Renewable green biomass fuel

A biomass fuel, green technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of insufficient combustion of fuel, low thermal efficiency of boiler, large blackness of flue gas, etc., achieve full combustion, high calorific value, combustion low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

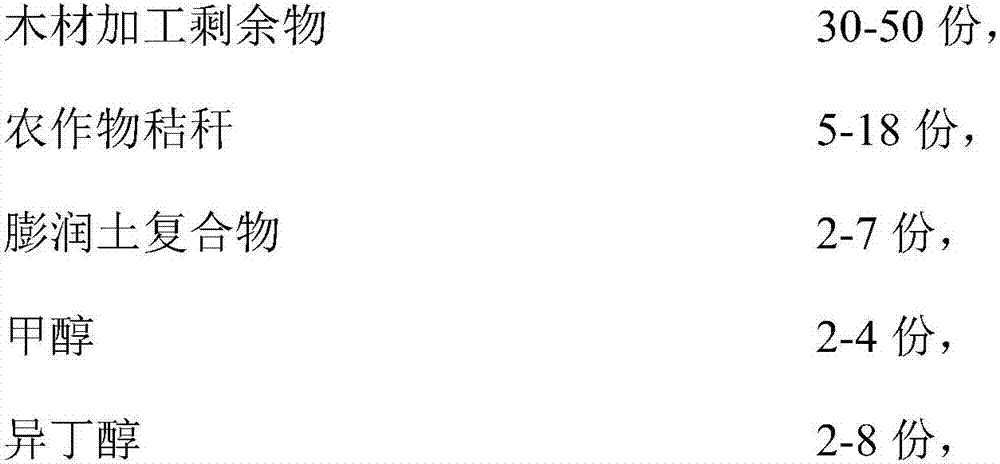

[0017] A kind of renewable green biomass fuel that the present invention proposes, its raw material comprises by weight:

[0018]

[0019]

Embodiment 2

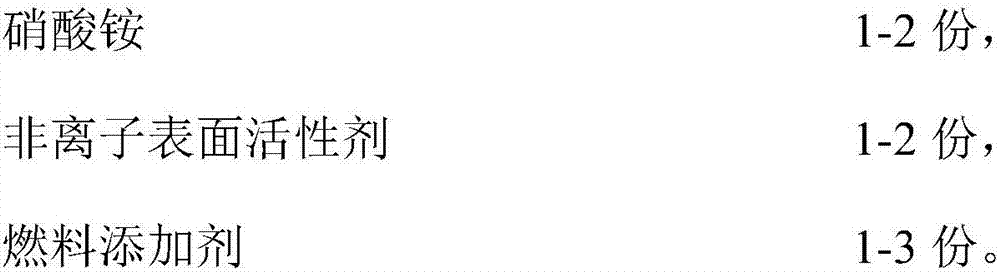

[0021] A kind of renewable green biomass fuel that the present invention proposes, its raw material comprises by weight:

[0022]

[0023] The fuel additive is composed of quicklime, magnesite and high clay.

[0024] The bentonite composite is prepared by the following process: mix and stir bentonite and water, adjust the pH value of the system to 3.4-4 with sulfuric acid solution, add polydimethyldiallylammonium chloride and stir, filter, wash, add potassium carbonate, water Continue to stir, filter, wash, dry to constant weight, grind, add soybean protein and water and mix evenly, add sodium hydroxide at room temperature and stir evenly, add maleic anhydride, heat up and stir to obtain a bentonite compound.

Embodiment 3

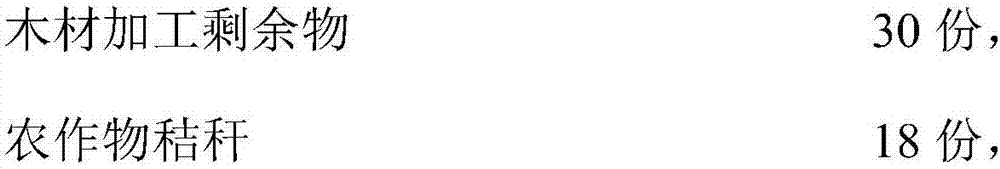

[0026] A kind of renewable green biomass fuel that the present invention proposes, its raw material comprises by weight:

[0027]

[0028] The fuel additive comprises by weight: 2 parts of quicklime, 3 parts of magnesite and 4 parts of high clay.

[0029] The bentonite composite is prepared by the following process: mix bentonite and water for 3 hours at a stirring speed of 700 r / min, adjust the pH of the system to 3.4-4 with a sulfuric acid solution with a concentration of 13 wt %, add polydimethyldiallyl chloride Stir with ammonium chloride for 35 hours, filter, wash, add potassium carbonate and water and continue stirring for 3 hours, the stirring temperature is 80°C, filter, wash, dry at 150°C to constant weight, grind, add soybean protein and water to mix well, add sodium hydroxide at room temperature Stir evenly, add maleic anhydride, raise the temperature to 124°C, and stir at a speed of 500r / min for 40min to obtain a bentonite composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com