Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Minimize pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

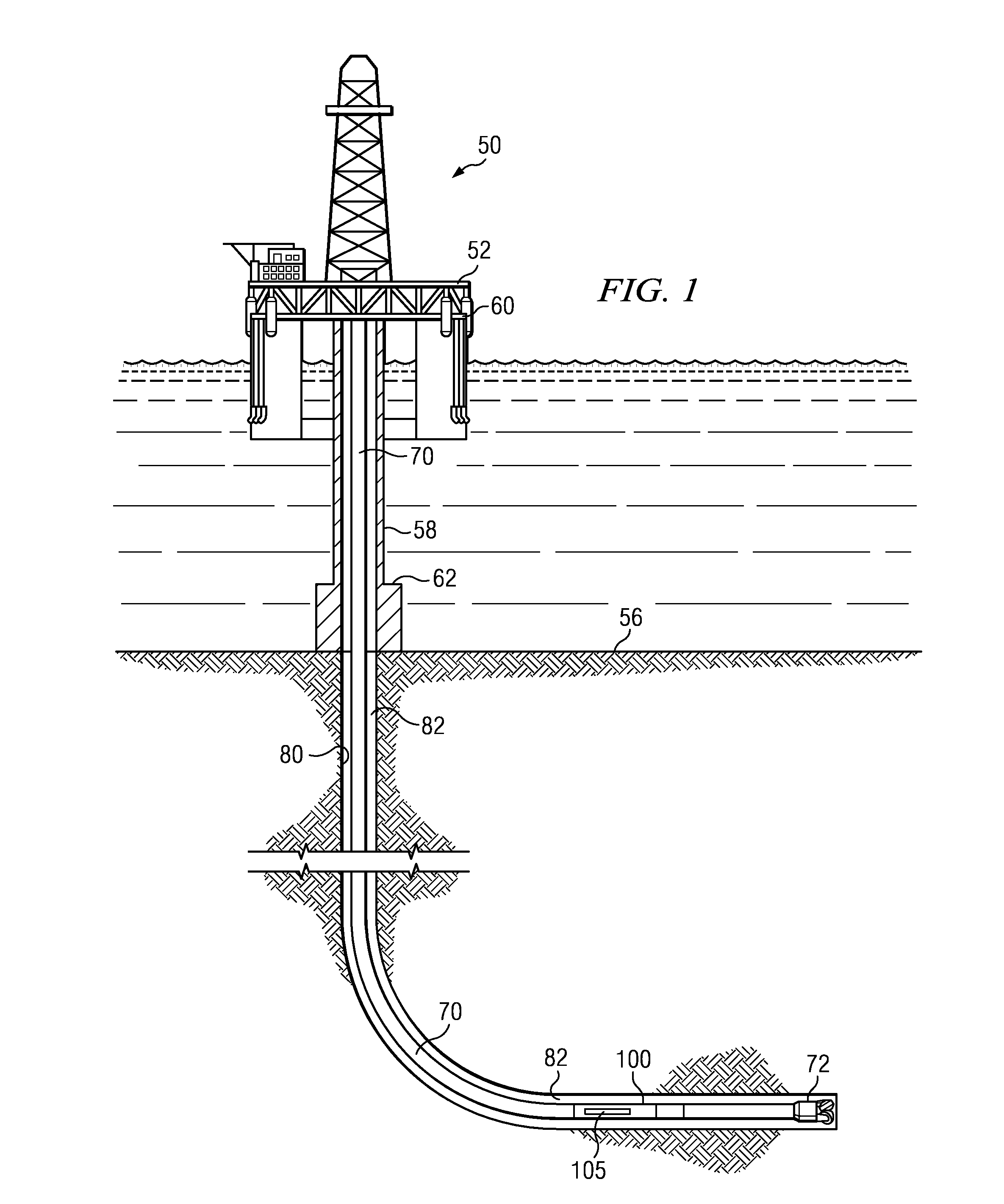

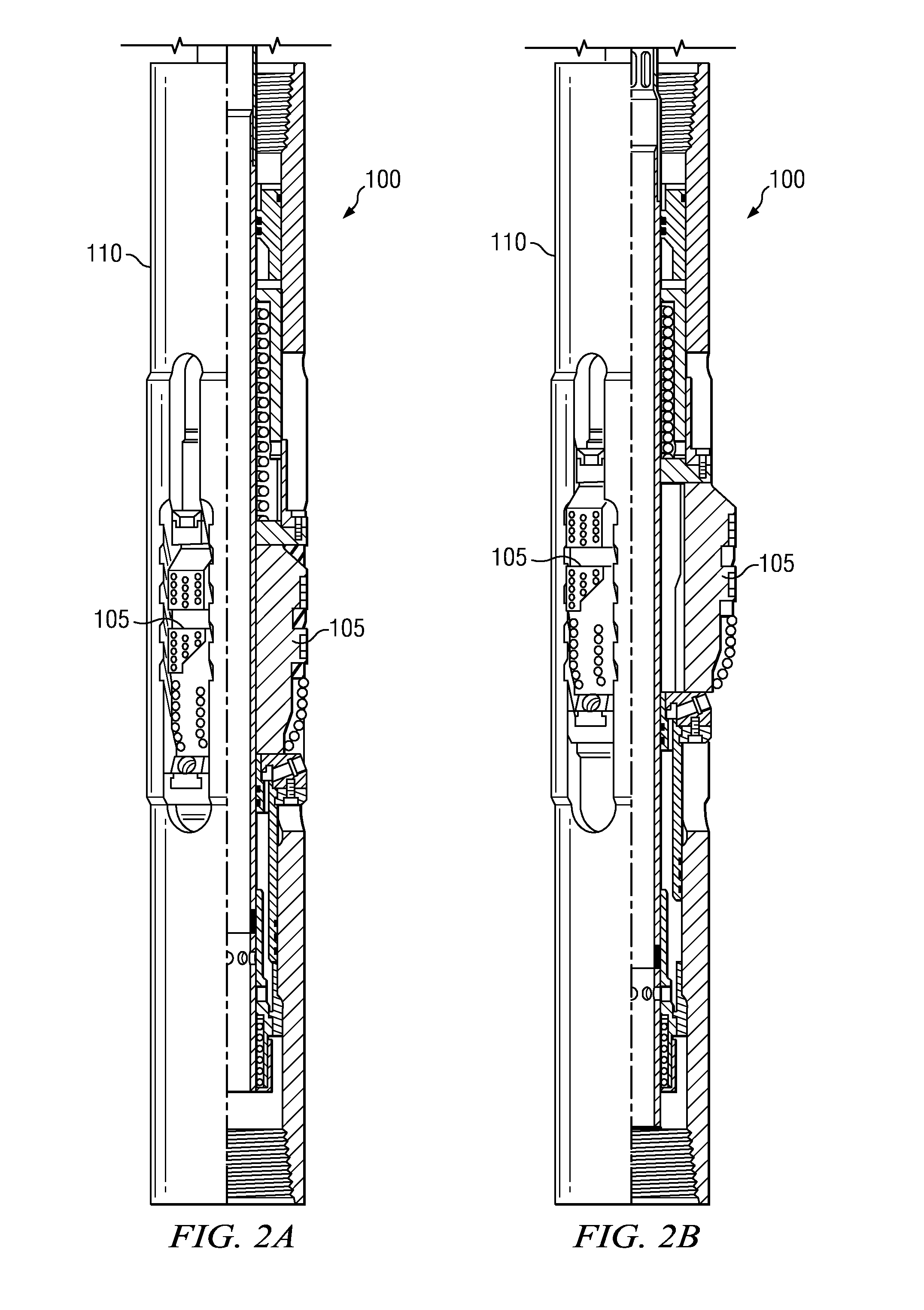

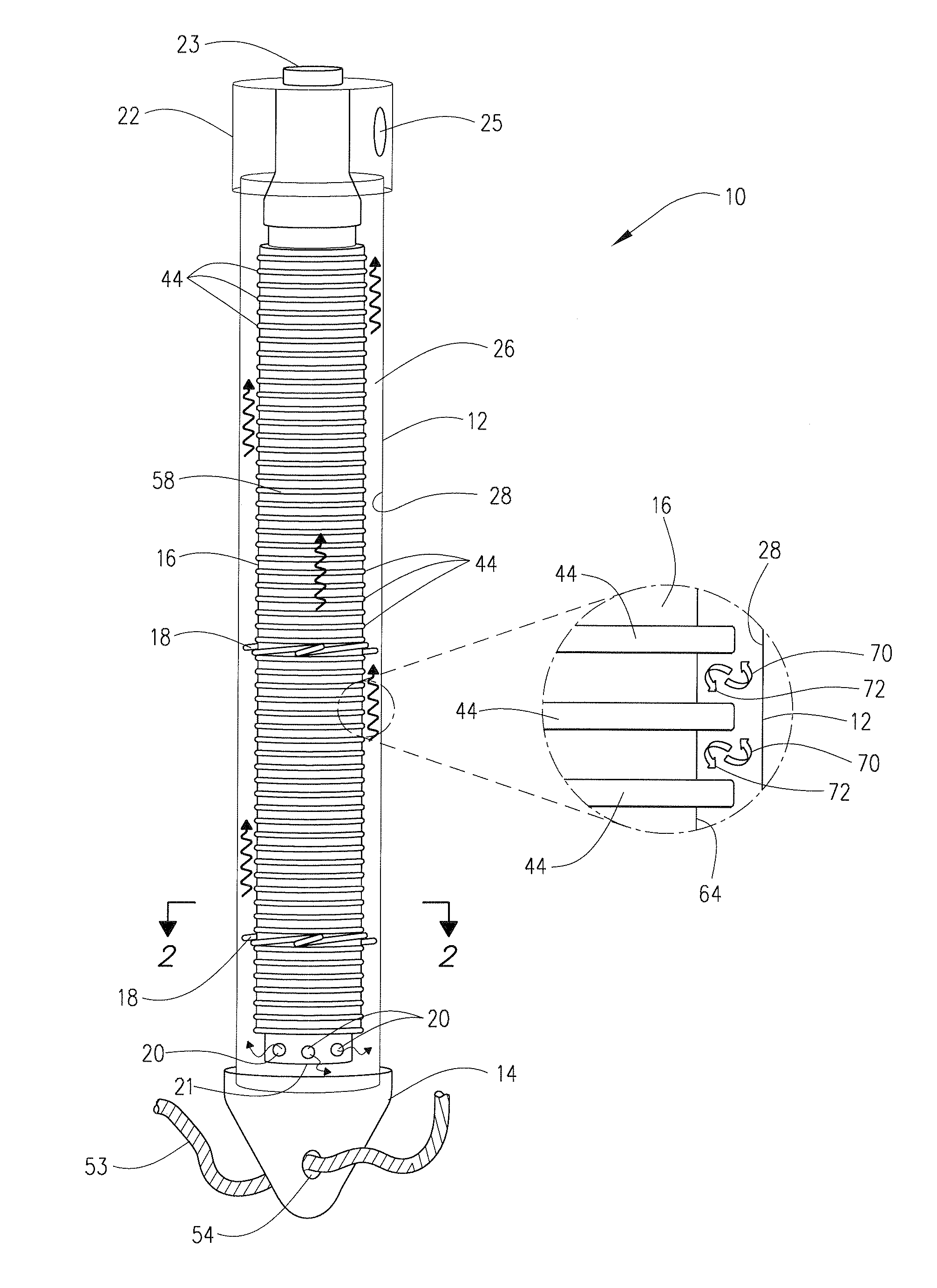

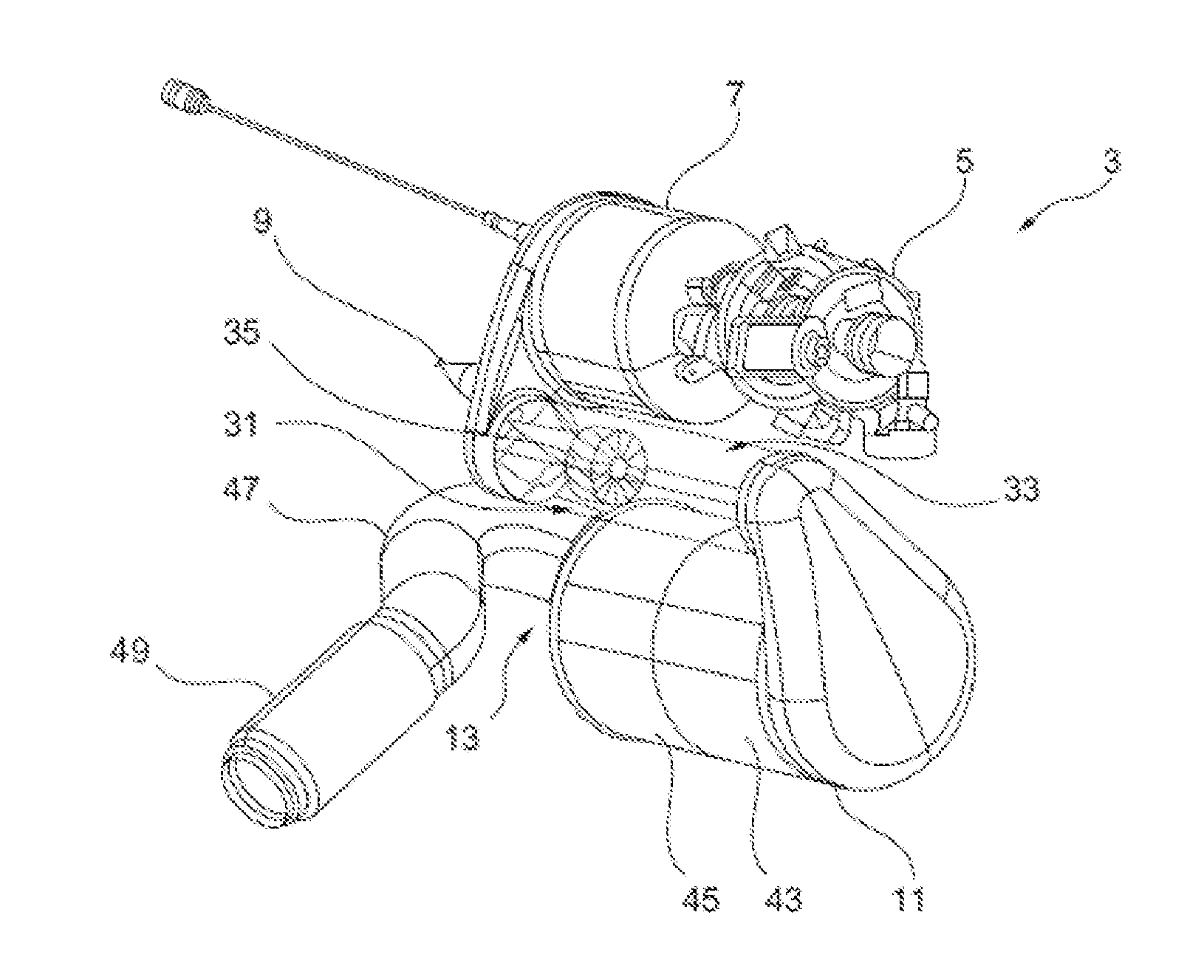

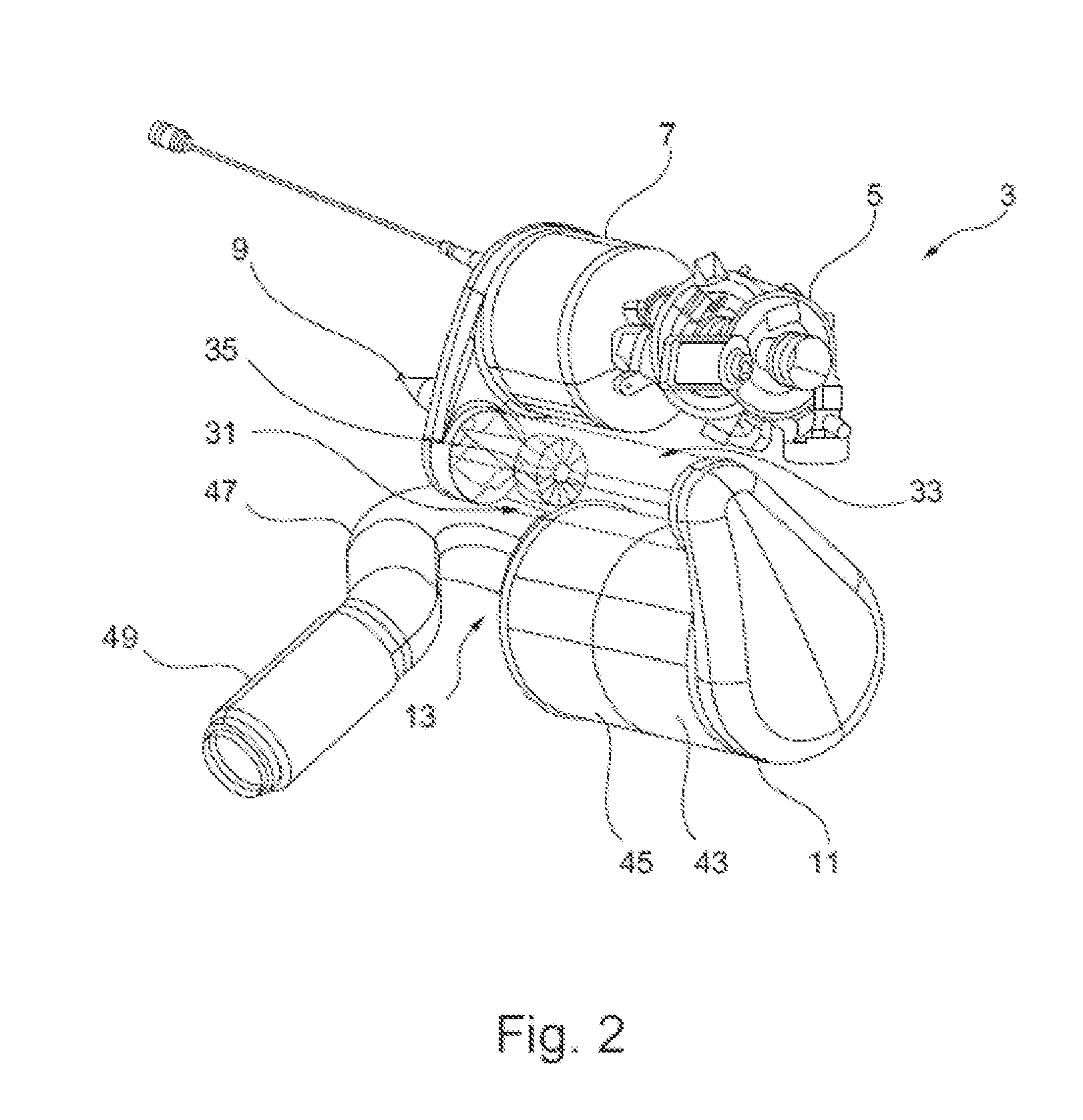

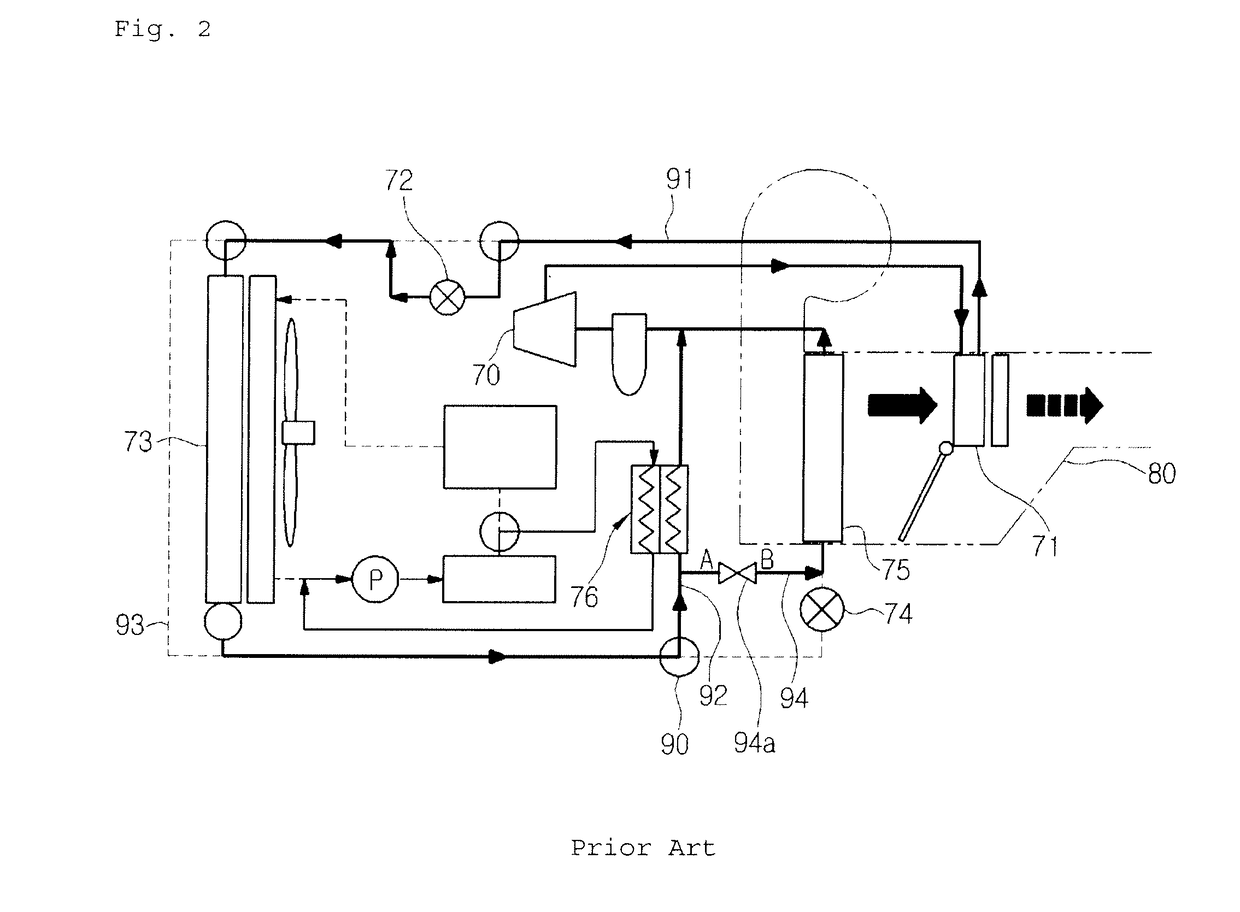

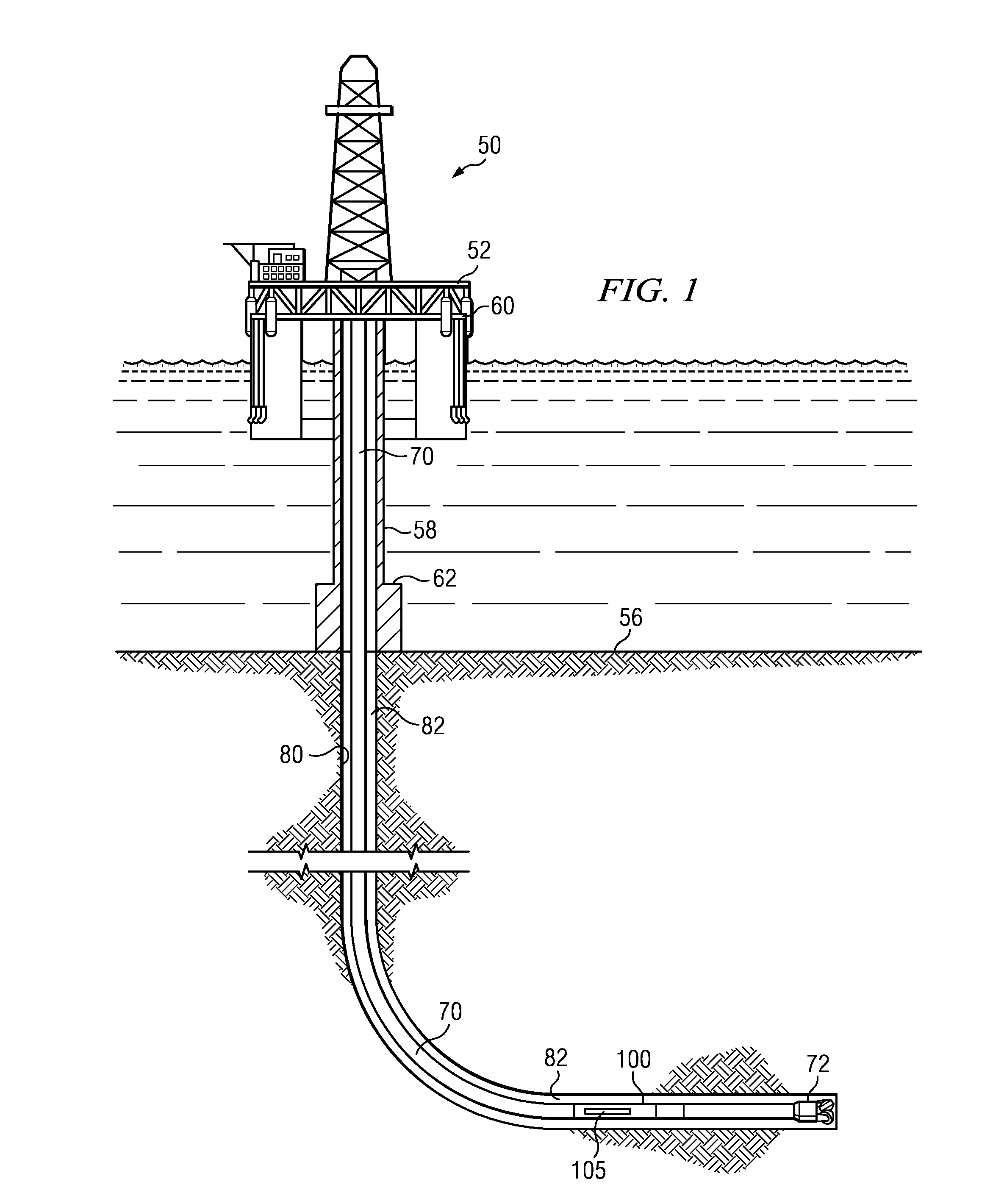

Hydraulic Actuation of a Downhole Tool Assembly

ActiveUS20110284233A1Improve reliabilityHighly serviceableDrill bitsFluid removalWell drillingReciprocating motion

A downhole tool assembly is configured for repeated and selective hydraulic actuation and deactuation. A piston assembly is configured to reciprocate axially in a downhole tool body. The piston assembly reciprocates between a first axial position and second and third axial positions that axially oppose the first position. The downhole tool is actuated when the piston assembly is in the third axial position and deactuated when the piston assembly is in either of the first or second axial positions. A spring member biases the piston assembly towards the first axial position while drilling fluid pressure in the tool body urges the piston assembly towards the second and third axial positions. Downhole tool actuation and deactuation may be controlled from the surface, for example, via cycling the drilling fluid flow rate.

Owner:SMITH INT INC

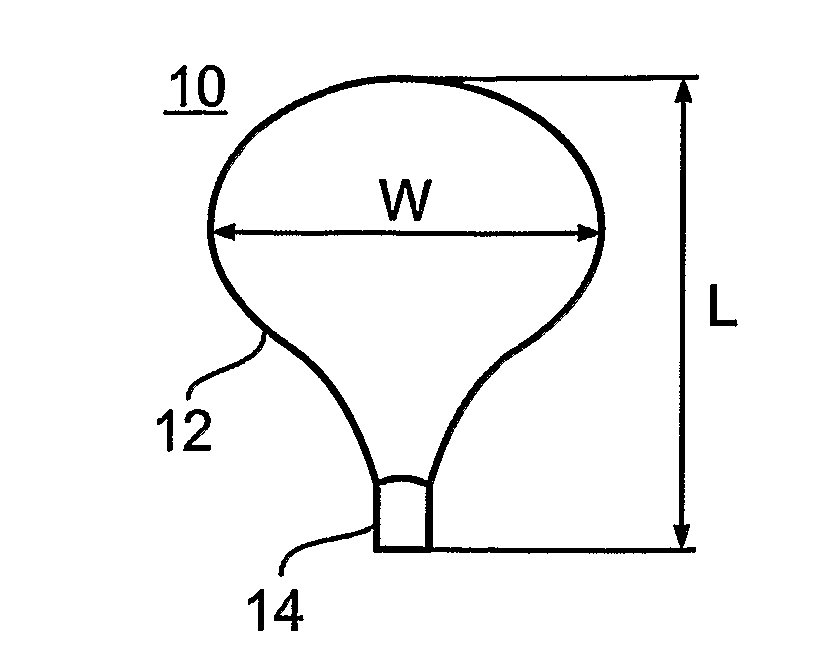

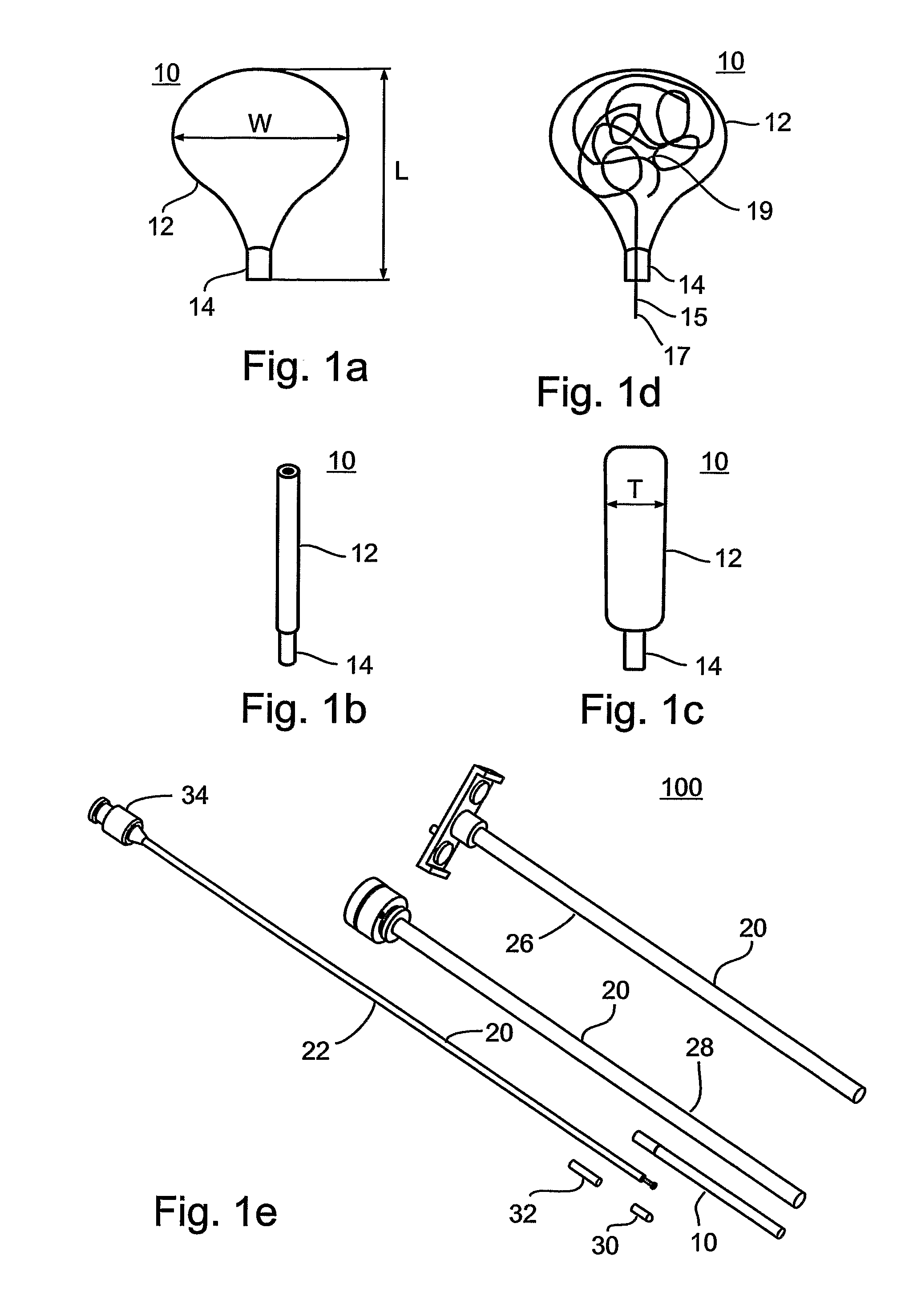

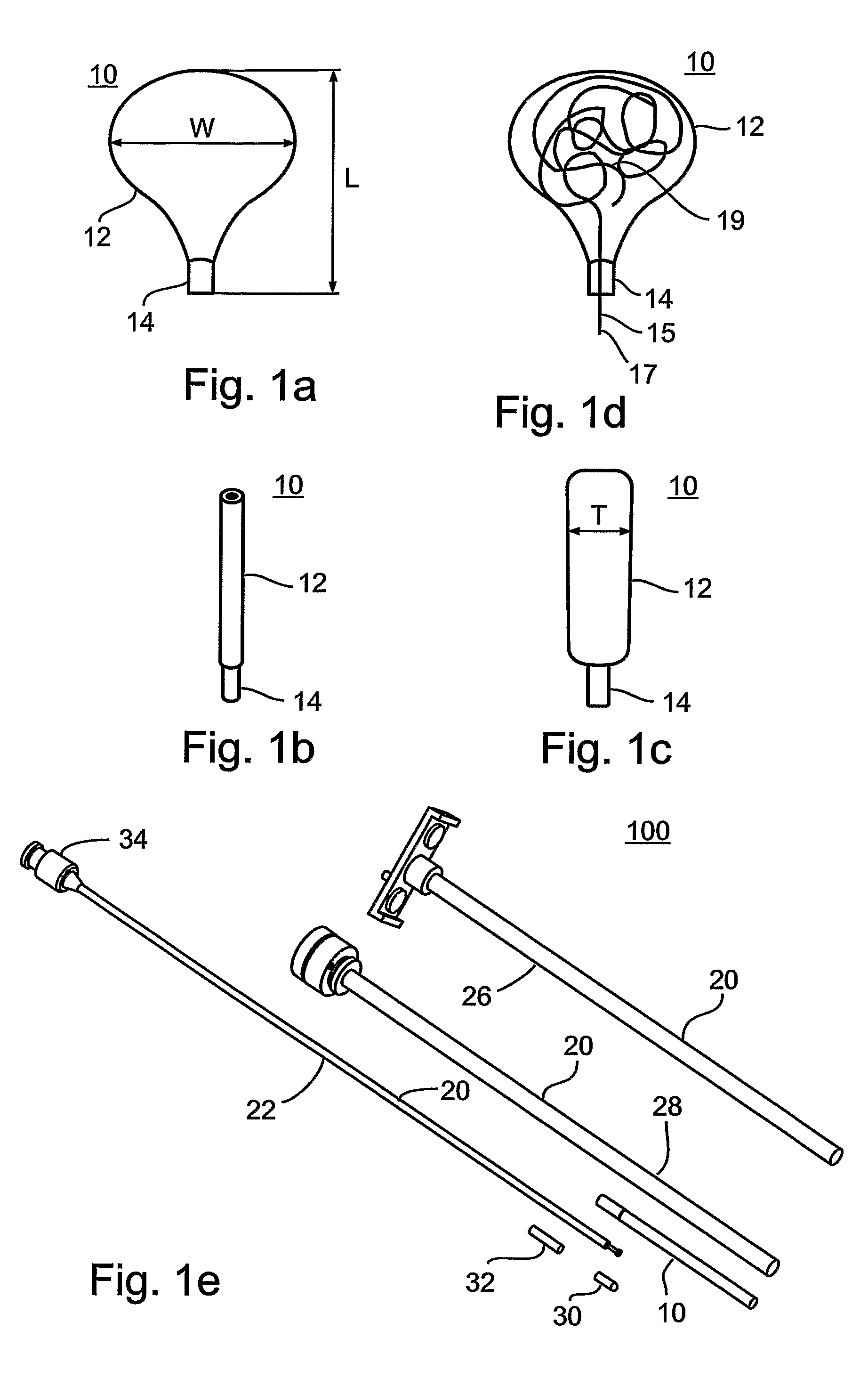

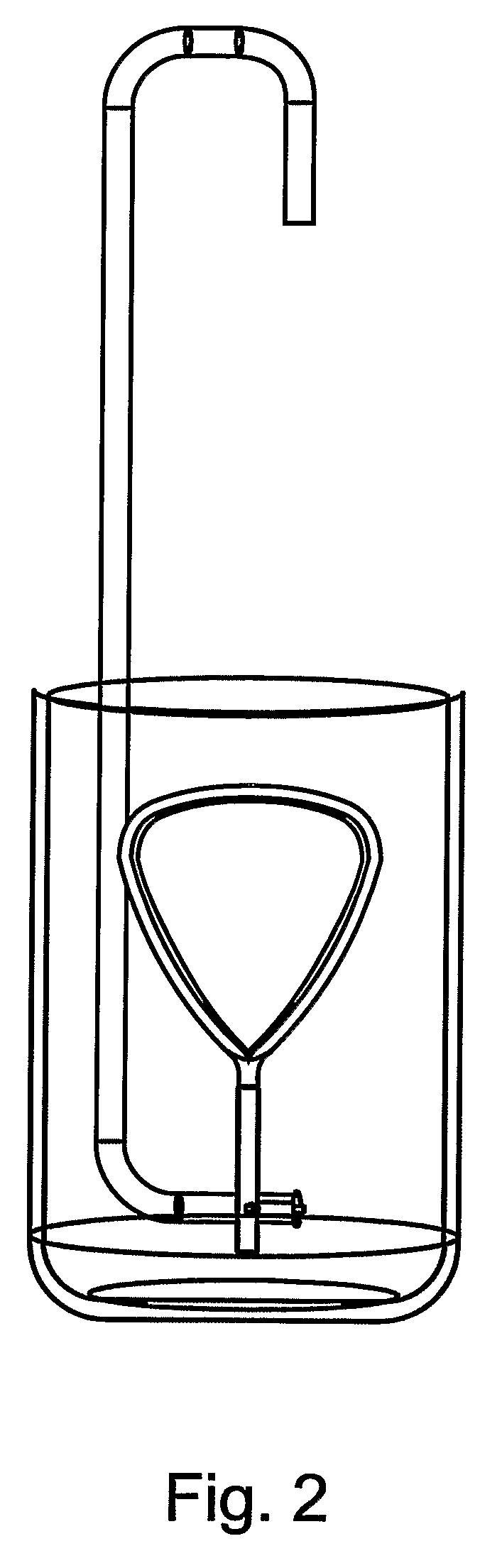

Device System And Method For Tissue Displacement Or Separation

ActiveUS20080033471A1Minimize injuryMinimize contactBalloon catheterDiagnosticsBiomedical engineering

Owner:BIOPROTECT

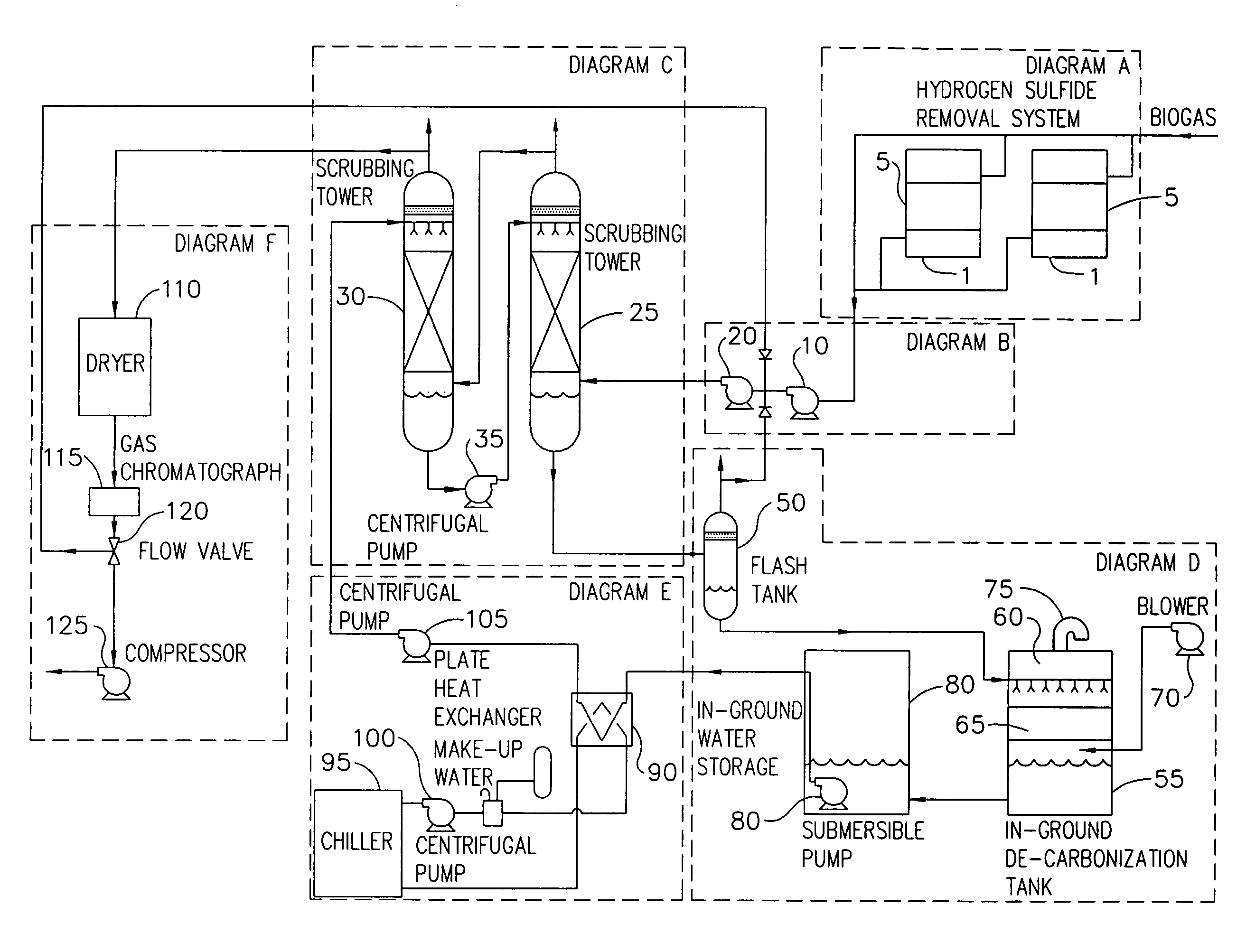

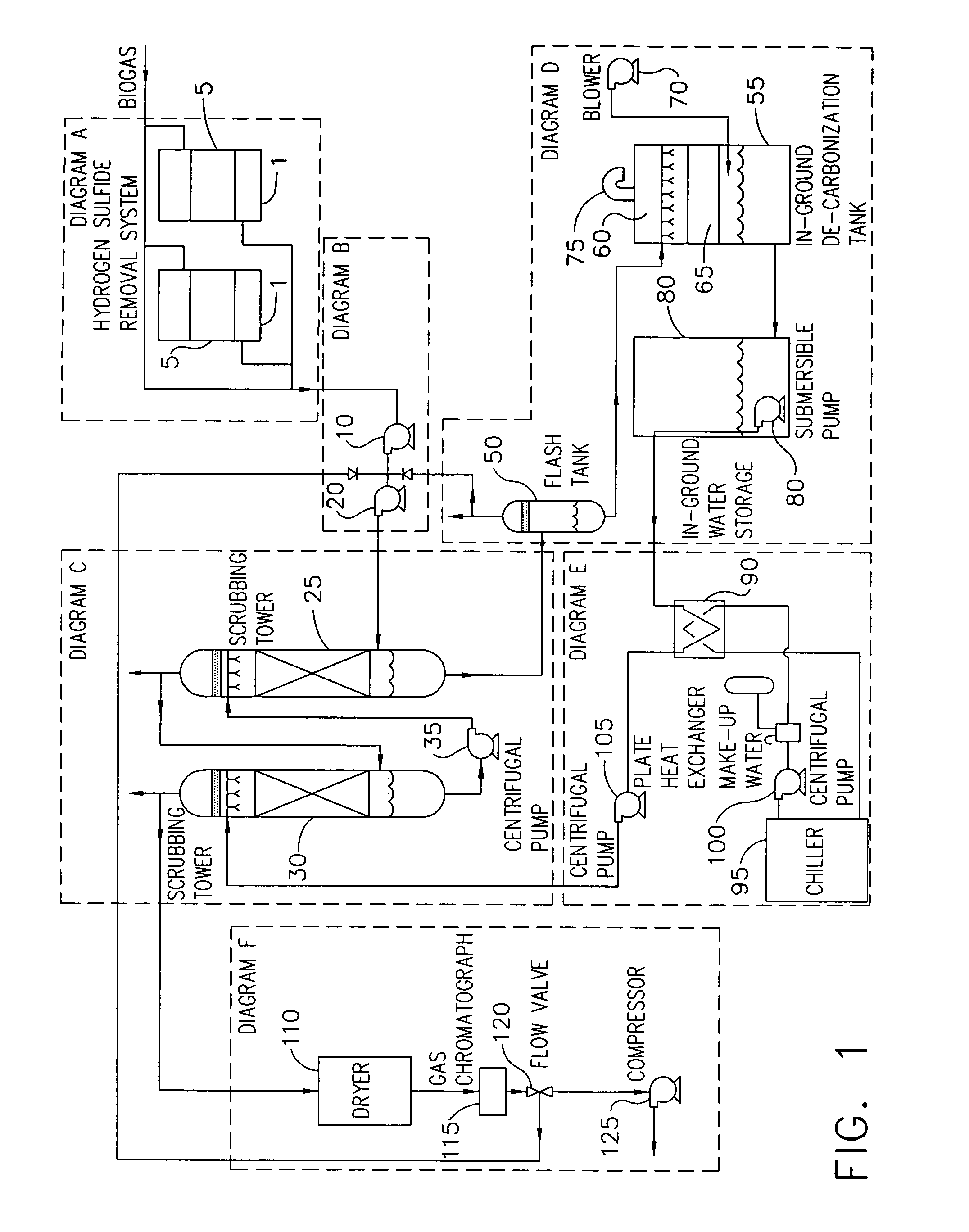

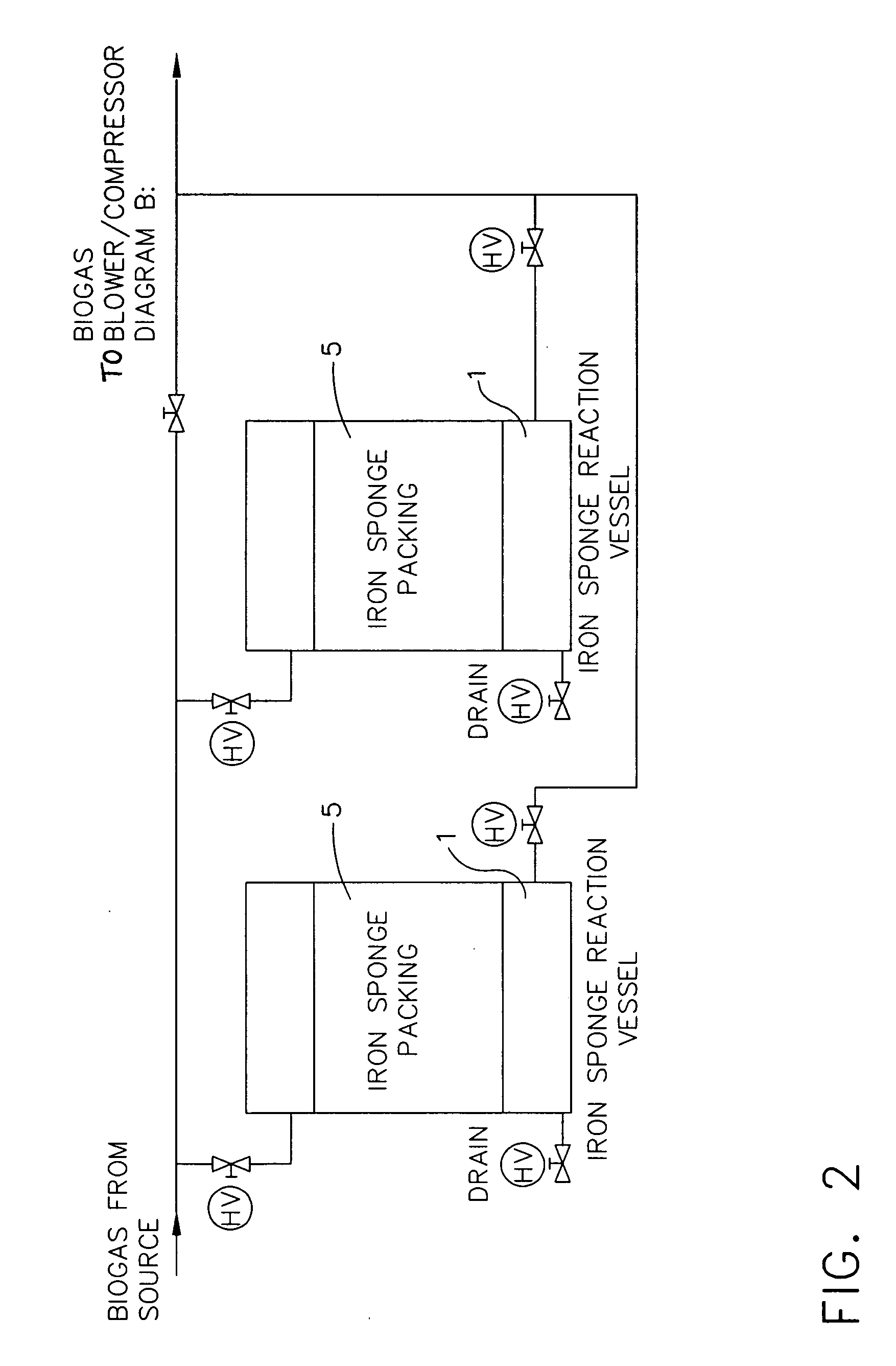

Process for converting biogas to a pipeline grade renewable natural gas

InactiveUS20080134754A1Minimize biogas pressureMinimize water flowGas treatmentSamplingExtreme weatherWater flow

A process purifies raw biogas created from a renewable source into pipeline grade natural gas and / or D.O.T. specification, or other predetermined specification, gas. The automated scrubbing processed employed and the particular attributes of the system allow the system to function under extreme weather conditions by employing specific tools to control the temperature of the scrubbing water to allow for efficient and effective removal of the carbon dioxide gas. The system also employs specific measures to use recycled scrubbing water, thus eliminating the need for excessive water generally needed to economically employ this type of scrubbing process. The recycled water is continuously de-carbonated to allow the recycled water stream to effectively scrub the raw biogas. Treated gas from the process is then dried, and compressed for introduction into storage tanks or a natural gas pipeline delivery system.

Owner:FUNK MICHAEL N

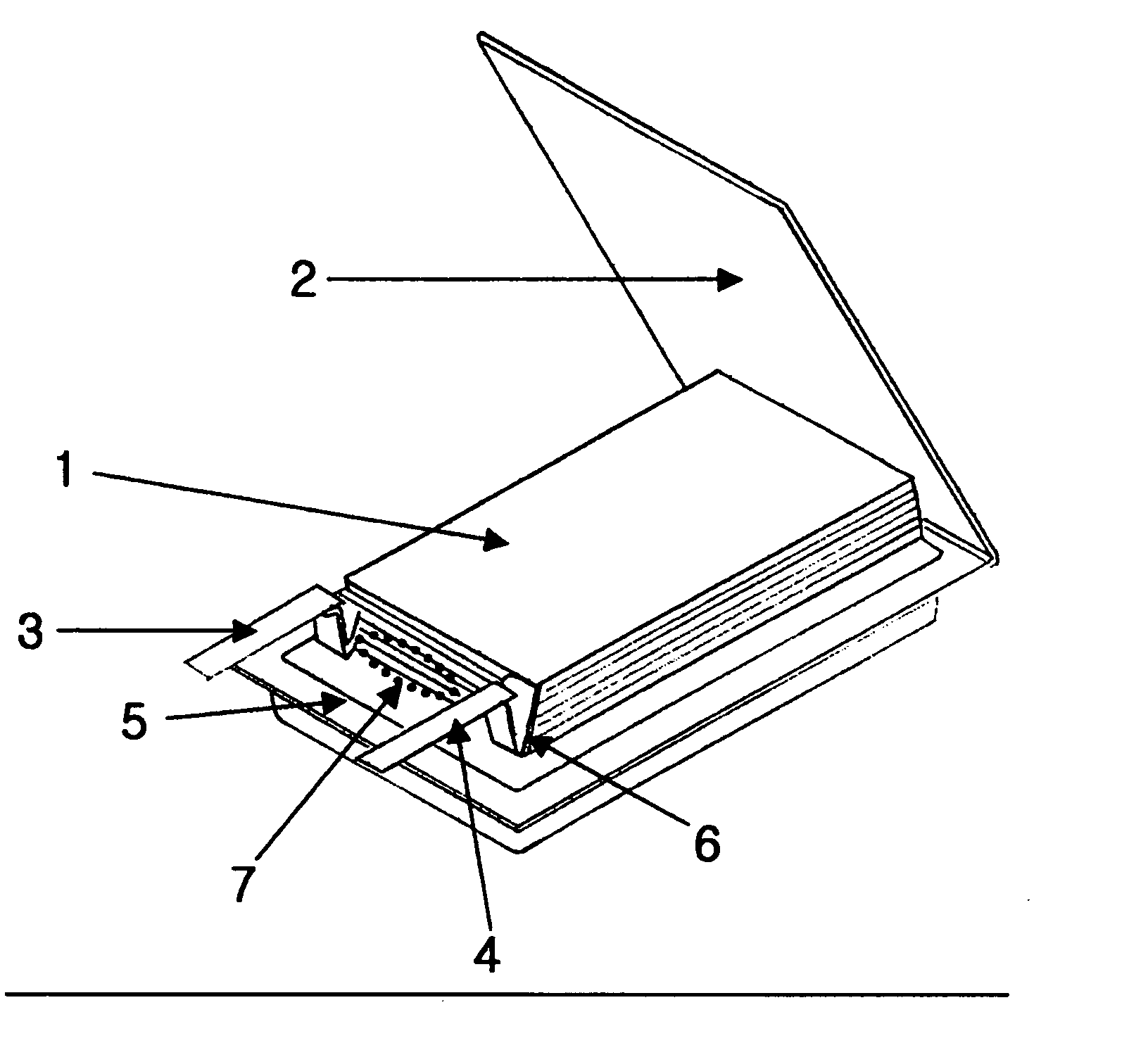

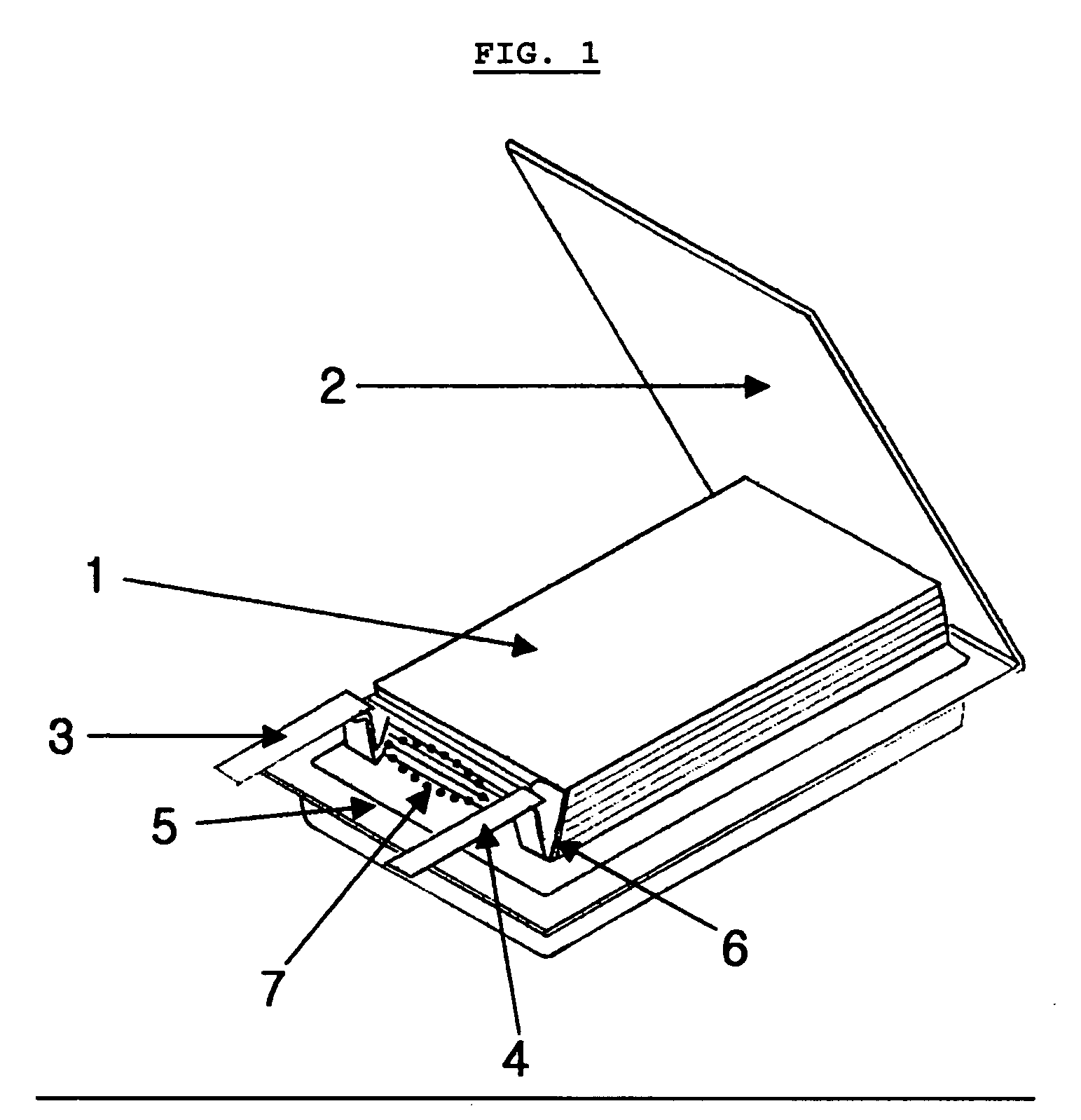

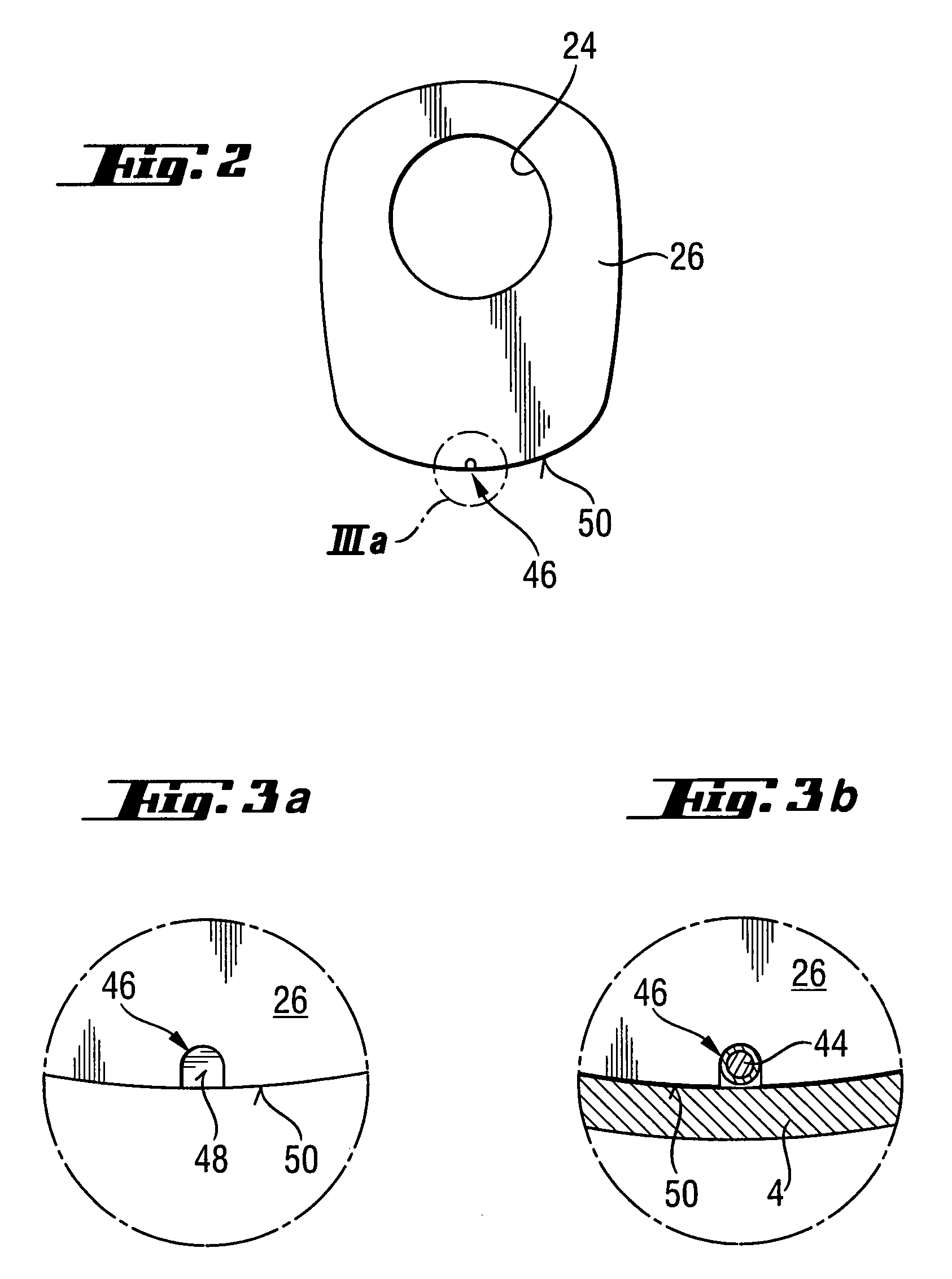

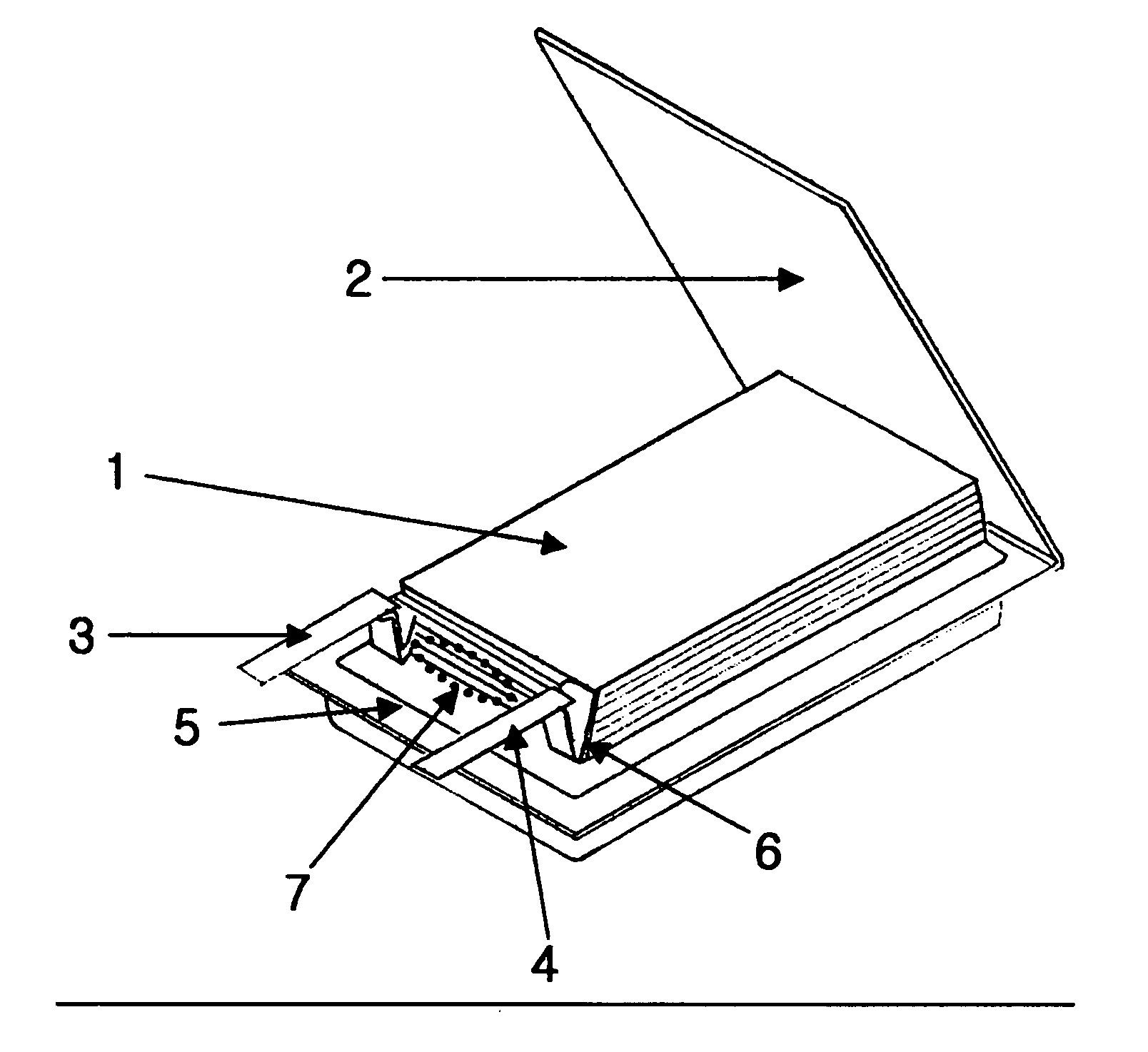

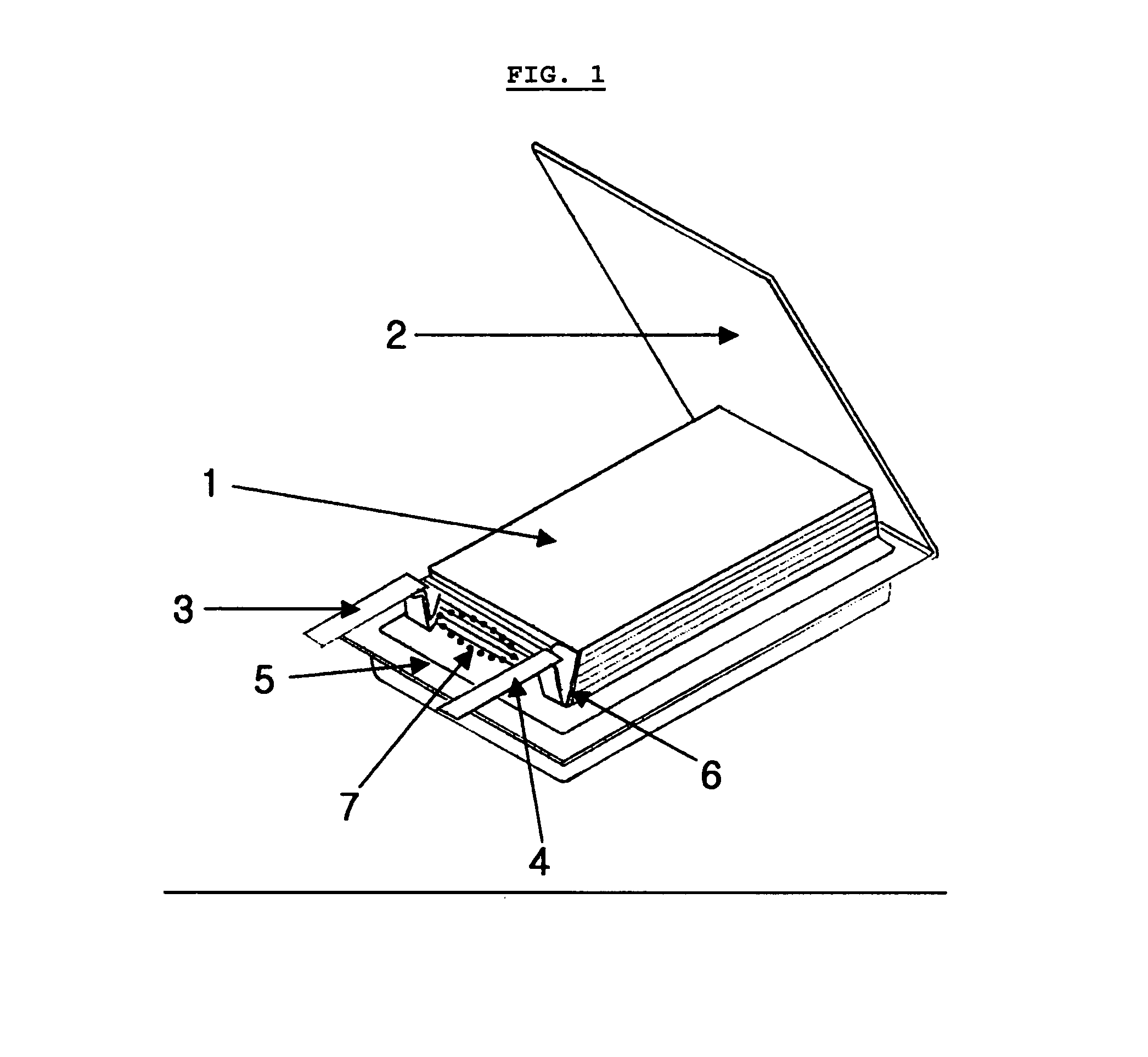

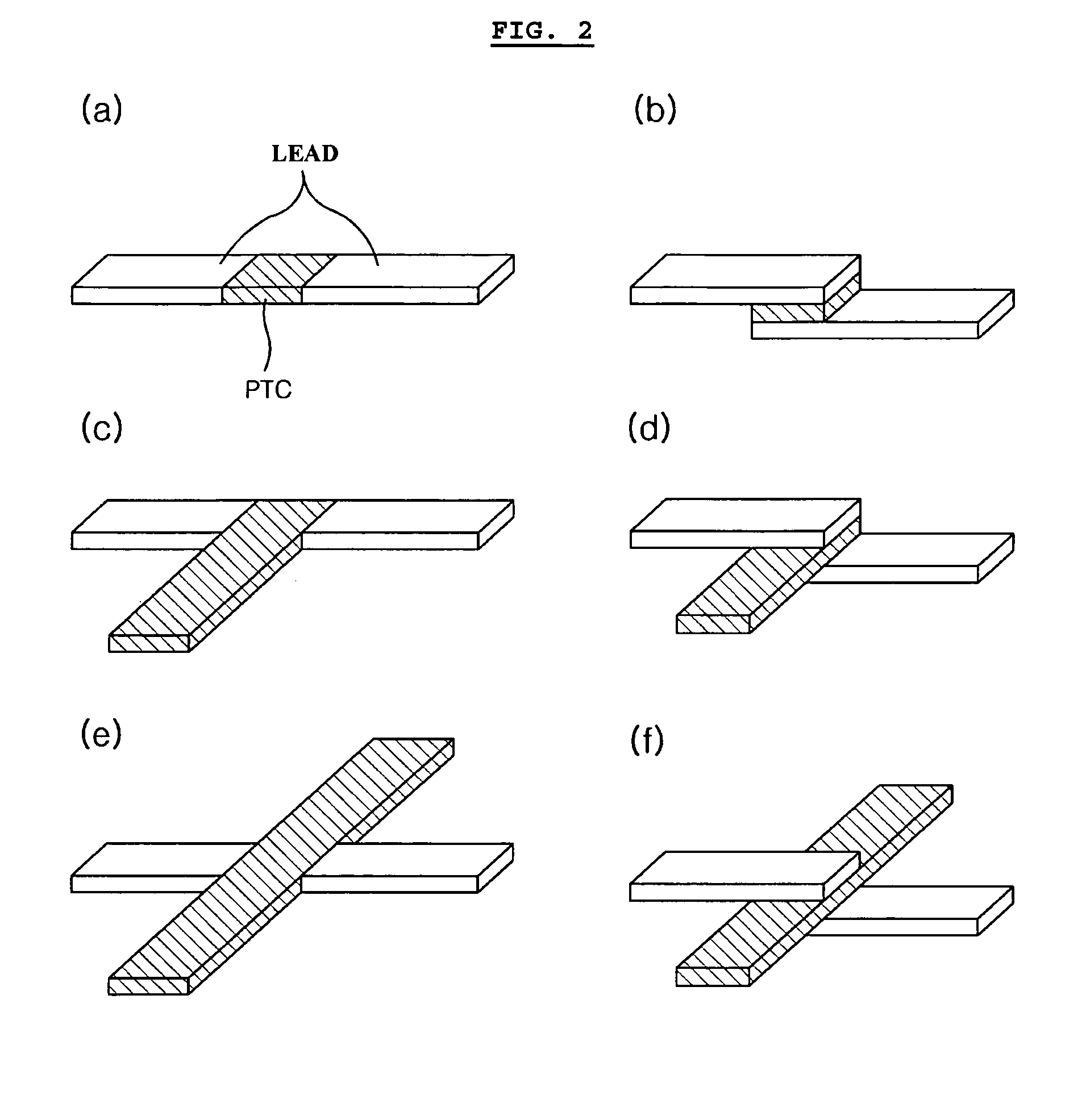

Electrochemical device comprising electrode lead having protection device

ActiveUS20060008698A1Minimized dropImprove the immunityPrimary cell maintainance/servicingNon-aqueous electrolyte accumulatorsEngineeringElectrochemistry

Disclosed is an electrochemical device including an electrode assembly having a cathode, anode and an electrolyte, and a casing surrounding the electrode assembly. The device further includes a protection device to which either or both of a cathode lead for connecting a cathode with an outer terminal and an anode lead for connecting an anode with an outer terminal are connected electrically, wherein the protection device is disposed in the inner space of the casing and the electrode lead equipped with the protection device is folded at both sides of the protection device so that the largest surface of the protection device is layered on a lateral surface of the casing where the electrode lead is present.

Owner:LG ENERGY SOLUTION LTD

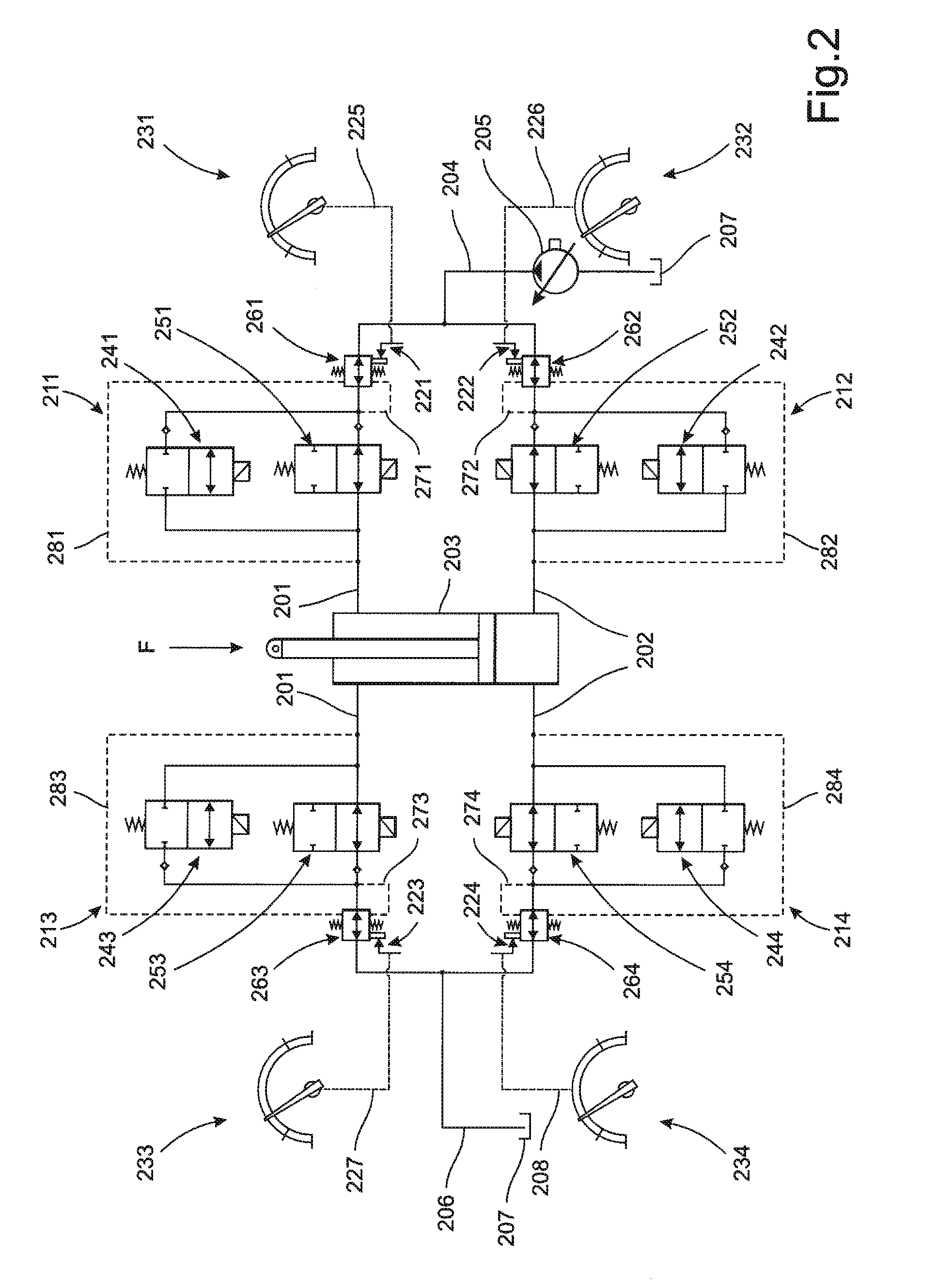

Fluid valve arrangement

InactiveUS20110017310A1Avoid connectionMinimized pressure lossOperating means/releasing devices for valvesServomotor componentsOperation modeControl valves

The invention relates to a method for controlling a fluid valve arrangement that includes a fluid conduit arrangement having a first conduit and a second conduit, the first and the second conduits being connectable with a fluid consumer; a supply connection arrangement having a pressure connection and a tank connection, and a number of valve arrangement for connecting the consumer to the pressure connection or the tank and a control device, which controls the valve arrangements. The method involves detecting output signals from opening degree sensors connected across at least the first and second valve arrangements to determine the magnitude and direction of a pressure drop across at least the first and second valve arrangements, and using the output signals to determine an operating mode for each valve arrangement.

Owner:PARKER HANNIFIN AB

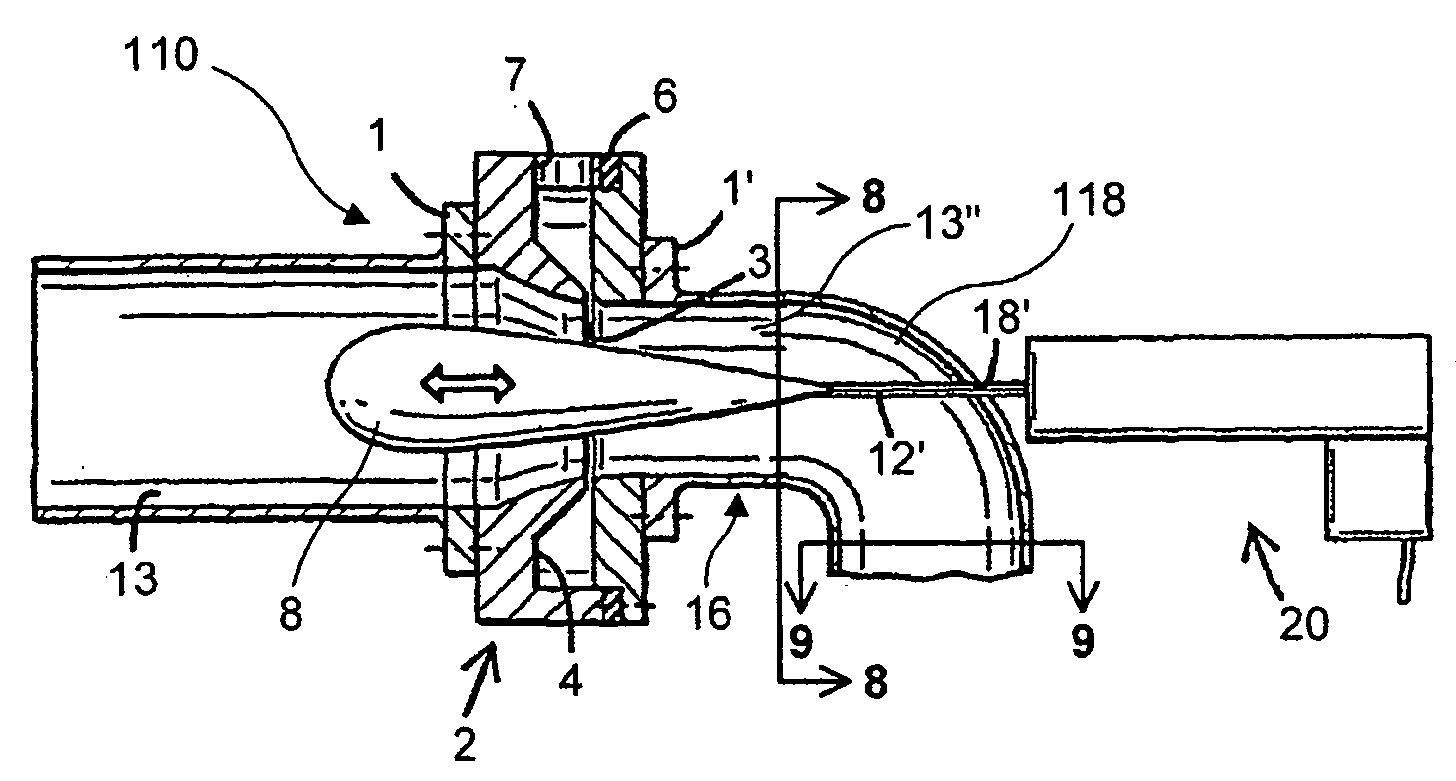

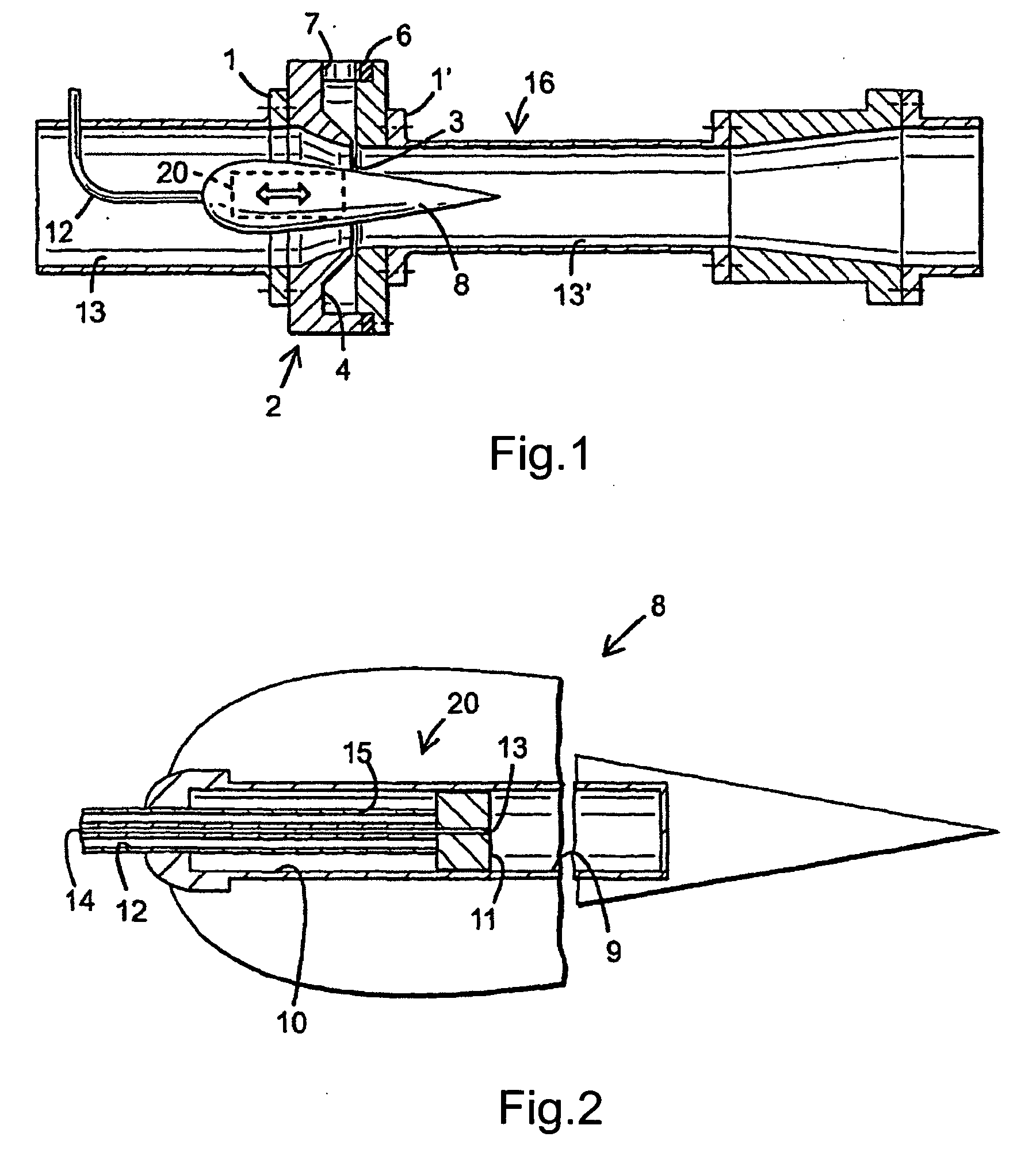

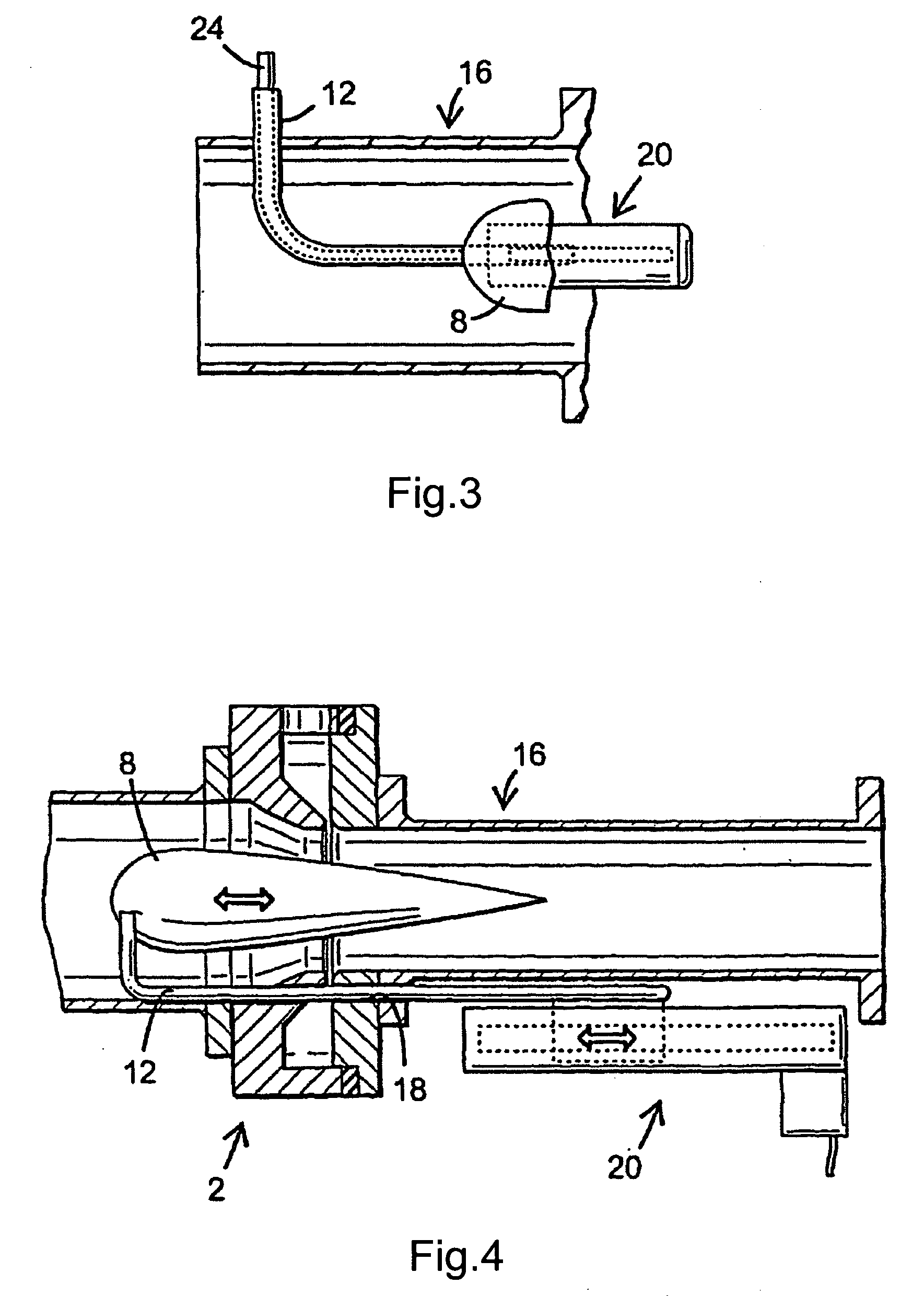

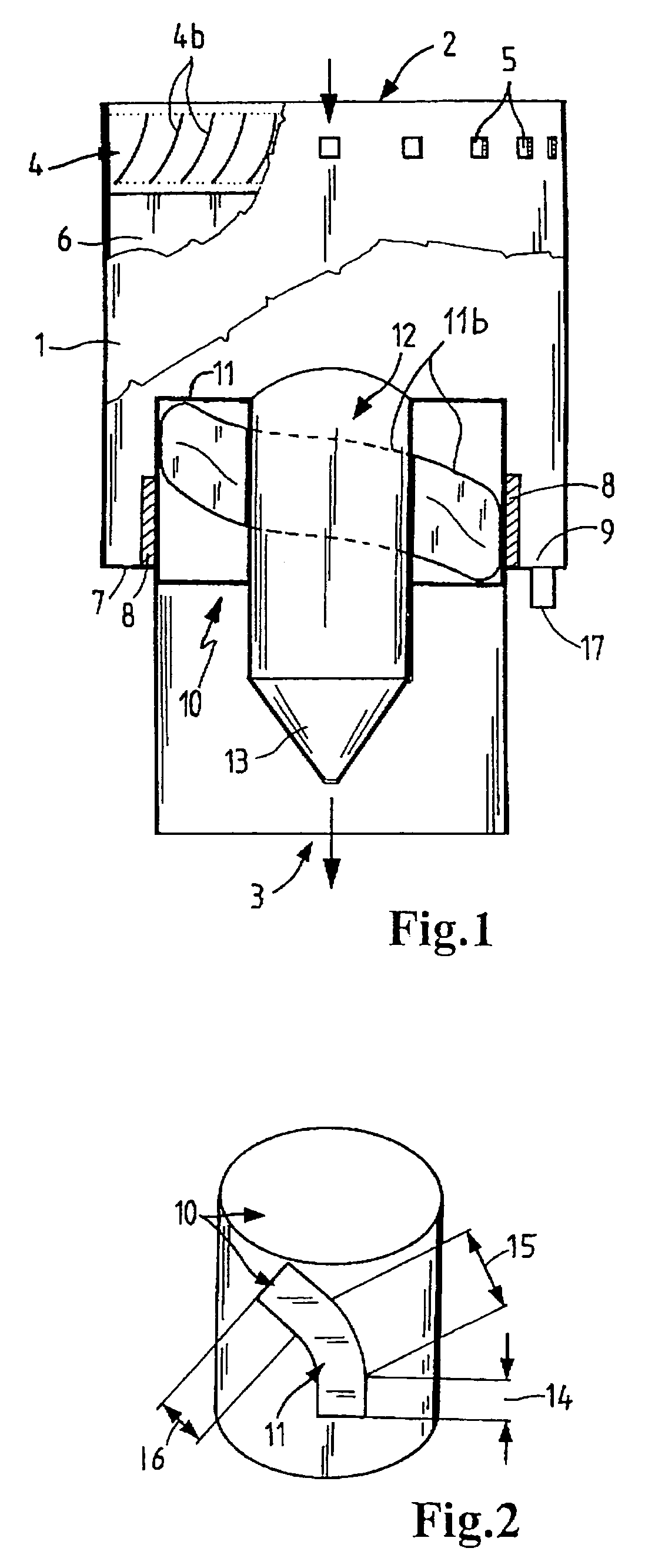

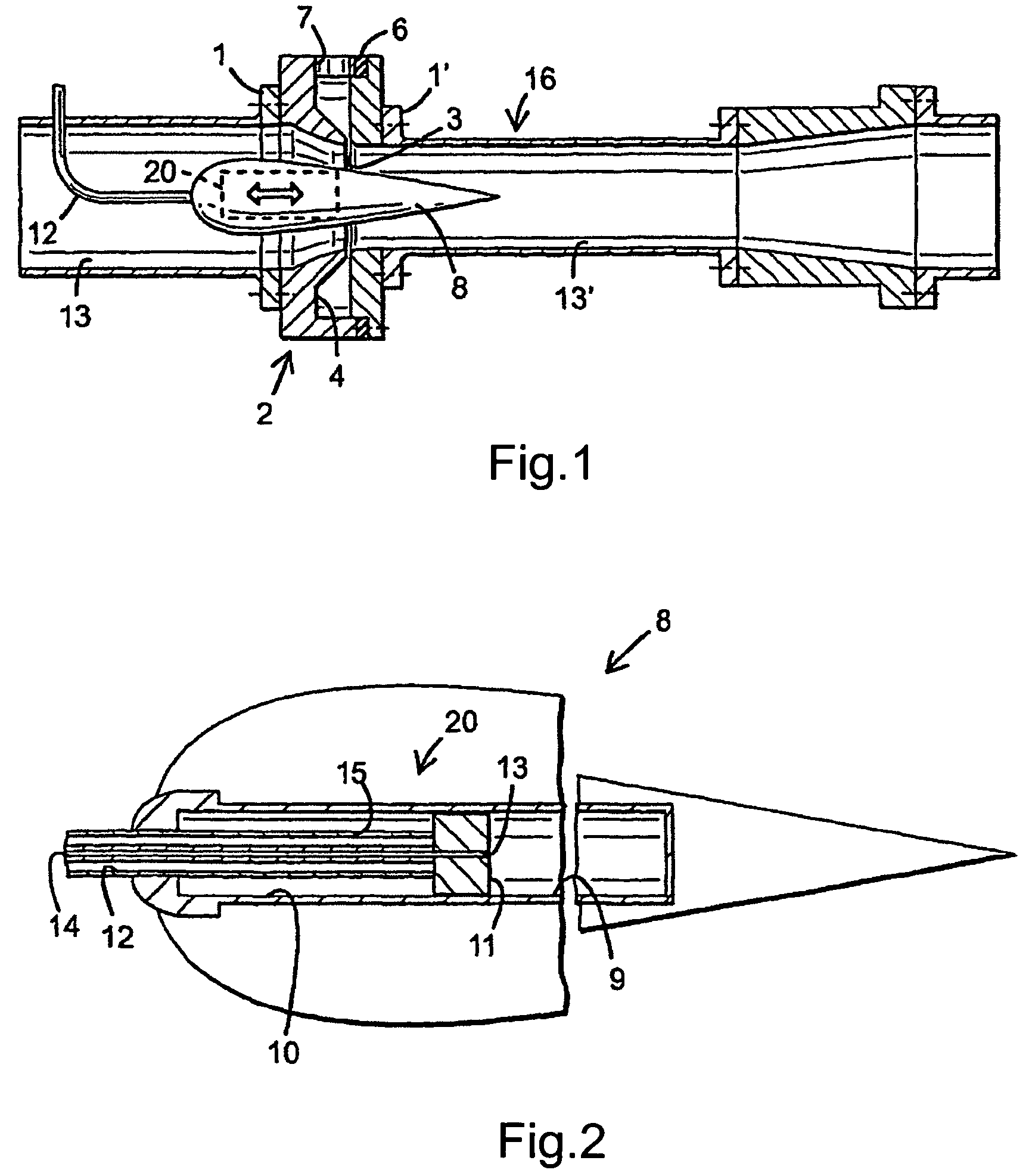

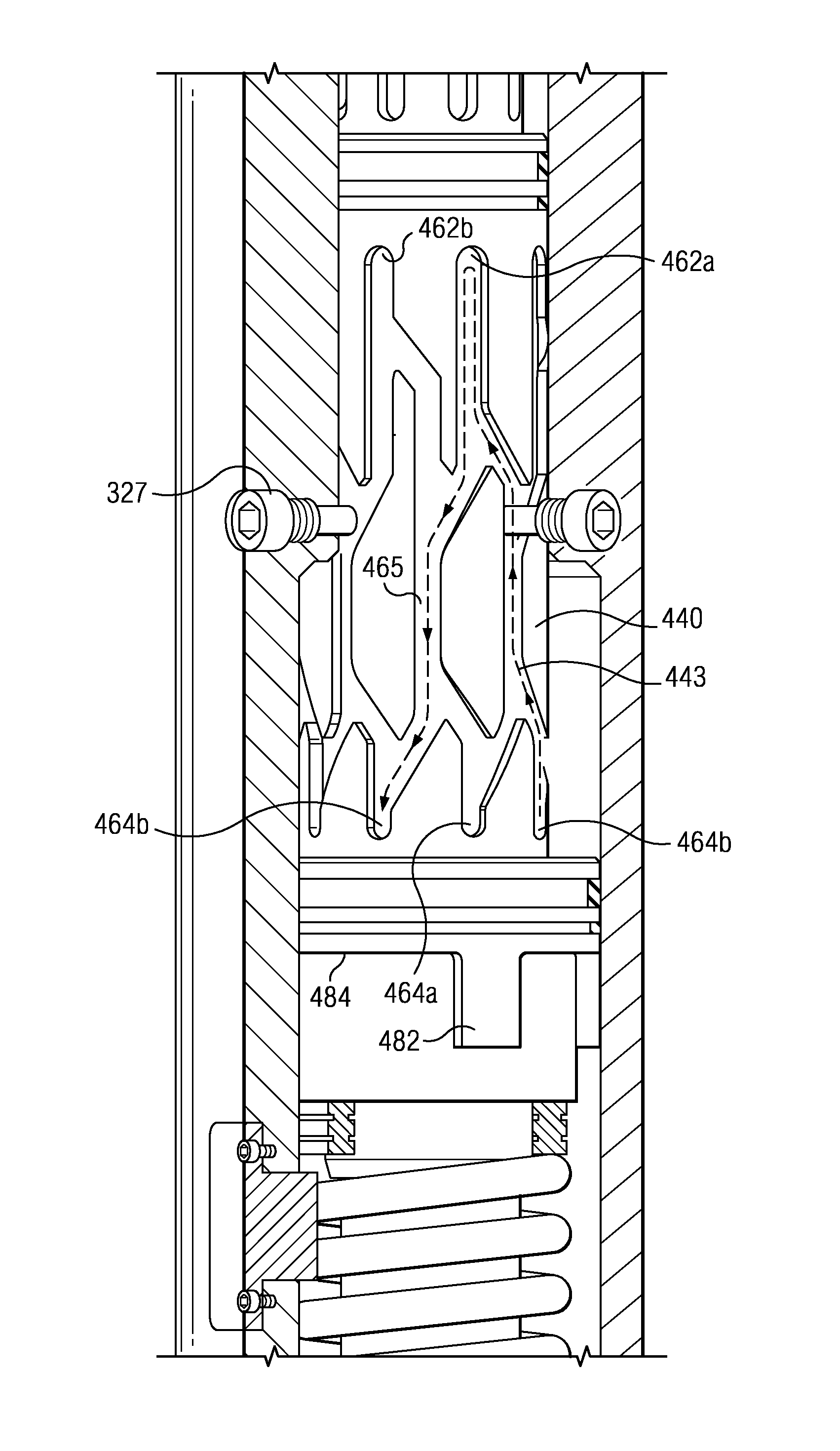

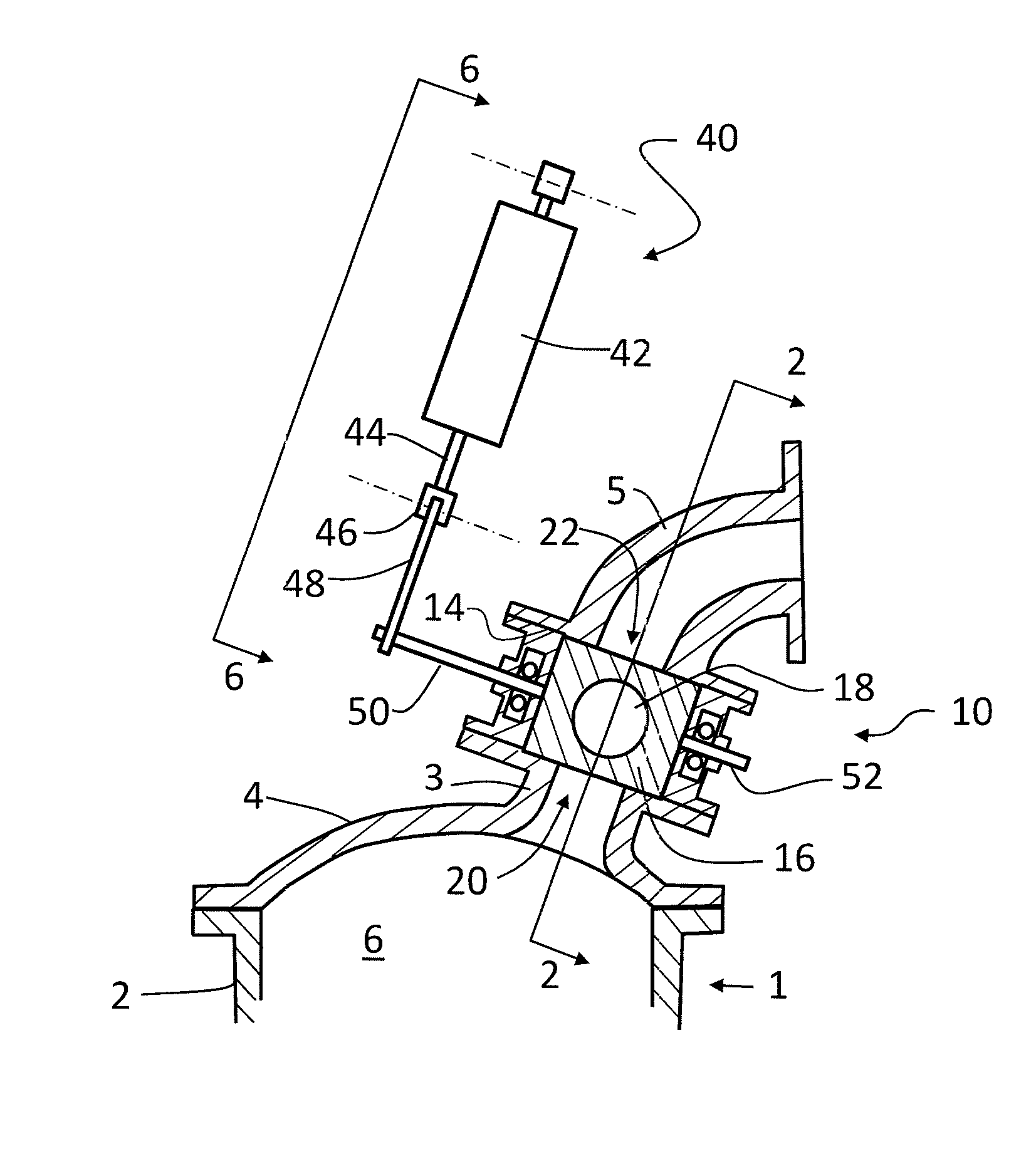

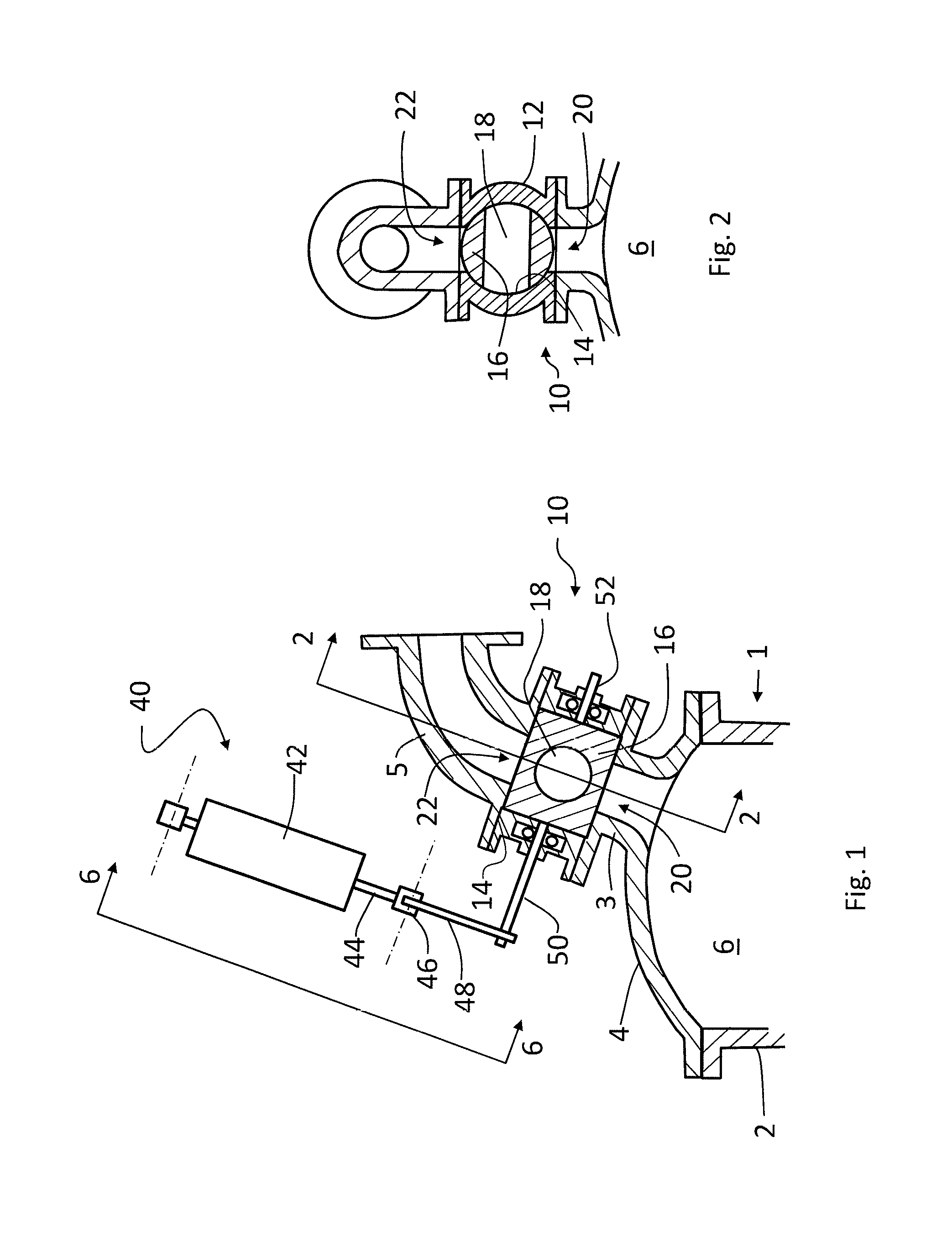

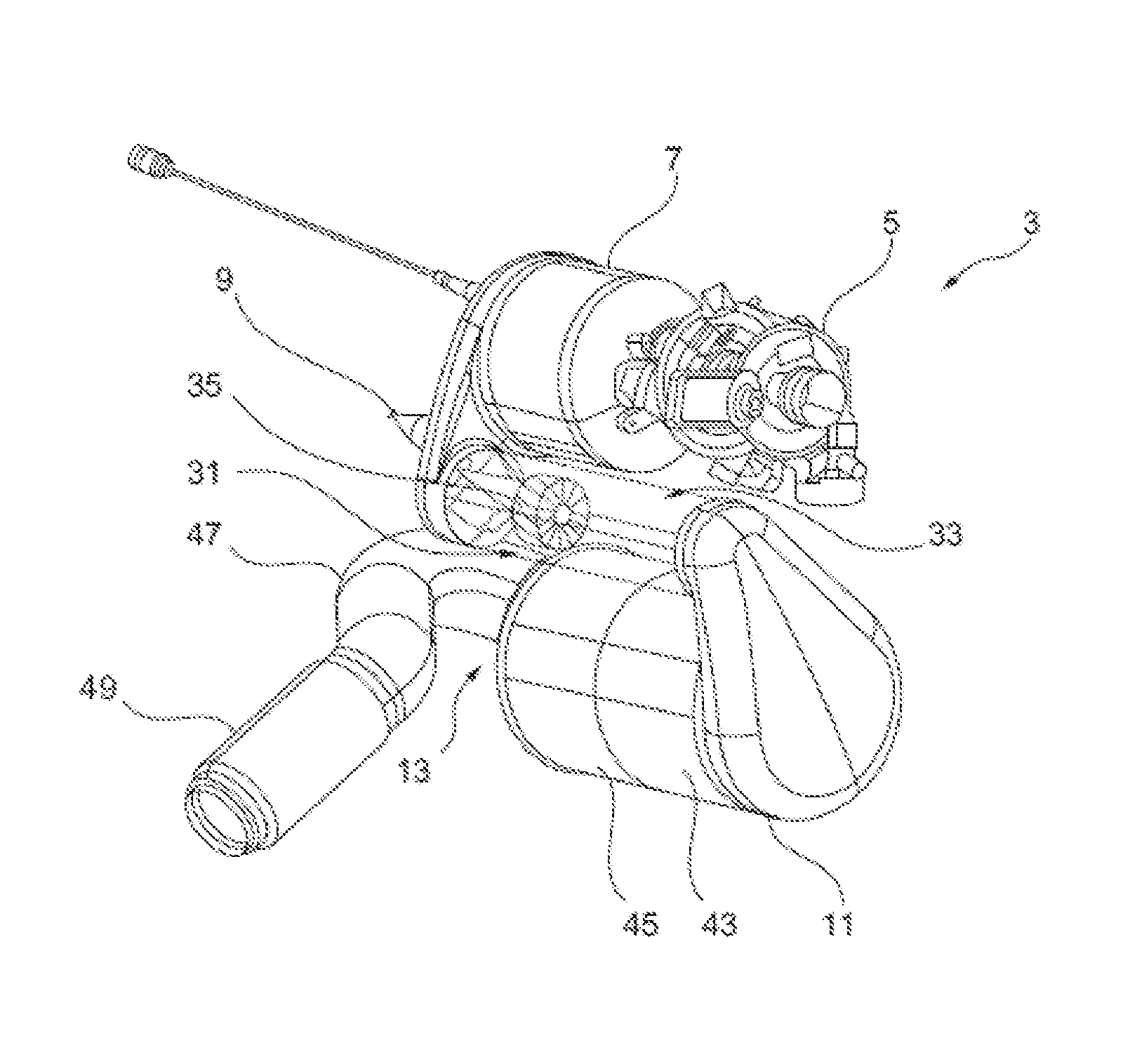

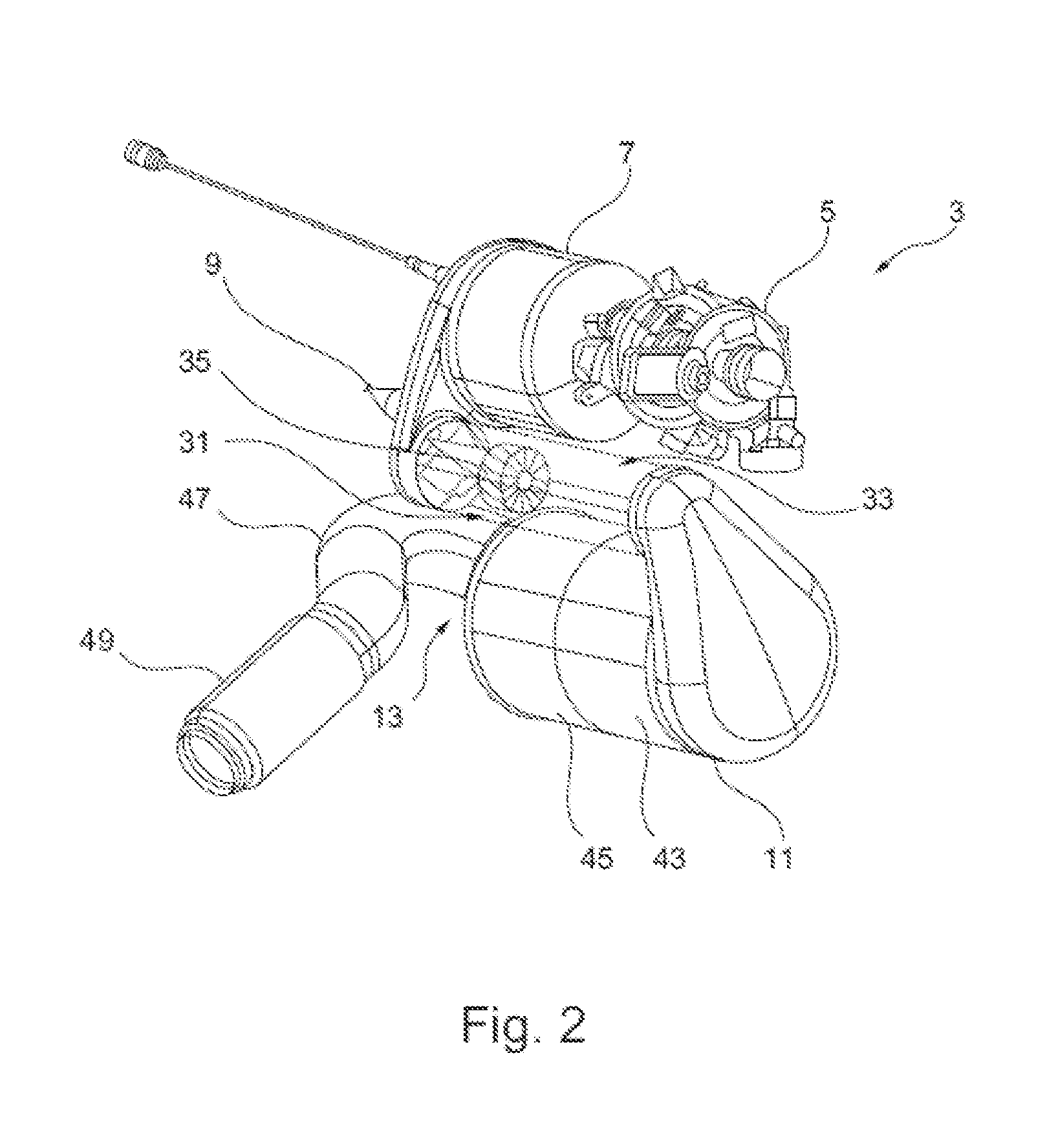

Arrangement for mixing a first and second gas flow with downstream control

InactiveUS20060180224A1Good mixing efficiencyMinimized pressure lossControlling ratio of multiple fluid flowsInternal combustion piston enginesCatheterActuator

A system for mixing a first gas flow and a second gas flow includes a conduit defined by a wall for communicating the first gas flow therethrough, an inlet passing through the wall of the conduit for introducing the second gas flow into the conduit, and a valve body disposed within the conduit, the valve body being displaceable in a longitudinal direction with respect to the conduit at the inlet. The conduit includes a bend downstream of the body with respect to a direction of the mixed gas flow. A holder is operably connected at a first end thereof to a downstream end of the valve body, the holder passing through a bore in the wall of the conduit at the bend. An actuator is operably connected to a second end of the holder, the actuator causing, via the holder, the valve body to be displaced in the longitudinal direction.

Owner:VARIVENT INNOVATIONS

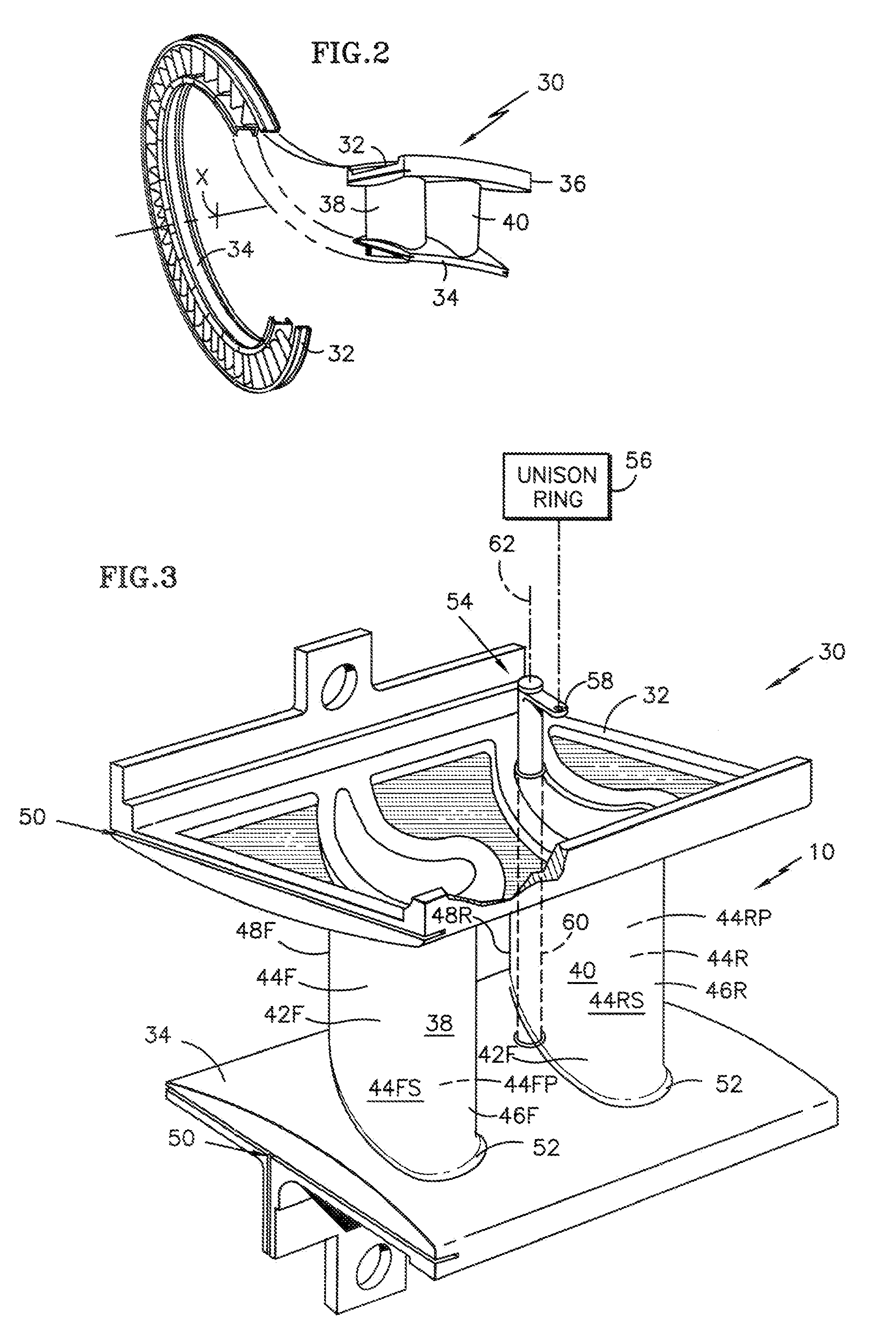

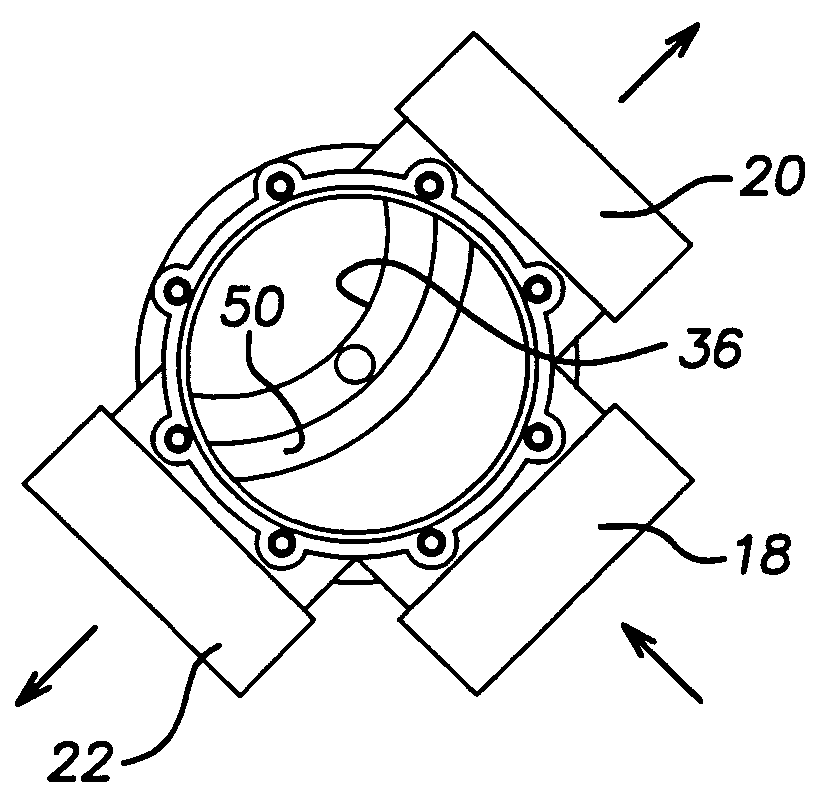

Variable area turbine vane arrangement

InactiveUS20090067978A1Minimize turbine pressure lossMinimize leakagePump componentsWind motor controlTurbine bladeGas turbines

A turbine section of a gas turbine engine includes a ring of turbine nozzle segments each having paired turbine vanes. Turbine throat area is modulated by rotating each rotational turbine vanes about an axis of rotation which is located such that rotation changes the turbine throat area concurrently between one rotational stator vane and two adjacent fixed turbine vanes. Each paired turbine vane doublet includes at least one rotational turbine vane between two fixed turbine vanes.

Owner:UNITED TECH CORP

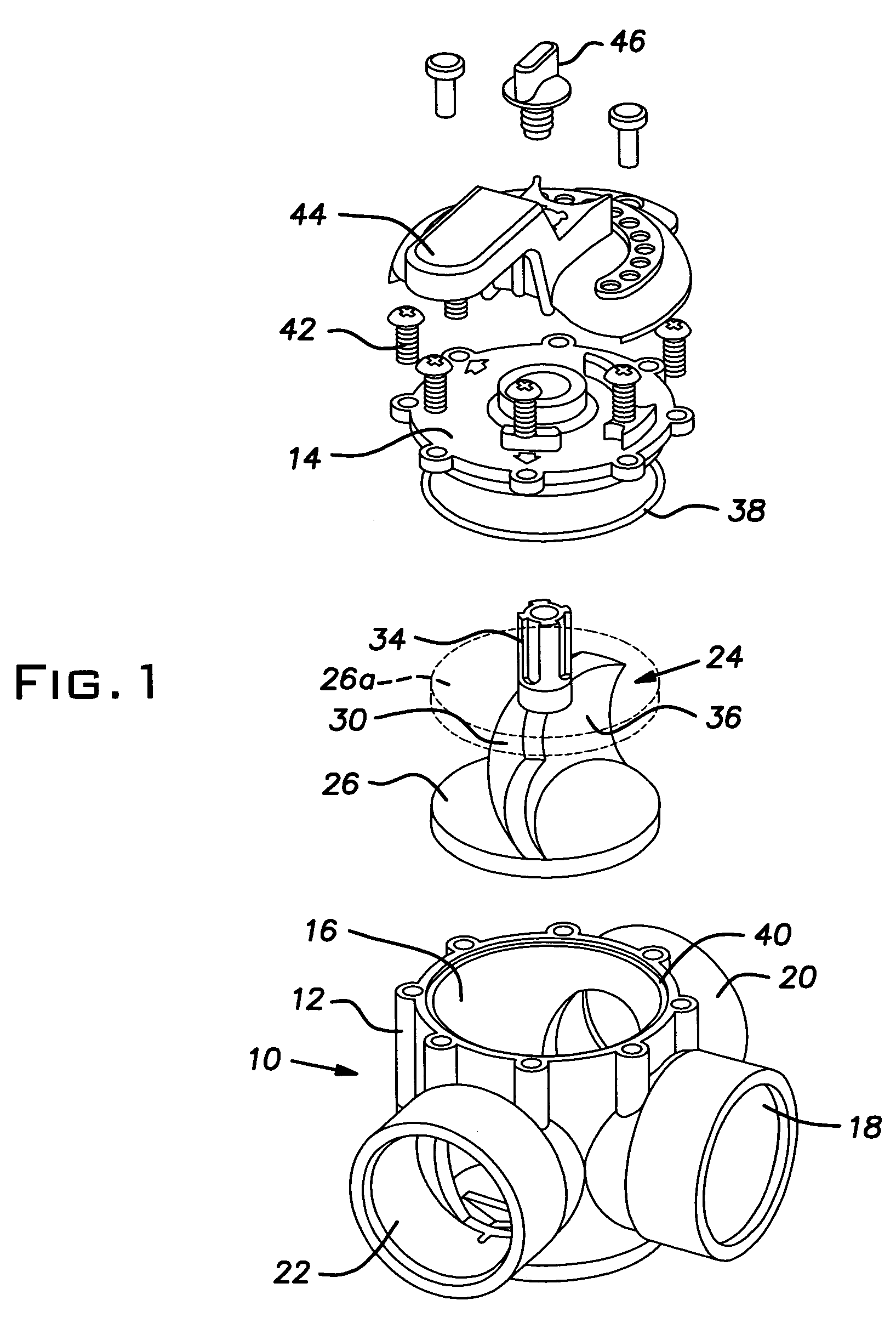

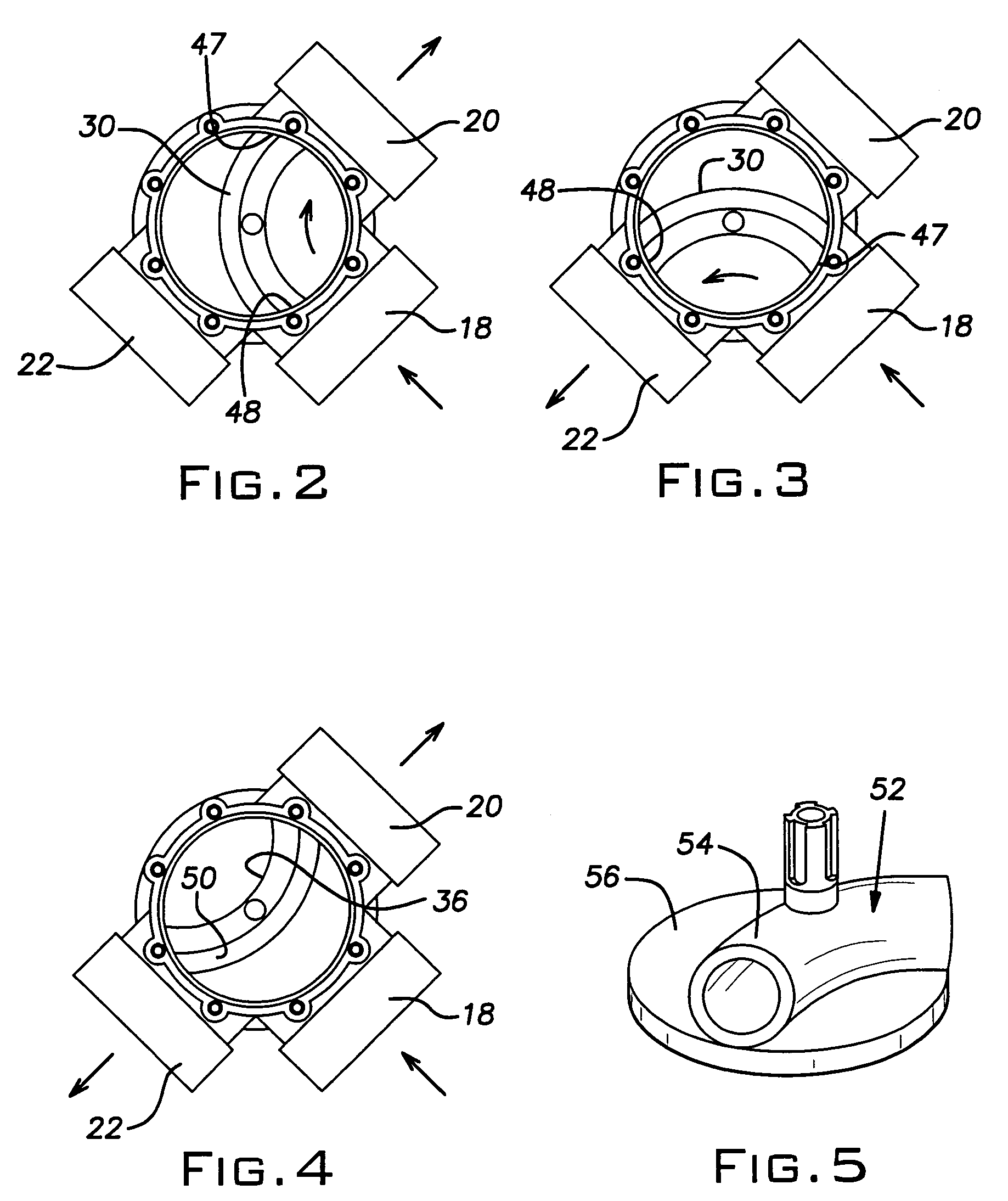

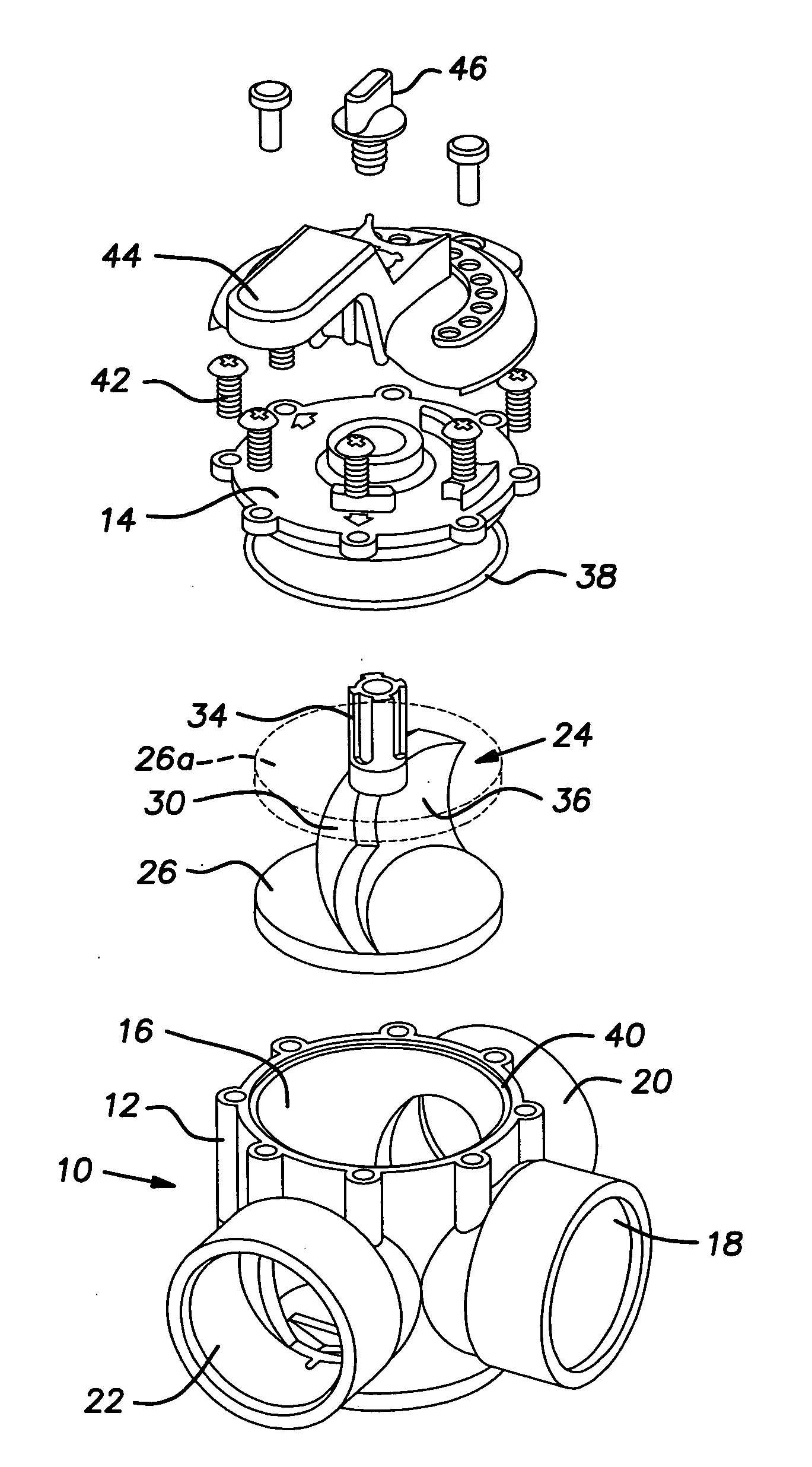

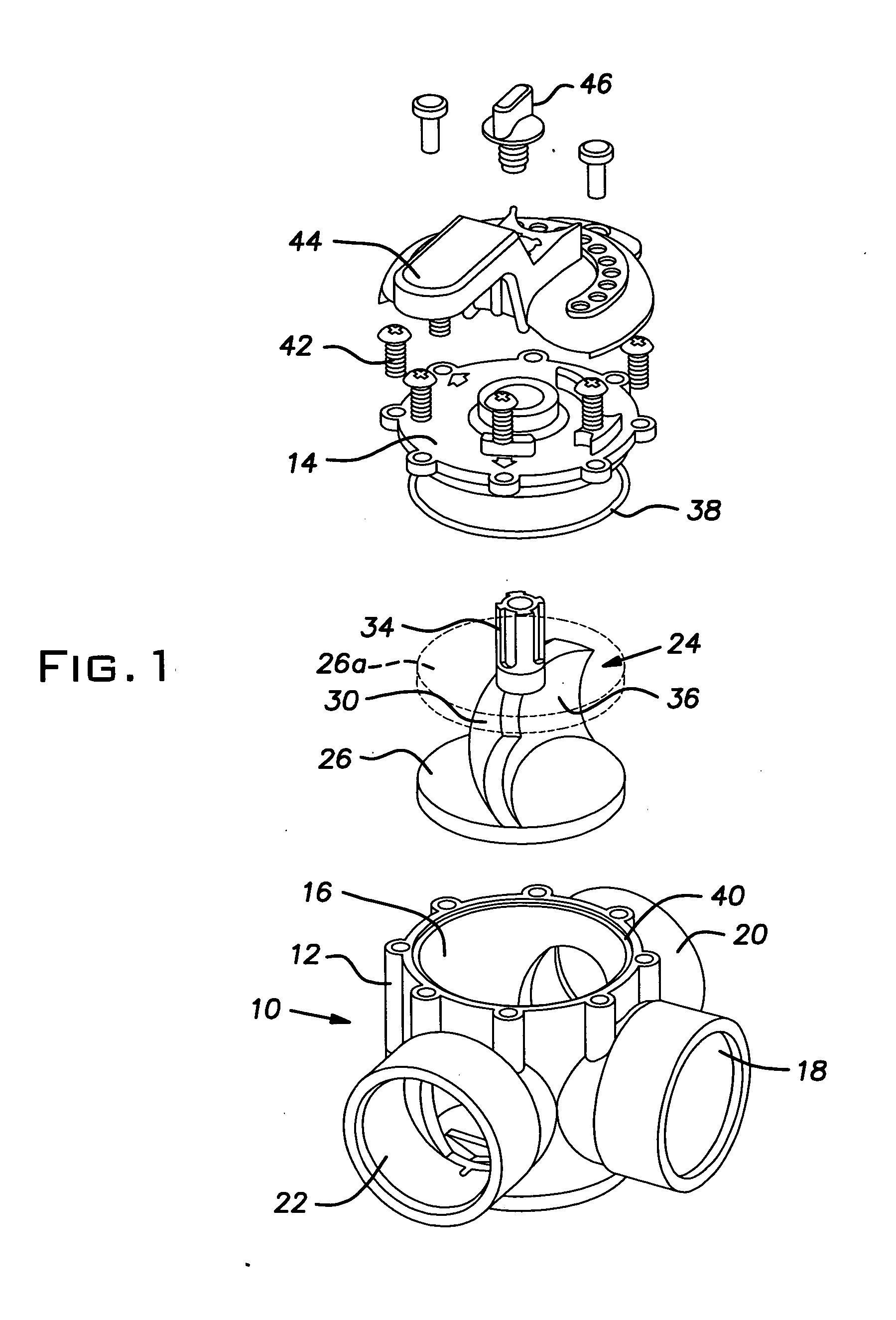

Valve with elbow joint diverter

InactiveUS7255129B2Minimize flowMinimize pressurePlug valvesMultiple way valvesEngineeringFlow diverter

A multiport diverter valve comprising a valve housing defining a valving chamber therein. A plurality of ports open into the chamber. A flow diverter is pivotally mounted in the chamber and has a concave diverter surface forming a portion of a torus. First and second ends of the torus communicate with a first adjacent pair of the ports to provide a flow path between the adjacent pair. A valve handle is adapted to pivot the diverter to a position connecting a second adjacent pair of the ports with the second pair of ports including one of the ports from the first pair. The handle is further adapted to pivot the diverter to a position connecting all of the ports.

Owner:PENTAIR WATER POOL & SPA INC

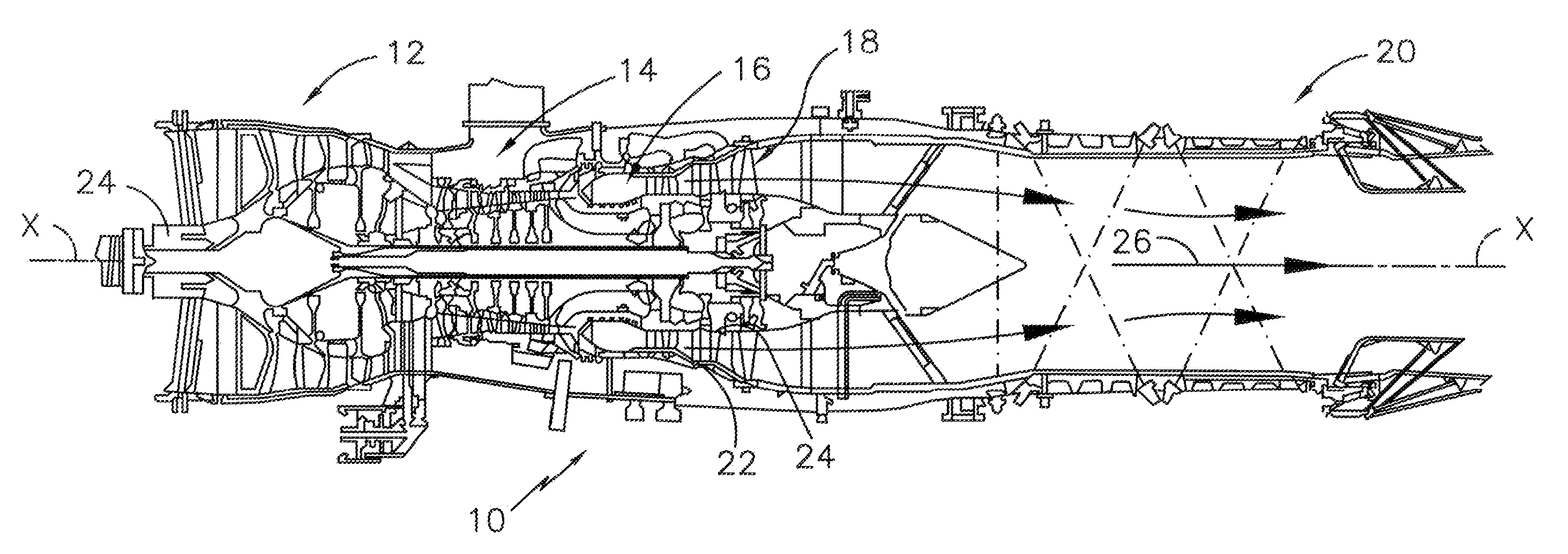

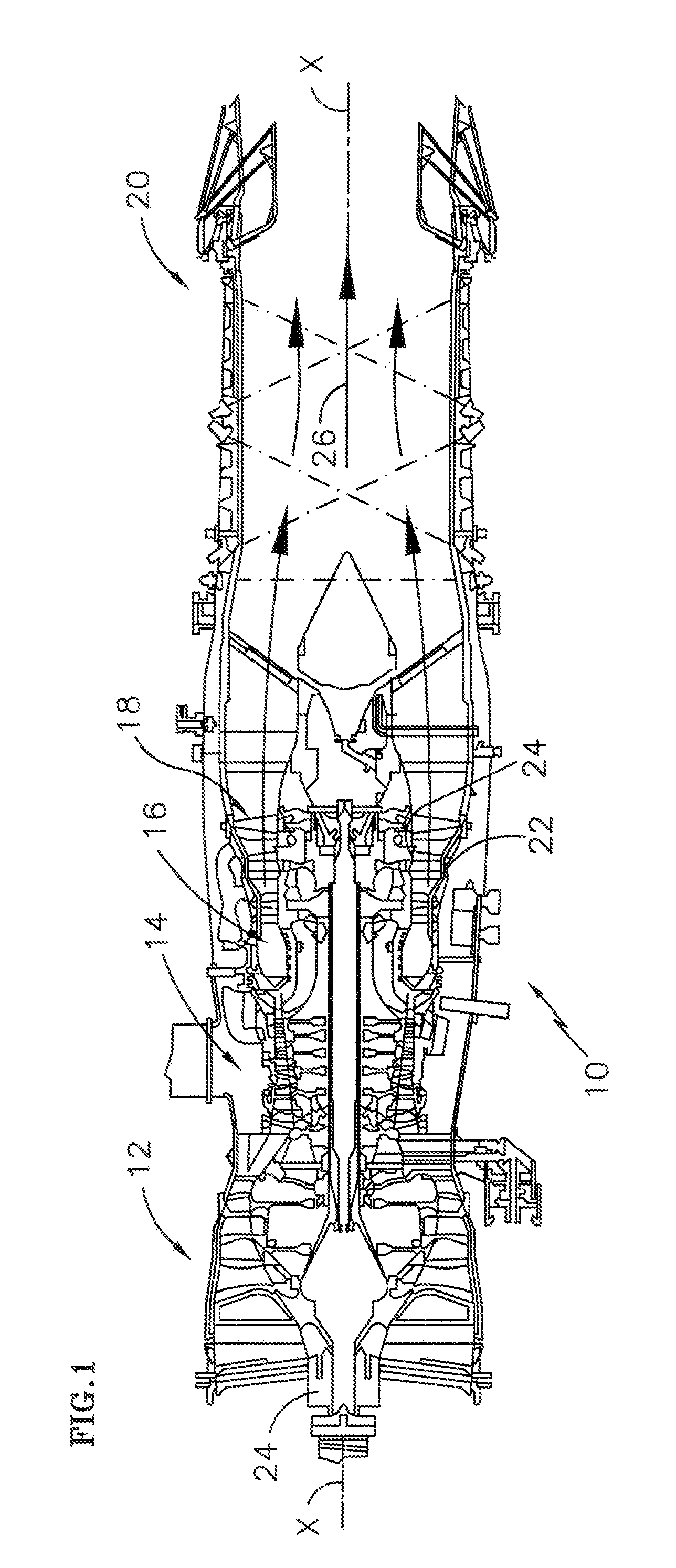

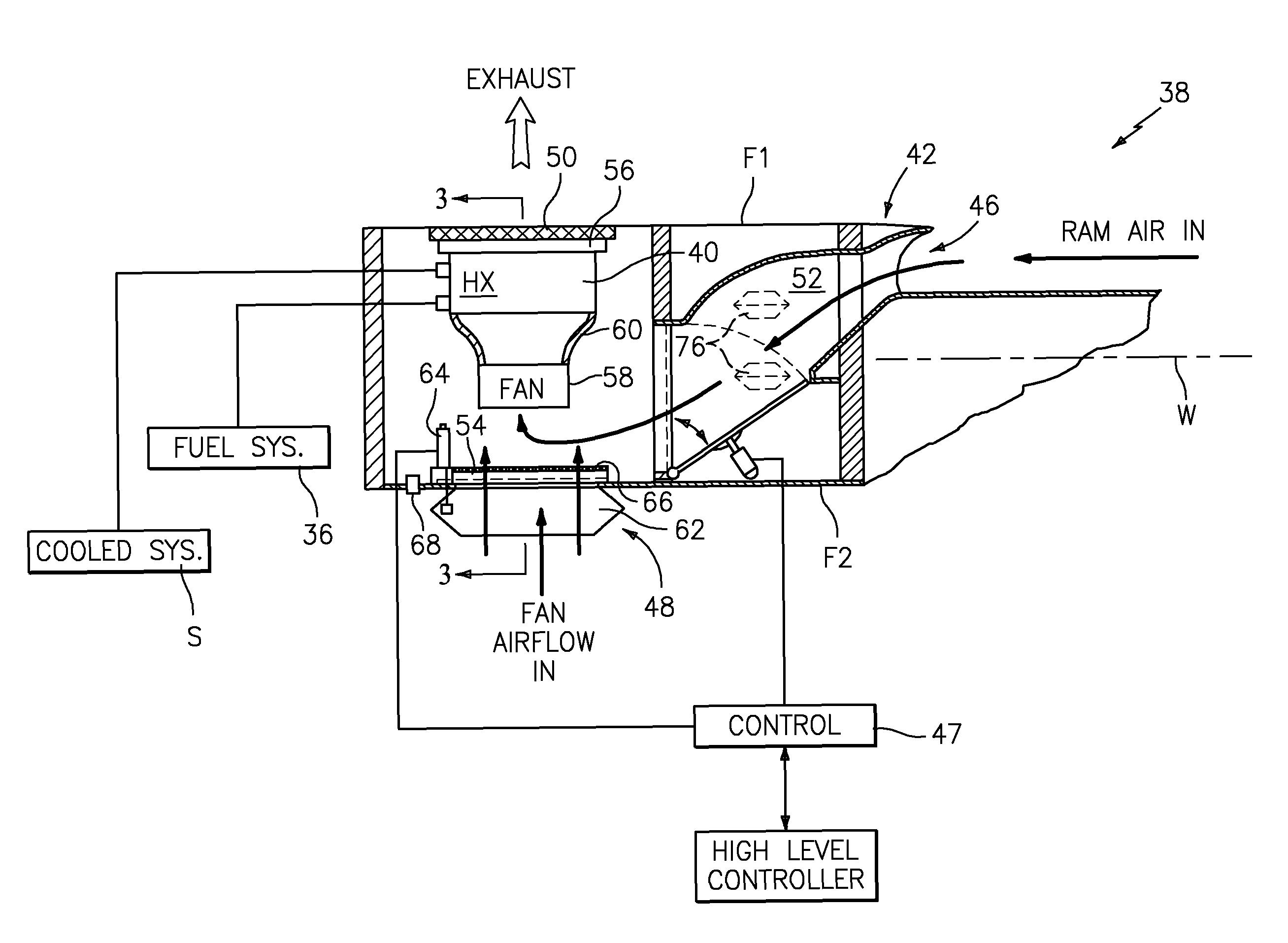

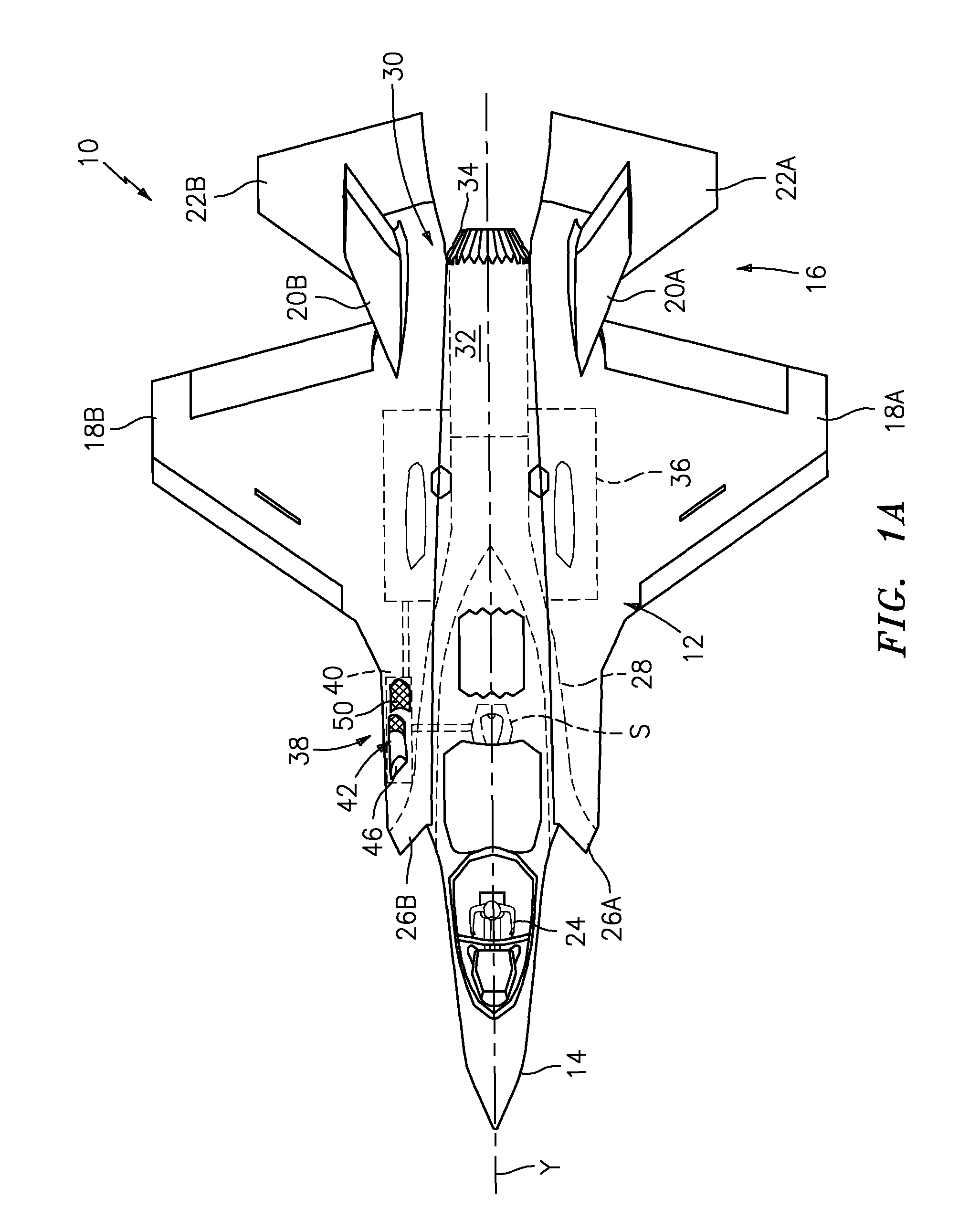

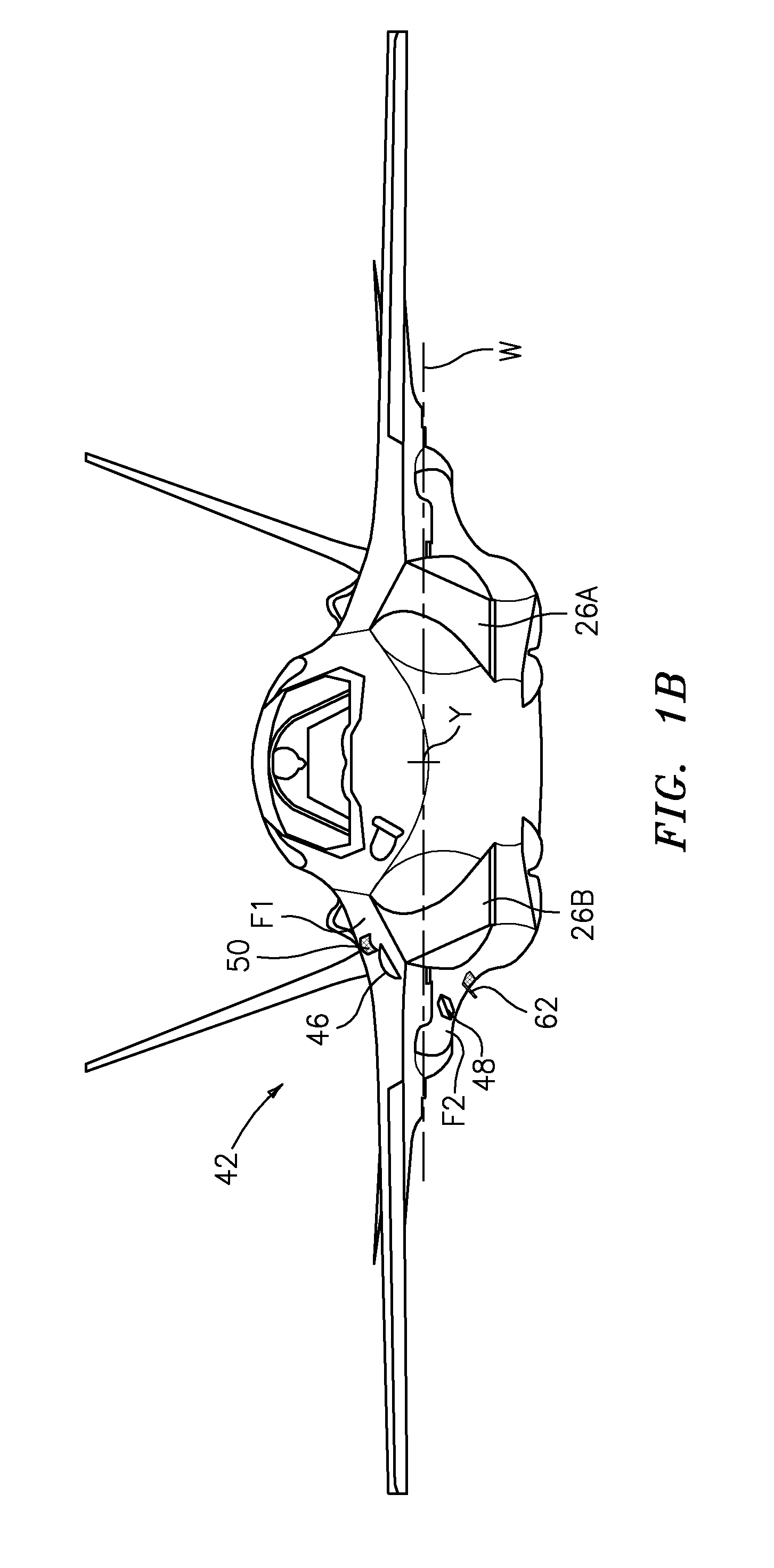

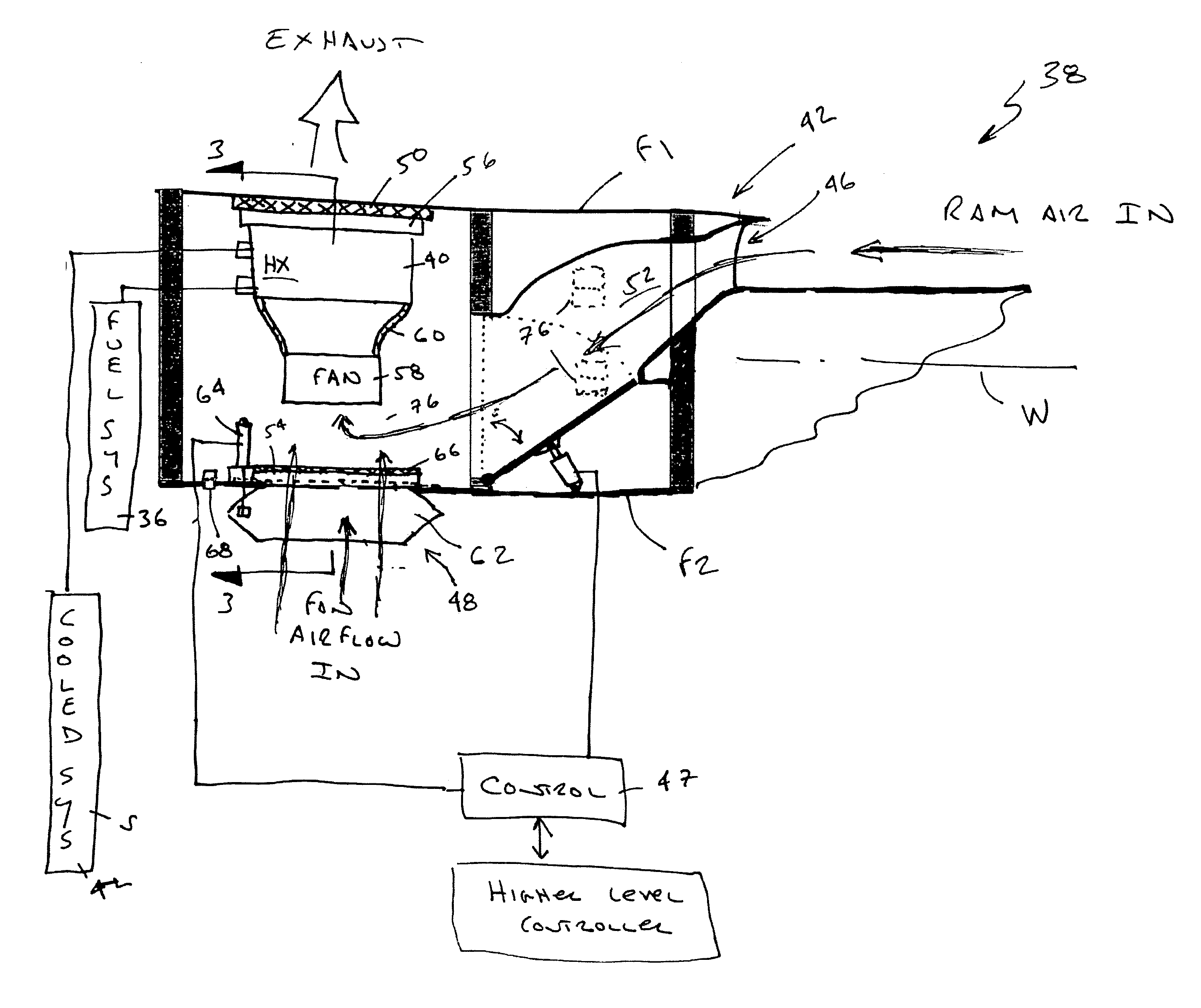

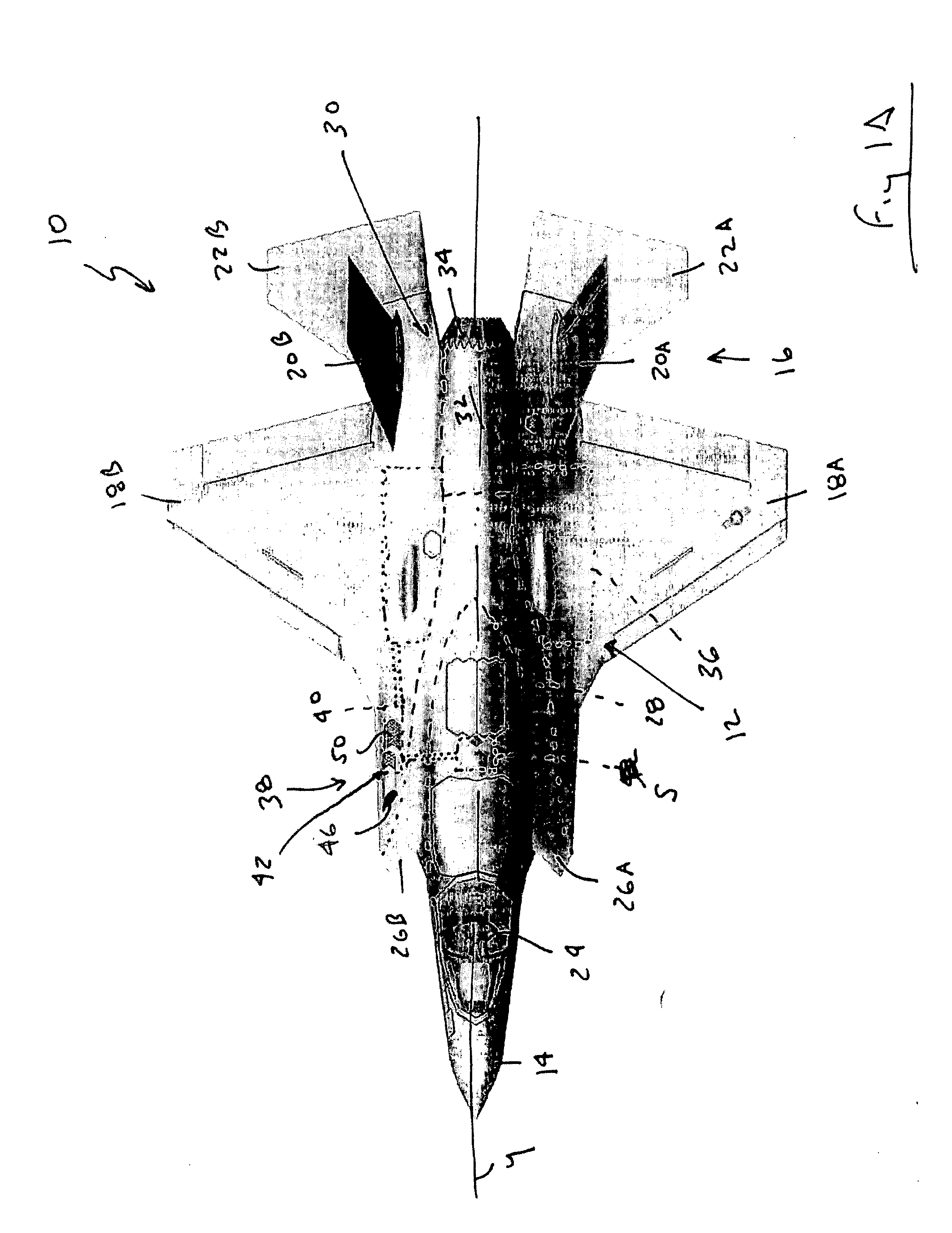

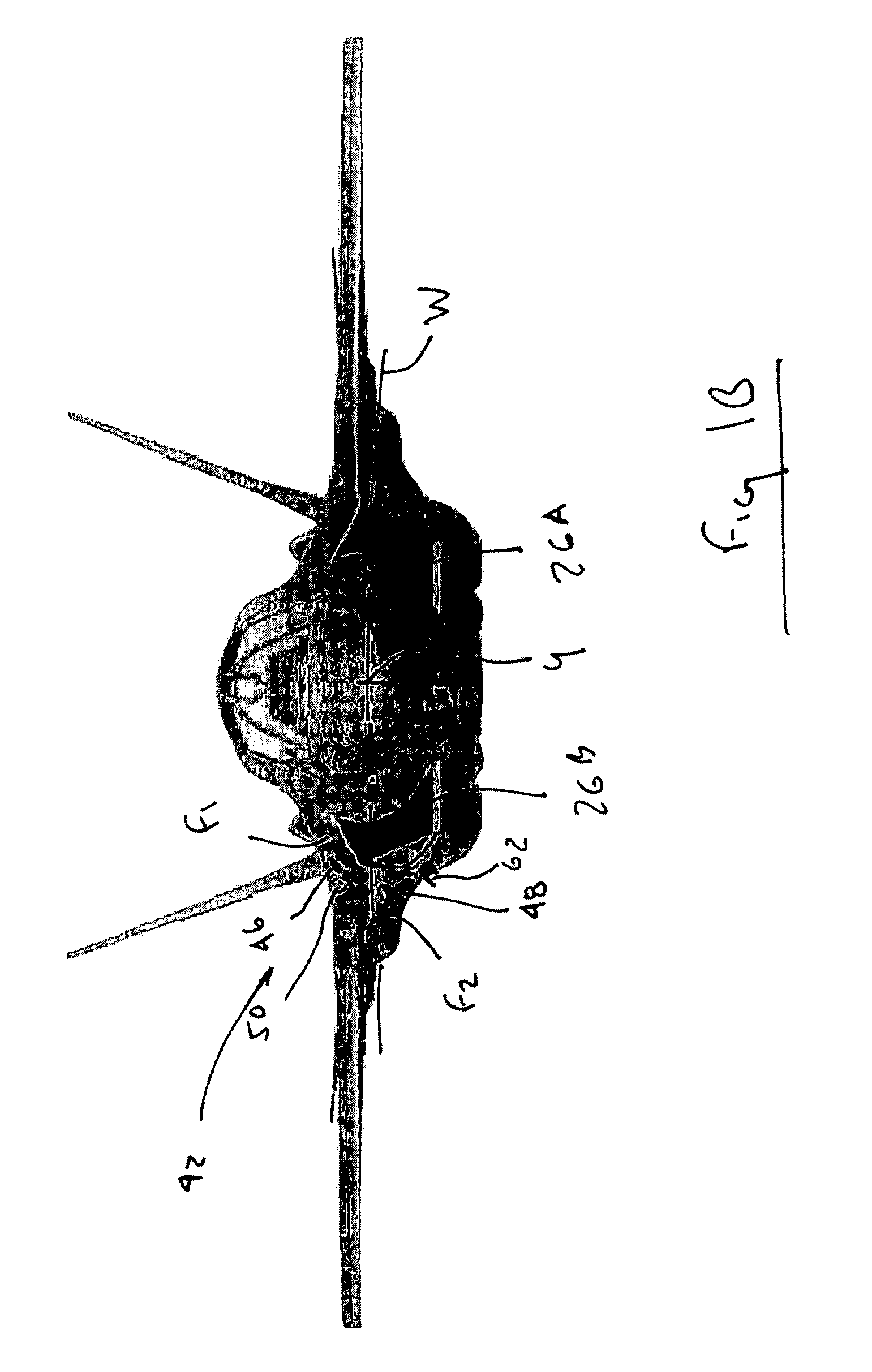

Aircraft thermal management system with reduced exhaust re-ingestion

InactiveUS7857257B2Minimize damageMinimize re-ingestion of heated exhaust airflowGas turbine plantsJet propulsion plantsRam-air intakeThermal management system

Owner:RTX CORP

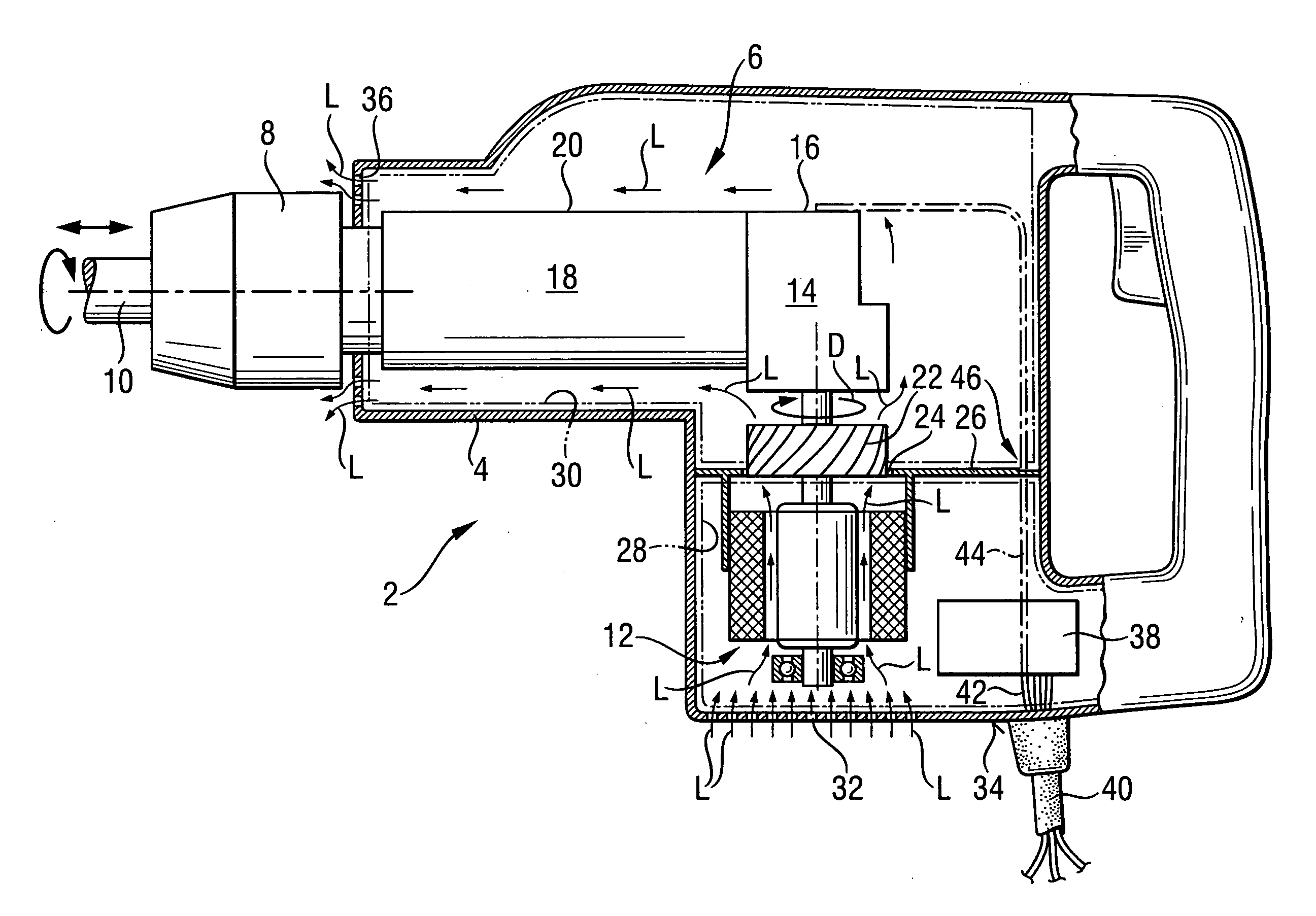

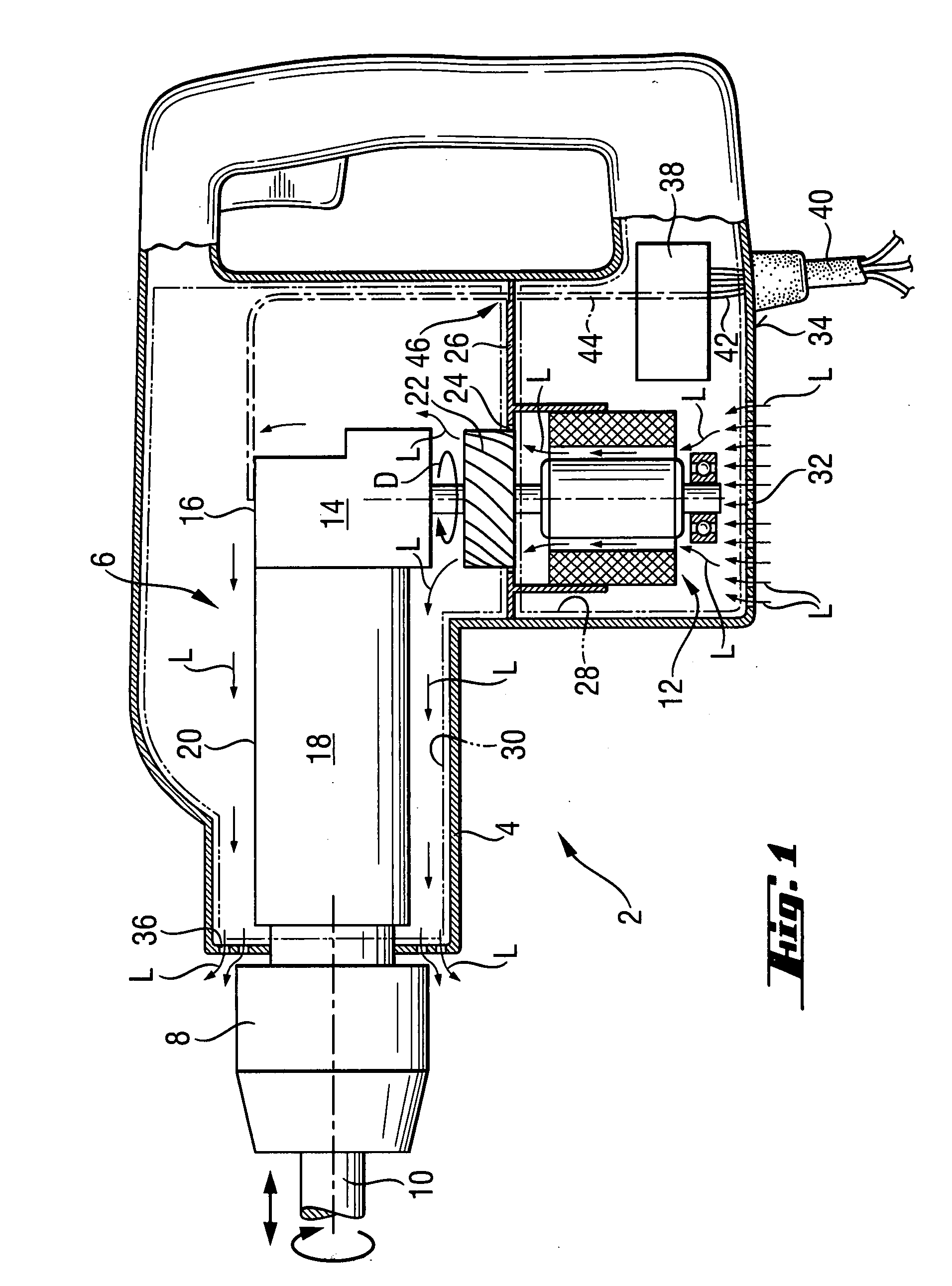

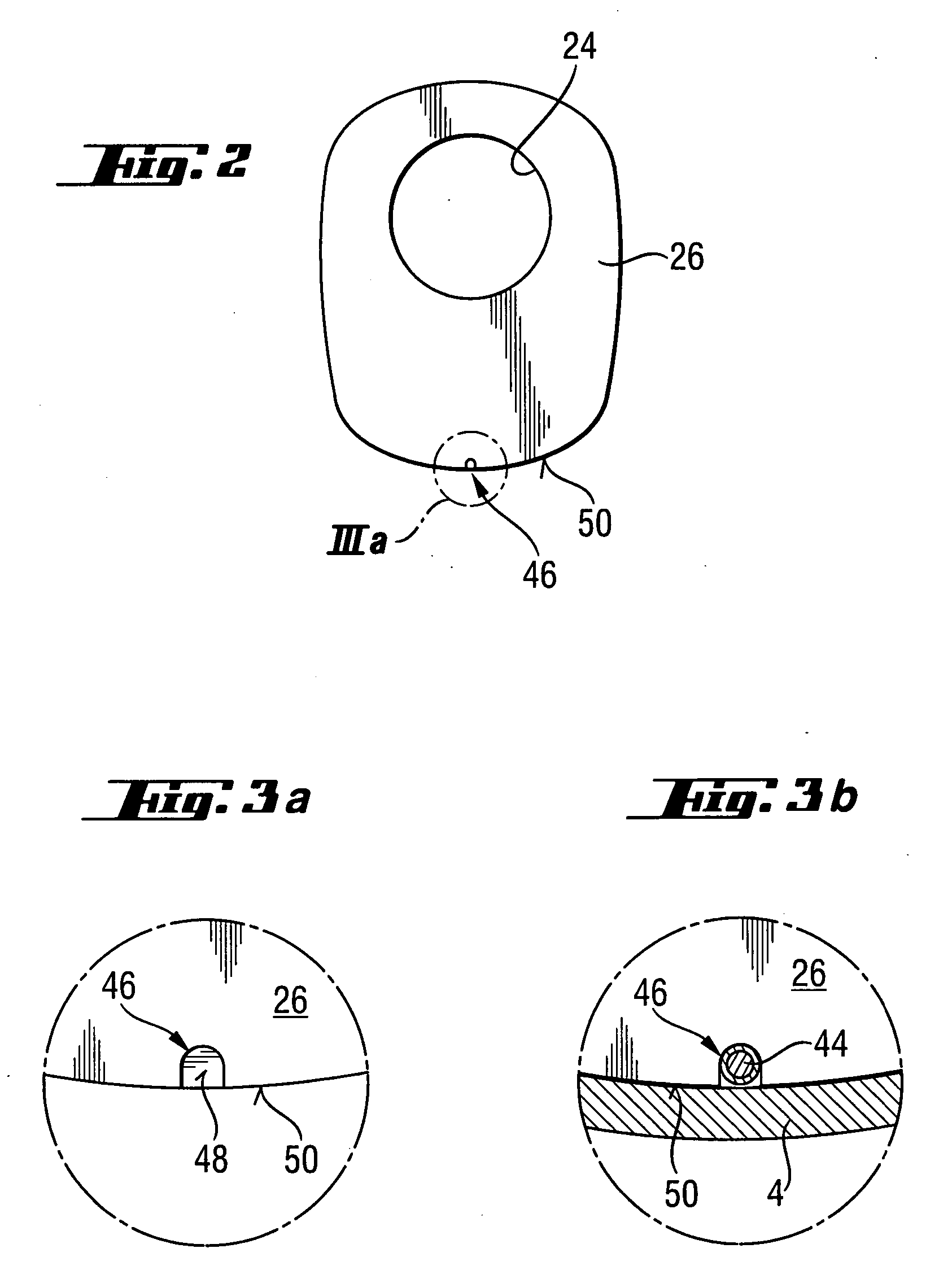

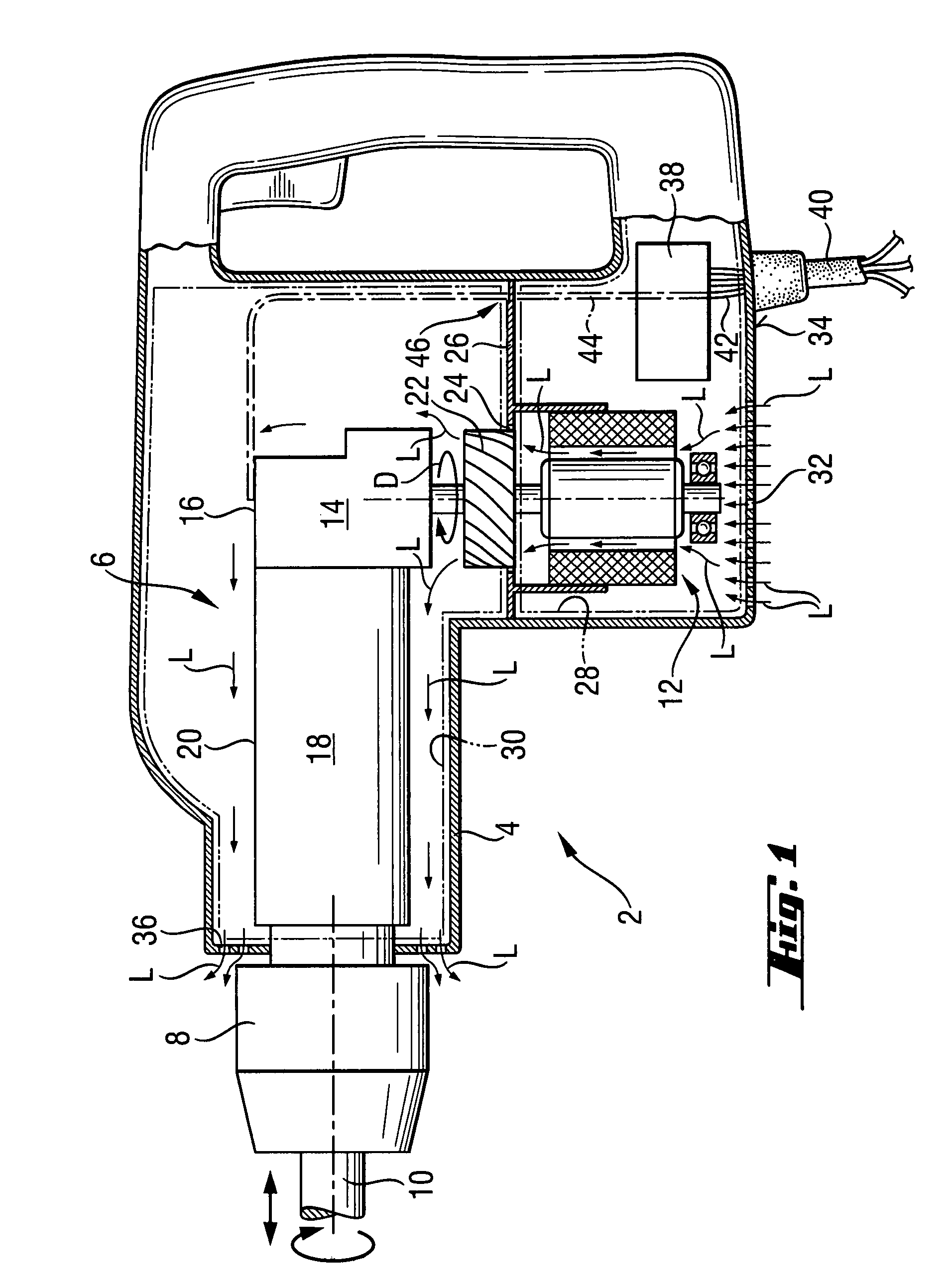

Hand-held power tool with grounding

An electrical hand-held power tool (2) includes a housing (4) in which a drive (6) is located, a ventilator (22) for forming a suction region (28) and a pressure region (30) in the housing (4) which provide for an air flow (L) that serves for cooling at least parts of the drive (6), and a separation element (26) arranged between the suction region (28) and the pressure region (30) and fixedly secured in the housing (4), the separation element (46) having an opening for forming a limited wire passage region (46) from the suction region (28) into the pressure region (30).

Owner:HILTI AG

Aircraft thermal management system with reduced exhaust re-ingestion

InactiveUS20080053101A1Minimizes leakageMinimized pressure lossGas turbine plantsJet propulsion plantsRam-air intakeThermal management system

A thermal management system includes a cooling duct system that locates a ram air intake and an exhaust through a first aircraft surface above a second aircraft surface which locates a fan intake. During ground operations, an anti-re-ingestion door is open and a ram air door is closed such that the fan system may draw relatively cooler air from below the aircraft and exhaust the heated air above the aircraft to minimize re-ingestion of the heated exhaust. During flight operations, the anti-re-ingestion door is closed and the ram air door is open such that ram airflow communicates through the fan system prior to communication through the heat exchanger. Both the anti-re-ingestion door and the ram air door may also be operated in flight.

Owner:RAYTHEON TECH CORP

Hand-held power tool with grounding

Owner:HILTI AG

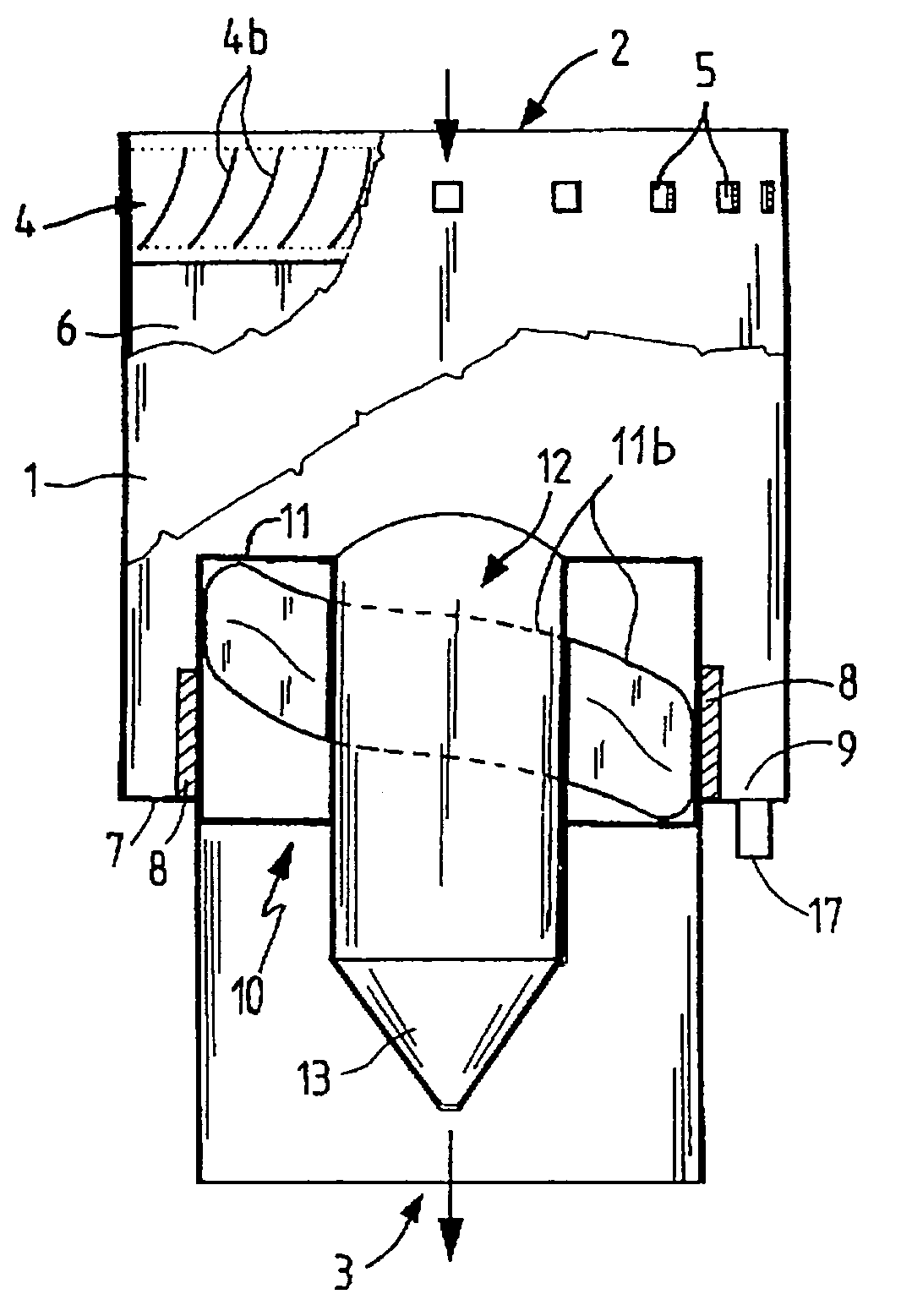

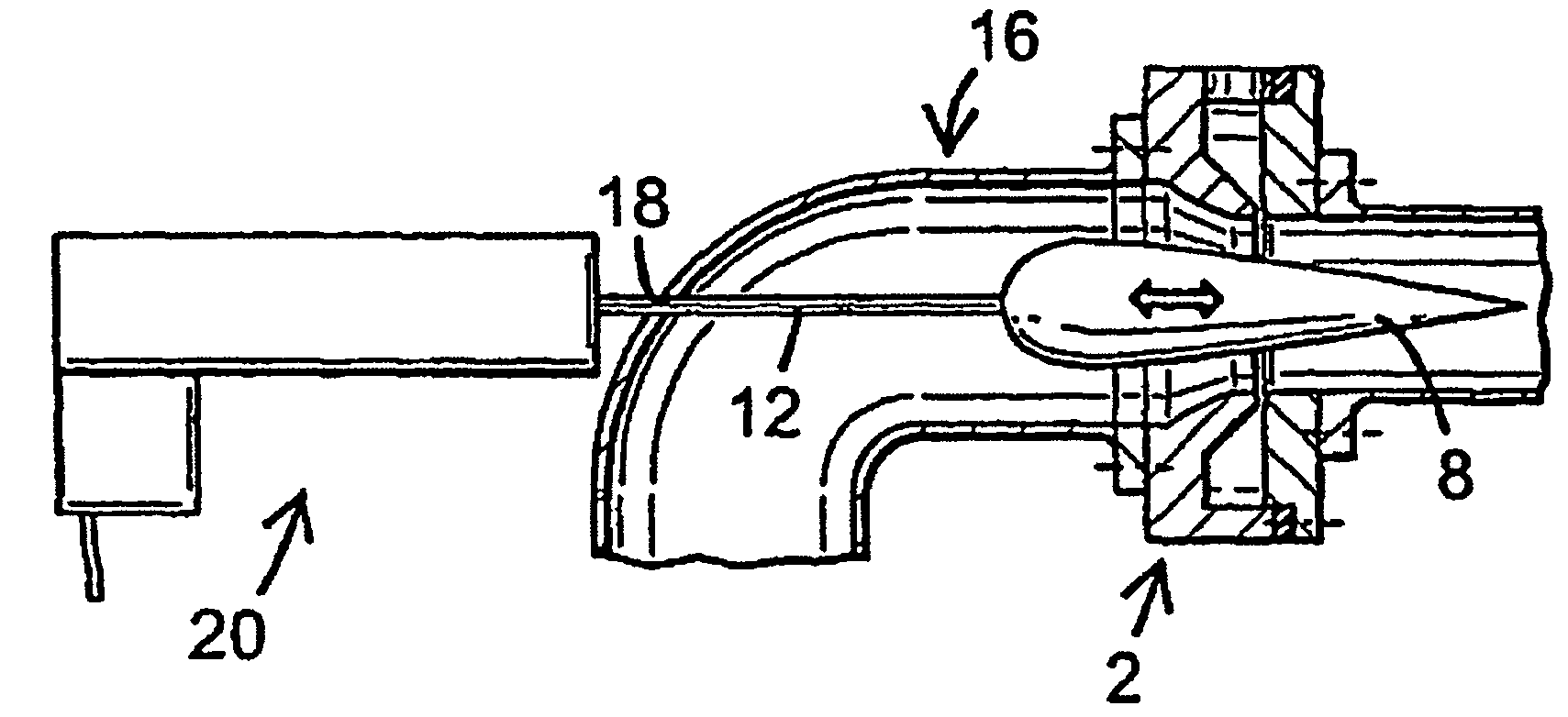

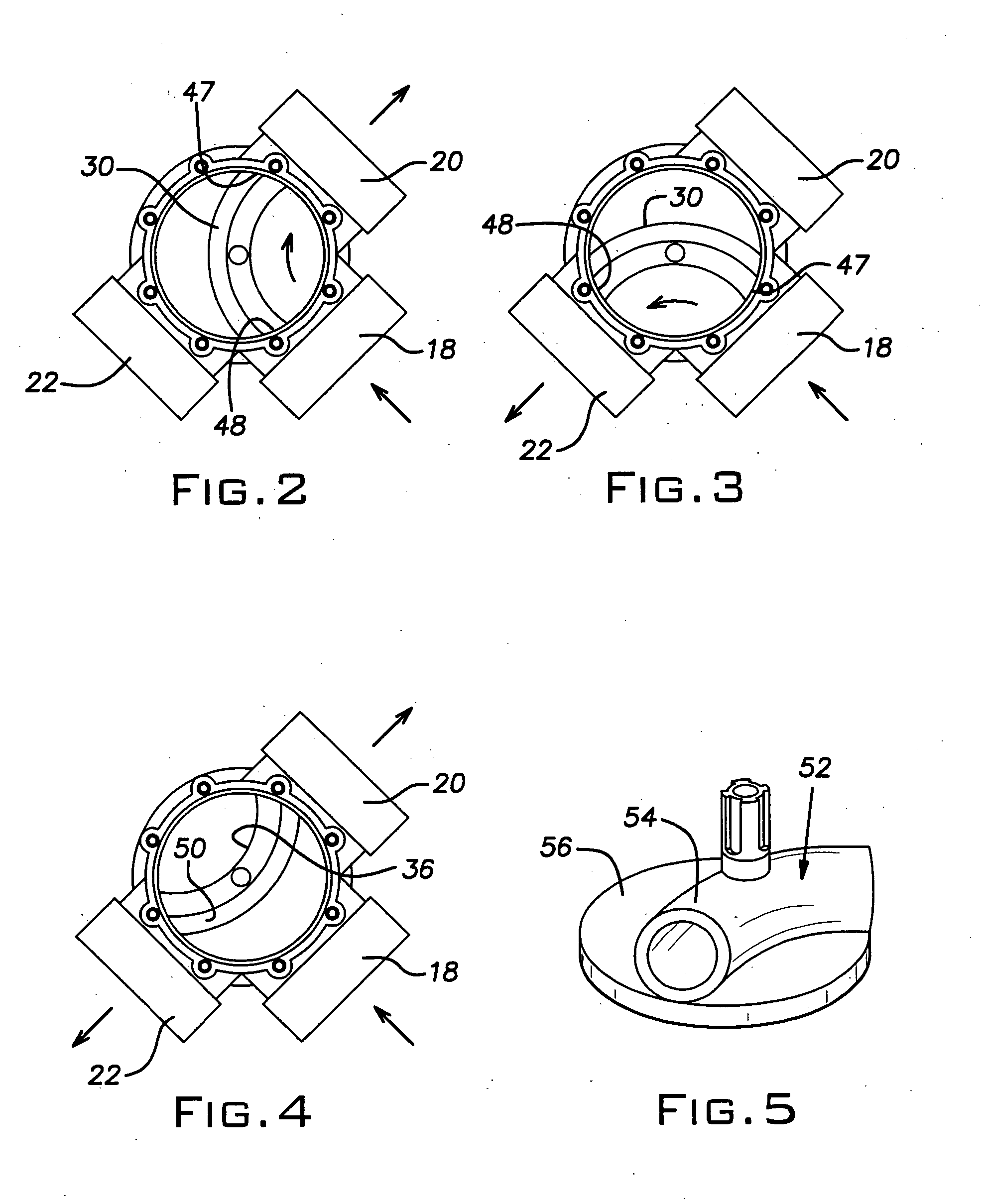

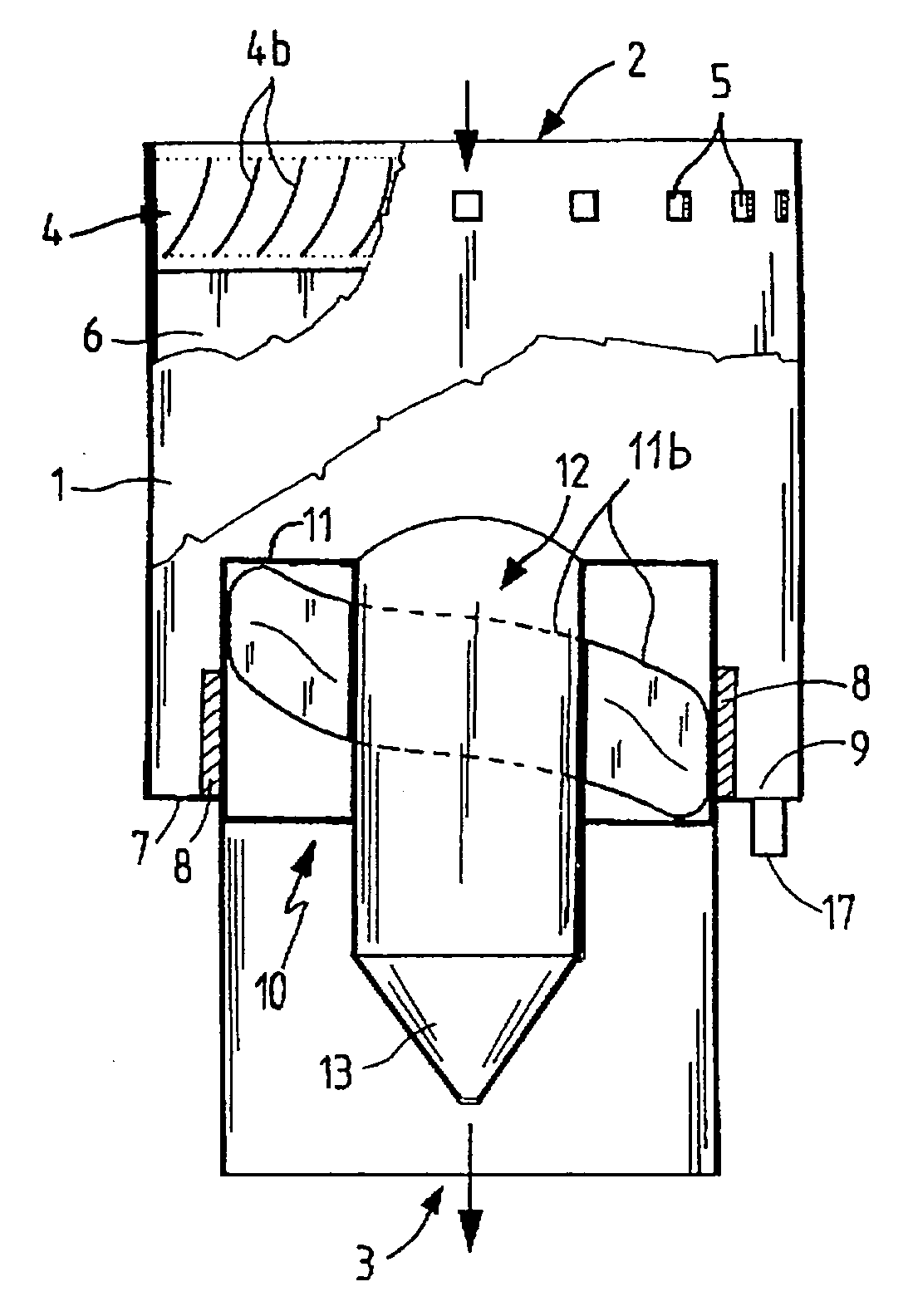

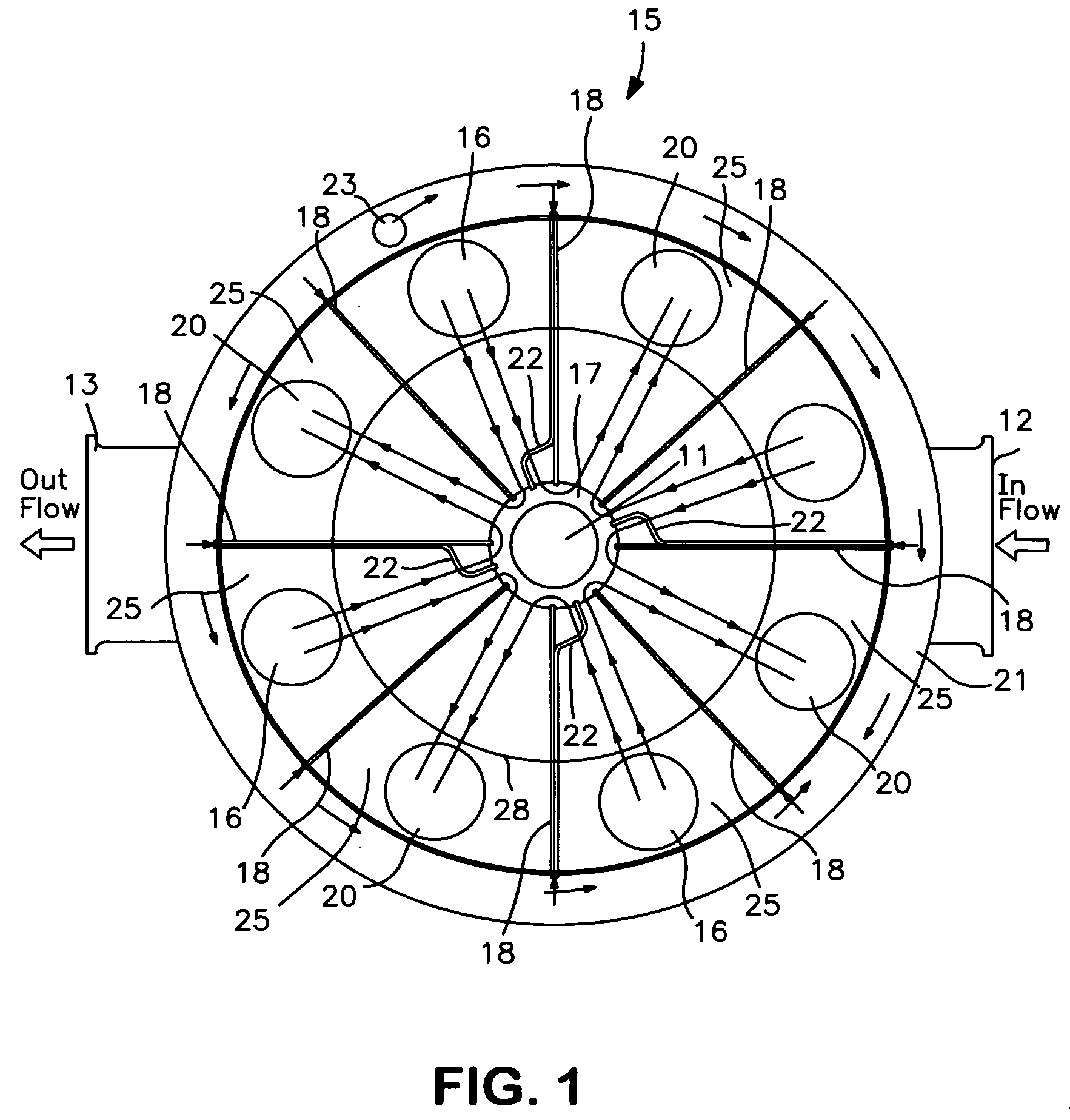

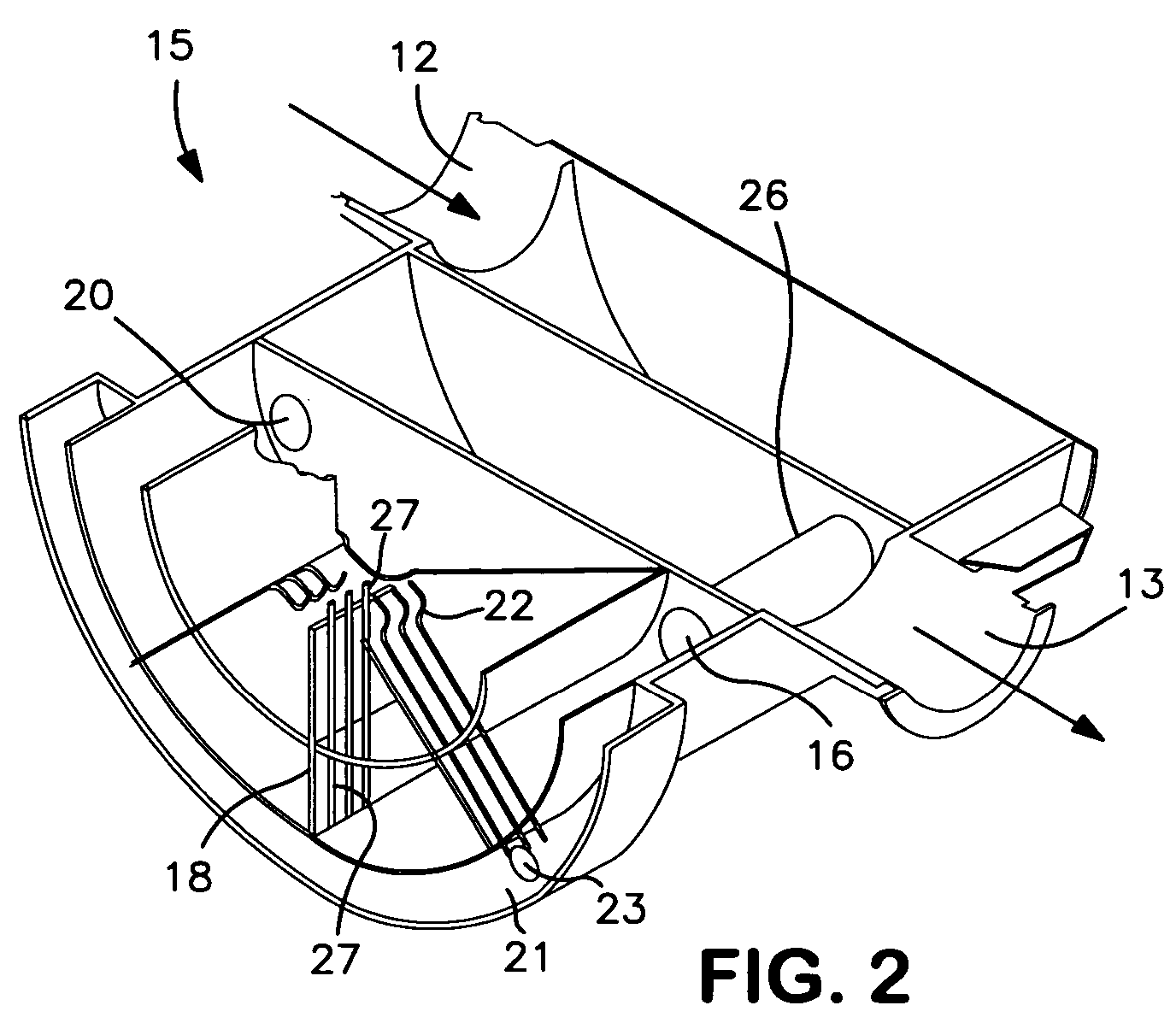

Apparatus for separating particles from a flowing medium

ActiveUS7258727B2Easy to separateLow pressure lossHuman health protectionCombination devicesCombustionEngineering

A separating apparatus which enables particles to be separated from a flowing medium by a preliminary separator which avoids the undesirably high pressure losses due to the flow resistance of known preliminary separators. The separating apparatus has a housing with an inlet and an outlet, in which a flow of air at the inlet end is caused to rotate by an inlet guide device, and is redirected again at the outlet end by an outlet guide device into a linear flow. The pressure recovery is achieved by a defined curvature and arrangement of the guide elements. The guide element curvature has an inlet contour, a retarding contour and a stabilizing contour. Preliminary separators of this type are used primarily in the air intake tracts of internal combustion engines exposed to heavy contamination, such as engines in farm machinery or construction machinery.

Owner:MANN HUMMEL GMBH

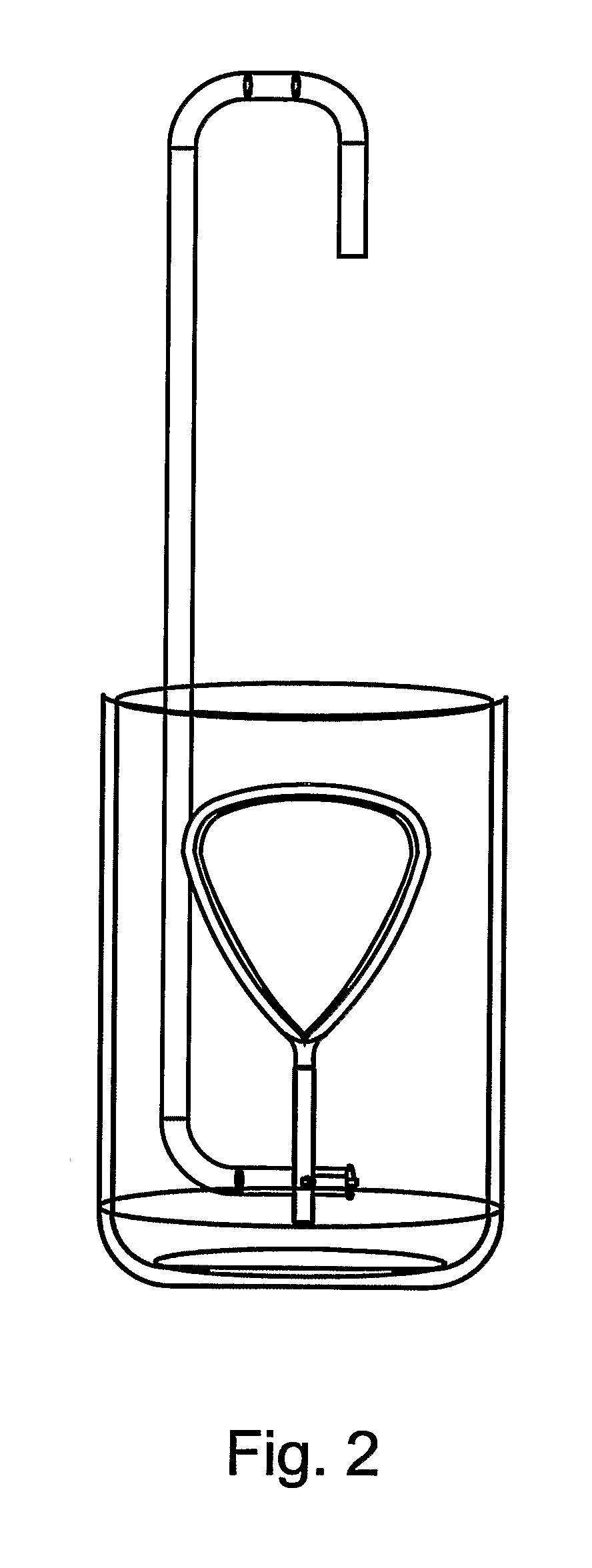

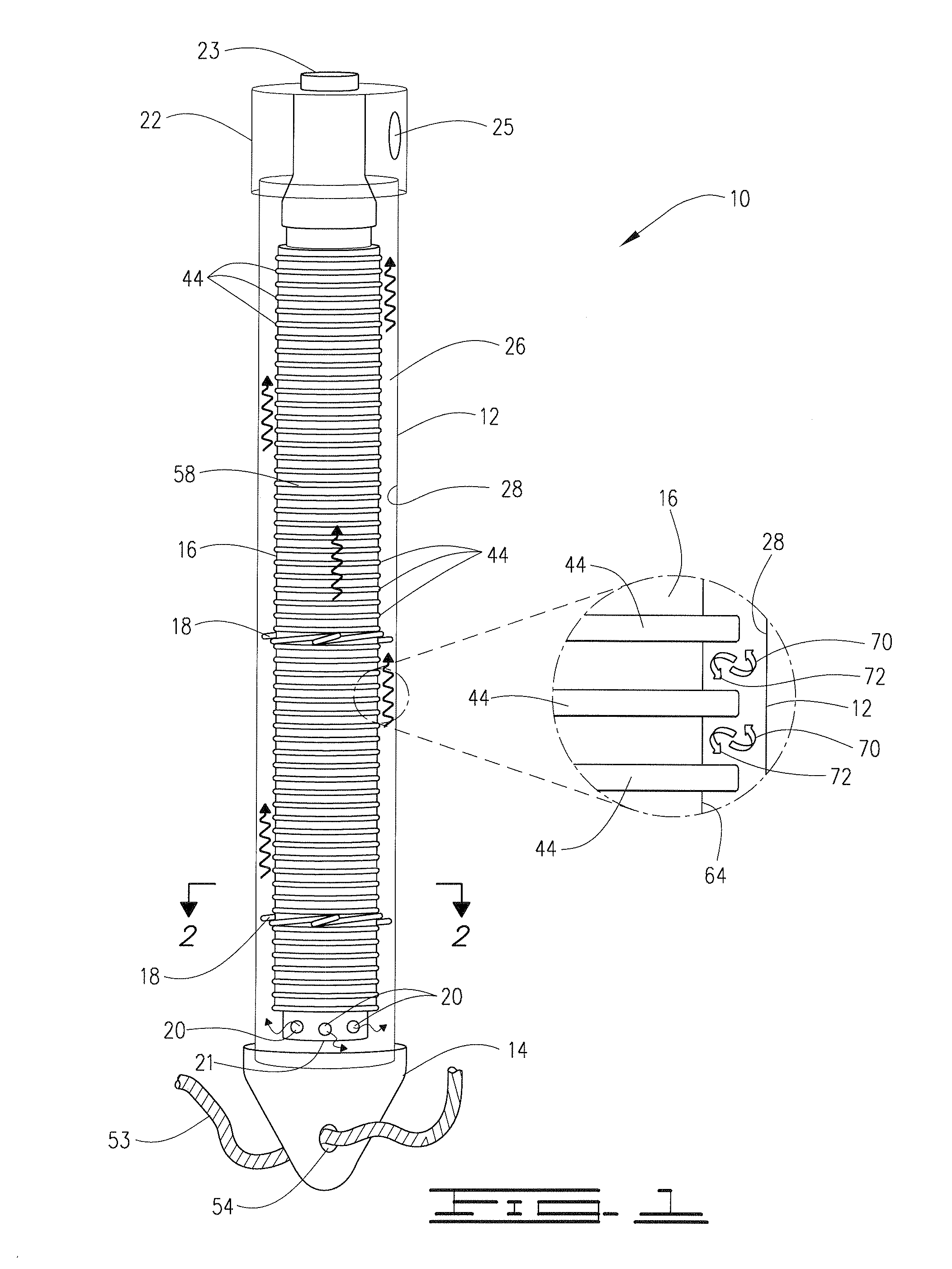

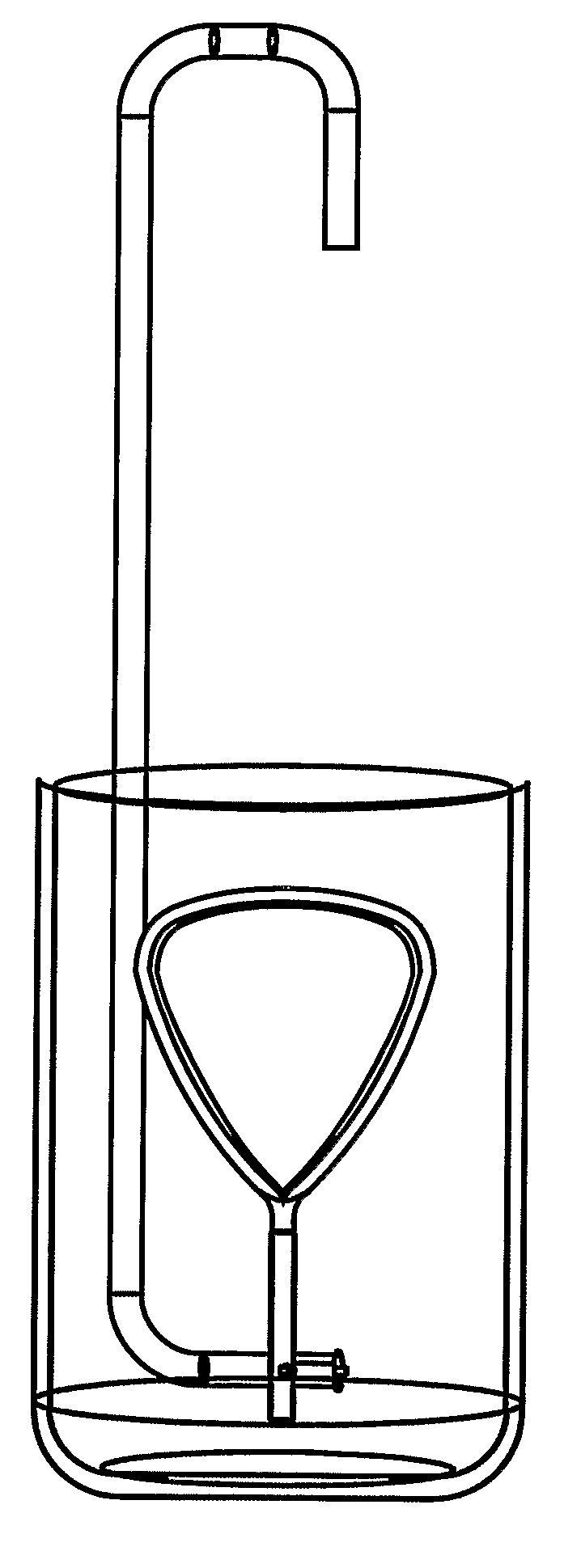

Method, apparatus, conduit, and composition for low thermal resistance ground heat exchange

ActiveUS9121630B1Minimize pressureMinimize transferSpacing meansGeothermal energy generationFiberGraphite

A method, apparatus, conduit, and composition for low thermal resistance ground heat exchange which preferably comprise, include, and / or use one or more of: a thin-walled, highly conductive filament wound conduit / casing formed using a thermosetting plastic composition containing a thermal conductivity enhancer; a grout backfill preferably including a sufficient amount of graphite, coke, or similar additive to provide a thermal conductivity of 3 Btu / hr-ft-° F. and higher; and a drop tube delivery conduit within the casing, the drop tube having radial exterior ribs which extend into the fluid return annulus formed between the interior wall of the casing and the exterior of the drop tube.

Owner:RYGAN CORP

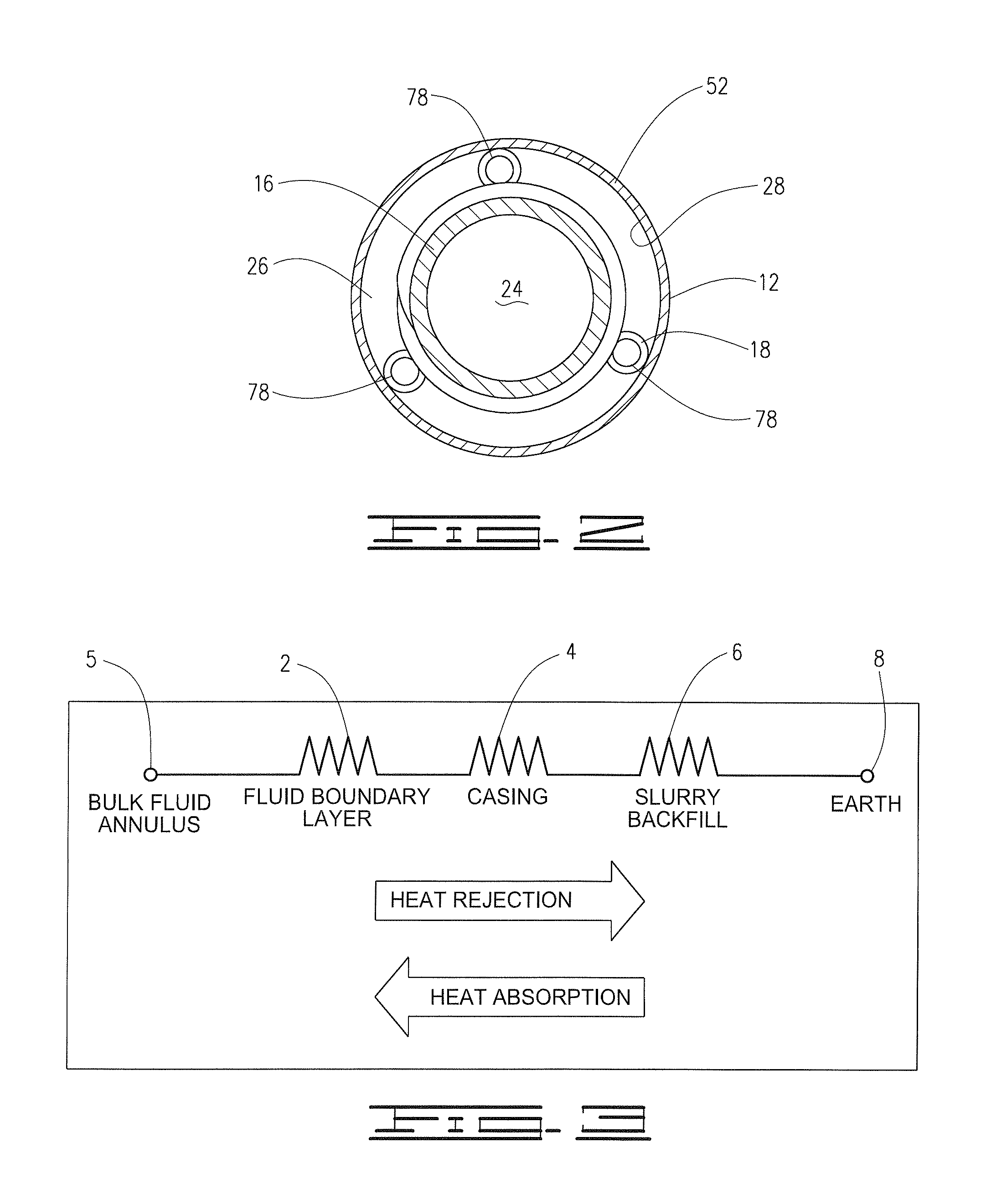

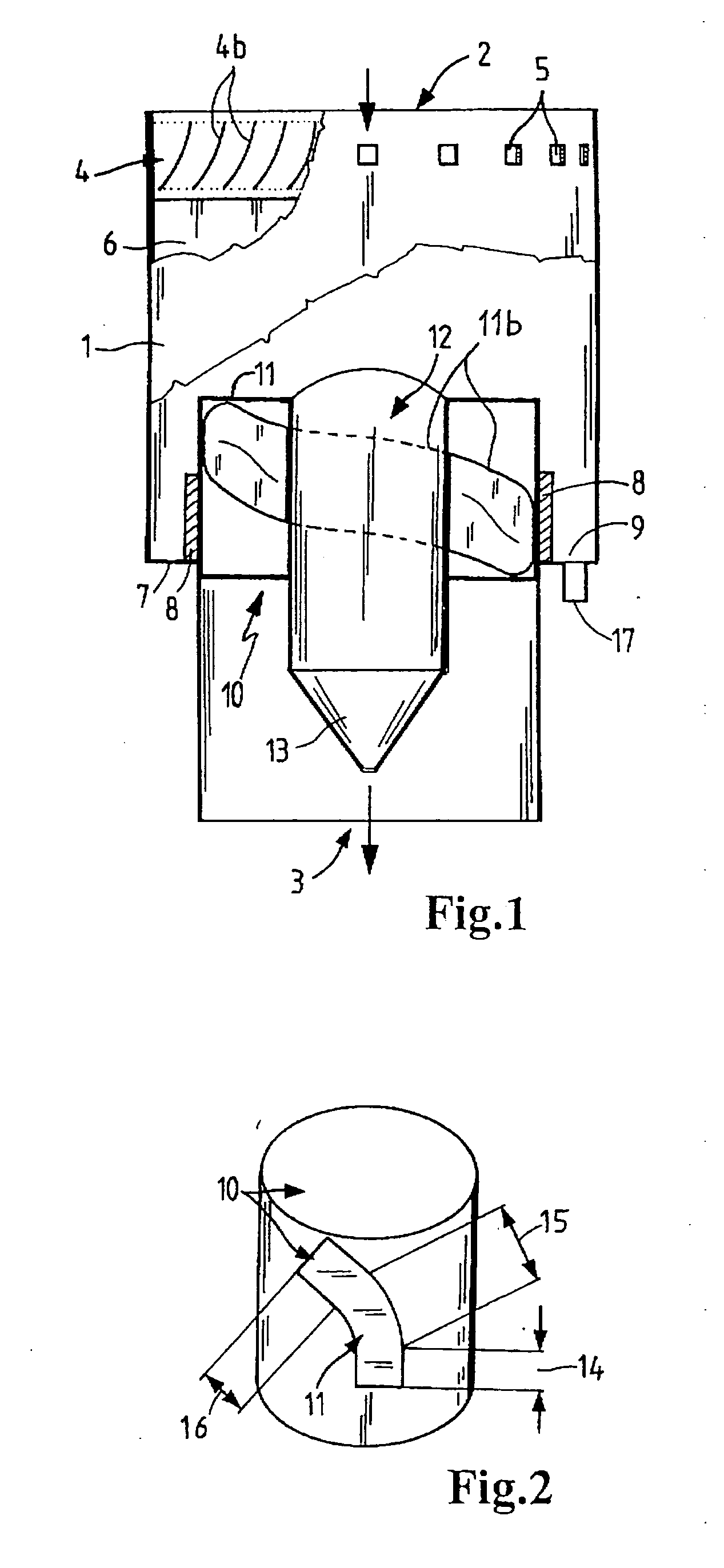

Heat pump system for vehicles

ActiveUS20150273981A1Speed up the flowNoise minimizationAir-treating devicesCompression machines with several condensersEngineeringHigh pressure

A heat pump system for a vehicle includes a dehumidification line for supplying some refrigerant circulating in a refrigerant circulation line to an evaporator before the refrigerant is introduced into an exterior heat exchanger after passing a first expansion means so as to dehumidify the interior of the vehicle in a heat pump mode, thereby allowing the refrigerant to smoothly flow to the evaporator at a low pressure through the dehumidification line before the refrigerant is introduced into the exterior heat exchanger which has a higher pressure than the evaporator when the interior of the vehicle is dehumidified, and smoothly dehumidifying the inside of the vehicle.

Owner:HANON SYST

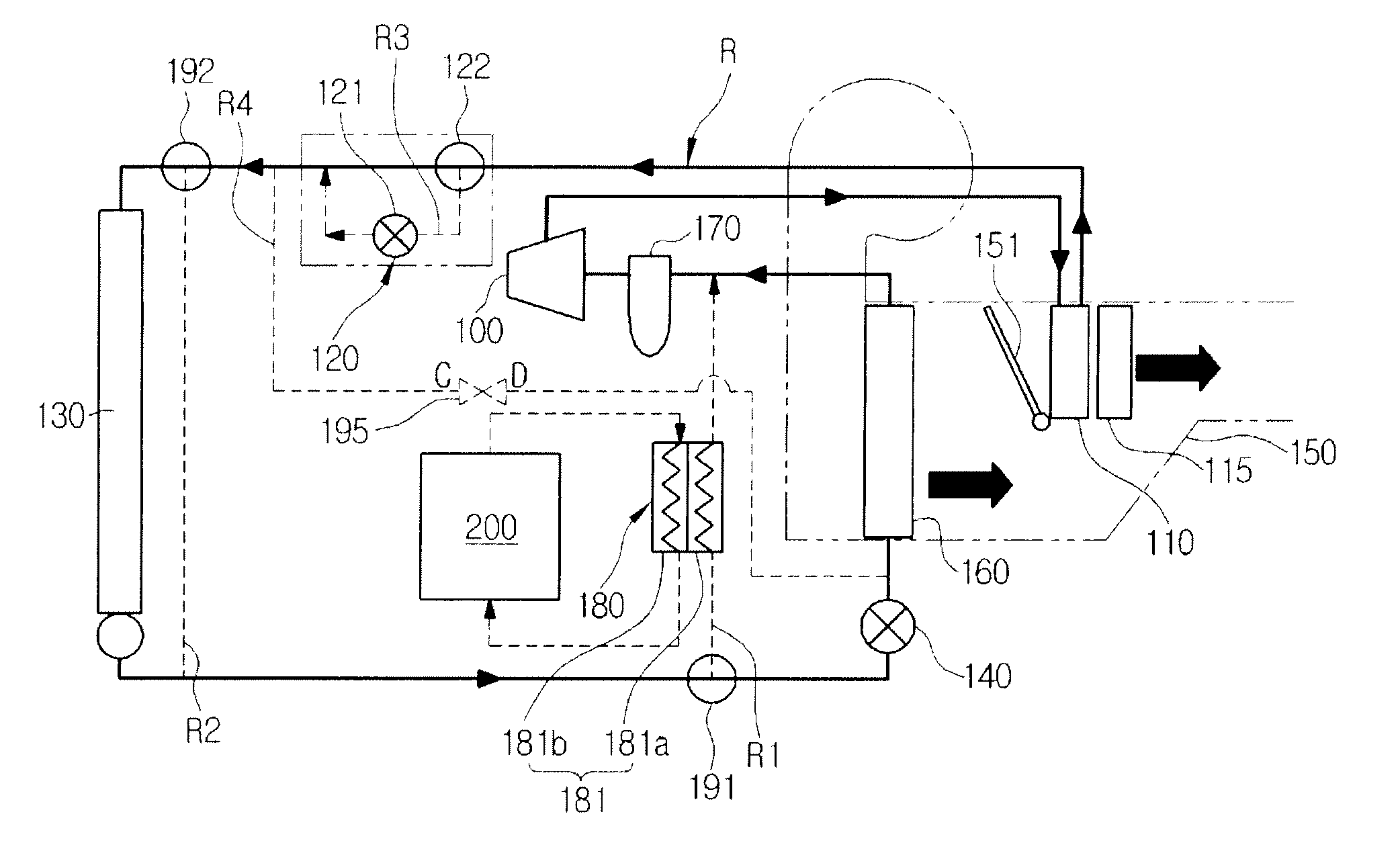

Arrangement for mixing a first and second gas flow with downstream control

InactiveUS7543600B2Good mixing efficiencyMinimized pressure lossControlling ratio of multiple fluid flowsNon-fuel substance addition to fuelActuatorGuide tube

A system for mixing a first gas flow and a second gas flow includes a conduit defined by a wall for communicating the first gas flow therethrough, an inlet passing through the wall of the conduit for introducing the second gas flow into the conduit, and a valve body disposed within the conduit, the valve body being displaceable in a longitudinal direction with respect to the conduit at the inlet. The conduit includes a bend downstream of the body with respect to a direction of the mixed gas flow. A holder is operably connected at a first end thereof to a downstream end of the valve body, the holder passing through a bore in the wall of the conduit at the bend. An actuator is operably connected to a second end of the holder, the actuator causing, via the holder, the valve body to be displaced in the longitudinal direction.

Owner:VARIVENT INNOVATIONS

Valve with elbow joint diverter

InactiveUS20060169337A1Minimized pressure dropMinimize turbulent flowPlug valvesMultiple way valvesFlow diverterEngineering

A multiport diverter valve comprising a valve housing defining a valving chamber therein. A plurality of ports open into the chamber. A flow diverter is pivotally mounted in the chamber and has a concave diverter surface forming a portion of a torus. First and second ends of the torus communicate with a first adjacent pair of the ports to provide a flow path between the adjacent pair. A valve handle is adapted to pivot the diverter to a position connecting a second adjacent pair of the ports with the second pair of ports including one of the ports from the first pair. The handle is further adapted to pivot the diverter to a position connecting all of the ports.

Owner:PENTAIR WATER POOL & SPA INC

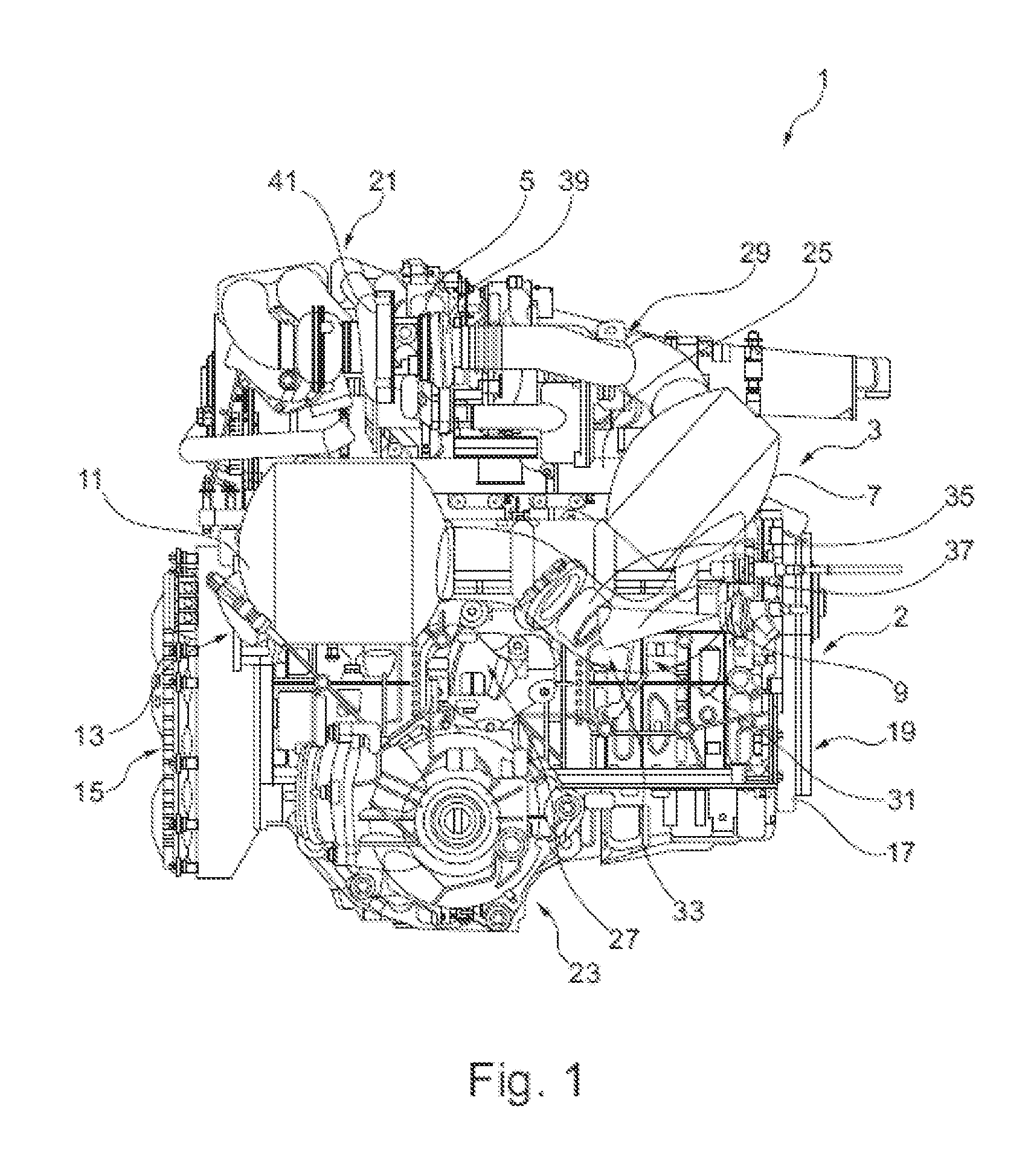

Cylinder Block Arrangement with an Exhaust Gas System

ActiveUS20140352297A1Minimized pressure lossMinimize temperatureInternal combustion piston enginesExhaust apparatusTurbochargerProcess engineering

An engine block arrangement includes an engine block and an exhaust gas system. The exhaust gas system, viewed in the flow direction of an exhaust gas flow, includes an exhaust gas turbocharger, an oxidation catalytic converter, a feed device for a urea-water solution, a particle filter, and an SCR catalytic converter arranged one behind the other. The exhaust gas turbocharger, the oxidation catalytic converter, the feed device for the urea-water solution, the particle filter, and the SCR catalytic converter are situated together on the engine block along one side thereof, the side being oriented essentially perpendicularly with respect to an output side of the engine block.

Owner:DAIMLER AG

Device system and method for tissue displacement or separation

ActiveUS8221442B2Minimize injuryMinimize contactDiagnosticsBlunt dissectorsMedicineBiomedical engineering

Owner:BIOPROTECT

Electrochemical device comprising electrode lead having protection device

ActiveUS7618724B2Minimized dropImprove the immunityNon-aqueous electrolyte accumulatorsPrimary cell maintainance/servicingEngineeringElectrochemistry

Disclosed is an electrochemical device including an electrode assembly having a cathode, anode and an electrolyte, and a casing surrounding the electrode assembly. The device further includes a protection device to which either or both of a cathode lead for connecting a cathode with an outer terminal and an anode lead for connecting an anode with an outer terminal are connected electrically, wherein the protection device is disposed in the inner space of the casing and the electrode lead equipped with the protection device is folded at both sides of the protection device so that the largest surface of the protection device is layered on a lateral surface of the casing where the electrode lead is present.

Owner:LG ENERGY SOLUTION LTD

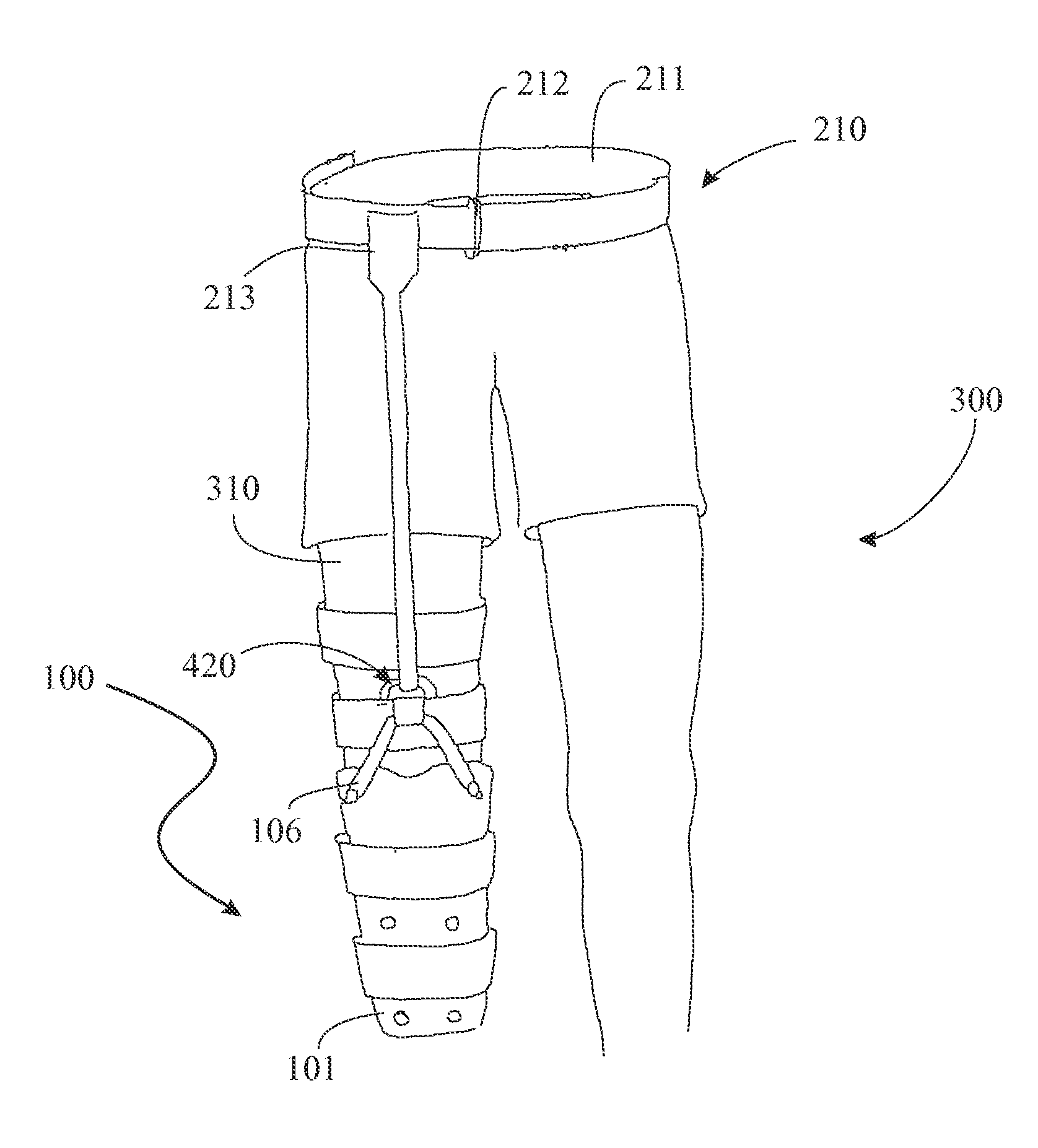

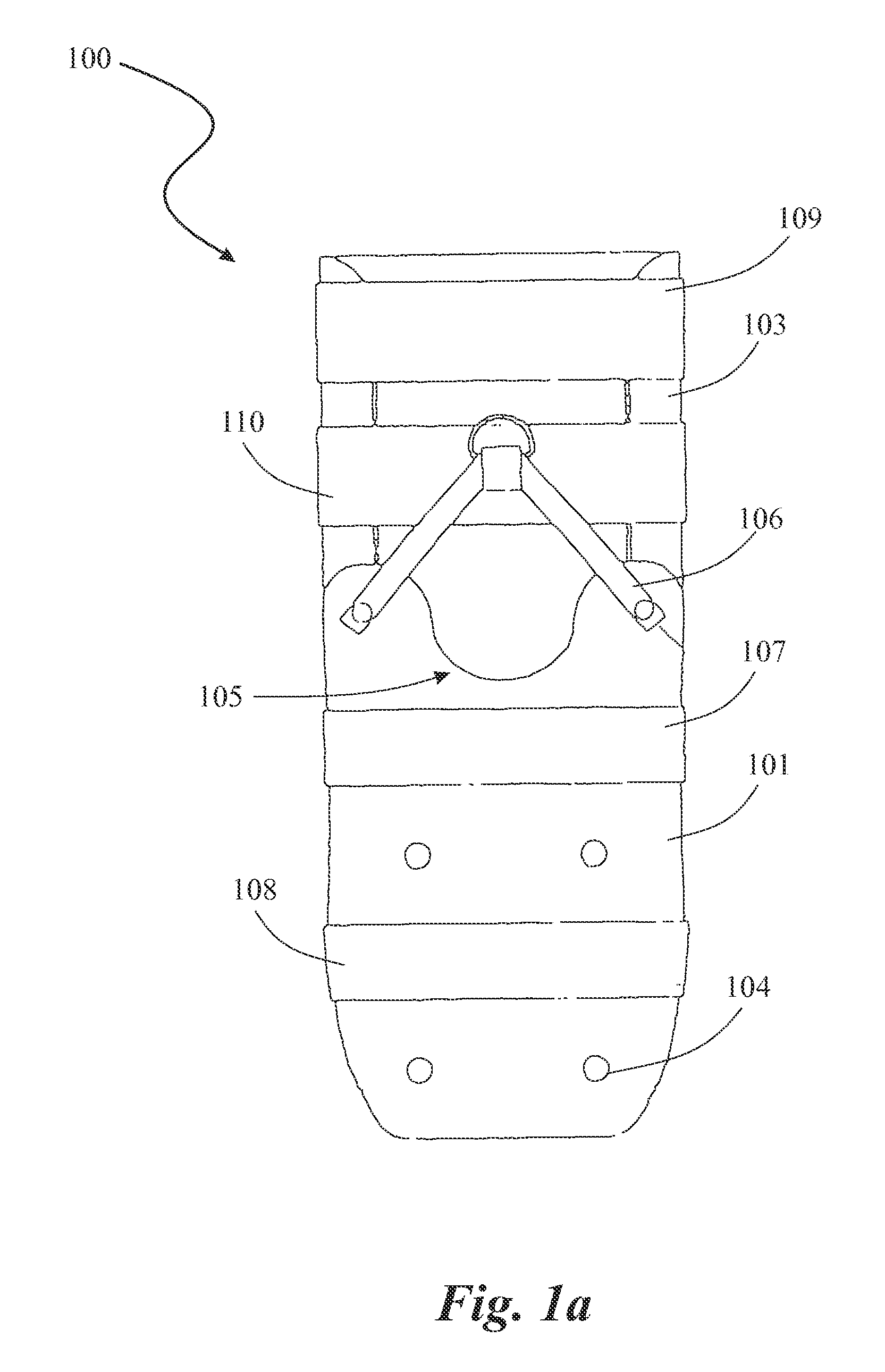

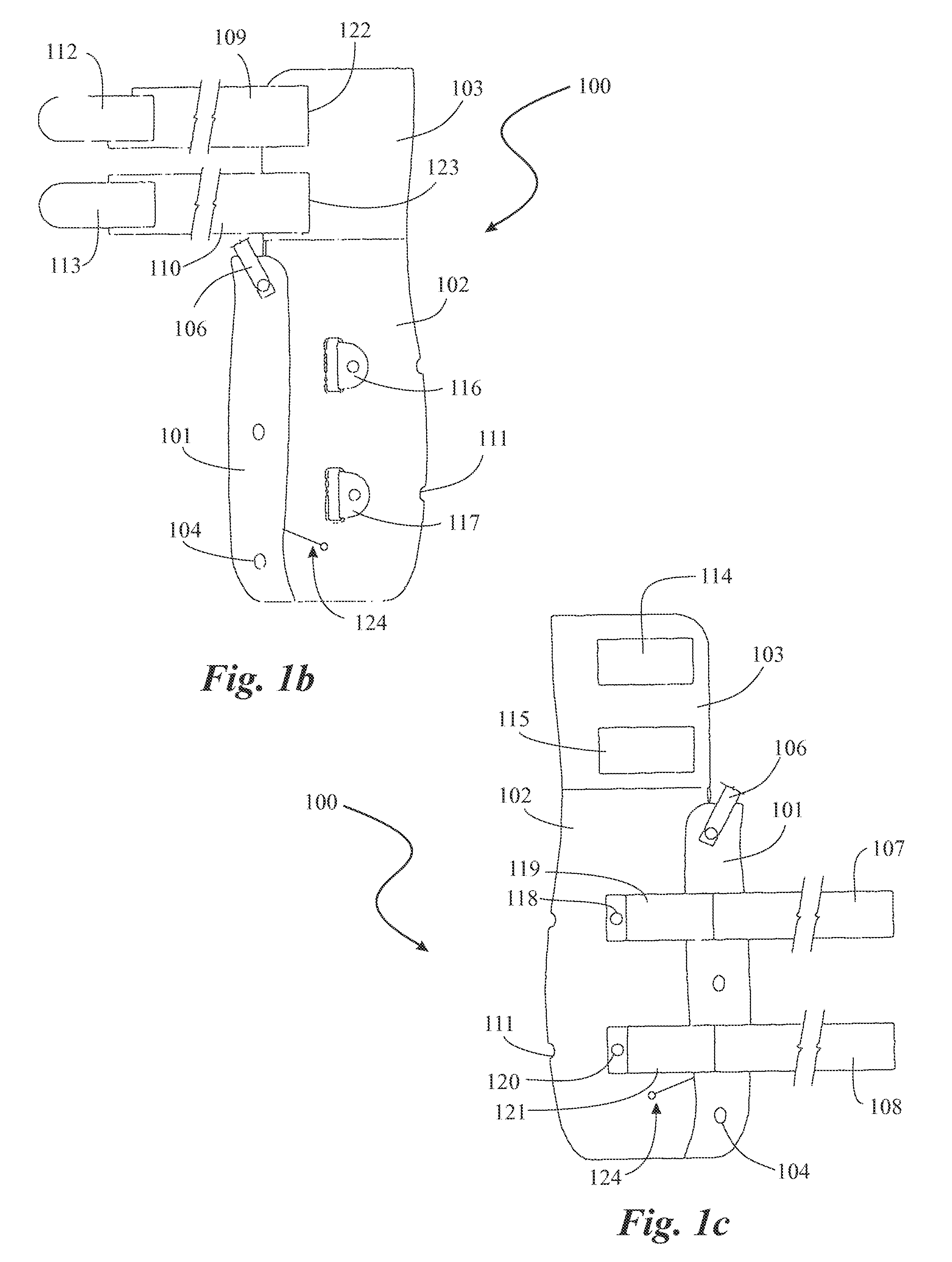

Rigid removable dressing

InactiveUS20160058634A1Barrier is createdMinimize irritationFeet bandagesPlaster of paris bandagesThighHollow shape

A postoperative transtibial amputee protection dressing for a distal stump comprising a first rigid brace having a semi-cylindrical hollow shape including a first distal end and a first proximal end, the first distal end having a closed-shape designed to essentially match the contour of the distal stump; a second rigid brace having a semi-cylindrical hollow shape including a second distal end and a second proximal end, the second distal end having an inner contour complementary to an external contour of the first brace; and a removable flexible sleeve located at the first proximal end adapted to provide a cushioned surface at a thigh portion of the amputee, creating a barrier between the first rigid brace and the thigh portion.

Owner:TOP SHELF MFG

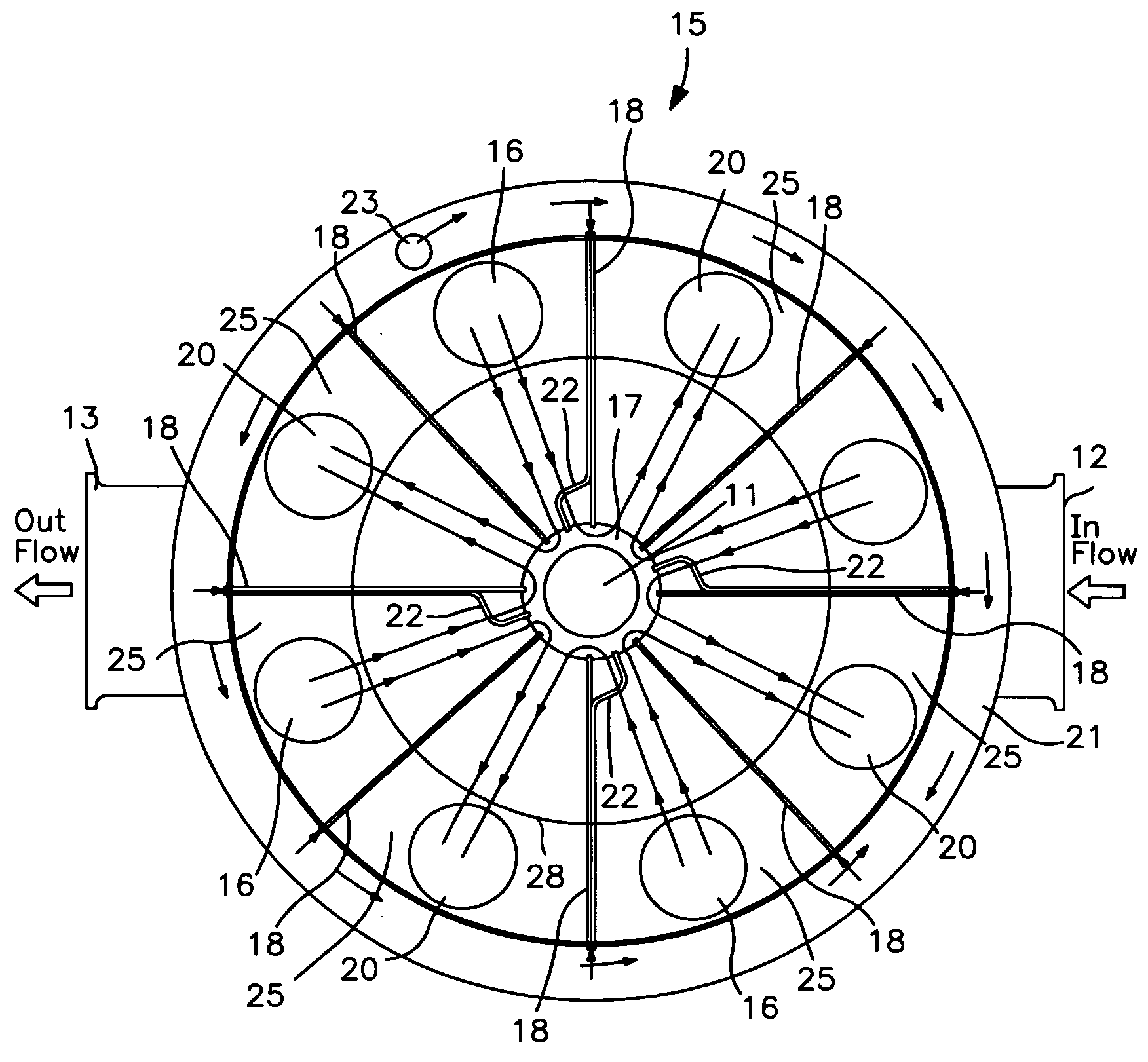

Apparatus for separating particles from a flowing medium

ActiveUS20050086915A1Low flow resistanceImprove pressure recoveryHuman health protectionCombination devicesCombustionEngineering

A separating apparatus which enables particles to be separated from a flowing medium by a preliminary separator which avoids the undesirably high pressure losses due to the flow resistance of known preliminary separators. The separating apparatus has a housing with an inlet and an outlet, in which a flow of air at the inlet end is caused to rotate by an inlet guide device, and is redirected again at the outlet end by an outlet guide device into a linear flow. The pressure recovery is achieved by a defined curvature and arrangement of the guide elements. The guide element curvature has an inlet contour, a retarding contour and a stabilizing contour. Preliminary separators of this type are used primarily in the air intake tracts of internal combustion engines exposed to heavy contamination, such as engines in farm machinery or construction machinery.

Owner:MANN HUMMEL GMBH

Heat pump system for vehicles

ActiveUS9643473B2Speed up the flowNoise minimizationAir-treating devicesCompression machines with several condensersEngineeringHigh pressure

A heat pump system for a vehicle includes a dehumidification line for supplying some refrigerant circulating in a refrigerant circulation line to an evaporator before the refrigerant is introduced into an exterior heat exchanger after passing a first expansion means so as to dehumidify the interior of the vehicle in a heat pump mode, thereby allowing the refrigerant to smoothly flow to the evaporator at a low pressure through the dehumidification line before the refrigerant is introduced into the exterior heat exchanger which has a higher pressure than the evaporator when the interior of the vehicle is dehumidified, and smoothly dehumidifying the inside of the vehicle.

Owner:HANON SYST

Hydraulic actuation of a downhole tool assembly

ActiveUS8863843B2Erosion minimizationMinimize pressureDrill bitsFluid removalReciprocating motionEngineering

A downhole tool assembly is configured for repeated and selective hydraulic actuation and deactuation. A piston assembly is configured to reciprocate axially in a downhole tool body. The piston assembly reciprocates between a first axial position and second and third axial positions that axially oppose the first position. The downhole tool is actuated when the piston assembly is in the third axial position and deactuated when the piston assembly is in either of the first or second axial positions. A spring member biases the piston assembly towards the first axial position while drilling fluid pressure in the tool body urges the piston assembly towards the second and third axial positions. Downhole tool actuation and deactuation may be controlled from the surface, for example, via cycling the drilling fluid flow rate.

Owner:SMITH INT INC

Solenoid-controlled rotary intake and exhaust valves for internal combustion engines

InactiveUS20140054480A1Avoid overall overheatingMinimize flowOperating means/releasing devices for valvesFuel injection apparatusExhaust valveCombustion

A solenoid-operated air inlet or combustion exhaust valve, for a rotary exhaust valve assembly or a sliding plate valve. The rotary exhaust valve has a fixed housing with a cylindrical bore in fluid communication with an air inlet port and / or a combustion gas outlet port, and a cylindrical valve body that rotates within the bore of the fixed housing. The valve body has a gas passage transverse to the axis. The sliding plate valve has a fixed housing with a cylindrical bore in fluid communication with a gas inlet passage and a gas outlet passage, and a plate between the gas inlet passage and the gas outlet passage with an aperture, moving between open and closed positions. An electric linear solenoid reciprocates linearly and operates the sliding plate valve or the rotary valve, directly or through a lever to rotate the rotary valve body, between the open and closed positions.

Owner:TAYLOR JACK R

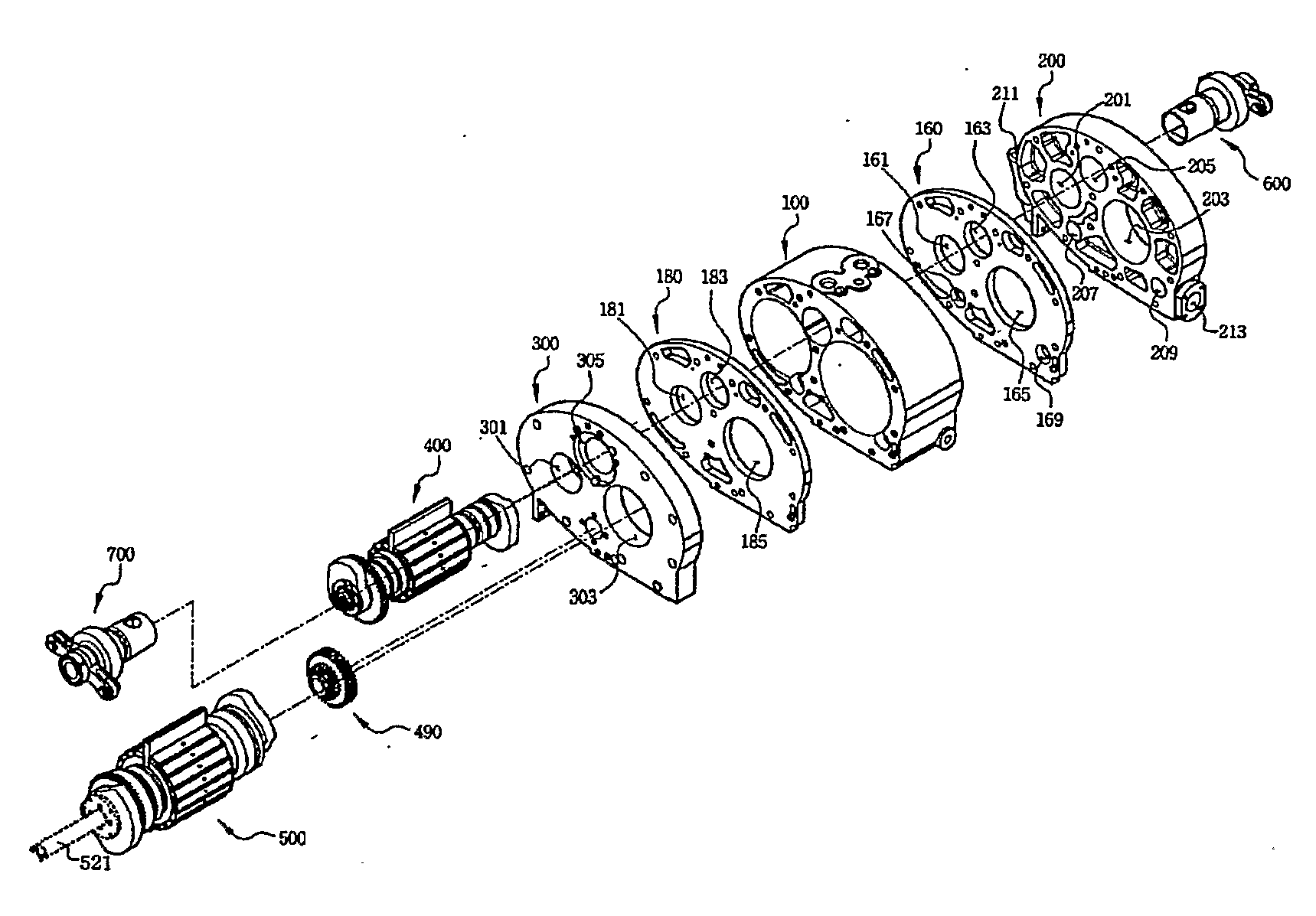

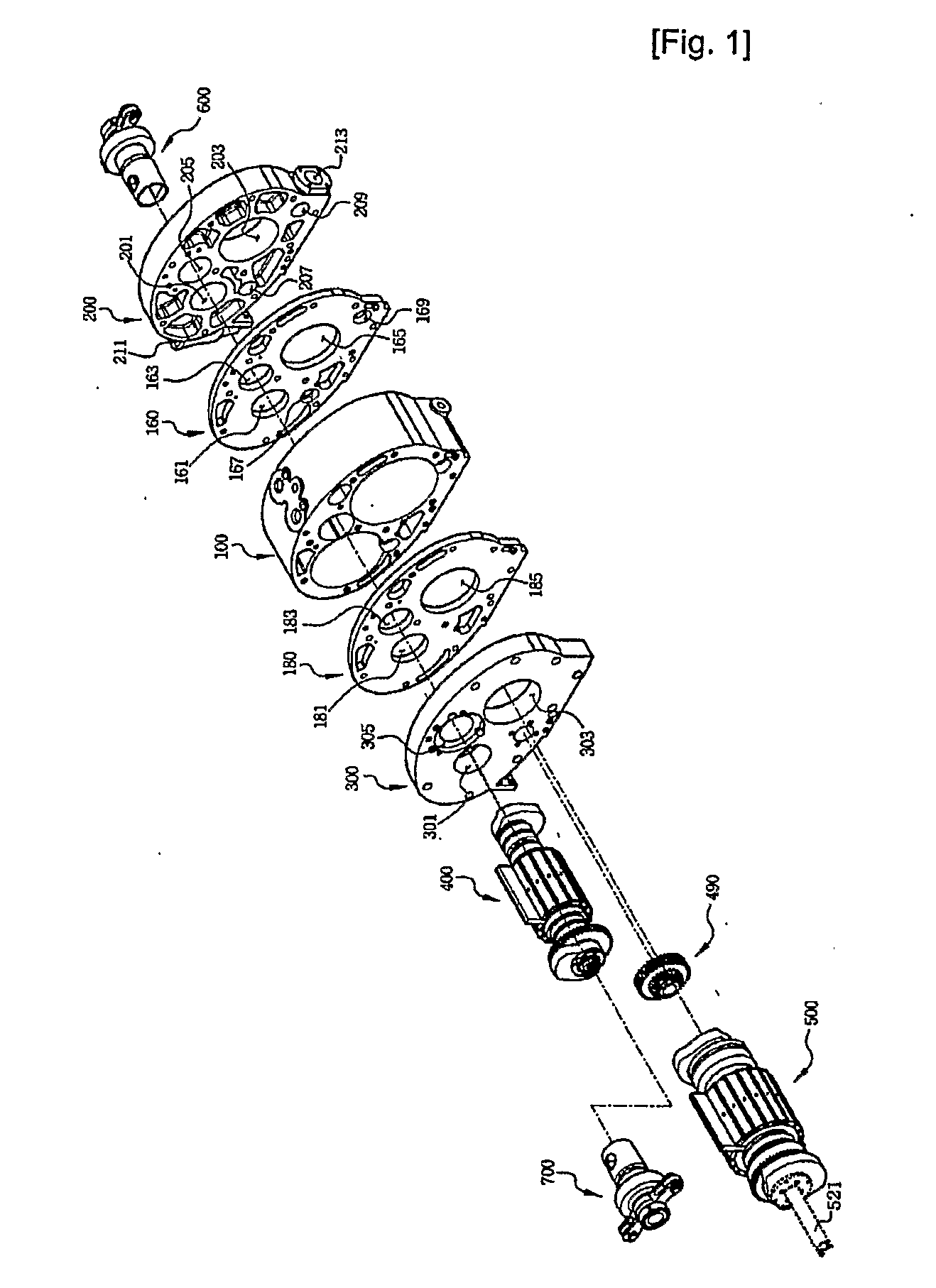

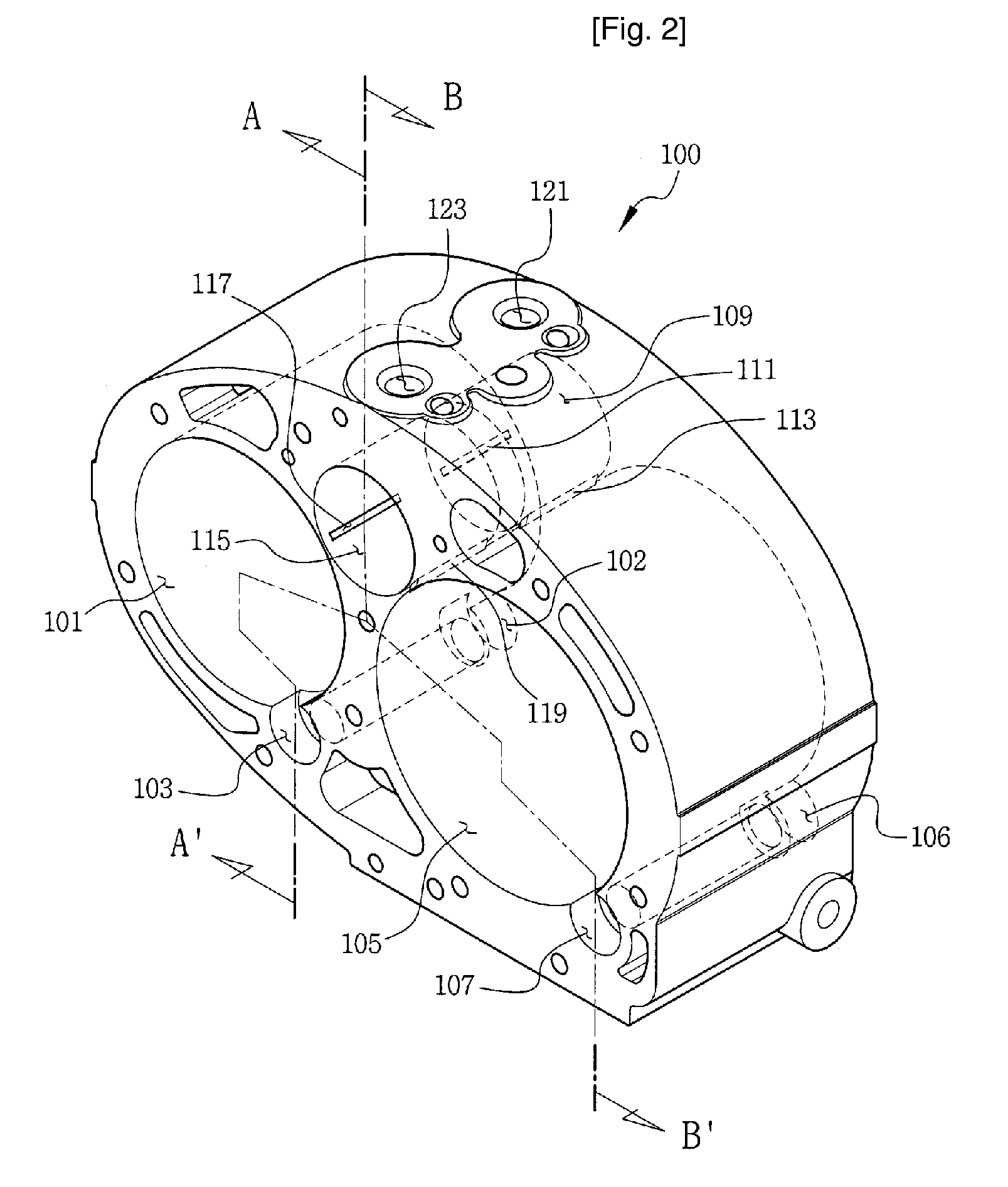

Rotary Engine

InactiveUS20080264379A1Maximize engine efficiencyMinimize vibration and noise and pressure leakageInternal combustion piston enginesValve drivesCombustion chamberRotary engine

A rotary engine is disclosed. The rotary engine of the present invention includes an engine body (100), which has therein a compression chamber (101), an output chamber (105) and a combustion chamber (109, 115), which is formed between the compression chamber and the output chamber. The rotary engine further includes a compression rotor (400) which is eccentrically provided in the compression chamber, an ignition device (125, 126) which is provided in the combustion chamber of the engine body, and an output rotor (500), which is eccentrically provided in the output chamber. The rotary engine further includes valves (600) which are provided in the respective bores of the combustion chamber, a synchronizing means for rotating the compression rotor in conjunction with rotation of the output rotor, and an axial sealing means for sealing the compression chamber, the combustion chamber and the output chamber.

Owner:MAENG HYUK JAE

Cylinder block arrangement with an exhaust gas system

ActiveUS9488090B2Rapid temperatureReduce heatInternal combustion piston enginesExhaust apparatusTurbochargerExhaust fumes

Owner:DAIMLER AG

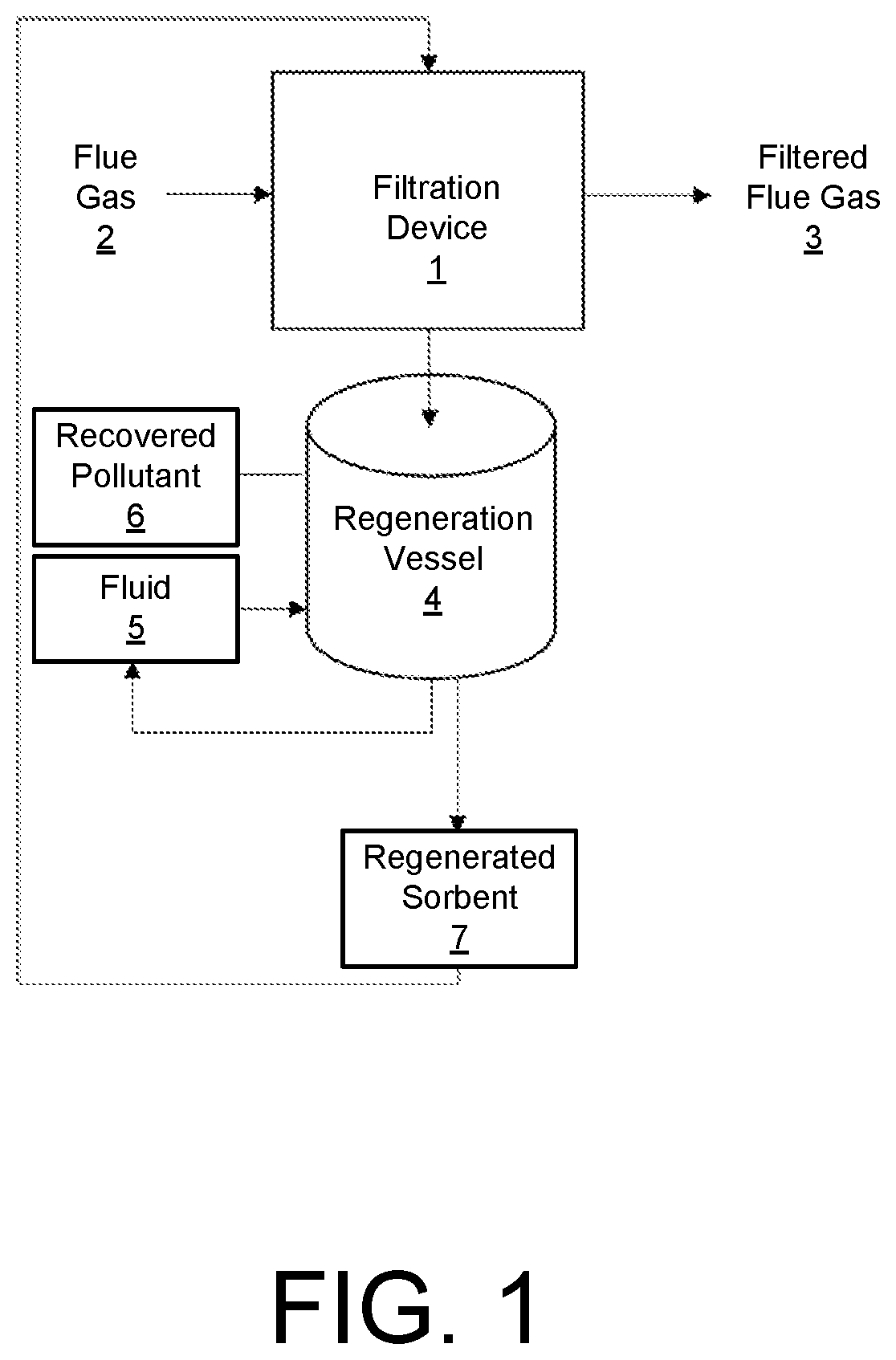

Collecting a gaseous pollutant from air within an animal enclosure

ActiveUS11331619B1Increase animal performanceEmission reductionNitrous oxide captureGas treatmentEnvironmental engineeringAnimal Enclosure

An apparatus for collecting a gaseous pollutant from air within a poultry or other concentrated animal feeding enclosure may comprise multiple vertical panel-beds each containing a solid sorbent; a fan to pass the air within the poultry enclosure through the multiple vertical panel-beds and over the solid sorbent; an outlet gate configured to release the solid sorbent from the multiple vertical panel-beds after the fan passes the air over the solid sorbent; a regeneration vessel configured to regenerate the released solid sorbent by recovering the gaseous pollutant from the released solid sorbent; and a conveyor configured to return the regenerated solid sorbent to the multiple vertical panel-beds.

Owner:MOVA TECH INC

Reaction chamber

InactiveUS20060113486A1Minimized pressure dropMinimize pressure dynamic pressureGas treatmentDispersed particle separationElectron sourceMolecular physics

A novel reaction chamber is described for the treatment of gases which either have a noxious odor or include toxic elements. The chamber is for treatment of the gases with energetic electrons and uses an extended electron source in the center of a chamber volume which creates electrons that move out of the source and radially into the chamber. The gases are flowed into the area of the source and away from the source as to result in uniform and efficient exposure of the flowing gases.

Owner:VALENCE CORP

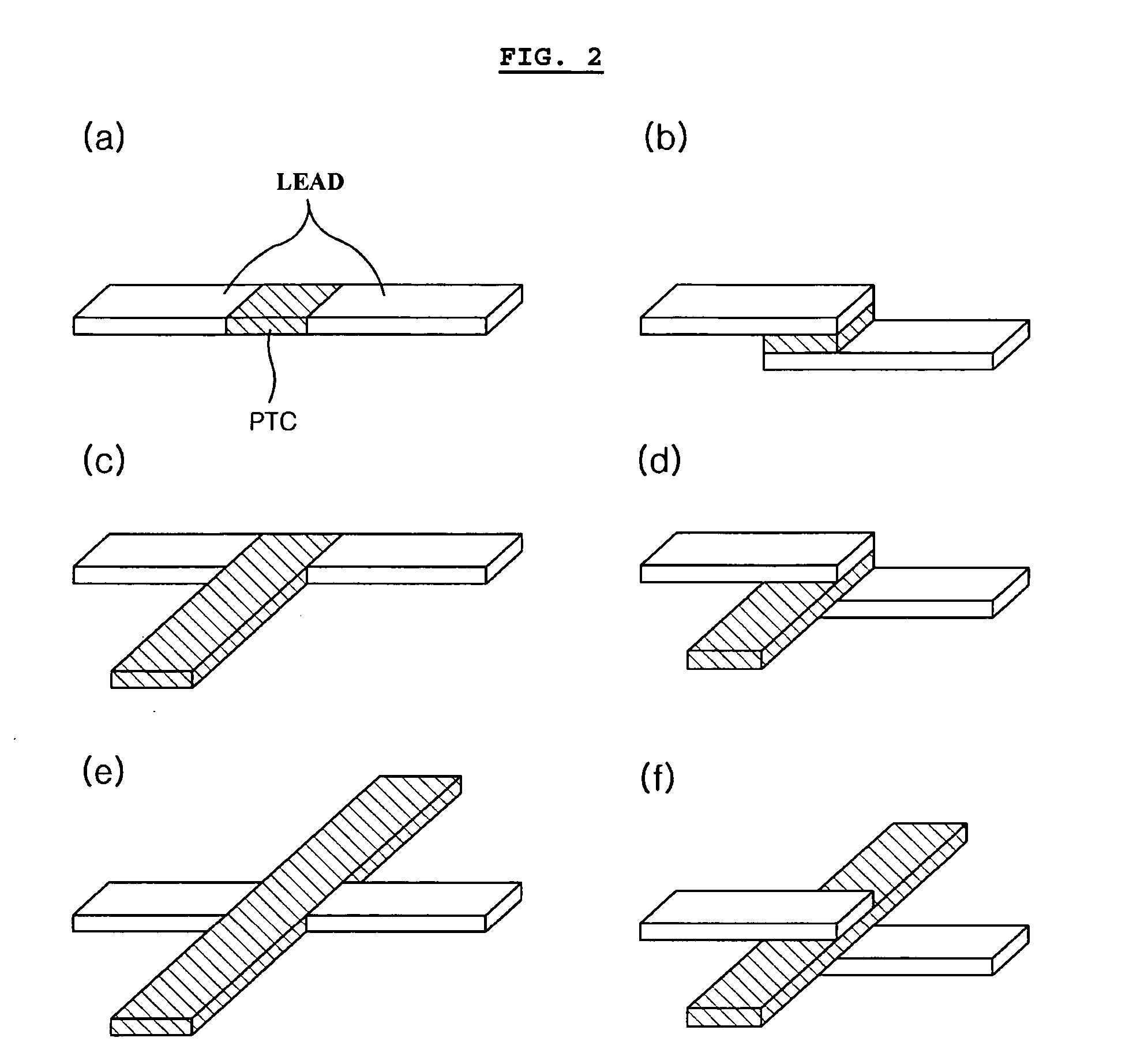

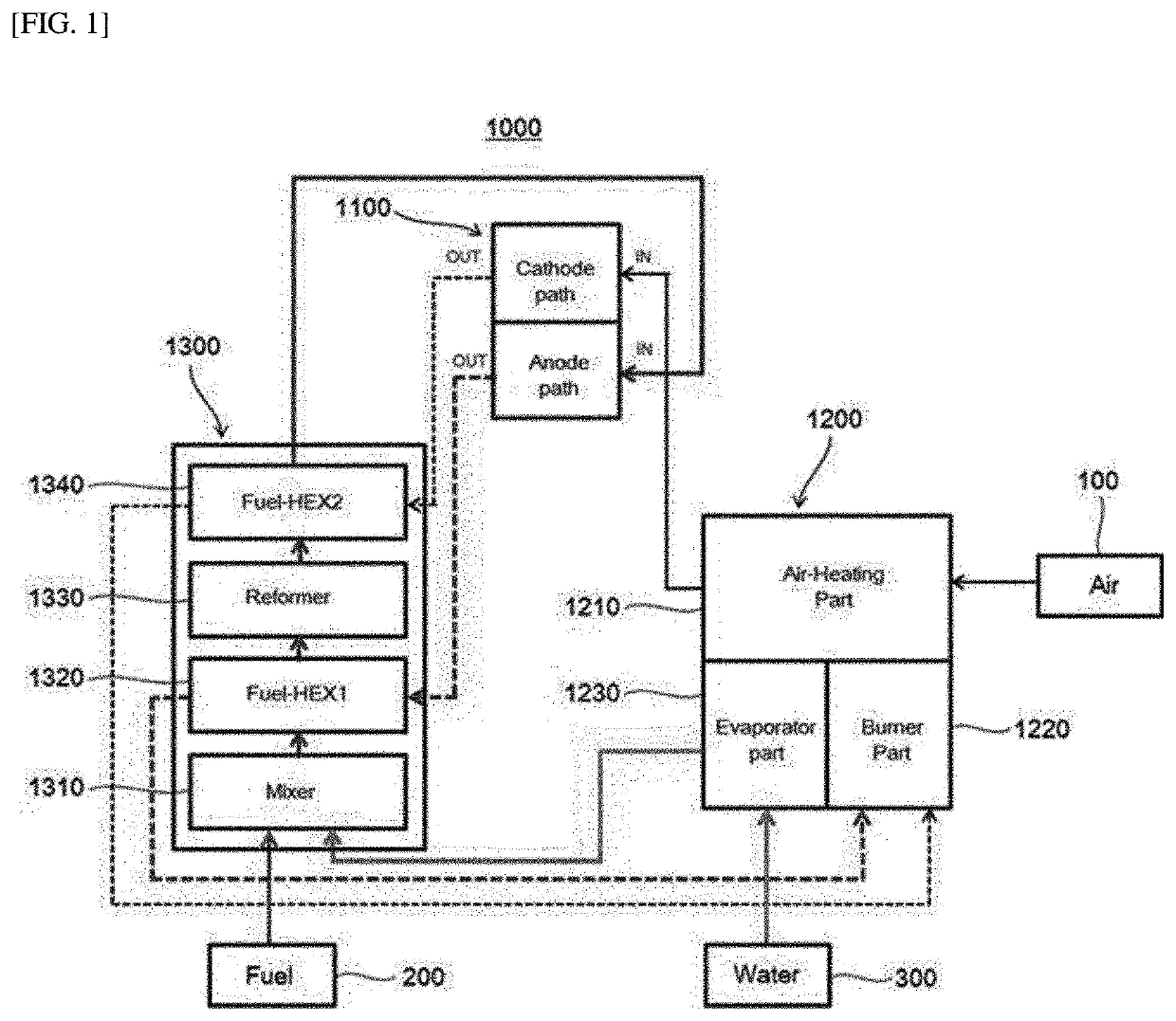

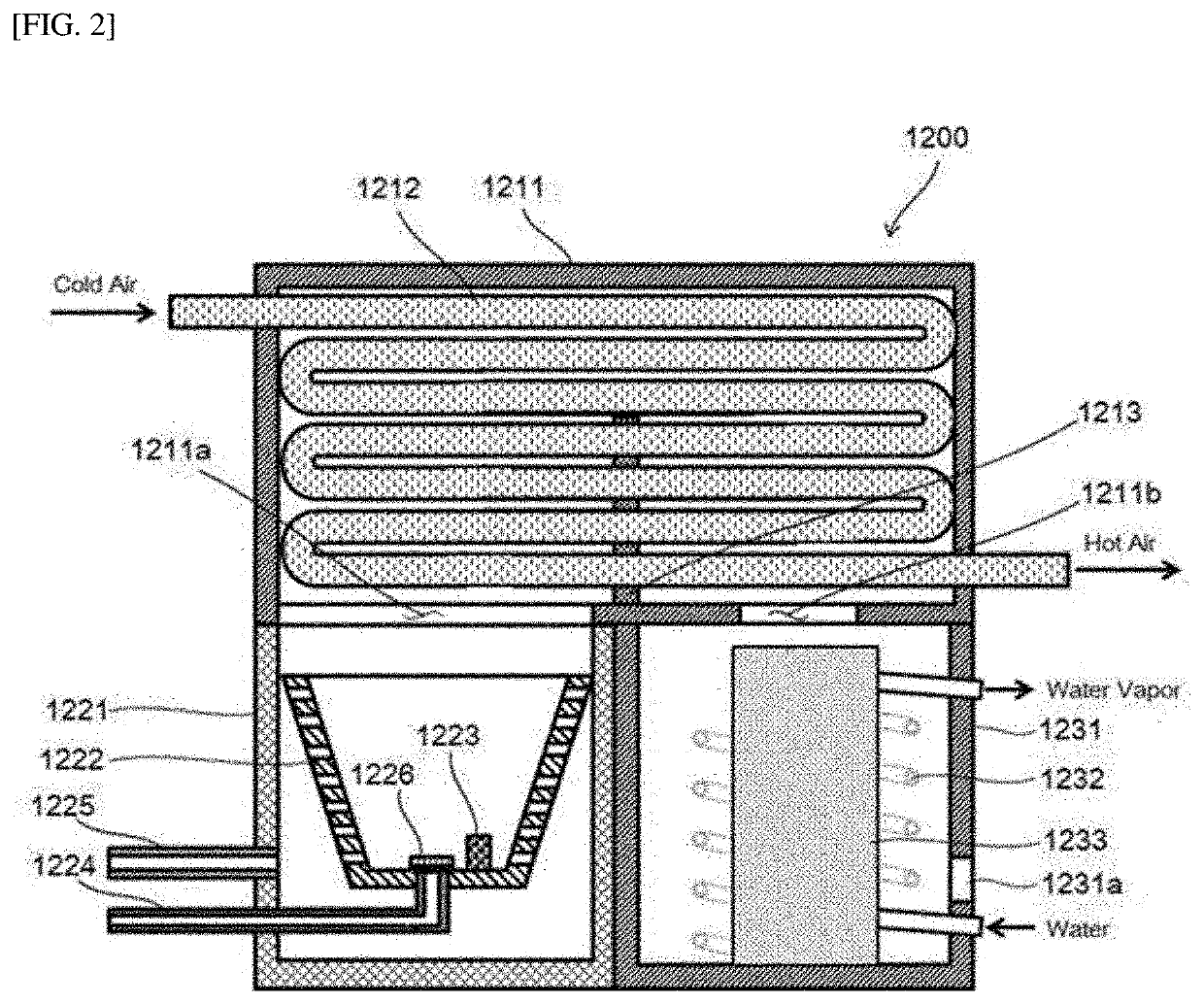

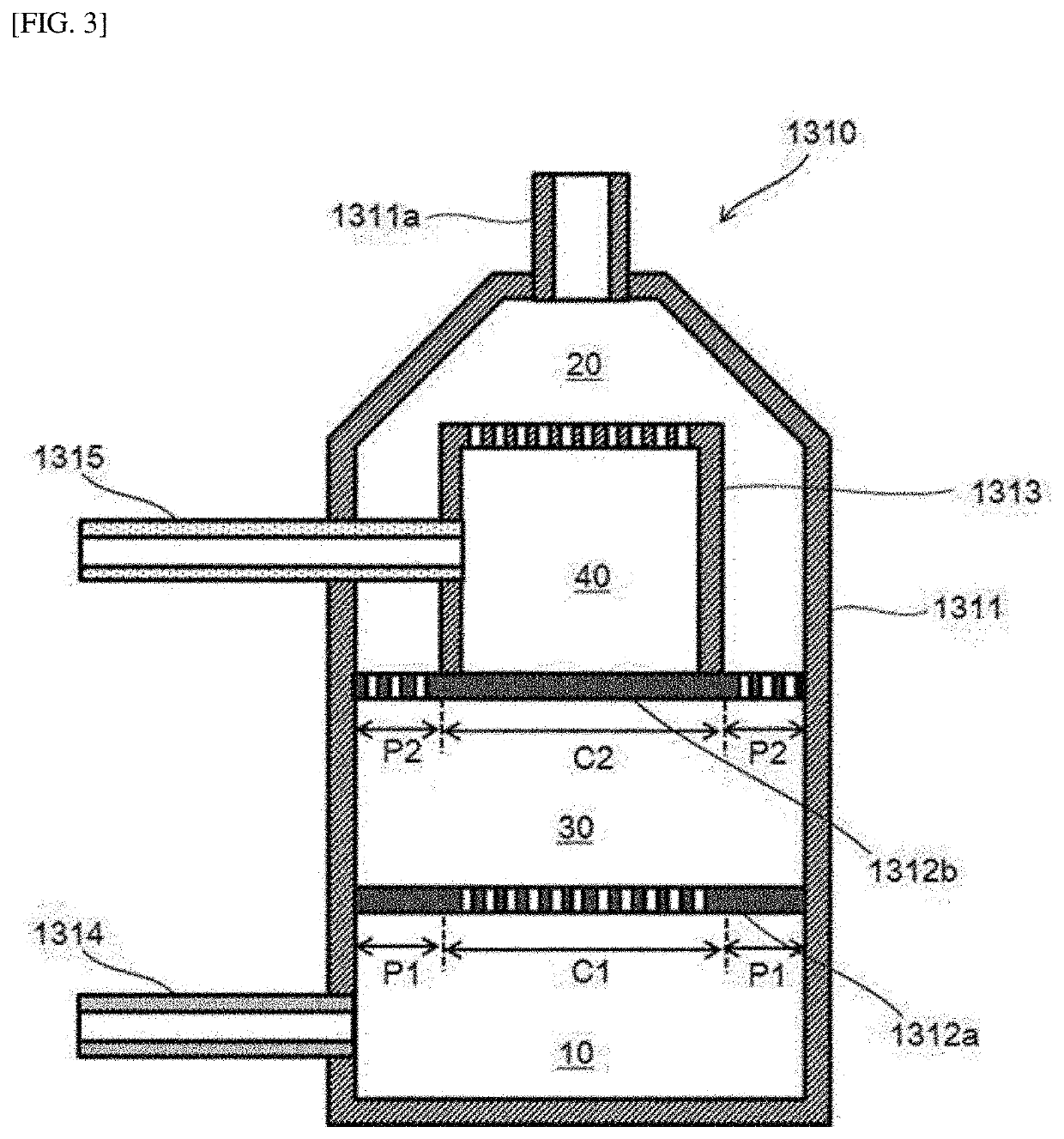

Fuel cell system

ActiveUS20210083307A1Simplify the assembly processMinimize heatFuel cell heat exchangeReactant parameters controlThermodynamicsFuel cells

A fuel cell system is disclosed. The fuel cell system comprises: a fuel cell module including a plurality of unit cells for generating electrical energy by using oxygen of air and hydrogen of a reformed fuel gas; a first module including a burner part which burns an unreacted fuel gas and air discharged from the fuel cell module, an air-heating part which heats air through heat exchange with a hot combustion gas and a flame generated by the burner part and supplies the heated air to the fuel cell module, and a water vapor generation part which converts water, flowing through an inner portion thereof, into water vapor through heat exchange with a hot combustion gas generated by the burner part; and a second module which mixes a fuel supplied from an external fuel supply source and water vapor supplied from an water-vapor generator part, allows a water vapor reformation reaction to occur, and supplies a reformed fuel gas to the fuel cell module.

Owner:MICO POWER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com