Copper salt alkalescent electroplating solution for PCB hole metallization and application of copper salt alkalescent electroplating solution

A hole metallization and weak alkaline technology, which is applied in the fields of electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of strong dependence on additives and difficult control, and achieve high dispersion ability of plating solution, high current efficiency, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

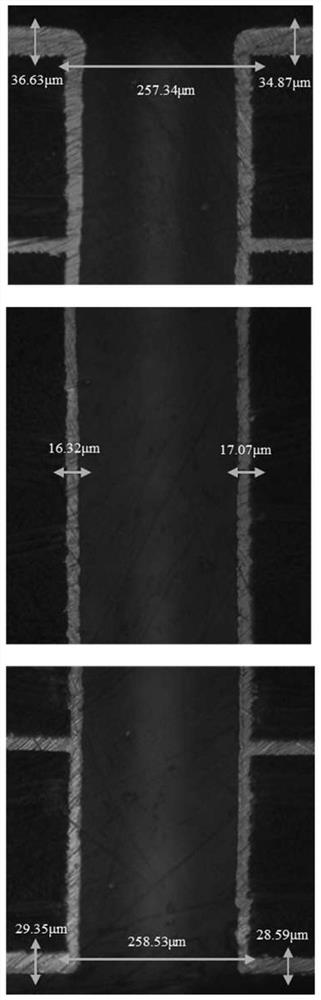

Image

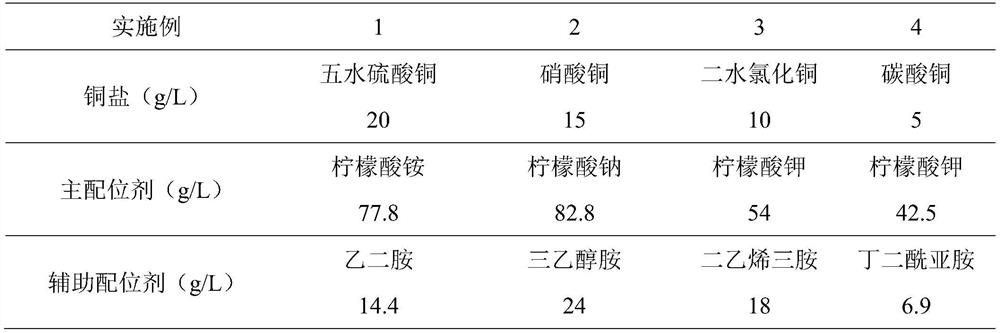

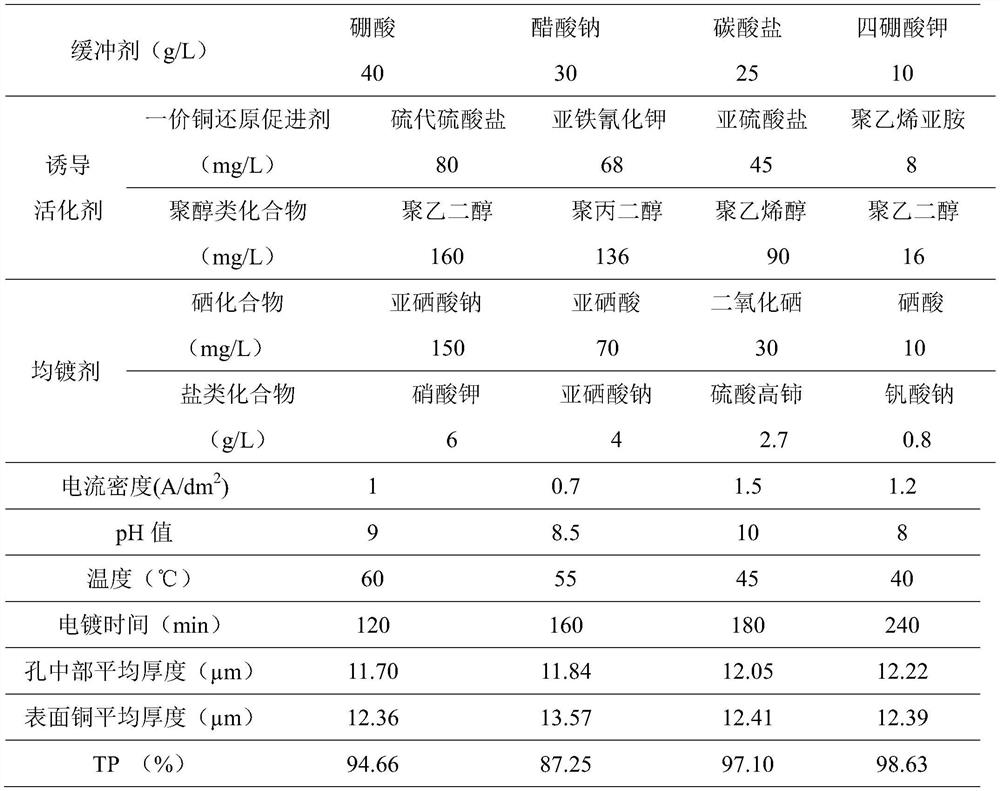

Examples

Embodiment 1

[0039] The specific preparation process of copper salt weak alkaline electroplating solution for PCB hole metallization is as follows (take the preparation of 1L as an example):

[0040] (1) Accurately weigh the main complexing agent and the auxiliary complexing agent, dissolve them in 400mL deionized water, then add and dissolve copper salts with an accurately weighed mass of 5-20g to obtain solution A;

[0041] (2) Accurately weigh the pH buffer and dissolve it in 200mL deionized water to obtain solution B;

[0042] (3) Accurately weigh leveling agent, dissolve in 100mL deionized water, obtain solution C;

[0043] (4) Accurately weigh the monovalent copper reduction accelerator and the polyalcohol compound, dissolve them in 200mL deionized water, and obtain solution D;

[0044] (4) Add solutions B, C, and D to solution A, and adjust the pH value in the range of 8.0-10.0 with water, and simultaneously set the volume to 1 L to obtain the copper salt weakly alkaline electropla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com