Self-compacting fiber toughened lightweight aggregate concrete and preparation method thereof

A light aggregate concrete and fiber toughening technology, applied in the field of concrete materials, can solve the problems of light aggregate concrete prone to brittle failure, floating, vibration segregation, etc., and achieve good durability, good volume stability, and crack resistance The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

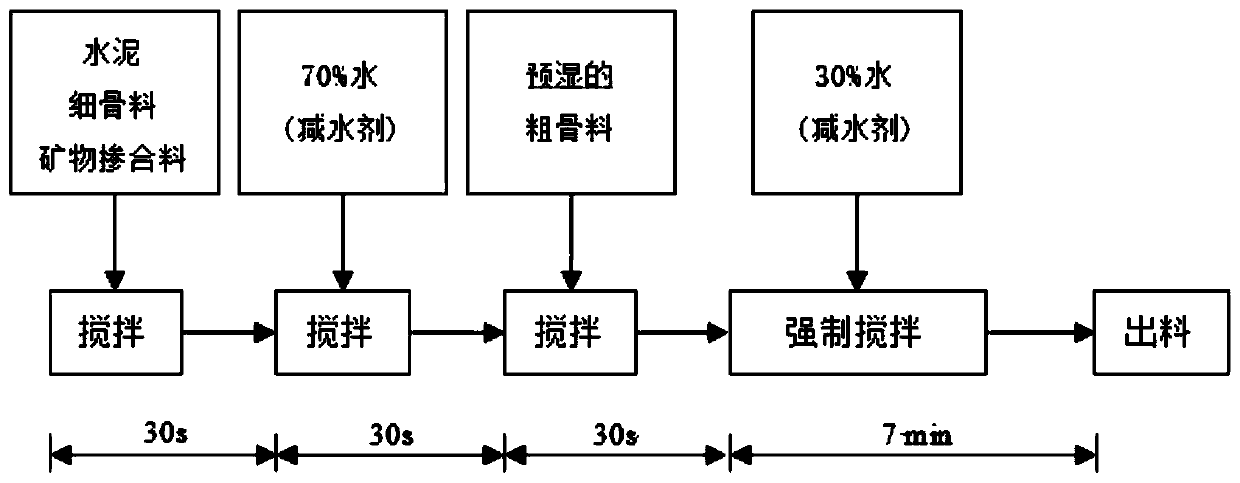

[0026] see figure 1 , the preparation method of the present invention comprises the following steps:

[0027] Step 1: Mix 100 parts of cement, 200 parts of sand, 45 parts of fly ash, and 6 parts of silica fume according to the parts by mass, then add 9 to 12 parts of steel fiber and 0 to 0.3 part of polypropylene fiber, and stir evenly to obtain mixture A;

[0028] Step 2: Mix 45 parts of water with 1 to 1.7 parts of water reducer, and stir evenly to obtain a mixture B of water reducer and water;

[0029] Step 3: Add 70% water reducer and water mixture B to mixture A, and stir to obtain mixture C;

[0030] Step 4, add 120 parts of coarse aggregate to the mixture C, stir evenly to obtain the mixture D;

[0031] Step 5: Add the remaining 30% water reducer and water mixture B into the mixture D, and stir evenly to obtain self-compacting fiber-toughened lightweight aggregate concrete.

[0032] The cement adopts P·O42.5 Portland cement.

[0033] The fly ash is Class I fly ash....

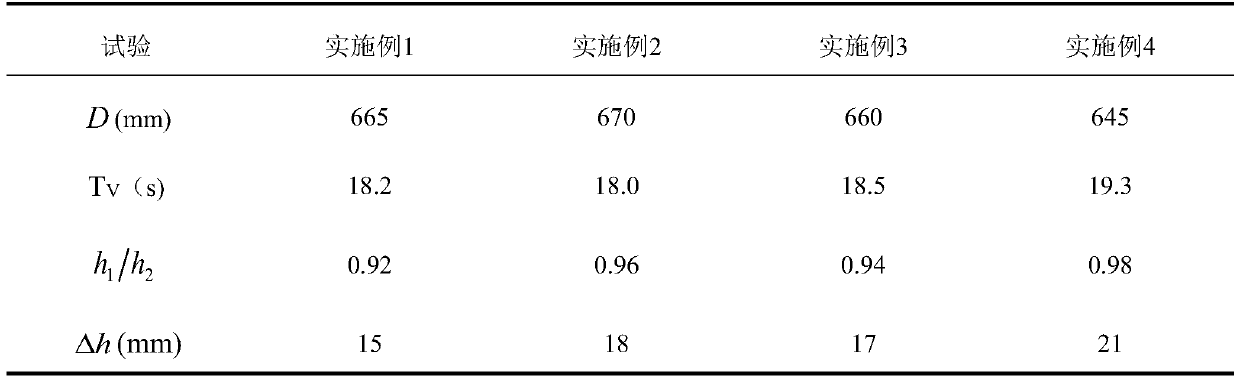

Embodiment 1

[0040] This embodiment provides a kind of self-compacting fiber toughened lightweight aggregate concrete, which is composed of cementitious material, river sand, lightweight aggregate, admixture and water. The dosage of each material in each cubic concrete is as follows: 170kg of water, 374kg of cement, Fly ash 170, silica fume 22.7kg, coarse aggregate 447kg, sand 760kg, water reducing agent 5.1kg, steel fiber 39kg.

[0041] see figure 1 , the preparation method of above-mentioned self-compacting fiber toughened lightweight aggregate concrete, comprises the steps:

[0042] 1) Preparation: Use a forced mixer for mixing, and use a concrete vibrating table for vibration. Before mixing concrete, add water and run it idle for a few minutes, then drain the remaining water to ensure that the wall of the mixing tank is completely wet.

[0043] 2) Dry mixing: Put the mineral admixture, fine aggregate and cement into the mixer, then add an appropriate amount of fiber material, followe...

Embodiment 2

[0048] This embodiment provides a kind of self-compacting fiber toughened lightweight aggregate concrete, which is composed of cementitious material, river sand, lightweight aggregate, admixture and water. The dosage of each material in each cubic concrete is as follows: 170kg of water, 374kg of cement, Fly ash 170, silica fume 22.7kg, coarse aggregate 447kg, sand 760kg, water reducing agent 5.3kg, steel fiber 39kg, polypropylene fiber 0.455kg.

[0049] The preparation method of the above self-compacting fiber toughened lightweight aggregate concrete is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com