw materials of the highway concrete comprise: Portland cement, gravel, ceramsite, pumice, expanded perlite, glazed hollow beads, fishbone dust, carbon fiber, polyimides fiber, a polychloroprene emulsion, epoxy resin, sulphur, sodium alkyl benzene sulfonate, a polycarboxylate superplasticizer and modifiedlignin fibre. The invention brings forward highway concrete with thermal insulation effect and good durability. The highway concrete with thermal insulation effect and good durability has a certain thermal insulation effect and good durability.

Owner:来安县塔鑫建材有限公司

C20 self-compaction concrete prepared from recycled aggregate and preparation method thereof

The invention is applicable to the field of construction materials, and provides a C20 self-compaction concrete prepared from recycled aggregate and a preparation method thereof. The concrete is prepared from the following raw materials in parts by weight: 1 part of cement, 3.97-4.49 parts of reclaimed sand, 4.46-4.83 parts of recycled aggregate, 0.95 part of fly ash, 0.44 part of ground ore powder, 0.015 part of admixture and 1.12-1.20 parts of water. The water-to-cement ratio is 0.469-0.502. The prepared C20 self-compaction concrete has the advantages of favorable filling property, favorable clearance throughput capacity, high segregation resistance and high stability, and is easy for construction. The cost of concrete is greatly lowered.

Owner:XINAO ECOLOGICAL CONSTR MATERIALS

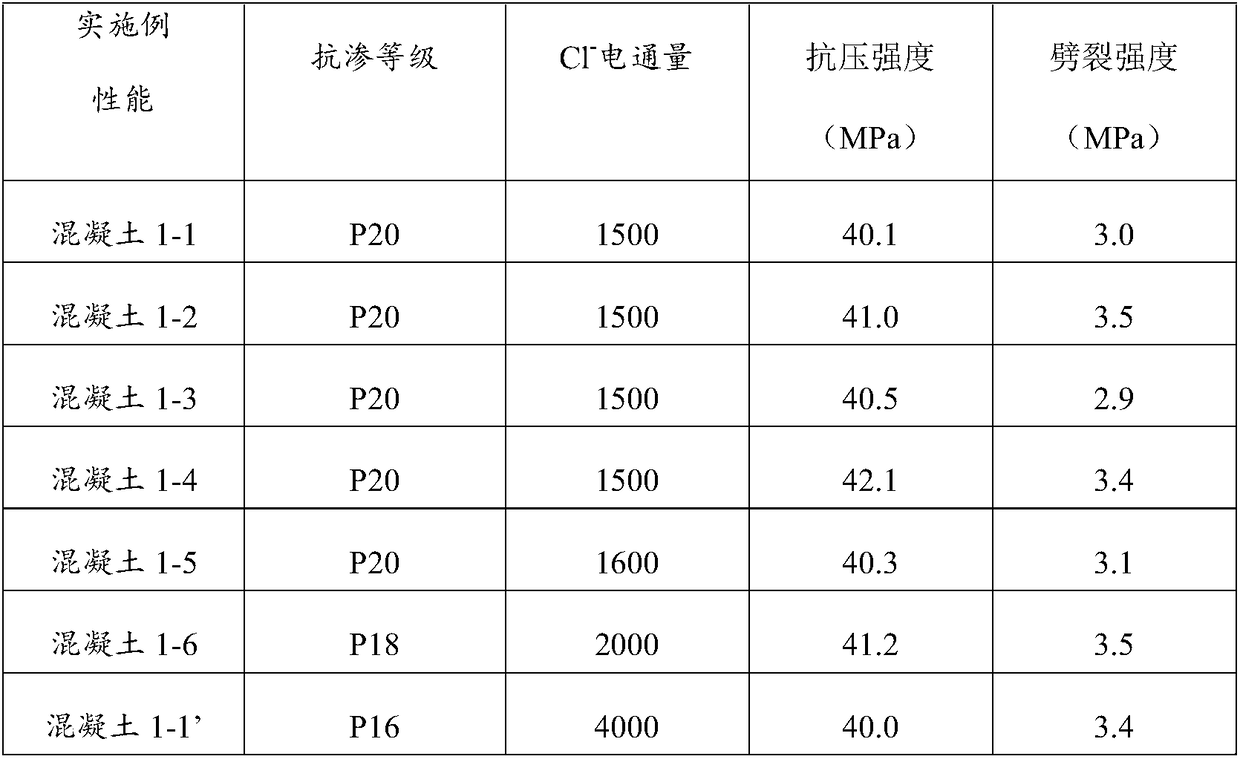

Ultrahigh-performance concrete waterproof composite liquid and preparation method thereof

ActiveCN108516727AImproves water retention and segregation resistanceReduce erosion damageRebarSilane coupling

The invention relates to ultrahigh-performance concrete waterproof composite liquid being prepared from, by weight, 10-30 parts of soluble aluminum salt, 20-50 parts of a silane coupling agent, 0.5-5parts of an antioxidant, 0.5-5 parts of a stabilizer, and 100-200 parts of water. The concrete waterproof composite liquid has anti-seepage and anti-seawater-corrosion effect; as a concrete additive,the composite liquid can greatly improve the water-retaining property and anti-separation effect of concrete, reduces erosive damage on a protective layer surface of steel bars due to sea wave and seasand, and reduces and fines capillaries on the surface of concrete, thereby reducing capillary inhalation of the concrete to salts, alkalis and the like and reducing slump loss of concrete.

Owner:山东好运新材料有限公司

Self-compacting concrete and preparation method thereof

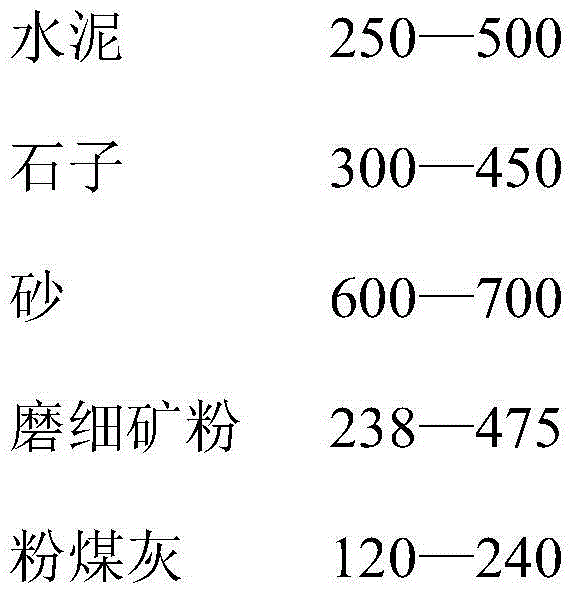

The invention provides a self-compacting concrete and a preparation method thereof. The concrete is composed of a dry mixing base stock and water, wherein the dry mixing base stock is composed of 250-500 parts of cement, 300-450 parts of gravel, 600-700 parts of sand, 238-475 parts of superfine slag powder, 120-240 parts of fly ash and 0.8-3 parts of a water reducing agent; the weight ratio of water and dry mixing base stock is 0.95-0.156. The preparation method is as follows: adding the cement, gravel, sand, superfine slag powder, fly ash and water reducing agent into a large-scale forced mixer, stirring for 30 min, then adding the gravel, stirring for 50 min to prepare the dry mixing base stock for standby; and mixing water and prepared dry mixing base stock according to ratio to prepare the self-compacting concrete, and stirring for no less than 120 min. The invention has the advantages of good filling, gap trafficability, segregation resistance and stability, and the preparation is more environment-friendly, and reduces the cost of concrete.

Owner:LANGFANG RONGSHENG CONCRETE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com