Optimized and passive micromixer of asymmetrical wall surface structure

A micro-mixer, asymmetric technology, applied in mixers, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult to process microfluidic chips, difficulties in active micro-mixers, and complex mixer components. , to achieve the effect of easy mass production, configuration and assembly, little influence of experimental environment interference, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

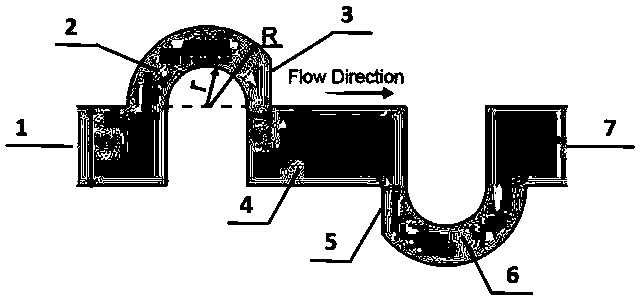

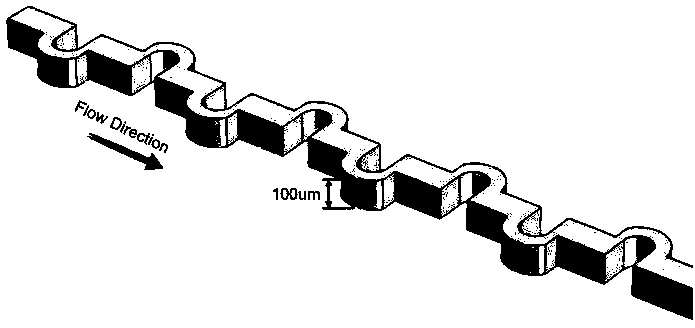

[0015] The present invention researches and designs a kind of optimized passive asymmetrical wall structure micro-mixer, this micro-mixer adopts PDMS as material, makes SU8 mold through process steps such as photolithography, developing; Then the PDMS material mixed with curing agent Apply on the mold, heat and cure and release the PDMS negative mold; then apply the PDMS material mixed with the curing agent on the PC sheet, heat and cure it, and then release the mold to obtain a PDMS flat plate; the PDMS negative mold is bonded to the flat plate The obtained microstructure can obtain the passive asymmetric wall structure micromixer.

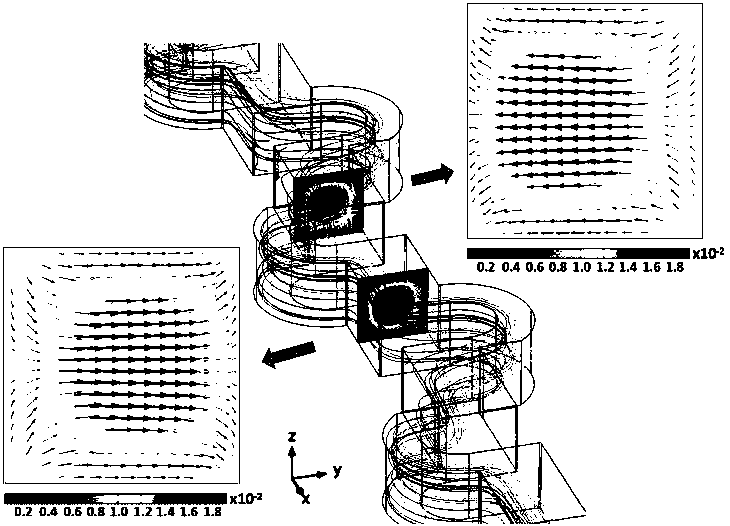

[0016] The passive asymmetric wall structure micro-mixer model was established using open source finite element software, and the high-efficiency performance of the mixer for reagent mixing was further confirmed through numerical calculations.

[0017] In the micro-mixer, two fluids flow in from the inlet at the same time. In the initial straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com