Energy-saving, environmental-friendly, clean and high-efficient compound floatation agent

An energy-saving and environmentally friendly flotation agent technology, which is applied in flotation, solid separation, etc., can solve the problems of large amount of flotation agent and narrow application range of flotation agent, and achieve high flotation efficiency, sufficient effect, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

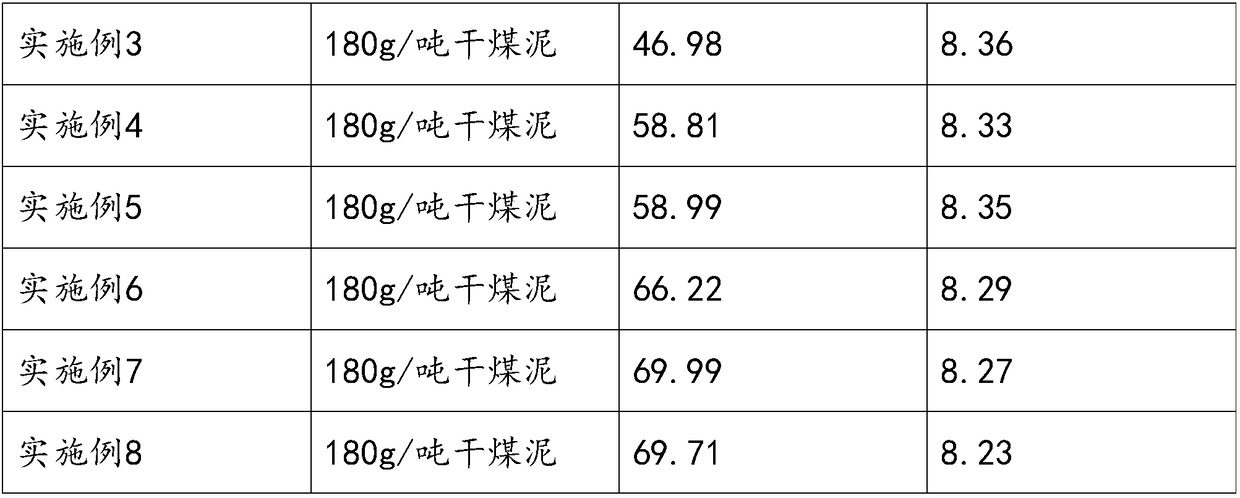

Examples

Embodiment 1

[0016] An energy-saving, environmentally friendly, clean and efficient composite flotation agent, which is composed of the following parts by weight: 40 parts of terpineol oil, 25 parts of ether alcohol oil, 35 parts of aromatic oil, 30 parts of alkane oil, 40 parts of kerosene, naphthene 40 parts of oil, 30 parts of alkylbenzene, 5 parts of methyl palmitate, 6 parts of monoalkenyl succinimide, 2.5 parts of caustic alkali.

[0017] The preparation method of the above-mentioned energy-saving, environment-friendly, clean and efficient composite flotation agent, according to parts by weight, takes 40 parts of terpineol oil, 25 parts of ether alcohol oil, 35 parts of aromatic oil, 30 parts of paraffin oil, 40 parts of kerosene, and 40 parts of naphthenic oil 40 parts, 30 parts of alkylbenzene, 5 parts of methyl palmitate, 6 parts of monoalkenyl succinimide, 2.5 parts of caustic alkali, stirring for 25 minutes, and then standing for 14 minutes to prepare.

Embodiment 2

[0019] An energy-saving, environment-friendly, clean and efficient composite flotation agent, which is composed of the following parts by weight: 30 parts of terpineol oil, 20 parts of ether alcohol oil, 30 parts of aromatic oil, 20 parts of alkane oil, 30 parts of kerosene, naphthene 30 parts of oil, 20 parts of alkylbenzene, 3 parts of alkylphenol polyoxyethylene ether, 3 parts of ε-caprolactone, 2 parts of QHS-3 sodium calcium.

[0020] The preparation method of the above-mentioned energy-saving, environment-friendly, clean and efficient composite flotation agent, according to parts by weight, takes 30 parts of terpineol oil, 20 parts of ether alcohol oil, 30 parts of aromatic oil, 20 parts of alkane oil, 30 parts of kerosene, and 30 parts of naphthenic oil 30 parts, 20 parts of alkylbenzene, 3 parts of alkylphenol polyoxyethylene ether, 3 parts of ε-caprolactone, 2 parts of QHS-3 sodium calcium, stirred for 20 minutes, and then stood for 10 minutes to prepare.

Embodiment 3

[0022] An energy-saving, environmentally friendly, clean and efficient composite flotation agent, which is composed of the following parts by weight: 50 parts of terpineol oil, 30 parts of ether alcohol oil, 40 parts of aromatic oil, 40 parts of alkane oil, 50 parts of kerosene, naphthene 50 parts of oil, 40 parts of alkylbenzene, 8 parts of sodium laureth sulfate, 8 parts of calcium petroleum sulfonate, and 3 parts of hydroxylamine hydrochloride.

[0023] The preparation method of the above-mentioned energy-saving, environment-friendly, clean and efficient composite flotation agent, according to parts by weight, takes 50 parts of terpineol oil, 30 parts of ether alcohol oil, 40 parts of aromatic oil, 40 parts of alkane oil, 50 parts of kerosene, and 50 parts of naphthenic oil 50 parts, 40 parts of alkylbenzene, 8 parts of sodium lauryl alcohol polyoxyethylene ether sulfate, 8 parts of calcium petroleum sulfonate, 3 parts of hydroxylamine hydrochloride, stirring for 35 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com