Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Good mixing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

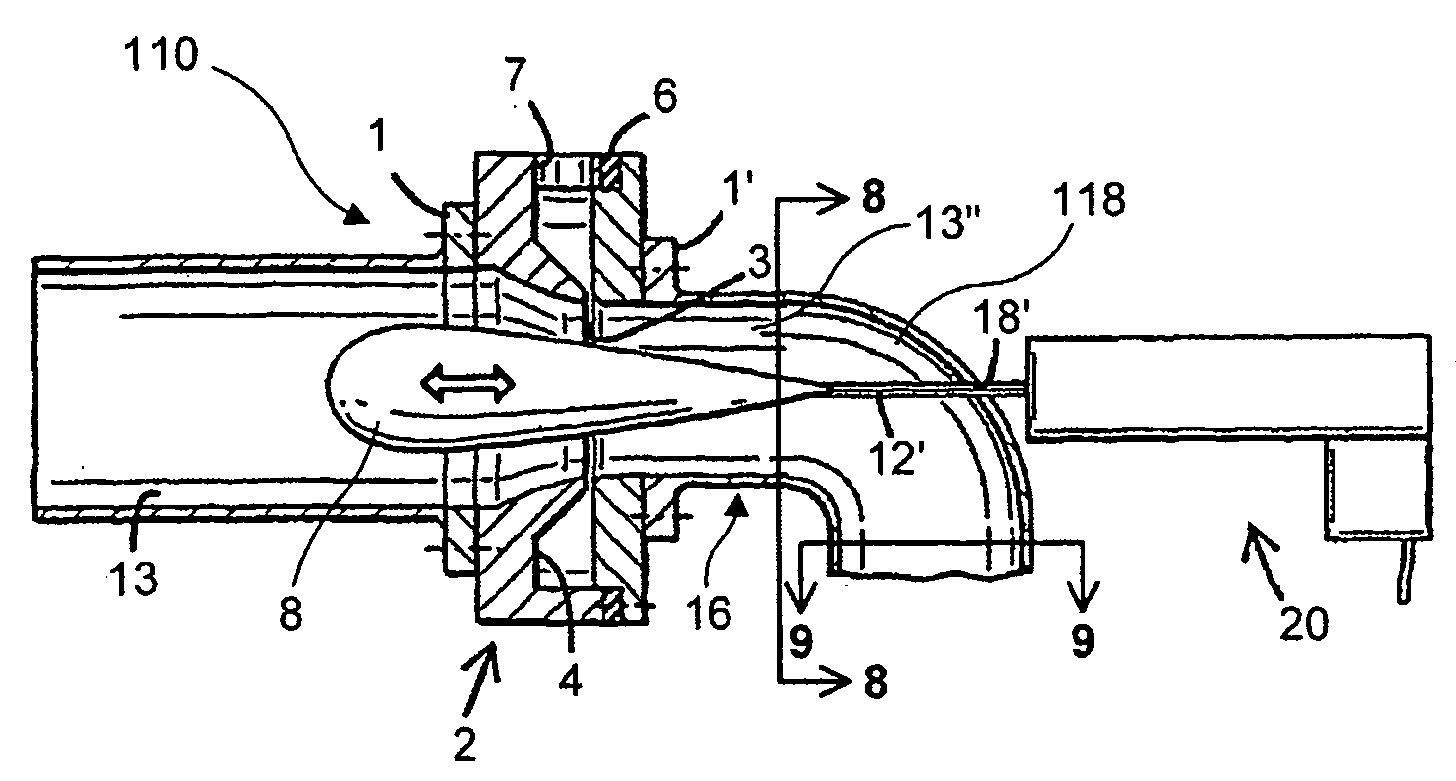

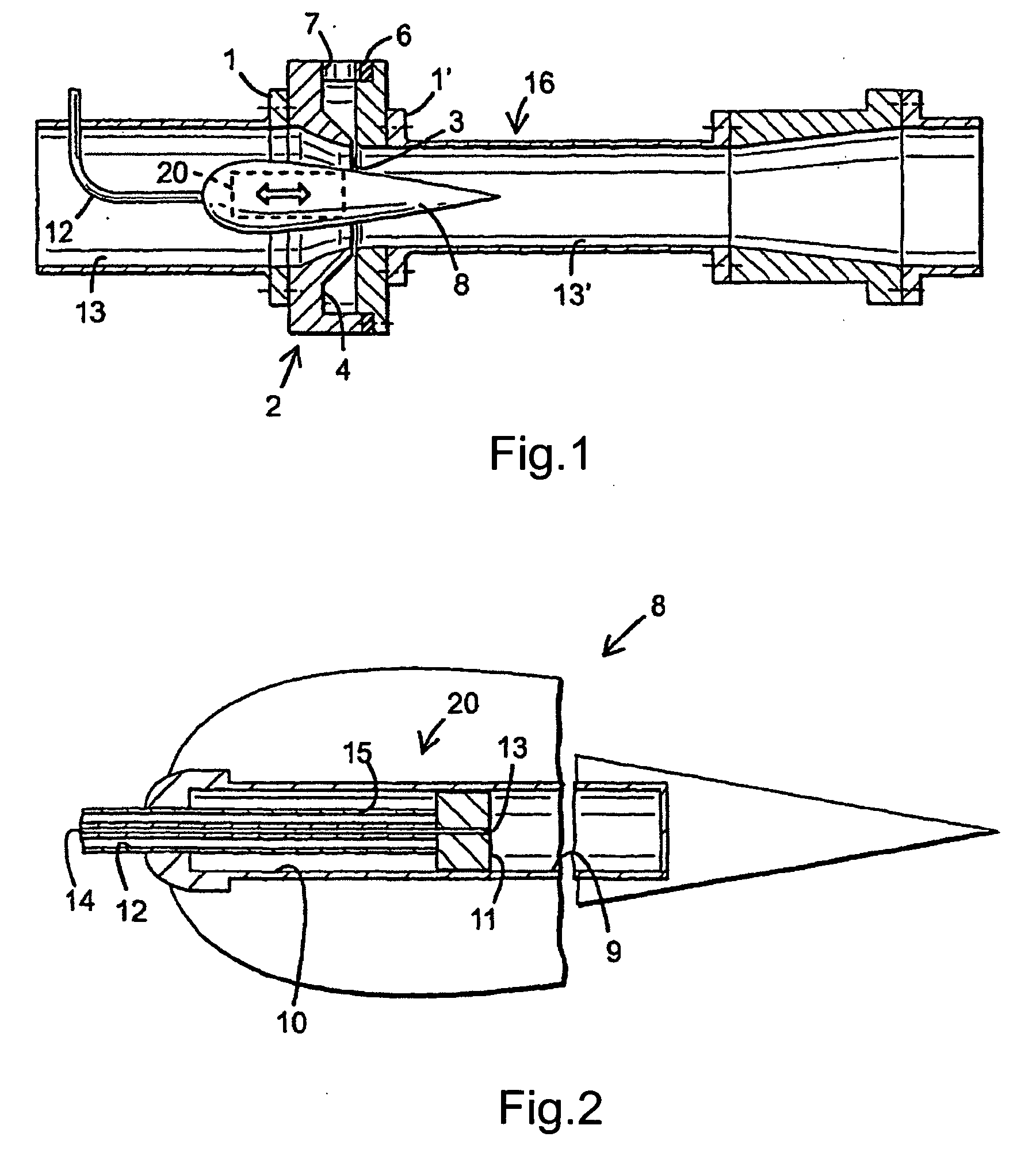

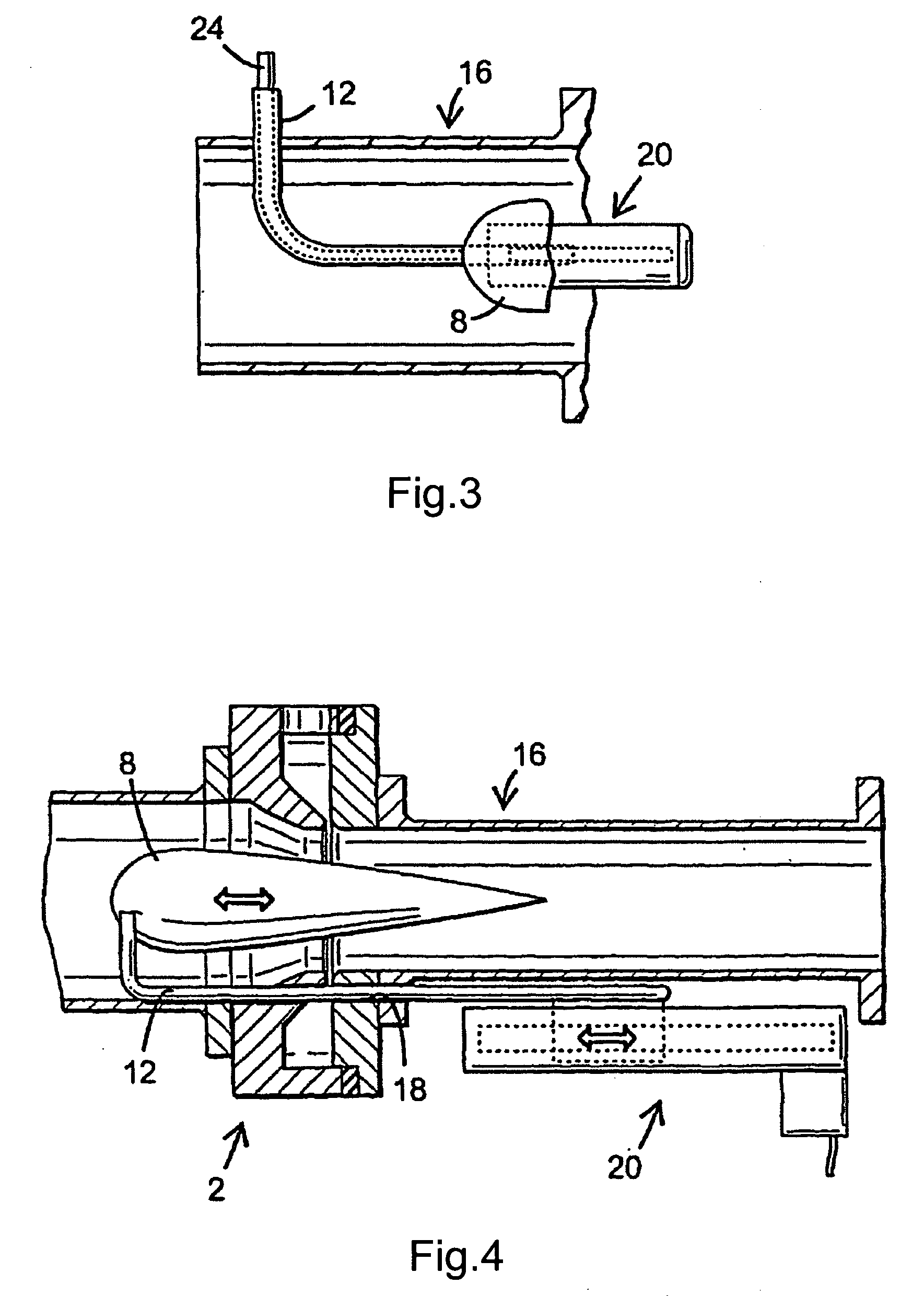

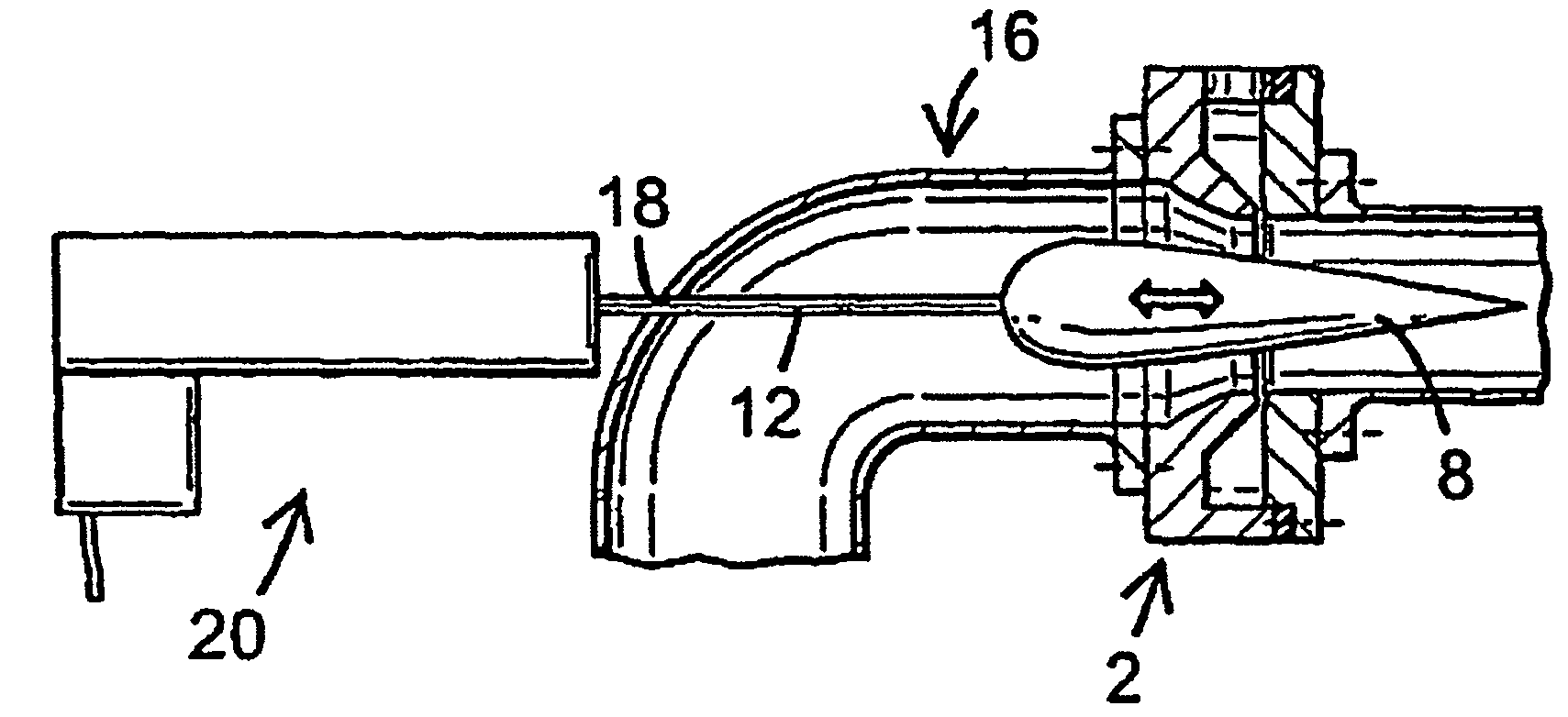

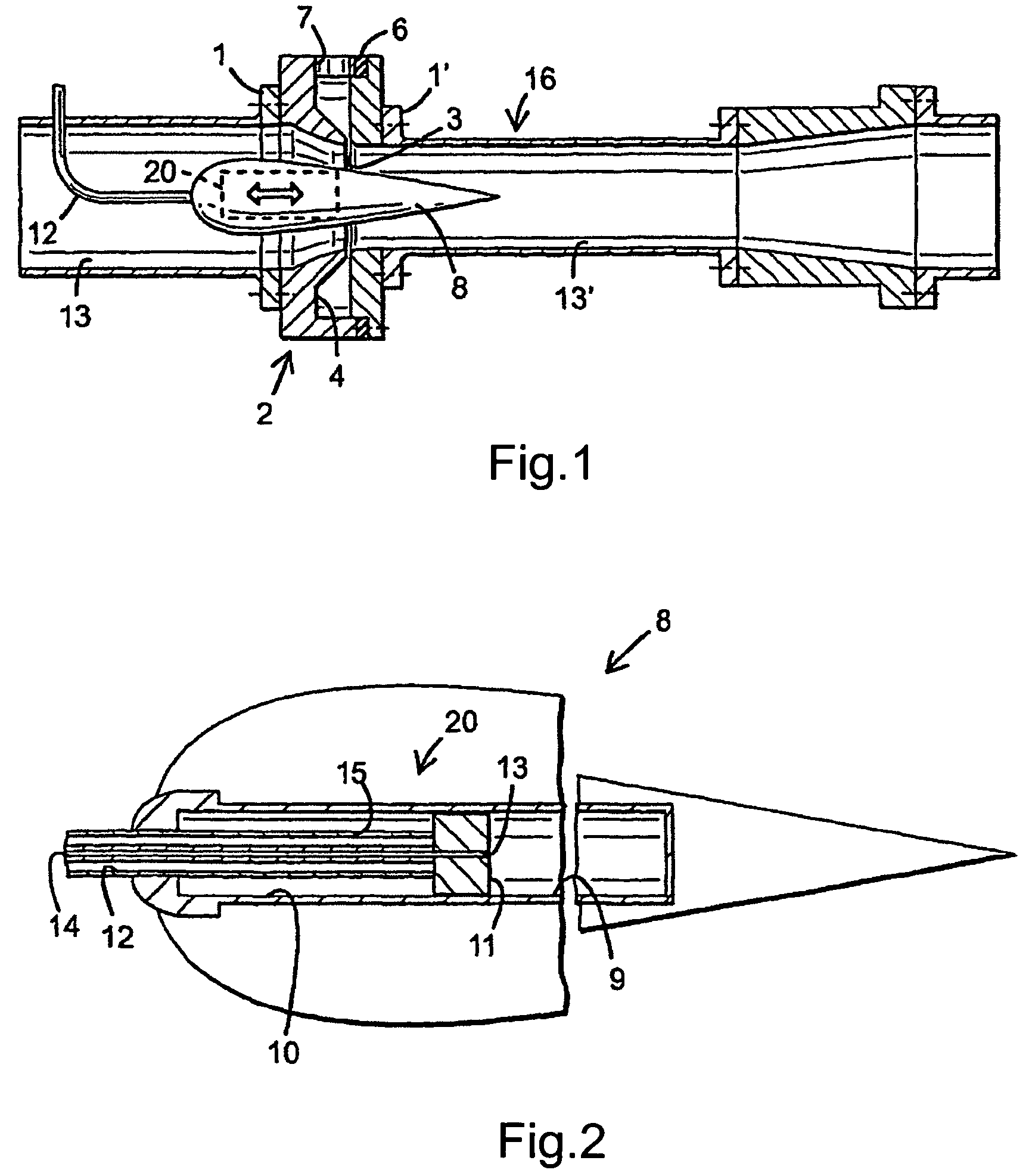

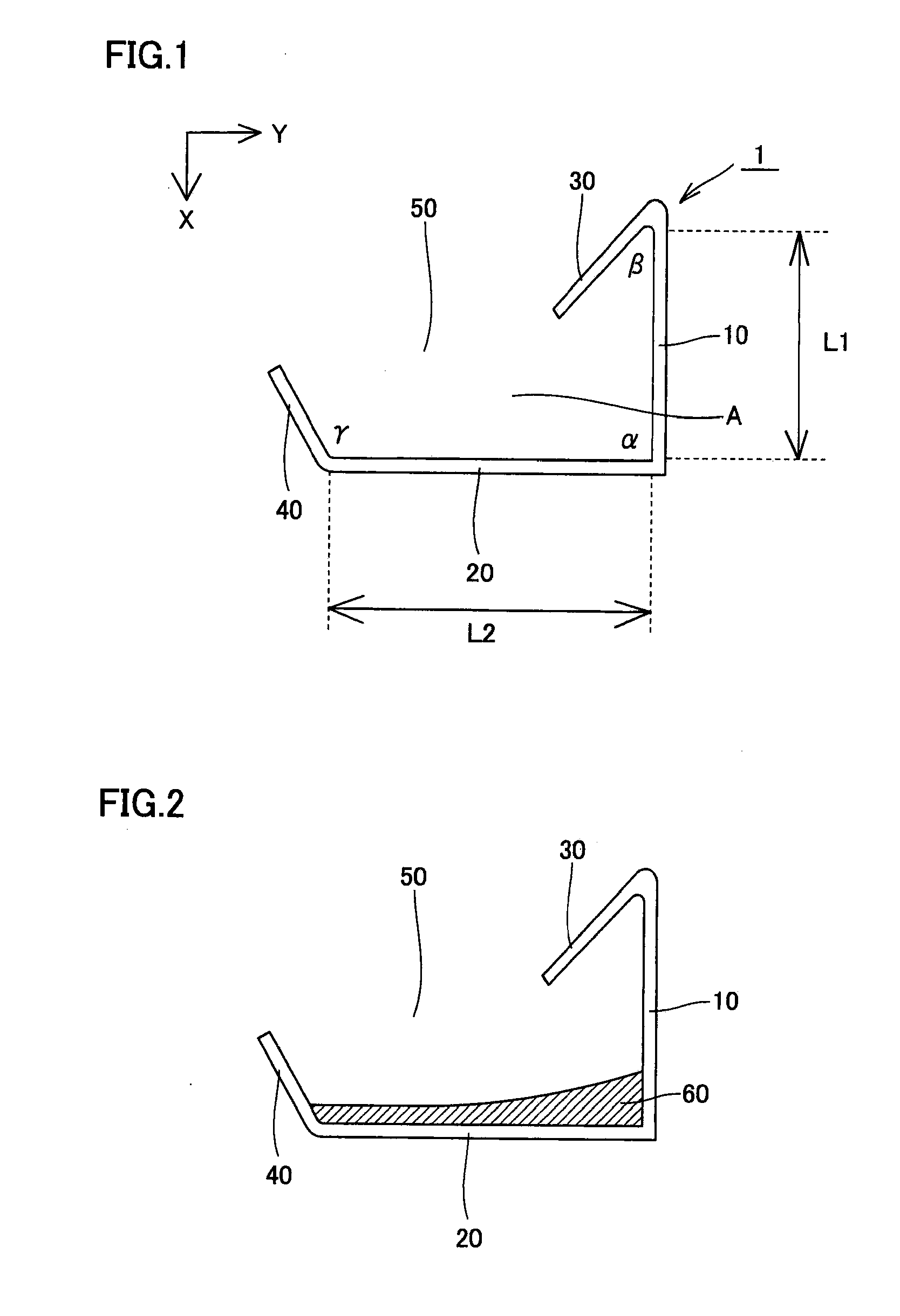

Arrangement for mixing a first and second gas flow with downstream control

InactiveUS20060180224A1Good mixing efficiencyMinimized pressure lossControlling ratio of multiple fluid flowsInternal combustion piston enginesCatheterActuator

A system for mixing a first gas flow and a second gas flow includes a conduit defined by a wall for communicating the first gas flow therethrough, an inlet passing through the wall of the conduit for introducing the second gas flow into the conduit, and a valve body disposed within the conduit, the valve body being displaceable in a longitudinal direction with respect to the conduit at the inlet. The conduit includes a bend downstream of the body with respect to a direction of the mixed gas flow. A holder is operably connected at a first end thereof to a downstream end of the valve body, the holder passing through a bore in the wall of the conduit at the bend. An actuator is operably connected to a second end of the holder, the actuator causing, via the holder, the valve body to be displaced in the longitudinal direction.

Owner:VARIVENT INNOVATIONS

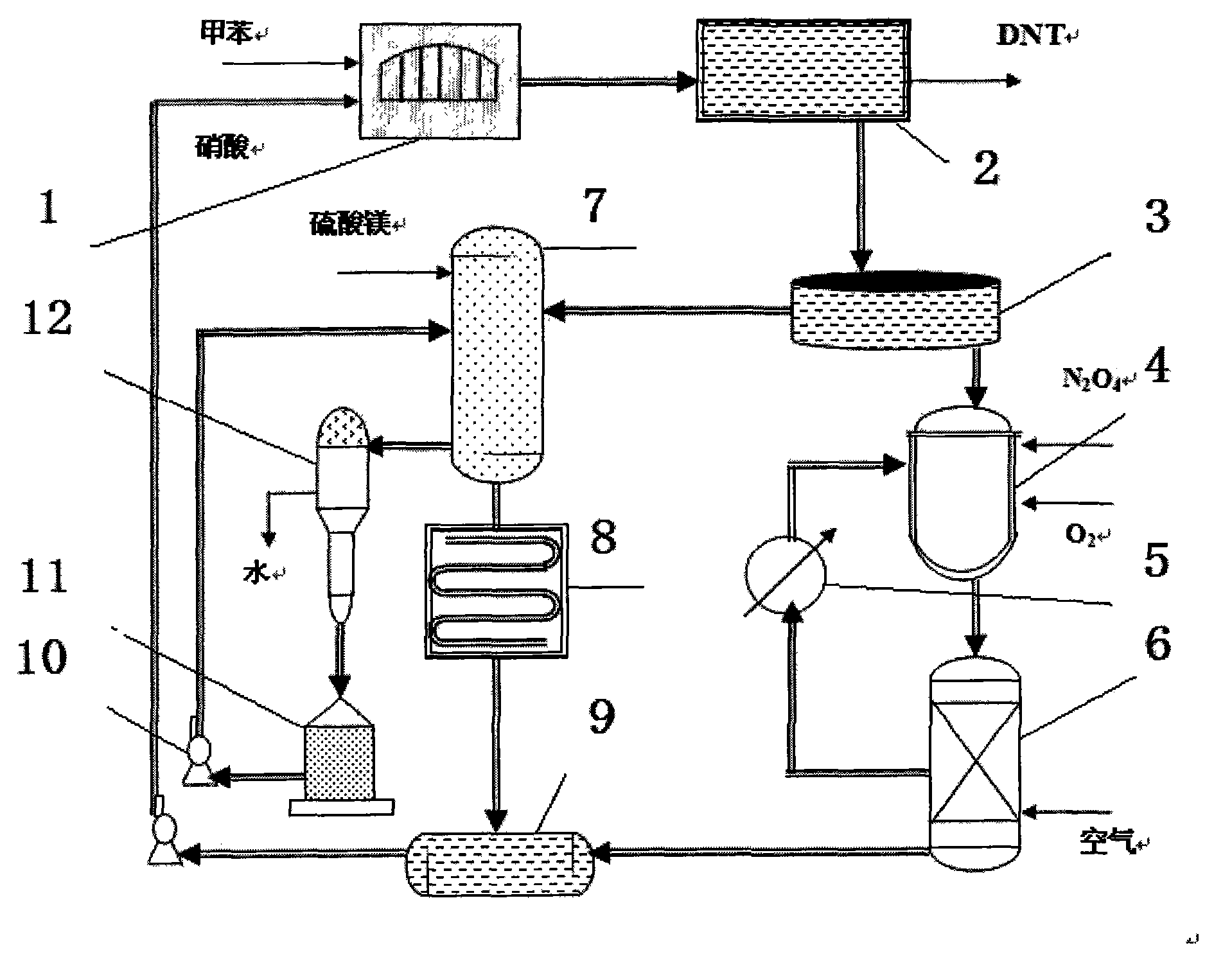

Clean production method and device of dinitrotoluene

InactiveCN102838489ASave resourcesSimple recycling processChemical industryNitro compound preparationChemistryEvaporator

The invention relates to a clean production method and a clean production device of dinitrotoluene, belonging to the field of chemical processes. The clean production method for preparing dinitrotoluene is realized through a methylbenzene micro-reactor nitration process, a fiber bed liquid-liquid separator separation process of nitric acid and dinitrotoluene mixture, and a dilute nitric acid thickening and concentration process. The clean production device of dinitrotoluene comprises a micro-reactor, a fiber bed separator, a mixing tank, a high-pressure kettle, a cooler, a bleaching tower, a concentrating tower, a condenser, a nitric acid storage tank, a delivery pump, a magnesium sulfate storage tank and an evaporator. Since nitration reaction is completed by using the micro-reactor, the micro-reactor consists of many micro-tubes which are connected in parallel, the specific surface area is very large and continuous production processes are formed, the heat exchange efficiency and the mixing efficiency are good, the reaction temperature can be accurately controlled, reaction materials can be accurately controlled to be instantly mixed according to accurate proportions, the yield, the selectivity and the safety are improved, and the reaction time is reduced.

Owner:LIAONING QINGYANG SPECIAL CHEM

Method for preparing crystal polymer/carbon nano-tube conductive composite material

InactiveCN101200563AImprove processing efficiencyMeet electrical performance requirementsCarbon nanotubeElectronic instrument

The present invention relates to a preparation method of crystal polymer / carbon nano-pipe conductive composite material. The method is characterized in that crystal polymer, carbon nano-pipe and inorganic powder are mixed according to a certain proportion and then the processing equipment of macromolecular material is adopted for fusing, mixing and completing the granulation. The present invention with simple method and easy operation can obtain the conductive composite material with good electric conduction and good comprehensive performance through one-step method, and can be applied in the fields of automobile, electric and electronic instrument, office equipment and industrial machinery. The present invention can meet and expand the requirements of crystal macromolecular material for various purposes.

Owner:TSINGHUA UNIV

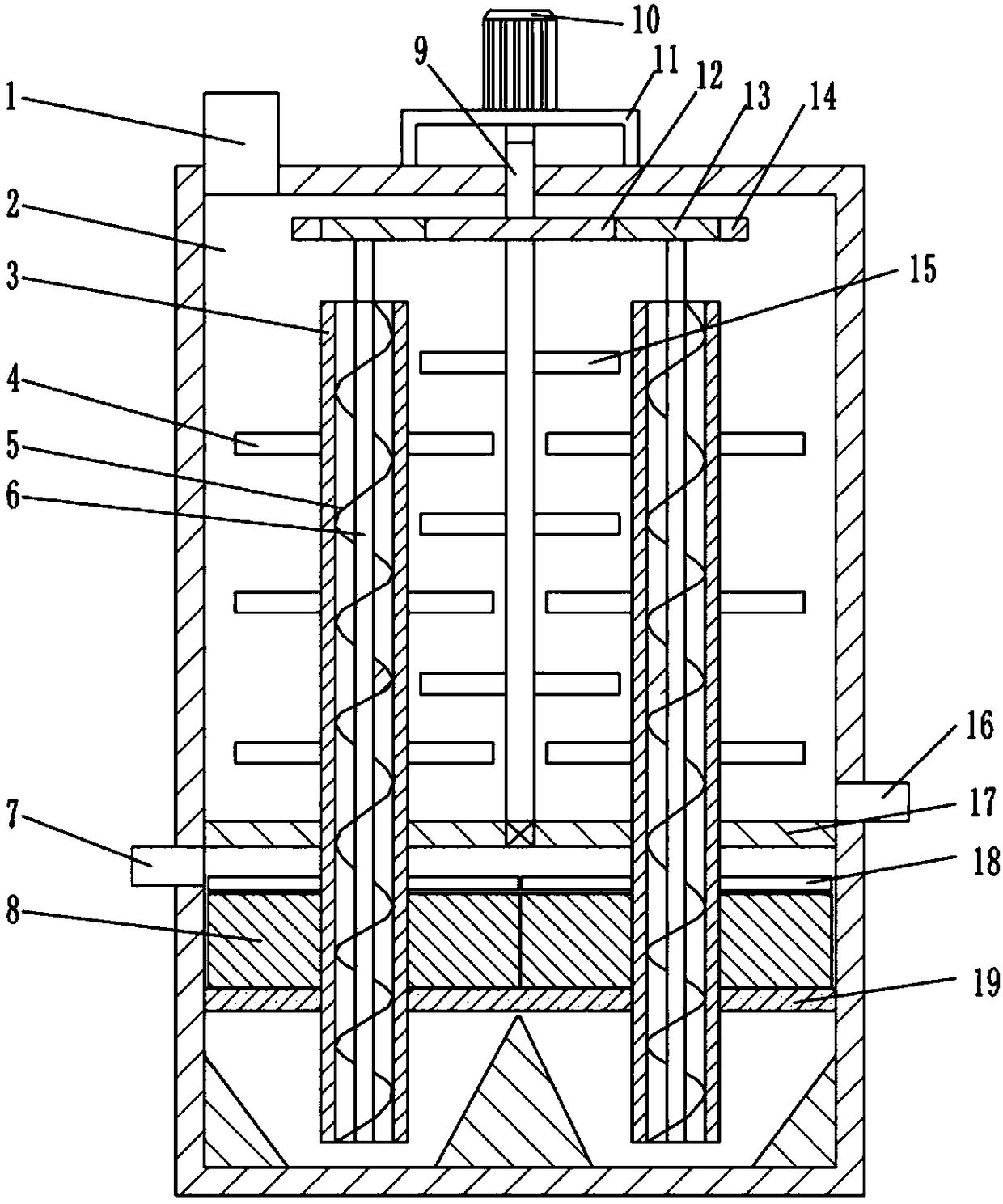

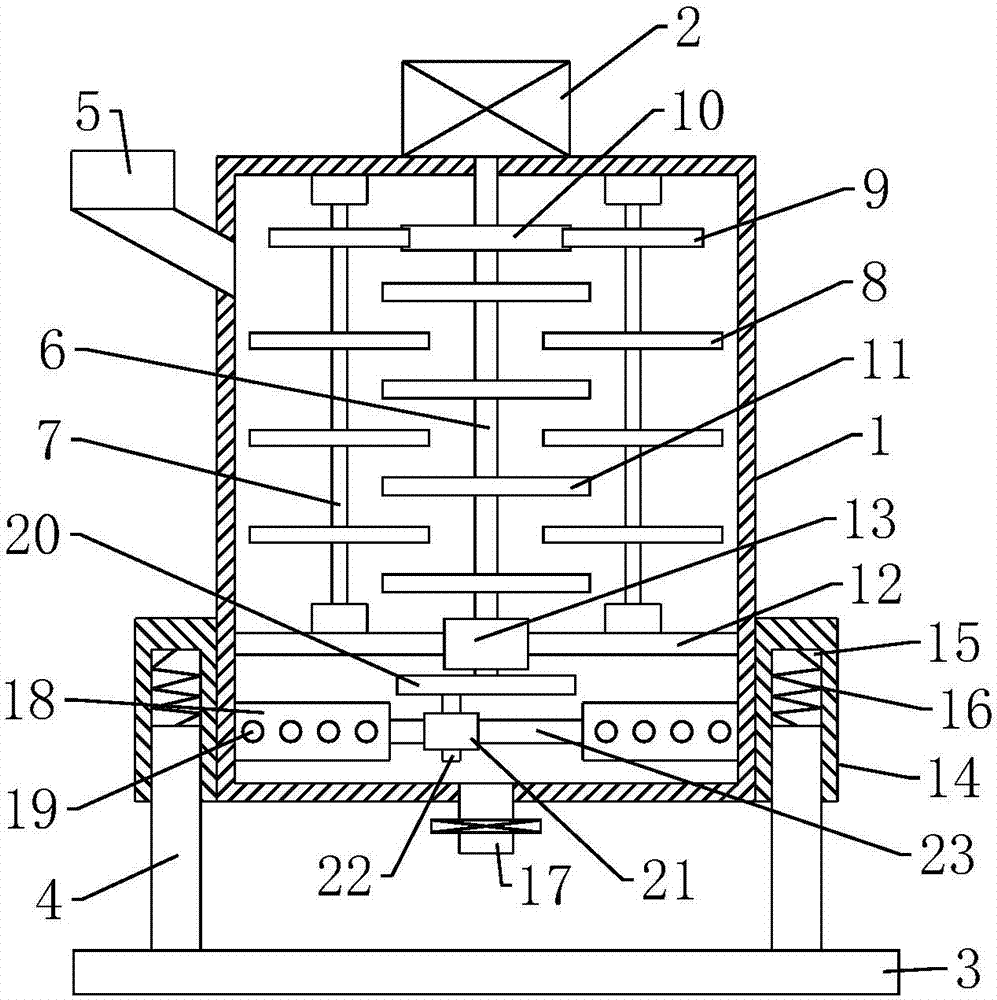

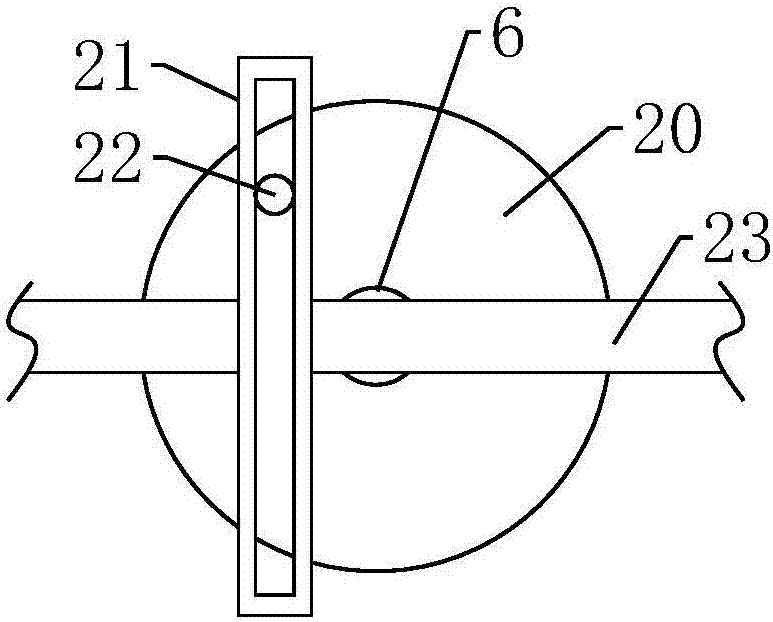

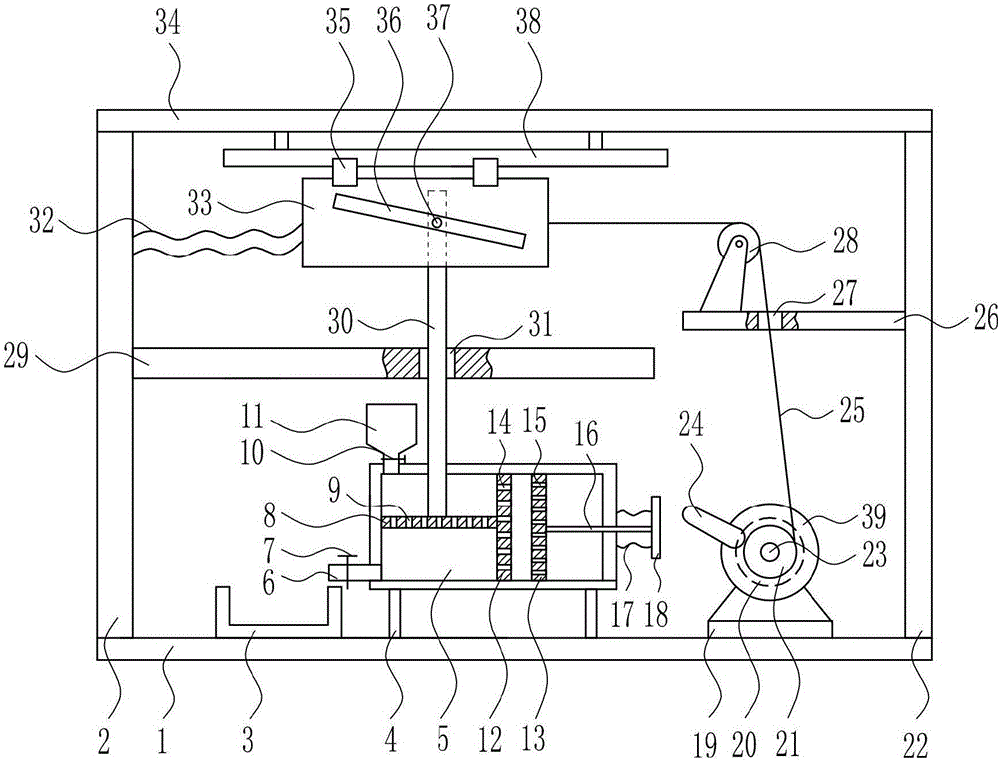

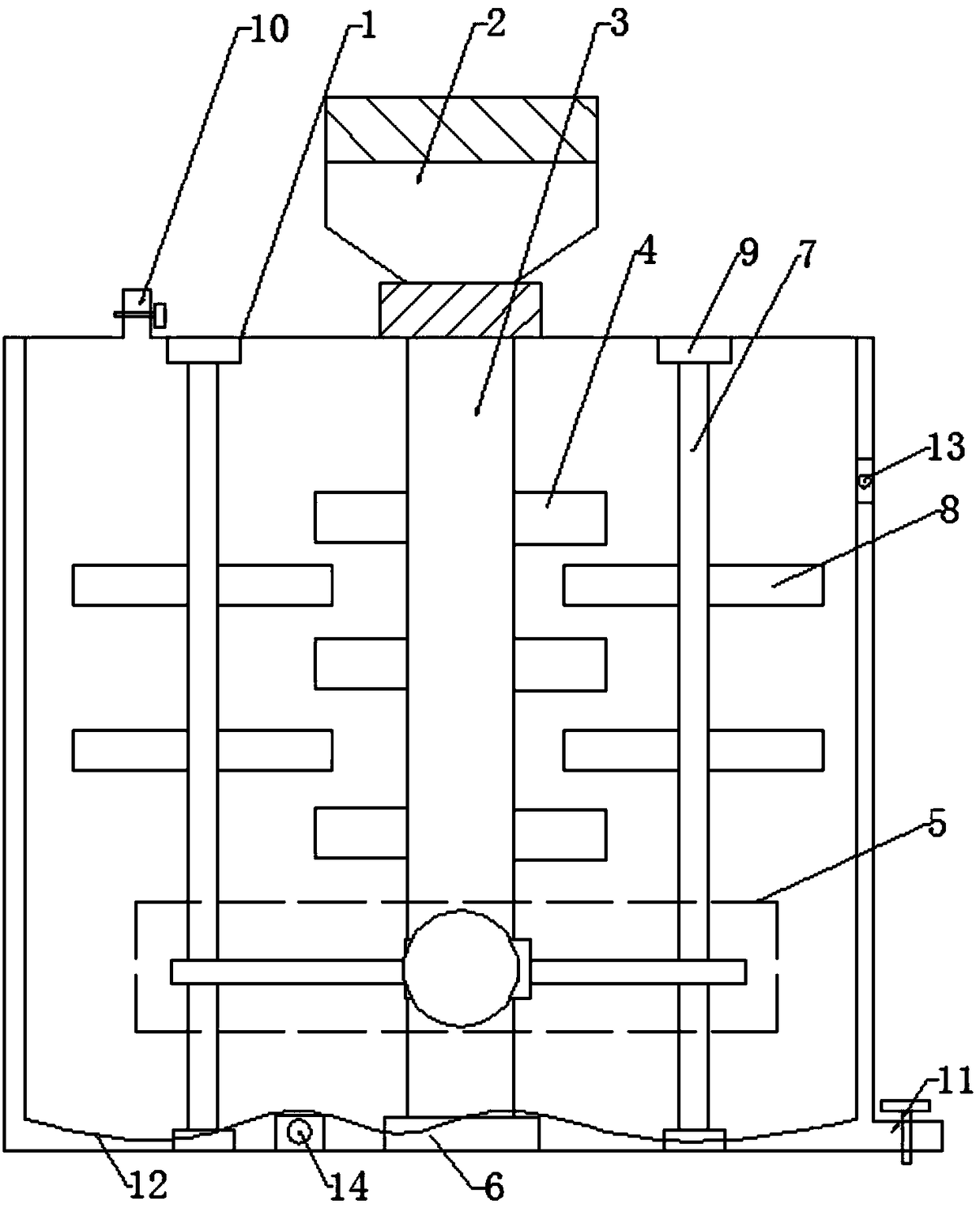

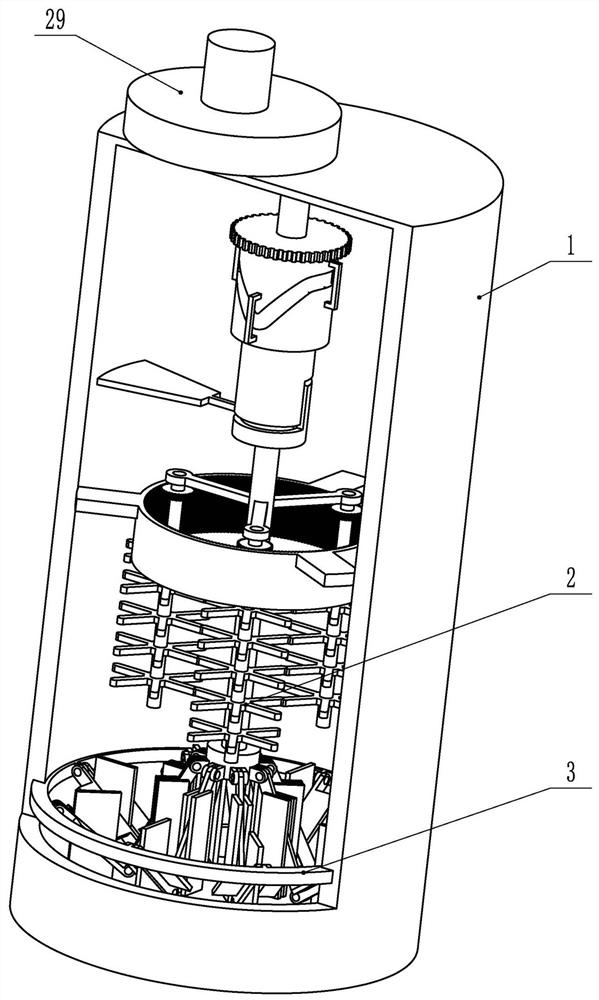

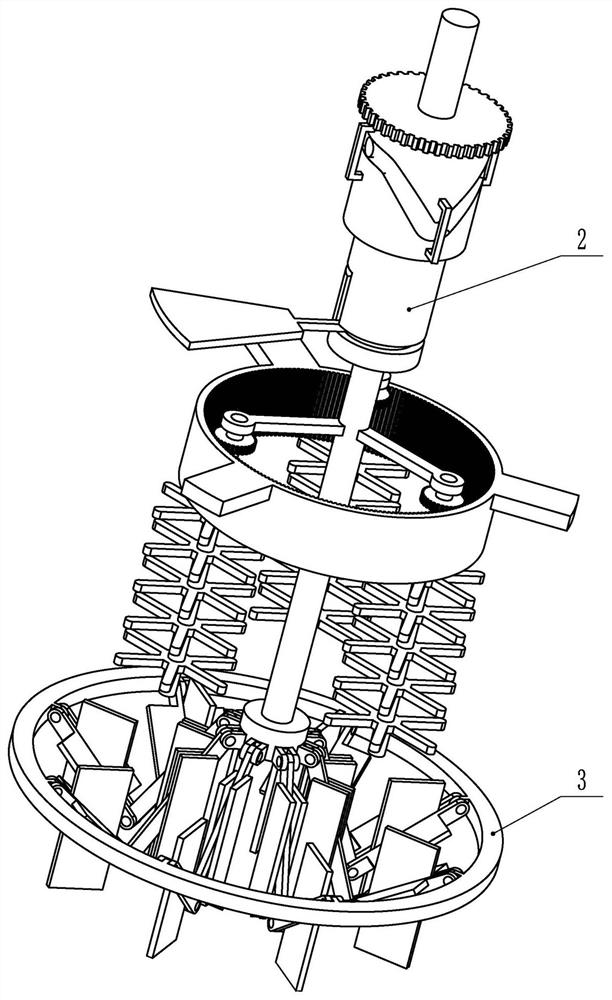

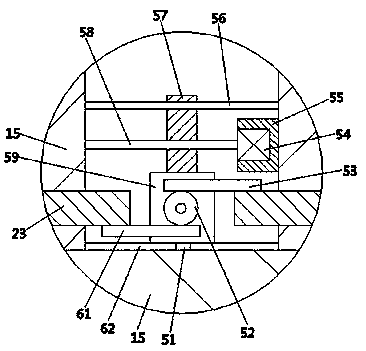

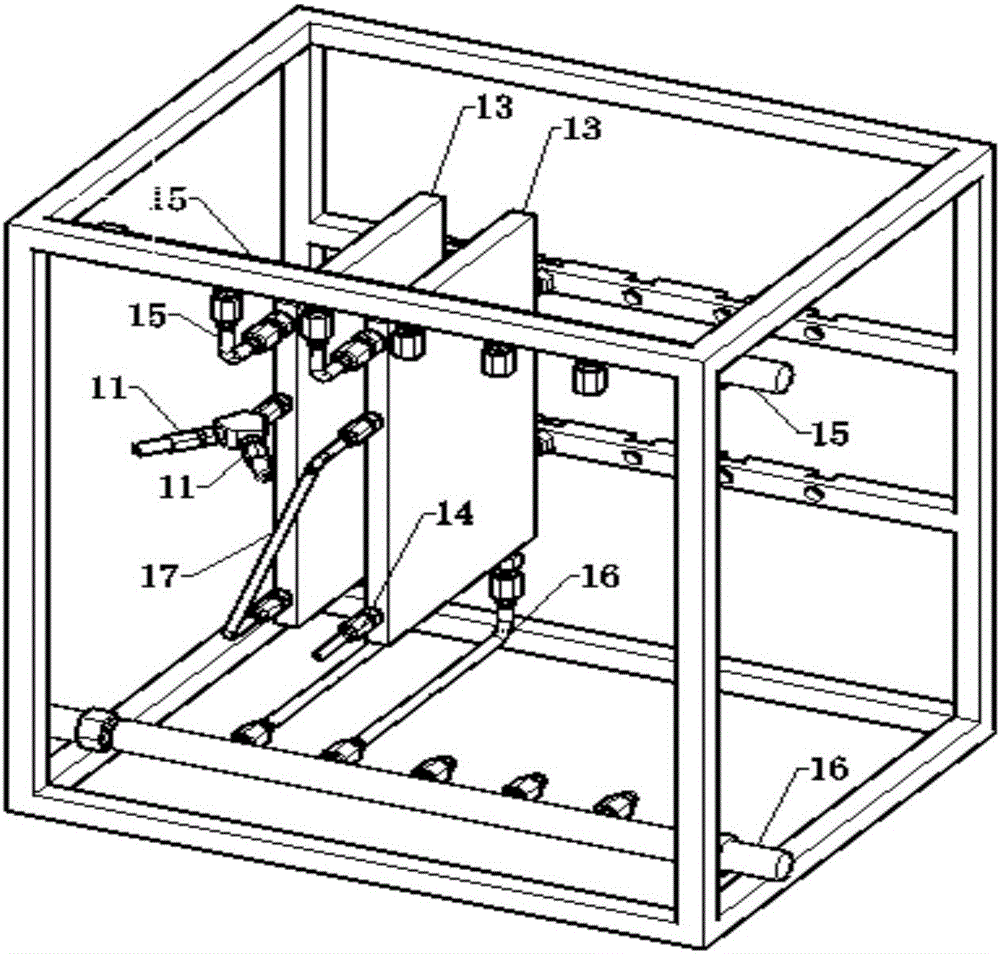

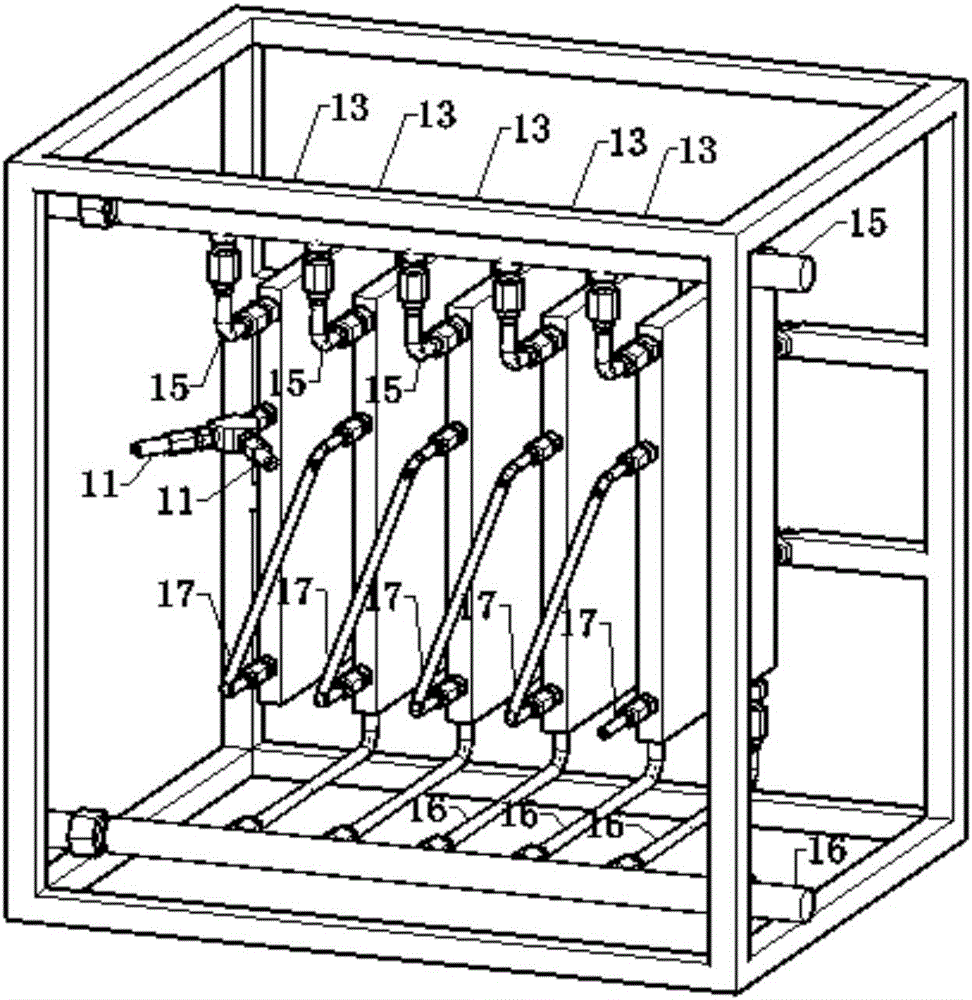

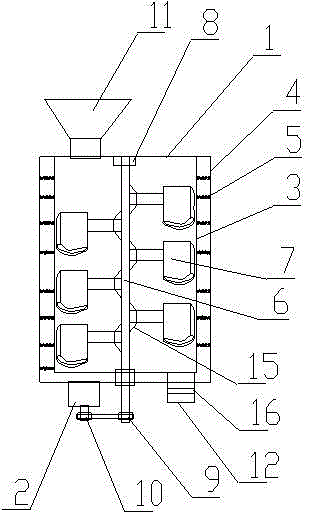

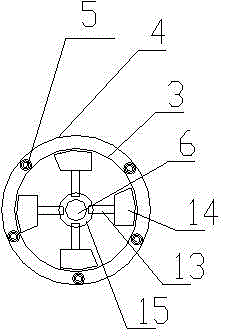

Carbon powder mixing device

ActiveCN107551854AEasy to fall outWell mixedRotary stirring mixersMixer accessoriesEngineeringLeft wall

The invention relates to a mixing device, in particular to a carbon powder mixing device. The invention provides the carbon powder mixing device. In order to solve the technical problems, the invention provides the carbon powder mixing device which comprises a mounting plate, charging boxes, a feeding pipe, a first baffle plate, a driving mechanism, a discharging mechanism, a first connecting plate, guide plates and the like, wherein the charging boxes are arranged on the left side and the right side of the top of the mounting plate; a discharging pipe is connected at the bottom of each of thecharging boxes; the guide plate is arranged on each of the lower sides of the right wall in the left charging box and the left wall in the right charging box; each of the guide plates is located in the corresponding discharging pipe; a stirring box is arranged on the front side of the mounting plate; a first through hole is formed in the middle of the top of the stirring box; the upper sides of the left wall and the right wall of the stirring box are connected with the tail ends of the discharging pipes. According to the carbon powder mixing device, carbon powder and an additive can conveniently drop out, uniform mixing of the carbon powder and the additive is facilitated, the mixing efficiency is high, the carbon powder is prevented from flying out of the device and polluting, and the device is strong in practicability and good in mixing effect.

Owner:唐山曹妃甸恒菱科技有限公司

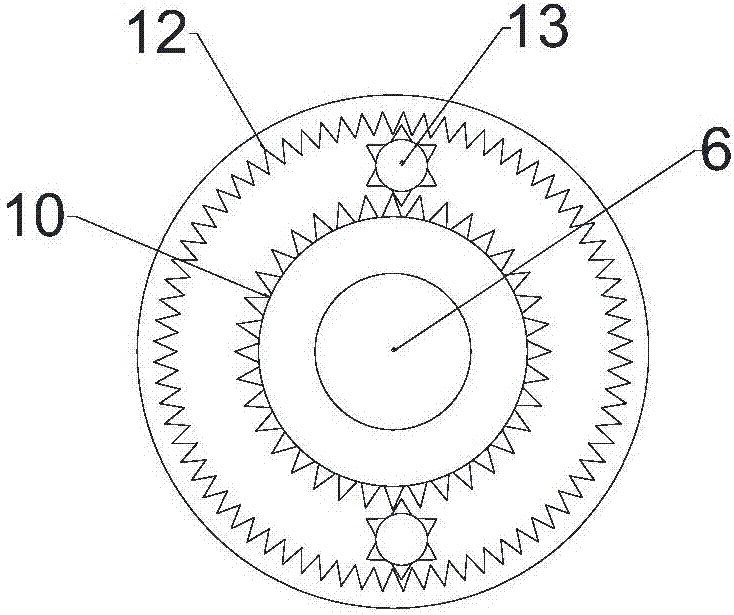

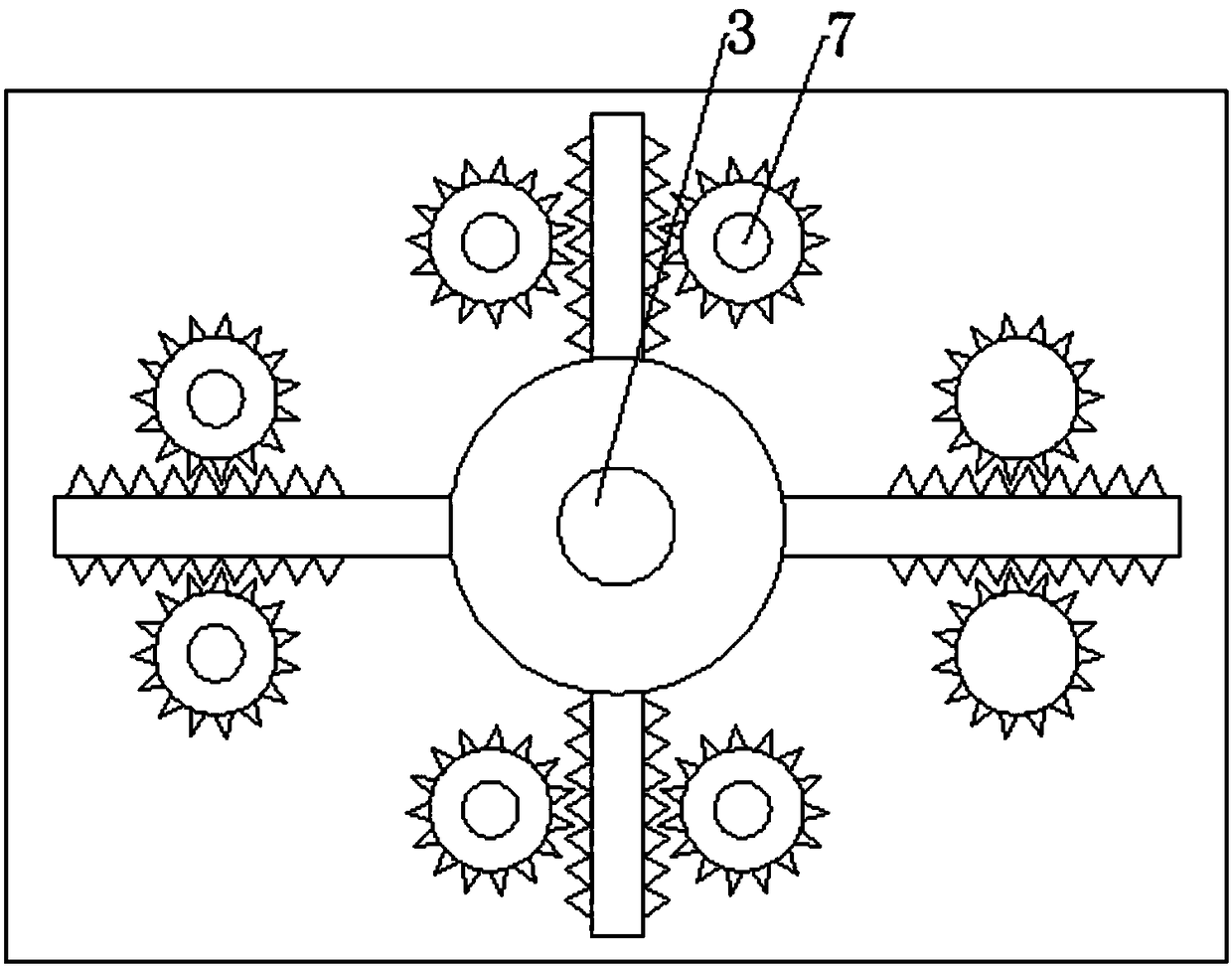

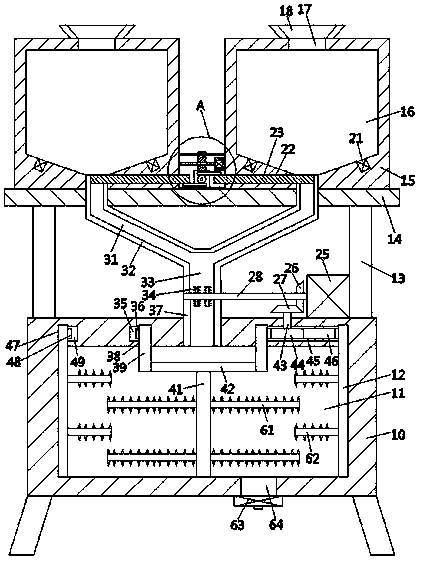

Sound-absorbing decoration material stirring device

ActiveCN108079885AStir wellAchieve cycleTransportation and packagingRotary stirring mixersSpiral bladeEngineering

The invention belongs to the technical field of processing of sound-absorbing decoration materials, and in particular, discloses a sound-absorbing decoration material stirring device which includes astirring barrel; a separation plate and a filter screen are arranged in the stirring barrel. The top wall of the stirring barrel is equipped with a motor, an output shaft of the motor is connected with a center shaft, the center shaft is equipped with a planetary gear structure, and the planetary gear structure includes a sun wheel and two planetary wheels. The center shaft is equipped with a plurality of stirring paddles, and the center of each of the two planetary wheels is fixedly connected with a rotating shaft. The separation plate and the filter screen are each rotatingly connected withan annular plate. Each rotating shaft is provided with a spiral blade, and the two rotating shafts are each sleeved with a feeding tube with two ends opening. The feeding tubes are fixedly connected on the annular plates, the outer walls, above the separation plate, of the feeding tubes are provided with a plurality of stirring blades, and the outer walls, between the filter screen and the separation plate, of the two feeding tubes are each rotatingly connected with a grinding roller. While raw materials are stirred, the raw materials are ground.

Owner:重庆李不凡商贸有限公司

Arrangement for mixing a first and second gas flow with downstream control

InactiveUS7543600B2Good mixing efficiencyMinimized pressure lossControlling ratio of multiple fluid flowsNon-fuel substance addition to fuelActuatorGuide tube

A system for mixing a first gas flow and a second gas flow includes a conduit defined by a wall for communicating the first gas flow therethrough, an inlet passing through the wall of the conduit for introducing the second gas flow into the conduit, and a valve body disposed within the conduit, the valve body being displaceable in a longitudinal direction with respect to the conduit at the inlet. The conduit includes a bend downstream of the body with respect to a direction of the mixed gas flow. A holder is operably connected at a first end thereof to a downstream end of the valve body, the holder passing through a bore in the wall of the conduit at the bend. An actuator is operably connected to a second end of the holder, the actuator causing, via the holder, the valve body to be displaced in the longitudinal direction.

Owner:VARIVENT INNOVATIONS

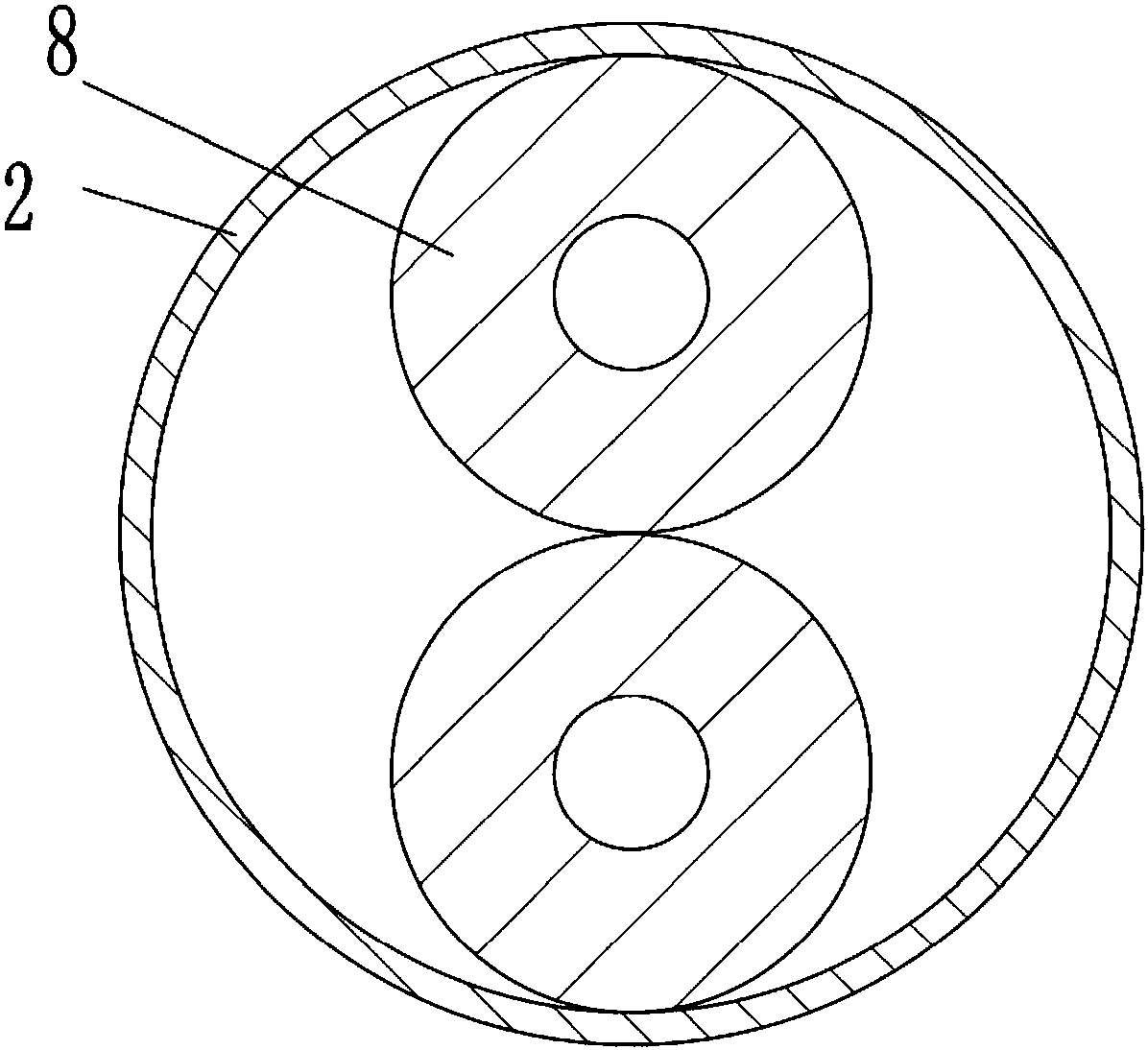

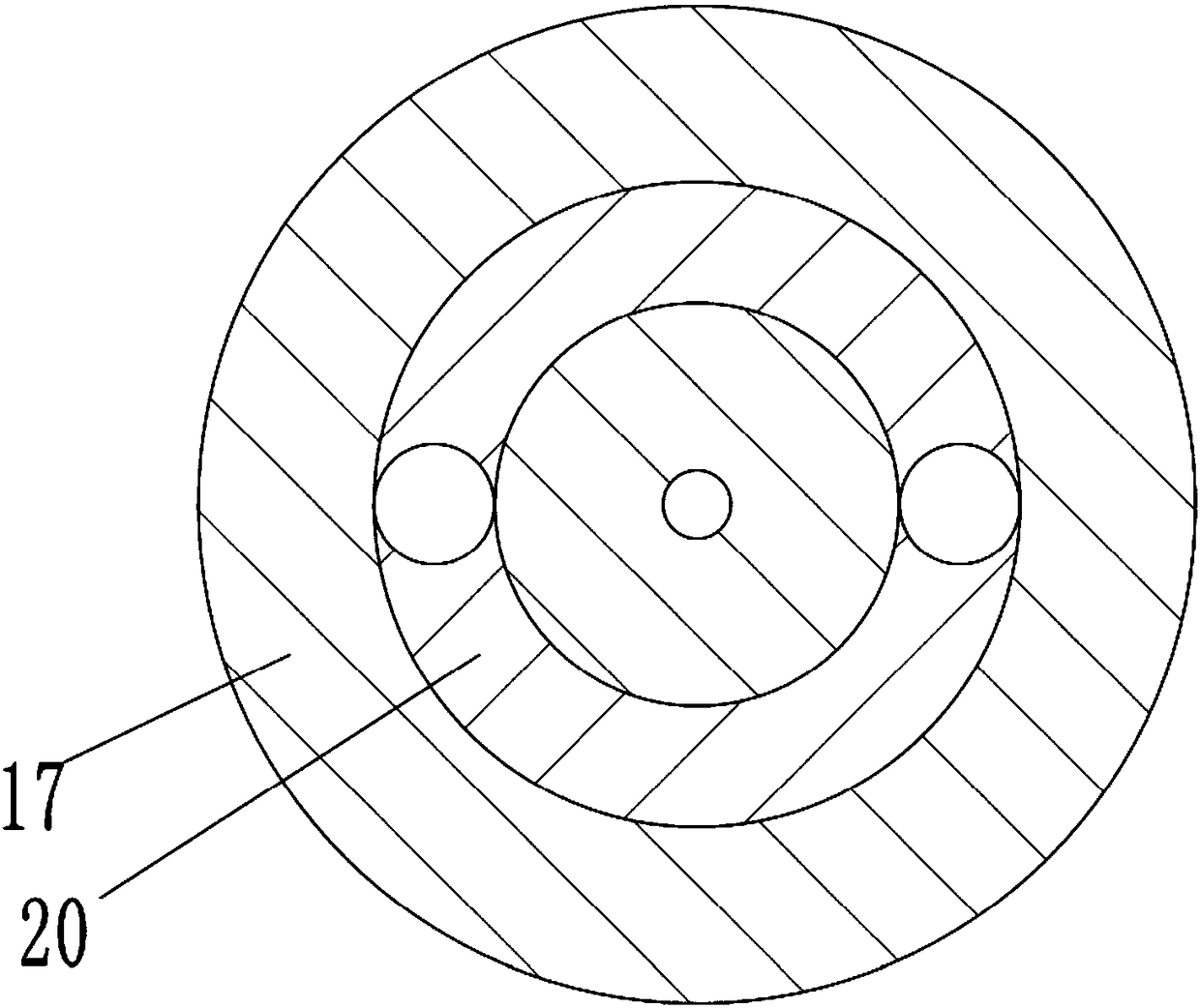

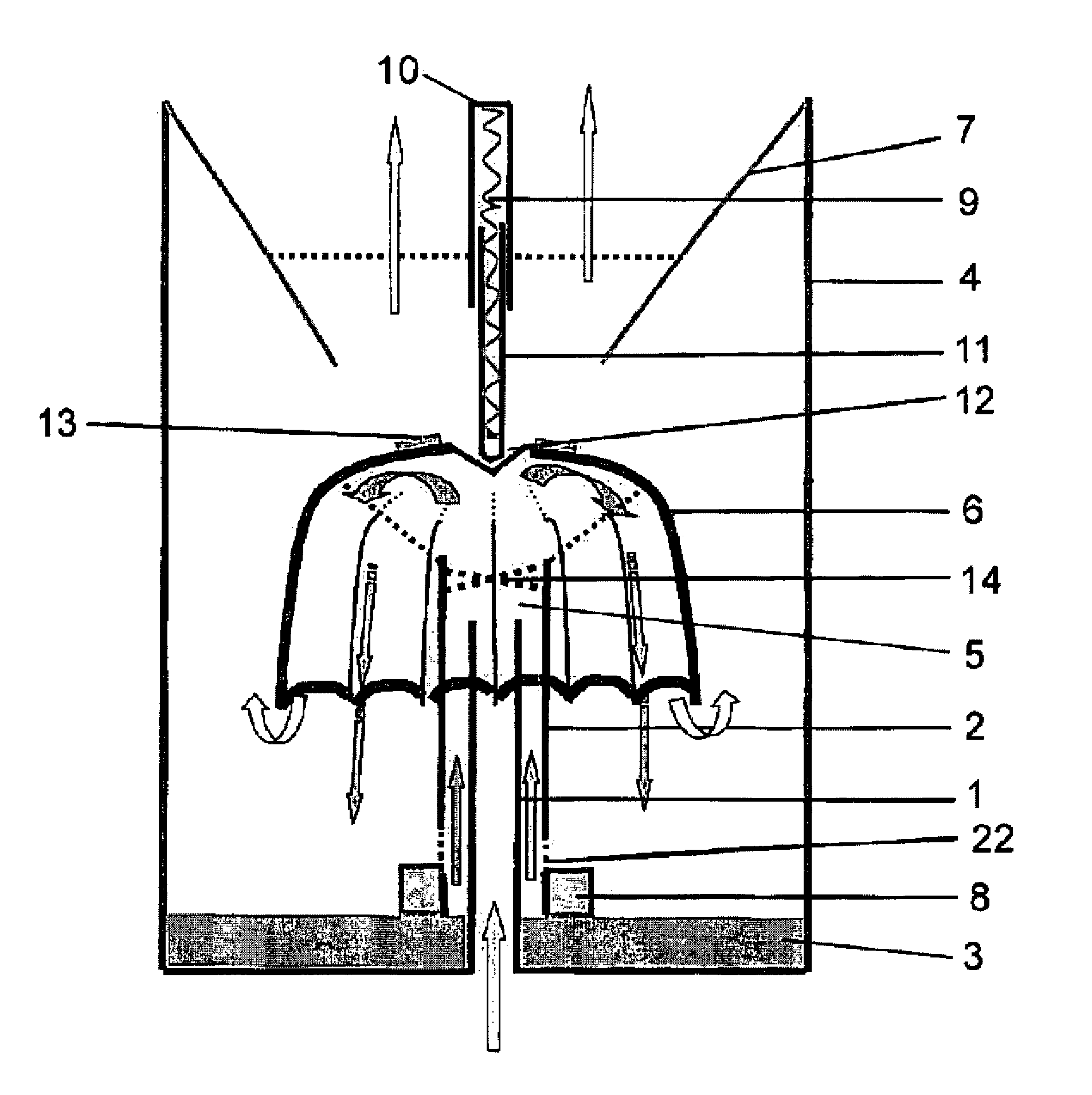

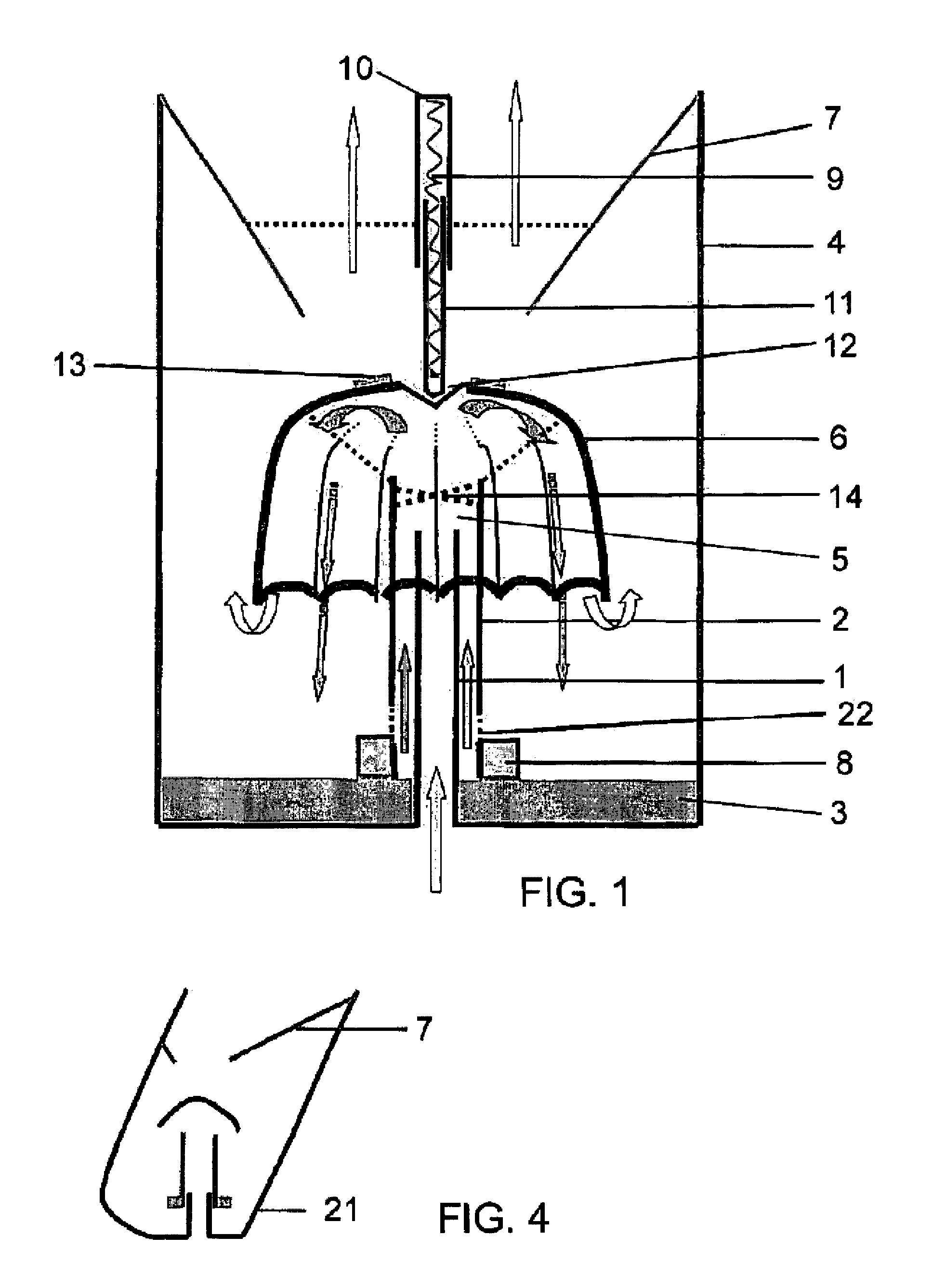

Gas-liquid mixing device

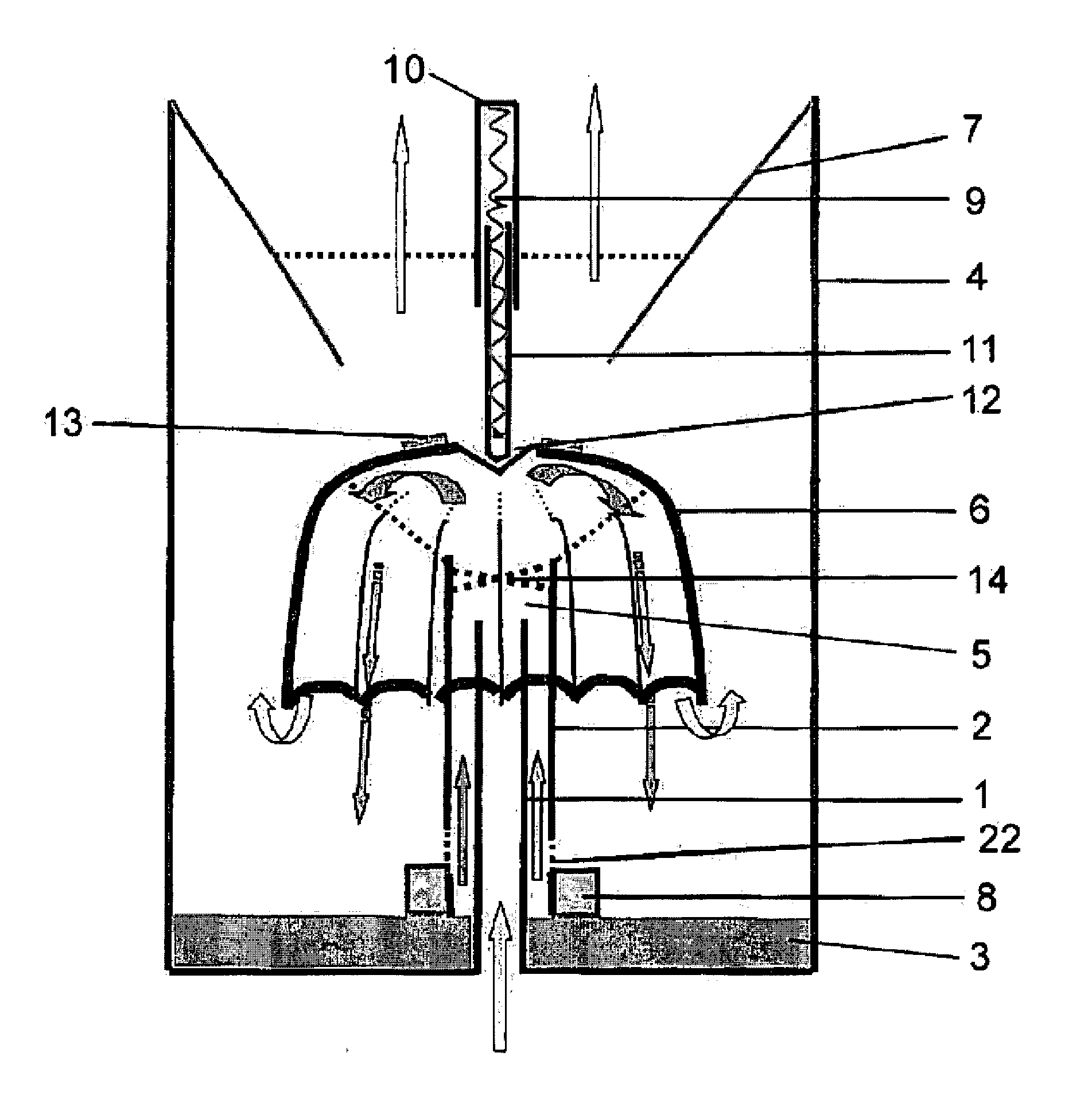

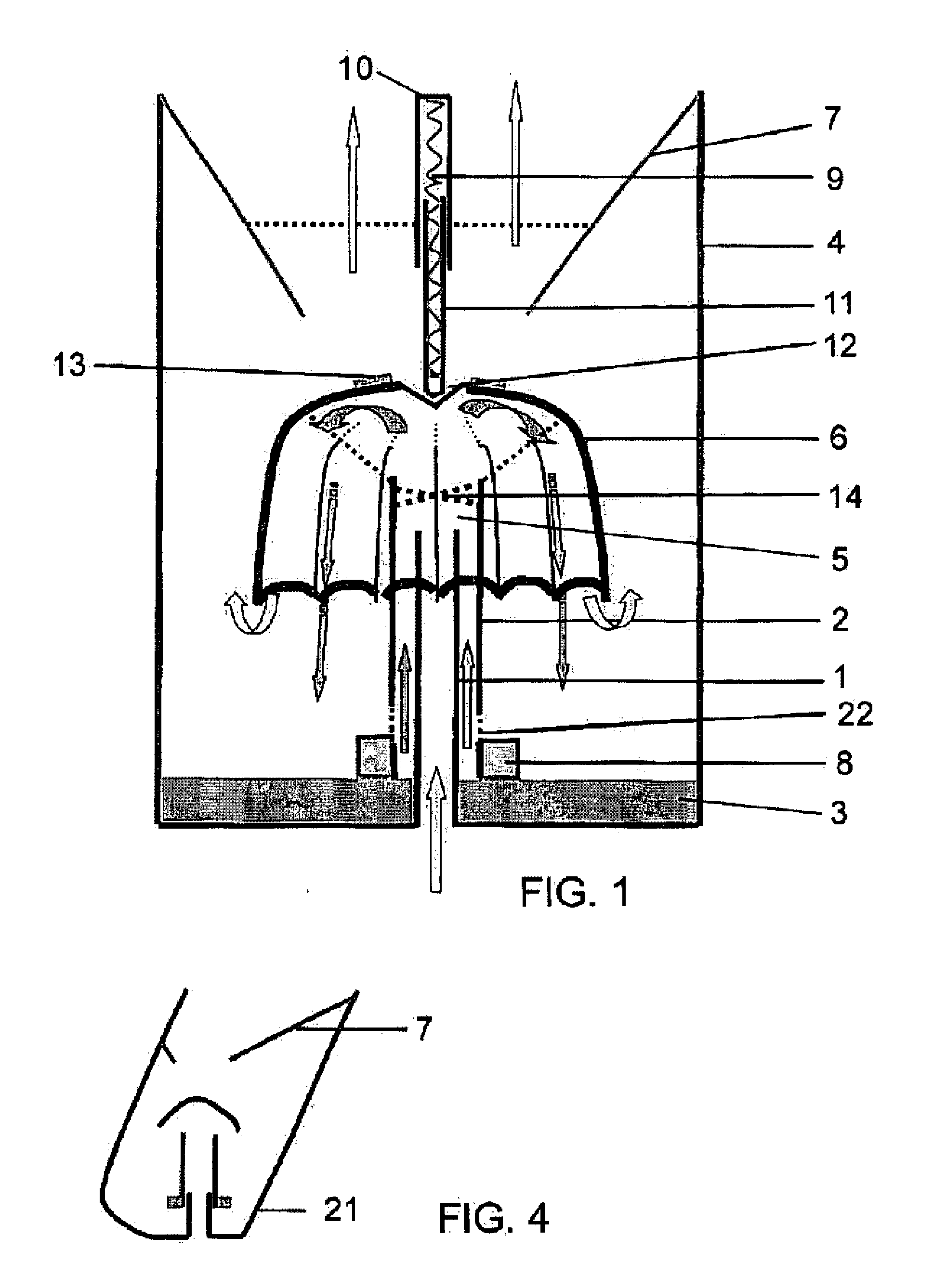

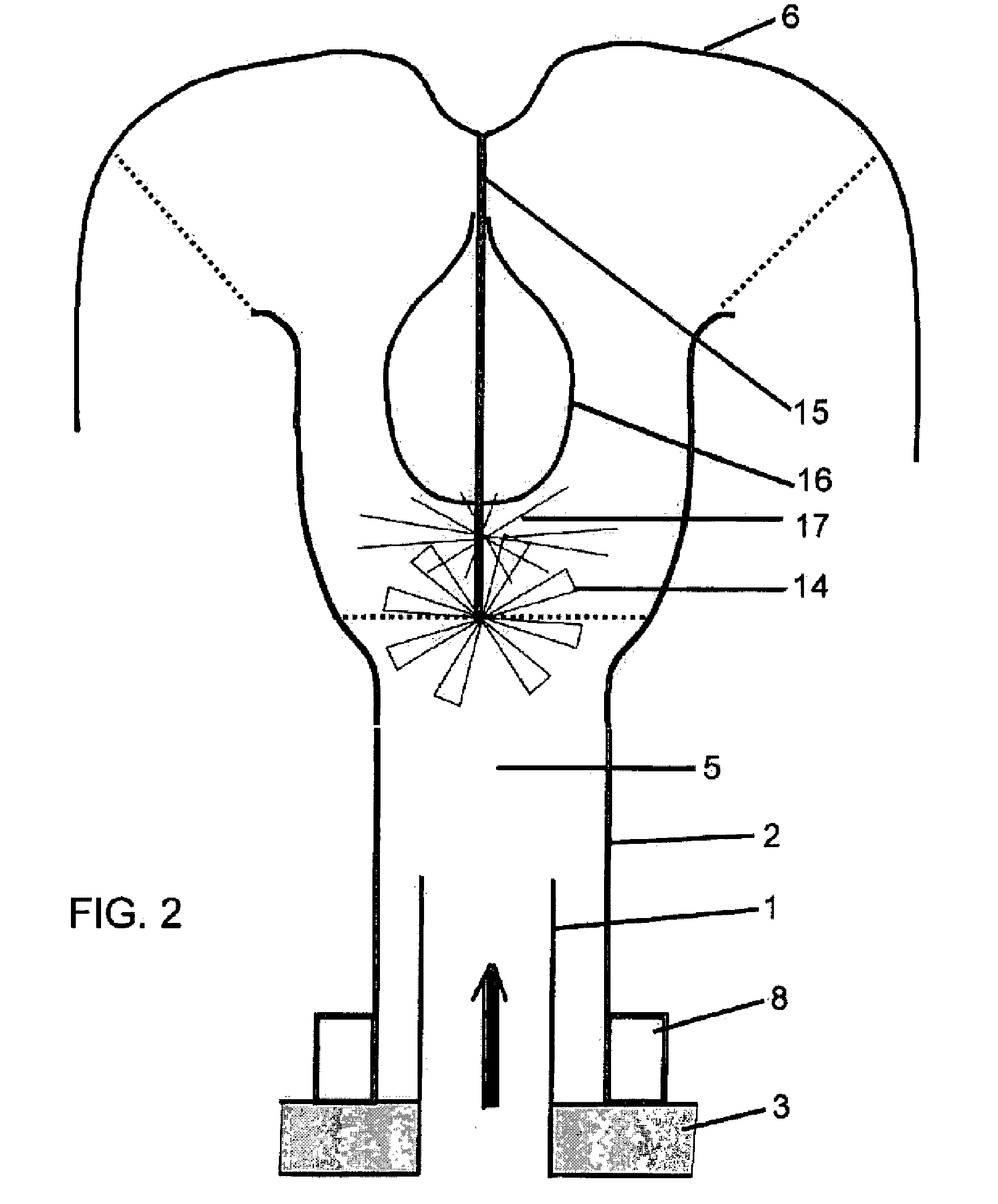

InactiveUS7950630B2Effective installationGood mixing efficiencyLighting and heating apparatusUsing liquid separation agentLiquid tankProduct gas

This invention relates to a gas-liquid mixing device, forming a safety valve, designed capable of being incorporated into a gas-cleaning installation including a liquid tank (4), an inlet (1) for gas to be cleaned and an outlet (7) through which the gas flow is evacuated. It is characterized in that it has:a tube (2) sliding around the gas inlet (1) and including a peripheral float (8) located in its lower end and designed capable of floating in said tank (4), said sliding tube (2) being open in its lower portion, in order to draw liquid from said tank (4) by a venturi effect and to create a mist in a pressure-relief zone (5);a mixing chamber (6) interposed between said sliding tube (2) and said outlet (7), and designed capable of conveying the flow of said mist towards the bottom of said tank (4).

Owner:WINDDROP

Device for rapidly mixing and preparing cutting fluid for milling machine

InactiveCN107497358AReduce noiseImprove preparation qualityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a device for rapidly mixing and preparing cutting fluid for a milling machine. The device comprises a box body, a pedestal, a driven gear, a No. one stirring rod, a liquid spraying barrel, a rotational disk and a swinging sleeve, wherein the rotational disk is fixedly arranged at the bottom end of a main rotational shaft, a guide pillar is fixedly arranged at the bottom of an outer ring of the rotational disk, the swinging sleeve sleeves the guide pillar in a sliding manner, two sides of the swinging sleeve are symmetrically and fixedly provided with compression bars, the liquid spraying barrel is fixedly arranged on an inner wall of an inner cavity at the bottom of the box body, an inner barrel is fixedly arranged in an inner cavity of the liquid spraying barrel, a ring-shaped cavity is formed between an inner wall of the inner cavity of the liquid spraying barrel and an outer ring surface of the inner barrel, a piston is arranged inside the inner barrel in a sliding manner, and the piston is fixedly arranged at one ends of the compression bars. The device is simple in structure, convenient to use and good in damping effect, the mixing efficiency of the raw materials is high and the effect is good, the preparation quality of the cutting fluid is improved, so that the device is suitable for promotion and application.

Owner:ZHENGZHOU UNIV

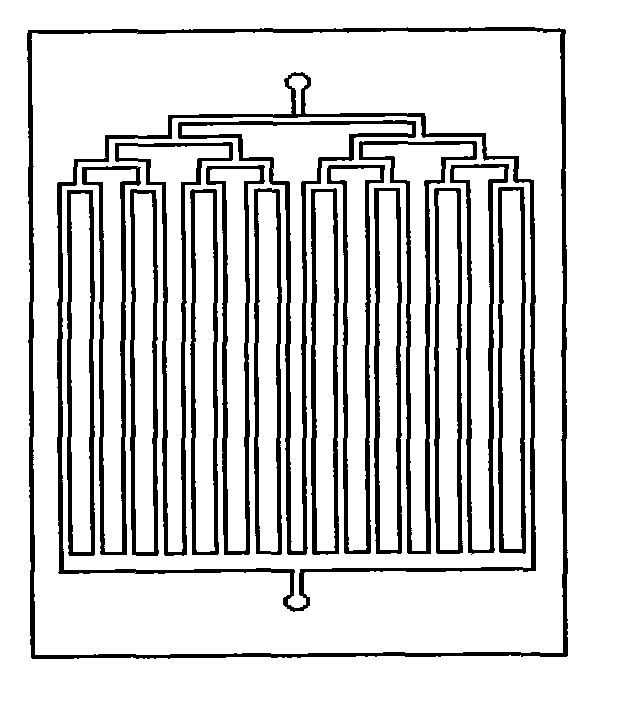

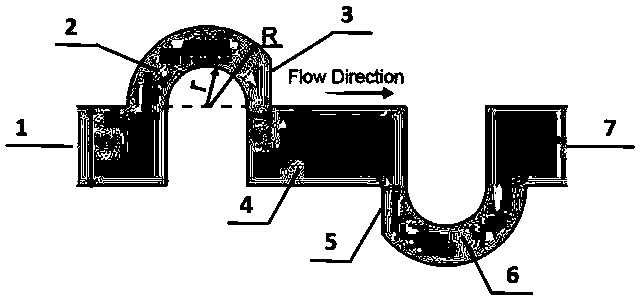

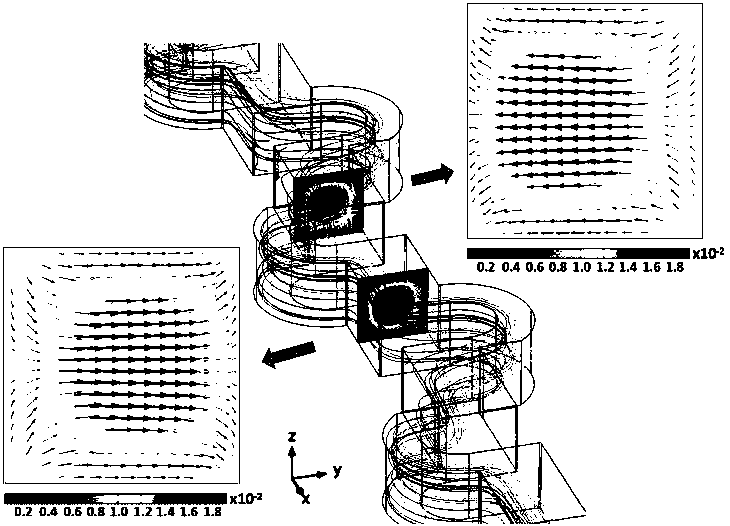

Optimized and passive micromixer of asymmetrical wall surface structure

PendingCN107649059AIncrease credibilityGood mixing efficiencyTransportation and packagingMixersEngineeringSurface structure

The invention belongs to the field of micro-fluidic chips, and particularly discloses an optimized and passive micromixer of an asymmetrical wall surface structure. The micromixer is mainly composed of an inlet pipe, a first lateral flow pipeline, a rectangular main flow channel, a second lateral flow pipeline and an outlet pipe, an optimized pipeline structure of a passive mixer is utilized to make fluid units in the mixer generate multi-disturbance and secondary flow perpendicular to the main-flow cross section, the contact area of fluids is effectively increased through eddy, the mixing time is shortened, and the mixing efficiency is improved.

Owner:HAINAN UNIVERSITY

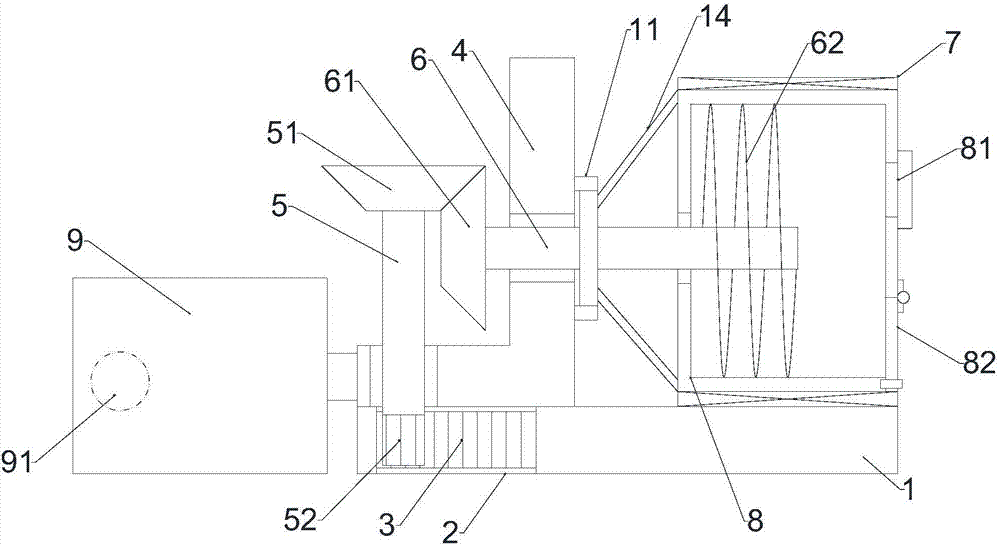

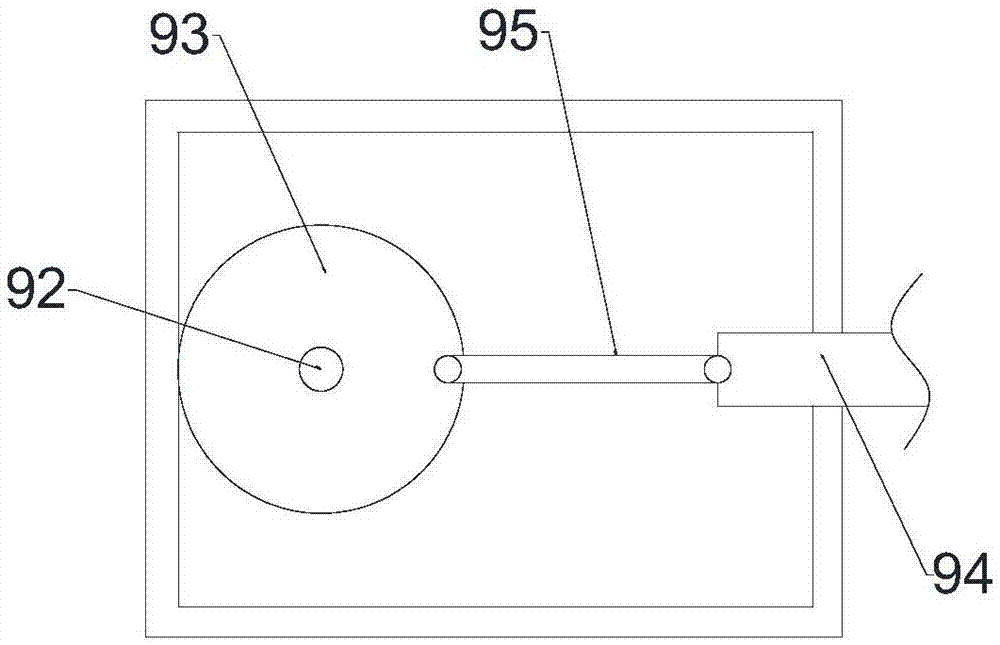

Production apparatus for gardening nutritional soil

InactiveCN107281958ASpeed up looseningEasy to integrateRotating receptacle mixersTransportation and packagingReciprocating motionEngineering

The invention discloses a production apparatus for gardening nutritional soil, which includes: a bottom board, a slide board, a rotational support sleeve, a stirring barrel, and a drawing box. The bottom board is provided with a sliding penetrating groove, inner wheel teeth, the slide board, the rotational support sleeve and the stirring barrel. The slide board is provided with a driving rotary shaft, a driving inclined gear, outer wheel teeth, a stirring rotary shaft, a transmission inclined gear, a spiral stirring blade, a rotating gear, a fixing annular sleeve, an inner gear, a planetary gear and a linking support. The stirring barrel is provided with a material inlet and a material discharge cover. The drawing box is arranged on the left side of the bottom board and is provided with a motor, a rotating shaft, a rotating disk, a drawing rod and a linking rod. The production apparatus is increased in soil processing efficiency through horizontal reciprocating movement as well as the spiral stirring blade rotating at the same time; meanwhile, with cooperation of the rotatable stirring barrel, better processing effect is achieved.

Owner:汪培杰

Lubricating oil stirring device for components and parts in pilotless automobile

InactiveCN106422834AStir wellImprove stirring efficiencyFlow mixersTransportation and packagingEngineeringControl valves

The invention relates to a lubricating oil stirring device, in particular to a lubricating oil stirring device for components and parts in a pilotless automobile, and aims to solve the technical problem of providing a lubricating oil stirring device which is uniform in stirring, high in stirring efficiency and time and labor saving, for the components and the parts in the pilotless automobile. To solve the technical problem, the invention provides the lubricating oil stirring device for the components and the parts in the pilotless automobile. The lubricating oil stirring device comprises a bottom plate, a left rack, a collecting frame, support rods, a box body, a discharge tube, a first electronic control valve, a first piston, a second electronic control, a lower hopper, a first mounting plate and the like, wherein the left rack is welded on the leftmost side of the top of the bottom plate; the collecting frame is placed on the left side of the top of the bottom plate; and two support rods are welded in the center of the top of the bottom plate. The lubricating oil stirring device has the effects of being uniform in stirring, high in stirring efficiency and time and labor saving, is not only good in stirring effect, but also simple in structure, low in manufacturing cost and advanced in performance.

Owner:洪东科

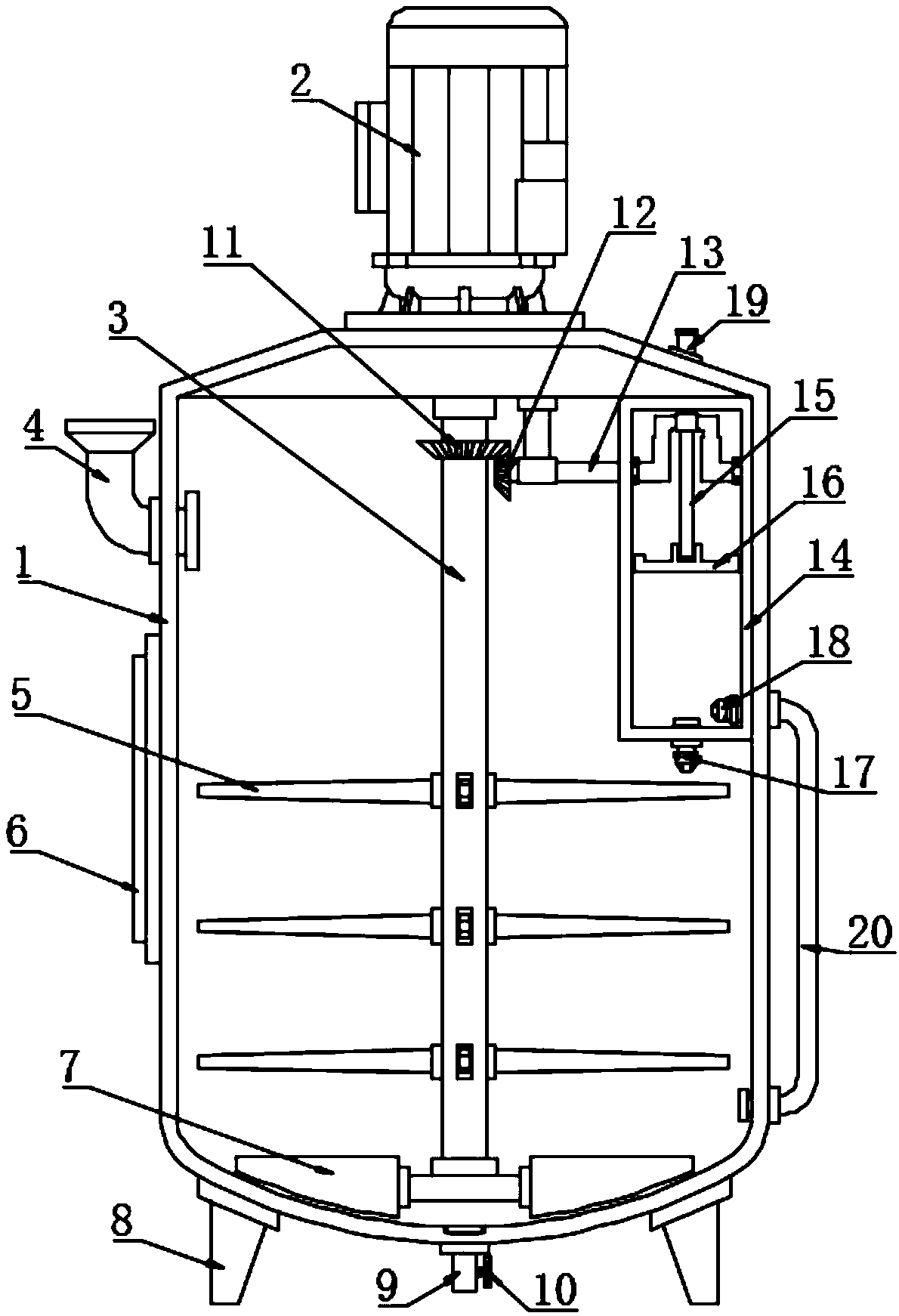

Cycle stirring reactor for chemical product manufacturing

InactiveCN109529749APrevent solidarity precipitationAdequate responseChemical/physical/physico-chemical stationary reactorsReaction rateChemical products

The invention discloses a cycle stirring reactor for chemical product manufacturing. A driving motor is fixedly mounted at the upper end of a reactor shell, the lower part of the driving motor is fixedly connected with the upper end of the reactor shell through a flange and bolts, the lower part of the driving motor is rotationally connected with a stirring shaft, and the driving motor is connected with a power supply and a switch through a lead wire; the stirring shaft is longitudinally equidistantly provided with a plurality of stirring blades, the stirring blades are circumferentially distributed on the stirring shaft, and two sides of the lower end of the stirring shaft are fixedly connected with scraping plates, and the lower parts of the scraping plates have the same counter with thereactor shell; and the sidewall of the reactor shell is fixedly provided with a control panel, the control panel is in signal connection with the driving motor, and the control panel is a touch panel. The driving motor drives the stirring shaft to rotate in order to drive the stirring blades and the scraping plates to rotate, the rotating stirring blades sufficiently mix materials in the reactorto improve the reaction rate, and the scraping plates can effectively prevent the materials from aggregating and precipitating to the bottom of the reactor.

Owner:孙洁

Microchip And Method Of Using The Same

InactiveUS20090291025A1Improve efficiencyImprove reliabilityAnalysis using chemical indicatorsTransportation and packagingEngineeringBiomedical engineering

Owner:ROHM CO LTD

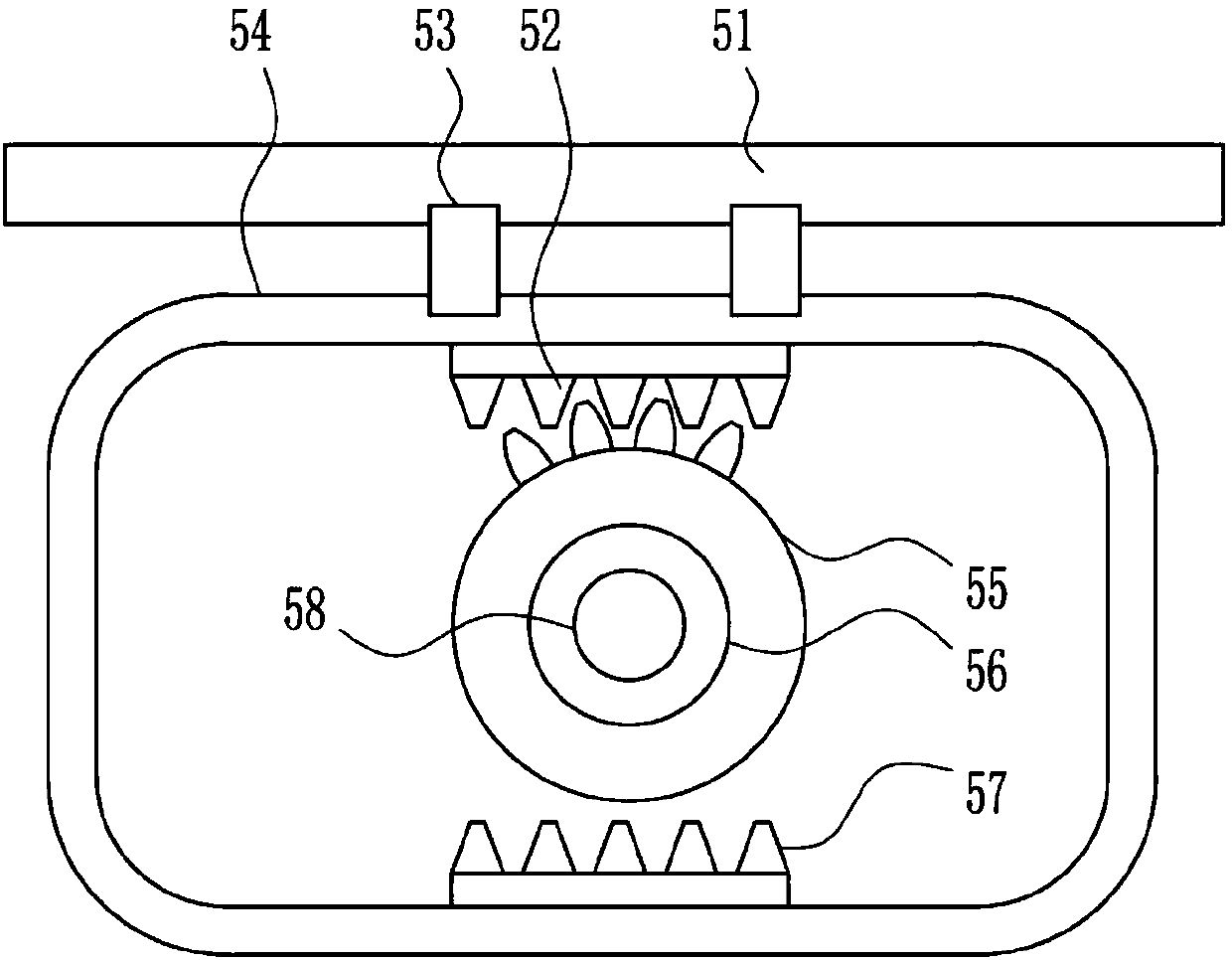

High efficiency mixing and stirring device for fluid feed

ActiveCN108295701AAvoid depositionWell mixedShaking/oscillating/vibrating mixersFeeding-stuffEngineeringMixing effect

The invention discloses a high efficiency mixing and stirring device for fluid feed. The device comprises a base, a mixing tank, a rotating motor, a ring-shaped base and a U-shaped rod, wherein the rotating motor is arranged in the middle of the base, an output end of the rotating motor is fixedly connected with a rotating shaft, a driving gear is fixedly installed on the rotating shaft, and a driven gear is meshed with the right side of the driving gear; the rotating shaft passes through the bottom of the mixing tank and is rotatably connected with the mixing tank; a crankshaft is arranged atthe upper end of the rotating shaft, a cylindrical barrel sleeves the crankshaft, first swing plates are respectively and symmetrically arranged at the left end and the right end of the cylindrical barrel, and the first swing plates are hinged with the cylindrical barrel; the upper end of the crankshaft is fixedly connected with a rotary rod; the rotary rod is also fixedly provided with a U-shaped rod, a sleeve sleeves the vertical part of the U-shaped rod, and the sleeve is rotatably connected with the U-shaped rod. The high efficiency mixing and stirring device for the fluid feed is novel in design and simple in structure, can enable the feed to be fully mixed, and is good in mixing effect, high in mixing efficiency and high in practicality, thus being worth popularizing.

Owner:山东利坤生物科技有限公司

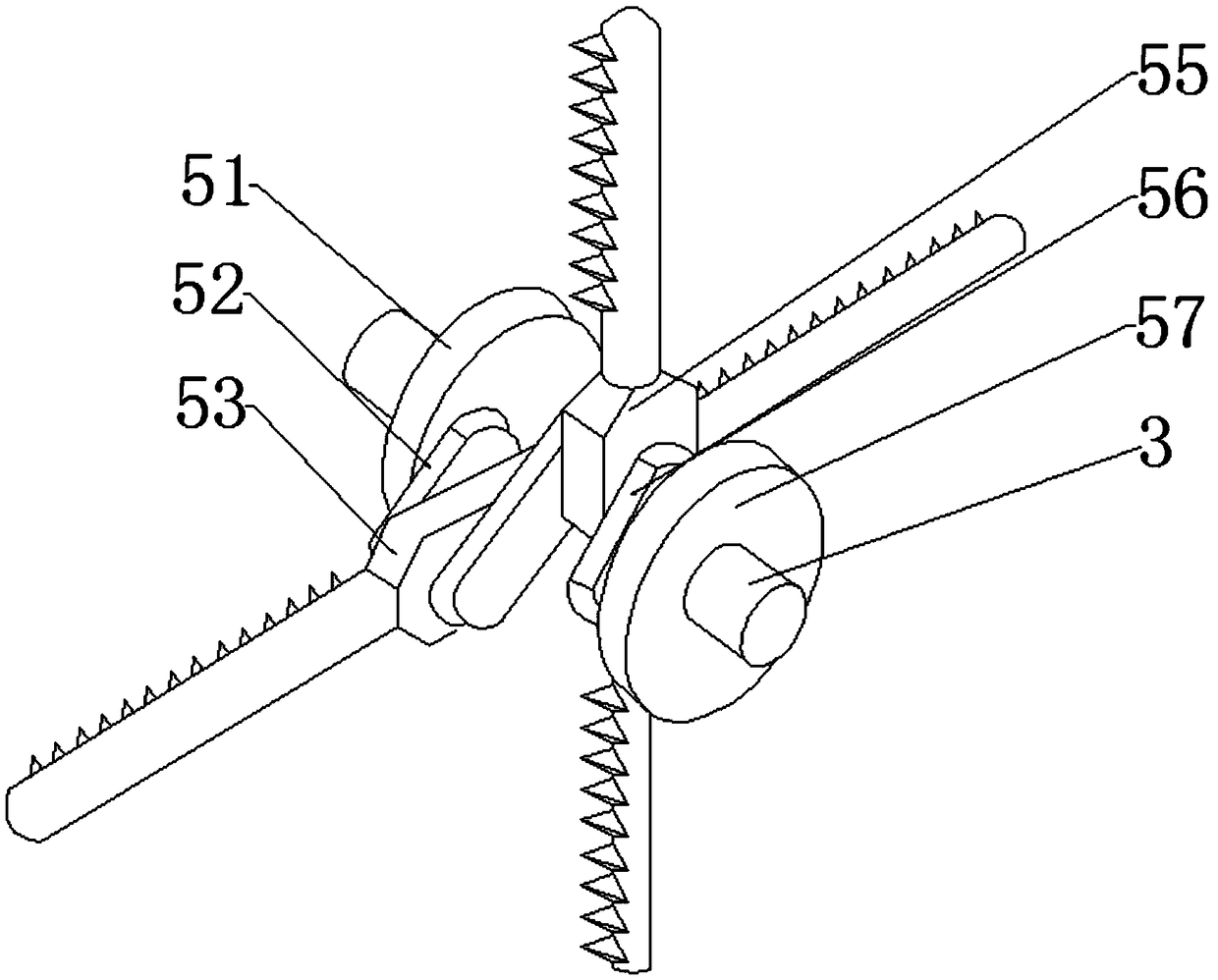

Efficient liquid medicine stirring device

InactiveCN108636207AImprove mixing efficiencyWell mixedShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionEngineering

The invention discloses an efficient liquid medicine stirring device, belongs to the technical field of medicine stirring, aims to solve the problem that rotating direction of a stirrer is difficult to change in the prior art, and provides the liquid medicine stirring device which is provided with a continuously direction-changeable stirring shaft and higher in mixing efficiency. The efficient liquid medicine stirring device comprises a stirring barrel, wherein a liquid inlet and a liquid outlet are formed in the top and the bottom of the stirring barrel respectively, a drive motor is arrangedon the stirring barrel, stirring blades are arranged on an output shaft of the drive motor, a crankshaft reciprocating assembly is connected between two sections of the output shaft of the drive motor and comprises a first reciprocating connecting rod and a second reciprocating connecting rod which reciprocate on a horizontal plane vertical to the axis of the output shaft, the first reciprocatingconnecting rod and the second reciprocating connecting rod drive auxiliary stirring shafts to perform direction-changeable movement continuously under meshing transmission of teeth, and accordingly,liquid medicines are stirred more efficiently.

Owner:CHENGDU JUNSHUO RUIZHI INFORMATION TECH CO LTD

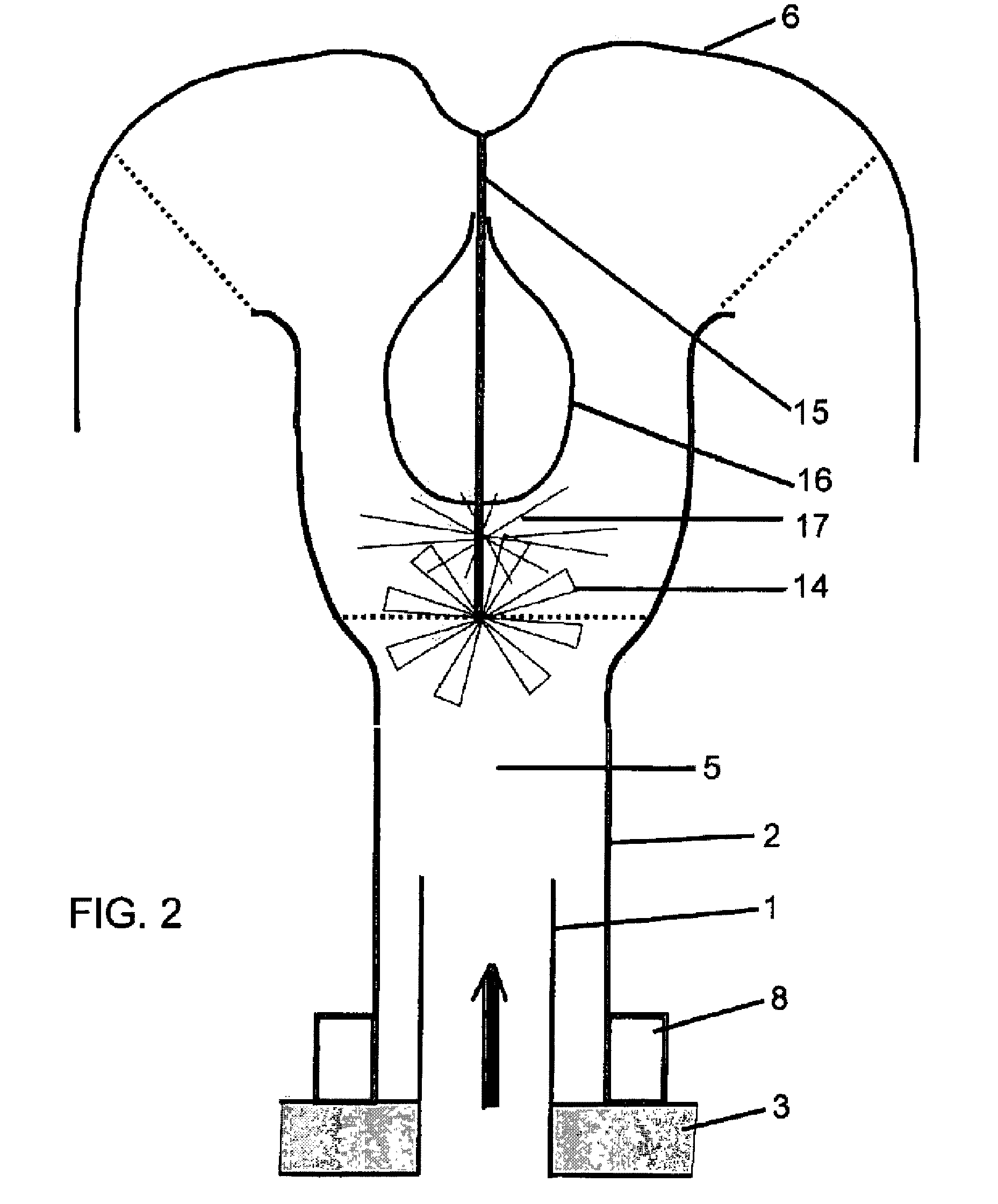

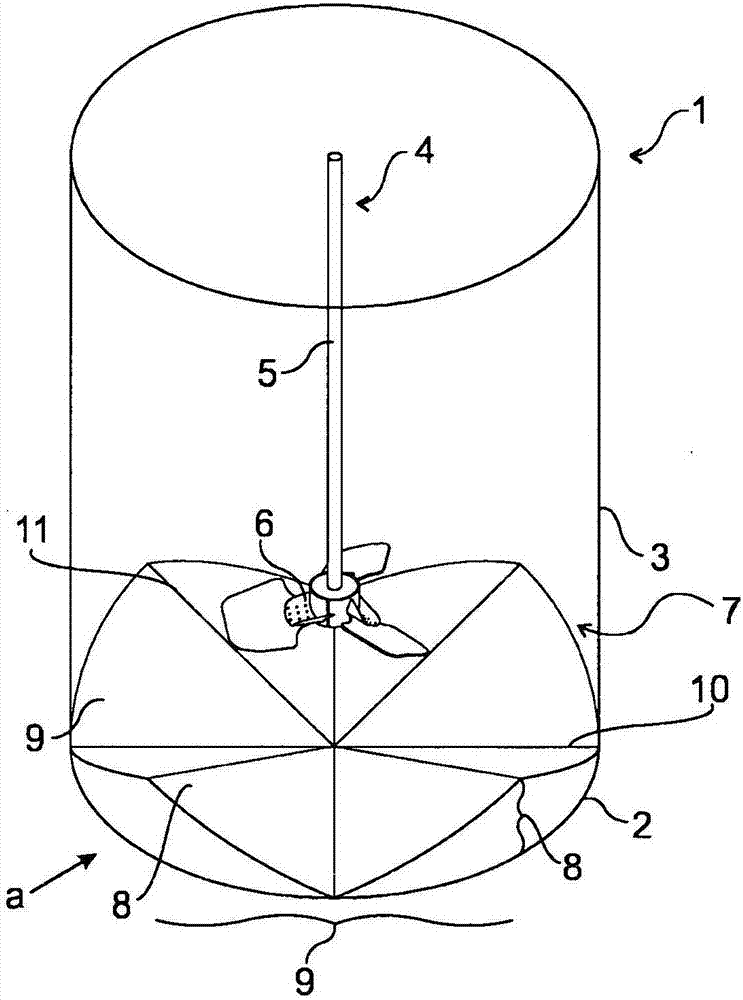

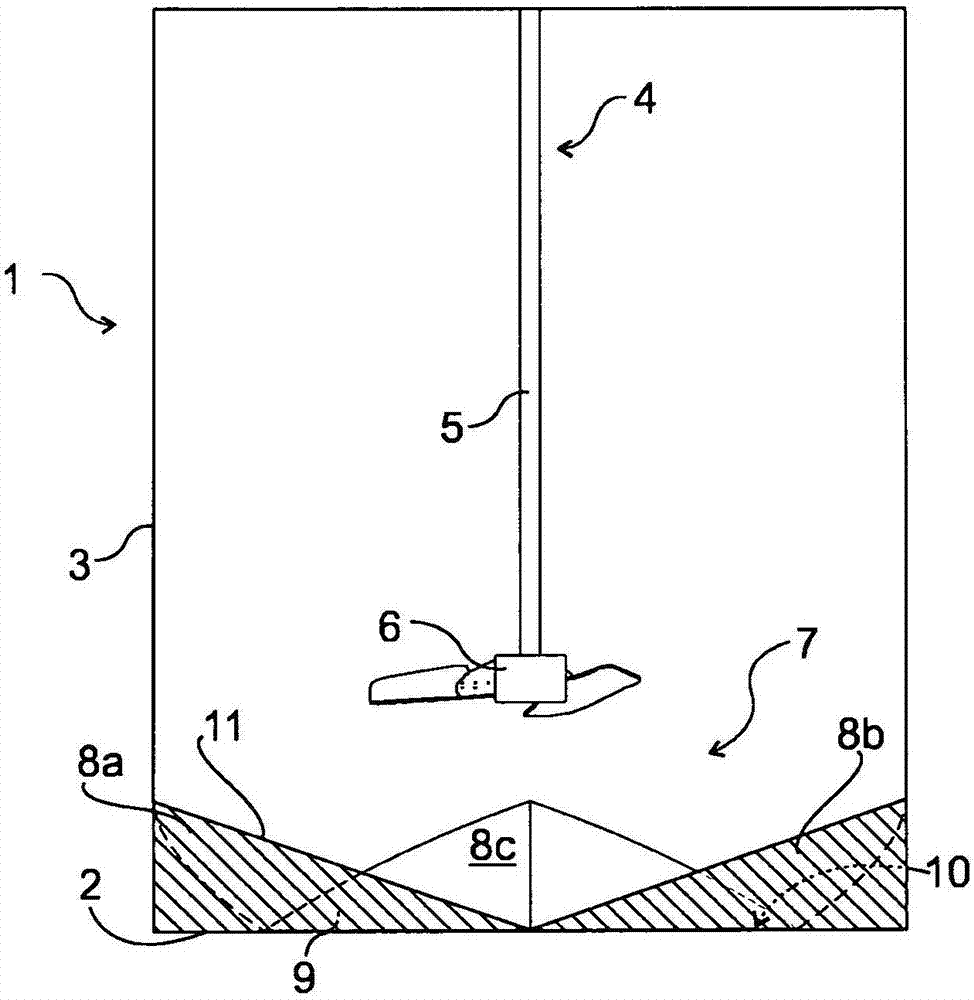

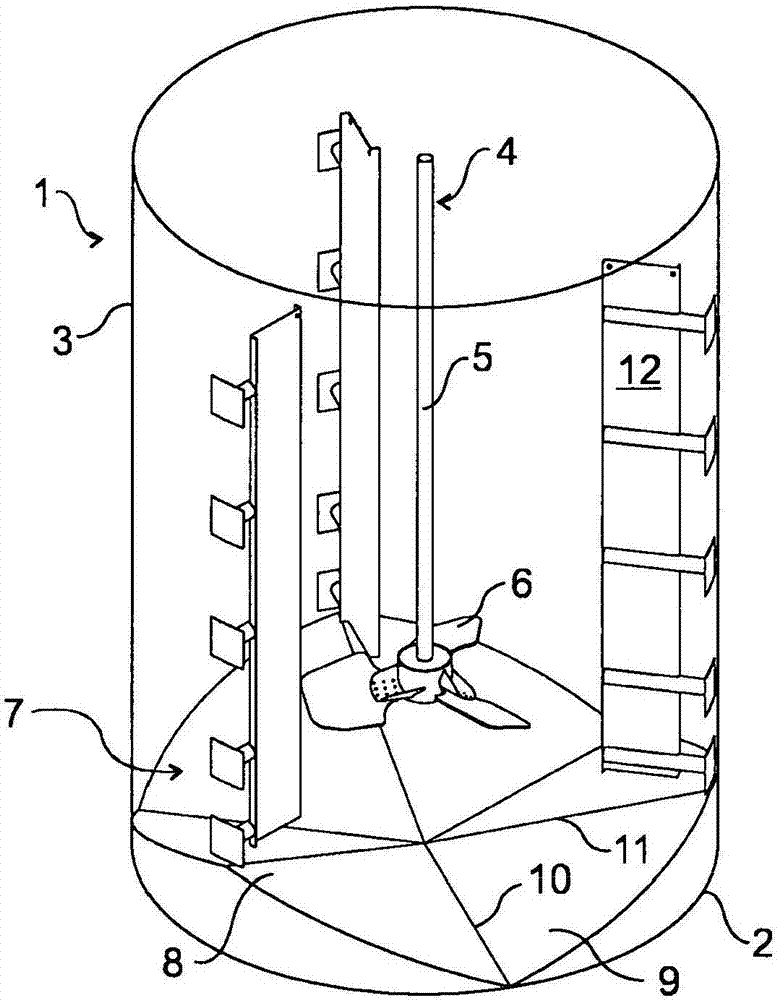

Mixing apparatus and its use

ActiveCN107073419AImprove suspension characteristicsIncrease flow rateRotating receptacle mixersRotary stirring mixersImpellerEngineering

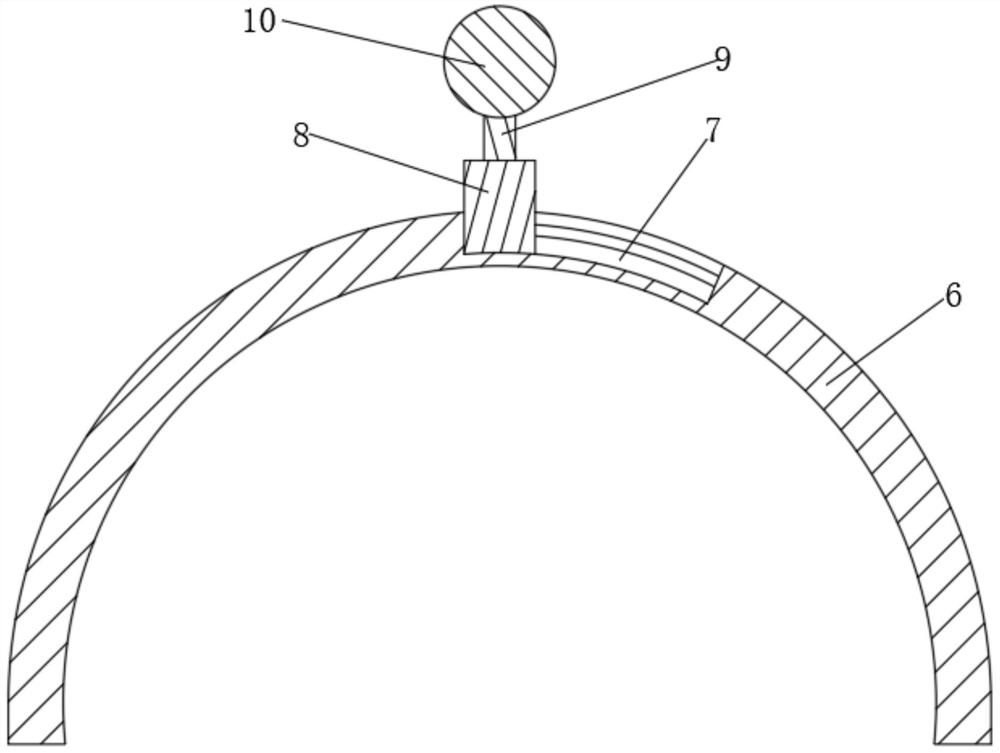

A mixing apparatus for mixing particles in a liquid and its use are disclosed. The mixing apparatus comprises a tank (1) having a bottom (2) and a substantially vertical side wall (3), an agitation means (4) comprising a rotation shaft (5) located vertically and centrally in the tank (1), and an impeller (6) arranged at a height above the bottom (2) at the end of the rotation shaft (5) and the impeller (6) being a downward pumping axial or mixed flow impeller. The bottom (2) is equipped with a corrugated formation (7) comprising alternate consecutive ridges (8) and valleys (9), the ridges (8) and valleys (9) extending radially in relation to a center of the bottom (2), whereby the valleys (9) concentrate and channel the mixing power near to the bottom (2) to direct the flow of the liquid and to increase the velocity of the flow near to the bottom (2).

Owner:METSO OUTOTEC (FINLAND) OY

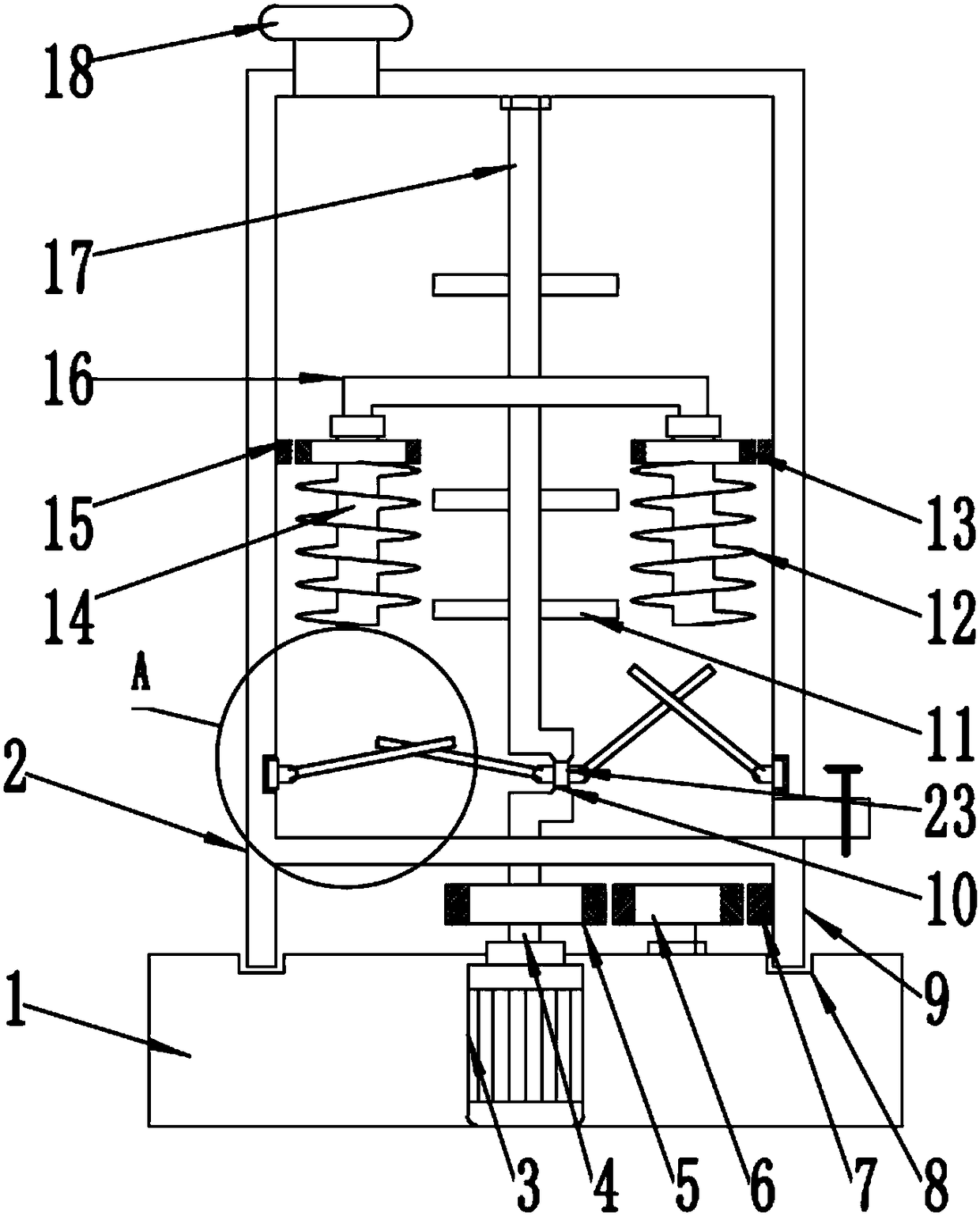

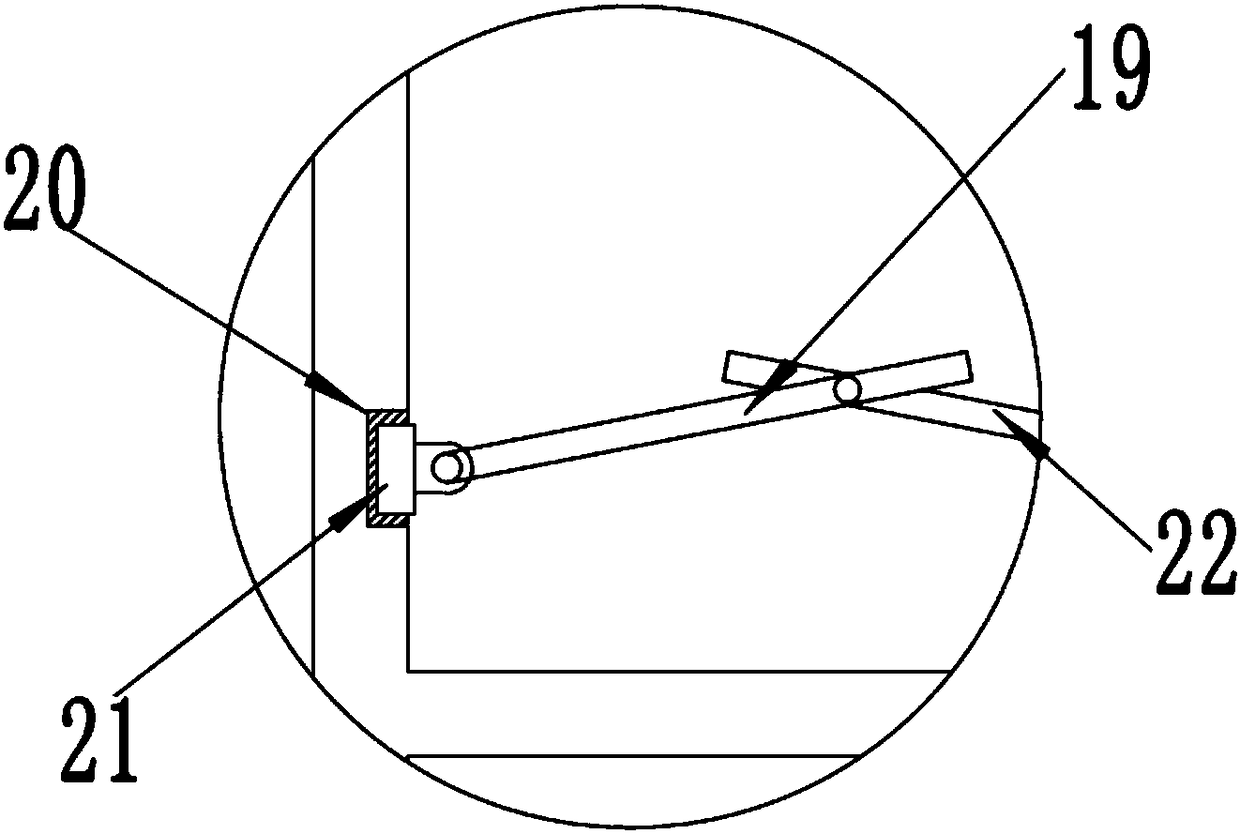

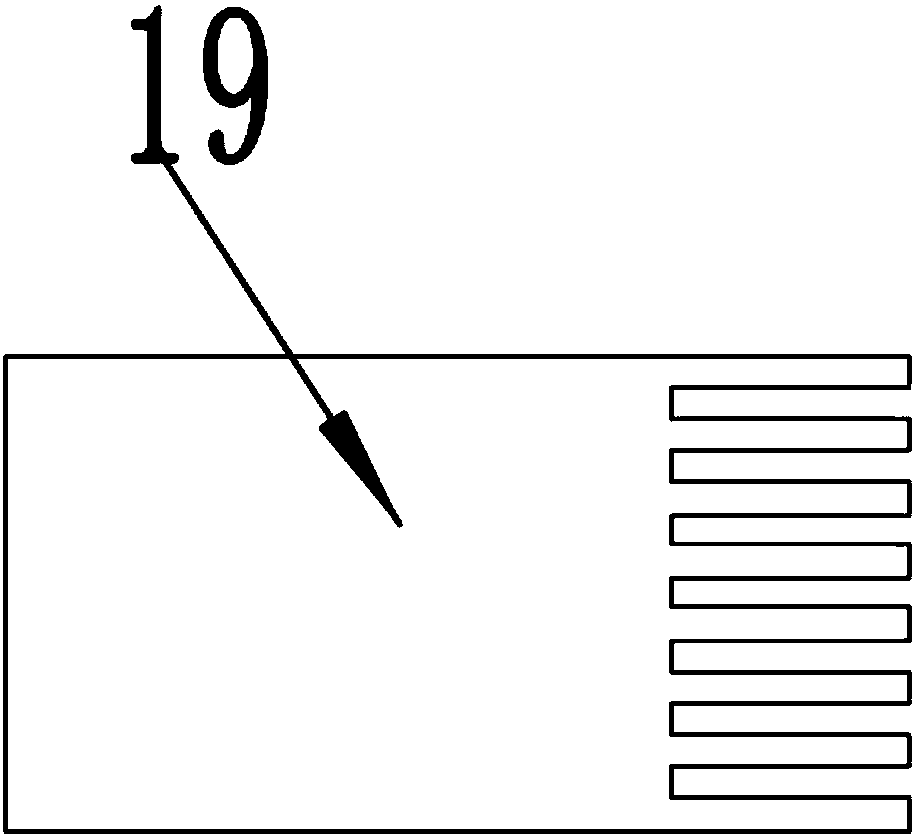

Sewage treatment device capable of fully stirring and mixing

InactiveCN113651379AImprove efficiencyImprove mixing efficiencyWater/sewage treatmentSewage treatmentSewage

The invention discloses a sewage treatment device capable of fully stirring and mixing, and solves the problem of low treatment efficiency during sewage mixing at present. The sewage treatment device comprises a hollow sewage treatment barrel and a stirring device which periodically descends, circumferentially rotates and ascends in the sewage treatment barrel, a disc is arranged below the stirring device and rotationally connected with the sewage treatment barrel, a first connecting rod is hinged to the inner end of the disc, a second connecting rod is hinged to the inner end of the first connecting rod, and the inner end of the second connecting rod is fixedly hinged to the stirring device. The stirring device is of a structure for driving the disc to rotate and changing the positions of the first connecting rod and the second connecting rod.

Owner:张兵伟

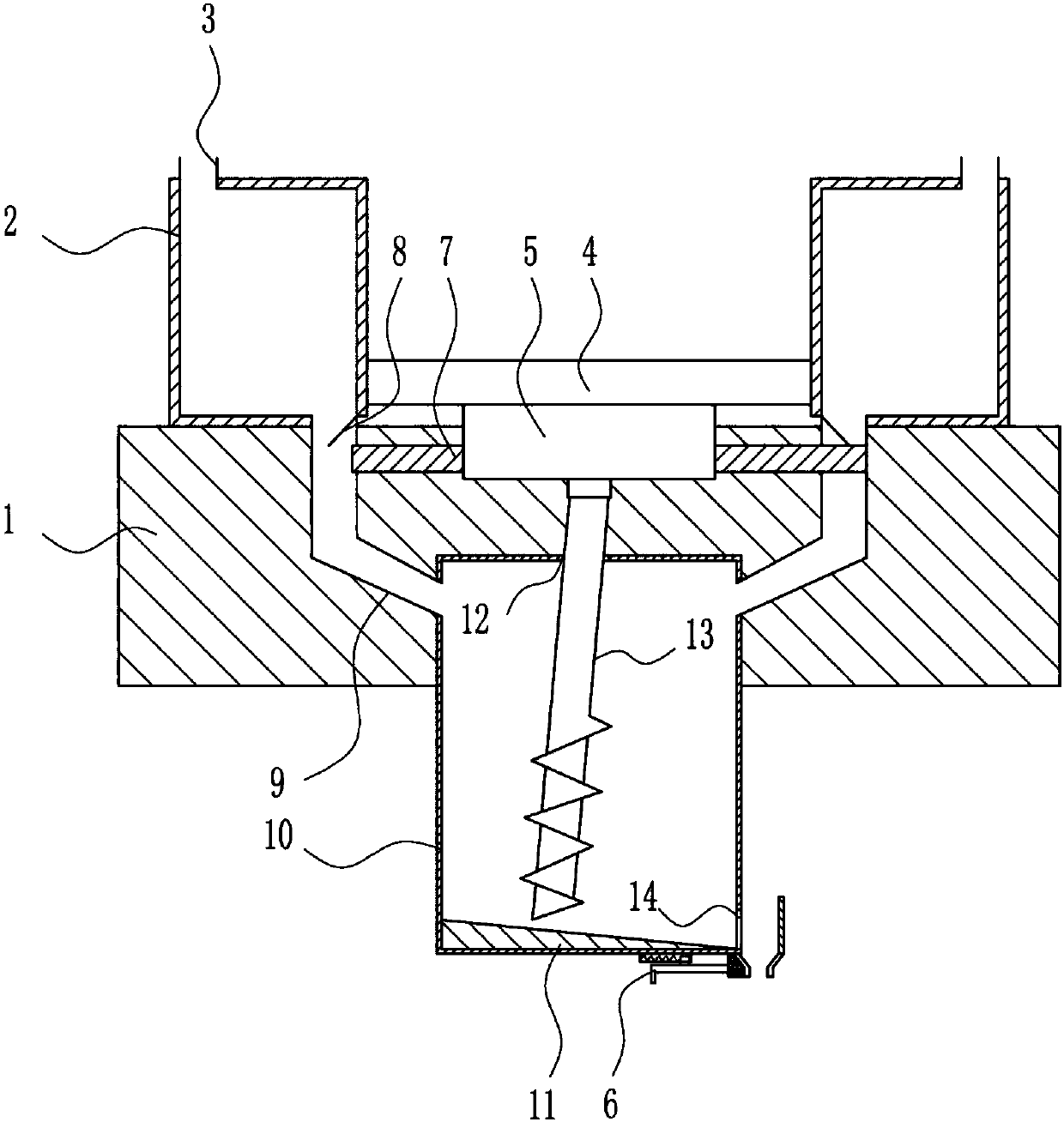

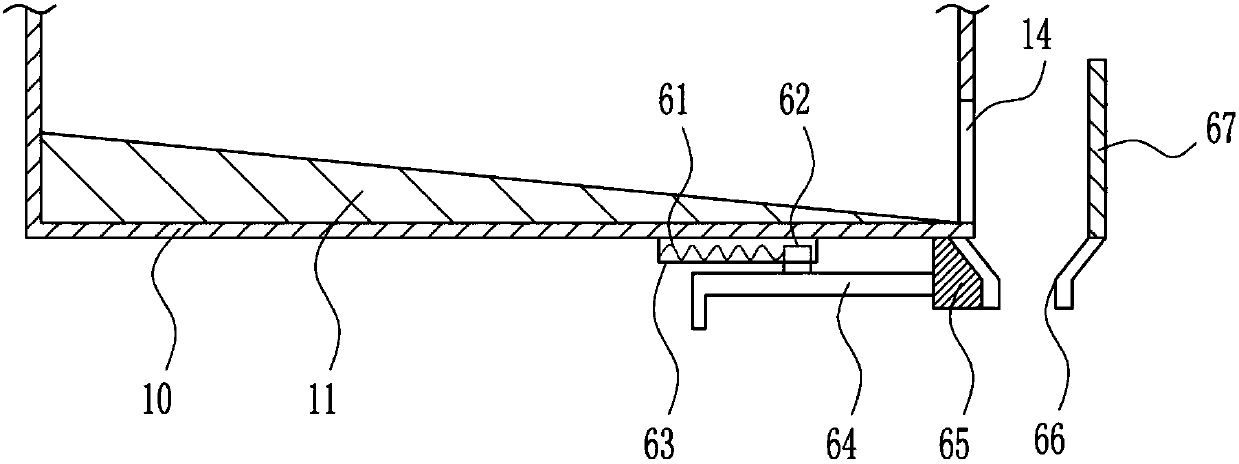

Mortar preparation equipment

InactiveCN109940759AImprove production efficiencyIngenious and reasonable structureDischarging apparatusMixing operation control apparatusBiochemical engineeringBilateral symmetry

The invention discloses mortar preparation equipment which comprises a preparation machine body, vertical plates installed on the preparation machine body in bilateral symmetry, a supporting plate installed on the vertical plates and two storage barrels installed on the supporting plate; each storage barrel is internally provided with a storage cavity; the top end of each storage cavity is provided with a feeding hole; the top end of the feeding hole is provided with a feeding funnel; the bottom end of each storage cavity is slantingly provided with a discharge branch pipe; a first dischargingspace is formed in each discharge branch pipe; and an opening and closing unit for controlling opening and closing of the first discharging spaces is arranged between the two storage barrels. By adopting the mortar making equipment provided by the invention, mortar raw materials entering a second discharging space are preliminarily stirred with a preliminary stirring unit, so that the stirring time of the mortar raw materials, entering a preparation cavity, is effectively reduced; and in addition, through simultaneous rotation of an inner side stirring unit and an outer side stirring unit inthe preparation cavity, the stirring efficiency is further improved, the mortar preparation efficiency is improved, and the mortar preparation equipment is worthy of popularization and application.

Owner:嘉兴咩哞贸易有限公司

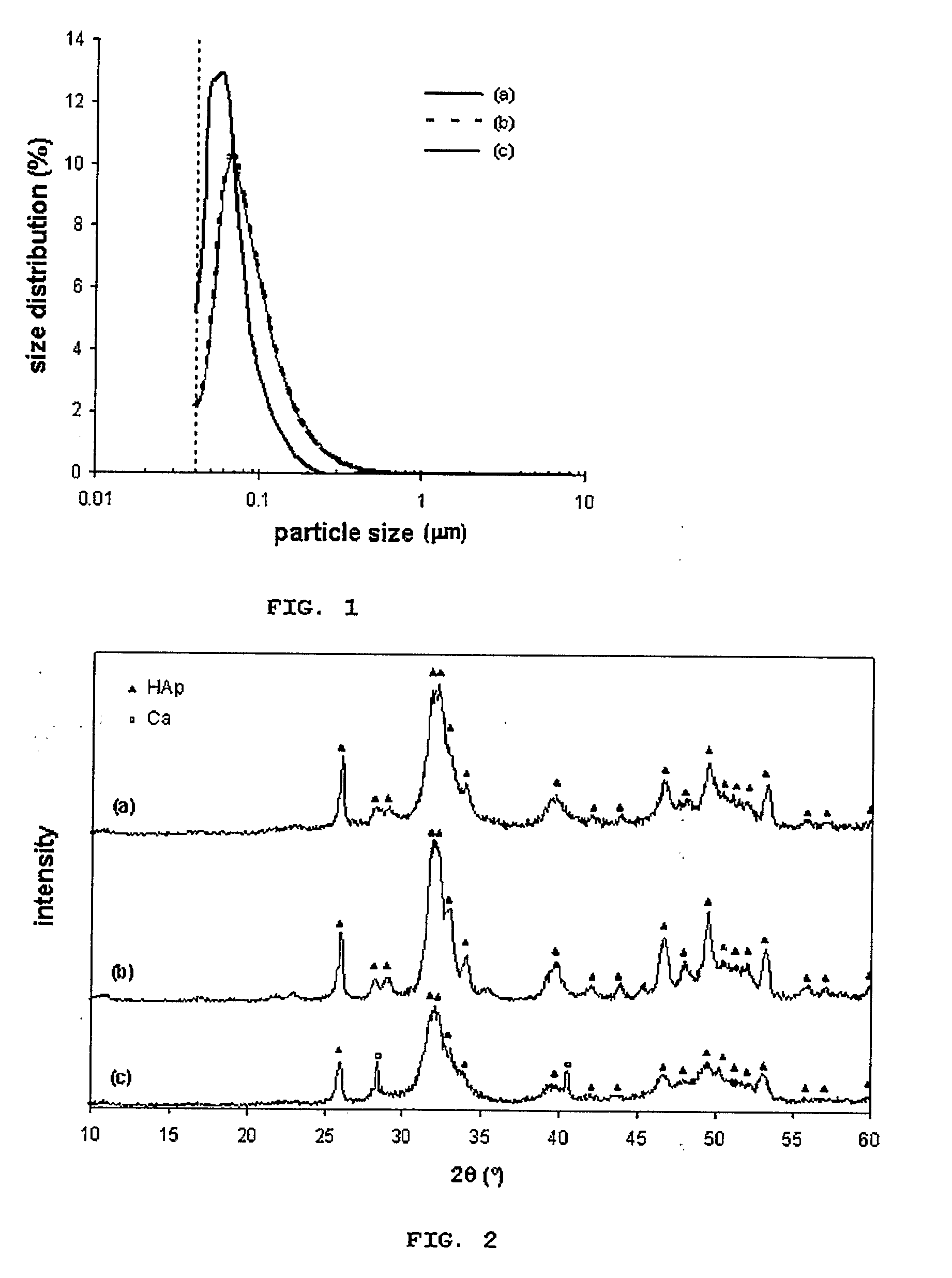

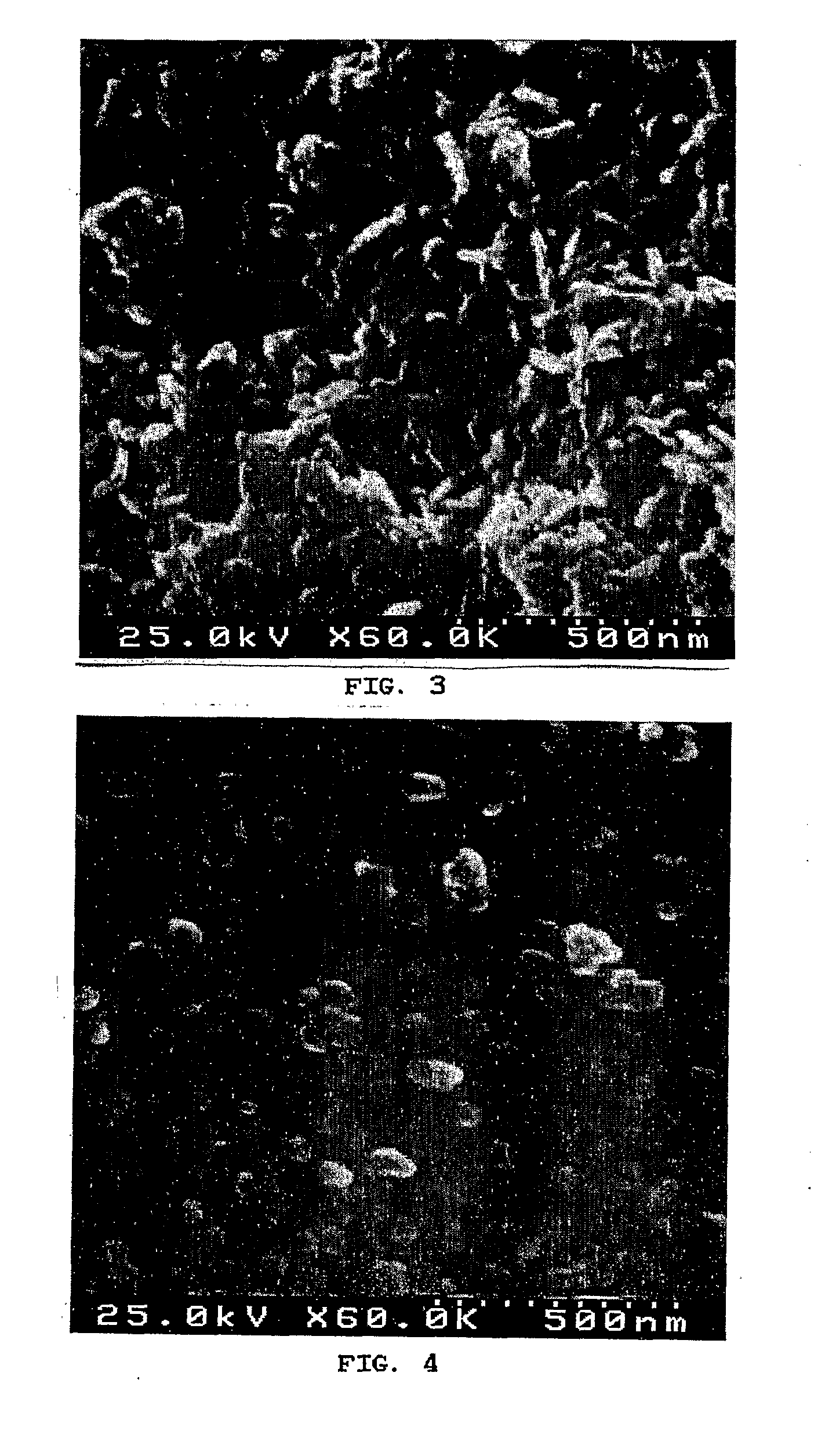

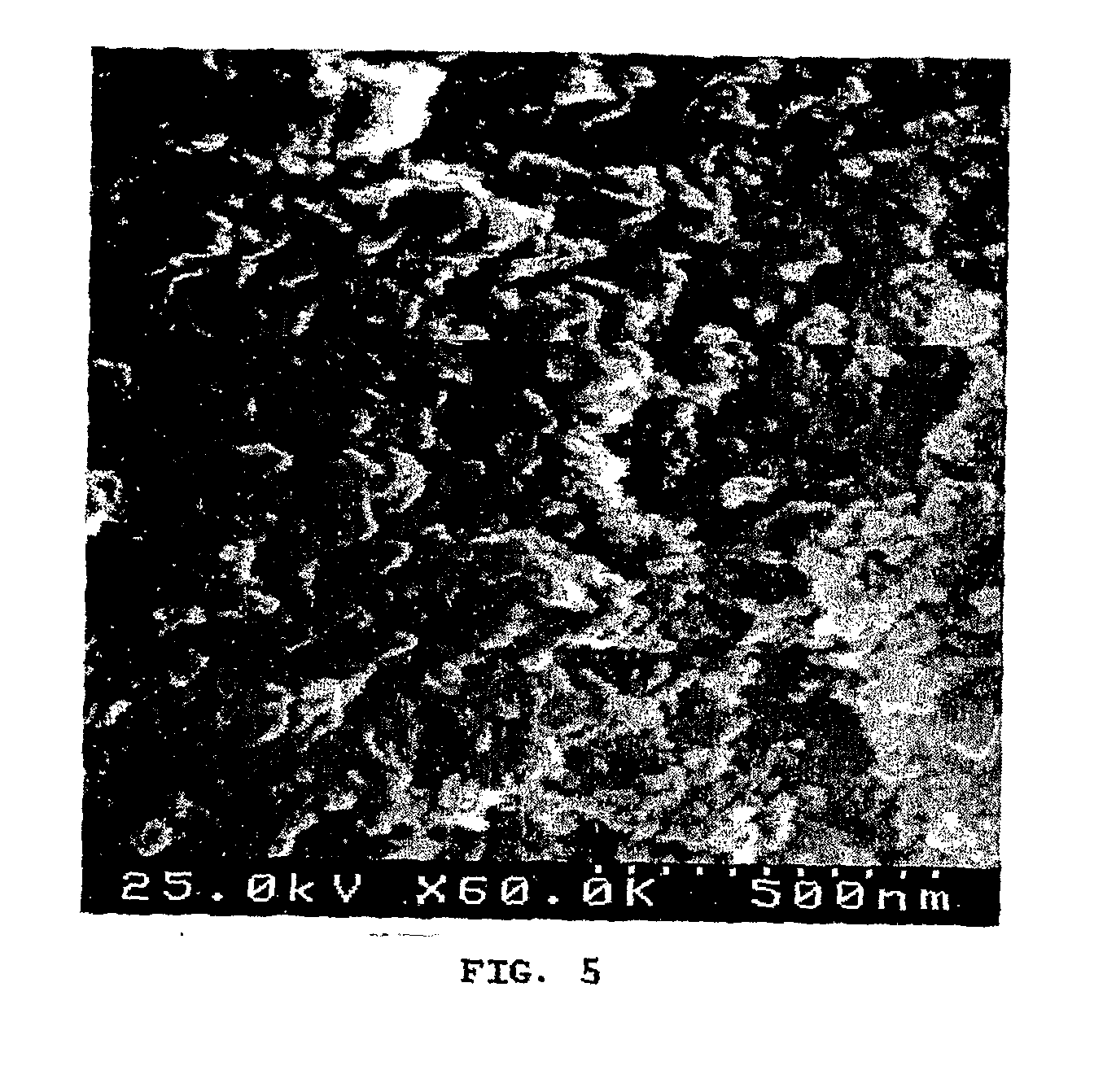

Production method for calcium phosphate nano-particles with high purity and their use

InactiveUS20090263497A1Increase costQuality improvementBiocideMaterial nanotechnologyNutritionToothpaste

The present invention provides a continuous process for producing calcium phosphate nanoparticles in a network mixer or static mixer reactor, fed by a calcium solution, a phosphorous solution and an alkaline solution and, optionally, one solvent or dispersing agent. The proposed process enables the micromixing control, which is essential to form nanometric structures, but it is also a determining factor in the crystals purity, crystallinity and morphology. The reactants distribution scheme at the inlet of the reactor and along the reactor, performed continuously or varying in time, is also a crucial factor to programme the pH of the reactant media along the reactor The calcium phosphate nanoparticles suspension that exits the reactor can be submitted to further aging, ultra-sounds, separation, drying, sintering and milling processes. Some calcium phosphates are considered biomaterials, used as: food additives and nutritional supplements; bone graft for bone replacement, growth and repair; biocements and coating of metallic implant. Some of the most recent applications include their use in cosmetics, toothpaste and in esthetical treatments for diminishing wrinkles by stimulating conjunctive tissue formation.

Owner:FLUDINOVA ENGENHARIA DE FLUIDOS S A OF TECMAIA +1

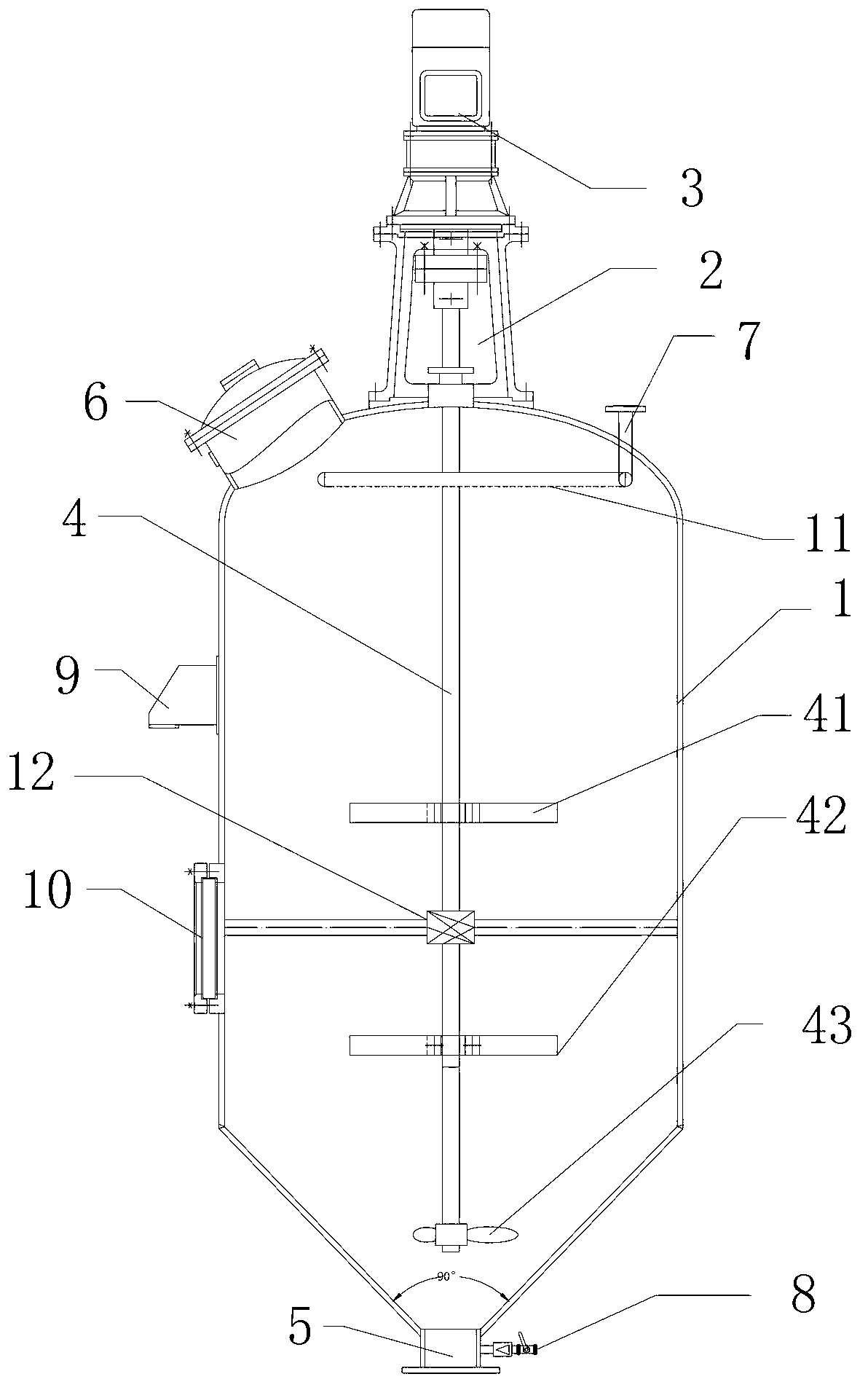

Solid-liquid mixing tank and using method thereof

The invention discloses a solid-liquid mixing tank which is suitable for mixing of a large quantity of solids and a small quantity of liquids. The bottom of a cylindrical closed tank body adopts an inverted cone shape; a stirring device is arranged inside the tank body and driven by a motor located on the top cover of the tank body; a feed inlet and a liquid inlet are formed in the top of the tank body, and the liquid inlet is connected with an ejector located at the upper part inside the tank body; the ejector is horizontally arranged, and the directions of spray holes of the ejector are downward; a discharge hole is formed in the bottom of the tank body; and the stirring device comprises three stages of stirring paddles coaxially connected from top to bottom. The invention further discloses a using method of the solid-liquid mixing tank. By means of the solid-liquid mixing tank and the using method thereof, the uniformity of solid-liquid mixing can be improved, and the mixing efficiency can be improved.

Owner:四川中方制药有限公司

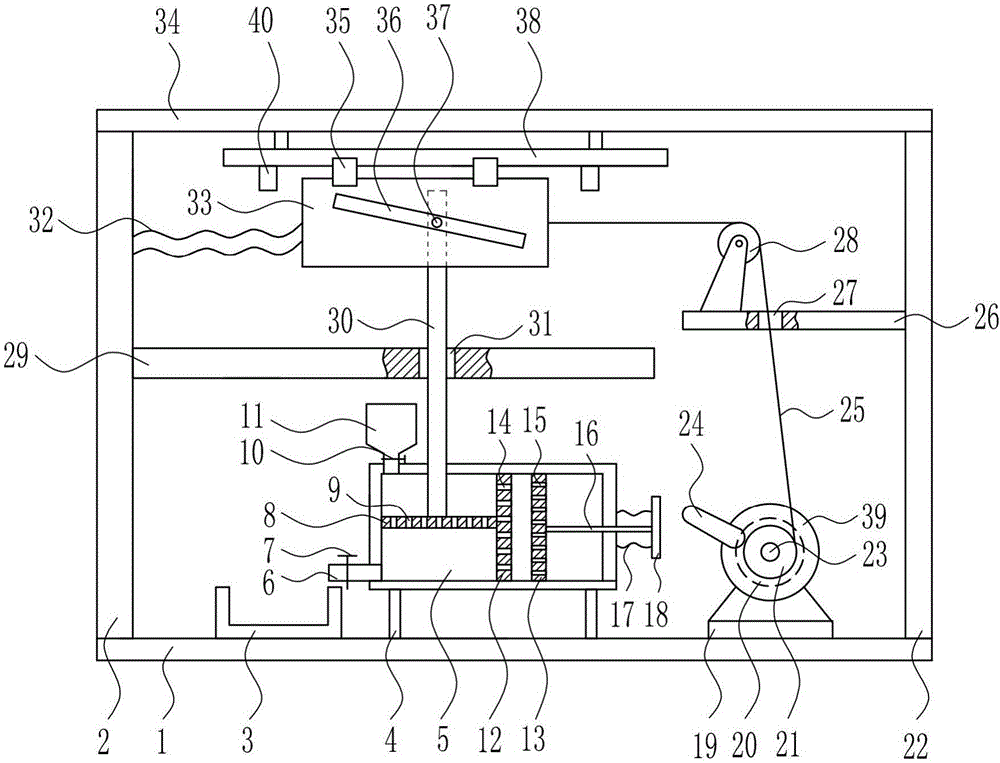

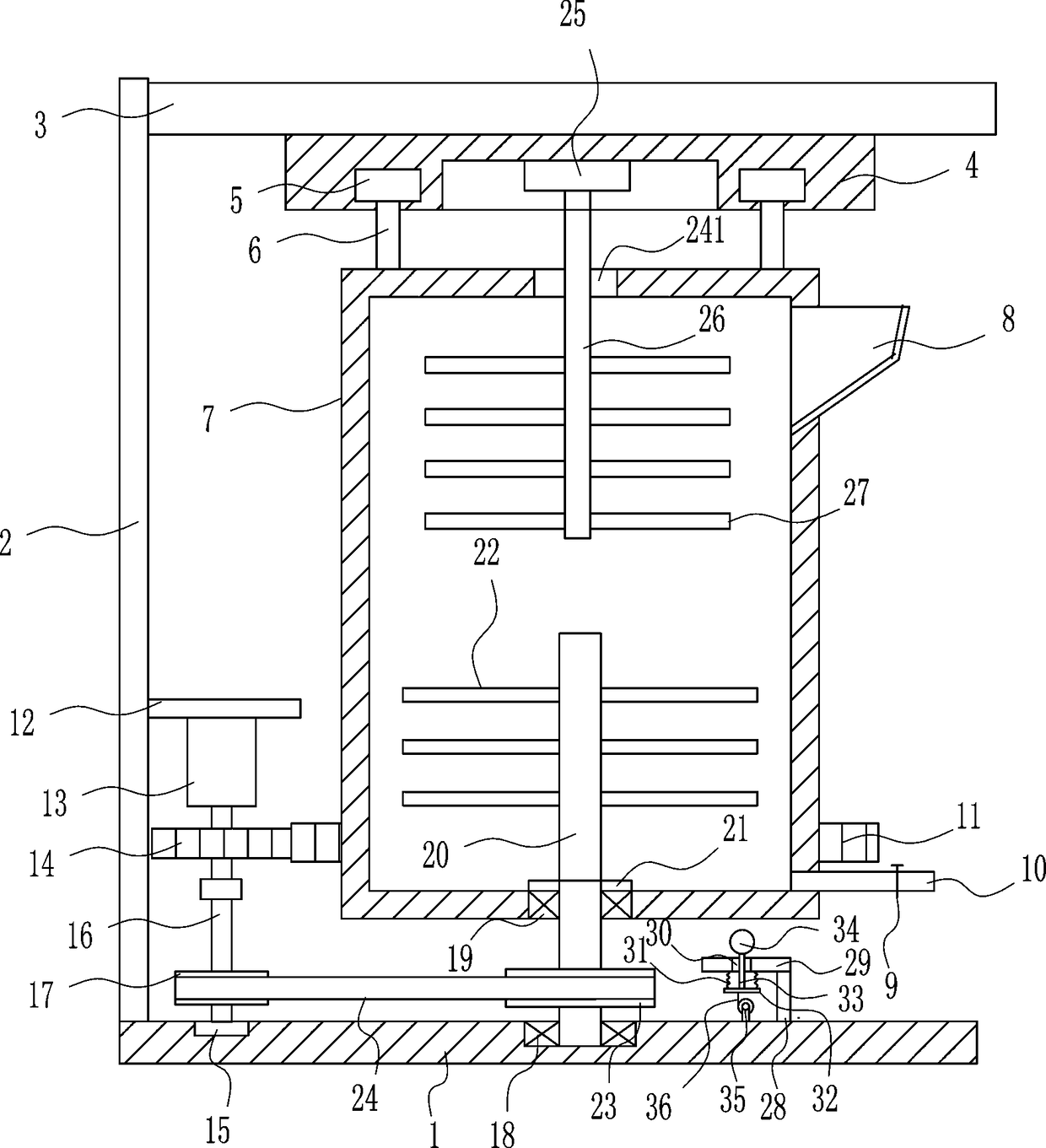

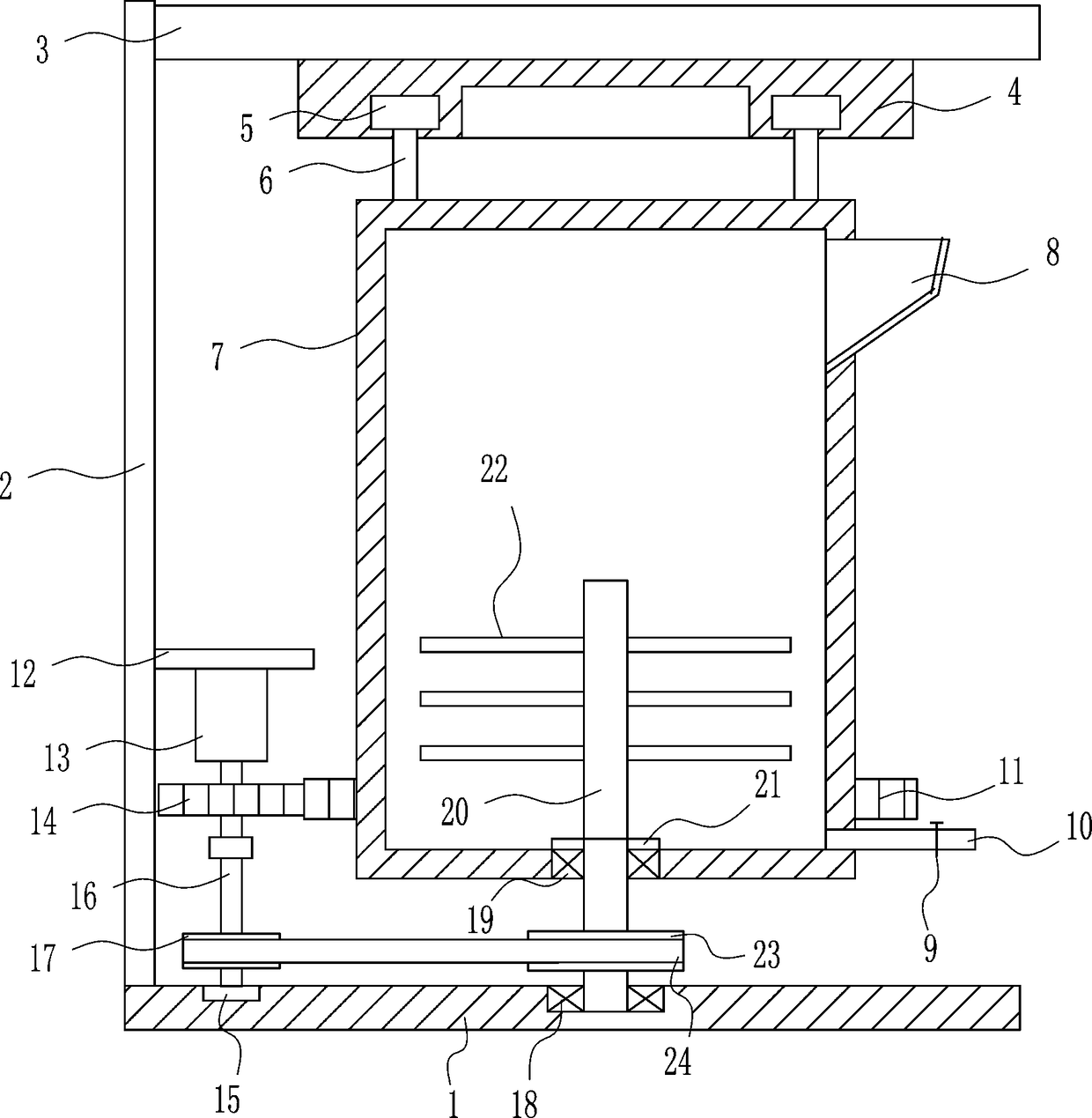

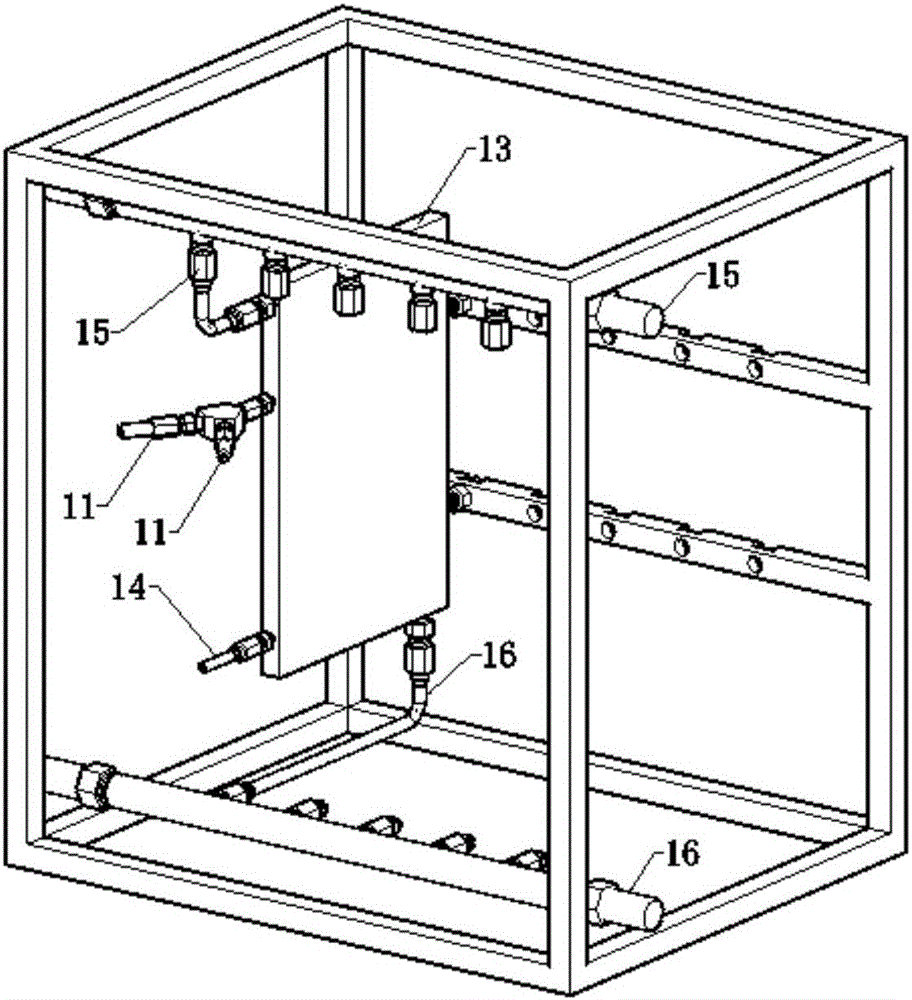

Agricultural liquid fertilizer stirring and uniform mixing equipment

InactiveCN108211936AImprove the mixing effectPlay the role of auxiliary stirringRotating receptacle mixersTransportation and packagingAgricultural engineeringMixing effect

The invention relates to stirring and uniform mixing equipment, in particular to agricultural liquid fertilizer stirring and uniform mixing equipment and aims at providing agricultural liquid fertilizer stirring and uniform mixing equipment which is high in mixing efficiency, saves manpower and is excellent in mixing effect. The invention provides the agricultural liquid fertilizer stirring and uniform mixing equipment which comprises a bottom plate, a left frame, a top plate, an annular sliding rail, sliding blocks, first connection rods, a mixing box, a feed hopper, an electric valve, a discharge pipe, an outer ring gear, a mounting plate and the like; the left frame is arranged on the left side of the top of the bottom plate; the top plate is arranged at the upper part of the right sideof the left frame; the annular sliding rail is arranged at the bottom of the top plate; the sliding blocks are connected to the annular sliding rail in a sliding manner; and the annular sliding railis matched with the sliding blocks. The agricultural liquid fertilizer stirring and uniform mixing equipment reaches the effects of high mixing efficiency, manpower conservation and excellent mixing effect, drives the mixing box and a first stirring blade to perform reversed rotation through rotation of a rotary motor, automatically realizes stirring of a fertilizer, saves manpower and is good inmixing effect.

Owner:毛孝人

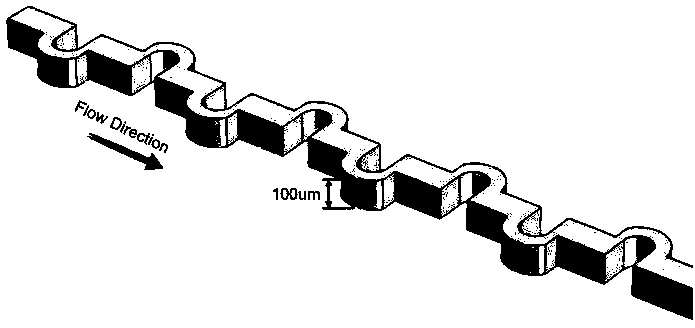

Micro reactor with bamboo joint-shaped micro structure

InactiveCN105964198AImprove mixing efficiencyIncrease speedChemical/physical/physico-chemical microreactorsNuclear engineeringCorrosion

The invention discloses a microreactor with a bamboo-shaped microstructure, and relates to the technical field of microreactors. Including material inlet pipe, module, material outlet pipe, heat exchanger inlet pipe and heat exchanger outlet pipe, modules and modules are alternately stacked between relatively parallel inlet pipes and outlet pipes, and the modules are separated by membrane blocks The connecting pipe is connected. The module is a sandwich structure made of metal materials, the outer layer is used for the circulation of the heat transfer fluid, and the inner layer is used for the mixing and chemical reaction of the reactive fluid, thus realizing the integration of mixing and heat transfer. This structure will not affect the heat transfer performance when maintaining a certain flux of fluid; and the fluid provides excellent flow control in the microchannel module, which can operate at minus 100°C to minus 350°C, and the maximum pressure can reach 10 megabytes Pa, and greatly improve production efficiency, reaction speed, safety, etc., with high strength and low density, good mechanical properties, good toughness and corrosion resistance.

Owner:CHANGZHOU UNIV

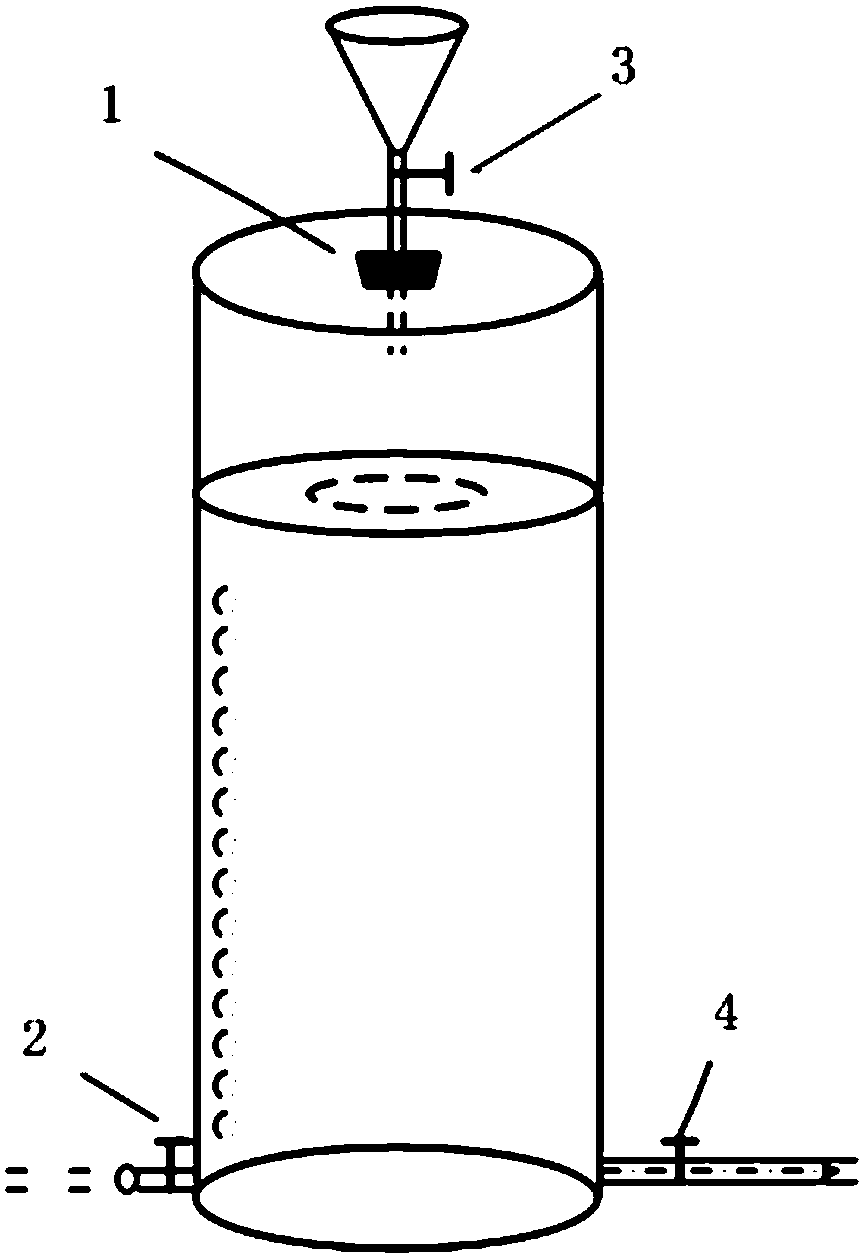

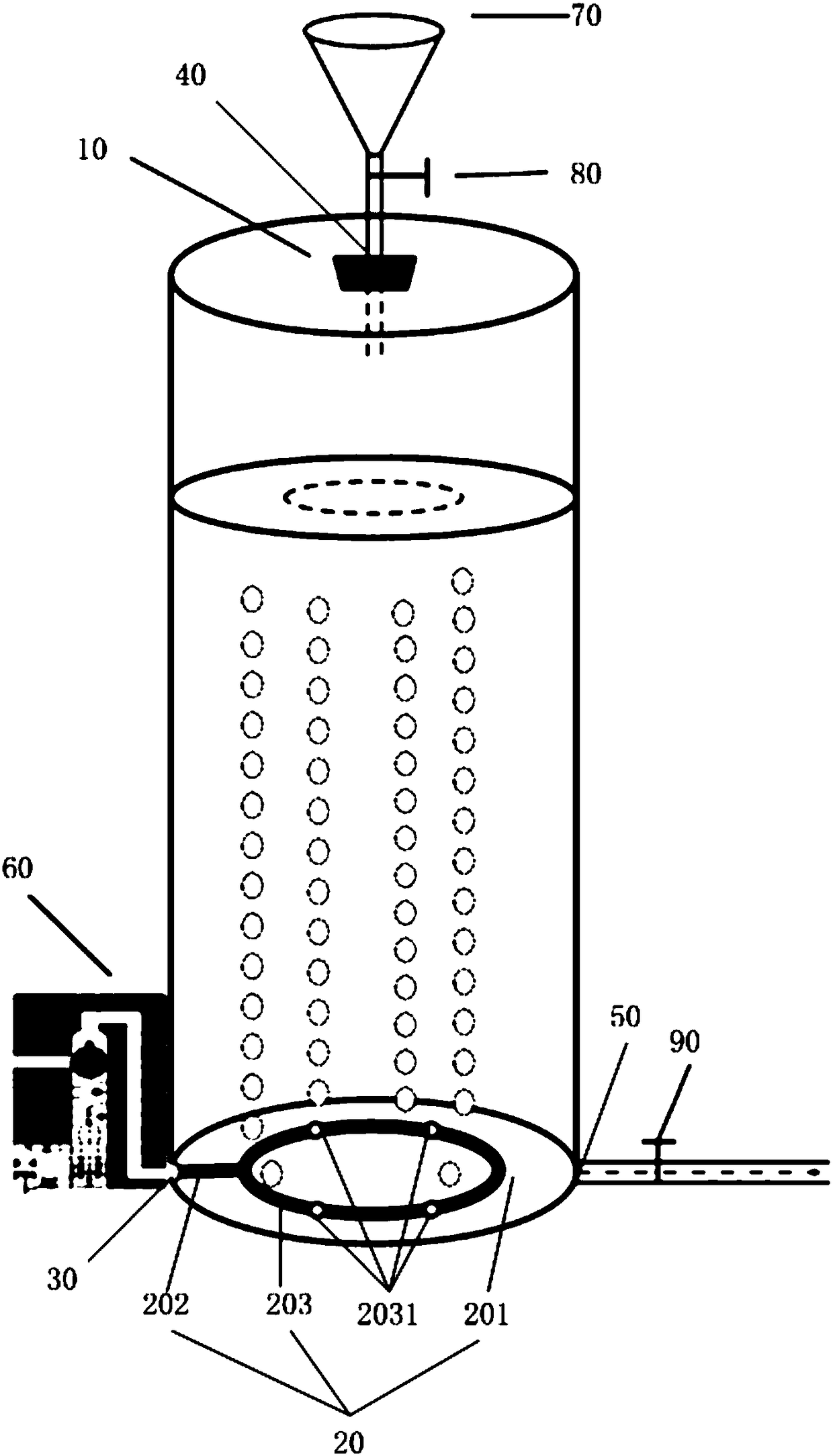

A multi-hole air intake Marriotte bottle and a using method

ActiveCN108536197AIncreased disturbance areaGood mixing efficiencyOperating means/releasing devices for valvesSimultaneous control of multiple variablesEngineeringBottle

The invention provides a multi-hole air intake Marriotte bottle and a using method. The multi-hole air intake Marriotte bottle comprises a Marriotte bottle body, an air intake module, an air inlet, awater inlet and a water outlet. The Marriotte bottle body is inside provided with a hollow cavity which communicates with the air inlet, the water inlet and the water outlet separately. The air intakemodule comprises a multi-hole shunt bottom plate, an air intake tube and a first hollow tube; the first hollow tube is provided with at least one air hole and communicates with one end of the air intake tube; the other end of the air intake tube is connected with the air inlet; the air intake tube and the first hollow tube are arranged on the surface of the multi-hole shunt bottom plate; the multi-hole shunt bottom plate is arranged in the hollow cavity. In the prior art, bubbles rise along the inner wall of a Marriotte bottle and a solution is stirred; according to the embodiments of the invention, the purpose of increasing the stirring area of bubbles is achieved by covering the first hollow tube and multiple air holes at the bottom of the hollow cavity of the multi-hole air intake Marriotte bottle, so that the solution stirring efficiency is higher.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

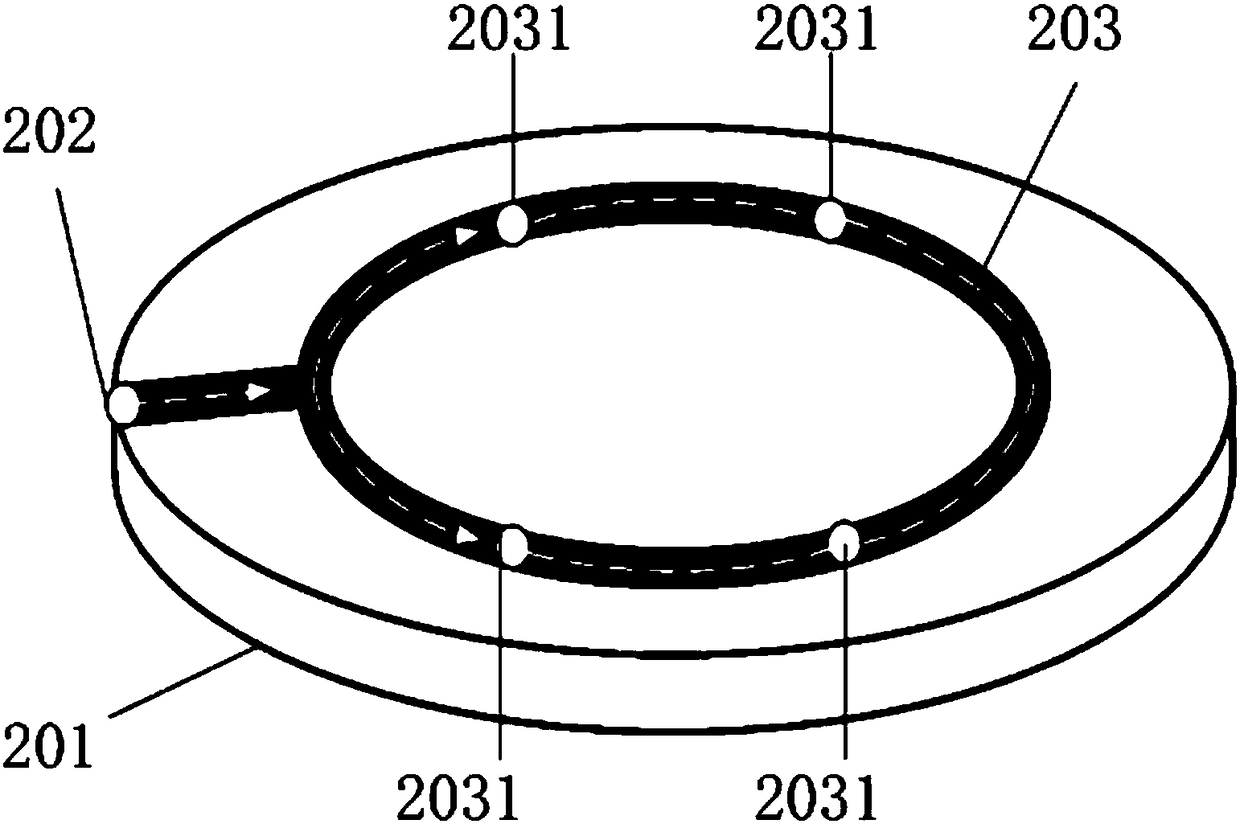

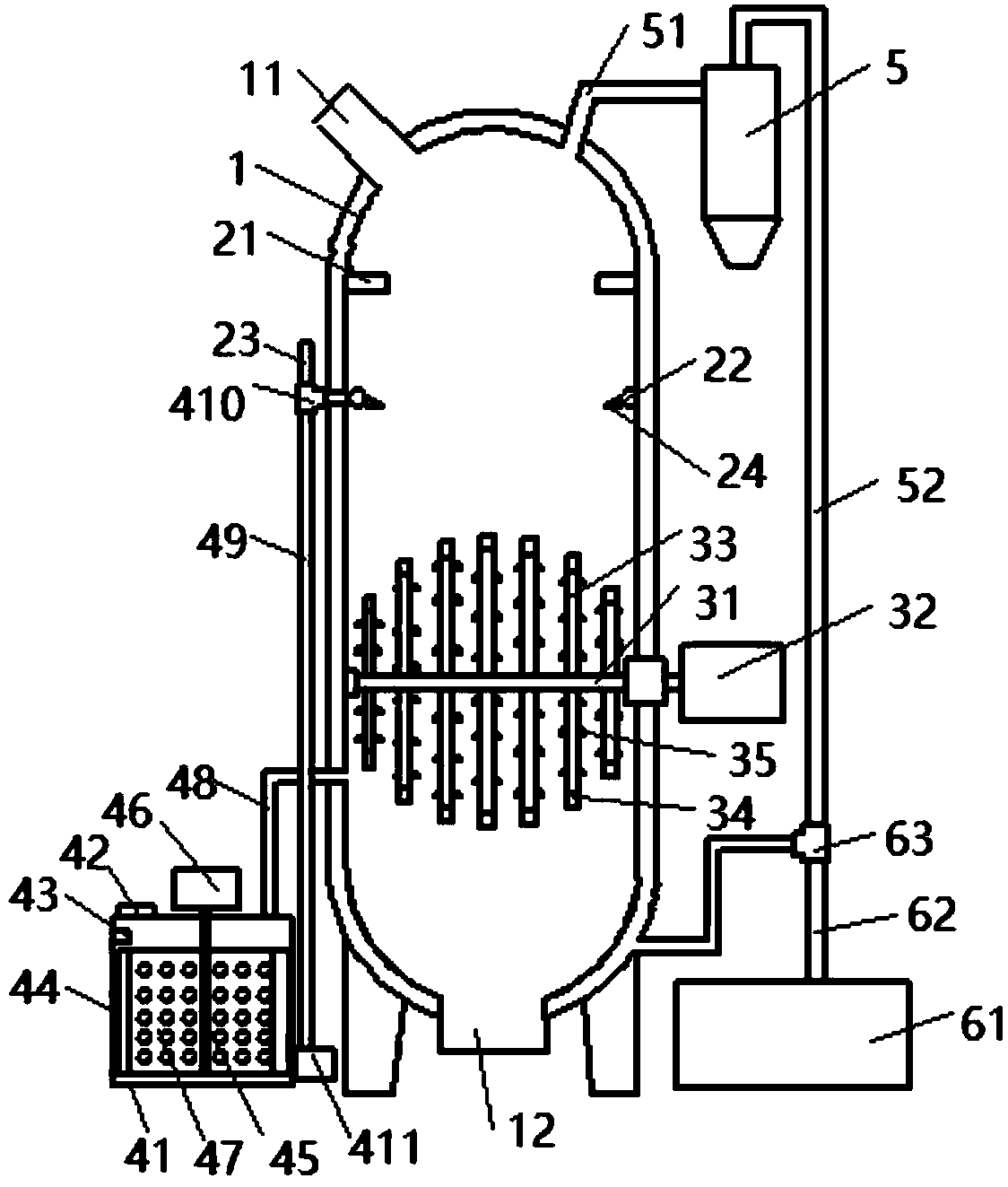

Anaerobic fermentation device

ActiveCN107916221AIncrease the area of actionPromote growth and reproductionBioreactor/fermenter combinationsBiological substance pretreatmentsCycloneCombustor

The invention discloses an anaerobic fermentation device. The anaerobic fermentation device comprises a tank, a carbonization assembly, an annular tube, sprayers, a stirring assembly, a circular culture assembly, cyclone separator and a controller, wherein the tank is provided with an interlayer tank; the carbonization assembly is arranged on the upper part of the tank and comprises a plurality ofcombustors; the combustors are arranged at intervals in the peripheral direction of the tank; the annular tube is arranged below the combustors; the sprayers are arranged on the annular tube at intervals and are downwards and obliquely arranged; the stirring assembly is arranged on the middle lower part of the tank; the circular culture assembly comprises a culture tank, a stirring shaft, a feeding tube and a discharging tube; a temperature sensor is arranged on one side of the upper part of the culture tank; an electric heating tube is arranged on one side of the middle of the culture tank;the stirring shaft is vertically arranged along the central axis of the culture tank and is driven to rotate through a motor; the stirring shaft is further provided with vertical stirring blades; a filter screen is arranged at the upper end of the feeding tube, the upper end of the feeding tube communicates with the lower part of the tank, and the lower end of the feeding tube communicates with the culture tank; and the upper end of the discharging tube communicates with the annular tube through a three-way valve, and the lower end of the discharging tube communicates with the bottom of the culture tank through a circulating pump. The anaerobic fermentation device has the advantages of high fermenting speed, high yield of methane and the like.

Owner:任栋

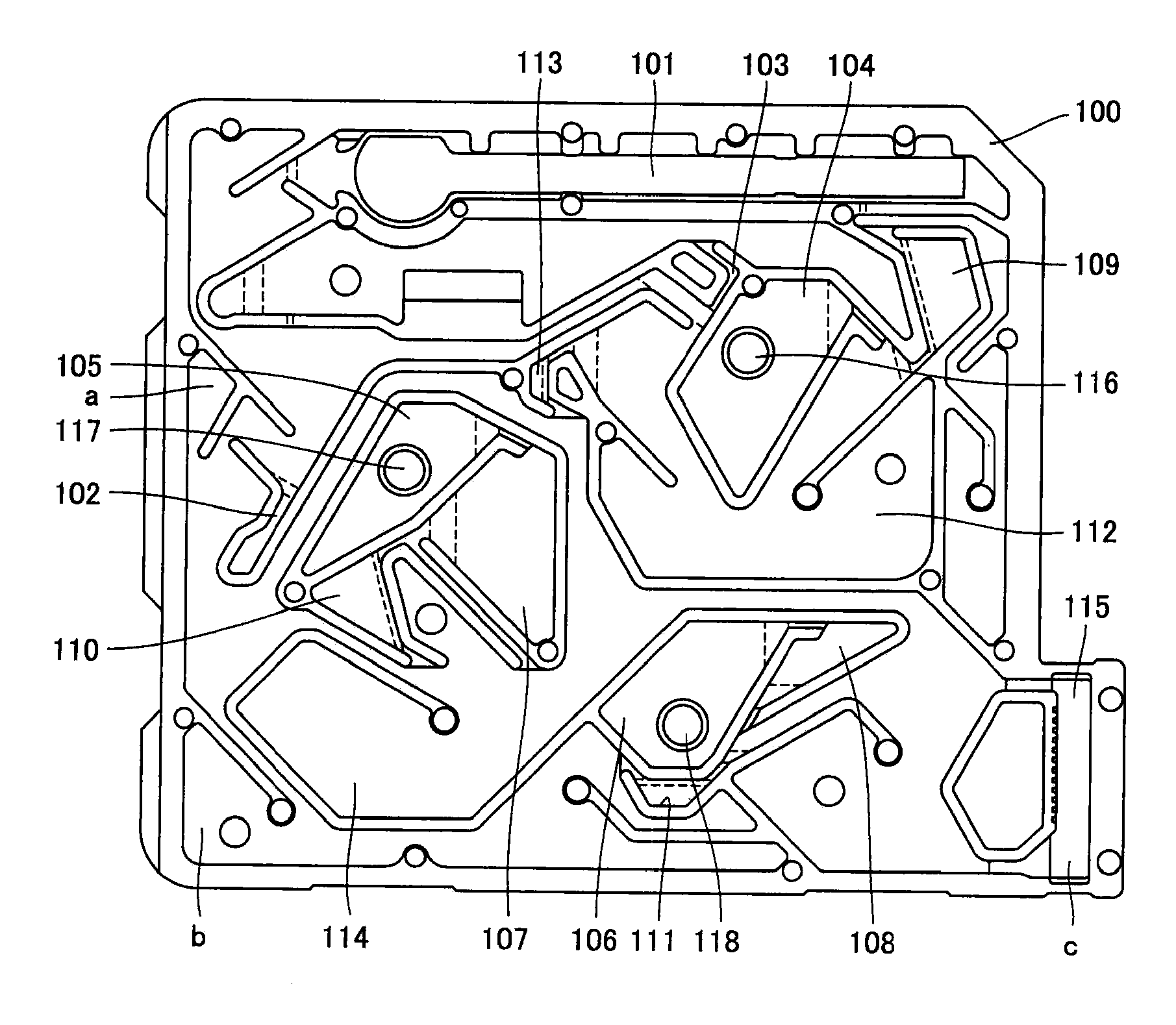

Intelligent mixing device and mixing method thereof

ActiveCN107774192AAvoid wastingReduce consumptionTransportation and packagingMixer accessoriesMachine controlControl system

The invention discloses an intelligent mixing device. The intelligent blending device comprises a pellet material blending system (A), an intelligent mixing system (C) and a material conveying belt (B) mounted between the blending system (A) and the intelligent mixing system (C), and is characterized in that the intelligent mixing system (C) comprises a mixing degree detecting instrument (namely,a pellet material mixing degree detector) (C1), a strong mixing control cabinet (C2) and a powerful mixing machine (C3); the mixing degree detecting instrument (C1) is arranged to a position near an outlet of the powerful mixing machine (C3); the mixing degree detecting instrument (C1) is electrically connected with the strong mixing control cabinet (C2); the strong mixing control cabinet (C2) iselectrically connected with the powerful mixing machine (C3); the strong mixing control cabinet (C2) is electrically connected with the blending system (A). The intelligent mixing device can detect the mixing degree indexes in real time and feed back the indexes to a powerful mixing machine control system and the blending system, so as to realize interlocking control, is based on the premise of guaranteeing the fresh pellet quality, reduces energy, equipment and bentonite consumption, and reduces the production cost.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

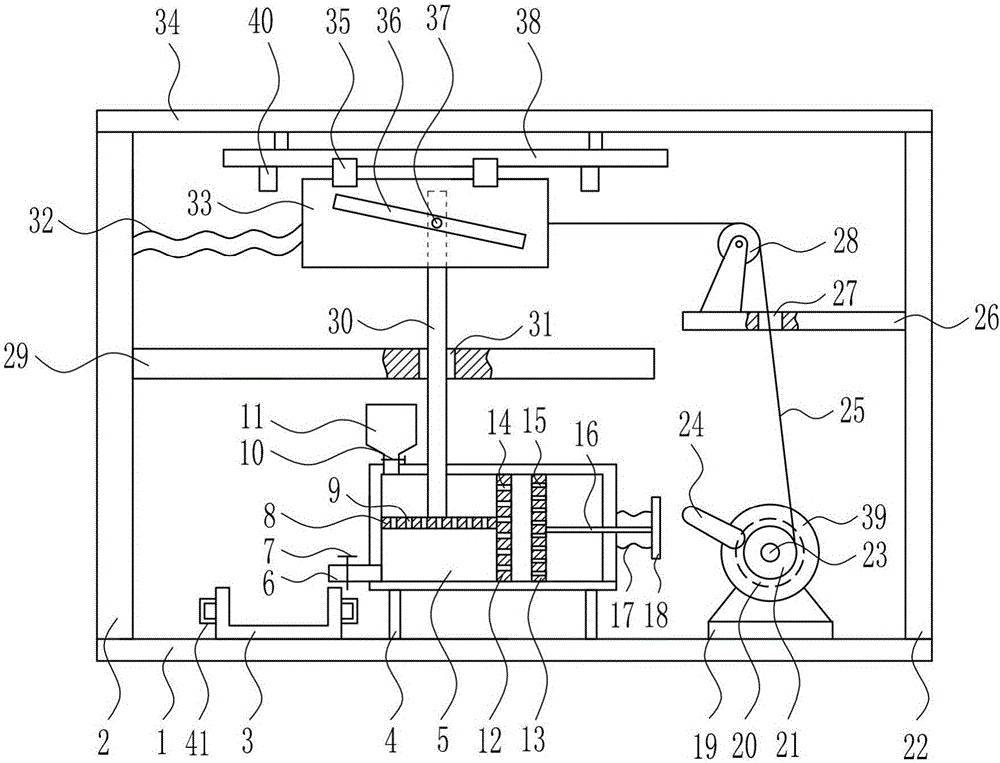

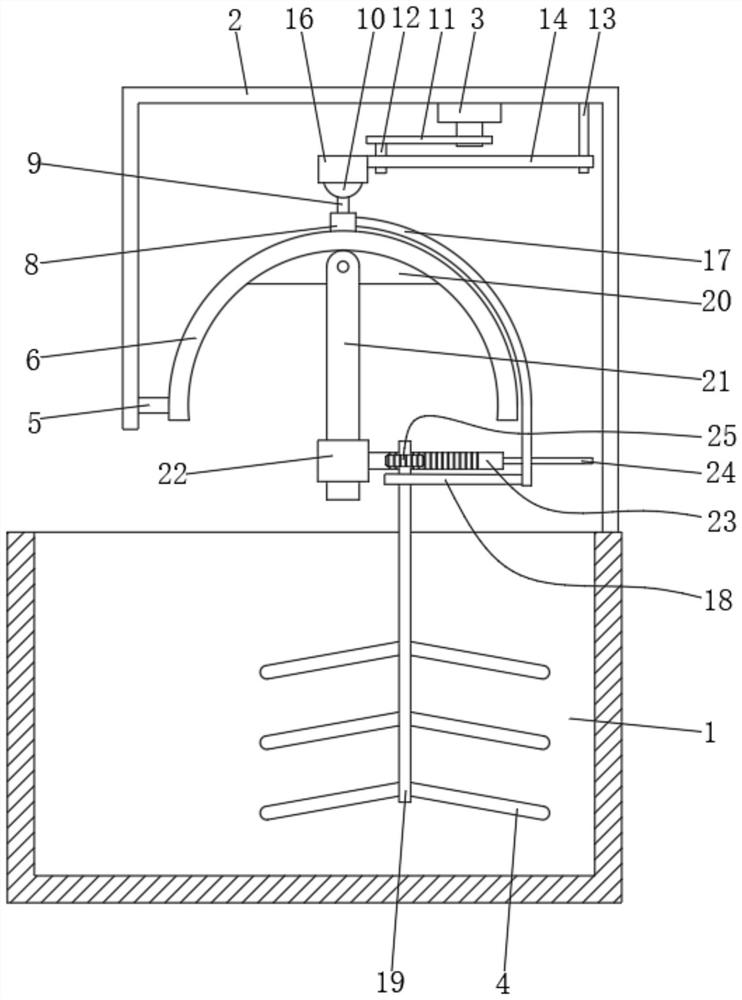

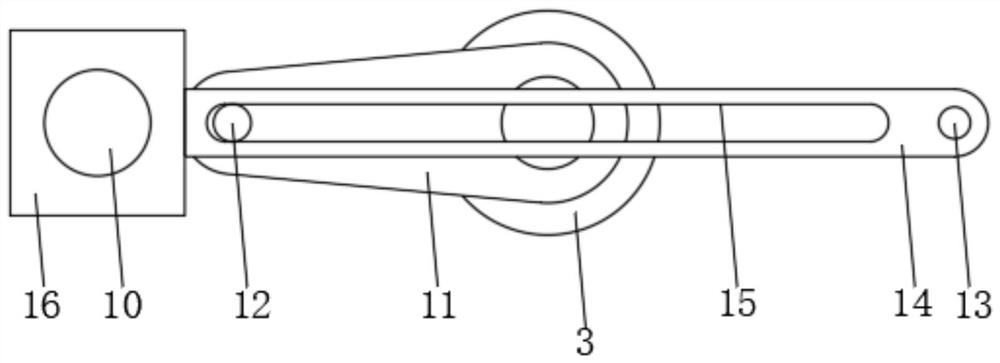

Coating stirring device and coating stirring method for building construction

InactiveCN112569854AWell mixedGood mixing efficiencyShaking/oscillating/vibrating mixersTransportation and packagingArchitectural engineeringSupport plane

The invention discloses a coating stirring device for building construction, belonging to the technical field of coating production. The coating stirring device comprises a box body, wherein the uppersurface of the box body is fixedly connected with a support frame, and the surface of the support frame is fixedly connected with a rotation driving source. The coating stirring device further comprises a transmission mechanism I. Through the driving of the rotation driving source and under the action of the transmission mechanism I, a stirring rod is driven to swing front and back. The coating stirring device also comprises a transmission mechanism II. Through the driving of the rotation driving source and under the co-action of the transmission mechanism I the transmission mechanism II, thestirring rod is driven to swing left and right while swinging front and back. According to the coating stirring device, the stirring rod can be driven to swing front and back and swing left and rightthrough a single driving source, and meanwhile, reciprocating autorotation is realized, so the mixing efficiency of coating stirring is greatly improved, and the device overcomes the problem that stirring efficiency is low in the prior art since existing coating stirring modes normally adopt stirring rods rotating in a single direction and a stirring mode is single.

Owner:陈昕昳

Gas-liquid mixing device

InactiveUS20100044891A1Effective installationGood mixing efficiencyLighting and heating apparatusUsing liquid separation agentLiquid tankProduct gas

This invention relates to a gas-liquid mixing device, forming a safety valve, designed capable of being incorporated into a gas-cleaning installation including a liquid tank (4), an inlet (1) for gas to be cleaned and an outlet (7) through which the gas flow is evacuated. It is characterized in that it has:a tube (2) sliding around the gas inlet (1) and including a peripheral float (8) located in its lower end and designed capable of floating in said tank (4), said sliding tube (2) being open in its lower portion, in order to draw liquid from said tank (4) by a venturi effect and to create a mist in a pressure-relief zone (5);a mixing chamber (6) interposed between said sliding tube (2) and said outlet (7), and designed capable of conveying the flow of said mist towards the bottom of said tank (4).

Owner:WINDDROP

Humidification agitator

InactiveCN106807284AEven by forceWon't breakRotary stirring mixersMixer accessoriesEngineeringDrive motor

The invention discloses a humidification agitator which comprises a vertically arranged cylindrical agitating barrel and a driving motor, wherein the agitating barrel comprises an inner barrel and an outer barrel; the inner barrel is arranged in the outer barrel in a sleeving manner, and the inner barrel and the outer barrel are concentrically arranged; springs are arranged between the inner barrel and the outer barrel; the inner barrel is an elastic rubber barrel; an agitating shaft is vertically arranged at the center of the inner barrel; agitating blades are arranged on the agitating shaft; the upper and lower ends of the agitating shaft are both fixed on the agitating barrel through bearings; the lower end of the agitating shaft penetrates through the agitating barrel; a driven belt wheel is arranged at a position, which is located outside the agitating barrel, on the agitating shaft; the driving motor is arranged below the agitating barrel; a driving belt wheel matched with the driven belt wheel is arranged on a rotating shaft of the driving motor; a material feeding opening is formed in the upper end of the agitating barrel; a material outlet is formed in the lower end of the agitating barrel. The humidification agitator has the advantages that the agitating efficiency is high, the structure is simple, and the blades are difficult to break and damage.

Owner:HENGYANG SHUANGYAN TRANSPORTATION MACHINERY

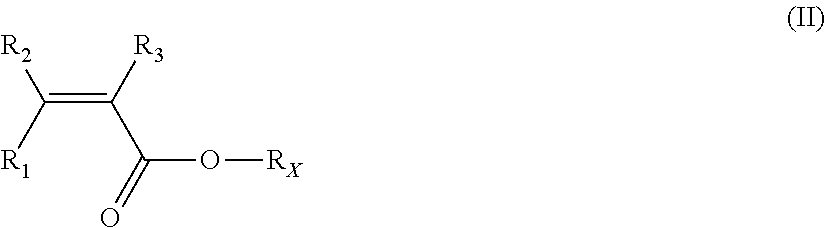

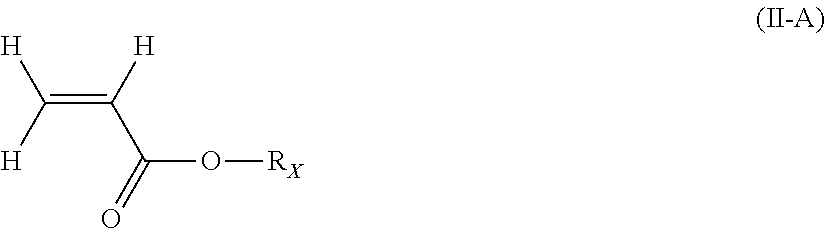

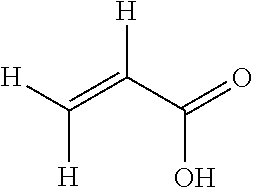

Dense fluoropolymer film

ActiveUS20150349309A1Good mixing efficiencyHigh strengthFinal product manufacturePrimary cellsHydrogen atomPolymer science

The present invention pertains to a process for the manufacture of a dense film, said process comprising, preferably consisting of the following steps: a) providing a solid composition [composition (C)] comprising, preferably consisting of: at least one vinylidene fluoride (VDF) fluoropolymer comprising one or more carboxylic acid functional end groups [polymer (F)], at least one poly(alkylene oxide) (PAO) of formula (I): HO—(CH2CH RAO)n—RB, wherein RA is a hydrogen atom or a C1-C5 alkyl group, RB is a hydrogen atom or a —CH3 alkyl group and n is an integer comprised between 2000 and 40000, preferably between 4000 and 35000, more preferably between 11500 and 30000, and optionally, at least one inorganic filler [filler (I)]; and b) processing said composition (C) in molten phase thereby providing a dense film having a thickness of from 5 μm to 30 μm. The present invention also pertains to the dense film provided by said process and to use of said dense film as dense separator in electrochemical devices.

Owner:SOLVAY SOLEXIS

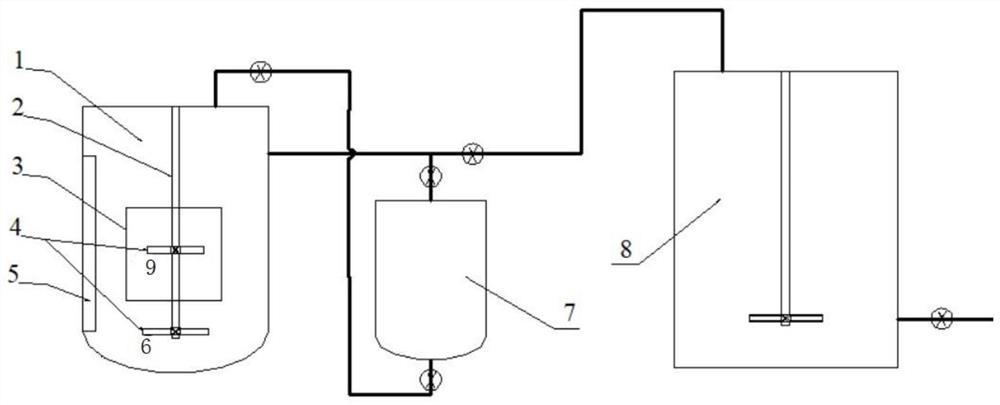

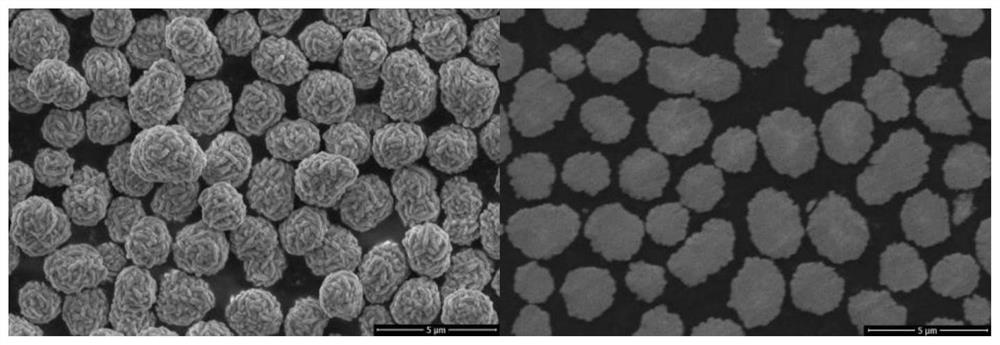

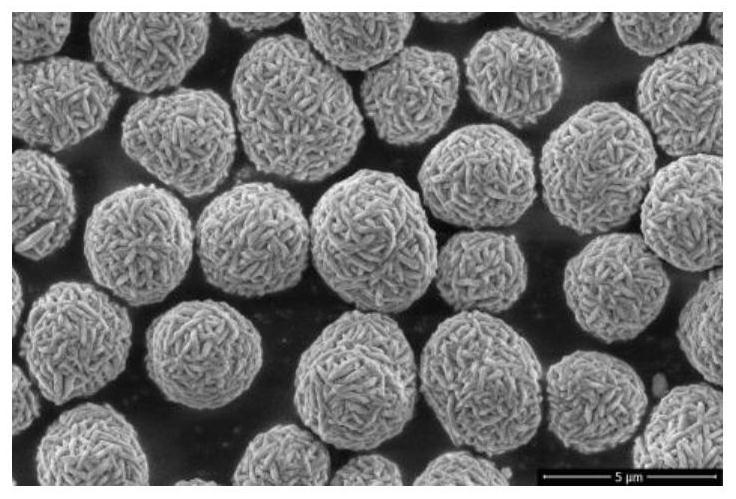

Preparation device and preparation method of high-tap-density ternary precursor material

PendingCN113896251AImproved shear distributionDense particlesCell electrodesSecondary cellsCrystallographyPhysical chemistry

The invention discloses a preparation device of a high-tap-density ternary precursor material, which comprises a seed crystal reaction kettle (1), a thickener (7) and a seed crystal tank (8), the seed crystal reaction kettle is respectively connected with the thickener and the seed crystal tank, and a pipeline connected between the seed crystal reaction kettle and the seed crystal tank is connected with the thickener; a stirrer (2) and a baffle (5) are arranged in the seed crystal reaction kettle, and a guide cylinder (3) is arranged on the inner wall of the seed crystal reaction kettle (1). The preparation method comprises the following steps: preparing a mixed sulfate solution of nickel, cobalt and manganese; preparing a base solution and introducing protective gas; adding a mixed sulfate solution, industrial liquid alkali and ammonia water to the height of an upper-layer paddle, and starting a stirrer; extracting supernate by the thickener, returning the supernate to the seed crystal reaction kettle, and overflowing the supernate to the seed crystal tank; and introducing seed crystal particles into the seed crystal reaction kettle for continuous reaction to obtain a material with a target particle size, and treating the material to obtain the high-tap-density ternary precursor material. The prepared material is high in tap density and good in particle uniformity.

Owner:JINGMEN GEM NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com