Preparation device and preparation method of high-tap-density ternary precursor material

A technology for preparing devices and precursors, which is applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve the problems of reducing the effective volume of reactors, promote orderly assembly, improve stability and energy density, and improve shear cut distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

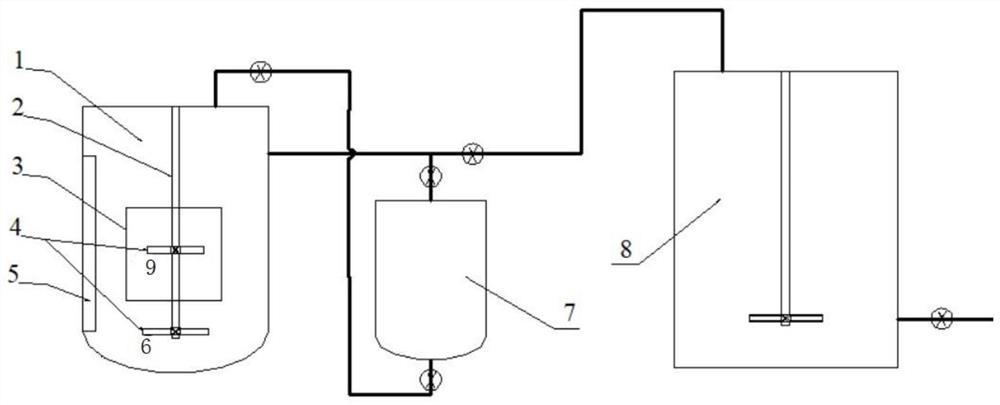

preparation example Construction

[0023] A preparation method for a preparation device of a high-tap ternary precursor material, comprising the following steps:

[0024] Step (1): prepare a mixed salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate; the molar ratio of nickel ion, cobalt ion, and manganese ion in the mixed salt solution is x:y:(100-x-y), wherein, 60≤x ≤98, 0≤y≤20, the sum of the concentration of nickel ions, cobalt ions and manganese ions in the mixed salt solution is 1mol / L-3mol / L; the industrial concentration of 8mol / L-12mol / L is used Liquid caustic soda is used as the precipitant solution, and ammonia water with a concentration of 0.5mol / L-2mol / L is used as the complexing agent solution.

[0025] Step (2): Prepare the bottom liquid in the seed crystal reactor 1, and pass protective gas into the seed crystal reactor 1; the bottom liquid is prepared from a precipitant solution and a complexing agent solution, and the pH of the bottom liquid is 11-12.5 , the concentration of ...

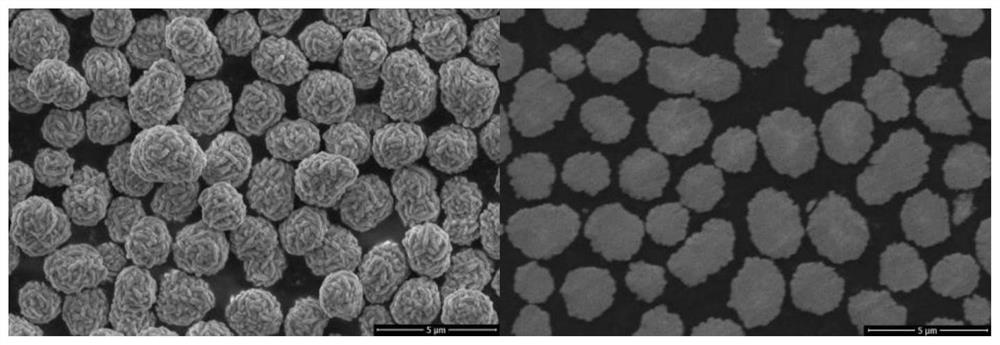

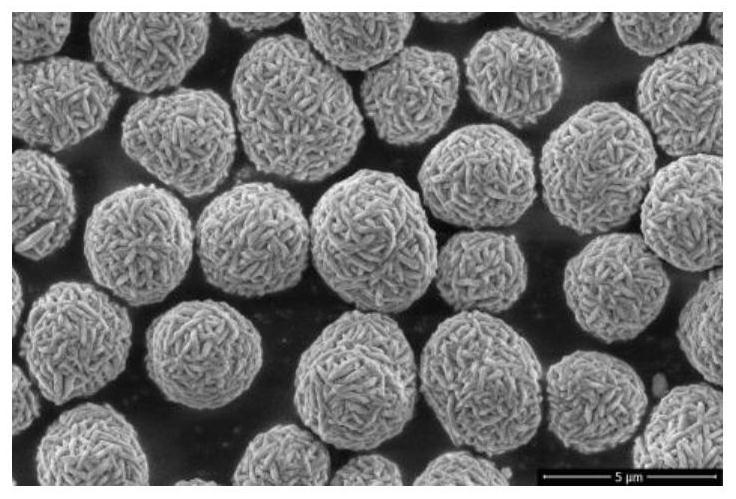

Embodiment 1

[0030] Prepare the mixed salt solution of nickel sulfate, cobalt sulfate, manganese sulfate; the mol ratio of nickel ion, cobalt ion, manganese ion in the mixed salt solution is 8:1:1, the concentration of nickel ion, the concentration of cobalt ion in the mixed salt solution, The sum of the concentrations of manganese ions is 2mol / L; industrial liquid caustic soda with a concentration of 8mol / L is used as the precipitant solution, and ammonia water with a concentration of 1mol / L is used as the complexing agent solution.

[0031] Prepare the bottom liquid in the seed crystal reactor 1, and pass protective gas into the seed crystal reactor 1; The concentration is 5g / L-10g / L, and the bottom liquid temperature is 40°C-50°C.

[0032] Add the mixed salt solution at a flow rate of 600L / h, the precipitant solution at a flow rate of 110L / h-120L / h, and the complexing agent solution at a flow rate of 45L / h-50L / h into the upper paddle in the seed crystal reactor 1 The co-precipitation r...

Embodiment 2

[0037] Prepare the mixed salt solution of nickel sulfate, cobalt sulfate, manganese sulfate; the mol ratio of nickel ion, cobalt ion, manganese ion in the mixed salt solution is 88:6:6, the concentration of nickel ion, the concentration of cobalt ion in the mixed salt solution, The sum of the concentrations of manganese ions is 2mol / L; industrial liquid caustic soda with a concentration of 8mol / L is used as the precipitant solution, and ammonia water with a concentration of 1mol / L is used as the complexing agent solution.

[0038] The bottom liquid is prepared in the seed crystal reactor 1, and a protective gas is introduced into the seed crystal reactor 1; the bottom liquid is prepared from a precipitant solution and a complexing agent solution, and the pH of the bottom liquid is 11.2-11.8, and ammonia water in the bottom liquid The concentration is 8g / L-13g / L, and the bottom liquid temperature is 45°C-55°C.

[0039] Add the mixed salt solution at a flow rate of 500L / h, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com